Research Progress in the Preparation of Aluminum Foam Composite Structures

Abstract

:1. Introduction

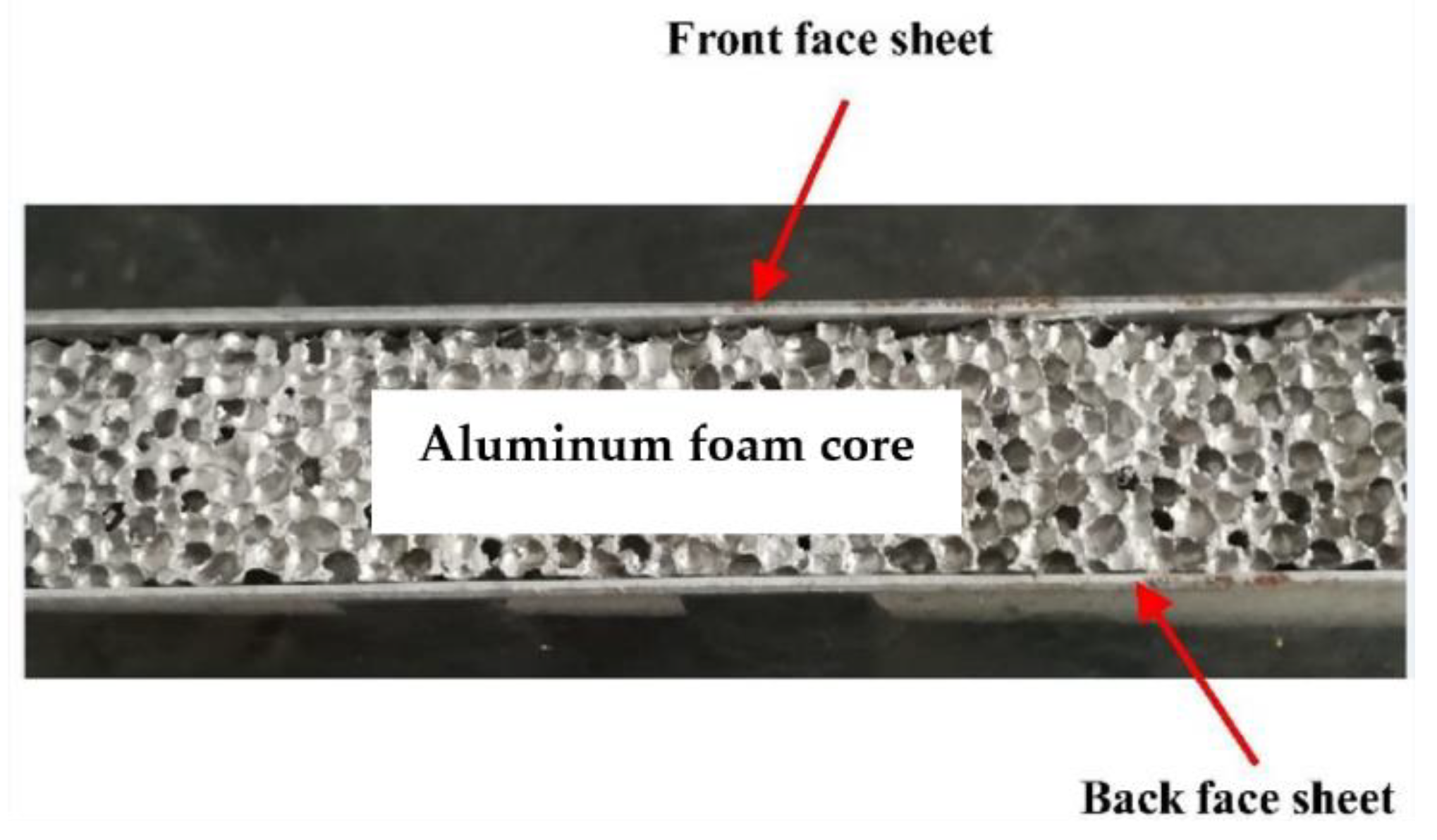

2. Aluminum Foam Sandwich

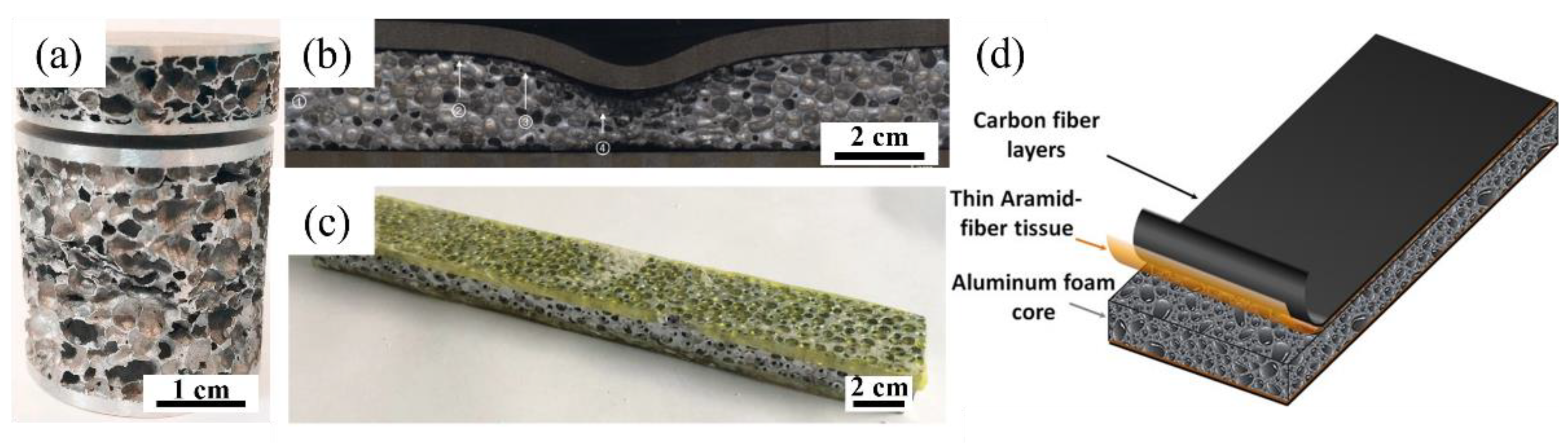

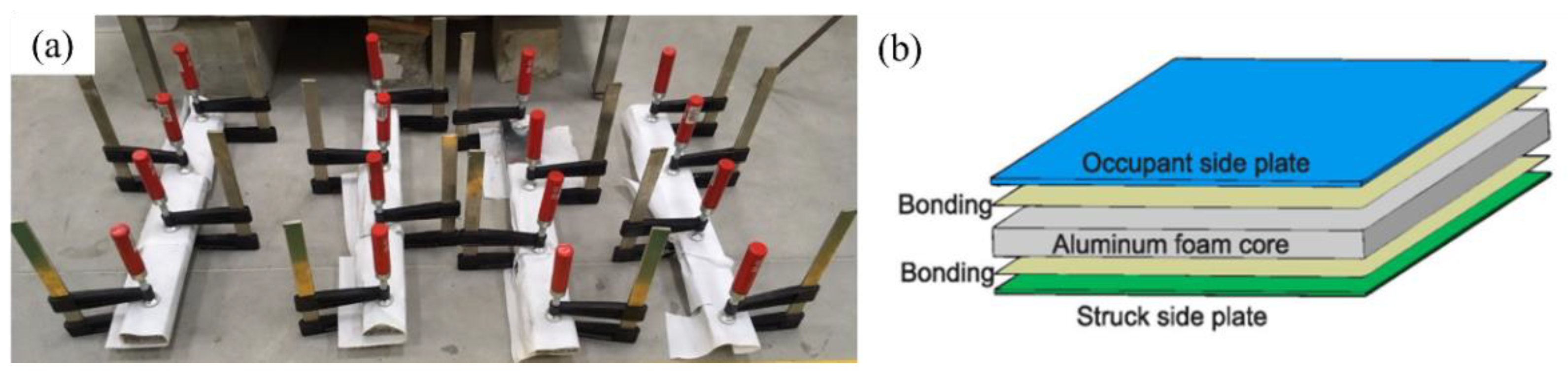

2.1. Adhesive Bonding Method

2.2. Welding Method

2.2.1. Brazing

2.2.2. Diffusion Welding

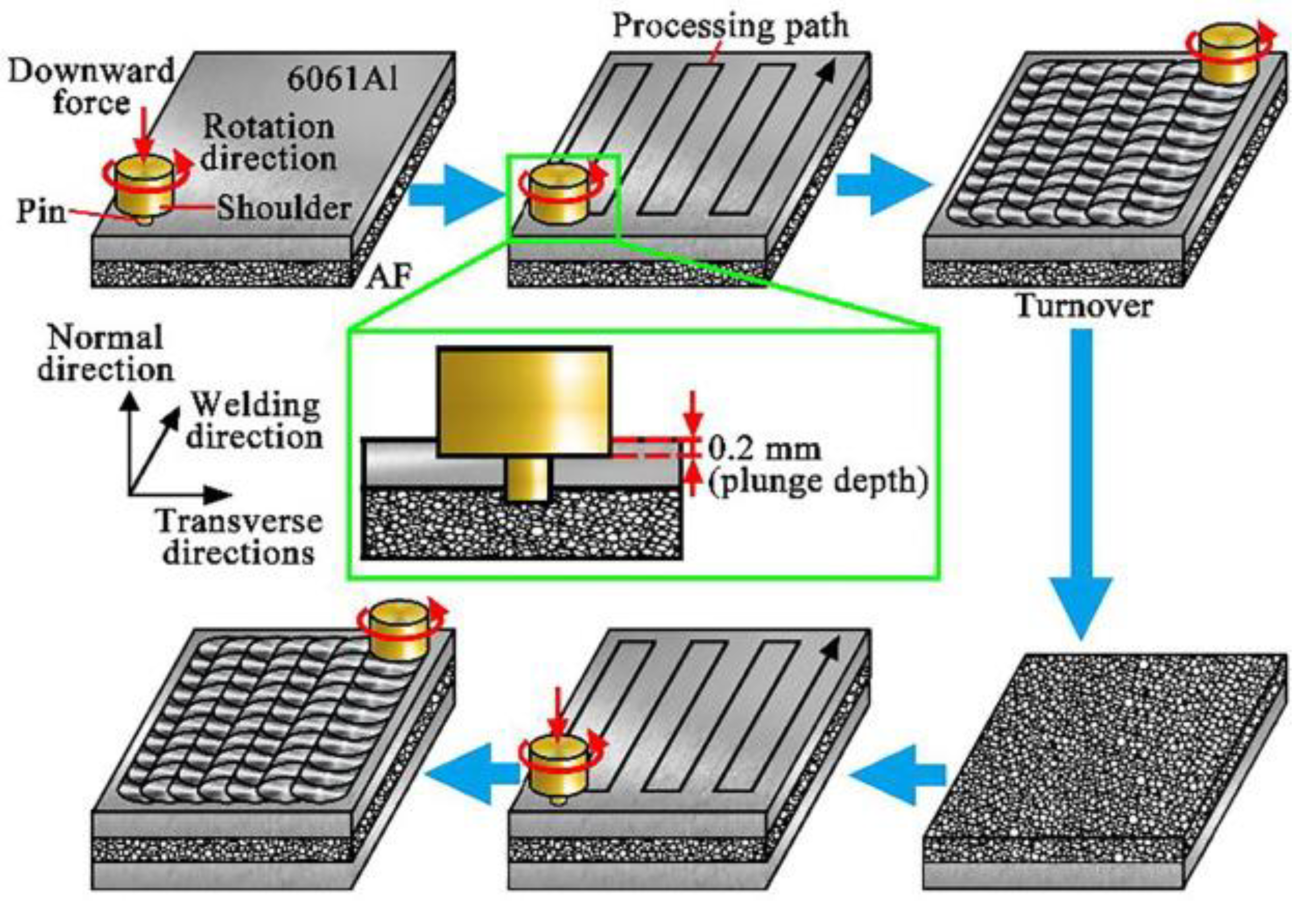

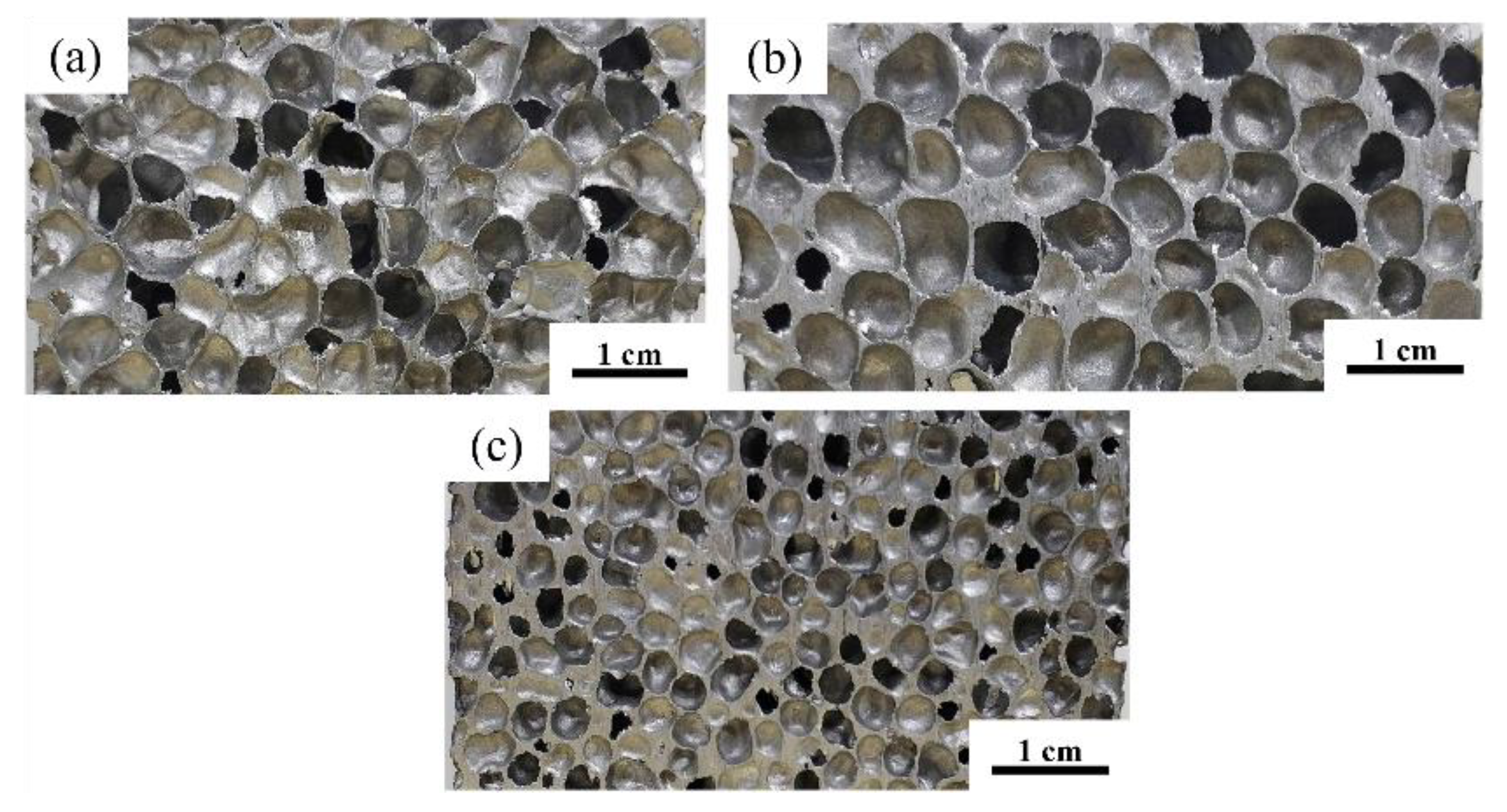

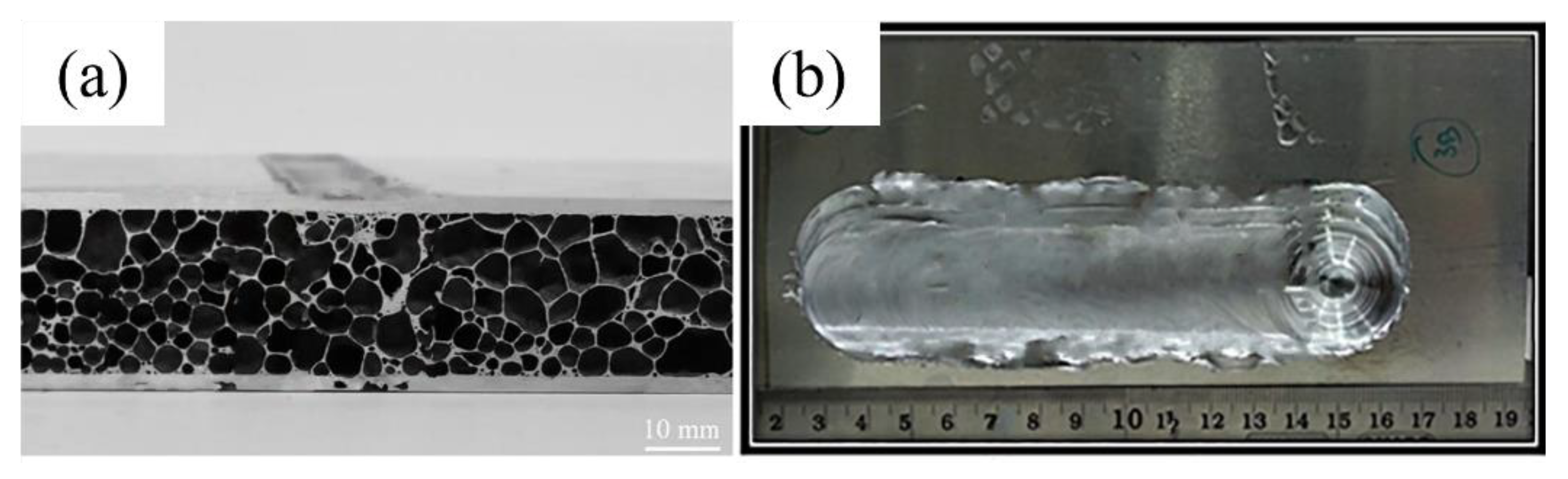

2.2.3. Friction Stir Welding

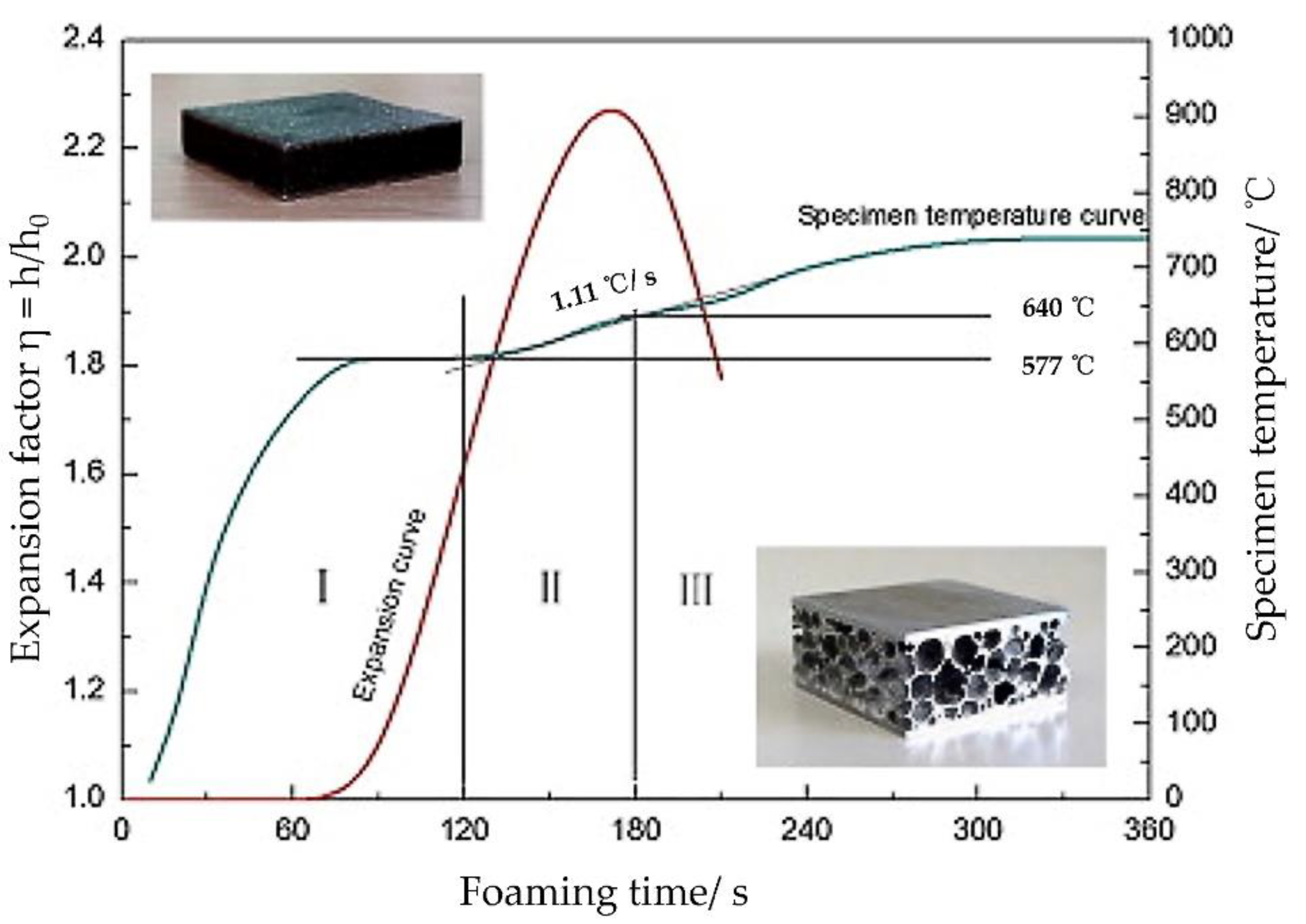

2.3. Powder Metallurgy Method

2.3.1. Cold- and Hot-Pressing Powder Metallurgy Method

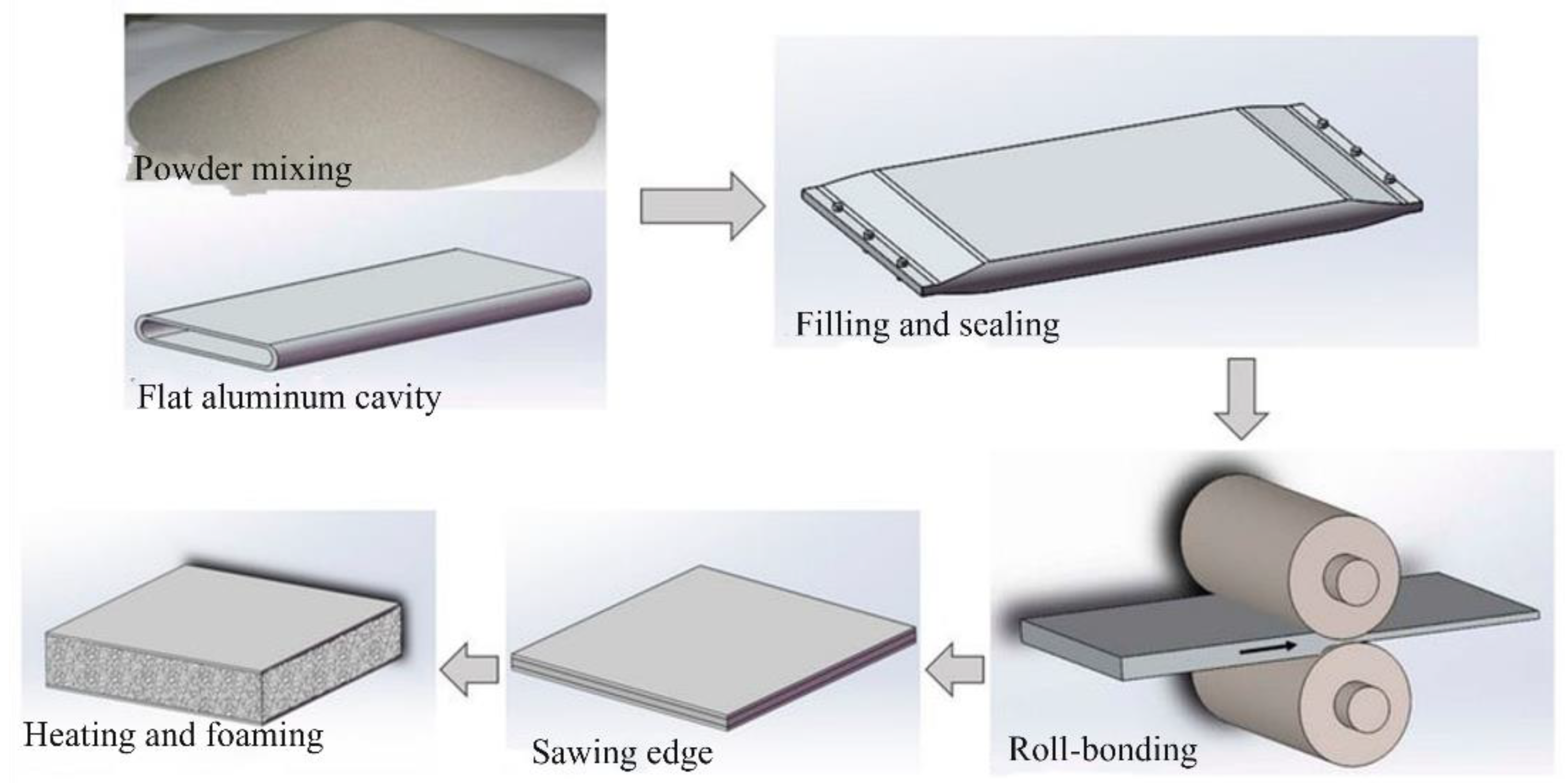

2.3.2. Rolling Powder Metallurgy Method

2.3.3. Jacketing Rolling Powder Metallurgy Method

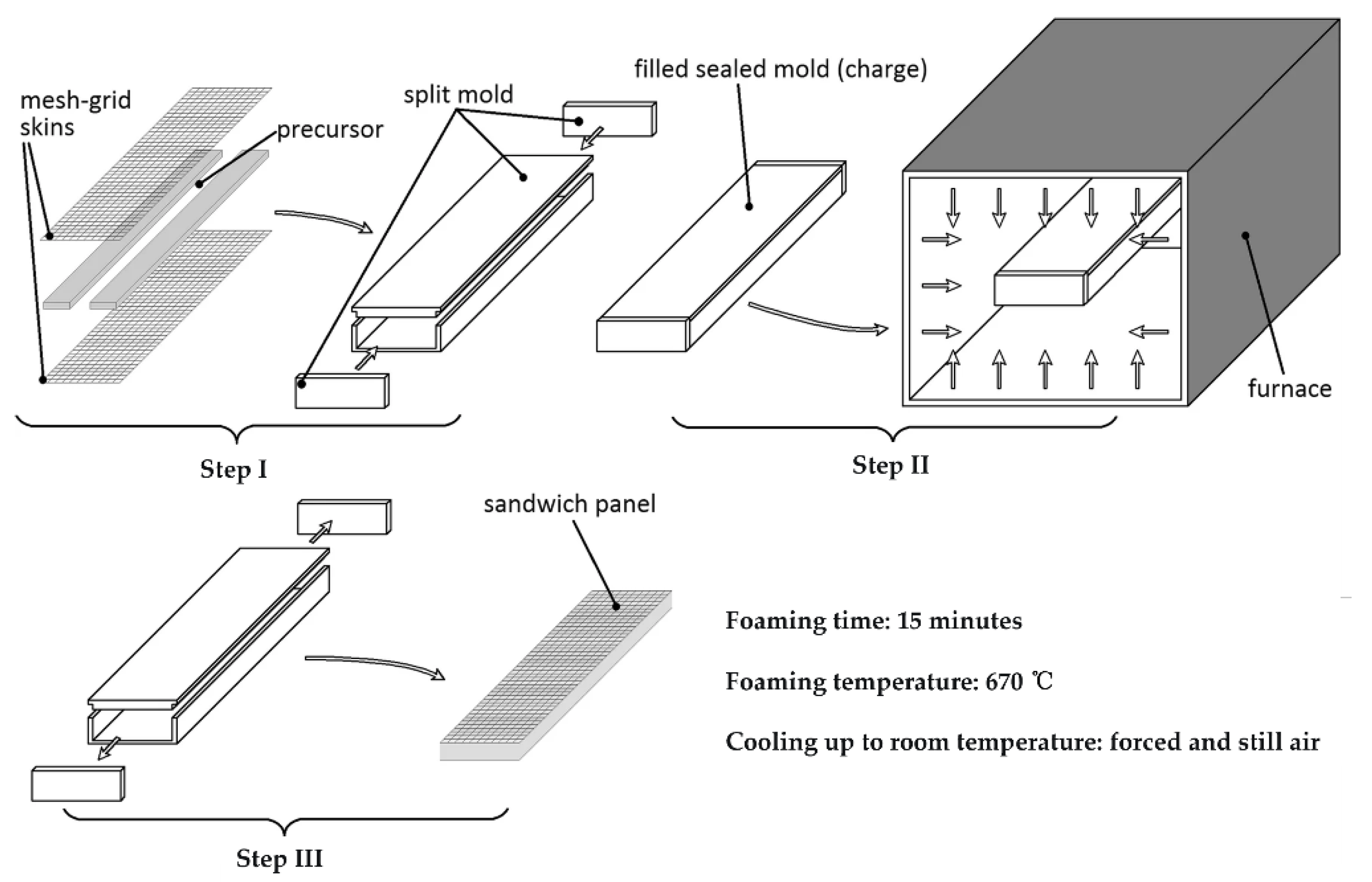

2.3.4. Other Methods

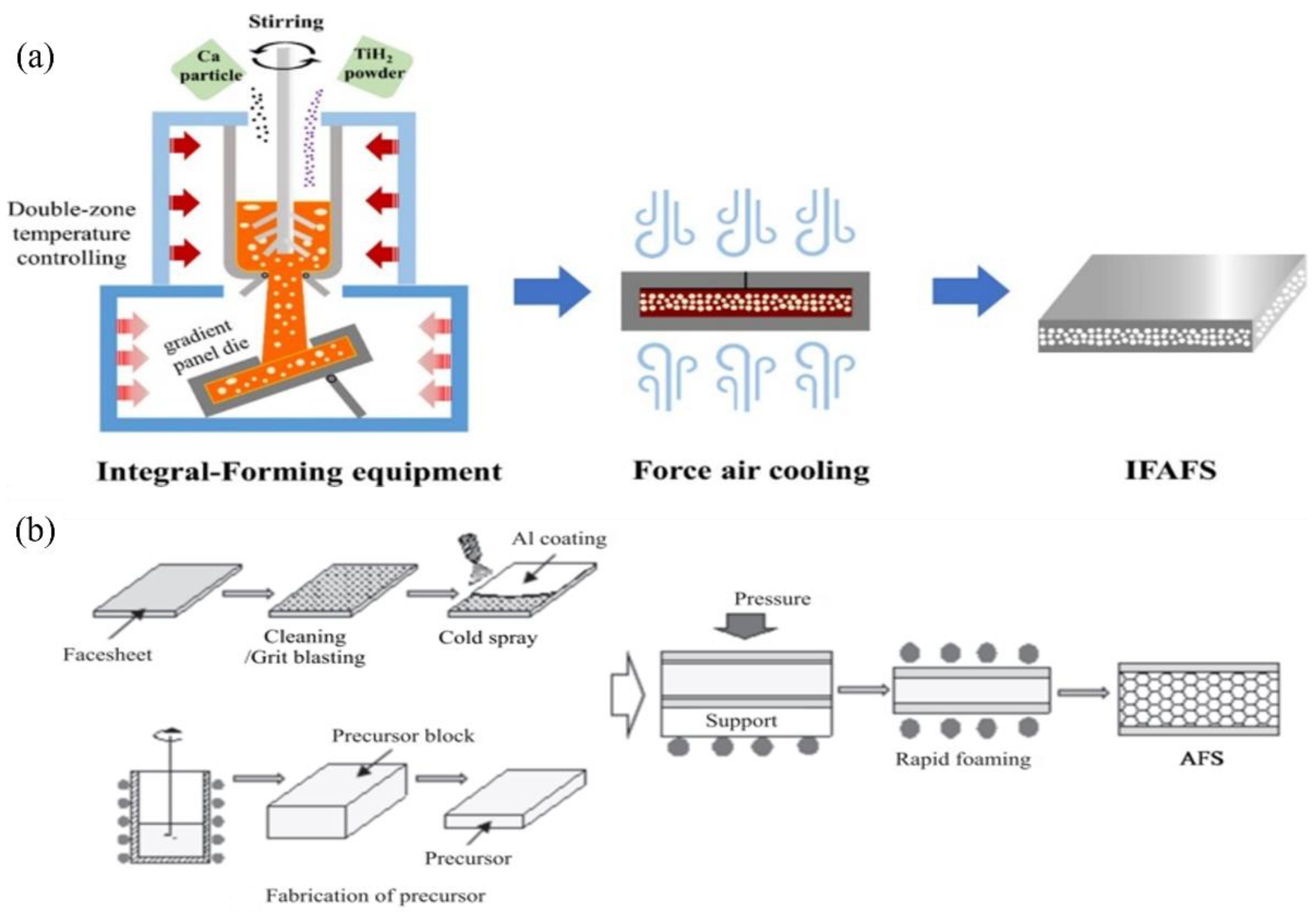

2.4. Melt Foaming Method

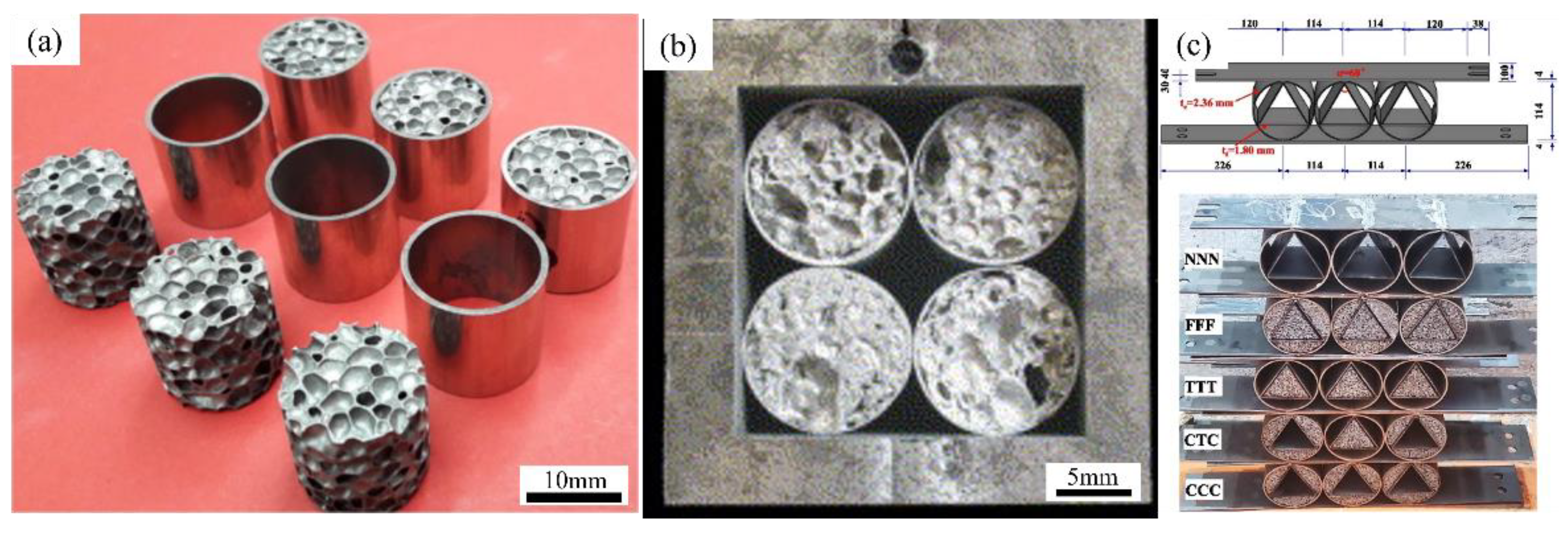

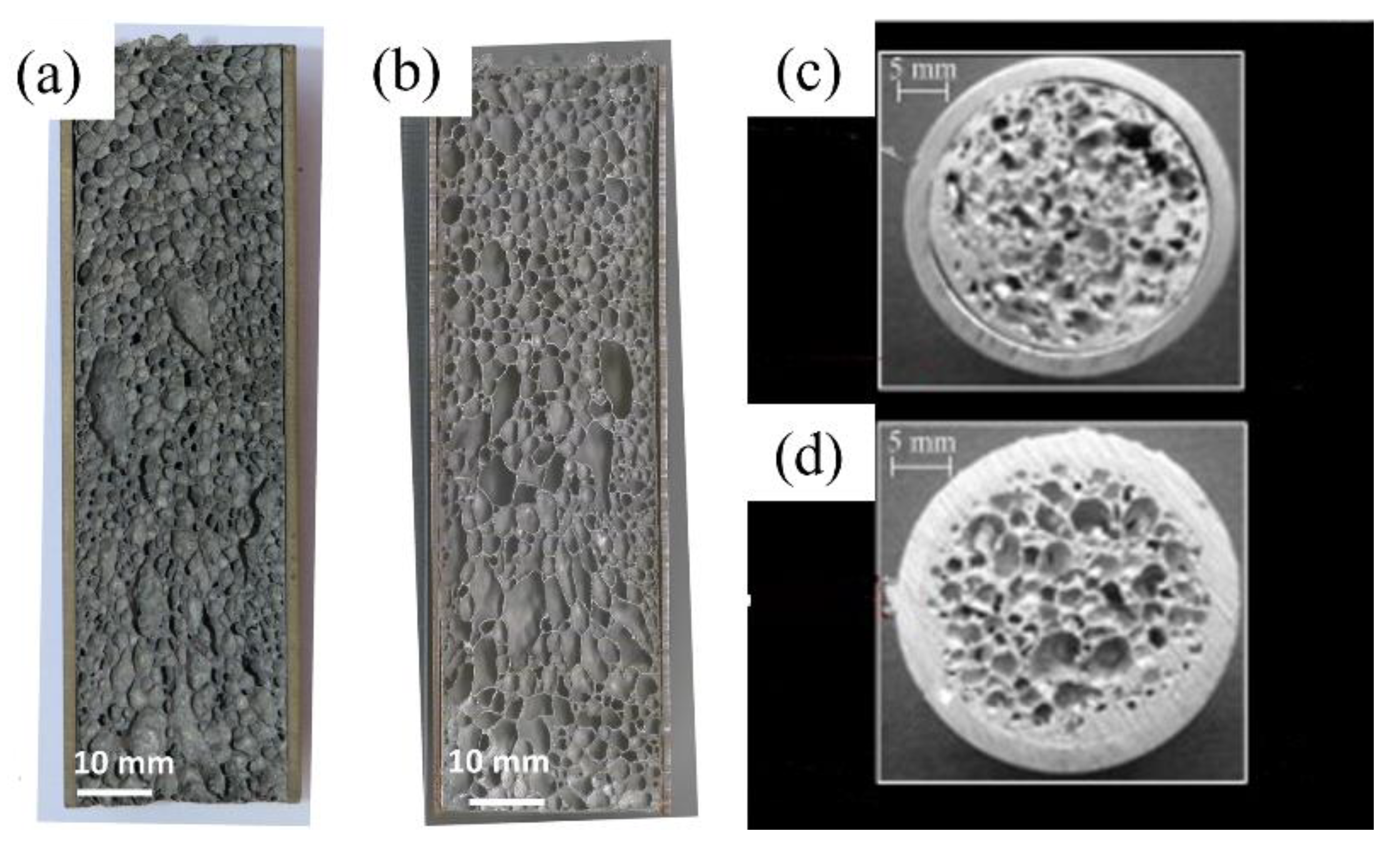

3. Aluminum-Foam-Filled Tube

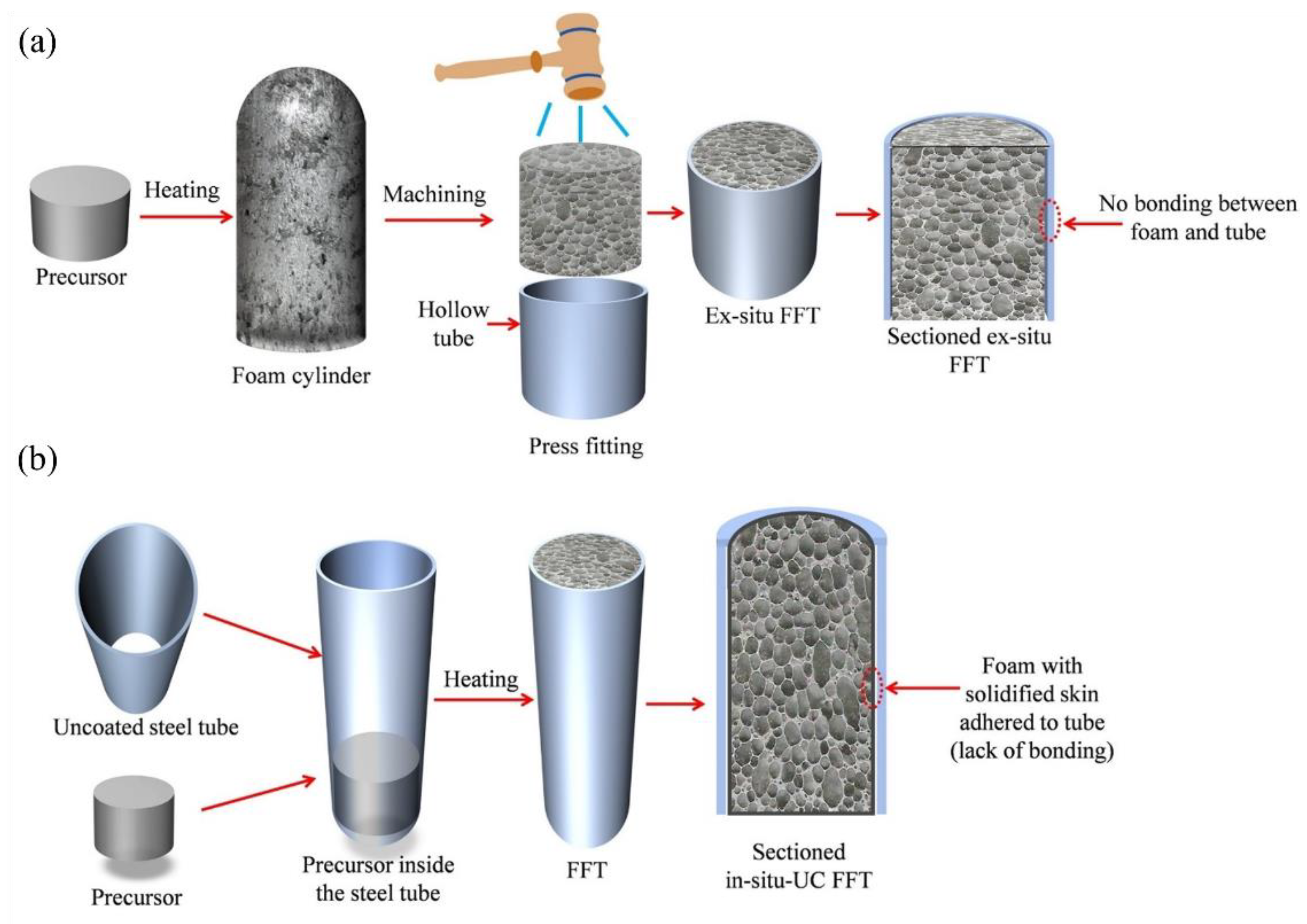

3.1. Ex Situ Filling Method

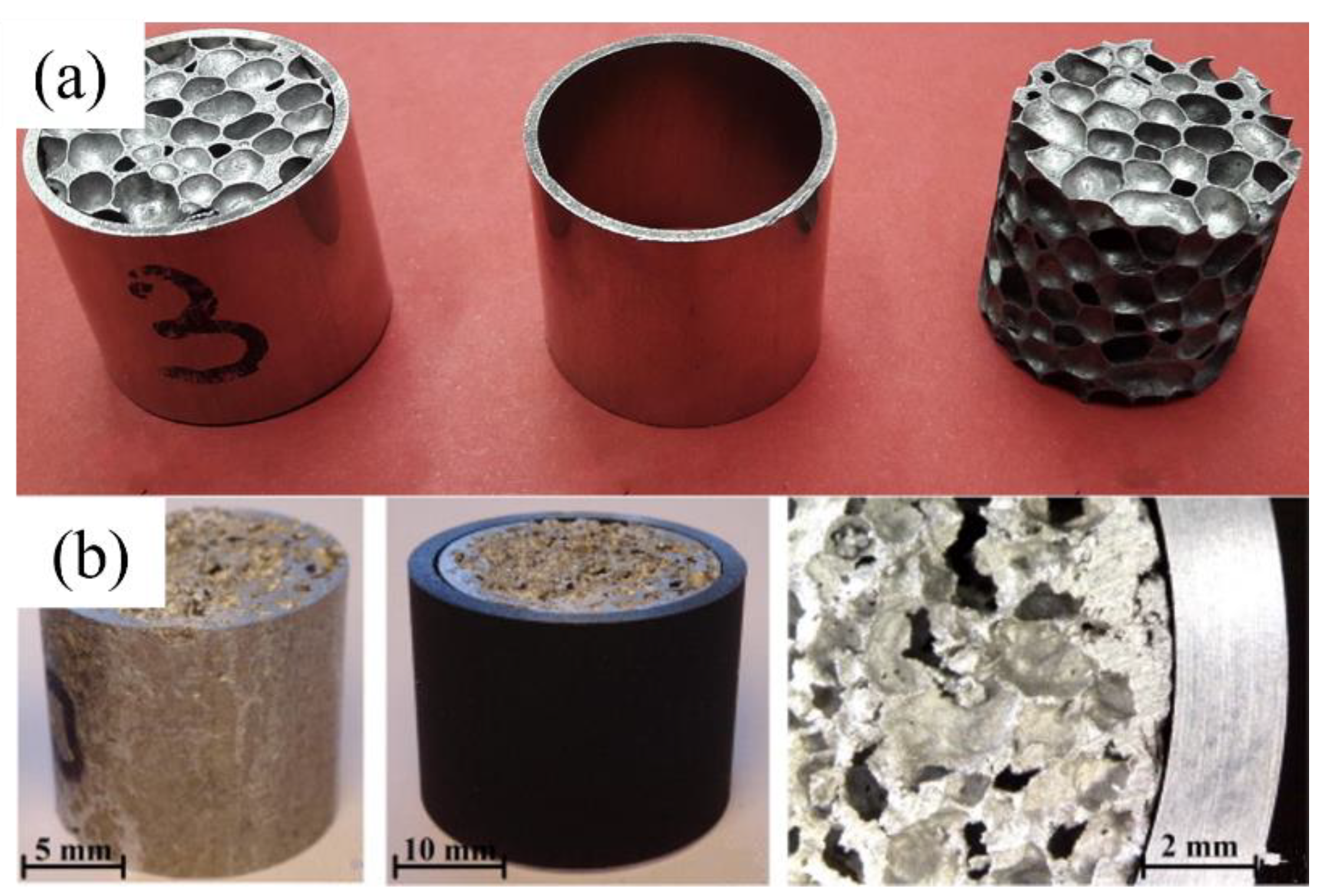

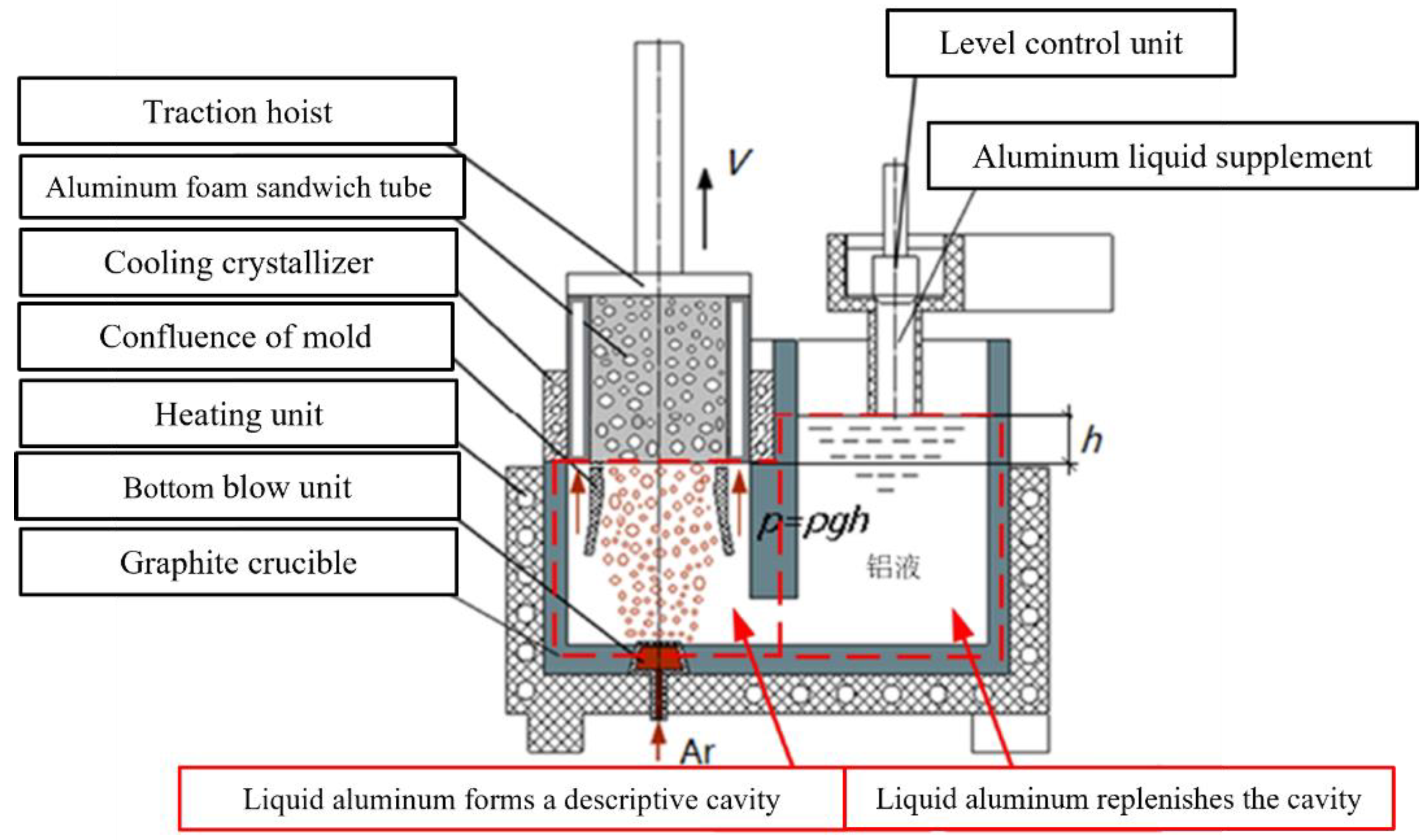

3.2. In Situ Preparation Method

3.3. Other Methods

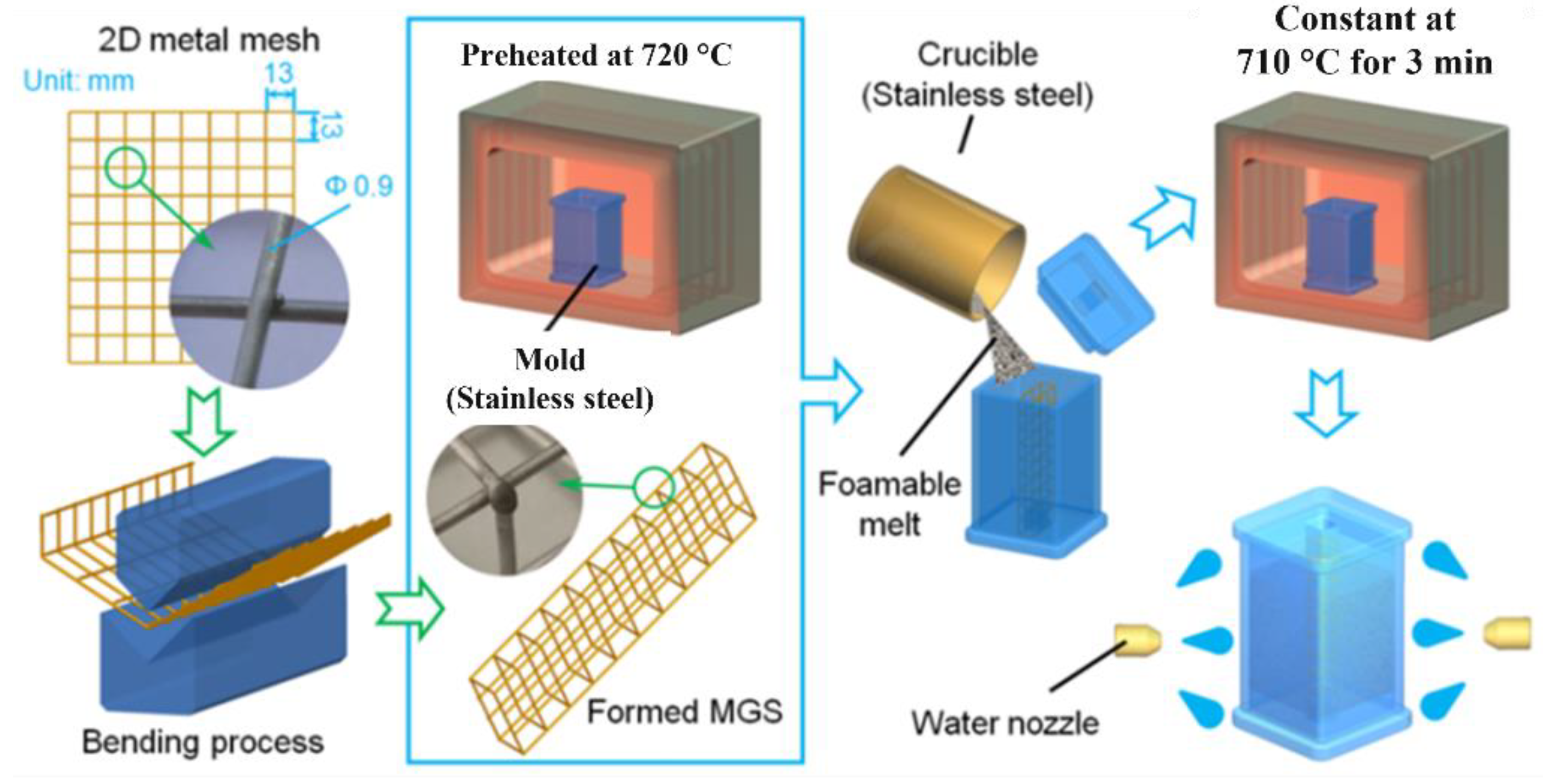

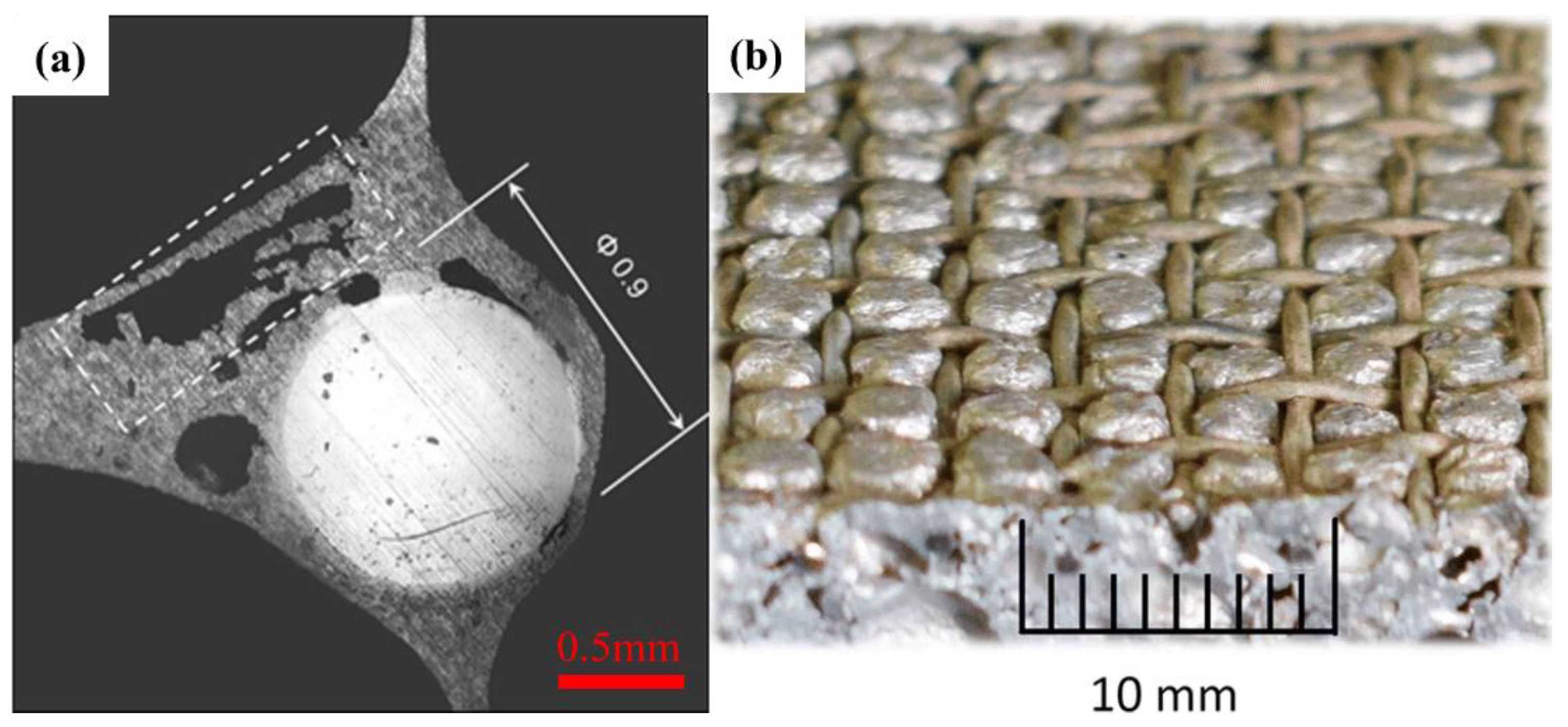

4. Metal Grid Structure Enhanced Aluminum Foam

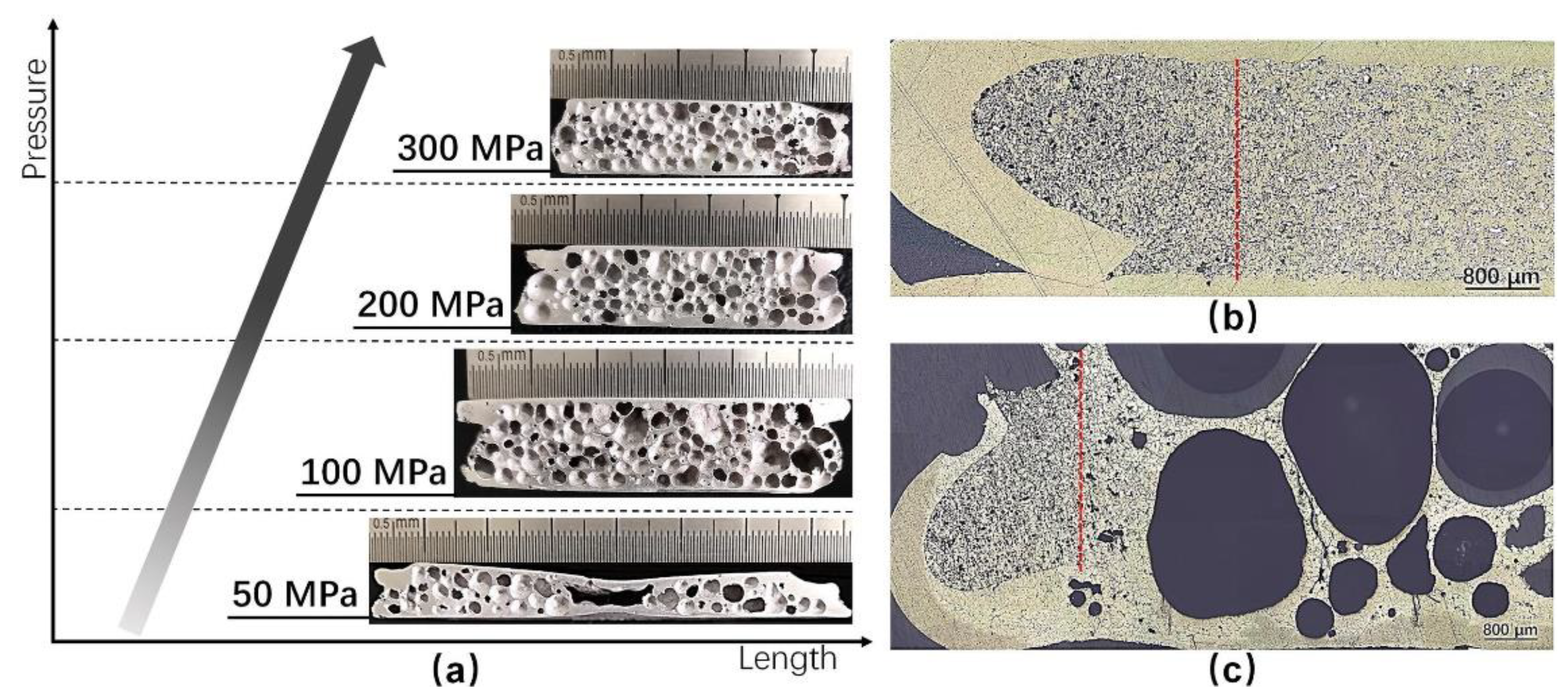

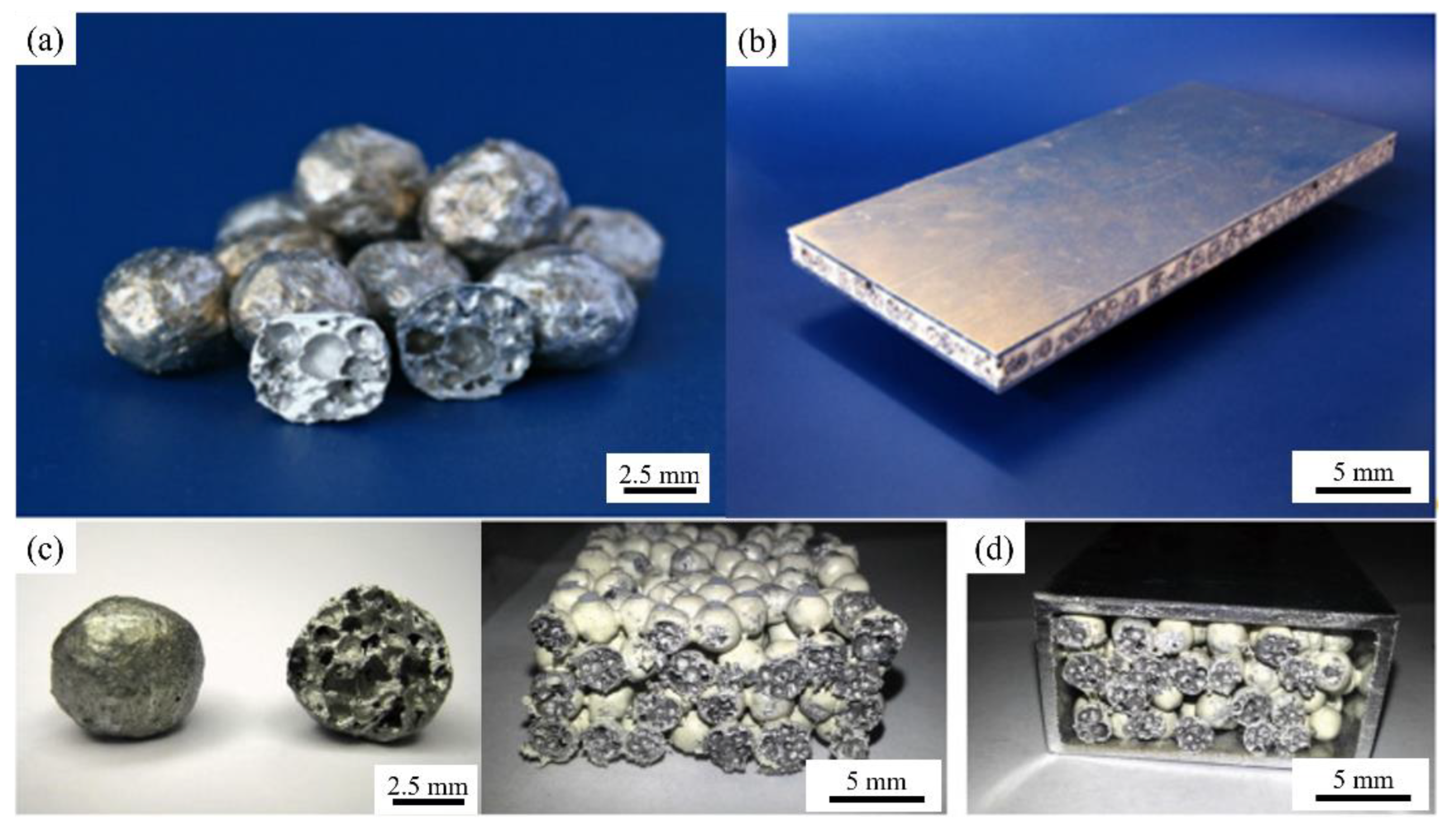

5. Advanced Pore Morphology Foam-Filled Composite Structure

6. Summary and Prospects

- (1)

- Most scholars have conducted additional research on the foaming mechanism and the improvement of the pore structure of traditional aluminum foam. For example, Banhart’s team conducted an in-depth study on the foaming mechanism of aluminum foam based on X-ray and tomography [117]. An’s team revealed the stabilizing agent of non-thickening foaming technology to produce aluminum foam with a uniform internal structure [118]. In AFCSs, the addition of solid plates and pipes greatly influences the pore structure during aluminum foaming. For example, the powder loss caused by the pressing and rolling processes, the influence of coated rolling on powder uniformity, and the obstruction of the metal tube wall to core layer foaming during the in situ preparation of FFTs have an impact on the pore morphology and pore size of aluminum foam. Further research is needed.

- (2)

- Although the adhesive bonding method is simple, the bonding strength between the panels and the foam core is not strong enough. Adhesive aging limits the use of AFCSs in harsh conditions such as high temperatures. The surface modification of the panels and the foam core should be researched.

- (3)

- It is difficult to control the porosity of AFCSs fabricated using the powder metallurgy method, and the size of the samples is limited by the mold and equipment used. However, the powder metallurgy method has great advantages for preparing special-shaped AFCS parts.

- (4)

- The advantages of the melt foaming method have not been fully displayed, especially in fabricating large-sized and uniform pore structure AFCSs. The flowing, expanding, and filling properties of the foamable melt during the foaming process should be studied in depth.

- (5)

- The industrial production method of AFCSs with the shape of a sandwich plate, block material, and filling tube should be focused on, and the application fields need to be expanded.

- (6)

- The key to the AFCS preparation process is to realize the effective combination between the core material and the pipe, plate, metal mesh, or other structures and ensure the structural integrity of the aluminum foam core as far as possible during the combination process. Different methods of preparing AFCSs often have distinct advantages and disadvantages.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liang, X.; Luo, H.; Lin, H.; Lu, X.; Wu, L. A Novel Method to Fabricate Steel-Al Foam Sandwich Panel with Metallic Bonding. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2019, 34, 1429–1432. [Google Scholar] [CrossRef]

- Shunmugasamy, V.C.; Mansoor, B. Flexural Response of an Aluminum Foam Core/Stainless Steel Facesheet Sandwich Composite. JOM J. Miner. Met. Mater. Soc. 2019, 71, 4024–4033. [Google Scholar] [CrossRef]

- Wang, T.; Shao, J.; Xu, T.; Wang, Z. Study on Axial Compression Properties of Aluminum Foam-filled Steel Tube Members After High Temperature. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 883–900. [Google Scholar] [CrossRef]

- Banhart, J.; Seeliger, H.W. Aluminium Foam Sandwich Panels: Manufacture, Metallurgy and Applications. Adv. Eng. Mater. 2008, 10, 793–802. [Google Scholar] [CrossRef]

- Baumgartner, F.; Duarte, I.; Banhart, J. Industrialization of powder compact foaming process. Adv. Eng. Mater. 2000, 2, 168–174. [Google Scholar] [CrossRef]

- Duarte, I.; Banhart, J. A study of aluminium foam formation—Kinetics and microstructure. Acta Mater. 2000, 48, 2349–2362. [Google Scholar] [CrossRef]

- Duarte, I.; Vesenjak, M.; Vide, M.J. Automated Continuous Production Line of Parts Made of Metallic Foams. Metals 2019, 9, 531. [Google Scholar] [CrossRef] [Green Version]

- Banhart, J.; Seeliger, H.W. Recent Trends in Aluminum Foam Sandwich Technology. Adv. Eng. Mater. 2012, 14, 1082–1087. [Google Scholar] [CrossRef]

- Formisano, A.; Durante, M.; Viscusi, A.; Carrino, L. Mechanical behavior and collapse mechanisms of innovative aluminum foam-based sandwich panels under three-point bending. Int. J. Adv. Manuf. Technol. 2021, 112, 1631–1639. [Google Scholar] [CrossRef]

- Han, M.S.; Bang, S.O.; Cho, J.U.; Lee, S.; Cho, C. Experimental study on the impact characteristics of a sandwich composite with an aluminum foam core. Int. J. Automot. Technol. 2013, 14, 61–66. [Google Scholar] [CrossRef]

- Yan, C.; Wang, J.; Song, X. Fatigue behavior and damage mechanism of aluminum foam sandwich with carbon-fiber face-sheets. J. Mech. Sci. Technol. 2020, 34, 1119–1127. [Google Scholar] [CrossRef]

- An, Y.K.; Yang, S.Y.; Zhao, E.T.; Huang, X. Diffusion Bonding in Fabrication TA2 Sheets Enhanced Aluminum Foam Sandwich. In Materials Science Forum; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2017; Volume 898, pp. 950–956. [Google Scholar]

- Neu, T.R.; Kamm, P.H.; von der Eltz, N.; Seeliger, H.W.; Banhart, J.; García-Moreno, F. Correlation between foam structure and mechanical performance of aluminium foam sandwich panels. Mater. Sci. Eng. A 2021, 800, 140260. [Google Scholar] [CrossRef]

- Liu, H.; Cao, Z.K.; Yao, G.C.; Luo, H.J.; Zu, G.Y. Performance of aluminum foam–steel panel sandwich composites subjected to blast loading. Mater. Des. 2013, 47, 483–488. [Google Scholar] [CrossRef]

- Cheng, S.; Xiao, B.; Zhao, X.; Xin, Y.; Li, H. Drop-weight impact test on an integrated composite sandwich panel of aluminum honeycomb and epoxy resin. J. Mater. Res. 2017, 32, 2258–2265. [Google Scholar] [CrossRef]

- Sun, Z.; Shi, S.; Hu, X.; Chen, H.; Wong, Z. Adhesive joints between carbon fiber and aluminum foam reinforced by surface-treated aramid fibers. Polym. Compos. 2014, 36, 192–197. [Google Scholar] [CrossRef]

- Yao, C.; Hu, Z.; Mo, F.; Wang, Y. Fabrication and Fatigue Behavior of Aluminum Foam Sandwich Panel via Liquid Diffusion Welding Method. Metals 2019, 9, 582. [Google Scholar] [CrossRef] [Green Version]

- Chung, H.J.; Rhee, K.Y.; Han, B.S.; Ryu, Y.M. Plasma treatment using nitrogen gas to improve bonding strength of adhesively bonded aluminum foam/aluminum composite. J. Alloys Compd. 2007, 459, 196–202. [Google Scholar] [CrossRef]

- Baştürk, S.B.; Tanoğlu, M. Development and Mechanical Behavior of FML/Aluminium Foam Sandwiches. Appl. Compos. Mater. 2013, 20, 789–802. [Google Scholar] [CrossRef]

- Baştürk, S.B.; Tanoğlu, M. Mechanical and energy absorption behaviors of metal/polymer layered sandwich structures. J. Reinf. Plast. Compos. 2011, 30, 1539–1547. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Zheng, Z.; Yu, J.; Qian, C.; Lu, F. Deformation and failure mechanisms of sandwich beams under three-point bending at elevated temperatures. Compos. Struct. 2014, 111, 285–290. [Google Scholar] [CrossRef]

- Sun, Z.; Jeyaraman, J.; Sun, S.; Hu, X.; Chen, H. Carbon-fiber aluminum-foam sandwich with short aramid-fiber interfacial toughening. Compos. Part A Appl. Sci. Manuf. 2012, 43, 2059–2064. [Google Scholar] [CrossRef]

- Latour, M.; D’Aniello, M.; Landolfo, R.; Rizzano, G. Experimental and numerical study of double-skin aluminium foam sandwich panels in bending. Thin-Walled Struct. 2021, 164, 107894. [Google Scholar] [CrossRef]

- Pratomo, A.N.; Santosa, S.P.; Gunawan, L.; Widagdo, D.; Putra, I.S. Design optimization and structural integrity simulation of aluminum foam sandwich construction for armored vehicle protection. Compos. Struct. 2021, 276, 114461. [Google Scholar] [CrossRef]

- Ren, C.; Hu, Z.; Yao, C.; Mo, F. Experimental study on the quasi-static compression behavior of multilayer aluminum foam sandwich structure. J. Alloys Compd. 2019, 810, 151860. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, Z.; Yu, T.; Xin, D. Mechanical properties and energy absorption capabilities of aluminium foam sandwich structure subjected to low-velocity impact. Constr. Build. Mater. 2021, 273, 121996. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Tang, Z.; Yang, H.; Xu, H. Dynamic response of aluminum-foam-based sandwich panels under hailstone impact. Explos. Shock. Waves 2018, 38, 373–380. [Google Scholar]

- Hackert, A.; Drebenstedt, C.; Timmel, T.; Osiecki, T.; Kroll, L. Composite Sandwich with Aluminum Foam Core and Adhesive Bonded Carbon Fiber Reinforced Thermoplastic Cover Layer. Key Eng. Mater. 2017, 744, 277–281. [Google Scholar] [CrossRef]

- Chen, N.; Feng, Y.; Chen, J.; Li, B.; Chen, F. Properties of aluminum foam joints during contact reactive brazing processes. Trans. China Weld. Inst. 2013, 34, 77–80. [Google Scholar]

- Wan, L.; Huang, Y.; Huang, T.; Lv, S.; Feng, J. Novel method of fluxless soldering with self-abrasion for fabricating aluminum foam sandwich. J. Alloys Compd. 2015, 640, 1–7. [Google Scholar] [CrossRef]

- Hangai, Y.; Ishii, N.; Koyama, S.; Utsunomiya, T.; Yoshikawa, N. Fabrication and Tensile Tests of Aluminum Foam Sandwich with Dense Steel Face Sheets by Friction Stir Processing Route. Mater. Trans. 2012, 53, 584–587. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Fan, M.; Li, J.; Tao, J. Interfacial Microstructure Evolution and Shear Strength of Titanium Sandwich Structures Fabricated by Brazing. J. Mater. Eng. Perform. 2016, 25, 774–780. [Google Scholar] [CrossRef]

- Li, Y.; Chen, C.; Yi, R. Recent development of ultrasonic brazing. Int. J. Adv. Manuf. Technol. 2021, 114, 27–62. [Google Scholar] [CrossRef]

- Ubertalli, G.; Ferraris, M.; Bangash, M.K. Joining of AL-6016 to Al-foam using Zn-based joining materials. Compos. Part A Appl. Sci. Manuf. 2017, 96, 122–128. [Google Scholar] [CrossRef]

- Song, Y.F.; Xiao, L.R.; Zhao, X.J.; Zhou, H.; Zhang, W.; Guo, L.; Wang, Y. Fabrication, Microstructure and Shear Properties of Al Foam Sandwich. Mater. Manuf. Process. 2016, 31, 1046–1051. [Google Scholar] [CrossRef]

- Song, Y.F.; Xiao, L.R.; Zeng, D.L.; Guo, L. Preparation and Structure Property Analysis of Aluminum Foam Sandwich Structure Material. Min. Metall. Eng. 2014, 34, 119–123. [Google Scholar]

- Huang, Y.; Gong, J.; Lv, S.; Leng, J.; Li, Y. Fluxless soldering with surface abrasion for joining metal foams–ScienceDirect. Mater. Sci. Eng. A 2012, 552, 283–287. [Google Scholar] [CrossRef]

- Wan, L.; Huang, Y.; Lv, S.; Feng, J. Fabrication and interfacial characterization of aluminum foam sandwich via fluxless soldering with surface abrasion. Compos. Struct. 2015, 123, 366–373. [Google Scholar] [CrossRef]

- Liu, K.; Chen, C.; Guo, W.; Liu, B.; Yang, B.; Li, Z.; Li, J.; Li, X.; Yin, F. Energy absorption and deformation behavior of multilayer aluminum foam structures. Mater. Sci. Eng. A 2022, 832, 142470. [Google Scholar] [CrossRef]

- Tensi, H.M.; Wittmann, M. Influence of Surface Preparation on the Diffusion Welding of High Strength Aluminium Alloys. In Diffusion Bonding 2; Stephenson, D.J., Ed.; Springer: Dordrecht, The Netherlands, 1991; pp. 101–110. [Google Scholar]

- Kitazono, K.; Kitajima, A.; Sato, E.; Matsushita, J.; Kuribayashi, K. Solid-state diffusion bonding of closed-cell aluminum foams. Mater. Sci. Eng. A 2002, 327, 128–132. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, Z.; Yao, C.; Zhang, Z.; Xu, T. Fabrication and fatigue behavior of aluminum foam sandwich via liquid diffusion welding. Acta Mater. Compos. Sin. 2018, 35, 1652–1660. [Google Scholar]

- Wang, H.; Yang, D.H.; He, S.Y.; He, D. Fabrication of Open-cell Al Foam Core Sandwich by Vibration Aided Liquid Phase Bonding Method and Its Mechanical Properties. J. Mater. Sci. Technol. 2010, 26, 423–428. [Google Scholar] [CrossRef]

- Born, C.; Wagner, G.; Eifler, D. Ultrasonically Welded Aluminium Foams/Sheet Metal–Joints. Adv. Eng. Mater. 2006, 8, 816–820. [Google Scholar] [CrossRef]

- Yue, Y.; Li, Z.; Ji, S.; Huang, Y.; Zhou, Z. Effect of Reverse-threaded Pin on Mechanical Properties of Friction Stir Lap Welded Alclad 2024 Aluminum Alloy. J. Mater. Sci. Technol. 2016, 32, 671–675. [Google Scholar] [CrossRef]

- Wei, Y.; Li, J.; Xiong, J.; Zhang, F. Effect of Tool Pin Insertion Depth on Friction Stir Lap Welding of Aluminum to Stainless Steel. J. Mater. Eng. Perform. 2013, 22, 3005–3013. [Google Scholar] [CrossRef]

- Zhang, D.; Zheng, X.; Wu, Z.; Hu, Z. Research on Foaming of Aluminum Foam by Friction Stir Welding. Hot Work. Technol. 2022, 51, 69–73. [Google Scholar]

- Su, X.; Huang, P.; Feng, Z.; Gao, Q.; Wei, Z.; Sun, X.; Zu, G.; Mu, Y. Study on aluminum foam sandwich welding by friction stir welding technology. Mater. Lett. 2021, 304, 130605. [Google Scholar] [CrossRef]

- Song, J.; Jin, L. Effect of Process Parameters on Aluminum Foam Prepared by Friction Stir Welding. Hot Work. Technol. 2022, 51, 27–31. [Google Scholar]

- Peng, P.; Wang, K.; Wang, W.; Huang, L.; Qiao, K.; Che, Q.; Xi, X.; Zhang, B.; Cai, J. High-performance aluminium foam sandwich prepared through friction stir welding. Mater. Lett. 2019, 236, 295–298. [Google Scholar] [CrossRef]

- Hangai, Y.; Koyama, S.; Hasegawa, M.; Utsunomiya, T. Fabrication of Aluminum Foam/Dense Steel Composite by Friction Stir Welding. Metall. Mater. Trans. A 2010, 41, 2184–2186. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S.; Engineering, D.M.; Idaho, U.O.; Engineering, D.; Texas, U. Effect of friction stir processed microstructure on tensile properties of an Al-Zn-Mg-Sc alloy upon subsequent aging heat treatment. J. Mater. Sci. Technol. 2018, 34, 214–218. [Google Scholar] [CrossRef]

- Nisa, S.U.; Pandey, S.; Pandey, P.M. Formation and characterization of 6063 aluminum metal foam using friction stir processing route. Mater. Today Proc. 2020, 26, 3223–3227. [Google Scholar] [CrossRef]

- Lin, H.; Luo, H.; Huang, W.; Zhang, X.; Yao, G. Diffusion bonding in fabrication of aluminum foam sandwich panels. J. Mater. Process. Technol. 2016, 230, 35–41. [Google Scholar] [CrossRef]

- Ibrahim, A.; Körner, C.; Singer, R.F. The Effect of TiH2 Particle Size on the Morphology of Al-Foam Produced by PM Process. Adv. Eng. Mater. 2010, 10, 845–848. [Google Scholar] [CrossRef]

- Ding, X.; Liu, Y.; Wan, T. A novel hot-pressing method to prepare foamable precursor of aluminum foam sandwich (AFS). Mater. Lett. 2020, 259, 126895. [Google Scholar] [CrossRef]

- García-Moreno, F.; Jürgens, M.; Banhart, J. Temperature dependence of film rupture and internal structural stability in liquid aluminium alloy foams. Acta Mater. 2020, 196, 325–337. [Google Scholar] [CrossRef]

- Nabavi, A.; Vahdati Khaki, J. A novel method for manufacturing of aluminum foam sandwich panels. Surf. Interface Anal. 2010, 42, 275–280. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Y.; You, X.; Wang, F.; Wu, J. Preparation of Al foam sandwiches and analysis of the interface microstructure. Powder Metall. Technol. 2010, 28, 434–438. [Google Scholar]

- Liu, J.; Zu, G.; Lu, R.; Sun, S. Preparation of aluminum foam sandwich panel by powder metallurgy technology. J. Mater. Metall. 2014, 13, 152–156. [Google Scholar]

- Wang, Y.; Ren, X.; Hou, H.; Zhang, Y.; Yan, W. Processing and pore structure of aluminium foam sandwich. Powder Technol. 2015, 275, 344–350. [Google Scholar] [CrossRef]

- Luo, H.; Lin, H.; Zhao, Z.; Liu, Y.; Yao, G. Preparation of Aluminum Foam Sandwich Reinforced by Steel Sheets. Procedia Mater. Sci. 2014, 4, 39–43. [Google Scholar] [CrossRef] [Green Version]

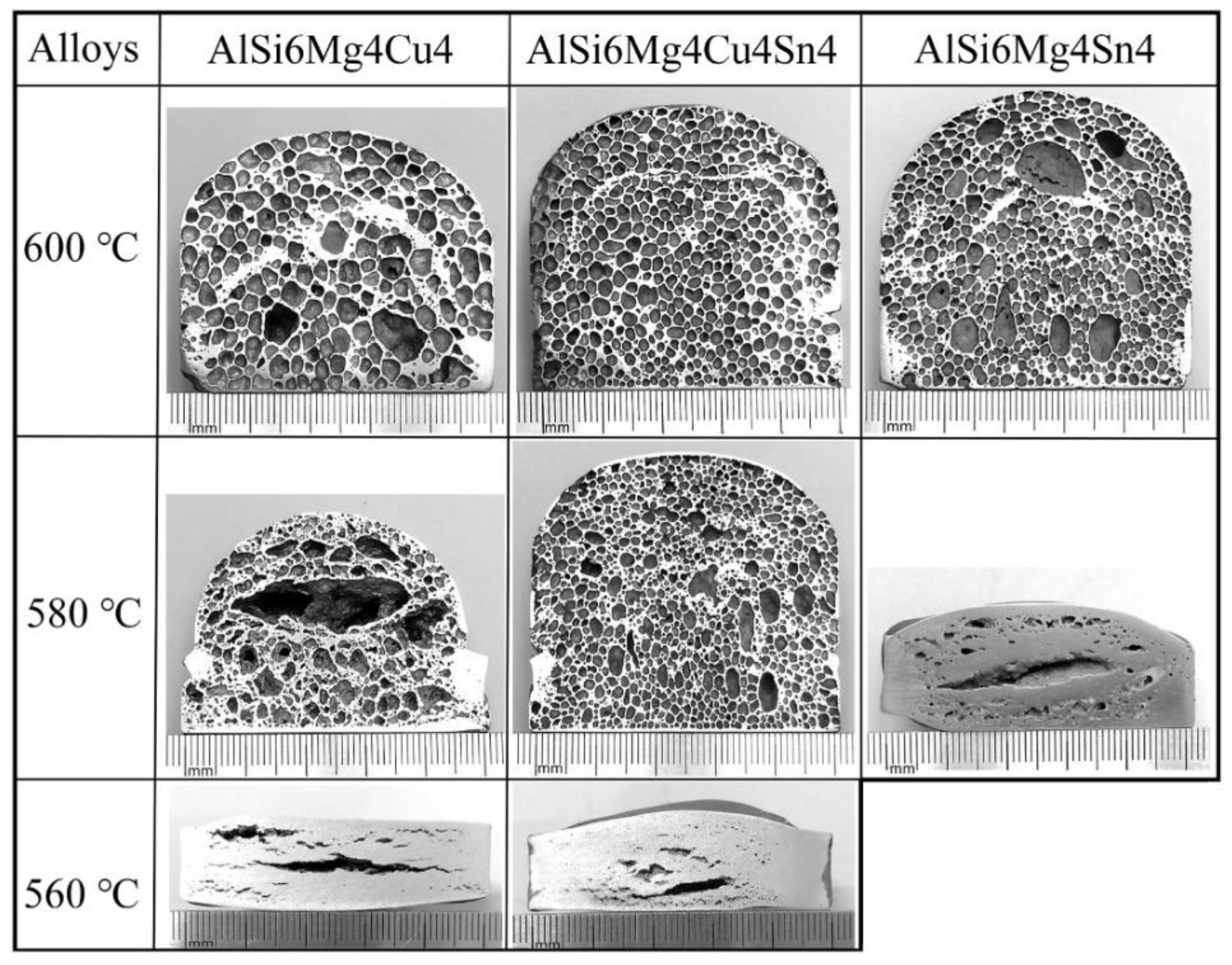

- Ding, X.; Peng, B.; Hu, X.; Pan, K.; Liu, Y.; Wan, T.; Ran, S. Effect of Cu and Sn additions on the cellular structure of Al–Si–Mg alloys foaming at low temperature (≤600 °C). Compos. Part B Eng. 2022, 234, 109693. [Google Scholar] [CrossRef]

- Ding, X.; Liu, Y.; Wan, T. Preparation Technology of Aluminum Foam Sandwich Panels by Powder Metallurgy and Optimization of Cellular Structure. Rare Met. Mater. Eng. 2020, 49, 3452–3459. [Google Scholar]

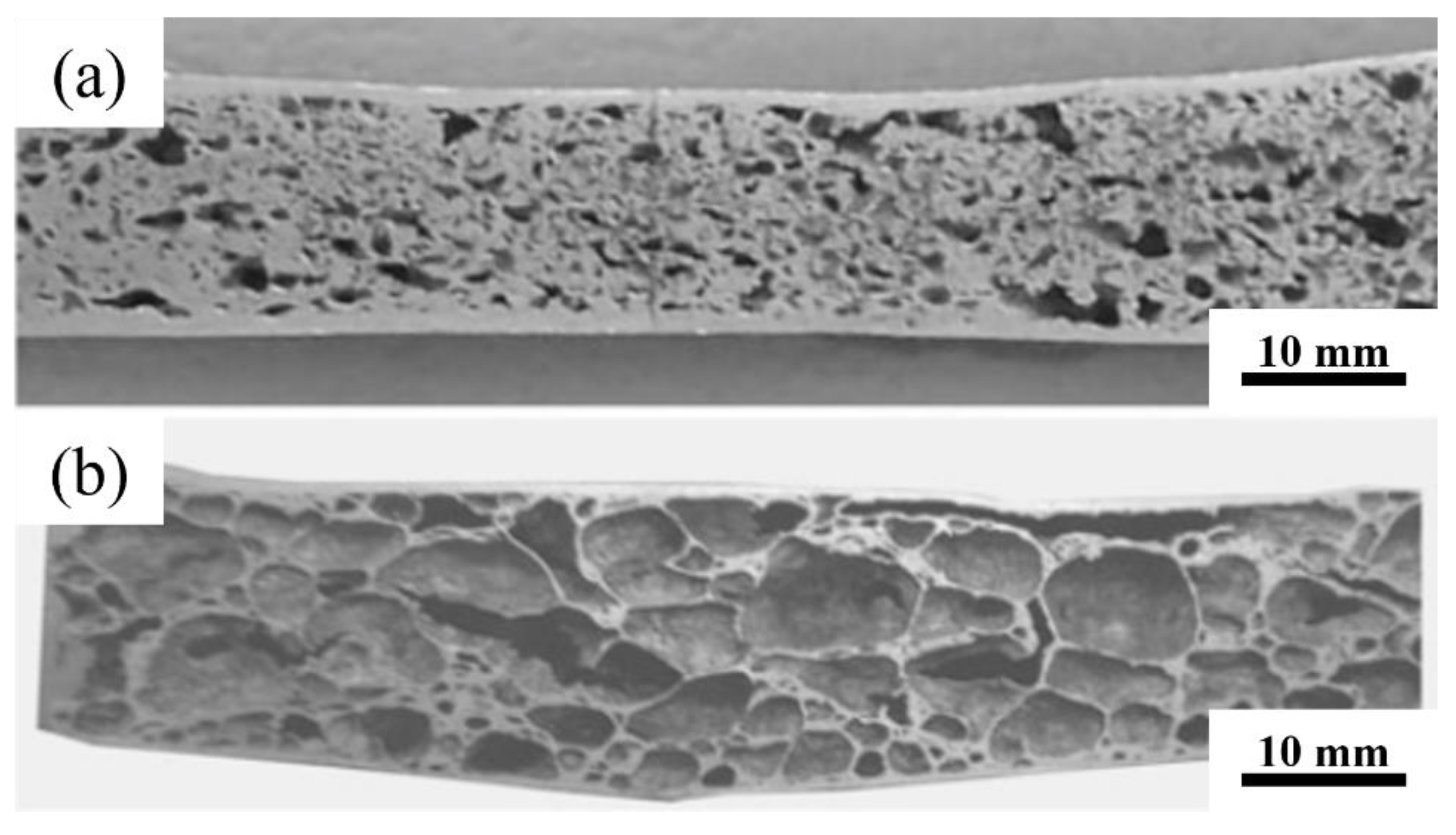

- Lu, X.; Luo, H.; Yang, S.; Wei, Y.; Xu, J.; Yao, Z. Two-step foaming process combined with hot-rolling in fabrication of an aluminium foam sandwich panel. Mater. Lett. 2020, 265, 127427. [Google Scholar] [CrossRef]

- Zu, G.; Zhang, M.; Yao, G.; Li, H. Aluminum Foam Sandwich by the Roll-bonding-powder Metallurgy Foaming Technique. Chin. J. Process Eng. 2006, 6, 973–977. [Google Scholar]

- Zu, G.; Li, H.; Li, B.; Yao, G. Preparation of Aluminum Foam Sandwich Perform by Roll-bonding Process. Spec. Cast. Nonferrous Alloys 2009, 29, 176–179. [Google Scholar]

- Zu, G.; Song, B.; Guan, Z.; Wang, L.; Yao, G. Powder Metallurgy-Foaming Process of Rolled Precursor for Aluminum Foam Sandwich. J. Northeast. Univ. (Nat. Sci.) 2009, 30, 246–249. [Google Scholar]

- Zu, G.; Song, B.; Guan, Z.; Wang, L.; Yao, G. Preparation of aluminum foam sandwich by rolling-bonding/powder metallurgy foaming technology. J. Wuhan Univ. Technol. (Mater. Sci. Ed.) 2011, 26, 4. [Google Scholar] [CrossRef]

- Zhang, M.; Yao, G.C.; Zu, G.Y.; Duan, S.L. Research on preparation of aluminum foam sandwich and steel plate/foam core interfacial microstructure. Gongneng Cailiao/J. Funct. Mater. 2006, 37, 281–283. [Google Scholar]

- Han, N.; Zhang, X.; Sun, X.; Huang, P.; Zu, G. Effect of foaming conditions on the pore structure and compression properties of aluminum foam sandwich panels. J. Mater. Metall. 2021, 20, 268–274. [Google Scholar]

- Sun, X.; Huang, P.; Zhang, X.; Han, N.; Lei, J.; Yao, Y.; Zu, G. Densification Mechanism for the Precursor of AFS under Different Rolling Temperatures. Materials 2019, 12, 3933. [Google Scholar] [CrossRef] [Green Version]

- Song, B.N.; Yao, G.C.; Guo, Y.Z.; Wang, L.; Hua, D. Preparing Aluminum Foam Sandwich Panels by the Pack-Rolling-Powder Metallurgy Foaming Technique. Adv. Mater. Res. 2010, 154–155, 613–616. [Google Scholar] [CrossRef]

- Song, B.; Zu, G.; Yao, G.; Guan, Z. Preparation of Aluminum Foam Sandwich Panels by Powder Filled Tube Rolling. J. Northeast. Univ. (Nat. Sci.) 2011, 32, 277–280. [Google Scholar]

- Kitazono, K.; Sato, E.; Kuribayashi, K. Novel manufacturing process of closed-cell aluminum foam by accumulative roll-bonding. Scr. Mater. 2003, 50, 495–498. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Habibolahzadeh, A.; Králík, V.; Němeček, J. Significant improvement in structural features, mechanical and physical properties of a novel CAR processed Al foam by nano-SiCp addition. Mater. Sci. Eng. A 2016, 670, 342–350. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Habibolahzadeh, A.; Petráňová, V.; Němeček, J. Influence of nano-SiCp on the foamability and microstructure of Al/TiH2 foam sheet manufactured by continual annealing and roll-bonding process. Mater. Des. 2016, 97, 483–491. [Google Scholar] [CrossRef]

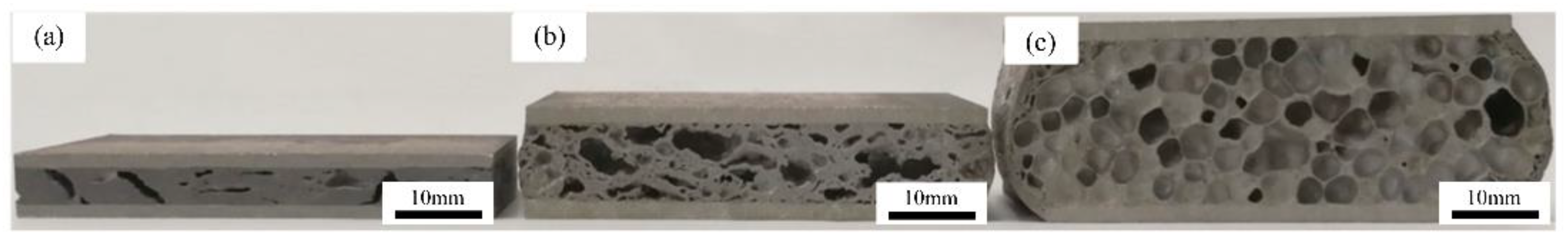

- Liu, N.; Zhang, Z.; Xia, X.; Xu, T.; Wang, Z.; Ding, J.; Liu, Y. Local Deform. Damping Perform. Integral-Form. Alum. Foam Sandw. Mater. Lett. 2022, 323, 132545. [Google Scholar]

- Zhang, Z.; Feng, H.; Xu, T.; Xin, W.; Ding, J.; Liu, N.; Wang, Z.; Wang, Y.; Xia, X.; Liu, Y. Compression performances of integral-forming aluminum foam sandwich. Compos. Struct. 2022, 283, 115090. [Google Scholar] [CrossRef]

- Zhou, X.Y.; Zhang, H.; Liu, X.Q.; Liu, H. Thermal decomposition behavior of novel gas-generating agent used for two steps foaming process of aluminum. Chin. J. Nonferrous Met. 2008, 18, 2265–2269. [Google Scholar]

- Orovčík, Ľ.; Nosko, M.; Švec, P.; Nagy, Š.; Čavojský, M.; Simančík, F.; Jerz, J. Effect of the TiH2 pre-treatment on the energy absorption ability of 6061 aluminium alloy foam. Mater. Lett. 2015, 148, 82–85. [Google Scholar] [CrossRef]

- Lotfizadeh, H.; Mehrizi, A.A.; Motlagh, M.S.; Rezazadeh, S. Thermal performance of an innovative heat sink using metallic foams and aluminum nanoparticles—Experimental study. Int. Commun. Heat Mass Transf. 2015, 66, 226–232. [Google Scholar] [CrossRef]

- Chen, S.; Bourham, M.; Rabiei, A. Neutrons attenuation on composite metal foams and hybrid open-cell Al foam. Radiat. Phys. Chem. 2015, 109, 27–39. [Google Scholar] [CrossRef] [Green Version]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- An, Y.K.; Yang, S.Y.; Wu, H.Y.; Zhao, E.T.; Wang, Z.S. Investigating the internal structure and mechanical properties of graphene nanoflakes enhanced aluminum foam. Mater. Des. 2017, 134, 44–53. [Google Scholar] [CrossRef]

- Chilla, V.; Mondal, D.P.; Ram, G.D.J.; Mukherjee, M. Processing of in-situ aluminium foam-filled stainless steel tube with foam-tube bonding for enhanced crashworthiness. J. Manuf. Process. 2022, 82, 488–500. [Google Scholar] [CrossRef]

- Duarte, I.; Krstulović-Opara, L.; Vesenjak, M. Axial crush behaviour of the aluminium alloy in-situ foam filled tubes with very low wall thickness. Compos. Struct. 2018, 192, 184–192. [Google Scholar] [CrossRef]

- Vesenjak, M.; Duarte, I.; Baumeister, J.; Göhler, H.; Krstulović-Opara, L.; Ren, Z. Bending performance evaluation of aluminium alloy tubes filled with different cellular metal cores. Compos. Struct. 2020, 234, 111748. [Google Scholar] [CrossRef]

- Xie, S.; Zhang, J.; Liu, X.; Zheng, S.; Liu, Z. A reinforced energy-absorbing structure formed by combining multiple aluminum foam-filled open-hole tubes. Int. J. Mech. Sci. 2022, 224, 107319. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, L.; Zhang, J.; Jiang, Y.; Wang, W.; Wu, G. Deformation and energy absorption properties of cenosphere/aluminum syntactic foam-filled circular tubes under lateral quasi-static compression. Int. J. Mech. Sci. 2021, 192, 106126. [Google Scholar] [CrossRef]

- Hanssen, A.G.; Langseth, M.; Hopperstad, O.S. Static and dynamic crushing of square aluminium extrusions with aluminium foam filler. Int. J. Impact Eng. 2000, 24, 347–383. [Google Scholar] [CrossRef]

- Linul, E.; Movahedi, N.; Marsavina, L. The temperature effect on the axial quasi-static compressive behavior of ex-situ aluminum foam-filled tubes. Compos. Struct. 2017, 180, 709–722. [Google Scholar] [CrossRef]

- Güden, M.; Kavi, H. Quasi-static axial compression behavior of constraint hexagonal and square-packed empty and aluminum foam-filled aluminum multi-tubes. Thin-Walled Struct. 2006, 44, 739–750. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Zhang, R.; Liu, S.; Zhai, X.; Zhi, X. Energy absorption behaviour of an aluminium foam-filled circular-triangular nested tube energy absorber under impact loading. Structures 2021, 34, 95–104. [Google Scholar] [CrossRef]

- Garai, F.; Béres, G.; Weltsch, Z. Development of tubes filled with aluminium foams for lightweight vehicle manufacturing. Mater. Sci. Eng. A 2020, 790, 139743. [Google Scholar] [CrossRef]

- Duarte, I.; Krstulovic-Opara, L.; Vesenjak, M. Characterisation of aluminium alloy tubes filled with aluminium alloy integral-skin foam under axial compressive loads. Compos. Struct. 2015, 121, 154–162. [Google Scholar] [CrossRef]

- Movahedi, N.; Linul, E. Quasi-static compressive behavior of the ex-situ aluminum-alloy foam-filled tubes under elevated temperature conditions. Mater. Lett. 2017, 206, 182–184. [Google Scholar] [CrossRef]

- Hangai, Y.; Otazawa, S.; Utsunomiya, T. Aluminum alloy foam-filled aluminum tube fabricated by friction stir back extrusion and its compression properties. Compos. Struct. 2018, 183, 416–422. [Google Scholar] [CrossRef]

- Leveles, B.; Kemény, A.; Szijártó, A. Mechanical investigation of in-situ produced aluminium matrix syntactic foam-filled tubes. Mater. Today Proc. 2021, 45, 4221–4224. [Google Scholar] [CrossRef]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L.; Anžel, I.; Ferreira, J.M. Manufacturing and bending behaviour of in situ foam-filled aluminium alloy tubes. Mater. Des. 2015, 66, 532–544. [Google Scholar] [CrossRef]

- Zare, J.; Manesh, H.D. A novel method for producing of steel tubes with Al foam core. Mater. Des. 2011, 32, 1325–1330. [Google Scholar] [CrossRef]

- Matteo, S.; Alessandro, M.; Valerio, M.; Massimo, G.; Philippe, B. Endurance of Damping Properties of Foam-Filled Tubes. Materials 2015, 8, 4061–4079. [Google Scholar]

- Taherishargh, M.; Vesenjak, M.; Belova, I.V.; Krstulović-Opara, L.; Murch, G.E.; Fiedler, T. In situ manufacturing and mechanical properties of syntactic foam filled tubes. Mater. Des. 2016, 99, 356–368. [Google Scholar] [CrossRef]

- Ce, J.; Wei, W.; Huagui, H.; Chuanyan, P. Physical simulation experimental research on bottom blowing anti-extrusion process of aluminum foam-filled tube. J. Yanshan Univ. 2019, 43, 306–312. [Google Scholar]

- Hanssen, A.G.; Langseth, M.; Hopperstad, O.S. Static and dynamic crushing of circular aluminium extrusions with aluminium foam filler. Int. J. Impact Eng. 2000, 24, 475–507. [Google Scholar] [CrossRef]

- Santosa, S.P.; Wierzbicki, T.; Hanssen, A.G.; Langseth, M. Experimental and numerical studies of foam-filled sections. Int. J. Impact Eng. 2000, 24, 509–534. [Google Scholar] [CrossRef]

- Rajaneesh, A.; Sridhar, I.; Rajendran, S. Impact modeling of foam cored sandwich plates with ductile or brittle faceplates. Compos. Struct. 2012, 94, 1745–1754. [Google Scholar] [CrossRef]

- Elnasri, I.; Zhao, H. Impact perforation of sandwich panels with aluminum foam core: A numerical and analytical study. Int. J. Impact Eng. 2016, 96, 50–60. [Google Scholar] [CrossRef]

- An, Y.; Yang, S.; Zhao, E.; Wang, Z. Characterization of metal grid-structure reinforced aluminum foam under quasi-static bending loads. Compos. Struct. 2017, 178, 288–296. [Google Scholar] [CrossRef]

- An, Y.; Yang, S.; Zhao, E.; Wang, Z. Fabrication and experimental investigation of metal grid structure-reinforced aluminum foams. Mater. Manuf. Process. 2018, 33, 528–533. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Viscusi, A.; Carrino, L. An innovative manufacturing method of aluminum foam sandwiches using a mesh-grid reinforcement as mold. Int. J. Adv. Manuf. Technol. 2020, 107, 3039–3048. [Google Scholar] [CrossRef]

- Baumeister, J.; Weise, J.; Hirtz, E.; Hhne, K.; Hohe, J. Applications of aluminium hybrid foam sandwiches in battery housings for electric vehicles. Mater. Werkst. 2014, 45, 1099–1107. [Google Scholar] [CrossRef]

- Kovačič, A.; Ren, Z. On the porosity of advanced pore morphology structures. Compos. Struct. 2016, 158, 235–244. [Google Scholar] [CrossRef]

- Duarte, I.; Vesenjak, M.; Krstulovic-Opara, L.; Ren, Z. Compressive performance evaluation of APM (Advanced Pore Morphology) foam filled tubes. Compos. Struct. 2015, 134, 409–420. [Google Scholar] [CrossRef]

- Qiaoyu, G. Study on Prcparation and Mechanical Properties of Aluminum Loam Composite Structure. Master’s Thesis, Taiyuan University of Science and Technology, Taiyuan, China, 2017. [Google Scholar]

- Sulong, M.A.; Vesenjak, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Compressive properties of Advanced Pore Morphology (APM) foam elements. Mater. Sci. Eng. A 2014, 607, 498–504. [Google Scholar] [CrossRef]

- García-Moreno, F.; Kamm, P.H.; Neu, T.R.; Bülk, F.; Mokso, R.; Schlepütz, C.M.; Stampanoni, M.; Banhart, J. Using X-ray tomoscopy to explore the dynamics of foaming metal. Nat. Commun. 2019, 10, 3762. [Google Scholar] [CrossRef] [Green Version]

- An, Y.; Ma, H.; Zhang, J.; Zhang, P.; Zhao, E.; Yang, S. Foaming stabilization and mechanical properties of high-toughness aluminum foam fabricated using non-thickening foaming technology. J. Mater. Process. Technol. 2021, 296, 117212. [Google Scholar] [CrossRef]

| Preparation Methods | Advantages | Disadvantages | Reference | |

|---|---|---|---|---|

| AFS | Adhesive bonding | Simple in process, high efficiency, and low cost. | Adhesive ages easily, corrodes easily, and does not survive high temperatures, as well as low bonding strength of prepared samples. | [17,18,21,22,26,27,28] |

| Brazing | Welded AFSs present good appearance quality at brazing joints, and low cost. | Brazed joint is prone to defects, incomplete melting of the solder layer, and easy to overburn both the panels and core material. | [36,39] | |

| Diffusion welding | Good bonding strength and without melting metal. | Requires a high surface quality. | [41,43,44] | |

| Friction stir welding | Without introducing new materials, good bonding strength, refines grain of panel, and improves panel. | Surface of welded AFS is not smooth, and core layer is prone to large pores. | [48,51,52,53] | |

| Cold- and hot-pressing powder metallurgy | AFSs prepared by this method form a tight metallurgical bonding layer with good bonding. | Preparation conditions are limited and cannot meet the requirements of industrial scale production, AFS core layer is prone to large pores, and process is complex. | [54,57,61,62] | |

| Rolling powder metallurgy | Can obtain higher densification of core and present better interface bonding strength, and large-sized AFSs can be prepared. | Flow and loss of core powder, and micro-cavities can be observed in the low-density area. | [65,66,67,68,69] | |

| Jacketing rolling powder metallurgy method | AFSs prepared have characteristics of good powder uniformity and high shape accuracy, density of the precursor is improved, and core powder loss is prevented. | Process requires high precision and complex preparation. | [70,71,74] | |

| ARB and CAR | Can be used for fabricating large-sized AFSs. | Large pores and extremely uneven pore distribution, and smooth surface of aluminum foam plate is degraded. | [75,76,77] | |

| Melt foaming | AFSs have characteristics of a short process, relatively uniform pore structures, and less limits in specimen size. | Acceptable bonding strength. | [12,79,80] | |

| FFT | Ex situ filling | Thermal expansion bonding process is simple and low cost, and bonding strength is effectively improved if adhesive bonding is employed. | Surface error is large, and existence of adhesive keeps FFT from being used in high temperatures and other harsh environments. | [95,96] |

| In situ preparation | Avoids secondary molding of FFTs, metallurgical bond is formed between panel and core layer, highly reproducible, and cost-effective. | Pore forming is random and uncontrollable. | [86,94,99,100,103] | |

| MGS-AF | Internal method | Full play to lightweight advancement of AFCSs, and prepared MGS-AF has perfect pore structure. | Process requires two-step preparation, and process is complex. | [109,110] |

| External enhancement method | Full play to lightweight advancement of AFCSs. | [2,111] | ||

| APM foam-filled composite structure | Adhesive bonding | Highly repeatable, simple process, and low cost. | Adhesive ages easily, corrodes easily, and does not survive high temperatures. | [112,113,114,115,116] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; An, Y.; Ma, H. Research Progress in the Preparation of Aluminum Foam Composite Structures. Metals 2022, 12, 2047. https://doi.org/10.3390/met12122047

Zhang J, An Y, Ma H. Research Progress in the Preparation of Aluminum Foam Composite Structures. Metals. 2022; 12(12):2047. https://doi.org/10.3390/met12122047

Chicago/Turabian StyleZhang, Junshan, Yukun An, and Haoyuan Ma. 2022. "Research Progress in the Preparation of Aluminum Foam Composite Structures" Metals 12, no. 12: 2047. https://doi.org/10.3390/met12122047

APA StyleZhang, J., An, Y., & Ma, H. (2022). Research Progress in the Preparation of Aluminum Foam Composite Structures. Metals, 12(12), 2047. https://doi.org/10.3390/met12122047