Corrosion Behaviour of Cemented Carbides with Co- and Ni-Alloy Binders in the Presence of Abrasion

Abstract

1. Introduction

2. Experimental

2.1. Sample Preparation

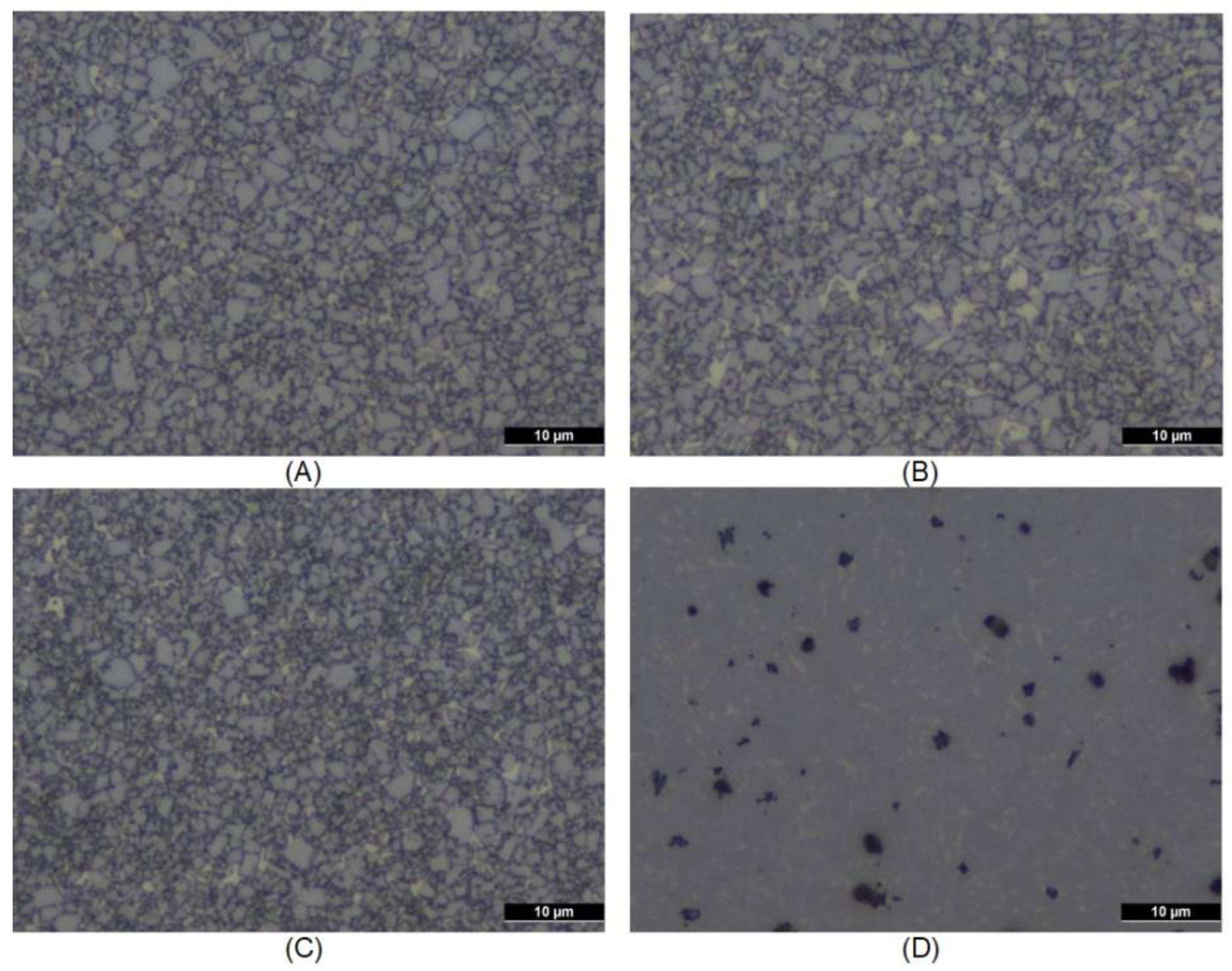

2.2. Physical Characterization

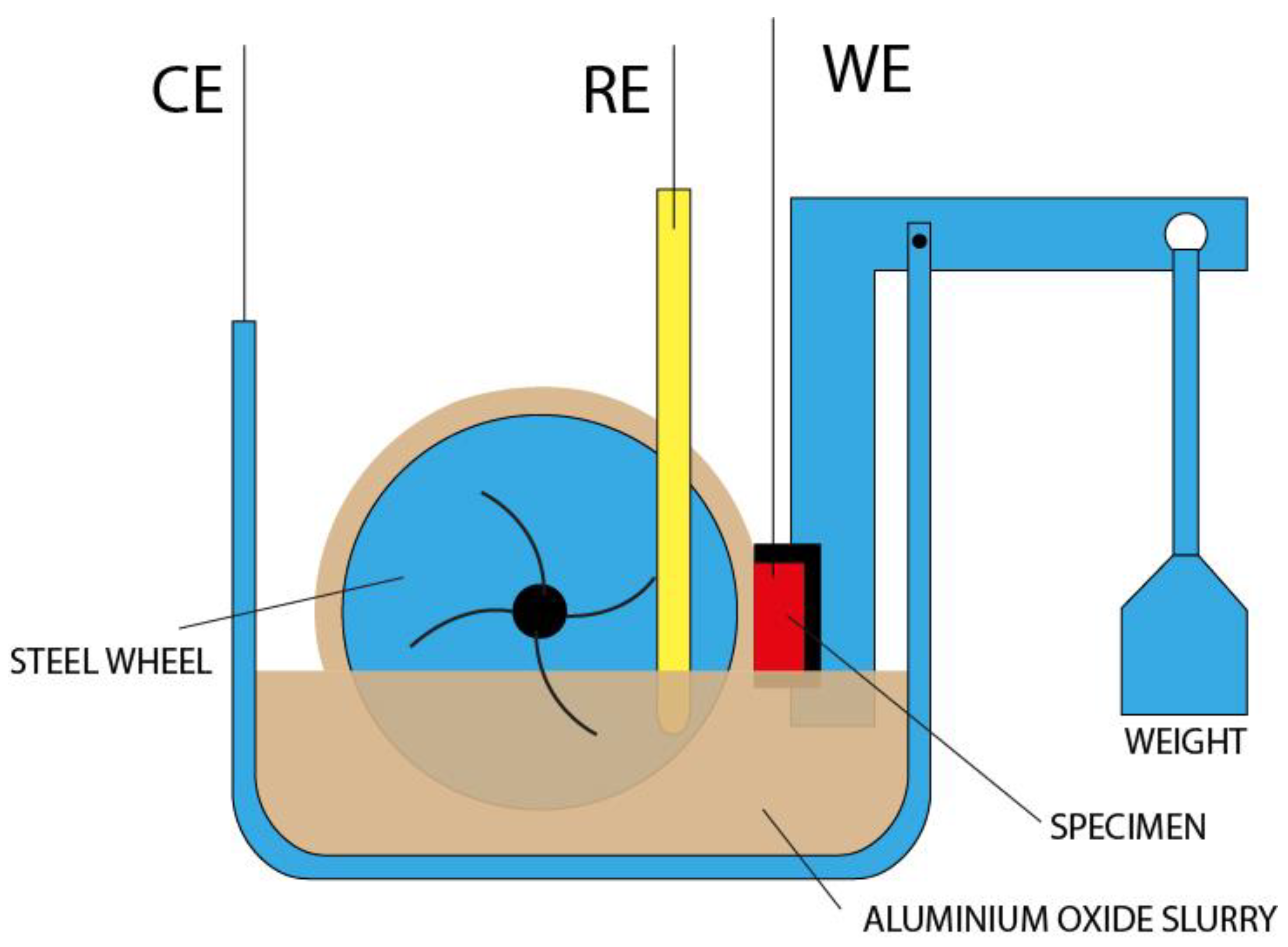

2.3. The Abrasion–Corrosion Test System

2.4. Linear Sweep Voltammetry Setups for Electrochemical Characterization

2.5. Data Analysis

2.5.1. Wear Volume

2.5.2. Steady-State Abrasion–Corrosion Performance

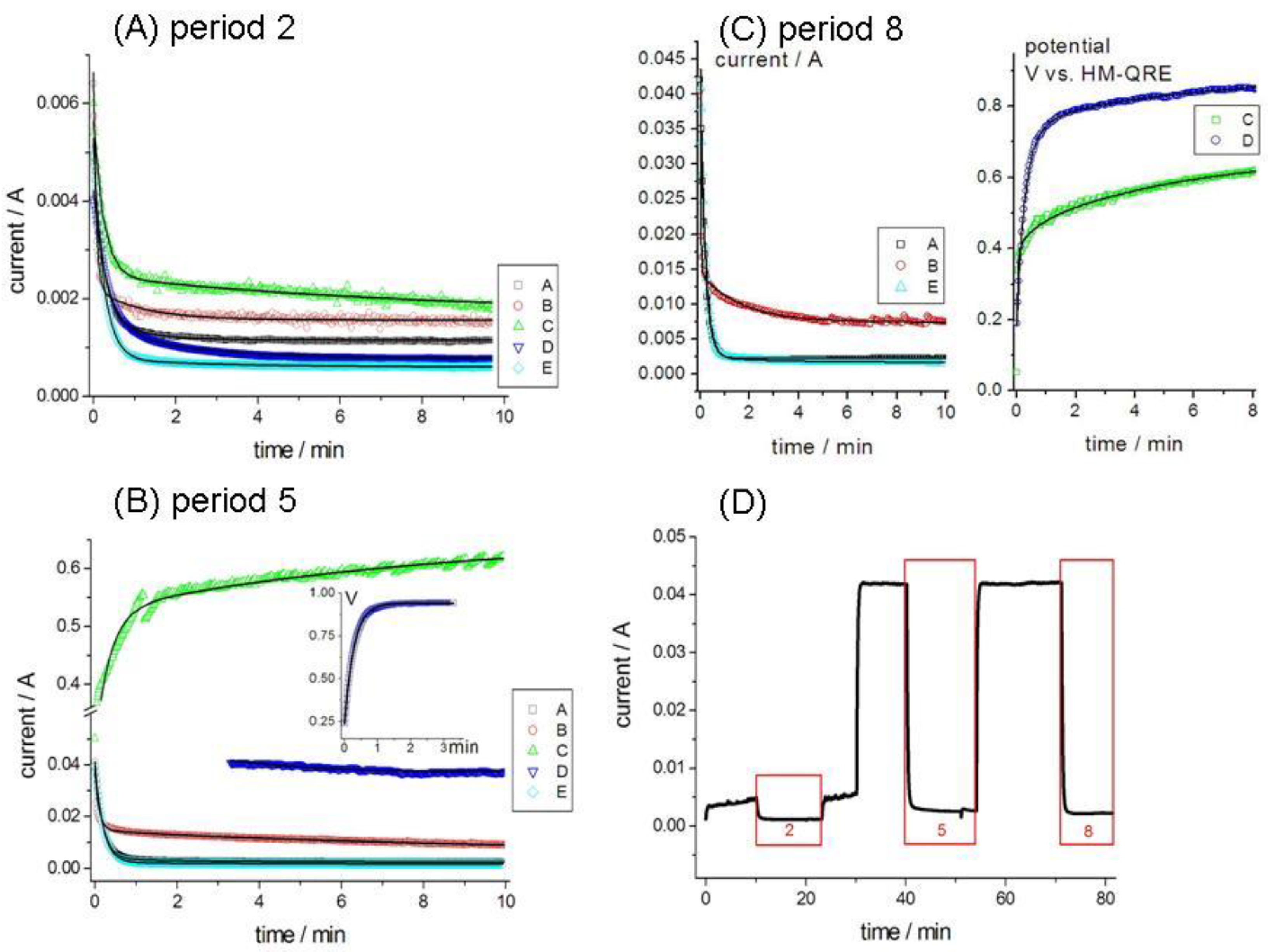

2.5.3. Transient Abrasion–Corrosion Performance

3. Discussion and Results

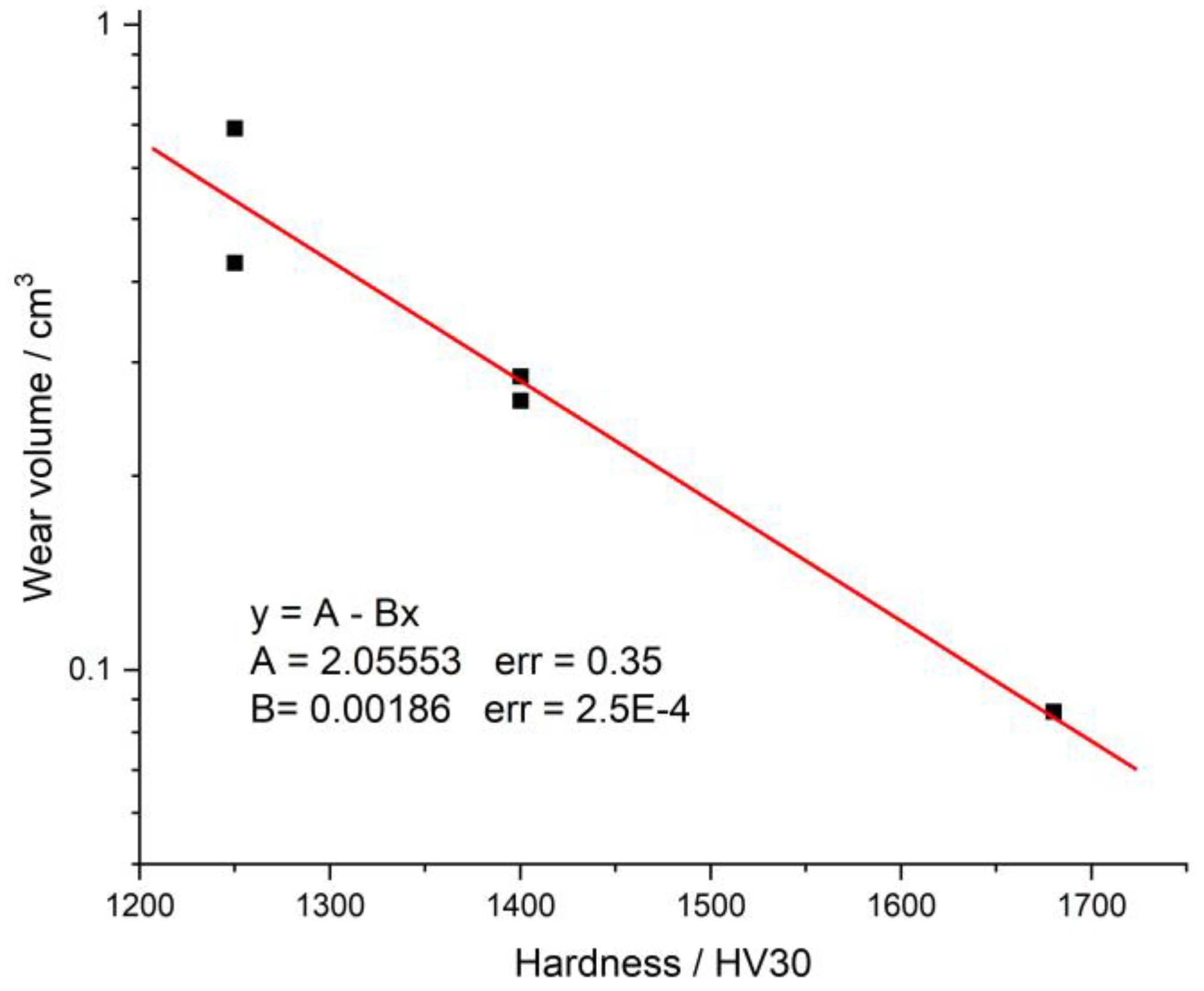

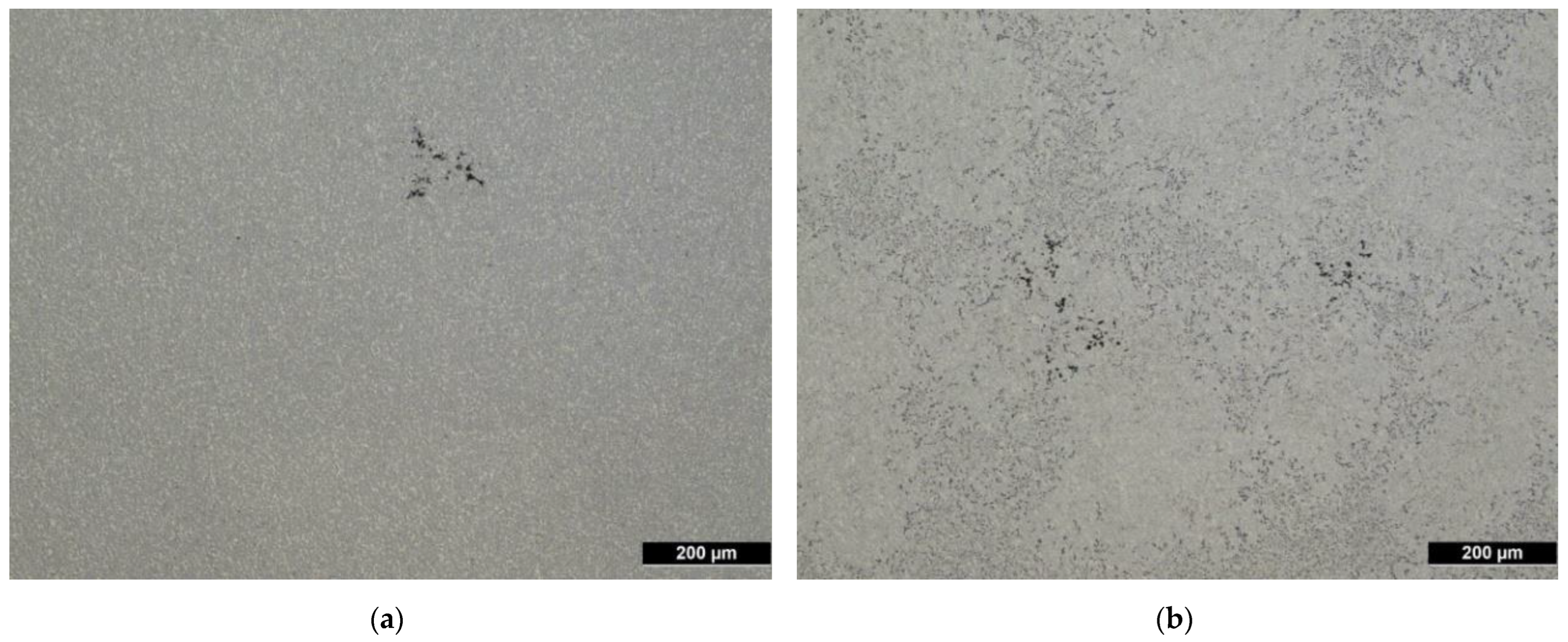

3.1. Abrasion Resistance

3.1.1. Co-, CoNi- and CoNiCr-Based Grades

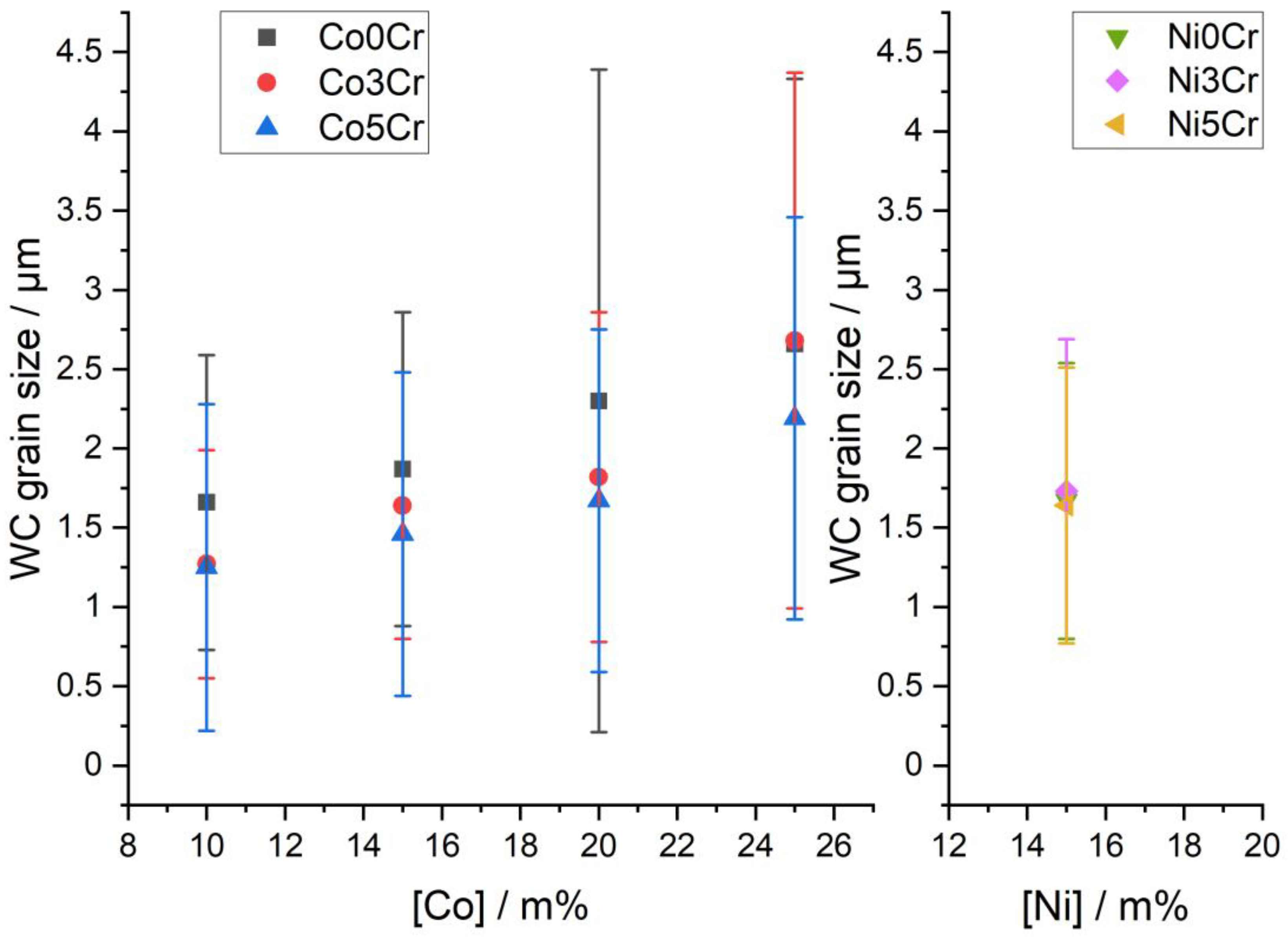

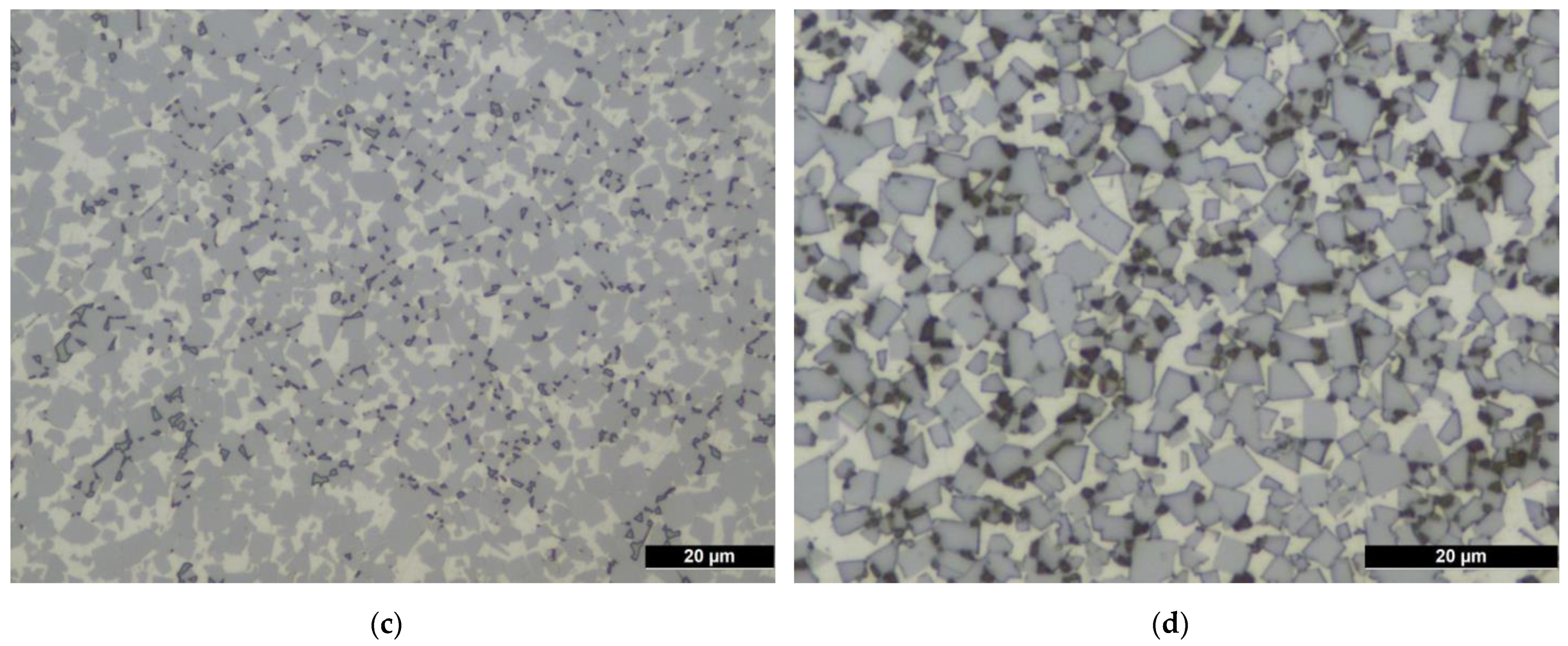

3.1.2. Impact of Systematic Variations of Cr Content

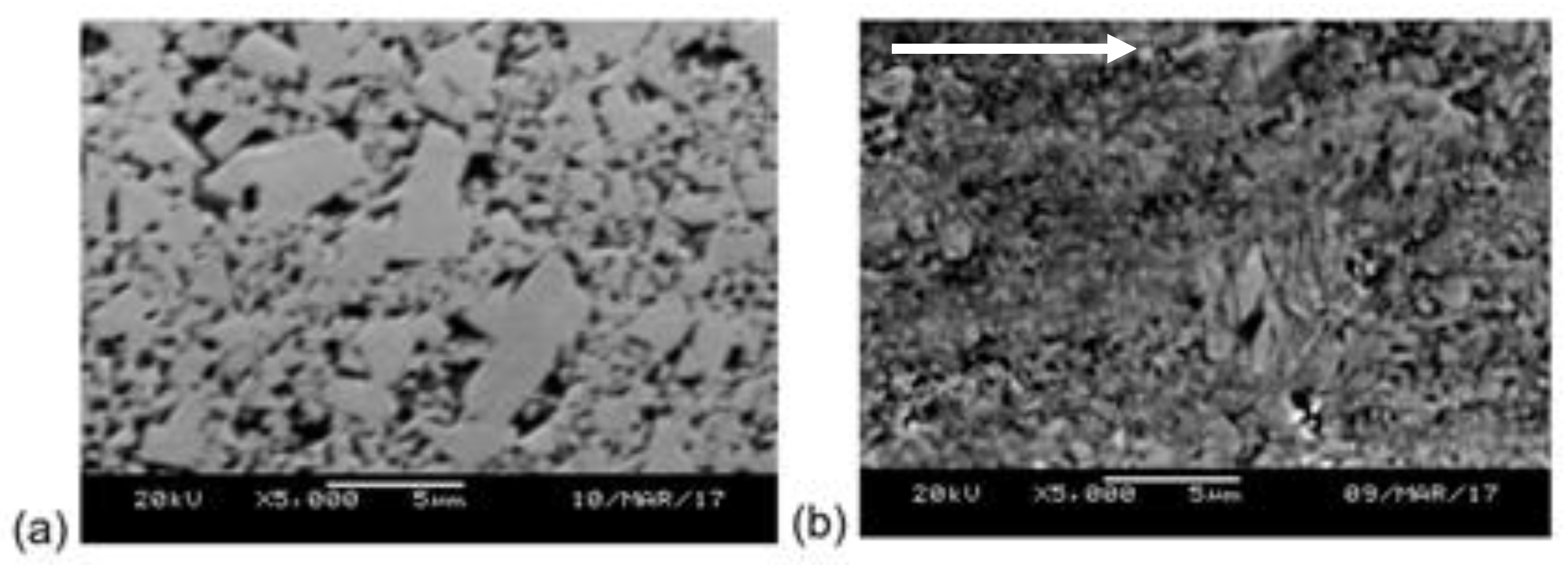

3.2. Corrosion Behaviour

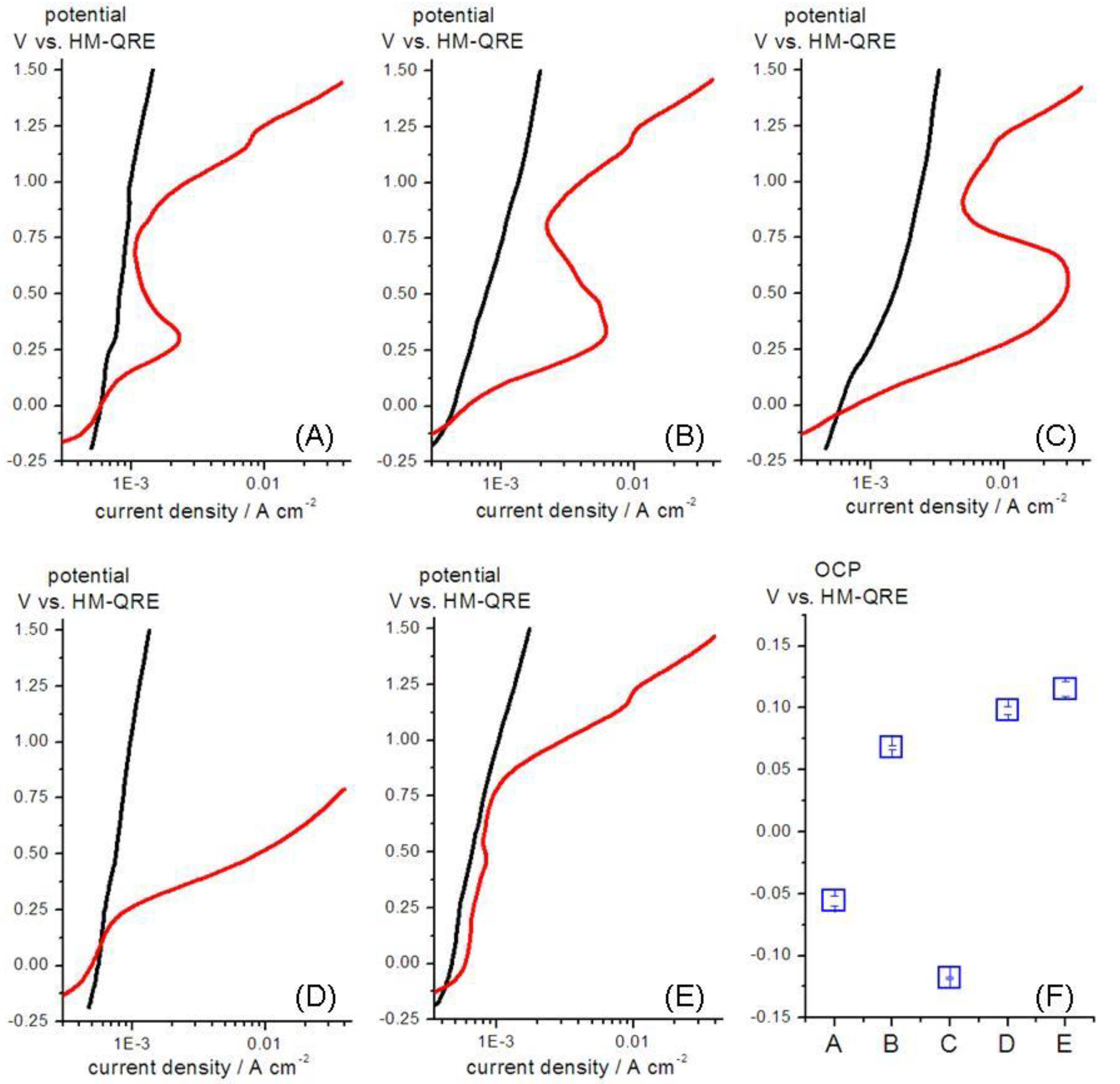

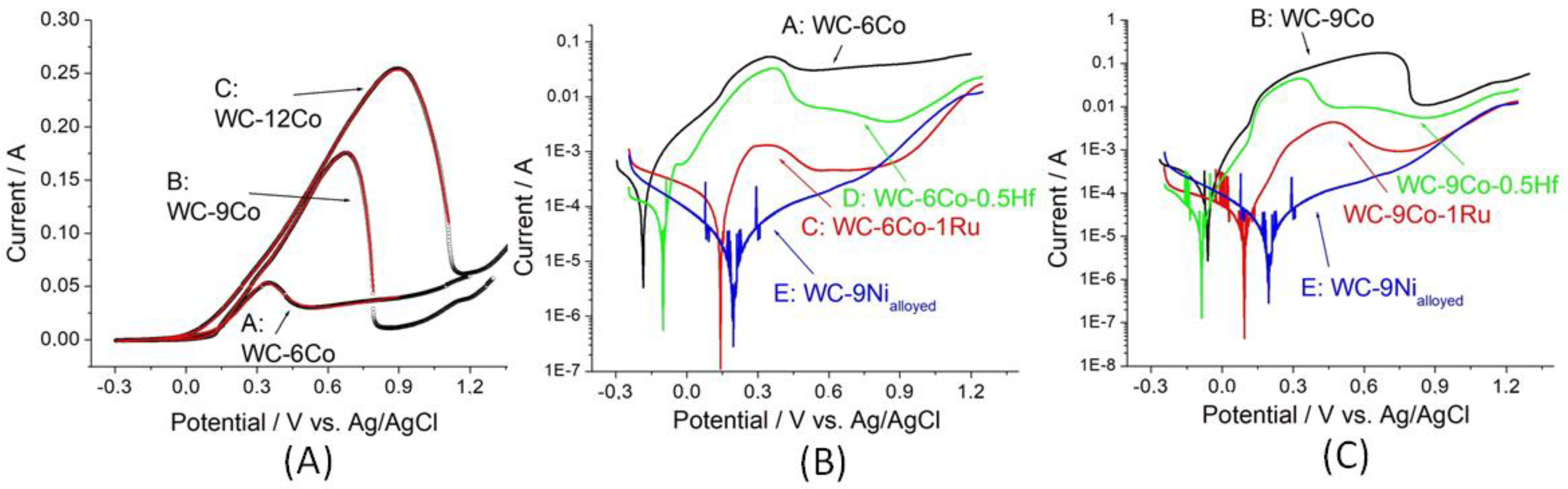

3.2.1. Co- and Ni-Based Grades with Cr, Hf and Ru Addition

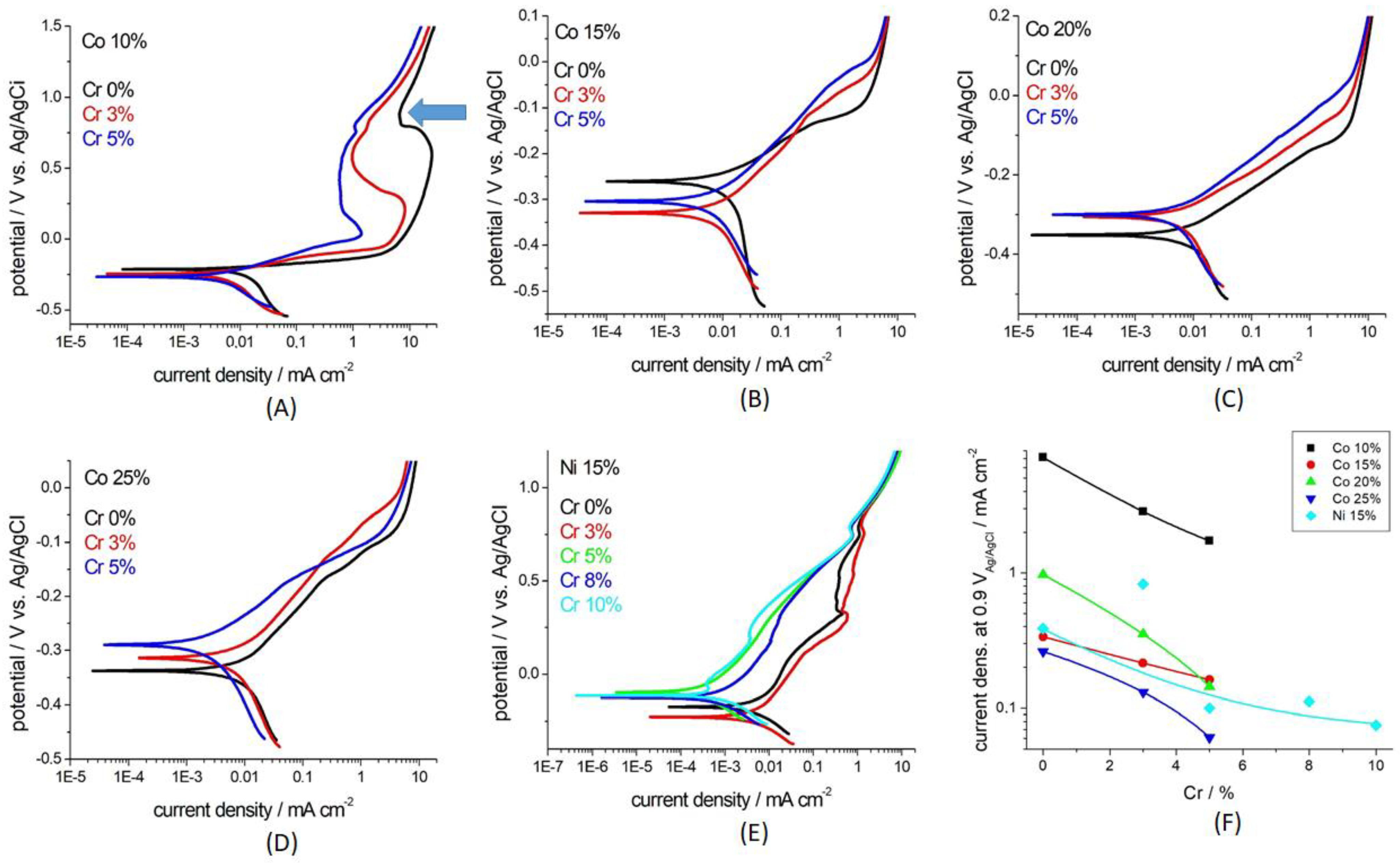

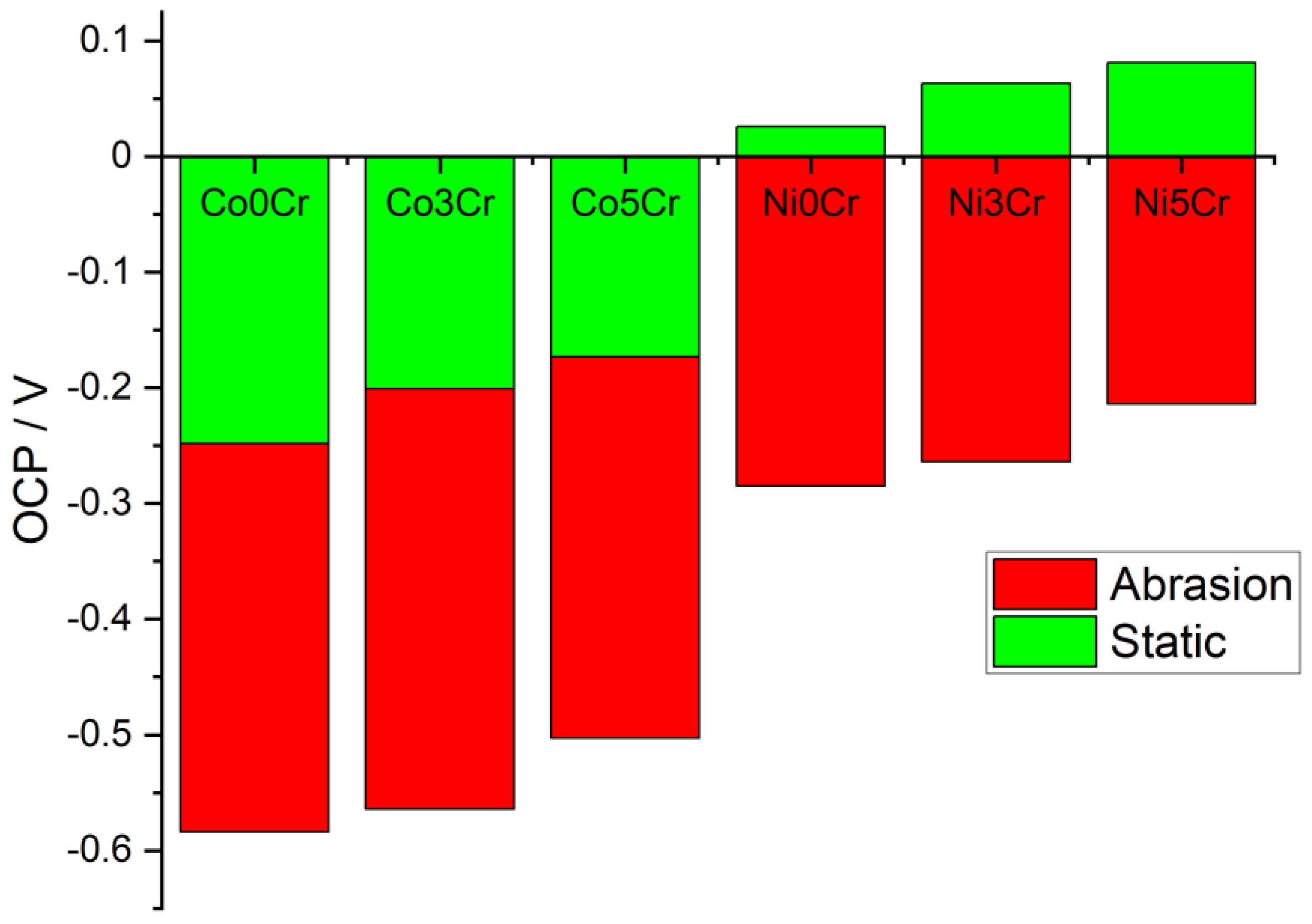

3.2.2. Impact of Systematic Variations of Cr Content

3.3. Abrasion–Corrosion Behaviour

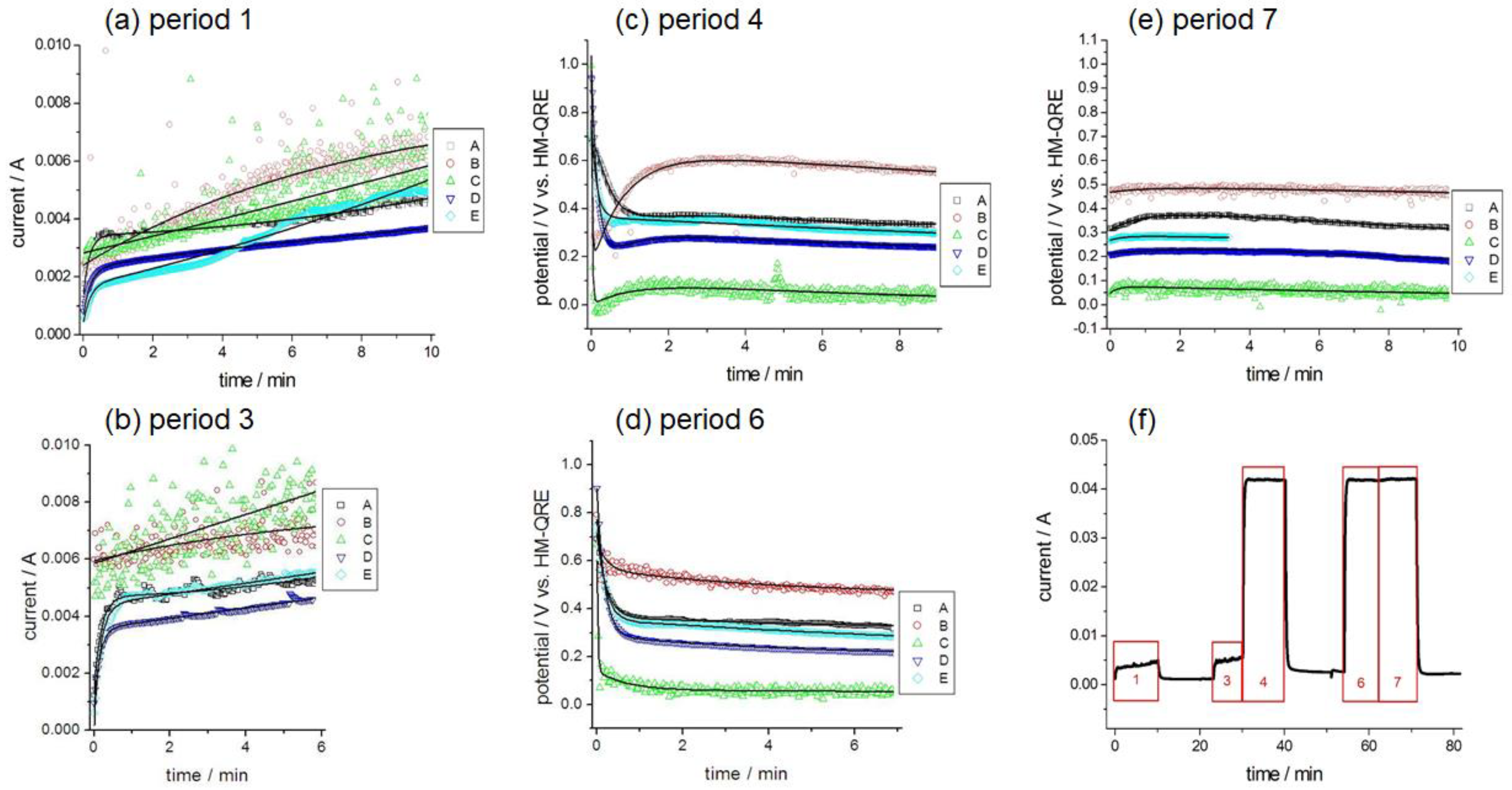

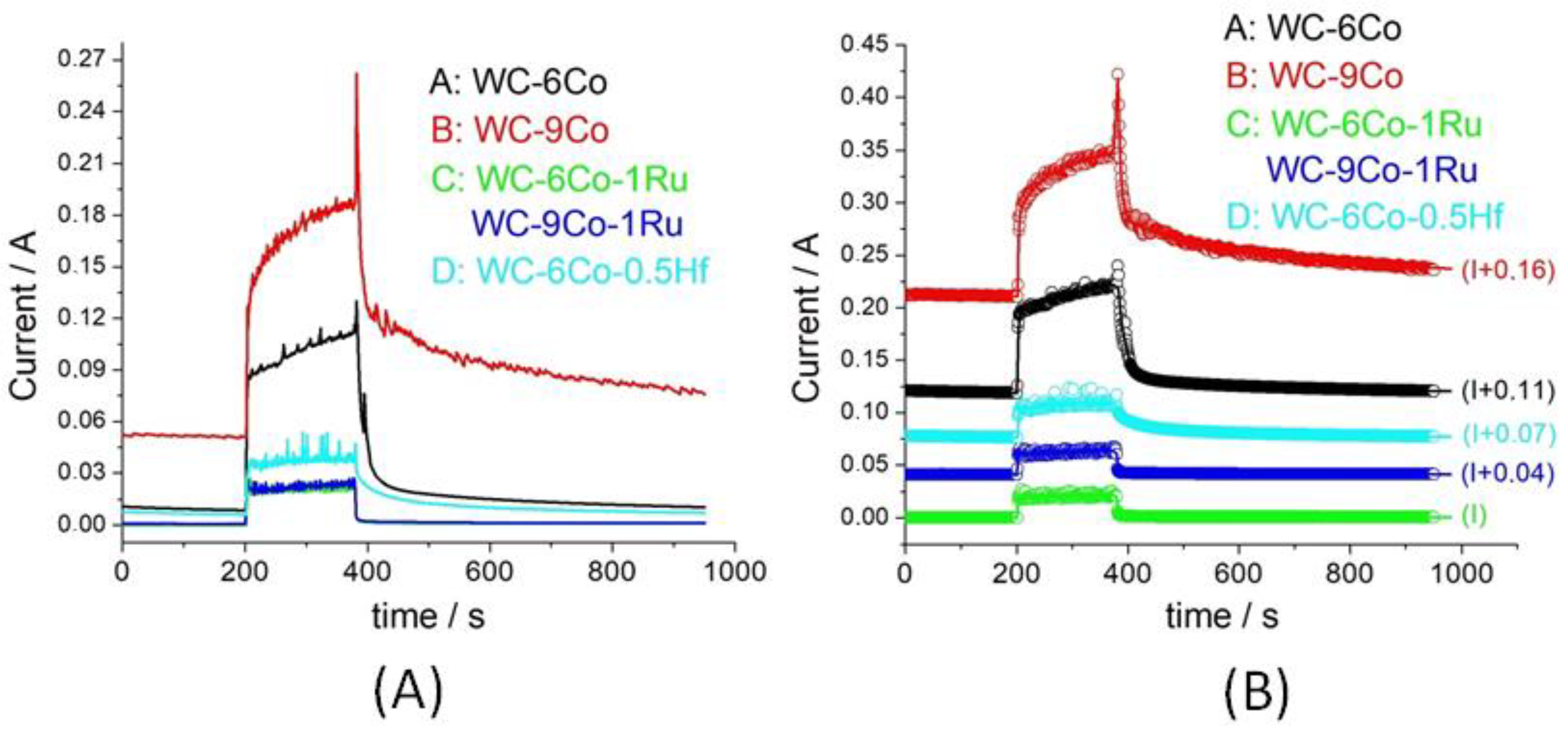

3.3.1. Co- and Ni-Based Grades with Cr, Hf and Ru Addition

3.3.2. Impact of Systematic Variations of Cr Content

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ettmayer, P.; Kolaska, H.; Ortner, H.M. History of Hardmetals. In Comprehensive Hard Materials—Hardmetals, Ceramics, Super Hard Materials; Mari, D., Llanes, L., Nebel, C.E., Eds.; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Wright, I.G.; Shetty, D.K.; Clauer, A.H. A comparison of the slurry erosion behaviour of WC-Co cermets and ceramics. In Proceedings of the Conference 11th International Plansee Seminar, Reutte, Austria, 20–24 May 1985; Bildstein, H., Ortner, H., Eds.; Plansee Metalwerke: Reutte, Austria, 1985; Volume 2, p. 643. [Google Scholar]

- Gee, M.G.; Gant, A.J.; Roebuck, B.; Mingard, K.P. Wear of Hardmetals. In Comprehensive Hard Materials—Hardmetals, Ceramics, Super Hard Materials; Mari, D., Llanes, L., Nebel, C.E., Eds.; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- De Gaudenzi, G.P.; Bozzini, B. Meccanismi di corrosione del metallo duro. Metall. Ital. 2017, 11, 39. [Google Scholar]

- De Gaudenzi, G.P.; Amati, M.; Gianoncelli, A.; Gregoratti, L.; Kiskinova, M.; Kourousias, G.; Tedeschi, S.; Bozzini, B. The spatial organization of corrosion products at the hardmetal/environment interface. In Proceedings of the 20th International Plansee Seminar, Reutte, Austria, 30 May–3 June 2022; Wex, K., Kestler, H., Pilz, A., Eds.; Plansee Group Functions Austria GmbH: Reutte/Tyrol, Austria, 2022. [Google Scholar]

- Mischler, S.; Debaud, S.; Landolt, D. Wear-Accelerated Corrosion of Passive Metals in Tribocorrosion Systems. J. Electrochem. Soc. 1998, 145, 750. [Google Scholar] [CrossRef]

- Mischler, S.; Spiegel, A.; Landolt, D. The role of passive oxide films on the degradation of steel in tribocorrosion systems. Wear 1999, 225, 1078–1087. [Google Scholar] [CrossRef]

- Mischler, S.; Spiegel, A.; Stemp, M.; Landolt, D. Influence of passivity on the tribocorrosion of carbon steel in aqueous solutions. Wear 2001, 251, 1295. [Google Scholar] [CrossRef]

- Landolt, D.; Mischler, S.; Stemp, M. Electrochemical methods in tribocorrosion: A critical appraisal. Electrochim. Acta 2001, 46, 3913. [Google Scholar] [CrossRef]

- Wood, R.J.K.; Sun, D.; Thakare, M.R.; de Frutos Rozas, A.; Wharton, J.A. Interpretation of electrochemical measurements made during micro-scale abrasion-corrosion. Tribol. Int. 2010, 43, 1218. [Google Scholar] [CrossRef]

- Thakare, M.R.; Wharton, J.A.; Wood, R.J.K.; Menger, C. Exposure effects of alkaline drilling fluid on the microscale abrasion–corrosion of WC-based hardmetals. Wear 2007, 263, 125. [Google Scholar] [CrossRef]

- Spriggs, G.E. A history of fine grained hardmetal. Int. J. Refract. Met. Hard Mater. 1995, 13, 241. [Google Scholar] [CrossRef]

- Exner, H.E.; Gurland, J. A review of parameters influencing some mechanical properties of tungsten carbide–cobalt alloys. Powder Metall. 1970, 13, 13–31. [Google Scholar] [CrossRef]

- Tracey, V.A.; Hall, N.R.V. Nickel matrices in cemented carbides. Powder Metall. Int. 1980, 12, 132. [Google Scholar]

- Ekemar, S.; Lindholm, L.; Hartzell, T. Nickel as a binder in WC-based cemented carbides. Int. J. Refract. Met. Hard Mater. 1982, 3, 37. [Google Scholar]

- Adorjan, A.; Schubert, W.; Schön, A.; Bock, A.; Zeiler, B. WC grain growth during the early stages of sintering. Int. J. Refract. Met. Hard Mater. 2006, 24, 365. [Google Scholar] [CrossRef]

- Garcia, J.; Ciprés, V.C.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40. [Google Scholar] [CrossRef]

- Warbichler, P.; Hofer, F.; Grogger, W.; Lackner, A. EFTEM-EELS characterization of VC and Cr3C2 doped cemented carbides. In Proceedings of the 15th International Plansee Seminar, Reutte, Austria, May 2001; Kneringer, G., Rodhammer, P., Wildner, H., Eds.; Plansee AG: Reutte, Austria, 2001; Volume 2, p. 65. [Google Scholar]

- Delanoe, A.; Lay, S. Evolution of the WC grain shape in WC–Co alloys during sintering: Cumulated effect of the Cr addition and of the C content. Int. J. Refract. Met. Hard Mater. 2009, 27, 189. [Google Scholar] [CrossRef][Green Version]

- Llanes, L.; Casas, B.; Idañez, E.; Marsal, M.; Anglada, M. Surface Integrity Effects on the Fracture Resistance of Electrical-Discharge-Machined WC–Co Cemented Carbides. J. Am. Ceram. Soc. 2004, 87, 1687–1693. [Google Scholar] [CrossRef]

- Human, A.M.; Roebuck, B.; Exner, H.E. Electrochemical polarisation and corrosion behaviour of cobalt and Co(W,C) alloys in 1 N sulphuric acid. Mater. Sci. Eng. A 1998, 241, 202. [Google Scholar] [CrossRef]

- Bozzini, B.; Busson, B.; de Gaudenzi, G.P.; Humbert, C.; Mele, C.; Tedeschi, S.; Tadjeddine, A. Corrosion of cemented carbide grades in petrochemical slurries. Part I—Electrochemical adsorption of CN−, SCN− and MBT: A study based on in situ SFG. Int. J. Refract. Met. Hard Mater. 2016, 60, 37. [Google Scholar] [CrossRef]

- Santos, R.F.; Rocha, A.M.F.; Bastos, A.C.; Cardoso, J.P.; Rodrigues, F.; Fernandes, C.M.; Sacramento, J.; Ferreira, M.G.S.; Senos, A.M.R.; Fonseca, C.; et al. The effect of Cr content on the corrosion resistance of WC-Ni-Cr-Mo composites. Int. J. Refract. Met. Hard Mater. 2021, 95, 105434. [Google Scholar] [CrossRef]

- Motitschka, R.; Ettmayer, P.; Kny, E. Constitution of the Systems Co-Cr-W-C and Ni-Cr-W-C in the Cobalt and Nickel Corner. In Proceedings of the 12th International Plansee Seminar, Reutte, Tirol, Austria, 8–12 May 1989; Bildstein, H., Ortner, H.M., Eds.; Metallwerk Plansee GmbH: Reutte, Austria, 1989; Volume 2, p. 863. [Google Scholar]

- Zackrisson, J.; Jansson, B.; Uphadyaya, G.S.; Andrén, H.-O. WC-Co based cemented carbides with large Cr3C2 additions. Int. J. Refract. Met. Hard Mater. 1998, 16, 417. [Google Scholar] [CrossRef]

- Markström, A.; Norgren, S.; Frisk, K.; Jansson, B.; Sterneland, T. Experimental and thermodynamic evaluation of the Co-Cr-C system. Int. J. Mater. Res. 2006, 97, 1243. [Google Scholar] [CrossRef]

- Kaplan, B.; Norgren, S.; Schwind, M.; Selleby, M. Thermodynamic calculations and experimental verification in the WC-Co-Cr cemented carbide system. Int. J. Refract. Met. Hard Mater. 2015, 48, 257. [Google Scholar] [CrossRef]

- De Calderon, R.; Edtmaier, C.; Schubert, W.-D. Novel binders for WC-based cemented carbides with high Cr contents. Int. J. Refract. Met. Hard Mater. 2019, 85, 105063. [Google Scholar] [CrossRef]

- Steinlechner, R.; de Oro Calderon, R.; Koch, T.; Linhardt, P.; Schubert, W.D. A study on WC-Ni cemented carbides: Constitution, alloy compositions and properties, including corrosion behaviour. Int. J. Refract. Met. Hard Mater. 2022, 103, 105750. [Google Scholar] [CrossRef]

- Lisovskii, A.F. Cemented carbides alloyed with ruthenium, osmium and rhenium. Powder Metall. Met. Ceram. 2000, 39, 428. [Google Scholar] [CrossRef]

- Shing, T.L.; Luyckx, S.; Northrop, I.T.; Wolff, I. The effect of ruthenium additions on the hardness, toughness and grain size of WC-Co. Int. J. Refract. Met. Hard Mater. 2001, 19, 41. [Google Scholar] [CrossRef]

- Bonjour, C.; Actis-Data, A. Effects of ruthenium additions on the properties of WC-Co ultra micrograins. In Proceedings of the Conference Euro PM2004, Vienna, Austria, 17–21 October 2004; EPMA: Shewsbury, UK, 2004; Volume 3. [Google Scholar]

- Ettmayer, P. Hardmetals and cermets. Annu. Rev. Mater. Sci. 1989, 19, 145. [Google Scholar] [CrossRef]

- Gant, A.J.; Gee, M.G.; Roebuck, B. Rotating wheel abrasion of WC/Co hardmetals. Wear 2005, 258, 178. [Google Scholar] [CrossRef]

- Kim, C.-S. Microstructural-Mechanical Properties Relationship in WC-Co Composites. Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, PA, USA, 2004. [Google Scholar]

- Frisk, K.; Markström, A. Effect of Cr and V on phase equilibria in Co–WC based hardmetals. Int. J. Mater. Res. 2008, 99, 287. [Google Scholar] [CrossRef]

- ISO 4499–2:2008; Hardmetals—Metallographic Determination of Microstructure—Part 2: Measurement of WC Grain Size. ISO: Geneva, Switzerland, 2008.

- Bozzini, B.; Gianoncelli, A.; Kourousias, G.; Boniardi, M.; Casaroli, A.; Zilio, S.D.; Hussain, R.; Abyaneh, M.K.; Kiskinova, M.; Mele, C.; et al. The role of chromium in the corrosion performance of cobalt- and cobalt-nickel based hardmetal binders: A study centred on X-ray absorption microspectroscopy. Int. J. Refract. Met. Hard Mater. 2020, 92, 105320. [Google Scholar] [CrossRef]

| Material | Metallic Binder | Additive Carbide | [MB] (wt%) | WC Grain Size | Density (×103 kg m−3) | Hardness (HV30) | MMS (%) | TRS (MPa) | PT (MN m−3/2) |

|---|---|---|---|---|---|---|---|---|---|

| A | Co | - | 8 | s | 14.72 ± 0.02 | 1679 ± 9 | 89 ± 1 | 3410 ± 90 | 9.5 ± 0.4 |

| A1 | Co | - | 6 | m | 14.91 ± 0.03 | 1442 ± 15 | 87 ± 1 | 3345 ± 76 | 11.8 ± 0.5 |

| B1 | Co | - | 9 | m | 14.58 ± 0.02 | 1291 ± 12 | 88 ± 1 | 3379 ± 112 | 18.2 ± 0.4 |

| B | Co | - | 10 | m | 14.46 ± 0.02 | 1398 ± 15 | 87 ± 1 | 3213 ± 64 | 18.0 ± 0.3 |

| C | Co | - | 15 | m | 14.02 ± 0.01 | 1256 ± 19 | 90 ± 1 | 3248 ± 99 | >20 |

| D | CoNiCr | - | 15 | m | 13.98 ± 0.02 | 1246 ± 7 | 86 ± 1 | 3137 ± 121 | >20 |

| E | NiCr | - | 8 | f | 14.69 ± 0.02 | 1400 ± 18 | - | 3118 ± 107 | 11.8 ± 0.3 |

| C1 | Co15Ru | - | 6 | m | 14.85 ± 0.02 | 1530 ± 13 | 77 ± 1 | 3276 ± 124 | 10.6 ± 0.4 |

| D1 | Co | 0.5HfC | 6 | m | 14.82 ± 0.02 | 1490 ± 14 | 90 ± 1 | 3176 ± 94 | 9.7 ± 0.5 |

| E1 | Alloyed Ni | - | 9 | m | 14.45 ± 0.03 | n.d. | - | n.d. | n.d. |

| Batch | [Binder Base] | [Cr]binder | [Cr]HM | Density | Coercivity Hc | Specific Magnetic Moment at Saturation σs | Abrasion Resistance (See Text) A |

|---|---|---|---|---|---|---|---|

| m% | m% | m% | ×103 kg m−3 | kA m−1 | 10−7 T m3 kg−1 | 10−11 m3 r−1 | |

| 584 | Co 10 | 0 | 0 | 14.51 ± 0.02 | 8.28 ± 0.80 | 11.3 ± 0.2 | 22.7 ± 4.8 |

| 585 | Co 10 | 3 | 0.3 | 14.46 ± 0.02 | 9.23 ± 0.72 | 10.4 ± 0.1 | 17.0 ± 4.3 |

| 586 | Co 10 | 5 | 0.5 | 14.44 ± 0.02 | 10.03 ± 0.79 | 9.6 ± 0.1 | 14.1 ± 4.7 |

| 587 | Co 15 | 0 | 0 | 14.02 ± 0.02 | 5.77 ± 0.59 | 11.5 ± 0.2 | 54.1 ± 5.6 |

| 588 | Co 15 | 3 | 0.45 | 13.96 ± 0.01 | 6.84 ± 0.63 | 11.4 ± 0.2 | 43.6 ± 3.7 |

| 589 | Co 15 | 5 | 0.75 | 13.91 ± 0.02 | 7.16 ± 0.65 | 10.4 ± 0.2 | 38.1 ± 4.6 |

| 590 | Co 20 | 0 | 0 | 13.54 ± 0.01 | 4.91 ± 0.53 | 12 ± 0.2 | 91.0 ± 6.1 |

| 591 | Co 20 | 3 | 0.6 | 13.48 ± 0.02 | 5.71 ± 0.55 | 10.8 ± 0.2 | 79.7 ± 1.8 |

| 592 | Co 20 | 5 | 1.0 | 13.41 ± 0.02 | 5.78 ± 0.60 | 10.5 ± 0.2 | 69.0 ± 7.3 |

| 605 | Co 20 | 8 | 1.6 | 13.32 ± 0.02 | 4.51 ± 0.51 | 10.3 ± 0.1 | - |

| 606 | Co 20 | 10 | 2.0 | 13.29 ± 0.02 | 4.98 ± 0.40 | 10.1 ± 0.1 | - |

| 593 | Co 25 | 0 | 0 | 13.10 ± 0.01 | 3.69 ± 0.37 | 12.4 ± 0.2 | 99.4 ± 2.9 |

| 594 | Co 25 | 3 | 0.75 | 13.01 ± 0.02 | 4.40 ± 0.41 | 11.2 ± 0.2 | 92.7 ± 3.8 |

| 595 | Co 25 | 5 | 1.25 | 12.95 ± 0.02 | 4.81 ± 0.48 | 11.4 ± 0.2 | 89.0 ± 4.1 |

| 596 | Ni 15 | 0 | 0 | 14.05 ± 0.03 | - | - | 82.7 ± 2.5 |

| 597 | Ni 15 | 3 | 0.45 | 13.95 ± 0.03 | - | - | 76.2 ± 2.9 |

| 598 | Ni 15 | 5 | 0.75 | 13.89 ± 0.03 | - | - | 78.1 ± 2.6 |

| 599 | Ni 15 | 8 | 1.2 | 13.79 ± 0.02 | - | - | 73.1 ± 2.7 |

| 600 | Ni 15 | 10 | 1.5 | 13.75 ± 0.02 | - | - | 68.7 ± 1.0 |

| 607 | Ni 15 | 12 | 1.8 | 13.87 ± 0.03 | - | - | - |

| 608 | Ni 15 | 15 | 2.25 | 13.82 ± 0.03 | - | - | - |

| Current growth | τ↑1 Fast component associated with the mechanical removal of the PPF. |

| τ↓1 Slow component associated with the mechanical damaging of the bare composite. | |

| Current decay | τ↑2 Fast component associated with the build-up of the surface coverage with the PPF. |

| τ↓2 Slow component associated with the growth of the resistive film. |

| Material | A | B | C | D | E |

|---|---|---|---|---|---|

| Weight loss | 1.2678 | 4.1363 | 9.6851 | 5.9901 | 3.8484 |

| Wear volume | 0.0862 | 0.2853 | 0.6918 | 0.4279 | 0.2618 |

| WC-xCo | WC-xCo-1Ru | WC-xCo-0.5Hf | WC-9Nialloyed | |

|---|---|---|---|---|

| x = 6 | −0.220 ± 0.006 V (samp. A1) | −0.100 ± 0.005 V (samp. C1) | −0.305 ± 0.001 V (samp. D1) | - |

| x = 9 | −0.275 V (samp. B1) | −0.110 ± 0.006 V | −0.331 ± 0.014 V | −0.081 ± 002 V (samp. E1) |

| x = 12 | −0.312 ± 0.007 V | - | - | - |

| A | B | C | D | E | |

|---|---|---|---|---|---|

| 1st | 0.170 ± 0.010 + parabola | 7.603 ± 1.024 + line | fast rise + line | 0.203 ± 0.001 + line | 0.2 + parabola |

| 2nd | 0.222 ± 0.003 0.934 ± 0.044 | 0.065 ± 002 1.139 ± 0.052 | 0.246 ± 0.007 8.165 ± 1.101 | 0.326 ± 0.003 1.922 ± 0.034 | 0.245 ± 0.001 2.574 ± 0.147 |

| 3rd | 0.183 ± 0.008 + parabola | 6.314 ± 3.173 | fast rise + line | 0.154 ± 0.002 | 0.173 ± 0.002 + line |

| 4th | 0.255 ± 0.083 + parabola | 0.028 ± 0.002 0.886 ± 0.027 56.77 ± 3.07 | 0.023 ± 0.001 1.198 ± 0.288 8.401 ± 1.103 | 0.164 ± 0.002 0.988 ± 0.667 50.58 ± 9.49 | 0.134 ± 0.003 43.52 ± 27.76 |

| 5th | 0.188 ± 0.001 2.628 ± 0.057 | 0.093 ± 0.002 6,448 ± 0.251 | 0.023 ± 0.008 0.356 ± 0.020 8.230 ± 1.558 | 0.282 ± 0.001 4.809 38.55 | 0.198 ± 0.001 3.115 ± 0.174 |

| 6th | 0.221 ± 0.002 8.756 ± 0.220 | 0.199 ± 0.029 4.014 ± 0.177 | 0.023 ± 0.002 0.734 ± 0.163 14.33 | 0.177 ± 0.000 4.726 ± 0.046 | 0.187 ± 0.001 17.17 ± 0.10 |

| 7th | 0.982 ± 0.020 40.25 ± 0.380 | 1.093 ± 0.250 173.9 ± 19.40 | 0.224 ± 0.094 20.54 ± 1.64 | 3.287 ± 0.272 22.81 ± 0.960 | 0.374 ± 0.023 128.7 ± 10.10 |

| 8th | 0.197 ± 0.001 | 0.034 ± 0.001 1.696 ± 0.027 | 0.031 ± 0.003 0.509 ± 0.112 5.425 ± 0402 | 0.218 ± 0.008 0.515 ± 0.043 6.112 ± 0.406 | 0.209 ± 0.001 3.152 ± 0.416 |

| Grade | RPP (%) | τ↑1 (s) | τ↑2 (s) | τ↓1 (s) | τ↓2 (s) |

|---|---|---|---|---|---|

| A: WC-6Co | 3.75 ± 0.34 | 1.70 ± 0.21 | 238.0 ± 11.0 | 13.13 ± 0.93 | 278.0 ± 12.0 |

| B: WC-9Co | 5.41 ± 0.67 | 2.03 ± 0.13 | 69.0 ± 7.6 | 5.096 ± 0.771 | 227.0 ± 8.0 |

| C: WC-6CoRu | 0.365 ± 0.023 | 0.97 ± 0.10 | 257.0 ± 14.0 | 0.690 ± 0.103 | 28.8 ± 1.7 |

| WC-9CoRu | 0.453 ± 0.065 | 1.12 ± 0.25 | 262.0 ± 21 | 0.739 ± 0.094 | 109 ± 8.0 |

| D: WC-6CoHf | 0.946 ± 0.134 | 0.97 ± 0.07 | 257.0 ± 12 | 24.44 ± 1.55 | 200.0 ± 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Gaudenzi, G.P.; Tavola, F.; Tedeschi, S.; Bozzini, B. Corrosion Behaviour of Cemented Carbides with Co- and Ni-Alloy Binders in the Presence of Abrasion. Metals 2022, 12, 1914. https://doi.org/10.3390/met12111914

De Gaudenzi GP, Tavola F, Tedeschi S, Bozzini B. Corrosion Behaviour of Cemented Carbides with Co- and Ni-Alloy Binders in the Presence of Abrasion. Metals. 2022; 12(11):1914. https://doi.org/10.3390/met12111914

Chicago/Turabian StyleDe Gaudenzi, Gian Pietro, Francesco Tavola, Sandra Tedeschi, and Benedetto Bozzini. 2022. "Corrosion Behaviour of Cemented Carbides with Co- and Ni-Alloy Binders in the Presence of Abrasion" Metals 12, no. 11: 1914. https://doi.org/10.3390/met12111914

APA StyleDe Gaudenzi, G. P., Tavola, F., Tedeschi, S., & Bozzini, B. (2022). Corrosion Behaviour of Cemented Carbides with Co- and Ni-Alloy Binders in the Presence of Abrasion. Metals, 12(11), 1914. https://doi.org/10.3390/met12111914