Design of In Situ Metal Matrix Composites Produced by Powder Metallurgy—A Critical Review

Abstract

1. Introduction

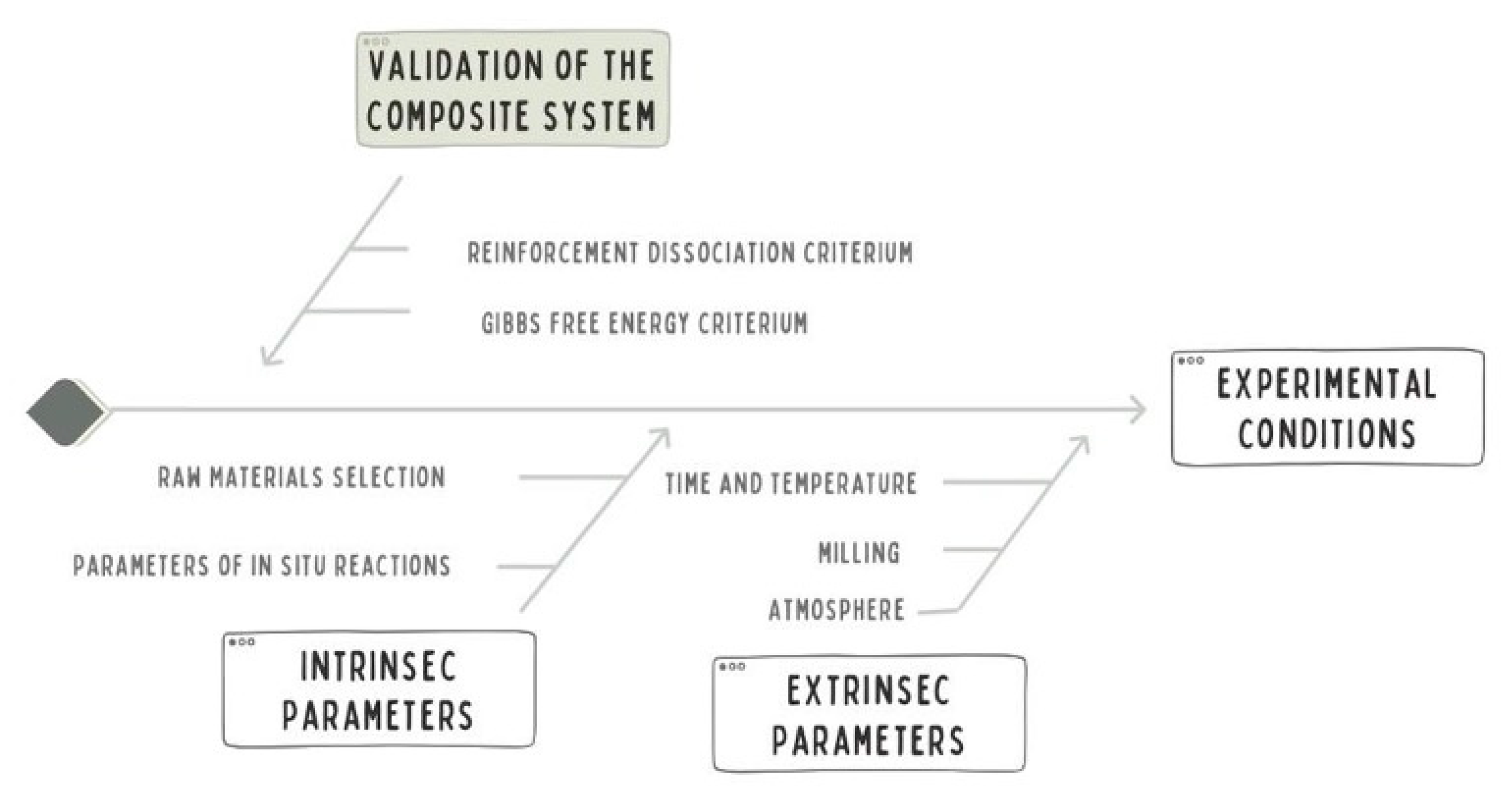

2. Concept

2.1. Validation of the Composite System

- Gibbs free energy criterion: the combination of desired phases should at least have a lower Gibbs free energy than the initial raw materials or, ideally, be stable upon equilibrium;

- Reinforcement dissociation criterion: the elements that are conceived as reinforcements should have sufficiently low solubility in the matrix.

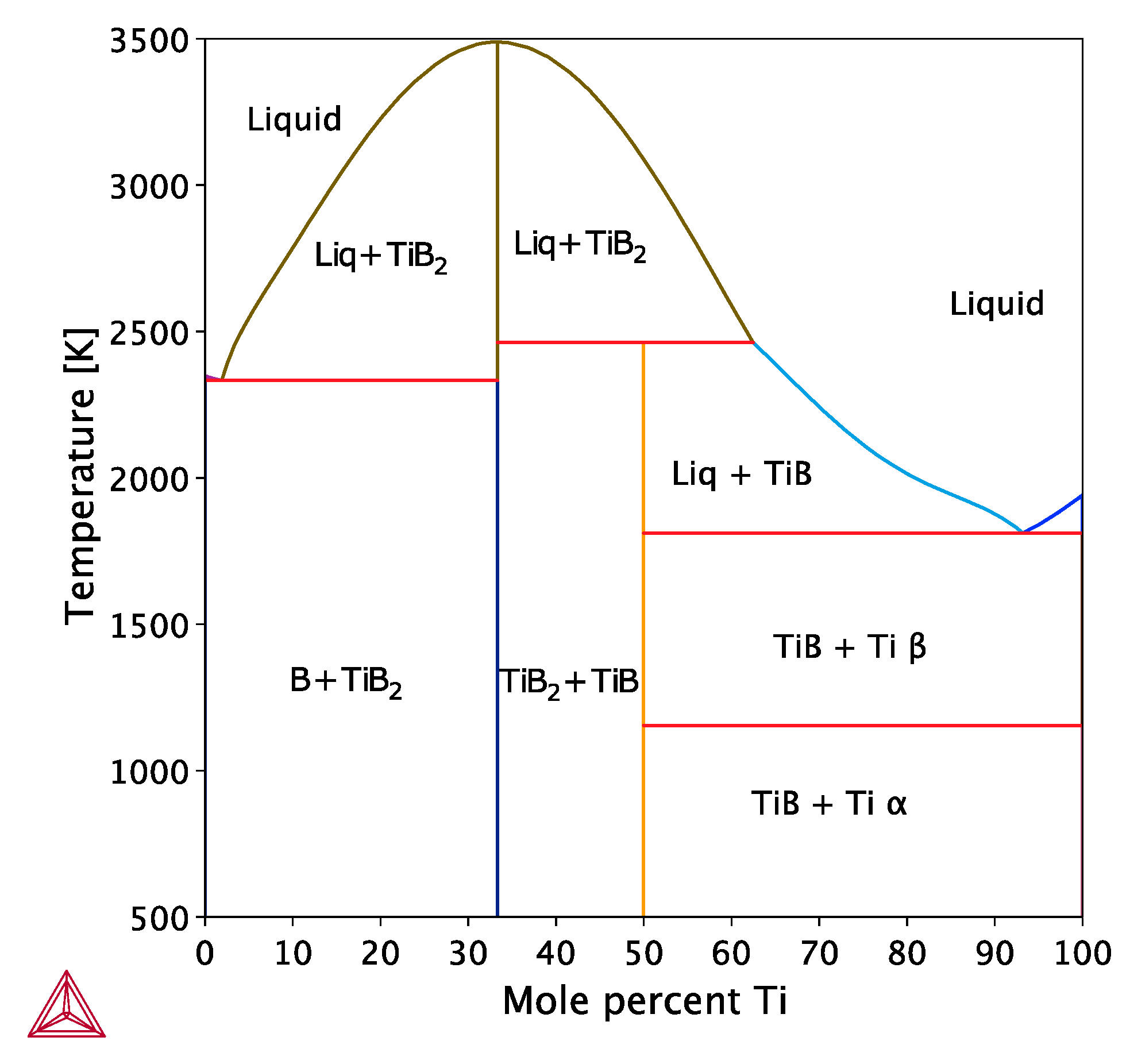

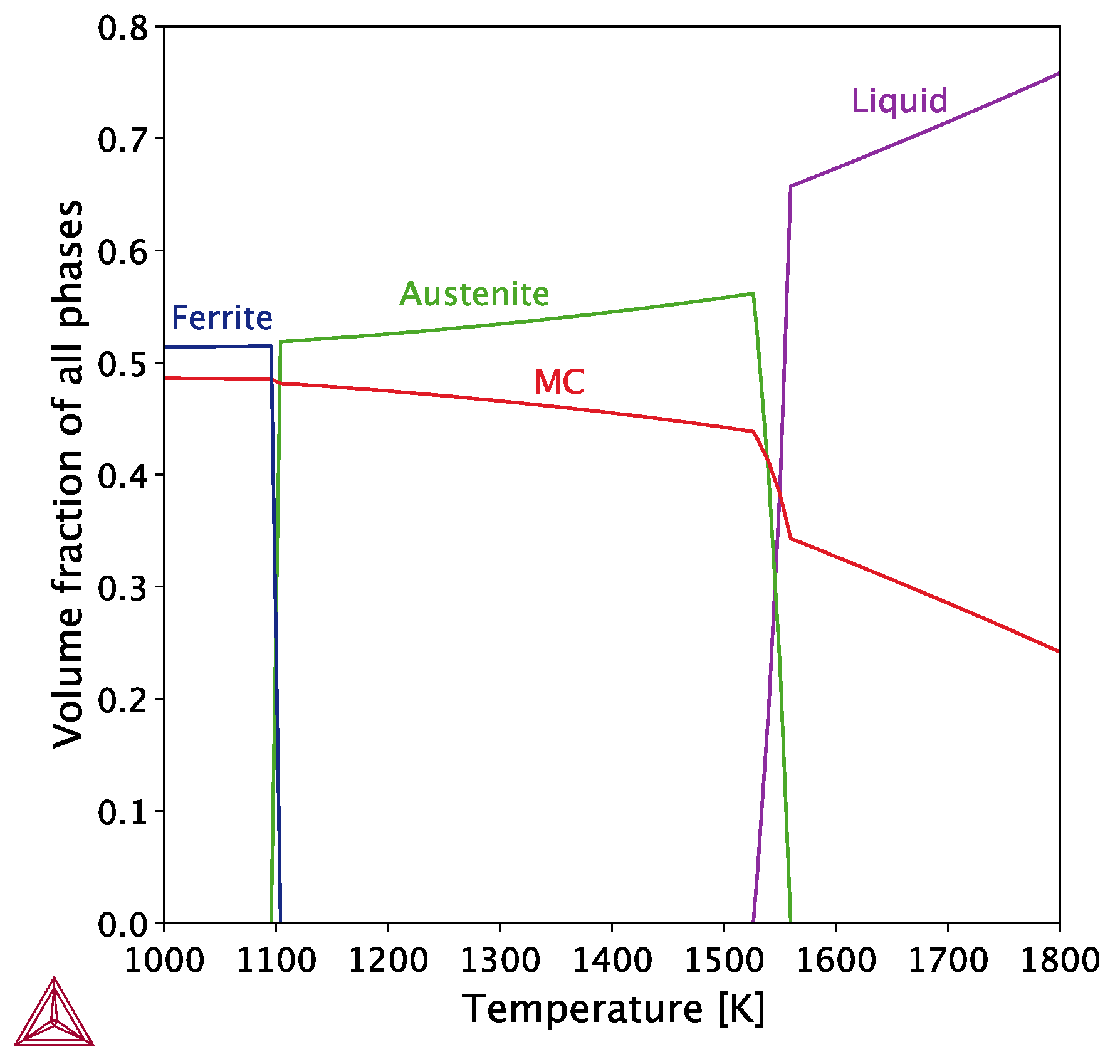

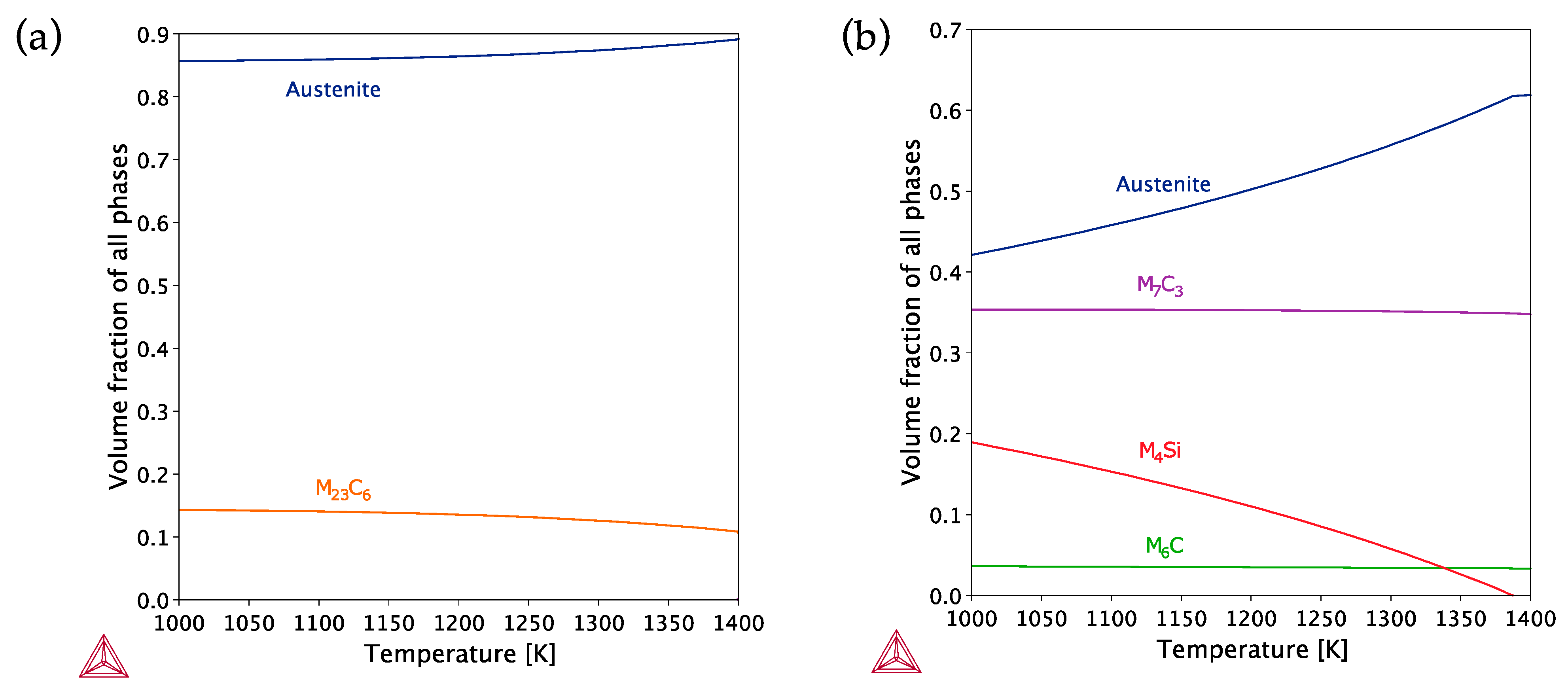

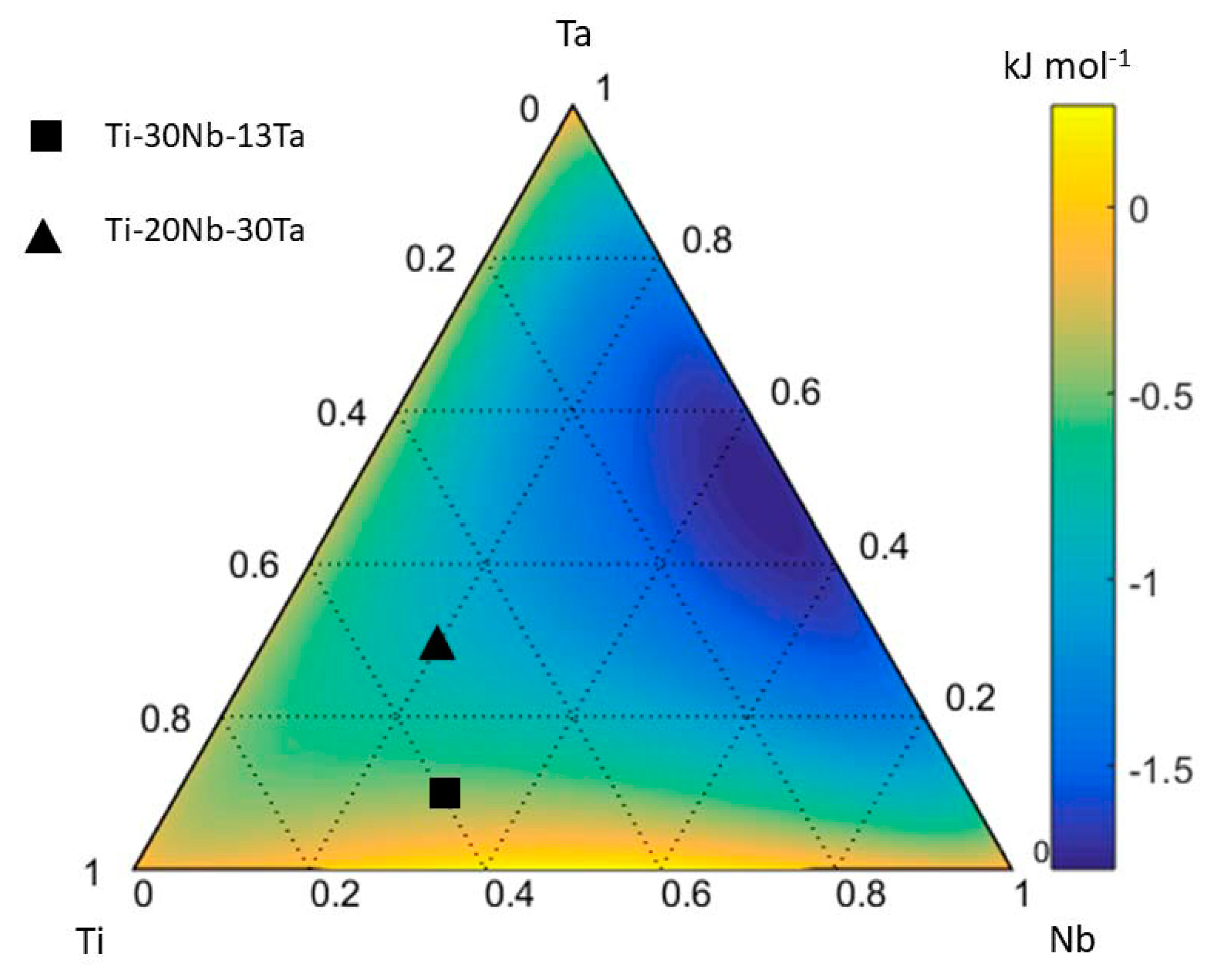

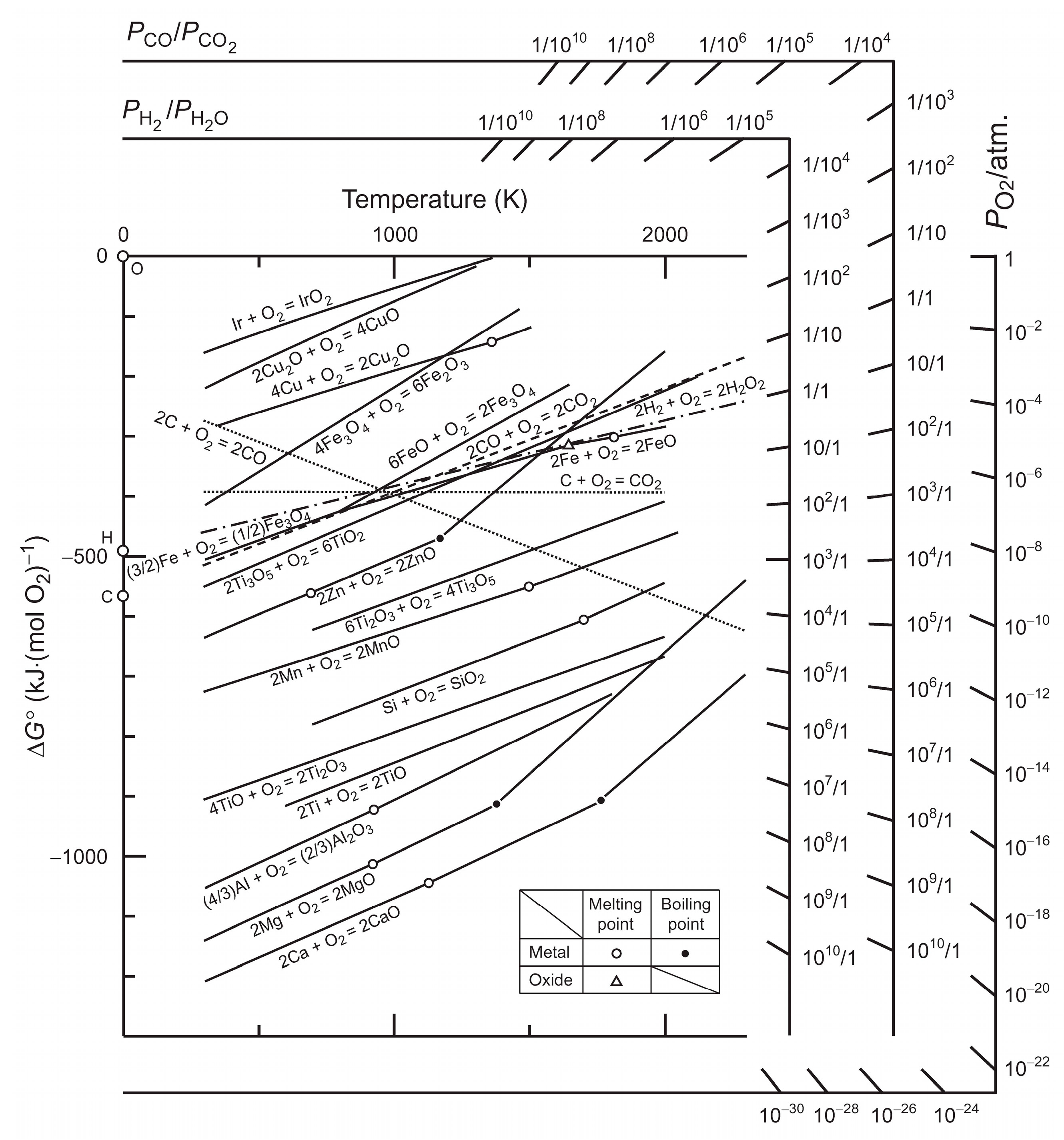

2.1.1. Gibbs Free Energy Criterion

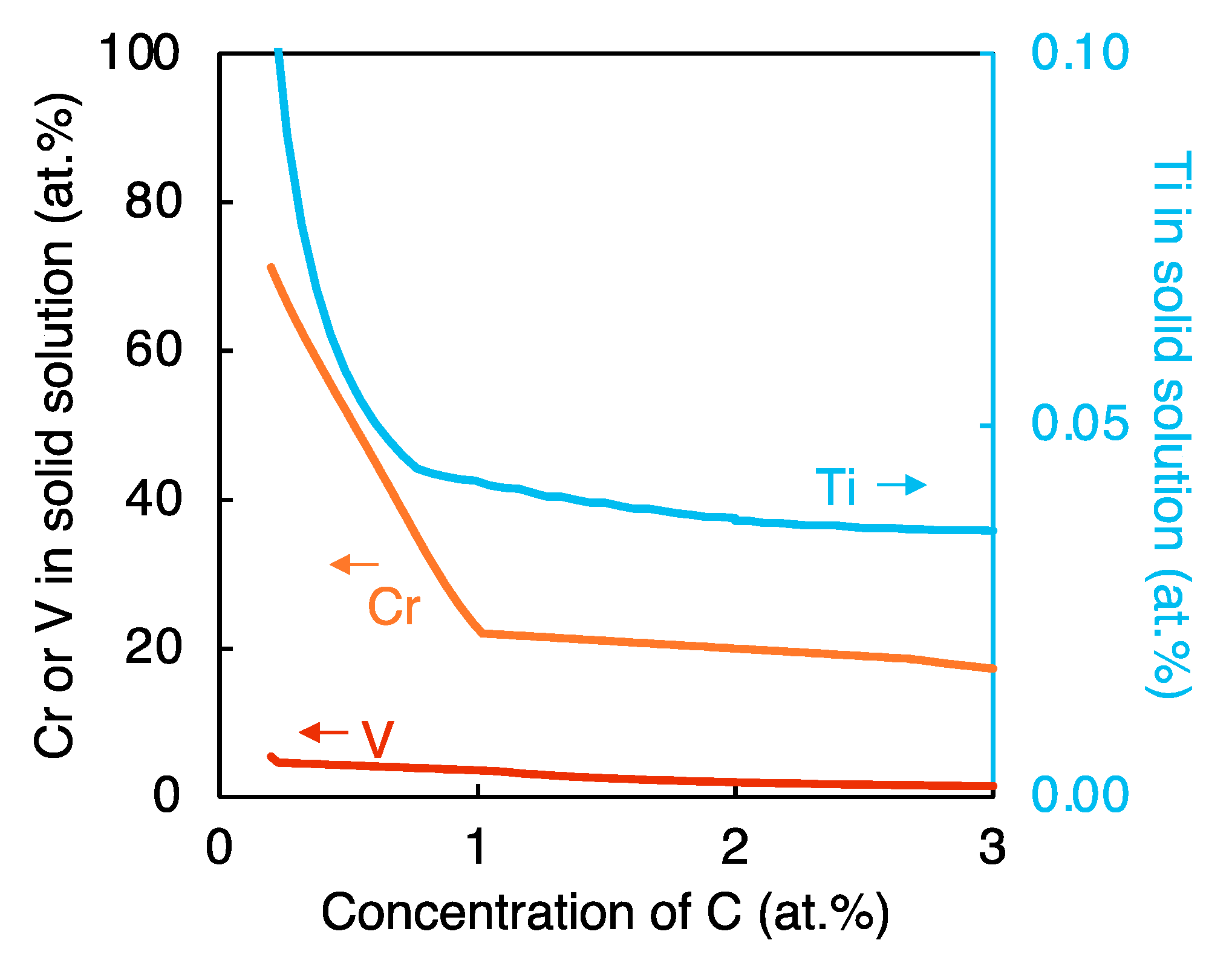

2.1.2. Reinforcement Dissociation Criterion

3. Intrinsic Parameters

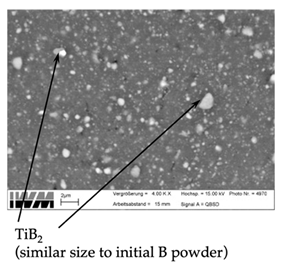

3.1. Raw Material Selection

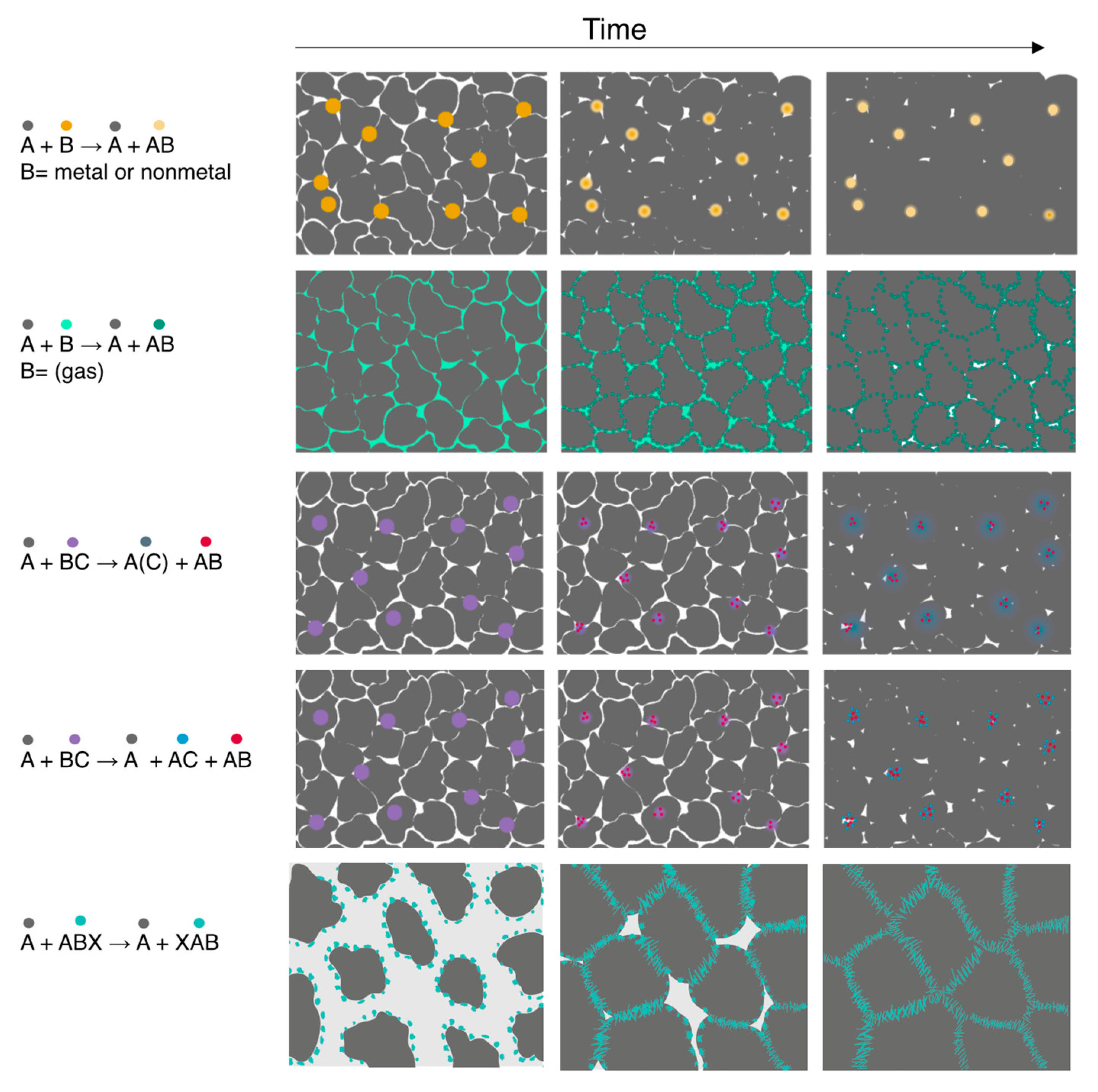

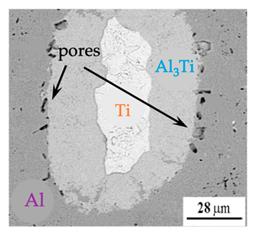

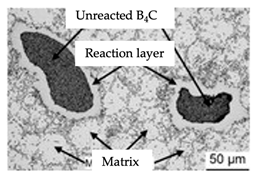

3.1.1. Composite A + AB

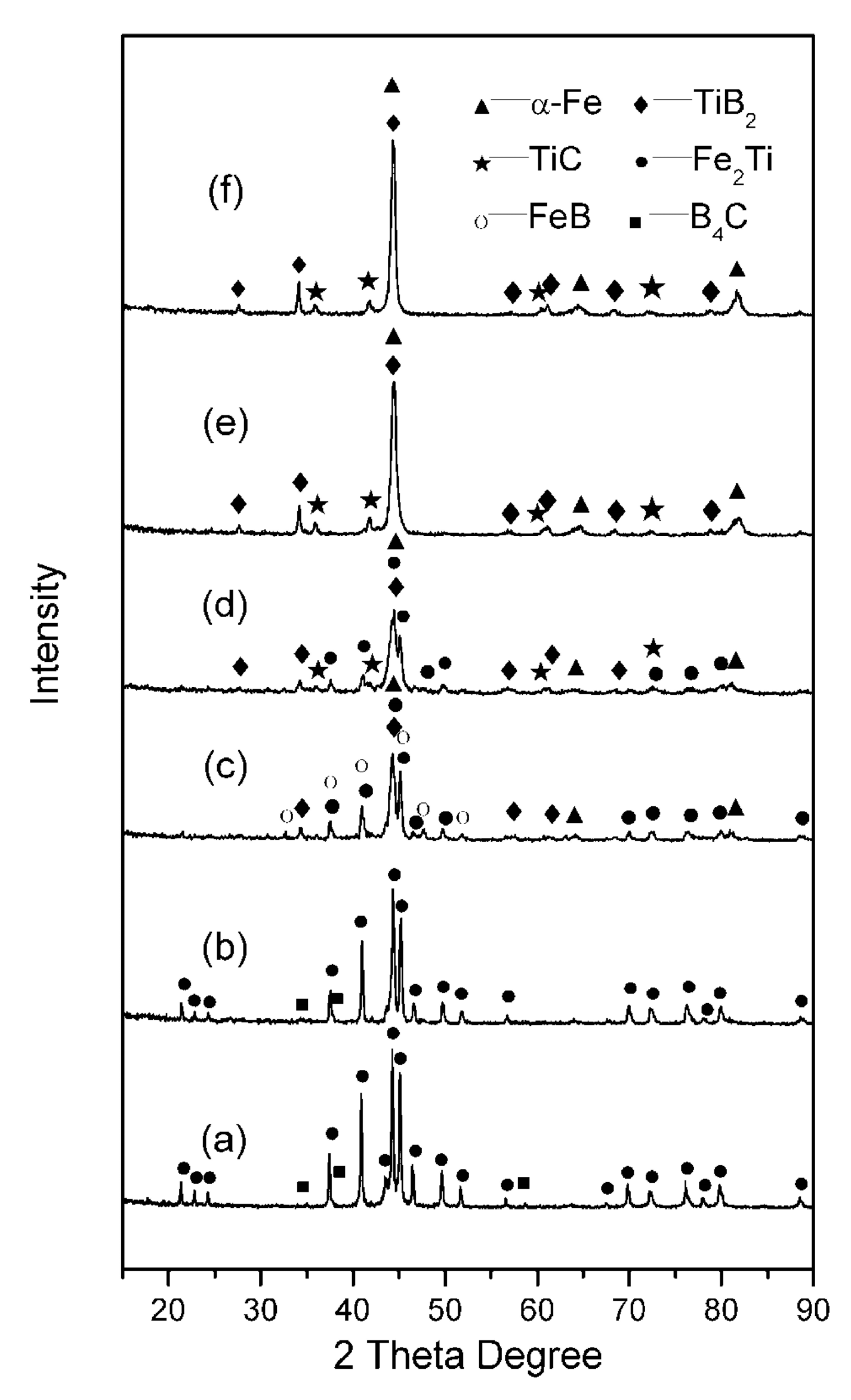

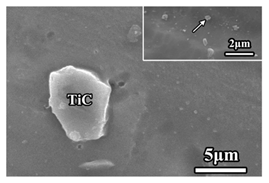

3.1.2. A + BC

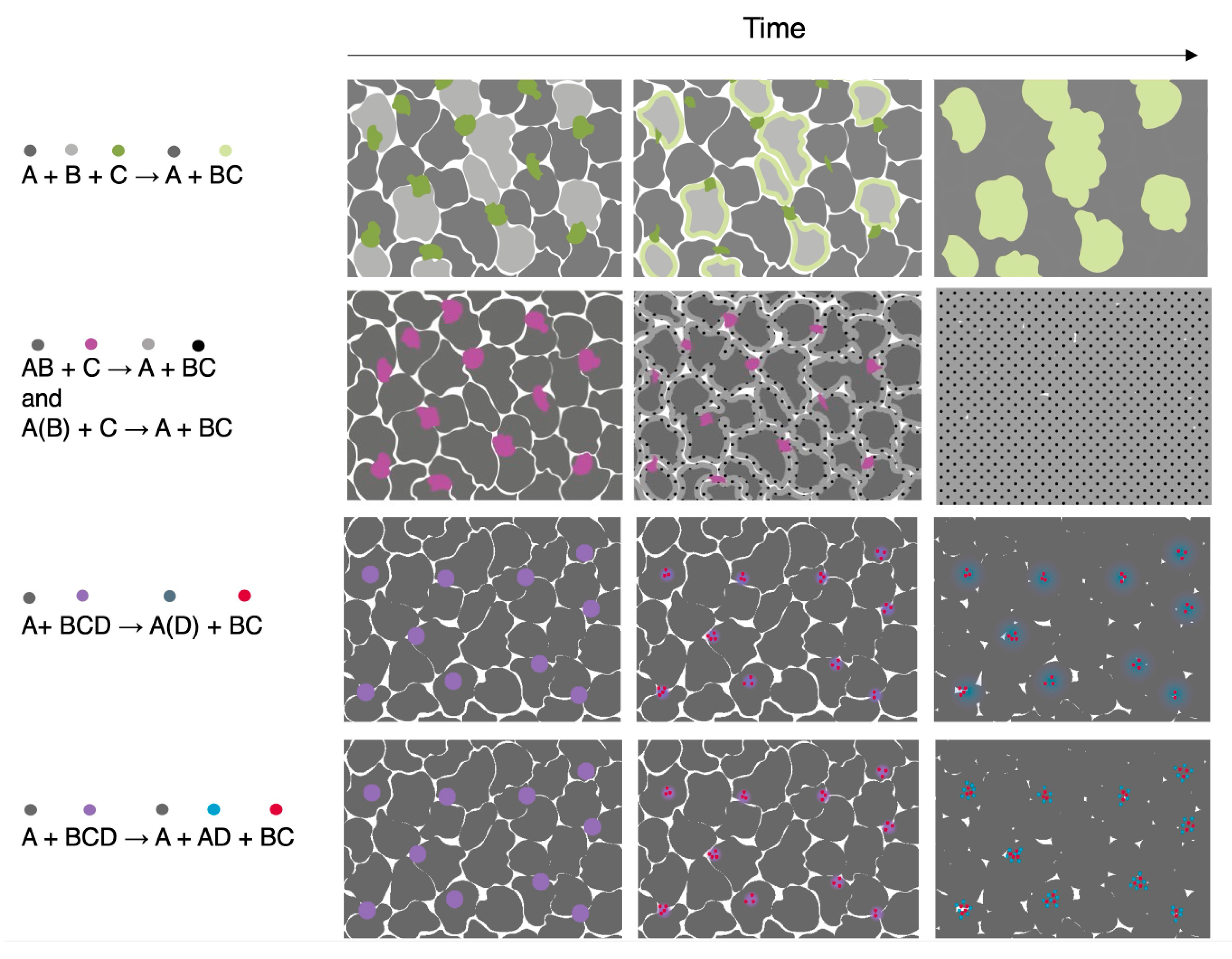

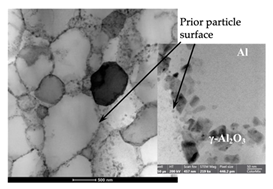

3.1.3. Multi-System Composites

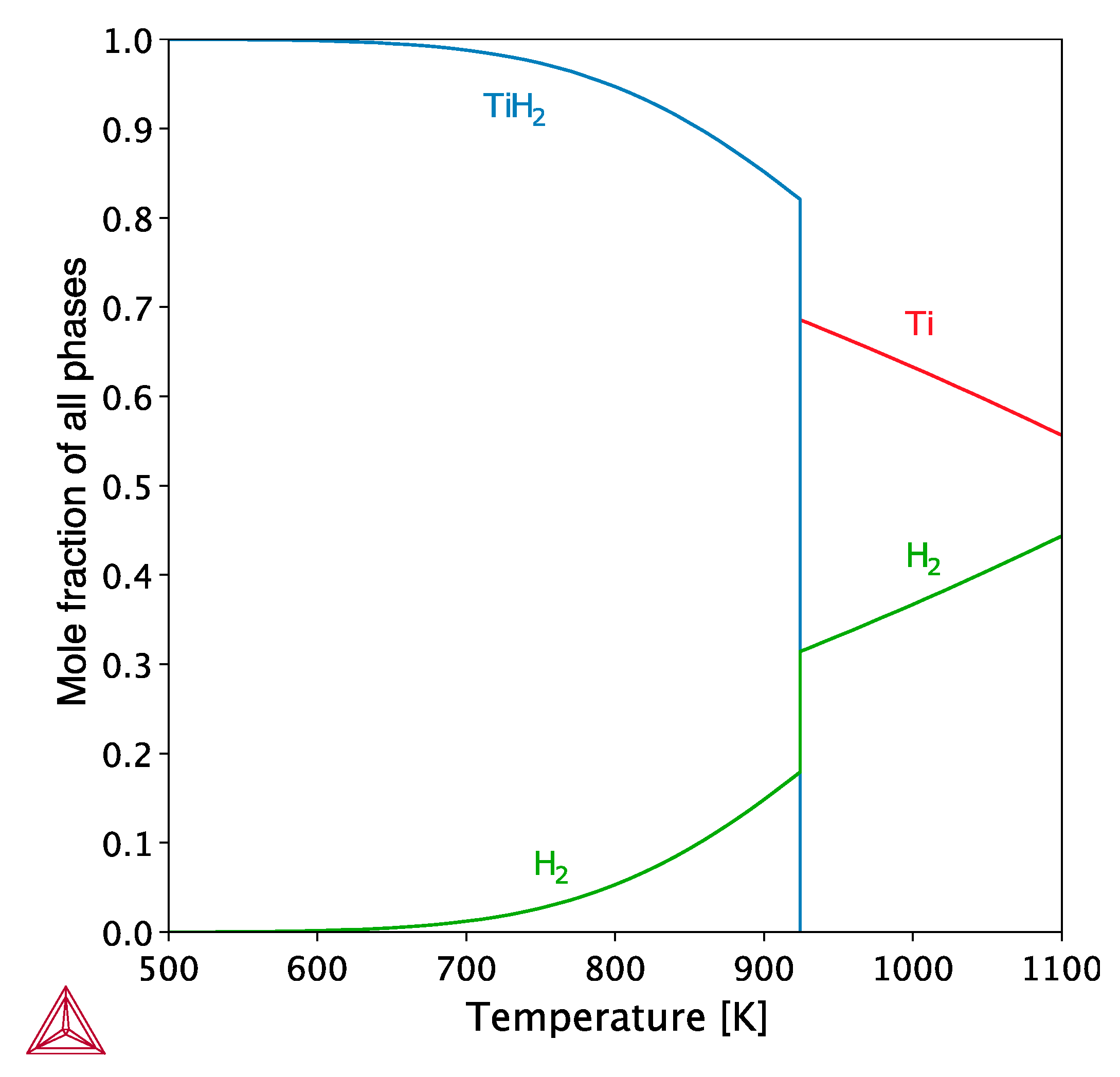

3.1.4. Decomposition Prior to In Situ Reactions

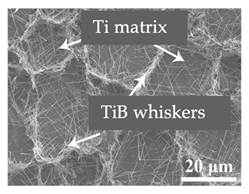

3.2. Parameters Regarding In Situ Reactions

3.2.1. Driving Force of Raw Materials’ Reaction

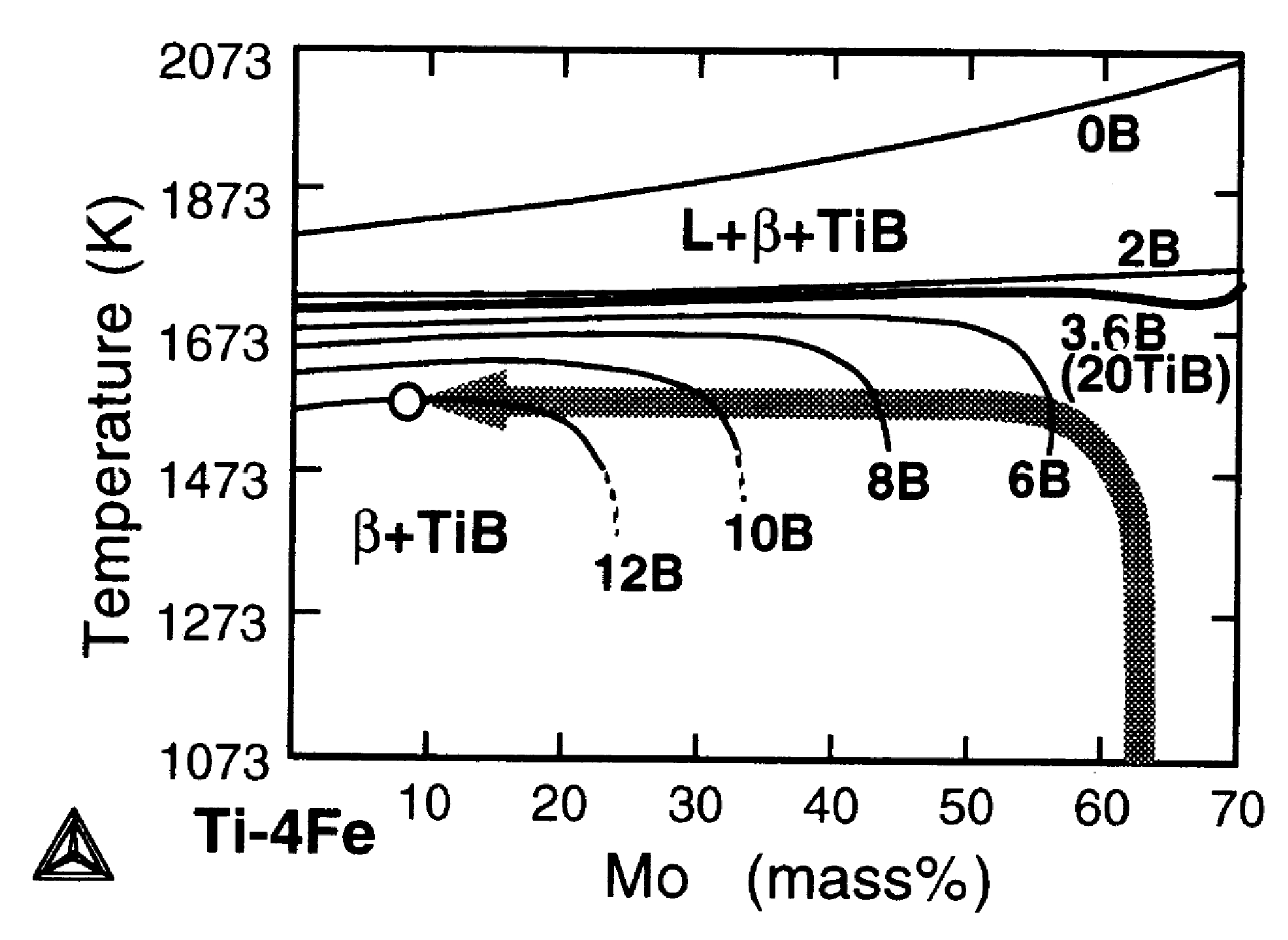

3.2.2. Solubility between Elements in the Composite

3.2.3. Diffusion during In Situ Reactions

3.2.4. In Situ Composites through Atomization

4. Extrinsic Parameters of In Situ Composites

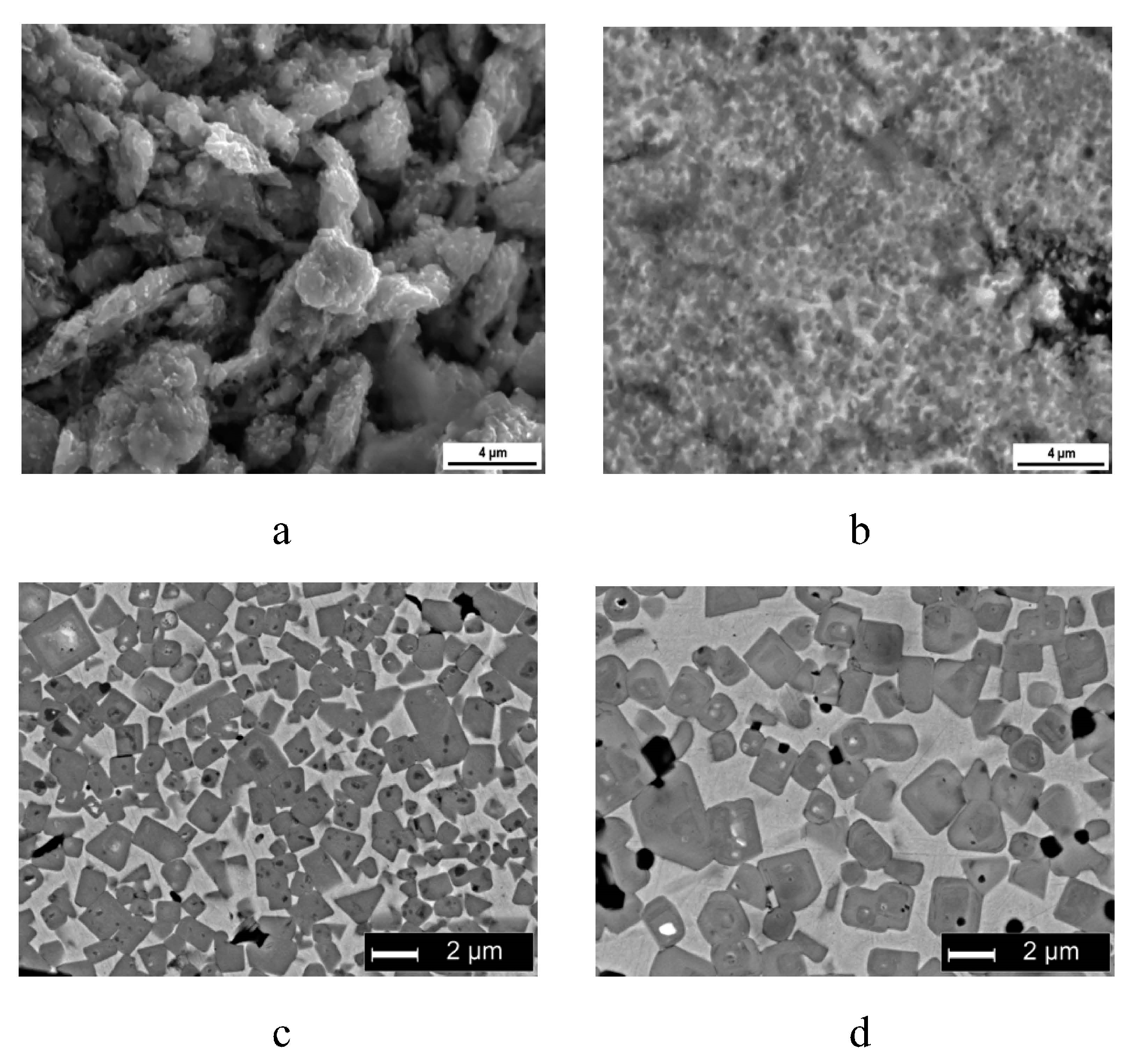

4.1. Milling

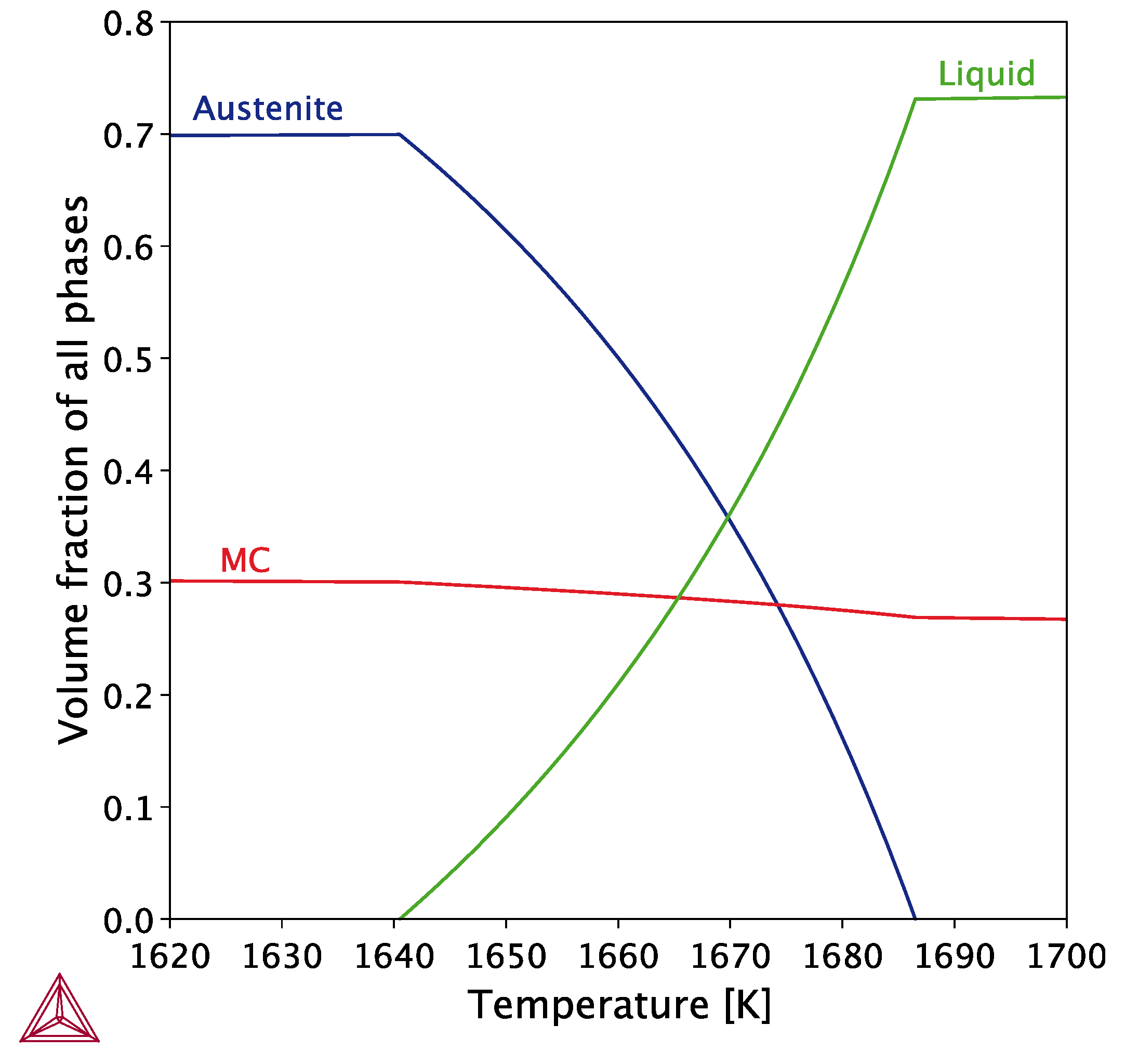

4.2. Time and Temperature

4.2.1. Nucleation and Coarsening

4.2.2. Densification

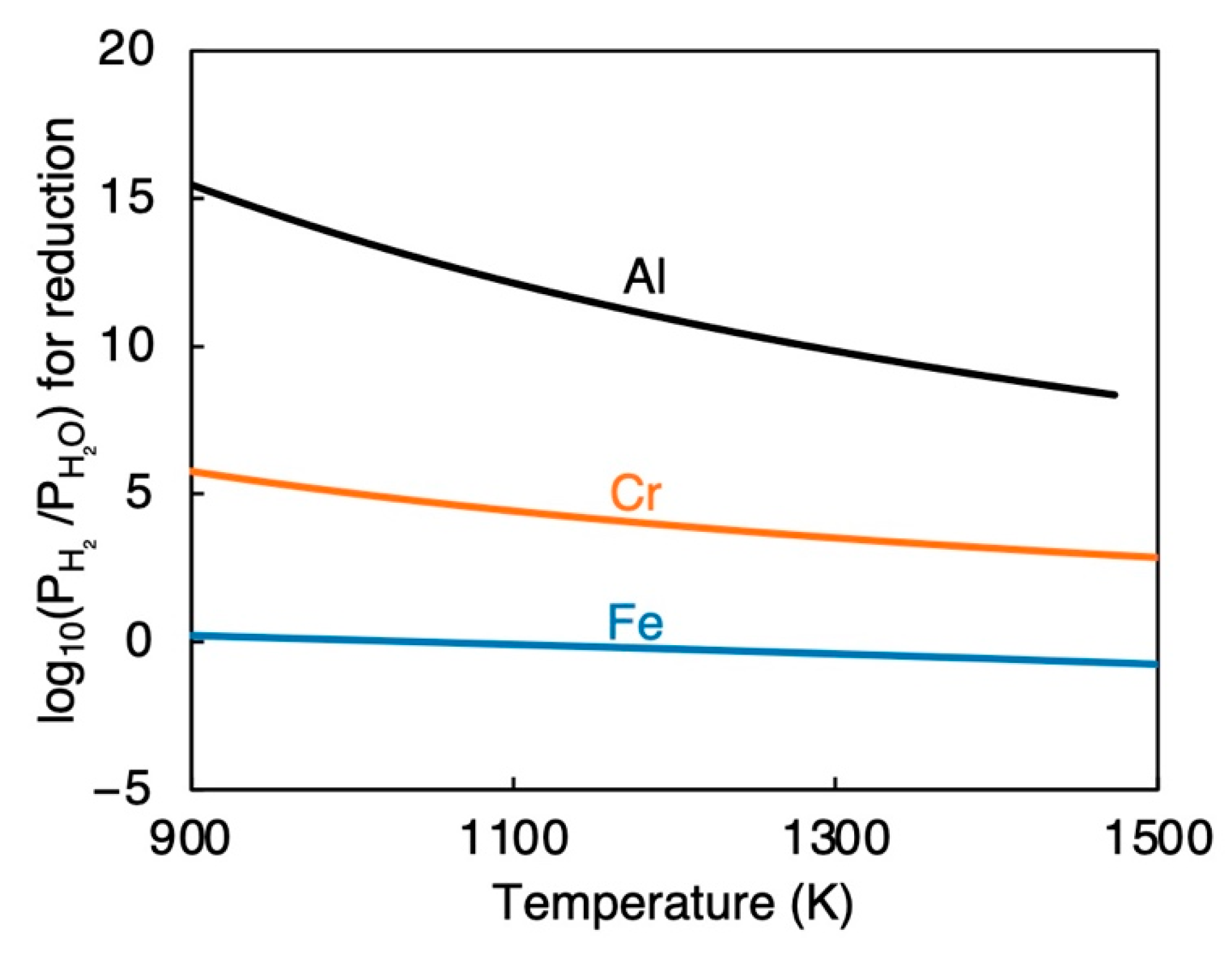

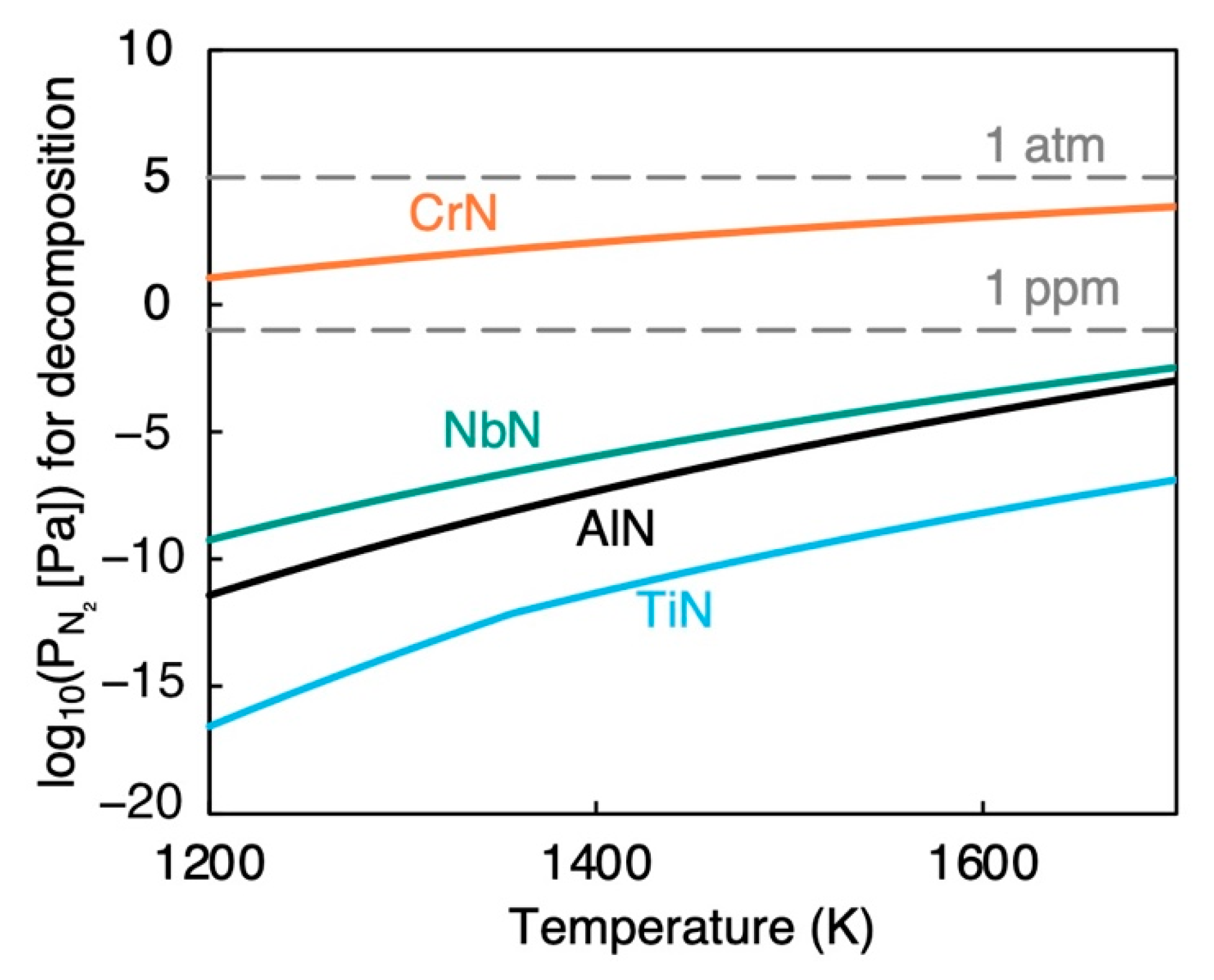

4.3. Atmosphere

5. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Database Search Queries

| Matrix. | Specific Keywords | General Keywords | Format for Scopus Advanced Search |

|---|---|---|---|

| Aluminum | “Aluminum”; “Aluminium”; “Al” | “Matrix” “Dispers*”; “Strength*”; “Composite”; “Nanocomposite”; “Sinter*”; “Powder metallurgy”; “PM”; “MIM”; “Injection mold*”; “SPS”; “SPH”; “HIP”; “In situ”; “In-situ”; “Insitu”; “Reactive sintering”; “Diffusion alloying” | TITLE-ABS-KEY ((aluminum OR aluminium OR al) W/3 (matrix OR (dispers* AND strength*) OR composite OR nanocomposite OR cermet) AND (sinter* OR “powder metallurgy” OR pm OR mim OR “injection mold*” OR sps OR sph OR hip) AND (“in situ” OR “in-situ” OR insitu OR “reactive sintering” OR “diffusion alloying”)) AND (EXCLUDE (DOCTYPE, “cp”) OR EXCLUDE (DOCTYPE, “cr”)) |

| Titanium | “Titanium”; “Ti” | TITLE-ABS-KEY ((titanium OR ti) W/3 (matrix OR (dispers* AND strength*) OR composite OR nanocomposite OR cermet) AND (sinter* OR “powder metallurgy” OR pm OR mim OR “injection mold*” OR sps OR sph OR hip) AND (“in situ” OR “in-situ” OR insitu OR “reactive sintering” OR “diffusion alloying”)) AND (EXCLUDE (DOCTYPE, “cp”) OR EXCLUDE (DOCTYPE, “cr”)) | |

| Nickel | “Nickel”; “Ni” | TITLE-ABS-KEY ((nickel OR ni) W/3 (matrix OR (dispers* AND strength*) OR composite OR nanocomposite OR cermet) AND (sinter* OR “powder metallurgy” OR pm OR mim OR “injection mold*” OR sps OR sph OR hip) AND (“in situ” OR “in-situ” OR insitu OR “reactive sintering” OR “diffusion alloying”)) AND (EXCLUDE (DOCTYPE, “cp”) OR EXCLUDE (DOCTYPE, “cr”)) | |

| Copper | “Cu”; “Copper”; “Brass”; “Bronze” | TITLE-ABS-KEY ((cu OR copper OR brass OR bronze) W/3 (matrix OR (dispers* AND strength*) OR composite OR nanocomposite OR cermet) AND (sinter* OR “powder metallurgy” OR pm OR mim OR “injection moud” OR sps OR sph OR hip) AND (“in situ” OR “in-situ” OR insitu OR “reactive sintering” OR “diffusion alloying”)) AND (EXCLUDE (DOCTYPE, “cp”) OR EXCLUDE (DOCTYPE, “cr”)) | |

| Iron | “Iron”; “Fe”; “Ferr*” | TITLE-ABS-KEY ((iron OR Fe or steel or ferr*) W/3 (matrix OR (dispers* AND strength*) OR composite OR nanocomposite OR cermet) AND (sinter* OR “powder metallurgy” OR pm OR mim OR “injection mold*” OR sps OR sph OR hip) AND (“in situ” OR “in-situ” OR insitu OR “reactive sintering” OR “diffusion alloying”)) AND (EXCLUDE (DOCTYPE, “cp”) OR EXCLUDE (DOCTYPE, “cr”)) |

Appendix B. Summary of Reviewed Literature

| Matrix | Reinforcement | Processing Method | Raw Materials | References |

|---|---|---|---|---|

| Al | Al0.5FeSi0.5 | Pressureless Sintering (PS) | Al; Fe; Si | [92] |

| Al | Al12W | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; W | [93] |

| AA2024 | Al13Co4; Al3Y | Hot Pressing (HP); Hot Extrusion (HE) | AA2024; Al84Ni8.4Y4.8La1.8Co1 | [94] |

| Al | Al13Fe4 | Spark Plasma Sintering (SPS) | Al; Fe | [62] |

| Al | Al2O3 | Pressureless Sintering (PS) | Al | [95] |

| Al(Zn) | Al2O3 | Hot Pressing (HP) | Al; ZnO | [96] |

| Al | Al2O3 | Hot Forging (HF) | Al; O2 | [97] |

| Al | Al2O3 | Hot Pressing (HP) | Al; Fe2O3; Al2O3 | [98] |

| Al(Si,Mg,Cu) | Al2O3 | Pressureless Sintering (PS) | Al; Mg; Cu; Si; SiO2 | [60] |

| Al | Al2O3 | Hot Pressing (HP); Hot Extrusion (HE); Quasi-Isostatic Forging (QIF) | Al; O2 | [41] |

| Al | Al2O3 | Hot Pressing (HP); Hot Extrusion (HE) | Al; O2 | [99] |

| Al | Al2O3 | Hot Pressing (HP); Hot Extrusion (HE) | Al; O2 | [100] |

| Al | Al2O3 | Hot Isostatic pressing (HIP) | Al; O2 | [101] |

| Al(Zn) | Al2O3 | Pressureless Sintering (PS) | Al; ZnO | [102] |

| Al(Zn) | Al2O3 | Pressureless Sintering (PS) | Al; ZnO | [103] |

| Al | Al2O3-(Al3Ti; Al3Zr; TiB2) | Pressureless Sintering (PS) | Al; TiO2; ZrO2; B2O3 | [104] |

| Al | Al2O3; Al11Ce3 | Pressureless Sintering (PS); Friction Stir Processing (FSP) | Al; CeO2 | [105] |

| Al | Al2O3; Al2Cu | Pressureless Sintering (PS) | Al; CuO | [106] |

| Al | Al2O3; Al3Ti | Hot Pressing (HP) | Al; TiO2 | [107] |

| Al | Al2O3; Al3Ti | Hot Pressing (HP) | Al; TiO2 | [108] |

| Al | Al2O3; Al3Ti | Pressureless Sintering (PS) | Al; TiO2 | [109] |

| Al-V | Al2O3; Al3V; Al10V | Pressureless Sintering (PS) | Al; V2O5 | [110] |

| Al | Al2O3; Al3Zr | Pressureless Sintering (PS) | Al; ZrO2 | [111] |

| Al | Al2O3; AlNi; Al3Ni; Al3Ni2 | Hot Pressing (HP) | Al; NiO | [23] |

| Al | Al2O3; Carbon Nanotube (CNT) | Spark Plasma Sintering (SPS); Hot Extrusion (HE) | Al; Multiwalled Carbon Nanotubes (MWCNTs); O2 | [112] |

| Al | Al2O3; CuAl2 | Pressureless Sintering (PS); Hot Pressing (HP) | Al; CuO | [113] |

| Al | Al2O3; CuAl2 | Pressureless Sintering (PS) | Al; CuO | [114] |

| Al | Al2O3; CuAl2 | Pressureless Sintering (PS) | Al; CuO | [115] |

| Al | Al2O3; FeAl2; FeAl3 | Spark Plasma Sintering (SPS) | Al; Fe2O3 | [116] |

| Al | Al2O3; Si | Pressureless Sintering (PS) | Al; SiO2 | [117] |

| Al | Al2O3; Si | Pressureless Sintering (PS) | Al; SiO2 | [118] |

| Al | Al2O3; Si | Hot Isostatic Pressing (HIP); High Pressure Torsion (HPT) | Al; SiO2 | [119] |

| Al | Al2O3; Si | Pressureless Sintering (PS) | Al; SiO2 | [120] |

| Al | Al2O3; SiC; Al4C3; Si | Pressureless Sintering (PS); Hot Pressing (HP) | Al; SiO2; C | [121] |

| Al | Al2O3; TiB2 | Pressureless Sintering (PS) | Al; TiO2; B2O3 | [122] |

| Al | Al2O3; TiB2; Al3Ti | Pressureless Sintering (PS); Hot Pressing (HP); Hot Extrusion (HE) | Al; TiO2; B | [123] |

| Al | Al2O3; TiB2; TiC | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; TiO2; B4C | [124] |

| Al | Al2O3; TiC | Hot Isostatic Pressing (HIP) | Al; TiO2; C | [125] |

| Al | Al2O3; TiC; Al3Ti; AlN | Pressureless Sintering (PS) | Al; C; TiO2; N2 | [126] |

| Al | Al2O3; WAl12 | Hot Pressing (HP); Hot Extrusion (HE) | Al; WO3 | [127] |

| Al | Al2O3; ZrB2 | Pressureless Sintering (PS); Hot Pressing (HP) | Al; ZrO2; B | [128] |

| Al | Al2OC-AlN; Al5O6N; Al7O3N5 | Pressureless Sintering (PS) | Al; Al2O3; N2 | [129] |

| Al | Al3(Zr, Ti) | Pressureless Sintering (PS); Hot Pressing (HP) | Al; Zr; Ti | [130] |

| Al | Al3CON; Al5O6N | Pressureless Sintering (PS) | Al; NH3; Ethylene-bis Stearamide | [131] |

| Al | Al3Ni; Al3Ni2; CeO2 | Pressureless Sintering (PS) | Al; Ni; CeO2 | [132] |

| Al | Al3Ti | Hot Extrusion (HE); Pressureless Sintering (PS) | Al; Ti | [22] |

| Al | Al3Ti | Pressureless Sintering (PS); Hot Pressing (HP) | Al; Ti | [133] |

| AA6061 | Al3Ti | Spark Plasma Sintering (SPS) | AA6061; Ti | [134] |

| Al | Al3Ti | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; Ti | [40] |

| A356 | Al3Ti | Pressureless Sintering (PS) | A356; Ti | [135] |

| Al | Al3Ti | Pressureless Sintering (PS) | Al; Ti | [136] |

| Al | Al3Ti | Spark Plasma Sintering (SPS) | Al; Ti | [137] |

| Al | Al3Ti | Spark Plasma Sintering (SPS); Hot Rolling (HR) | Al; Ti | [138] |

| Al | Al3Ti | Spark Plasma Sintering (SPS) | Al; Ti | [139] |

| Al | Al3Ti | Hot Extrusion (HE); Hot Isostatic Pressing (HIP) | Al; Ti | [140] |

| Al | Al3Ti | Hot Pressing (HP); Friction Stir Processing (FSP) | Al; Ti | [141] |

| AA2024 | Al3Ti; Al2O3 | Hot Pressing (HP) | Al; TiO2 | [1] |

| Al | Al3Ti; Al2O3 | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; Al2TiO5 | [142] |

| Al | Al3Ti; Al3O2 | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; Al2TiO5 | [143] |

| AA7075 | Al3Ti; B4C | Pressureless Sintering (PS) | AA7075; Ti; B4C | [144] |

| Al | Al3Zr | Spark Plasma Sintering (SPS); Hot Forging (HF) | Al; ZrH2 | [145] |

| Al | Al3Zr; Al2O3 | Hot Pressing (HP); Hot Extrusion (HE); Hot Rolling (HR) | Al; ZrO2 | [146] |

| Al | Al3Zr; Al2O3 | Hot Pressing (HP); Hot Extrusion (HE); Hot Rolling (HR) | Al; ZrO2 | [147] |

| Al | Al4C3 | Hot Pressing (HP) | Al; Polyvinyl Butyral (PVB) | [72] |

| Al | Al4C3 | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; C | [148] |

| Al | Al4C3 | Pressureless Sintering (PS) | Al; C | [149] |

| Al | Al4C3 | Pressureless Sintering (PS) | Al; C | [150] |

| Al | Al4C3 | Pressureless Sintering (PS) | Al; C | [151] |

| Al-O | Al4C3 | Hot Pressing (HP) | Al; Polyvinyl Buyral (PVB) | [152] |

| Al | Al4C3 | Spark Plasma Sintering (SPS); Hot Extrusion (HE) | Al; CNTs | [153] |

| Al | Al4C3 | Spark Plasma Sintering (SPS); Hot Extrusion (HE) | Al; Multiwalled Carbon Nanotubes (MWCNTs) | [154] |

| Al | Al5Fe2; Al13Fe4-Fe | Gas-Pressure Sintering (GPS) | Al; Fe | [63] |

| Al | Al5Fe2; AlN | Gas-Pressure Sintering (GPS) | Al; Fe; N2 | [64] |

| Al | Al9Co2 | Pressureless Sintering (PS) | Al; Co | [155] |

| Al | AlB2 | Spark Plasma Sintering (SPS); Hot Rolling (HR) | Al; B | [156] |

| AA6061 | AlN | Pressureless Sintering (PS); Equal Channel Angular Pressing (ECAP) | AA6061; Mg; Sn; Nylon; N2 | [157] |

| Al | AlN | Pressureless Sintering (PS); Hot Extrusion (HE) | AA6061; Mg; Sn; Nylon; N2 | [158] |

| Al | AlN | Pressureless Sintering (PS); Hot Forging (HF) | Al(Si,Ni,Mg); N2 | [159] |

| Al | AlN | Pressureless Sintering (PS); Hot Forging (HF) | Al(Si, Ni, Mg, Fe); N2 | [160] |

| Al | AlN | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; Mg; Sn; N2 | [89] |

| Al | AlN | Hot Pressing (HP) | Al; N2 | [161] |

| Al | AlN | Pressureless Sintering (PS) | Al; NH3 | [162] |

| AA2024 | AlN | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; Al-Mg; Cu; N2 | [163] |

| Al | AlN | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; Sn; N2 | [164] |

| Al | AlN; AlB2 | Pressureless Sintering (PS) | Al; hBN | [165] |

| Al | AlN; Si | Pressureless Sintering (PS); Hot Extrusion (HE) | Al(Si, Ni, Mg, Fe); N2 | [166] |

| AA6061 | La2Si2O7 | Pressureless Sintering (PS) | AA6061; La | [167] |

| AA6061 | Mg(Al)B2 | Hot Pressing (HP); Hot Forging (HF); Hot Rolling (HR) | AA6061; B4C | [168] |

| AA6061 | MgAl2O4 | Pressureless Sintering (PS); Hot Extrusion (HE) | AA6061; Mg; H3BO3 | [169] |

| AA6061 | MgAl2O4 | Hot Pressing (HP) | AA6061; Mg; H3BO3 | [170] |

| AA6061 | MgAl2O4 | Pressureless Sintering (PS); Hot Extrusion (HE) | AA6061; Mg; H3BO3 | [171] |

| Al | MgAl2O4 | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; Mg; H3BO3 | [172] |

| Al | MgAl2O4 | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; Mg; H3BO3 | [173] |

| Al | MgAl2O4; (Mg,Al)B2 | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; Mg; H3BO3 | [13] |

| Al | MgAl2O4; MgZn2 | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; Mg; ZnO | [174] |

| Al | MgAlB4 | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; Mg; B | [175] |

| Al | MoAl12; MoAl5; MoAl4; Al2O3 | Pressureless Sintering (PS) | Al; MoO3 | [176] |

| Al | Nano-C; Al2O3; Si | Hot Isostatic Pressing (HIP); Equal Channel Angular Pressing (ECAP) | Al; SiO2; CNTs; GNPs | [177] |

| Al | Ni-(Al3Ni2; Al3Ni; AlN) | Gas-Pressure Sintering (GPS) | Al; Ni; N2 | [178] |

| AA2014 | Ni3Al; NiAl | Hot Extrusion (HE) | AA2014; Ni | [21] |

| Al | Ni3Al; NiAl; Al3Ni | Hot Pressing (HP) | Al; Ni3Al | [179] |

| Al | Si; Al2O3; Multiwalled Carbon Nanotubes (MWCNTs) | Hot Pressing (HP) | Al; SiO2; Multiwalled Carbon Nanotubes (MWCNTs) | [180] |

| Al | SiC; AlN | Spark Plasma Sintering (SPS) | SiCN; Al | [181] |

| Al | Ti-Al3Ti | Spark Plasma Sintering (SPS) | Al; Ti | [182] |

| Al | Ti-Al3Ti | Gas-Pressure Sintering (GPS) | Al; Ti | [183] |

| AA7050 | TiB2 | Hot Isostatic Pressing (HIP) | AA7050; TiB2 | [184] |

| Al | TiB2 | Spark Plasma Sintering (SPS); Hot Extrusion (HE) | Al; Ti; B | [46] |

| Al | TiB2 | Pressureless Sintering (PS) | Al; Ti; B | [53] |

| Al | TiB2; Al2O3 | Pressureless Sintering (PS) | Al; B; TiO2 | [51] |

| Al | TiB2; Al2O3; Al2Cu | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; Cu; TiO2; B2O3 | [185] |

| Al(Cu) | TiB2; TiAl3 | Microwave Heating (MH) | Al; Ti; B; Cu | [186] |

| Al | TiC | Pressureless Sintering (PS); Hot Pressing (HP) | Al; Ti; C | [14] |

| Al | TiC | Pressureless Sintering (PS) | Al; K2TiF6; C | [187] |

| Al | TiO; Al2O3 | Pressureless Sintering (PS) | Ti2CO; Al | [188] |

| Al | WAl12 | Spark Plasma Sintering (SPS) | Cu; Zr; Al; Ti; Ni; W | [189] |

| Al | WAl12 | Hot Pressing (HP) | Al; W | [190] |

| Al | WAl12 | Hot Pressing (HP) | Al; W | [191] |

| Al | y-LiAlO2 | Pressureless Sintering (PS); Arc Melting (AM) | Al; Li2O | [192] |

| Al | Y2O3; Al5Y3O12; CaO; CaAl4O7; CuAl2; FeAl3 | Hot Pressing (HP); Hot Extrusion (HE) | Al-Ca; Al-Y; CuO; Fe2O3 | [193] |

| Al | α-Al2O3; Al2Cu | Pressureless Sintering (PS) | Al; CuO | [194] |

| Al | α-Al2O3; Si | Pressureless Sintering (PS) | Al; SiO2 | [195] |

| Al | α-Al2O3; ZrB2 | Hot Pressing (HP) | Al; ZrO2; B | [16] |

| Al | β-Al3Mg2 | Hot Extrusion (HE) | Al; Mg | [196] |

| Al | β-Al3Mg2; γ-Al12Mg17 | Hot Pressing (HP) | Al; Mg | [56] |

| Al | γ-Al2O3 | Pressureless Sintering (PS); Hot Extrusion (HE) | Al; H3BO3; C18H36O2 | [15] |

| Matrix | Reinforcement | Processing Method | Raw Materials | References |

|---|---|---|---|---|

| Ti | GNPs; TiB; TiC | Spark Plasma Sintering (SPS) | Ti; Graphene Nanoplatelets (GNPs); TiB2 | [197] |

| Ti | Ti(C,N); TiC | Spark Plasma Sintering (SPS) | Ti; Graphene Nanoplatelets (GnP); g-C3N4 | [198] |

| Ti | Ti2Co | Spark Plasma Sintering (SPS) | GO; Co; Ti | [199] |

| Ti(Al,Zr,Mo,V) | Ti3AlC; TiC | Spark Plasma Sintering (SPS) | Ti(Al,Zr,Mo,V); Ti3AlC2 | [200] |

| Ti | Ti5Si3 | Spark Plasma Sintering (SPS) | Ti; Si | [201] |

| Ti | Ti5Si3 | Spark Plasma Sintering (SPS) | Ti; SiO2 | [202] |

| Ti(Mo) | Ti5Si3 | Spark Plasma Sintering (SPS); Hot Rolling (HR) | Ti; Mo; Si | [203] |

| Ti | Ti5Si3; Ti2C | Hot Pressing (HP) | Ti; SiC | [204] |

| Ti (Fe, Mo, Al); β-Ti | TiB | Electric Field Assisted Sintering (EFAS) | Ti; TiB2; Mo; Fe; Al | [85] |

| Ti | TiB | Coupled Multi-Physical Fields Activation Sintering Technology (CMPFAST) | Ti6Al4V; TiB2 | [205] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2 | [206] |

| Ti6Al4V | TiB | Spark Plasma Sintering (SPS) | Ti6Al4V; TiB2 | [207] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2 | [208] |

| Ti | TiB | Pressureless Sintering (PS) | Ti; TiB2 | [209] |

| Ti | TiB | Pressureless Sintering (PS) | Ti; TiB2 | [210] |

| Ti6Al4V | TiB | Hot Isostatic Pressing (HIP) | Ti6Al4V; TiB2 | [211] |

| Ti | TiB | Pulse Plasma Sintering (PPS) | Ti; B | [212] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2 | [213] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2 | [214] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2 | [215] |

| Ti; β-Ti | TiB | Spark Plasma Sintering (SPS) | Ti; KBF4; Al; Fe | [216] |

| Ti6Al4V | TiB | Spark Plasma Sintering (SPS) | Ti6Al4V; Ti; TiB2 | [217] |

| Ti(Al,Mo,V,Cr) | TiB | Pressureless Sintering (PS); Extrusion (E) | Ti-Al-Mo-V-Zr; TiB2 | [218] |

| Ti6Al4V | TiB | Pressureless Sintering (PS); Hot Extrusion (HE) | Ti6Al4V; TiB2 | [219] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2 | [220] |

| Ti | TiB | Pulse Plasma Sintering (PPS) | Ti; B | [221] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2 | [222] |

| Ti6Al4V | TiB | Pressureless Sintering (PS); Hot Extrusion (HE) | Ti6Al4V; TiB2 | [223] |

| Ti6Al4V | TiB | Hot Isostatic Pressing (HIP) | Ti6Al4V; TiB2 | [224] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2 | [225] |

| Ti | TiB | Pressureless Sintering (PS) | Ti; B | [226] |

| Ti6Al4V | TiB | Pressureless Sintering (PS); Hot Extrusion (HE) | Ti6Al4V; TiB2 | [227] |

| Ti6Al4V | TiB | Hot Isostatic Pressing (HIP) | Ti6Al4V; TiB2 | [228] |

| Ti6Al4V | TiB | Spark Plasma Sintering (SPS) | Ti6Al4V; Ti; TiB2 | [229] |

| Ti-Al-Mo-Fe | TiB | Pressureless Sintering (PS) | Ti; Al; Mo; Fe; TiB2; LaB6 | [230] |

| Ti | TiB | Pressureless Sintering (PS); Selective Laser Melting (SLM) | Ti; TiB2 | [231] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; KBF4 | [232] |

| Ti6Al4V | TiB | Hot Pressing (HP) | Ti6Al4V; TiB2 | [233] |

| Ti6Al4V | TiB | Hot Pressing (HP) | Ti6Al4V; TiB2 | [234] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2 | [235] |

| Ti(Fe,Mo) | TiB | Spark Plasma Sintering (SPS) | Ti; Fe-Mo; TiB2 | [236] |

| Ti60 | TiB | Hot Pressing (HP) | T60; TiB2 | [237] |

| Ti6Al4V | TiB | Hot Pressing (HP) | Ti6Al4V; TiB2 | [238] |

| Ti | TiB | Hot Pressing (HP) | Ti; TiB2 | [239] |

| Ti6Al4V | TiB | Spark Plasma Sintering (SPS) | Ti6Al4V; TiB2 | [240] |

| Ti6Al4V | TiB | Hot Pressing (HP) | Ti6Al4V; TiB2 | [241] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2 | [242] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2 | [243] |

| Ti | TiB | Current-Activated Pressure-Assisted Sintering (CAPAS); Pressureless Sintering (PS) | Ti; TiB2 | [31] |

| Ti | TiB | Current-Activated Pressure-Assisted Sintering (CAPAS); Pressureless Sintering (PS) | Ti; B; TiB2 | [244] |

| Ti(Mo, Fe) | TiB | Hot Pressing (HP) | Ti; Fe65Mo; B; TiB2 | [245] |

| Ti(Fe,Mo) | TiB | Spark Plasma Sintering (SPS) | Ti; Fe65Mo; B; TiB2 | [246] |

| Ti(Fe,Mo) | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2; Fe65Mo | [247] |

| Ti(Fe,Mo) | TiB | Spark Plasma Sintering (SPS) | Ti; Fe65Mo; B | [248] |

| Ti | TiB | Hot Pressing (HP) | Ti; TiB2 | [249] |

| β-Ti | TiB | Hot Pressing (HP) | β-Ti(Mo, Nb, Al, Si); TiB2; α-Ti; Fe-Mo; Mo; Nb | [87] |

| β-Ti | TiB | Hot Pressing (HP) | Ti; Fe-Mo, TiB2 | [250] |

| Ti6Al4V | TiB | Hot Isostatic Pressing (HIP) | Ti6Al4V; B | [251] |

| Ti | TiB | Hot Pressing (HP) | Ti; TiB2 | [252] |

| Ti(Al,Sn,Zr,Mo) | TiB | Pressureless Sintering (PS); Hot Isostatic Pressing (HIP) | Ti(Al,Sn,Zr,Mo); TiB2 | [253] |

| Ti(N) | TiB | Spark Plasma Sintering (SPS); Hot Extrusion (HE) | Ti; h-BN | [34] |

| Ti | TiB | Spark Plasma Sintering (SPS) | Ti; TiB2 | [254] |

| Ti6Al4V | TiB | Plasma Activated Sintering (PAS) | Ti6Al4V; TiB2 | [255] |

| Ti | TiB | Pressureless Sintering (PS); Binder Jetting Printing (BJP) | TiH2; TiB2 | [256] |

| Ti(Ta,Ni) | TiB | Pressureless Sintering (PS) | Ti(Ta,N)i; TiB2 | [257] |

| Ti | TiB | Pressureless Sintering (PS) | Ti; BN | [35] |

| Ti | TiB | Hydrogen-Assisted Blended Elemental Powder Metallurgy (HABEPM) | TiH; TiB2 | [258] |

| Ti(Al,Zr,Mo,V) | TiB | Hot Pressing (HP); Canned Extrusion (CE) | Ti(Al,Zr,Mo,V); TiB2 | [259] |

| Ti | TiB | Pressureless Sintering (PS) | Ti; BN | [36] |

| Ti6Al4V | TiB | Spark Plasma Sintering (SPS); Pressureless Sintering (PS) | Ti6Al4V; B4C | [260] |

| β-Ti | TiB | Pressureless Sintering (PS); Hot Forging (HF) | Ti; Fe-62Mo; Al-50V; TiB2 | [86] |

| Ti(Zr) | TiB | Pressureless Sintering (PS); Hot Rolling (HR) | Ti; ZrB2 | [261] |

| T(Al,Mo,V,Cr,Fe) | TiB | Hot Pressing (HP) | T(Al,Mo,V,Cr,Fe); TiB2 | [262] |

| Ti6Al4V | TiB | Pressureless Sintering (PS) | TiH2, TiB2, and master alloy (Al–V) | [263] |

| Ti | TiB | Pressureless Sintering (PS) | TiH2; Ti; TiB2 | [264] |

| Ti6Al4V | TiB | Spark Plasma Sintering (SPS); Hot Extrusion (HE) | Ti6Al4V; TiB2 | [265] |

| Ti | TiB | Pressureless Sintering (PS) | TiH; TiB2 | [266] |

| Ti | TiB | Electric Field Assisted Sintering (EFAS) | Ti; TiB2; Fe; Mo | [267] |

| Ti | TiB; FeTi | Spark Plasma Sintering (SPS) | Ti; TiB2; Fe | [268] |

| Ti | TiB; Si3N4 | Pressureless Sintering (PS) | Ti; TiB2; Si3N4 | [269] |

| Ti6Al4V | TiB; Ti5Si3 | Spark Plasma Sintering (SPS) | Ti6Al4V; TiB2; Si | [270] |

| Ti6Al4V | TiB; Ti5Si3 | Hot Pressing (HP) | Ti6Al4V; TiB2; Si | [271] |

| Ti | TiB; TiB2 | Plasma Activated Sintering (PAS) | Ti-Al-V-Fe-C; B | [272] |

| Ti | TiB; TiC | Spark Plasma Sintering (SPS) | Ti; Mo; B4C | [273] |

| Ti(Al,Mo,V,Cr) | TiB; TiC | Spark Plasma Sintering (SPS) | Ti-Al-Mo-V-Cr; B4C | [71] |

| Ti4Al2Fe | TiB; TiC | Spark Plasma Sintering (SPS) | Ti; Al; Fe; KBF4; Graphite foils | [274] |

| Ti | TiB; TiC | Spark Plasma Sintering (SPS) | Ti; TiB2; B4C | [275] |

| Ti | TiB; TiC | Spark Plasma Sintering (SPS) | Ti; B4C | [45] |

| Ti6Al4V | TiB; TiC | Spark Plasma Sintering (SPS) | Ti6Al4V; B4C; B | [276] |

| Ti | TiB; TiC | Spark Plasma Sintering (SPS); Hot Extrusion (HE) | Ti; B4C | [277] |

| Ti | TiB; TiC | Spark Plasma Sintering (SPS) | Ti; B4C | [278] |

| Ti6Al4V | TiB; TiC | Spark Plasma Sintering (SPS); Hot Rolling (HR) | Ti6Al4V; B4C | [279] |

| Ti | TiB; TiC | Spark Plasma Sintering (SPS); Hot Extrusion (HE) | Ti; B4C | [280] |

| Ti | TiB; TiC | Spark Plasma Sintering (SPS); Hot Extrusion (HE) | Ti; B4C | [281] |

| Ti | TiB; TiC | Spark Plasma Sintering (SPS); Hot Extrusion (HE) | Ti; B4C | [282] |

| Ti | TiB; TiC | Spark Plasma Sintering (SPS) | Ti; B4C | [283] |

| Ti6Al4V | TiB; TiC | Hot Pressing (HP) | Ti; Ti6Al4V; B4C; C | [284] |

| Ti | TiB; TiC | Pressureless Sintering (PS) | Ti; B4C | [285] |

| Ti | TiB; TiC | Hot Pressing (HP) | Ti; TiB2; B4C | [286] |

| Ti | TiB; TiC | Pre-Sintered (PreS); Hot Isostatic Pressing (HIP) | Ti; TiB2; B4C | [287] |

| Ti(Al,Fe); Ti(Al,Cr) | TiB; TiC | Pressureless Sintering (PS); Hot Isostatic Pressing (HIP) | Ti; Al3Ti; FeB; Cr3C2 | [288] |

| Ti6Al4V | TiB; TiC | Spark Plasma Sintering (SPS) | Ti6Al4V; TiC; B | [289] |

| Ti | TiB; TiC | Pressureless Sintering (PS); Binder Jetting Printing (BJP) | TiH2; TiB2; TiC | [290] |

| Ti(Mo) | TiB; TiC | Spark Plasma Sintering (SPS) | TiB2; Ti; TiC; Mo | [291] |

| Ti6Al4V | TiB; TiC | Spark Plasma Sintering (SPS) | Ti6Al4V; B4C | [292] |

| Ti | TiB; TiC; Nd2O3 | Pressureless Sintering (PS) | NdB6; Ti(O); B4C | [90] |

| Ti | TiB; TiC; TiAl | Hot Pressing (HP) | Ti; B4C; Al | [293] |

| Ti | TiB; TiC; TiAl | Hot Pressing (HP) | Ti; B4C; Al | [294] |

| Ti | TiB; TiFe | Arc Melting (AM); Pressureless Sintering (PS); Hot Isostatic Pressing (HIP) | Ti; FeB | [295] |

| Ti | TiB; TiN | Pressureless Sintering (PS) | Ti; BN; Urea | [37] |

| Ti | TiC | Hot Pressing (HP) | Ti; Diamond | [296] |

| Ti6Al4V | TiC | Spark Plasma Sintering (SPS) | Ti6Al4V; Graphite | [297] |

| β-Ti(Nb) | TiC | High Pressure Sintering (HPS) | Ti; Nb; Stearic Acid | [298] |

| Ti | TiC | Pressureless Sintering (PS) | TiH2; CH4 | [299] |

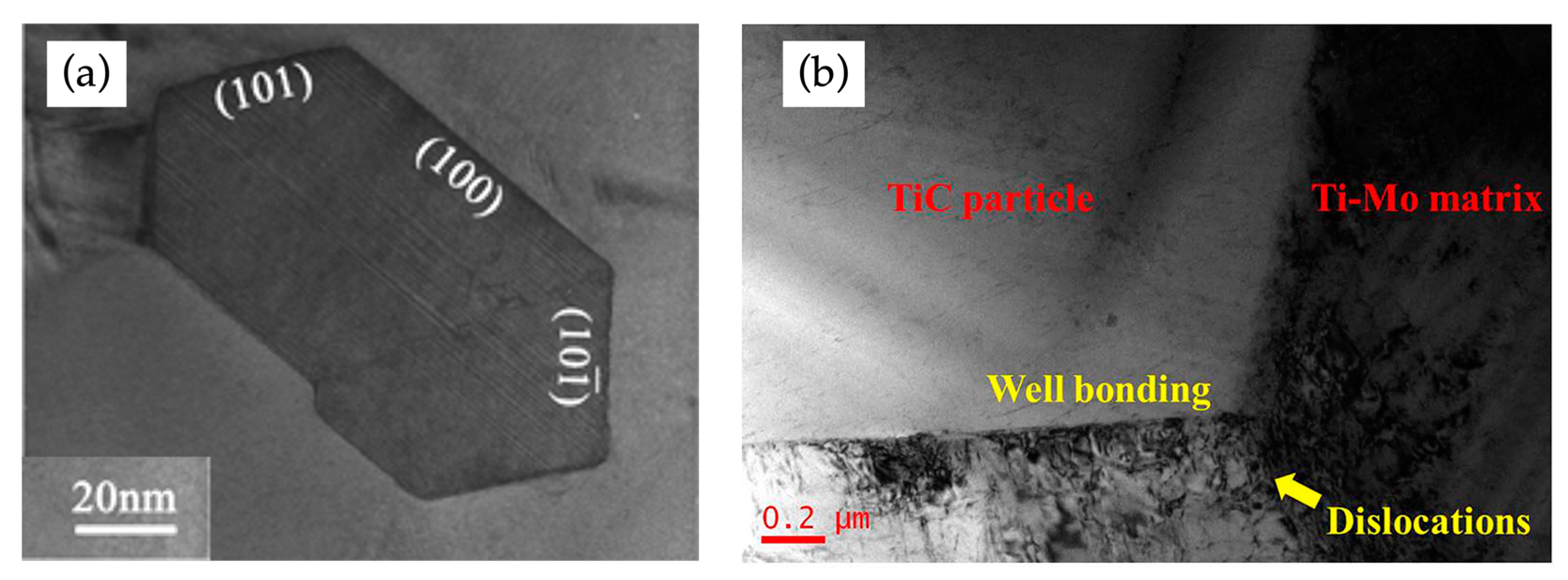

| Ti(Mo) | TiC | Pressureless Sintering (PS); Hot Swaging (HS) | Ti; Mo; MoC | [43] |

| Ti6Al4V | TiC | Spark Plasma Sintering (SPS) | Ti6Al4V; Carbon Nanotubes (MWCNT) | [300] |

| Ti | TiC | Hot Pressing (HP); Hot Rolling (HR) | Ti; Carbon Nanotubes (MWCNT) | [301] |

| Ti | TiC | Spark Plasma Sintering (SPS) | Ti; Graphene | [41] |

| Ti | TiC | Pressureless Sintering (PS); Hot Extrusion (HE) | TiH2; Carbon Nanotubes (MWCNT) | [302] |

| β-Ti70Nb30 | TiC | Spark Plasma Sintering (SPS) | β-Ti70Nb30; C | [303] |

| Ti5Sn3C; Ti13Cr5Sn3C | TiC | Spark Plasma Sintering (SPS) | Ti; Cr; Sn; Carbon Black | [304] |

| Ti(Mo); Ti(V) | TiC | Pressureless Sintering (PS); Hot Rolling (HR) | Ti; Mo2C; VC | [305] |

| Ti | TiC | Spark Plasma Sintering (SPS); Hot Extrusion (HE) | Ti; Carbon Nanotubes (VGCFs) | [306] |

| Ti-Fe | TiC | Pressureless Sintering (PS) | Ti; Fe[C, O, SiO2]; Graphite | [307] |

| Ti(V); Ti(Mo) | TiC | Pressureless Sintering (PS); Hot Rolling (HR) | Ti; Mo2C; VC | [308] |

| Ti(Fe, Mo, V) | TiC | Pressureless Sintering (PS) | Ti; Fe; Mo; Mo2C; VC | [309] |

| Ti | TiC | Spark Plasma Sintering (SPS); Hot Extrusion (HE) | Ti; Carbon Black | [310] |

| Ti6Al4V | TiC | Pressureless Sintering (PS); Extrusion (E) | Ti6Al4V; Ti; C3H8 | [311] |

| Ti | TiC | Pressureless Sintering (PS); Hot Isostatic Pressing (HIP) | Ti; CH4 | [312] |

| Ti(Ta) | TiC | Spark Plasma Sintering (SPS); Hot Rolling (HR) | Ti; Ta; Stearic Acid | [313] |

| Ti | TiC | Hot Pressing (HP) | Ti; TiC | [314] |

| Ti6Al4V | TiC | Hot Pressing (HP) | Ti6Al4V; VC | [315] |

| Ti | TiC; Ti3Si | Pressureless Sintering (PS) | Ti; (SiH(CH3)–CH2-)n (PCS) | [316] |

| Ti–Al–Sn–Zr | TiC; Ti5Si3 | Pressureless Sintering (PS) | Ti(Al,Sn,Zr); Ti; SiC | [317] |

| Ti(Nb,Al,Mo) | TiC; Ti5Si3 | Spark Plasma Sintering (SPS) | Ti; Nb; Al; Mo; Si; SiC | [318] |

| Ti(Al,Sn,Zr,Nb,Mo,Si) | TiC; Ti5Si3 | Pressureless Sintering (PS) | Ti; Ti(Al,Sn,Zr,Nb,Mo,Si); SiC | [319] |

| Ti; β-Ti | TiC; TiB | Spark Plasma Sintering (SPS) | Ti; B4C | [320] |

| Ti | TiC; TiB | Spark Plasma Sintering (SPS) | Ti; B4C | [321] |

| Ti | TiC; TiB | Spark Plasma Sintering (SPS) | Ti; B4C | [322] |

| Ti6Al4V | TiC; TiB | Hot Pressing (HP) | Ti; B4C; Graphite; TiB2; TiC; Ti6Al4V | [323] |

| Ti6Al4V | TiC; TiB | Hot Pressing (HP) | Ti6Al4V; TiB2; Graphite | [324] |

| Ti(Al,Mo,V,Cr) | TiC; TiB | Spark Plasma Sintering (SPS) | Ti-Al-Mo-V-Cr; B4C; Graphite | [44] |

| Ti | TiC; TiB | Spark Plasma Sintering (SPS) | Ti; B4C | [325] |

| Ti | TiC; TiB | Pressureless Sintering (PS); Hot Extrusion (HE) | Ti; B4C | [326] |

| Ti(Al) | TiC; TiB; Ti3Al; TiAl | Hot Pressing (HP) | Ti; Al; B4C; Ti-Al | [327] |

| Ti | TiC; TiO2 | Spark Plasma Sintering (SPS) | Ti; Toluene | [328] |

| Ti5V | TiN | Spark Plasma Sintering (SPS) | Ti; V; N2 | [329] |

| Ti | TiN | Mechanosynthesis (M); Hot Pressing (HP) | Ti; NH3 | [330] |

| Ti | TiN | Mechanosynthesis (M); Hot Pressing (HP) | Ti; NH3 | [331] |

| Ti | TiN; Ti2Ni; TiCN | Spark Plasma Sintering (SPS) | Ti; Ni; TiCN | [332] |

| Matrix | Reinforcement | Processing Method | Raw Materials | References |

|---|---|---|---|---|

| Ni(Cr) | (Cr, Ni)3C2; (Cr, Mo)3C2; (Cr, Mo, Ni)7C3 | Pressureless Sintering (PS) | Cr; C; Ni; Mo | [333] |

| Ni | (Ti, Mo)C | Pressureless Sintering (PS) | Ti; C; Ni; Mo | [12] |

| Ni | (Ti, Mo)C | Pressureless Sintering (PS) | Ti; Ni; Mo; C | [76] |

| Ni | (Ti, Mo)C | Gas-Pressure Sintering (GPS) | Ni; Ti; Mo; C | [334] |

| Ni | (Ti, Mo)C | Pressureless Sintering (PS) | Ni; Ti; Mo; C | [335] |

| Ni | (Ti,W)C | Hot Isostatic Pressing (HIP) | Ni; Ti; W; C | [336] |

| Ni | (Ti,W)C | Pressureless Sintering (PS) | Ti; W; Ni; C | [337] |

| Ni | (Ti,W)C; WC | Pressureless Sintering (PS) | Ti; W; Graphite | [338] |

| Ni | Al2O3; NiAl2O4 | Hot Pressing (HP) | NiO; Al | [339] |

| Ni | Al2O3; TiC | Hot Pressing (HP) | Ni; Mo; Al; Ti; C; TiC; Al2O3; TiO2 | [340] |

| Ni | Cr3C2 | Pressureless Sintering (PS) | Ni; Cr; C; Mo | [341] |

| Ni | Cr3C2 | Hot Isostatic Pressing (HIP) | Ni; Cr; C | [342] |

| Ni | Cr3C2 | Pressureless Sintering (PS) | Ni; Cr; C | [343] |

| Ni | Cr3C2 | Pressureless Sintering (PS); Hot Isostatic Pressing (HIP) | Ni; Cr; C | [344] |

| Ni | Cr3C2 | Pressureless Sintering (PS) | Ni; Cr; C | [345] |

| Ni | Cr3C2 | Pressureless Sintering (PS) | Ni; Cr; C | [346] |

| Ni | Graphene | Pressureless Sintering (PS) | Sucrose; Ni | [25] |

| Ni | Graphene | Pressureless Sintering (PS) | Sucrose; Ni | [347] |

| Ni | Graphene | Hot Pressing (HP) | Ni; PMMA | [348] |

| Ni | Graphene | Hot Pressing (HP) | Ni; PMMA | [349] |

| Ni | Mo2NiB2 | Pressureless Sintering (PS) | Mo; Ni; N-B | [350] |

| Ni | NiAl2O4; Al2O3 | Hot Pressing (HP) | Ni(NO3)2.6H2O; Al(NO3)3.9H2O; NaOH; Na2CO3 | [91] |

| Ni(Mo) | Ti(C,N) | Gas-Pressure Sintering (GPS) | Ti; TiO2; Ni; Mo; Graphite; N2 | [351] |

| Ni(Mo) | Ti(C,N) | Pressureless Sintering (PS) | Ti; TiO2; Ni; Mo; Graphite; N2 | [352] |

| Ni(Mo) | Ti(C,N) | Pressureless Sintering (PS) | Ti; TiO2; Ni; Mo; Graphite; N2 | [353] |

| Ni | Ti(C,N) | Pressureless Sintering (PS) | Ni; TiO2; TiN; Mo; WC; C | [354] |

| Ni | Ti(C,N) | Pressureless Sintering (PS) | Ni; TiO2; TiN; Mo; WC; C | [355] |

| Ni | Ti(C,N) | Pressureless Sintering (PS) | Ni; TiO2; TiN; Mo; WC; C | [356] |

| Ti-Ni | TiB; La2O3 | Hot Pressing (HP) | Ti-Ni; LaB6 | [357] |

| Ni(Si,Ti) | TiC | Pressureless Sintering (PS) | Ti3SiC2; Ni | [80] |

| Ni | TiC | Pressureless Sintering (PS) | Ti-Ni; Graphite | [38] |

| Ni(Si,Ti) | TiC | Pressureless Sintering (PS) | Ti3SiC2; Ni | [358] |

| Ni | TiC | Spark Plasma Sintering (SPS) | Ni; Ti; C | [359] |

| Ni | TiC | Pressureless Sintering (PS) | Ni; Ti; Graphite | [360] |

| Ni(Al) | TiC | Hot Pressing (HP) | Ni; Ti2AlC | [361] |

| Ni | TiC | Pressureless Sintering (PS) | Ni; Ti; Graphite | [362] |

| Ni | TiC | Spark Plasma Sintering (SPS) | Ni; Ti; C | [363] |

| Ni | TiC; (NiCu)3Al; CuNi2Ti | Pressureless Sintering (PS) | Ni; Cu; Ti3AlC2 | [364] |

| Ni | TiC; Graphite | Spark Plasma Sintering (SPS) | Ni; Ti; Graphite | [365] |

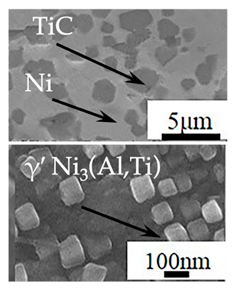

| Ni | TiC; γ′-Ni3(Al,Ti) | Hot Pressing (HP) | Ti2AlC; Ni | [366] |

| Ni | TiC; γ′-Ni3(Al,Ti) | Hot Pressing (HP) | Ti2AlC; Ni | [50] |

| Ni | TiC; γ′-Ni3(Al,Ti) | Hot Pressing (HP) | Ti3AlC2; Ni(Cr, Si, Fe, B) | [367] |

| Ni | TiC; γ′-Ni3(Al,Ti) | Hot Pressing (HP) | Ti2AlC; Ni | [368] |

| Ni(Ti, Al) | TiC; γ′-Ni3(Al,Ti) | Pressureless Sintering (PS) | Ni; Ti2AlC | [369] |

| Ni(Mo); Ni(Cr) | TiCxNy; TiB2 | Hot Pressing (HP) | Ti; BN; B4C; Cr; Mo | [370] |

| Ni | TiN; TiCN; Ti2Ni | Spark Plasma Sintering (SPS) | Ti; Ni; TiCN | [371] |

| Ni | TiN; TiO2 | Pressureless Sintering (PS) | Ni; Ti; CONDAT | [372] |

| Ni(W) | WC | Spark Plasma Sintering (SPS) | Ni; W | [373] |

| Ni | WC | Hot Pressing (HP) | W; Ni; Graphite | [374] |

| Matrix | Reinforcement | Processing Method | Raw Materials | References |

|---|---|---|---|---|

| Cu | Al2O3 | Spark Plasma Sintering (SPS) | Cu(Al); Oxidants | [375] |

| Cu | Al2O3 | Pressureless Sintering (PS); Hot Extrusion (HE) | Cu-Al; O2 | [376] |

| Cu | Al2O3 | Spark Plasma Sintering (SPS) | Cu-Al; CuO; Cu | [377] |

| Cu(Sn) | Al2O3 | Pressureless Sintering (PS) | Sn; Cu2O; Cu-Al | [81] |

| Cu | Al2O3; CeO2; Cu2O | Spark Plasma Sintering (SPS) | CuAl2O3; Ce; La | [378] |

| Cu | Al2O3; TiC | Spark Plasma Sintering (SPS) | Cu; Ti2AlC; Cu2O | [379] |

| Cu | Cr2O3 | Hot Pressing (HP) | Cu; Cr; Cu2O | [380] |

| Cu | Cr3C2; Graphene; CeO2 | Spark Plasma Sintering (SPS) | Cu; Graphene Oxide; Cr; Ce | [381] |

| Cu | Cu5Zr; ZrB2 | Rapid Solidification Process (RSP); Nd:YAG Pulsed Laser | Cu; Zr; B | [24] |

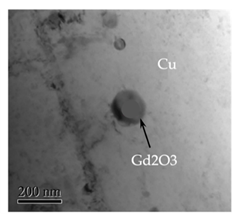

| Cu | Gd2O3 | Hot Pressing (HP) | Cu(Gd); CuO2; O2 | [48] |

| Cu | Graphene | Hot Pressing (HP) | Cu; Paraffin | [382] |

| Cu | Graphene | Spark Plasma Sintering (SPS) | Cu; Wheat flour | [383] |

| Cu | Graphene; Al2O3 | Hot Pressing (HP) | Cu; C9H21AlO3 | [384] |

| Cu(Ti) | Graphene; TiC | Pressureless Sintering (PS) | Cu; Graphene; Ti | [385] |

| Cu | Mo2C | Hot Pressing (HP) | Cu; Mo; C | [386] |

| Cu | Mo2C | Pressureless Sintering (PS); Spark Plasma Sintering (SPS) | Cu; Mo; C | [387] |

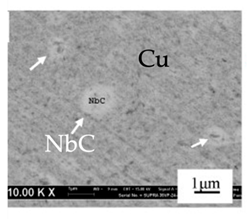

| Cu | NbC | Pressureless Sintering (PS); Hot Extrusion (HE) | Cu-Nb; Nb; Stearic Acid | [388] |

| Cu | NbC | Pressureless Sintering (PS) | Cu; Nb; Graphite | [389] |

| Cu | NbC | Pressureless Sintering (PS) | Cu; Nb; Graphite | [390] |

| Cu | NbC | Spark Plasma Sintering (SPS) | Cu; Nb; Graphite | [49] |

| Cu | NbC | Pressureless Sintering (PS) | Cu; Nb; Graphite | [391] |

| Cu | NbC | Spark Plasma Sintering (SPS) | Cu; Nb; Graphite | [392] |

| Cu | NbC | Pressureless Sintering (PS) | Cu; Nb; Graphite | [393] |

| Cu | NbC | Pressureless Sintering (PS) | Cu; Nb; Graphite | [394] |

| Cu | NbC | Hot Pressing (HP) | Cu; Nb; Graphite | [395] |

| Cu | TiB2 | Hot Pressing (HP) | Cu; Ti; B | [396] |

| Cu | TiB2 | Hot Pressing (HP); Hot Extrusion (HE) | Cu; Ti; B | [397] |

| Cu | TiB2; TiB | Hot Pressing (HP) | Cu; Ti; TiH2; B | [398] |

| Cu | TiB2; TiB | Pressureless Sintering (PS) | Cu; Ti; B | [399] |

| Cu | TiB2; TiC | Laser Sintering (LS) | Cu; B4C; Ni; Ti | [400] |

| Cu | TiC | Spark Plasma Sintering (SPS) | Ti25Cu75; C | [401] |

| Cu | TiC | Spark Plasma Sintering (SPS) | Ti25Cu75; Carbon black; Nanodiamonds | [402] |

| Cu | TiC | Hot Pressing (HP) | Cu; Ti; Graphite | [403] |

| Cu | TiC | Spark Plasma Sintering (SPS) | Cu; Ti; Graphite | [404] |

| Cu | TiC | Spark Plasma Sintering (SPS) | Cu; Ti; TiH2; Graphite | [405] |

| Cu | TiC | Pressureless Sintering (PS) | Cu; Ti; Graphite | [406] |

| Cu | TiC | Spark Plasma Sintering (SPS) | Cu; Ti; Graphite | [407] |

| Cu(Ti) | TiC | Spark Plasma Sintering (SPS); Hot Rolling (HR) | Cu; Ti; Graphite | [39] |

| Cu | TiC | Spark Plasma Sintering (SPS); Hot Pressing (HP) | Cu; Ti; Carbon Black | [408] |

| Cu | TiC | Spark Plasma Sintering (SPS) | Cu; TiH2; C; TiC | [409] |

| Cu | TiC | Spark Plasma Sintering (SPS) | Cu; Ti; C; Graphite; Nanodiamonds | [410] |

| Cu | TiC; C | Pressureless Sintering (PS) | Cu; Ti; Graphite; Carbon nanotube (CNT); Graphene | [411] |

| Cu | TiC; CuTi4 | Hot Extrusion (HE) | CuTi; Graphite | [412] |

| Cu | TiC; Graphene | Pressureless Sintering (PS) | Cu; Ti; Graphite | [413] |

| Cu(Sn) | V2C | Hot Pressing (HP) | Cu; V2SnC | [414] |

| Cu | WC | Hot Pressing (HP) | Cu, W; Graphite | [68] |

| Cu(W) | WC | Hot Pressing (HP) | Cu; W; GCI | [415] |

| Cu | WC; W2C | Pressureless Sintering (PS) | Cu; W; Graphite | [70] |

| Cu | Y2Ti2O7 | Spark Plasma Sintering (SPS) | Cu(Y); TiO2 | [416] |

| Matrix | Reinforcement | Processing Method | Raw Materials | References |

|---|---|---|---|---|

| Fe | (Ti,V)C | Pressureless Sintering (PS) | Ti; Fe; FeV; C | [417] |

| Fe | (Ti,V)C | Pressureless Sintering (PS) | Fe; FeV; FeCr; FeMo; Ti; C | [418] |

| Fe | (Ti,V)C | Pressureless Sintering (PS) | Fe; FeV; FeCr; FeMo; Ti; C | [419] |

| Fe | (Ti,V)C | Pressureless Sintering (PS) | Ti; Fe; Fe–V; Fe–Cr; Fe–Mo; C | [420] |

| Fe(Al) | Al2O3; Fe3Al | Hot Pressing (HP) | Fe-Al | [421] |

| Fe | Al2O3; FeAl2O4 | Pressureless Sintering (PS) | Fe-Al2O3 | [422] |

| 316L Steel | Cr7C3; Cr3C2; Fe2Si | Spark Plasma Sintering (SPS) | 316L; PCS | [423] |

| 316L Steel | Cr7C3; FeSi | Spark Plasma Sintering (SPS) | 316L; PCS | [33] |

| HCWI | Cr7C3; TiC | Pressureless Sintering (PS); Hot Pressing (HP) | HCWI; TiC; Ti3AlC2 | [424] |

| Fe | Fe3O4 | Pressureless Sintering (PS) | Fe; O2 | [425] |

| Fe | Fe3O4 | Pressureless Sintering (PS) | Fe; H2O | [426] |

| Fe | Fe3O4 | Pressureless Sintering (PS) | Fe; Fe2O3 | [427] |

| Fe | FeAl2O4 | Hot Pressing (HP) | Fe; Fe2O3; Al2O3 | [428] |

| Fe | FeAl2O4 | Pressureless Sintering (PS) | Fe; Al2O3 | [429] |

| Fe | FeAl2O4; Al2O3 | Pressureless Sintering (PS) | Fe; Al2O3 | [430] |

| Fe | FeB; Fe2B | Hot Pressing (HP); Pressureless Sintering (PS) | Fe; B4C | [82] |

| Fe(Mo) | FeS; TiC; VC | Pressureless Sintering (PS) | Fe2O3; FeO; TiO2; V2O5; Al2O3; SiO2; MgO; Fe; Graphite; MoS2 | [431] |

| Fe(Cr,C) | M7C3; TiC | Pressureless Sintering (PS); Hot Pressing (HP) | HCWI; Ti3AlC2 | [432] |

| Fe-Si | MnO-SiO2 | Spark Plasma Sintering (SPS) | Fe-Si; MnO2 | [433] |

| Fe | Mo(Ti)2FeB | Pressureless Sintering (PS) | Mo; FeB; Fe; Ti | [434] |

| Fe-Ni | Nanodiamonds | Spark Plasma Sintering (SPS) | Fe30Ni; MWCNTs | [435] |

| Fe | NbC | Pressureless Sintering (PS) | Fe; Nb; Graphite | [436] |

| Fe | TiB2 | Spark Plasma Sintering (SPS) | FeTi; FeB | [437] |

| Fe-Cr-Mn-Al | TiB2 | Spark Plasma Sintering (SPS) | Cr; Fe; Mn; Al; Ti; B | [438] |

| Fe | TiB2 | Spark Plasma Sintering (SPS); Pressureless Sintering (PS) | FeB; TiH2 | [75] |

| Steel | TiB2; TiC | Spark Plasma Sintering (SPS) | Fe2Ti; B4C | [55] |

| Steel | TiB2; TiC | Spark Plasma Sintering (SPS) | FeTi; B4C | [17] |

| Steel | TiB2; TiC | Pressureless Sintering (PS) | 465 stainless steel; FeB; Ti; C | [20] |

| Fe/Steel | TiB2; TiC | Pressureless Sintering (PS) | 465 stainless steel; FeB; Ti; C | [439] |

| Fe | TiB2; TiC | Pressureless Sintering (PS) | Ti; C; FeB | [440] |

| Steel | TiC | Pressureless Sintering (PS); Hot Isostatic Press (HIP) | Fe; TiH2; C | [19] |

| Fe | TiC | Pressureless Sintering (PS) | Fe2O3; TiO2; Graphite | [52] |

| Fe | TiC | Pressureless Sintering (PS) | Fe; Ti; C | [441] |

| Fe | TiC | Pressureless Sintering (PS) | Fe3O4; FeTiO3; Al2O3; SiO2; MgO; CaO; Fe; La2O3; CeO2; Graphite | [442] |

| Fe(Ni, Mo, Cu) | TiC | Pressureless Sintering (PS) | Fe; Ti; Mo; Ni; Cu; Graphite | [443] |

| Fe | TiC | Pressureless Sintering (PS) | FeTi70; Sucrose | [74] |

| Fe | TiC | Hot Isostatic Pressing (HIP); Hot Pressing (HP) | Graphite; Steel; FeTi; WCI | [444] |

| Fe | TiC | Pressureless Sintering (PS) | FeTiO3; Graphite | [445] |

| Steel | TiC; TiB2 | Pressureless Sintering (PS) | 465 stainless steel; FeB; Ti; C | [446] |

| Fe | TiN | Spark Plasma Sintering (SPS); Pressureless Sintering (PS) | Fe(Cr,Ni,Ti); N2 | [447] |

| Steel | TiN; TiB2 | Spark Plasma Sintering (SPS) | FeTi; BN | [448] |

| Steel | TiN; VN | Hot Isostatic Pressing (HIP) | X4CrMoV15–1; FeTi; X4CrMo15–1; FeV; Graphite; N2 | [449] |

| Fe(Cr, V) | V3B4; V8C7 | Pressureless Sintering (PS) | FeV; C; Fe45 | [450] |

| Fe(Cr,Mo) | VC | Pressureless Sintering (PS) | Fe; FeV; FeCr; FeMo; C | [32] |

| Fe | VC | Spark Plasma Sintering (SPS) | FeV; C | [45] |

| Fe | WC; Fe3W3C; W2C | Spark Plasma Sintering (SPS) | Fe; Cu; W; C | [451] |

| Fe | WC; W2C; Fe3W3C | Spark Plasma Sintering (SPS) | Fe; C; W; Cu; WC | [452] |

| Fe | ZrO2; Zr6Fe3O | Pressureless Sintering (PS) | Fe; ZrO2 | [453] |

References

- Chao, Z.; Zhang, L.; Jiang, L.; Qiao, J.; Xu, Z.; Chi, H.; Wu, G. Design, microstructure and high temperature properties of in-situ Al3Ti and nano-Al2O3 reinforced 2024Al matrix composites from Al-TiO2 system. J. Alloy. Compd. 2019, 775, 290–297. [Google Scholar] [CrossRef]

- Tanprayoon, D.; Srisawadi, S.; Sato, Y.; Tsukamoto, M.; Suga, T. Microstructure and hardness response of novel 316L stainless steel composite with TiN addition fabricated by SLM. Opt. Laser Technol. 2020, 129, 106238. [Google Scholar] [CrossRef]

- Behera, M.P.; Dougherty, T.; Singamneni, S. Conventional and Additive Manufacturing with Metal Matrix Composites: A Perspective. Procedia Manuf. 2019, 30, 159–166. [Google Scholar] [CrossRef]

- Lloyd, D.; Lagace, H.; McLeod, A.; Morris, P. Microstructural aspects of aluminium-silicon carbide particulate composites produced by a casting method. Mater. Sci. Eng. A 1989, 107, 73–80. [Google Scholar] [CrossRef]

- Pandey, U.; Purohit, R.; Agarwal, P.; Dhakad, S.; Rana, R. Effect of TiC particles on the mechanical properties of aluminium alloy metal matrix composites (MMCs). Mater. Today Proc. 2017, 4, 5452–5460. [Google Scholar] [CrossRef]

- Maurya, M.; Kumar, S.; Bajpai, V.; Maurya, N.K. Process parameters, development and applications of stir cast composite: A review. Mater. Test. 2020, 62, 196–208. [Google Scholar] [CrossRef]

- Lawley, A.; Apelian, D. Spray Forming of Metal Matrix Composites. Powder Met. 1994, 37, 123–128. [Google Scholar] [CrossRef]

- Bains, P.S.; Sidhu, S.; Payal, H.S. Fabrication and Machining of Metal Matrix Composites: A Review. Mater. Manuf. Process. 2015, 31, 553–573. [Google Scholar] [CrossRef]

- Rahimipour, M.R.; Sobhani, M. Evaluation of Centrifugal Casting Process Parameters for In Situ Fabricated Functionally Gradient Fe-TiC Composite. Met. Mater. Trans. Mater. Process. Sci. 2013, 44, 1120–1123. [Google Scholar] [CrossRef]

- Shin, D.-S.; Lee, J.-C.; Yoon, E.-P.; Lee, H.-I. Effect of the processing methods on the formation of Al4C3 in SiCp/2024 Al composites. Mater. Res. Bull. 1997, 32, 1155–1163. [Google Scholar] [CrossRef]

- Veeravalli, R.R.; Nallu, R.; Sarcar, M.M.M. Mechanical and tribological properties of AA7075–TiC metal matrix composites under heat treated (T6) and cast conditions. J. Mater. Res. Technol. 2016, 5, 377–383. [Google Scholar] [CrossRef]

- Jõeleht, M. The Influence of Sintering Temperature of Reactive Sintered (Ti, Mo)C-Ni Cermets. Mater. Sci. 2015, 21, 435–438. [Google Scholar] [CrossRef]

- Wang, F.; Li, J.; Shi, C.; Zhao, N.; Liu, E.; He, C.; He, F. Preparation and mechanical properties of in-situ synthesized nano-MgAl2O4 particles and MgxAl(1-x)B2 whiskers co-reinforced Al matrix composites. Mater. Sci. Eng. A 2018, 735, 236–242. [Google Scholar] [CrossRef]

- Duygulu, O. High-resolution transmission electron microscopy investigation of in situ TiC/Al composites. Met. Mater. 2018, 56, 265–275. [Google Scholar] [CrossRef] [PubMed]

- Qu, X.; Wang, F.; Shi, C.; Zhao, N.; Liu, E.; He, C.; He, F. In situ synthesis of a gamma-Al2O3 whisker reinforced aluminium matrix composite by cold pressing and sintering. Mater. Sci. Eng. A 2018, 709, 223–231. [Google Scholar] [CrossRef]

- Mokhnache, E.O.; Wang, G.-S.; Geng, L.; Balasubramaniam, K.; Henniche, A.; Ramdani, N. In situ (α-Al2O3 + ZrB2)/Al composites with network distribution fabricated by reaction hot pressing. Int. J. Miner. Met. Mater. 2016, 22, 1092–1100. [Google Scholar] [CrossRef]

- Li, B.; Liu, Y.; Li, J.; Cao, H.; He, L. Effect of sintering process on the microstructures and properties of in situ TiB2–TiC reinforced steel matrix composites produced by spark plasma sintering. J. Mater. Process. Technol. 2010, 210, 91–95. [Google Scholar] [CrossRef]

- Verezub, O.; Kálazi, Z.; Buza, G.; Verezub, N.V.; Kaptay, G. Classification of laser beam induced surface engineering technologies andin situsynthesis of steel matrix surface nanocomposites. Surf. Eng. 2011, 27, 428–435. [Google Scholar] [CrossRef]

- Lee, J.; Lee, D.; Song, M.H.; Rhee, W.; Ryu, H.J.; Hong, S.H. In-situ synthesis of TiC/Fe alloy composites with high strength and hardness by reactive sintering. J. Mater. Sci. Technol. 2018, 34, 1397–1404. [Google Scholar] [CrossRef]

- Akhtar, F. Microstructure evolution and wear properties of in situ synthesized TiB2 and TiC reinforced steel matrix composites. J. Alloy. Compd. 2008, 459, 491–497. [Google Scholar] [CrossRef]

- da Costa, C.; Zapata, W.; Velasco, F.; Ruiz-Prieto, J.; Torralba, J. Wear behaviour of aluminum reinforced with nickel aluminide MMCs. J. Mater. Process. Technol. 1999, 92–93, 66–70. [Google Scholar] [CrossRef]

- Rezaei, A.; Hosseini, H.R.M. Investigating the effect of heat treatment on the fracture toughness of a hot extruded Al–Ti composite produced by powder metallurgy route. Mater. Sci. Eng. A 2020, 771, 138573. [Google Scholar] [CrossRef]

- Fogagnolo, J.; Pallone, E.; Martin, D.; Kiminami, C.; Bolfarini, C.; Botta, W. Processing of Al matrix composites reinforced with Al–Ni compounds and Al2O3 by reactive milling and reactive sintering. J. Alloy. Compd. 2009, 471, 448–452. [Google Scholar] [CrossRef]

- Stašić, J.; Rajković, V.; Ružić, J.; Božić, D. An investigation on synthesis development of high hardened, high conductivity Cu-Zr and Cu-Zr-ZrB2 alloys through green compact laser sintering. Int. J. Adv. Manuf. Technol. 2015, 80, 1049–1057. [Google Scholar] [CrossRef]

- Jiang, J.; He, X.; Du, J.; Pang, X.; Yang, H.; Wei, Z. In-situ fabrication of graphene-nickel matrix composites. Mater. Lett. 2018, 220, 178–181. [Google Scholar] [CrossRef]

- Tjong, S.C. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R Rep. 2000, 29, 49–113. [Google Scholar] [CrossRef]

- Amosov, A.P. Nanomaterials of SHS technology for tribological applications: A review. Russ. J. Non-Ferrous Met. 2017, 58, 530–539. [Google Scholar] [CrossRef]

- Subrahmanyam, J.; Vijayakumar, M. Self-propagating high-temperature synthesis. J. Mater. Sci. 1992, 27, 6249–6273. [Google Scholar] [CrossRef]

- Karanjai, M.; Sundaresan, R.; Rao, G.V.N.; Mohan, T.R.R.; Kashyap, B.P. Development of titanium based biocomposite by powder metallurgy processing with in situ forming of Ca–P phases. Mater. Sci. Eng. A 2007, 447, 19–26. [Google Scholar] [CrossRef]

- Karanjai, M.; Kumar, B.M.; Sundaresan, R.; Basu, B.; Mohan, T.R.; Kashyap, B. Fretting wear study on Ti–Ca–P biocomposite in dry and simulated body fluid. Mater. Sci. Eng. A 2008, 475, 299–307. [Google Scholar] [CrossRef]

- Patel, V.; El-Desouky, A.; Garay, J.; Morsi, K. Pressure-less and current-activated pressure-assisted sintering of titanium dual matrix composites: Effect of reinforcement particle size. Mater. Sci. Eng. A 2009, 507, 161–166. [Google Scholar] [CrossRef]

- Wang, J.; Fu, S. Production of in situ Vanadium Carbide Particulate Reinforced Iron Matrix Composite. Mater. Sci. 2014, 20, 409–413. [Google Scholar] [CrossRef]

- Guan, D.; He, X.; Zhang, R.; Li, R.; Qu, X. Tribological and corrosion properties of PM 316L matrix composites reinforced by in situ polymer-derived ceramics. Vacuum 2018, 148, 319–326. [Google Scholar] [CrossRef]

- Pan, D.; Li, S.; Gao, L.; Liu, L.; Zhang, X.; Ji, X.; Umeda, J.; Kondoh, K. TiB Whisker and Nitrogen Solid-Solution Synergistic-Strengthened Titanium Matrix Composites by Ti–BN via Spark Plasma Sintering and Hot Extrusion. Adv. Eng. Mater. 2021, 23. [Google Scholar] [CrossRef]

- Otte, J.A.; Zou, J.; Patel, R.; Lu, M.; Dargusch, M.S. TiB Nanowhisker Reinforced Titanium Matrix Composite with Improved Hardness for Biomedical Applications. Nanomaterials 2020, 10, 2480. [Google Scholar] [CrossRef] [PubMed]

- Otte, J.A.; Zou, J.; Huang, Y.; Dargusch, M.S. Ultrahigh Aspect Ratio TiB Nanowhisker-Reinforced Titanium Matrix Composites as Lightweight and Low-Cost Replacements for Superalloys. ACS Appl. Nano Mater. 2020, 3, 8208–8215. [Google Scholar] [CrossRef]

- Toptan, F. Corrosion and wear behaviour of highly porous Ti-TiB-TiNxin situ composites in simulated physiological solution. Turk. J. Chem. 2020, 44, 805–816. [Google Scholar] [CrossRef] [PubMed]

- Kwon, H.; Jung, S.-A.; Suh, C.-Y.; Roh, K.-M.; Kim, W.; Kim, J. Highly toughened dense TiC–Ni composite by in situ decomposition of (Ti,Ni)C solid solution. Ceram. Int. 2015, 41, 4656–4661. [Google Scholar] [CrossRef]

- Wang, F.; Li, Y.; Yamanaka, K.; Wakon, K.; Harata, K.; Chiba, A. Influence of two-step ball-milling condition on electrical and mechanical properties of TiC-dispersion-strengthened Cu alloys. Mater. Des. 2014, 64, 441–449. [Google Scholar] [CrossRef]

- Rezaei, A.; Hosseini, H.R.M. Evolution of microstructure and mechanical properties of Al-5 wt% Ti composite fabricated by P/M and hot extrusion: Effect of heat treatment. Mater. Sci. Eng. A 2017, 689, 166–175. [Google Scholar] [CrossRef]

- Zhang, X.; Song, F.; Wei, Z.; Yang, W.; Dai, Z. Microstructural and mechanical characterization of in-situ TiC/Ti titanium matrix composites fabricated by graphene/Ti sintering reaction. Mater. Sci. Eng. A 2017, 705, 153–159. [Google Scholar] [CrossRef]

- Krizik, P.; Balog, M.; Nagy, S. Small punch testing of heat resistant ultrafine-grained Al composites stabilized by nano-metric Al2O3 (HITEMAL©) in a broad temperature range. J. Alloy. Compd. 2021, 887, 161332. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, C.; Liu, Y.; Liu, B.; Li, K. Microstructure and mechanical properties of Ti-15Mo-xTiC composites fabricated by in-situ reactive sintering and hot swaging. J. Alloy. Compd. 2018, 738, 188–196. [Google Scholar] [CrossRef]

- Grützner, S.; Krüger, L.; Radajewski, M.; Schneider, I. Characterization of In-Situ TiB/TiC Particle-Reinforced Ti-5Al-5Mo-5V-3Cr Matrix Composites Synthesized by Solid-State Reaction with B4C and Graphite through SPS. Metals 2018, 8, 377. [Google Scholar] [CrossRef]

- Huang, L.; Qian, M.; Liu, Z.; Nguyen, V.T.; Yang, L.; Wang, L.; Zou, J. In situ preparation of TiB nanowires for high-performance Ti metal matrix nanocomposites. J. Alloy. Compd. 2018, 735, 2640–2645. [Google Scholar] [CrossRef]

- Sadeghian, Z.; Lotfi, B.; Enayati, M.; Beiss, P. Microstructural and mechanical evaluation of Al–TiB2 nanostructured composite fabricated by mechanical alloying. J. Alloy. Compd. 2011, 509, 7758–7763. [Google Scholar] [CrossRef]

- He, L.; Liu, Y.; Li, B.; Cao, H.; Li, J. Reaction synthesis of in situ vanadium carbide particulates-reinforced iron matrix composites by spark plasma sintering. J. Mater. Sci. 2010, 45, 2538–2542. [Google Scholar] [CrossRef]

- Cao, H.; Zhan, Z.; Lv, X. Microstructure Evolution and Properties of an In-Situ Nano-Gd2O3/Cu Composite by Powder Metallurgy. Materials 2021, 14, 5021. [Google Scholar] [CrossRef]

- Long, B.; Othman, R.; Umemoto, M.; Zuhailawati, H. Spark plasma sintering of mechanically alloyed in situ copper–niobium carbide composite. J. Alloy. Compd. 2010, 505, 510–515. [Google Scholar] [CrossRef]

- Hu, W.; Huang, Z.; Cai, L.; Lei, C.; Zhai, H.; Zhou, Y. Exploring the interfacial state and tensile behaviors in nickel matrix composite with in-situ TiC and γ′-Ni3(Al,Ti) reinforcements. J. Alloy. Compd. 2018, 765, 987–993. [Google Scholar] [CrossRef]

- Chen, Z.-C.; Takeda, T.; Ikeda, K. Microstructural evolution of reactive-sintered aluminum matrix composites. Compos. Sci. Technol. 2008, 68, 2245–2253. [Google Scholar] [CrossRef]

- Ghiasabadi, S.M.; Raygan, S. In Situ Production of Fe-TiC Nanocomposite by Mechanical Activation and Heat Treatment of the Fe2O3/TiO2/C Powder. J. Mater. Eng. Perform. 2012, 21, 2295–2302. [Google Scholar] [CrossRef]

- Brinkman, H.; Duszczyk, J.; Katgerman, L. In-situ formation of TiB 2 in a P/M aluminum matrix. Scr. Mater. 1997, 37, 293–297. [Google Scholar] [CrossRef]

- Andrieux, J.; Dezellus, O.; Bosselet, F.; Viala, J.C. Low-Temperature Interface Reaction Between Titanium and the Eutectic Silver-Copper Brazing Alloy. J. Phase Equilibria Diffus. 2009, 30, 40–45. [Google Scholar] [CrossRef]

- Li, B.H.; Liu, Y.; Li, J.; Cao, H.; He, L. Fabrication of in situ TiB2–TiC reinforced steel matrix composites by spark plasma sintering. Powder Met. 2011, 54, 222–224. [Google Scholar] [CrossRef]

- Shahid, R.N.; Scudino, S. Microstructure and Mechanical Behavior of Al-Mg Composites Synthesized by Reactive Sintering. Metals 2018, 8, 762. [Google Scholar] [CrossRef]

- Ediger, M. Dynamics of Polymer Glasses and Melts: Probe Diffusion. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar] [CrossRef]

- Shi, H.; Zhao, Y.; Gao, H.-B.; Zhang, M.-S.; Jiang, Y.-H.; Cao, F.; Zou, J.-T.; Liang, S.-H. In-situ spherical TiB2/Cu composite powder: A new method of liquid phase reaction coupled with gas atomization. Mater. Charact. 2022, 191, 112096. [Google Scholar] [CrossRef]

- German, R.M. Powder Metallurgy & Particulate Materials Processing; Metal Powder Industry: Princeton, NJ, USA, 2005. [Google Scholar]

- Woo, K.D.; Lee, H.B. Fabrication of Al alloy matrix composite reinforced with subsive-sized Al2O3 particles by the in situ displacement reaction using high-energy ball-milled powder. Mater. Sci. Eng. A 2007, 449–451, 829–832. [Google Scholar] [CrossRef]

- Aguilar, C.; Martin, P.; Pio, E.; Salvo, C.; Neves, G. Materials analysis applying thermodynamic (MAAT) software: A friendly and free tool to analyze the formation of solid solutions, amorphous phases and intermetallic compounds. Comput. Phys. Commun. 2021, 259, 107573. [Google Scholar] [CrossRef]

- Gu, J.; Gu, S.; Xue, L.; Wu, S.; Yan, Y. Microstructure and mechanical properties of in-situ Al13Fe4/Al composites prepared by mechanical alloying and spark plasma sintering. Mater. Sci. Eng. A 2012, 558, 684–691. [Google Scholar] [CrossRef]

- Xue, Y.; Shen, R.; Ni, S.; Xiao, D.; Song, M. Effects of Sintering Atmosphere on the Mechanical Properties of Al-Fe Particle-Reinforced Al-Based Composites. J. Mater. Eng. Perform. 2015, 24, 1890–1896. [Google Scholar] [CrossRef]

- Xue, Y.; Shen, R.; Ni, S.; Song, M.; Xiao, D. Fabrication, microstructure and mechanical properties of Al–Fe intermetallic particle reinforced Al-based composites. J. Alloy. Compd. 2015, 618, 537–544. [Google Scholar] [CrossRef]

- Miedema, A.; de Châtel, P.; de Boer, F. Cohesion in alloys—Fundamentals of a semi-empirical model. Phys. B+C 1980, 100, 1–28. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, S.; He, Z.; Jing, J.; Sheng, S. Miedema Calculator: A thermodynamic platform for predicting formation enthalpies of alloys within framework of Miedema’s Theory. Comput. Phys. Commun. 2016, 209, 58–69. [Google Scholar] [CrossRef]

- Aguilar, C.; Martinez, C.; Tello, K.; Palma, S.; Delonca, A.; Martín, F.S.; Alfonso, I. Thermodynamic Analysis of the Formation of FCC and BCC Solid Solutions of Ti-Based Ternary Alloys by Mechanical Alloying. Metals 2020, 10, 510. [Google Scholar] [CrossRef]

- Li, J.; Ni, J.; Huang, B.; Chen, J.; Xu, Z.; Liao, S.; Wang, C.; Luo, W. Long-term ball milling and hot pressing of in-situ nanoscale tungsten carbides reinforced copper composite and its characterization. Mater. Charact. 2019, 152, 134–140. [Google Scholar] [CrossRef]

- Chookajorn, T.; Murdoch, H.A.; Schuh, C.A. Design of Stable Nanocrystalline Alloys. Science 2012, 337, 951–954. [Google Scholar] [CrossRef]

- Yusoff, M.; Zuhailawati, H. In Situ Tungsten Carbide Formation in Nanostructured Copper Matrix Composite Using Mechanical Alloying and Sintering. Materials 2022, 15, 2340. [Google Scholar] [CrossRef]

- Grützner, S.; Krüger, L.; Schimpf, C.; Radajewski, M.; Schneider, I. Microstructure and Mechanical Properties of In Situ TiB/TiC Particle-Reinforced Ti-5Al-5Mo-5V-3Cr Composites Synthesized by Spark Plasma Sintering. Met. Mater. Trans. A 2018, 49, 5671–5682. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, J.; Luo, G.; Sun, Y.; Shen, Q.; Zhang, L. Design and Synthesis of C-O Grain Boundary Strengthening of Al Composites. Nanomaterials 2020, 10, 438. [Google Scholar] [CrossRef]

- Karak, S.; Chudoba, T.; Witczak, Z.; Lojkowski, W.; Manna, I. Development of ultra high strength nano-Y2O3 dispersed ferritic steel by mechanical alloying and hot isostatic pressing. Mater. Sci. Eng. A 2011, 528, 7475–7483. [Google Scholar] [CrossRef]

- Wang, J.-J.; Hao, J.-J.; Guo, Z.-M.; Wang, S. Plasma preparation and low-temperature sintering of spherical TiC–Fe composite powder. Int. J. Miner. Met. Mater. 2015, 22, 1328–1333. [Google Scholar] [CrossRef]

- Cho, H.-R.; Kim, J.-S.; Chung, K.-H. Microstructure, mechanical, and tribological properties of pressureless sintered and spark plasma sintered Fe TiB2 nanocomposites. Tribol. Int. 2019, 131, 83–93. [Google Scholar] [CrossRef]

- Viljus, M.; Pirso, J.; Juhani, K.; Letunovitš, S. Structure Formation in Ti-C-Ni-Mo Composites during Reactive Sintering. Mater. Sci. 2012, 18, 62–65. [Google Scholar] [CrossRef]

- Porter, D.A. Phase Transformations in Metals and Alloys; Springer: Berlin/Heidelberg, Germany, 1992. [Google Scholar]

- Lifshitz, I.; Slyozov, V. The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 1961, 19, 35–50. [Google Scholar] [CrossRef]

- Wagner, C. Theorie der Alterung von Niederschliigen durch Umlosen (Ostwald-Reifung). Z. Elektrochem. Ber. Bunsenges. Phys. Chem. 1961, 65, 581–591. [Google Scholar]

- Chiker, N.; Benamor, A.; Hadji, Y.; Haddad, A.; Hakem, M.; Azzaz, M.; Sahraoui, T.; Hadji, M. Microstructure and Tribological Behavior of In Situ TiC-Ni(Si,Ti) Composites Elaborated from Ni and Ti3SiC2 Powders. J. Mater. Eng. Perform. 2020, 29, 1995–2005. [Google Scholar] [CrossRef]

- Chen, F.; Yan, Z.; Wu, X.; Liu, B.; Liu, Y. Microstructures and properties of Cu-10Sn oil bearings reinforced by Al2O3 nanoparticles. Adv. Powder Technol. 2021, 32, 710–717. [Google Scholar] [CrossRef]

- Nair, F.; Hamamcı, M. Effect of In-Situ Synthesized Boride Phases on the Impact Behavior of Iron-Based Composites Reinforced by B4C Particles. Metals 2020, 10, 554. [Google Scholar] [CrossRef]

- Tokita, M. The Potential of Spark Plasma Sintering (SPS) Method for the Fabrication on an Industrial Scale of Functionally Graded Materials. Adv. Sci. Technol. 2010, 63, 322–331. [Google Scholar] [CrossRef]

- Cavaliere, P. Spark plasma sintering of materials: Advances in processing and applications. In Spark Plasma Sintering of Materials; Advances in Processing and Applications; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Degnah, A.; Du, J.; Chandran, K.R. CALPHAD Approach and processing of a multicomponent titanium matrix composite for high strength and fracture toughness. Mater. Sci. Eng. A 2020, 781, 139210. [Google Scholar] [CrossRef]

- Saito, T.; Takamiya, H.; Furuta, T. Thermomechanical properties of P/M β titanium metal matrix composite. Mater. Sci. Eng. A 1998, 243, 273–278. [Google Scholar] [CrossRef]

- Panda, K.B.; Chandran, K.S.R. Synthesis of ductile titanium-titanium boride (Ti-TiB) composites with a beta-titanium matrix: The nature of TiB formation and composite properties. Met. Mater. Trans. A 2003, 34, 1371–1385. [Google Scholar] [CrossRef]

- Klein, A.N.; Furlan, K.P.; Schroeder, R.M.; Hammes, G.; Binder, C.; Neto, J.B.R.; Probst, S.H.; de Mello, J.D.B. Thermodynamic aspects during the processing of sintered materials. Powder Technol. 2015, 271, 193–203. [Google Scholar] [CrossRef]

- Balog, M.; Krizik, P.; Svec, P.; Orovcik, L. Industrially fabricated in-situ Al-AlN metal matrix composites (part A): Processing, thermal stability, and microstructure. J. Alloy. Compd. 2021, 883, 160858. [Google Scholar] [CrossRef]

- Lu, J.; Qin, J.; Lu, W.; Liu, Y.; Gu, J.; Zhang, D. In situ preparation of (TiB+TiC+Nd2O3)/Ti composites by powder metallurgy. J. Alloy. Compd. 2009, 469, 116–122. [Google Scholar] [CrossRef]

- Rodeghiero, E.D.; Chisaki, J.; Giannelis, E.P. In Situ Microstructural Control of Ni/Al2O3 and Ni/NiAl2O4 Composites from Layered Double Hydroxides. Chem. Mater. 1997, 9, 478–484. [Google Scholar] [CrossRef]

- Zhao, L.; Jiao, Y.; Zhao, M.; Zhang, J. Investigation on in situ Al0.5FeSi0.5/Al composites prepared by transient liquid phase sintering. Mater. Des. 2014, 59, 70–75. [Google Scholar] [CrossRef]

- Feng, Y.; Geng, L.; Li, A.; Zheng, Z. Fabrication and characteristics of in situ Al12W particles reinforced aluminum matrix composites by reaction sintering. Mater. Des. 2010, 31, 965–967. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, Y.; Zhang, H.; Zheng, R.; Xiao, W.; Ma, C. Fabrication of Al-based composites reinforced with in situ devitrified Al84Ni8.4Y4.8La1.8Co1 particles by hot pressing consolidation. J. Alloy. Compd. 2015, 648, 382–388. [Google Scholar] [CrossRef]

- Nalivaiko, A.Y.; Arnautov, A.N.; Zmanovsky, S.V.; Ozherelkov, D.; Shurkin, P.K.; Gromov, A.A. Al–Al2O3 powder composites obtained by hydrothermal oxidation method: Powders and sintered samples characterization. J. Alloy. Compd. 2020, 825, 154024. [Google Scholar] [CrossRef]

- Haghi, S.M.A.; Sajjadi, S.A.; Babakhani, A. In-situ fabrication of Al(Zn)−Al2O3 graded composite using the aluminothermic reaction during hot pressing. Int. J. Miner. Met. Mater. 2018, 25, 832–839. [Google Scholar] [CrossRef]

- Moreno, M.F.; Balog, M.; Krizik, P. Mechanical characterization of PM aluminum composites by small punch test. Matéria 2018, 23. [Google Scholar] [CrossRef]

- Nicoara, M.; Locovei, C.; Opris, C.; Ursu, D.; Vasiu, R.; Stoica, M. Optimizing the parameters for in situ fabrication of hybrid Al-Al2O3 composites. J. Therm. Anal. 2017, 127, 115–122. [Google Scholar] [CrossRef]

- Kováč, P.; Balog, M.; Hušek, I.; Kopera, L.; Križik, P.; Rosová, A.; Kováč, J.; Kulich, M.; Čaplovičová, M. Properties of near- and sub-micrometre Al matrix composites strengthened with nano-scale in-situ Al2O3 aimed for low temperature applications. Cryogenics 2017, 87, 58–65. [Google Scholar] [CrossRef]

- Balog, M.; Simancik, F.; Walcher, M.; Rajner, W.; Poletti, M.C. Extruded Al–Al2O3 composites formed in situ during consolidation of ultrafine Al powders: Effect of the powder surface area. Mater. Sci. Eng. A 2011, 529, 131–137. [Google Scholar] [CrossRef]

- Dirras, G.; Gubicza, J.; Tingaud, D.; Billard, S. Microstructure of Al–Al2O3 nanocomposite formed by in situ phase transformation during Al nanopowder consolidation. Mater. Chem. Phys. 2011, 129, 846–852. [Google Scholar] [CrossRef]

- Durai, T.; Das, K.; Das, S. Synthesis and characterization of Al matrix composites reinforced by in situ alumina particulates. Mater. Sci. Eng. A 2007, 445-446, 100–105. [Google Scholar] [CrossRef]

- Yu, P.; Deng, C.-J.; Ma, N.-G.; Ng, D.H. A new method of producing uniformly distributed alumina particles in Al-based metal matrix composite. Mater. Lett. 2004, 58, 679–682. [Google Scholar] [CrossRef]

- Lakra, S.; Bandyopadhyay, T.K.; Das, S.; Das, K. Thermal conductivity of in-situ dual matrix aluminum composites with segregated morphology. Mater. Res. Bull. 2021, 144, 111515. [Google Scholar] [CrossRef]

- Chen, C.-F.; Huang, C.-N.; Kao, P.-W. Nanometer-sized δ*-Al2O3-reinforced aluminum composites using the friction stir process: A TEM study. Mater. Charact. 2020, 170, 110704. [Google Scholar] [CrossRef]

- Yu, P.; Kwok, C.; To, C.; Li, T.; Ng, D.H. Enhanced precipitation hardening in an alumina reinforced Al–Cu alloy matrix composite. Compos. Part B Eng. 2008, 39, 327–331. [Google Scholar] [CrossRef]

- Kleiner, S.; Bertocco, F.; Khalid, F.A.; Beffort, O. Reactively Synthesized Nanostructured PM Aluminium Composite—Microstructure Stability and Elevated Temperature Hardness Response. Adv. Eng. Mater. 2005, 7, 380–383. [Google Scholar] [CrossRef]

- Roy, D.; Basu, B.; Mallick, A.B. Tribological properties of Ti-aluminide reinforced Al-based in situ metal matrix composite. Intermetallics 2005, 13, 733–740. [Google Scholar] [CrossRef]

- Lakra, S.; Bandyopadhyay, T.K.; Das, S.; Das, K. Synthesis and characterization of in-situ (Al–Al3Ti–Al2O3)/Al dual matrix composite. J. Alloy. Compd. 2020, 842, 155745. [Google Scholar] [CrossRef]

- Woo, K.D.; Kim, J.H.; Kwon, E.P.; Moon, M.S.; Lee, H.B.; Sato, T.; Liu, Z. Fabrication of Al matrix composite reinforced with submicrometer-sized Al2O3 particles formed by combustion reaction between HEMM Al and V2O5 composite particles during sintering. Met. Mater. Int. 2010, 16, 213–218. [Google Scholar] [CrossRef]

- Mandal, A.; DAS, K.; DAS, S. Characterization of microstructure and properties of Al–Al3Zr–Al2O3 composite. Bull. Mater. Sci. 2016, 39, 913–924. [Google Scholar] [CrossRef][Green Version]

- Chen, B.; Zhou, X.; Zhang, B.; Kondoh, K.; Li, J.; Qian, M. Microstructure, tensile properties and deformation behaviors of aluminium metal matrix composites co-reinforced by ex-situ carbon nanotubes and in-situ alumina nanoparticles. Mater. Sci. Eng. A 2020, 795, 139930. [Google Scholar] [CrossRef]

- Dikici, B.; Gavgali, M. The effect of sintering time on synthesis of in situ submicron α-Al2O3 particles by the exothermic reactions of CuO particles in molten pure Al. J. Alloy. Compd. 2013, 551, 101–107. [Google Scholar] [CrossRef]

- Zahid, G.; Azhar, T.; Musaddiq, M.; Rizvi, S.; Ashraf, M.; Hussain, N.; Iqbal, M. In situ processing and aging behaviour of an aluminium/Al2O3 composite. Mater. Des. 2011, 32, 1630–1635. [Google Scholar] [CrossRef]

- Rong, X.; Zhang, X.; Zhao, D.; He, C.; Shi, C.; Liu, E.; Zhao, N. In-situ Al2O3-Al interface contribution towards the strength-ductility synergy of Al-CuO composite fabricated by solid-state reactive sintering. Scr. Mater. 2021, 198, 113825. [Google Scholar] [CrossRef]

- Mallik, B.; Sikdar, K.; Roy, D. Tribological Performance of In Situ Reinforced Al-Based Metal Matrix Composite Processed by Spark Plasma Sintering. Mater. Perform. Charact. 2019, 8, 62–71. [Google Scholar] [CrossRef]

- Huo, H.; Woo, K.D. In situ synthesis of Al2O3 particulate-reinforced Al matrix composite by low temperature sintering. J. Mater. Sci. 2006, 41, 3249–3253. [Google Scholar] [CrossRef]

- Mintzer, S.; Ipohorski, M. Microstructure of aluminium-alumina-silica participate composites obtained by reactive sintering. J. Mater. Sci. 1995, 30, 4703–4709. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, X.; Lyu, L.; Li, Y.; Christian, P.; Sun, H.; Shu, R. Microstructure and properties of nano-C and in-situ Al2O3 reinforced aluminum matrix composites processed by high-pressure torsion. Compos. Interfaces 2022, 29, 579–595. [Google Scholar] [CrossRef]

- Sharma, A.; Lee, H.; Ahn, B. Microstructure and properties of in-situ Al–Si/Al2O3 composites prepared by displacement reaction. Powder Met. 2021, 64, 192–197. [Google Scholar] [CrossRef]

- Mokhnache, E.O.; Wang, G.; Geng, L.; Kaveendran, B.; Henniche, A.; Ramdani, N. In Situ Al Based Composites Fabricated in Al-SiO2-C System by Reaction Sintering. JOM 2015, 67, 1505–1514. [Google Scholar] [CrossRef]

- Lakra, S.; Bandyopadhyay, T.K.; Das, S.; Das, K. In situ dual matrix composite with segregated microstructure fabricated from Al–TiO2–B2O3 system by mechanical thermal process. J. Alloy. Compd. 2021, 860, 158527. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Li, J.H.; Li, S.X.; Ning, X.G.; Lu, Y.X.; Bi, J. Property-microstructure correlation in in situ formed Al2O3, TiB2 and Al3Ti mixture-reinforced aluminium composites. J. Mater. Sci. 1996, 31, 741–747. [Google Scholar] [CrossRef]

- Odhiambo, J.O.; Yoshida, M.; Otsu, A.; Yi, L.-F.; Onda, T.; Chen, Z.-C. Microstructure and tensile properties of in-situ synthesized and hot-extruded aluminum-matrix composites reinforced with hybrid submicron-sized ceramic particles. J. Compos. Mater. 2022, 56, 1987–2001. [Google Scholar] [CrossRef]

- Yu, P.; Mei, Z.; Tjong, S. Structure, thermal and mechanical properties of in situ Al-based metal matrix composite reinforced with Al2O3 and TiC submicron particles. Mater. Chem. Phys. 2005, 93, 109–116. [Google Scholar] [CrossRef]

- Liu, H.; Ruiying, Z.; Sen, Y.; Jinxuan, L.; Han, Y. Effect of TiO2 particle size on reinforcements, reaction mode and kinetics in Al-TiO2-C system. Mater. Res. Express 2019, 6, 116505. [Google Scholar] [CrossRef]

- Fan, G.; Wang, Q.; Geng, L.; Wang, G.; Feng, Y. Preparation and characterization of aluminum matrix composites based on Al–WO3 system. J. Alloy. Compd. 2012, 545, 130–134. [Google Scholar] [CrossRef]

- Feng, C.; Froyen, L. In-situ P/M Al/(ZrB2 + Al2O3) MMCs: Processing, microstructure and mechanical characterization. Acta Mater. 1999, 47, 4571–4583. [Google Scholar] [CrossRef]

- Wu, X.; Li, Y.; Jiang, P.; Sun, J. In situ formation mechanism of spinel-like Al5O6N and plate-like Al7O3N5 in the two-step sintered Al–Al2O3 composites. Mater. Chem. Phys. 2021, 271, 124951. [Google Scholar] [CrossRef]

- Xu, D.; Long, W.; Zhou, X. Microstructure and corrosion resistance of Al3(Zr, Ti)/Al composite prepared by powder metallurgy. Adv. Compos. Lett. 2020, 29, 2633366X20906160. [Google Scholar] [CrossRef]

- Cintas, J.; Cuevas, F.; Montes, J.M.; Caballero, E.; Herrera, E. Strengthening of ultrafine PM aluminium using nano-sized oxycarbonitride dispersoids. Mater. Sci. Eng. A 2011, 528, 8286–8291. [Google Scholar] [CrossRef]

- Akçamlı, N.; Şenyurt, B. Fabrication and characterization of in-situ Al3Ni intermetallic and CeO2 particulate-reinforced aluminum matrix composites. Ceram. Int. 2021, 47, 21197–21206. [Google Scholar] [CrossRef]

- Wan, Q.; Li, F.; Wang, W.; Hou, J.; Cui, W.; Li, Y. Study on In-Situ Synthesis Process of Ti–Al Intermetallic Compound-Reinforced Al Matrix Composites. Materials 2019, 12, 1967. [Google Scholar] [CrossRef]

- Goyal, V.; Ravi, R.; Bakshi, S.R.; Soni, P.R. Development and Mechanical Properties of In Situ Al3Ti-Reinforced Nanostructured AA6061 via Mechanical Alloying. J. Mater. Eng. Perform. 2019, 28, 117–122. [Google Scholar] [CrossRef]

- Dursun, Ö.; Tansel, T.; Hatice, E. Ibrahim, Synthesis, Characterization and Dry Sliding Wear Behavior of In-situ Formed TiAl3 Precipitate Reinforced A356 Alloy Produced by Mechanical Alloying Method. Mater. Res. 2015, 18, 813–820. [Google Scholar] [CrossRef]

- Chianeh, V.A.; Hosseini, H.M.; Nofar, M. Micro structural features and mechanical properties of Al–Al3Ti composite fabricated by in-situ powder metallurgy route. J. Alloy. Compd. 2009, 473, 127–132. [Google Scholar] [CrossRef]

- Sun, Z.; Hashimoto, H.; Wang, Q.; Park, Y.; Abe, T. Synthesis of Al–Al3Ti Composites using Pulse Discharge Sintering Process. Mater. Trans. JIM 2000, 41, 597–600. [Google Scholar] [CrossRef][Green Version]

- Guo, B.; Song, M.; Zhang, X.; Cen, X.; Li, W.; Chen, B.; Wang, Q. Achieving high combination of strength and ductility of Al matrix composite via in-situ formed Ti-Al3Ti core-shell particle. Mater. Charact. 2020, 170, 110666. [Google Scholar] [CrossRef]

- Vorotilo, S.; Nepapushev, A.; Moskovskikh, D.; Buinevich, V.; Trusov, G.; Kovalev, D.Y.; Semenyuk, A.; Stepanov, N.; Nalivaiko, A.; Gromov, A. Engineering of strong and hard in-situ Al-Al3Ti nanocomposite via high-energy ball milling and spark plasma sintering. J. Alloy. Compd. 2022, 895, 162676. [Google Scholar] [CrossRef]

- Krizik, P.; Balog, M.; Nosko, M.; Riglos, M.V.C.; Dvorak, J.; Bajana, O. Ultrafine-grained Al composites reinforced with in-situ Al3Ti filaments. Mater. Sci. Eng. A 2016, 657, 6–14. [Google Scholar] [CrossRef]

- Zhang, Q.; Xiao, B.; Wang, D.; Ma, Z. Formation mechanism of in situ Al3Ti in Al matrix during hot pressing and subsequent friction stir processing. Mater. Chem. Phys. 2011, 130, 1109–1117. [Google Scholar] [CrossRef]

- Azarniya, A.; Hosseini, H.R.M.; Jafari, M.; Bagheri, N. Thermal decomposition of nanostructured Aluminum Titanate in an active Al matrix: A novel approach to fabrication of in situ Al/Al2O3–Al3Ti composites. Mater. Des. 2015, 88, 932–941. [Google Scholar] [CrossRef]

- Azarniya, A.; Hosseini, H.R.M. A new method for fabrication of in situ Al/Al 3 Ti–Al 2 O 3 nanocomposites based on thermal decomposition of nanostructured tialite. J. Alloy. Compd. 2015, 643, 64–73. [Google Scholar] [CrossRef]

- Yıldırım, M.; Ōzyūrek, D. An Investigation of Wear Behaviors of AA7075 Al Hybrid Composites. High Temp. Mater. Process. 2018, 37, 619–624. [Google Scholar] [CrossRef]

- Umeda, J.; Nishimura, N.; Fujii, H.; Jia, L.; Kondoh, K. In-Situ Formed Al3Zr Compounds Reinforced Al Composites and Tribological Application. Crystals 2021, 11, 227. [Google Scholar] [CrossRef]

- Geng, L.; Imai, T.; Mao, J.; Takagi, M.; Yao, C. Microstructure and high strain rate superplasticity ofin situcomposite synthesised from aluminium and nano ZrO2 particles by powder metallurgy. Mater. Sci. Technol. 2001, 17, 187–194. [Google Scholar] [CrossRef]

- Geng, L.; Zheng, Z.Z.; Yao, C.K.; Mao, J.F.; Imai, T. A new in situ composite fabricated by powder metallurgy with aluminum and nanocrystalline ZrO2 particles. J. Mater. Sci. Lett. 2000, 19, 985–987. [Google Scholar] [CrossRef]

- Velgosová, O.; Besterci, M.; Balloková, B. Influence of Al4C3 nanophase on structural stability and mechanical properties of Al-Al4C3 composites after thermal exposure. Met. Res. Technol. 2018, 115, 606. [Google Scholar] [CrossRef]

- Ozdemir, A.T.; Bostan, B. Microstructure and electrical resistivity features in Al-Al4C3 in-situ composite after attrition milling and double sequence of compaction and high temperature treatment. Met. Mater. 2012, 50, 89–95. [Google Scholar] [CrossRef]

- Arik, H.; Aydin, M.; Kurt, A.; Turker, M. Weldability of Al4C3–Al composites via diffusion welding technique. Mater. Des. 2005, 26, 555–560. [Google Scholar] [CrossRef]

- Arik, H. Production and characterization of in situ Al4C3 reinforced aluminum-based composite produced by mechanical alloying technique. Mater. Des. 2004, 25, 31–40. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, J.; Luo, G.; Sun, Y.; Shen, Q.; Zhang, L. Effectively enhanced strength by interfacial reactions in in-situ carbon reinforced Al matrix composites. Vacuum 2021, 188, 110148. [Google Scholar] [CrossRef]

- Wan, J.; Chen, B.; Feng, D.; Cao, L.; Shen, J.; Guo, B.; Li, J. Strengthening efficiency competition between carbon nanotubes (CNTs) and in-situ Al4C3 nanorods in CNTs/Al composites influenced by alumina characteristics. Compos. Part A Appl. Sci. Manuf. 2022, 152, 106704. [Google Scholar] [CrossRef]

- Chen, B.; Jia, L.; Li, S.; Imai, H.; Takahashi, M.; Kondoh, K. In Situ Synthesized Al4C3Nanorods with Excellent Strengthening Effect in Aluminum Matrix Composites. Adv. Eng. Mater. 2014, 16, 972–975. [Google Scholar] [CrossRef]

- Lekatou, A.; Sfikas, A.; Karantzalis, A. The influence of the fabrication route on the microstructure and surface degradation properties of Al reinforced by Al9CO2. Mater. Chem. Phys. 2017, 200, 33–49. [Google Scholar] [CrossRef]

- Yuan, L.; Han, J.; Liu, J.; Jiang, Z. Mechanical properties and tribological behavior of aluminum matrix composites reinforced with in-situ AlB2 particles. Tribol. Int. 2016, 98, 41–47. [Google Scholar] [CrossRef]

- Balog, M.; Yu, P.; Qian, M.; Behulova, M.; Švec, P.; Cicka, R. Nanoscaled Al–AlN composites consolidated by equal channel angular pressing (ECAP) of partially in situ nitrided Al powder. Mater. Sci. Eng. A 2013, 562, 190–195. [Google Scholar] [CrossRef]

- Yu, P.; Balog, M.; Yan, M.; Schaffer, G.; Qian, M. In situ fabrication and mechanical properties of Al–AlN composite by hot extrusion of partially nitrided AA6061 powder. J. Mater. Res. 2011, 26, 1719–1725. [Google Scholar] [CrossRef]

- Kondoh, K.; Umeda, J.; Watanabe, R. Cavitation erosion of aluminum matrix sintered composite with AlN dispersoids. Wear 2009, 267, 1511–1515. [Google Scholar] [CrossRef]

- Kondoh, K.; Kimura, A.; Watanabe, R. Cavitation toughness ofin situnitrided Al–AlN composite sintered material. Powder Met. 2001, 44, 157–160. [Google Scholar] [CrossRef]

- Balog, M.; Krizik, P.; Dvorak, J.; Bajana, O.; Krajcovic, J.; Drienovsky, M. Industrially fabricated in-situ Al-AlN metal matrix composites (part B): The mechanical, creep, and thermal properties. J. Alloy. Compd. 2022, 909, 164720. [Google Scholar] [CrossRef]

- Caballero, E.S.; Cuevas, F.G.; Ternero, F.; Astacio, R.; Montes, J.M.; Cintas, J. In Situ Synthesis of Al-Based MMCs Reinforced with AlN by Mechanical Alloying under NH3 Gas. Materials 2018, 11, 823. [Google Scholar] [CrossRef]

- Yang, W.-W.; Guo, Z.-M.; Guo, L.-C.; Cao, H.-Q.; Luo, J.; Ye, A.-P. In situ fabrication and properties of AlN dispersion strengthened 2024 aluminum alloy. Int. J. Miner. Met. Mater. 2014, 21, 1228–1232. [Google Scholar] [CrossRef]

- Balog, M.; Krizik, P.; Yan, M.; Simancik, F.; Schaffer, G.; Qian, M. SAP-like ultrafine-grained Al composites dispersion strengthened with nanometric AlN. Mater. Sci. Eng. A 2013, 588, 181–187. [Google Scholar] [CrossRef]

- Gostariani, R.; Asadabad, M.A.; Paydar, M.H.; Ebrahimi, R. Morphological and phase evaluation of Al/15 wt.% BN nanocomposite synthesized by planetary ball mill and sintering. Adv. Powder Technol. 2017, 28, 2232–2238. [Google Scholar] [CrossRef]

- Kondoh, K.; Takeda, Y. Tribological property of in situ directly nitrided and sintered Al/AlN composite. Powder Met. 2000, 43, 69–75. [Google Scholar] [CrossRef]

- Chen, C.-L.; Lin, C.-H. In-situ dispersed La oxides of Al6061 composites by mechanical alloying. J. Alloy. Compd. 2019, 775, 1156–1163. [Google Scholar] [CrossRef]

- Zhou, Y.; Zan, Y.; Zheng, S.; Shao, X.; Jin, Q.; Zhang, B.; Wang, Q.; Xiao, B.; Ma, X.; Ma, Z. Thermally stable microstructures and mechanical properties of B4C-Al composite with in-situ formed Mg(Al)B. J. Mater. Sci. Technol. 2019, 35, 1825–1830. [Google Scholar] [CrossRef]

- Hao, G.; Shi, C.-S.; Zhao, N.-Q.; Liu, E.-Z.; He, C.-N.; He, F.; Ma, L.-Y. Microstructural evolution and mechanical behavior of in situ synthesized MgAl2O4 whiskers reinforced 6061 Al alloy composite after hot extrusion and annealing. Rare Met. 2018, 1–11. [Google Scholar] [CrossRef]

- Xing, L.; Zhang, Y.; Shi, C.; Zhou, Y.; Zhao, N.; Liu, E.; He, C. In-situ synthesis of MgAl2O4 nanowhiskers reinforced 6061 aluminum alloy composites by reaction hot pressing. Mater. Sci. Eng. A 2014, 617, 235–242. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, N.; Shi, C.; Liu, E.; Du, X.; He, C. In-situ processing and aging behaviors of MgAl2O4 spinel whisker reinforced 6061Al composite. Mater. Sci. Eng. A 2014, 598, 114–121. [Google Scholar] [CrossRef]

- Zhou, Y.; Yu, Z.; Zhao, N.; Shi, C.; Liu, E.; Du, X.; He, C. Microstructure and properties of in situ generated MgAl2O4 spinel whisker reinforced aluminum matrix composites. Mater. Des. 2013, 46, 724–730. [Google Scholar] [CrossRef]

- Yu, Z.; Zhao, N.; Liu, E.; Shi, C.; Du, X.; Wang, J. Fabrication of aluminum matrix composites with enhanced mechanical properties reinforced by in situ generated MgAl2O4 whiskers. Compos. Part A Appl. Sci. Manuf. 2012, 43, 631–634. [Google Scholar] [CrossRef]

- Jia, L.; Rong, X.; Zhao, D.; Zhang, X.; He, C.; Zhao, N. Microstructural characteristic and mechanical properties of the in-situ MgAl2O4 reinforced Al matrix composite based on Al-Mg-ZnO system. J. Alloy. Compd. 2022, 891, 161991. [Google Scholar] [CrossRef]