Hydriding, Oxidation, and Ductility Evaluation of Cr-Coated Zircaloy-4 Tubing

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

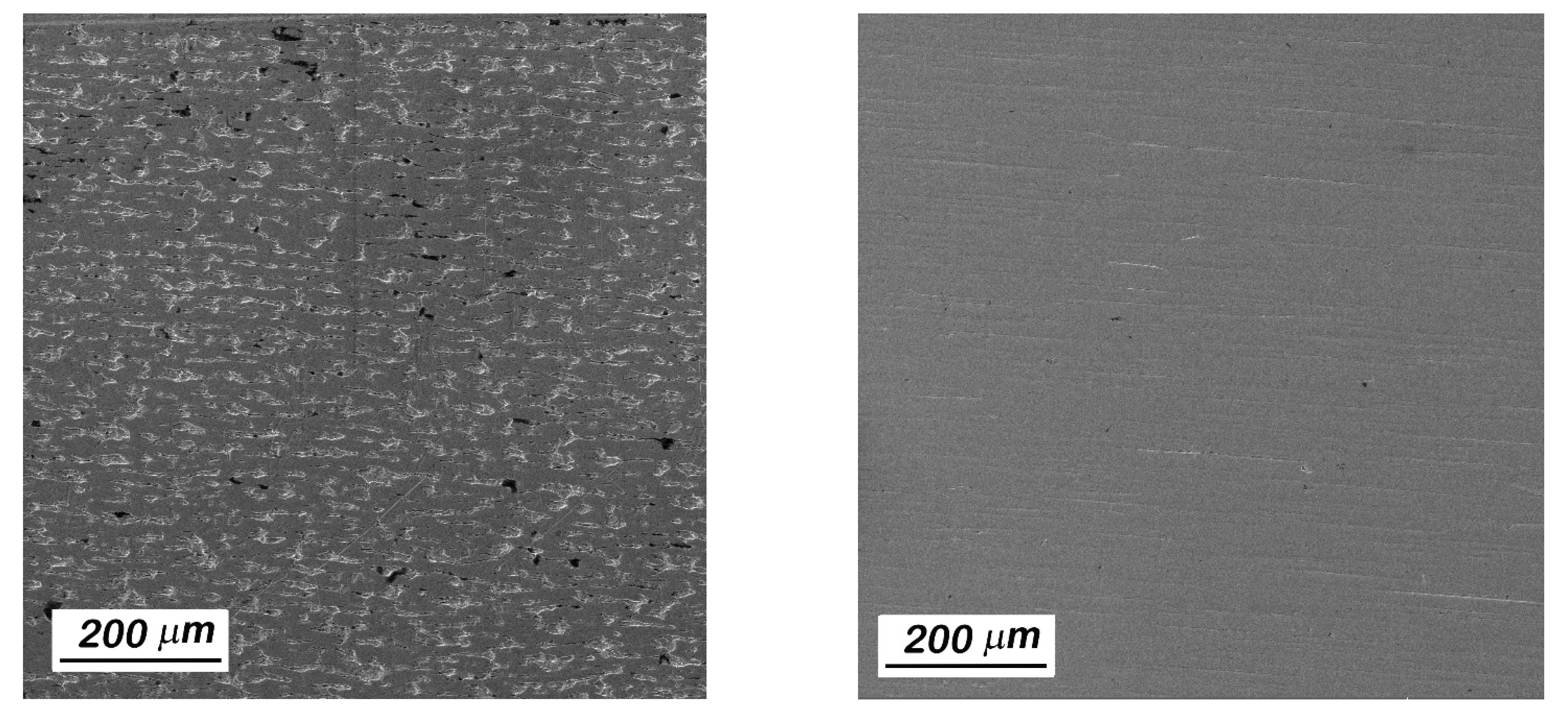

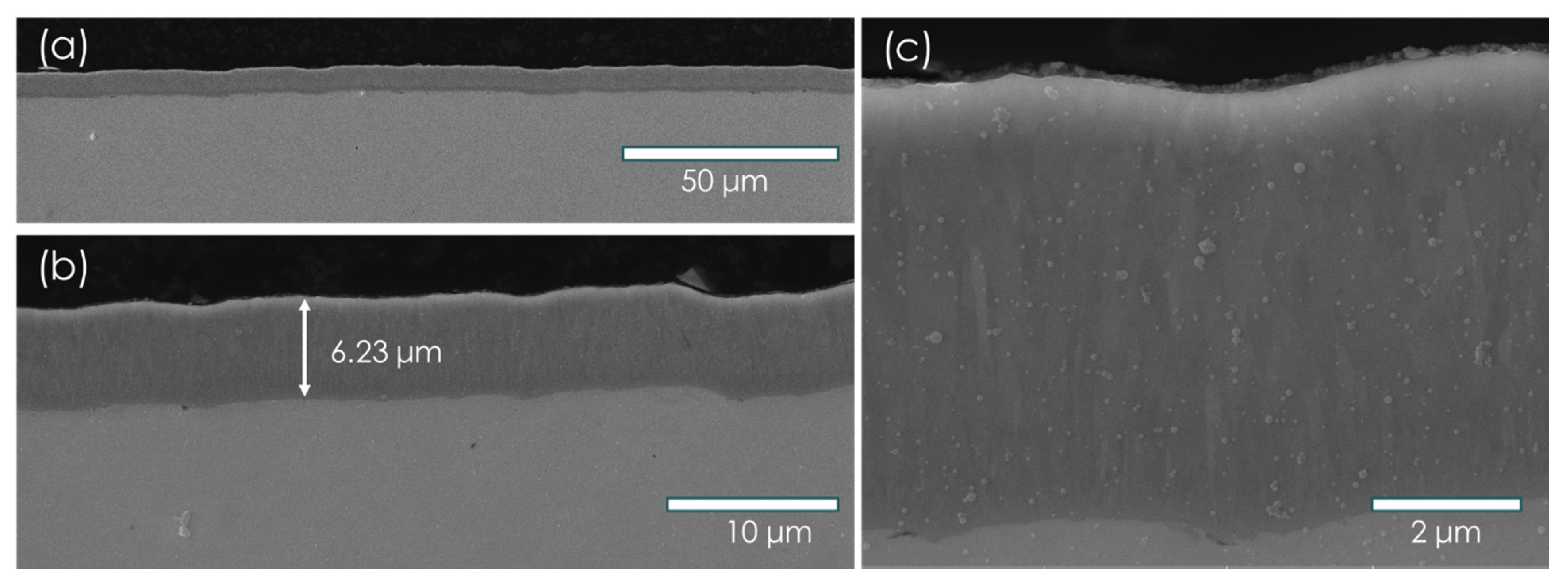

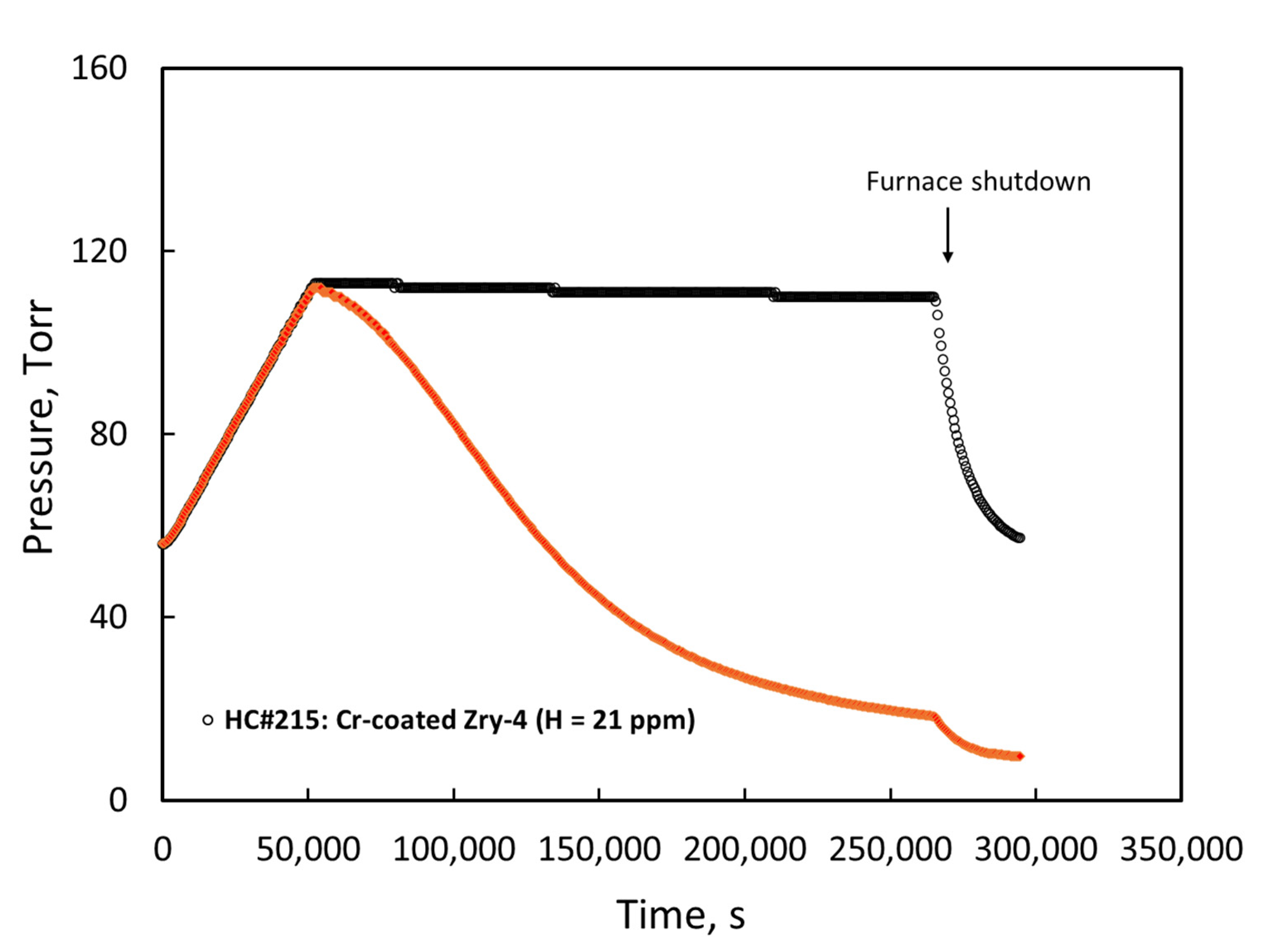

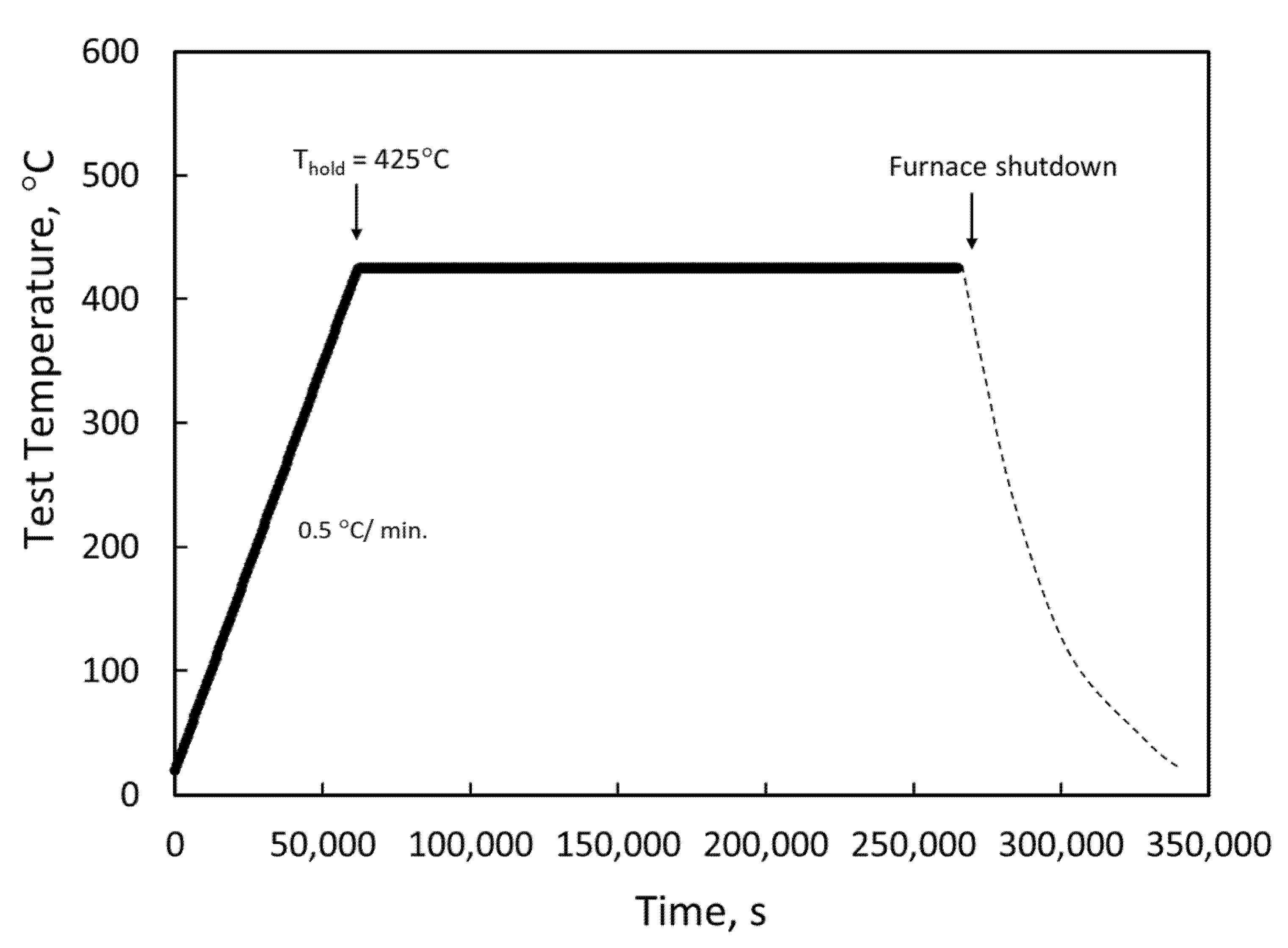

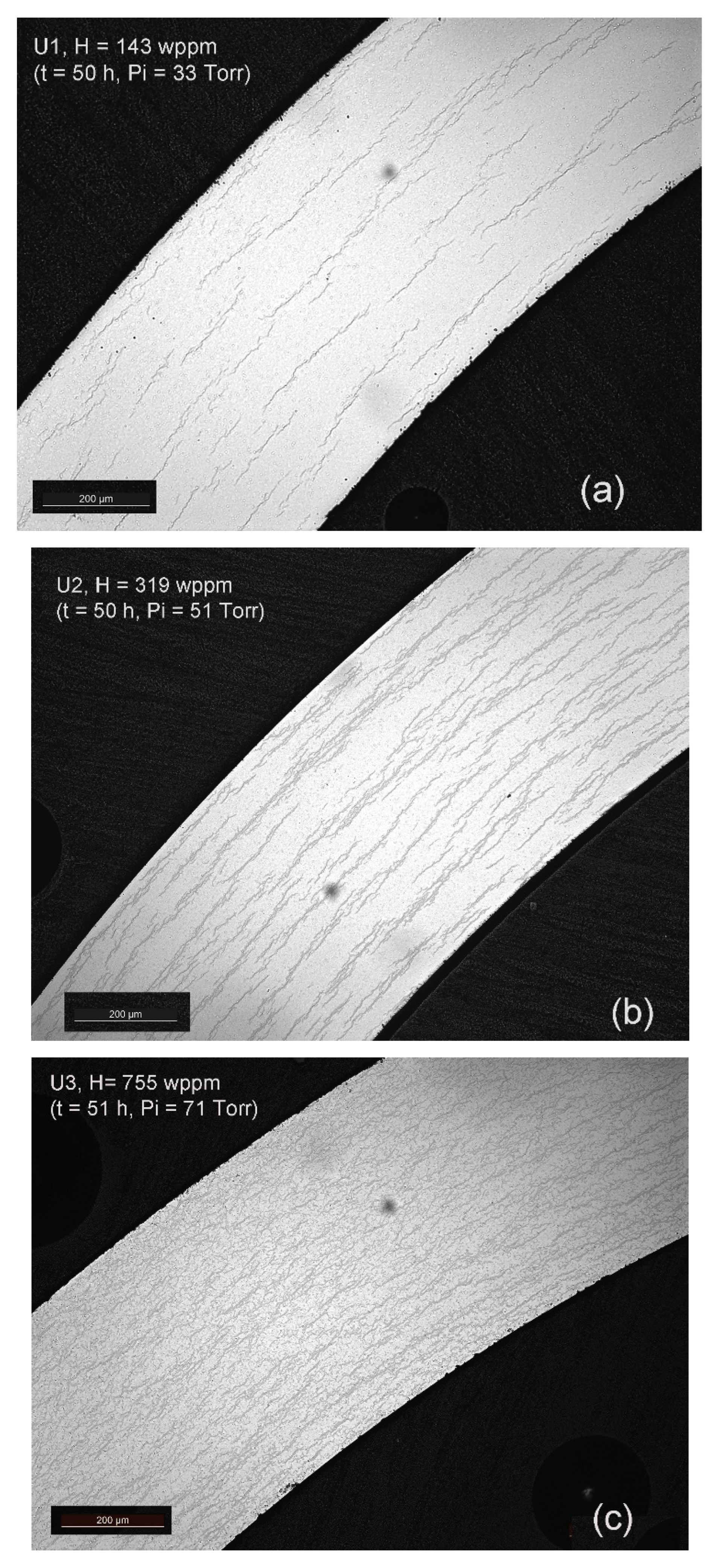

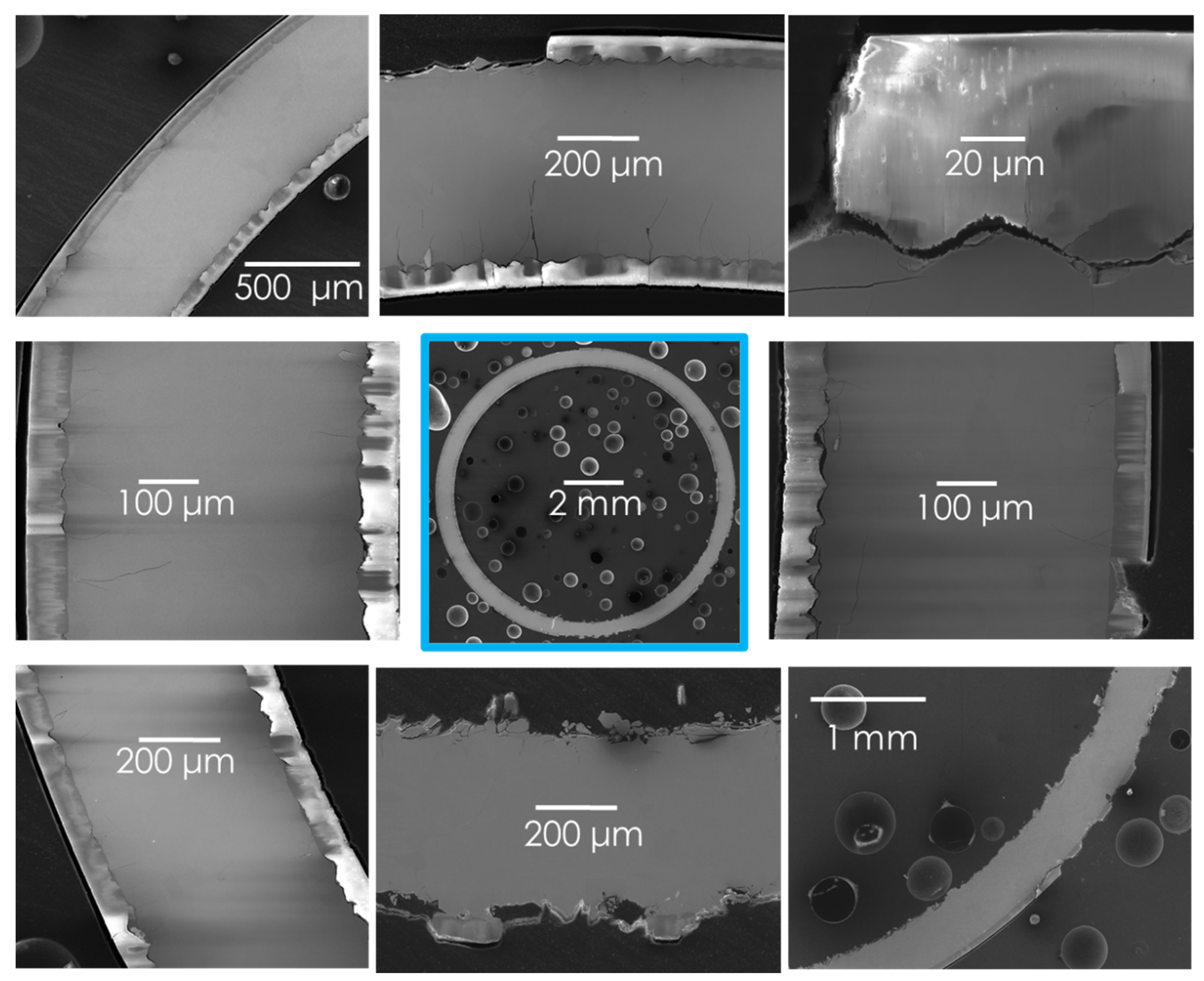

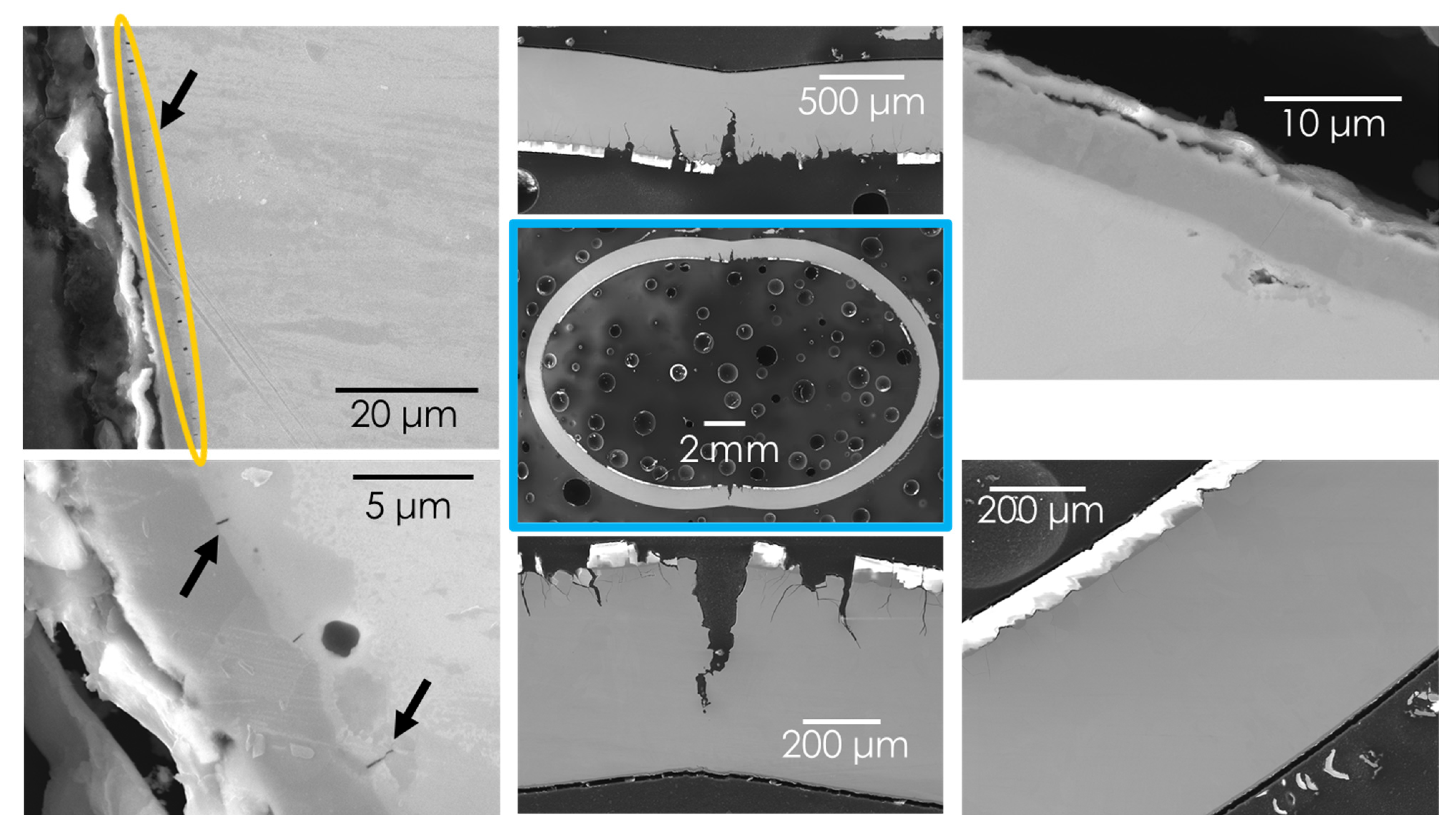

3.1. Materials Hydriding and Characterization

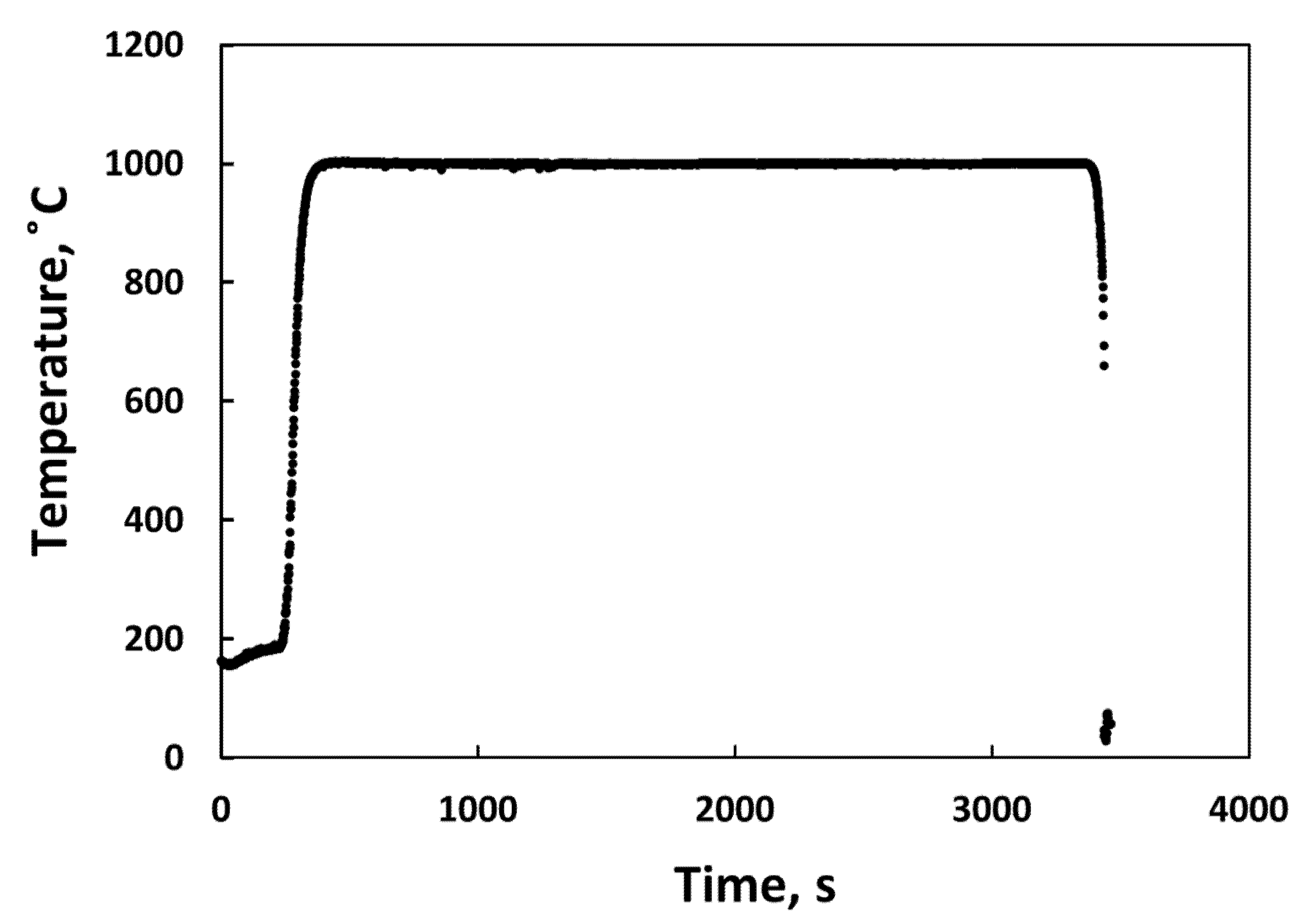

3.2. High Temperature Steam Oxidation Tests

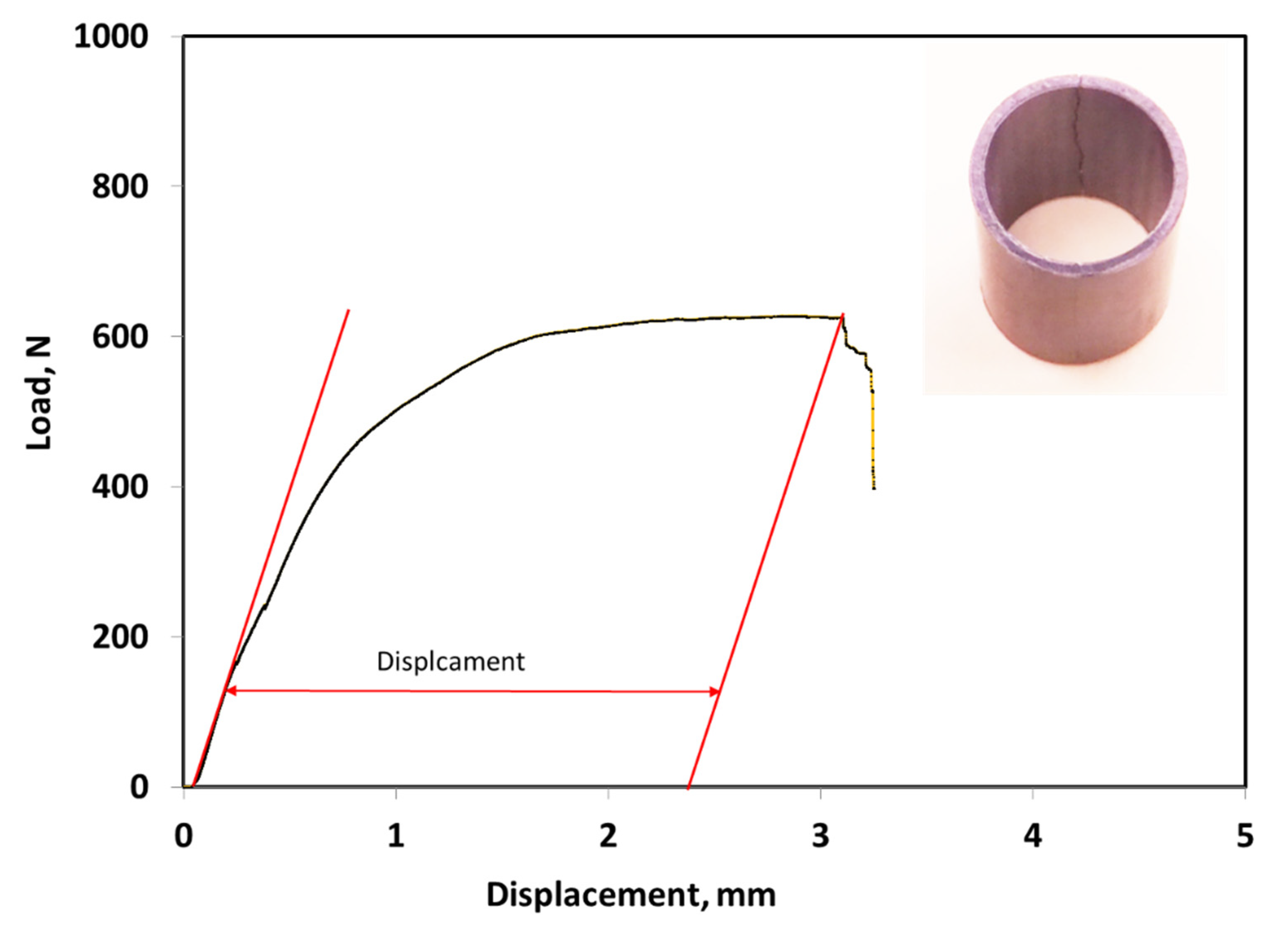

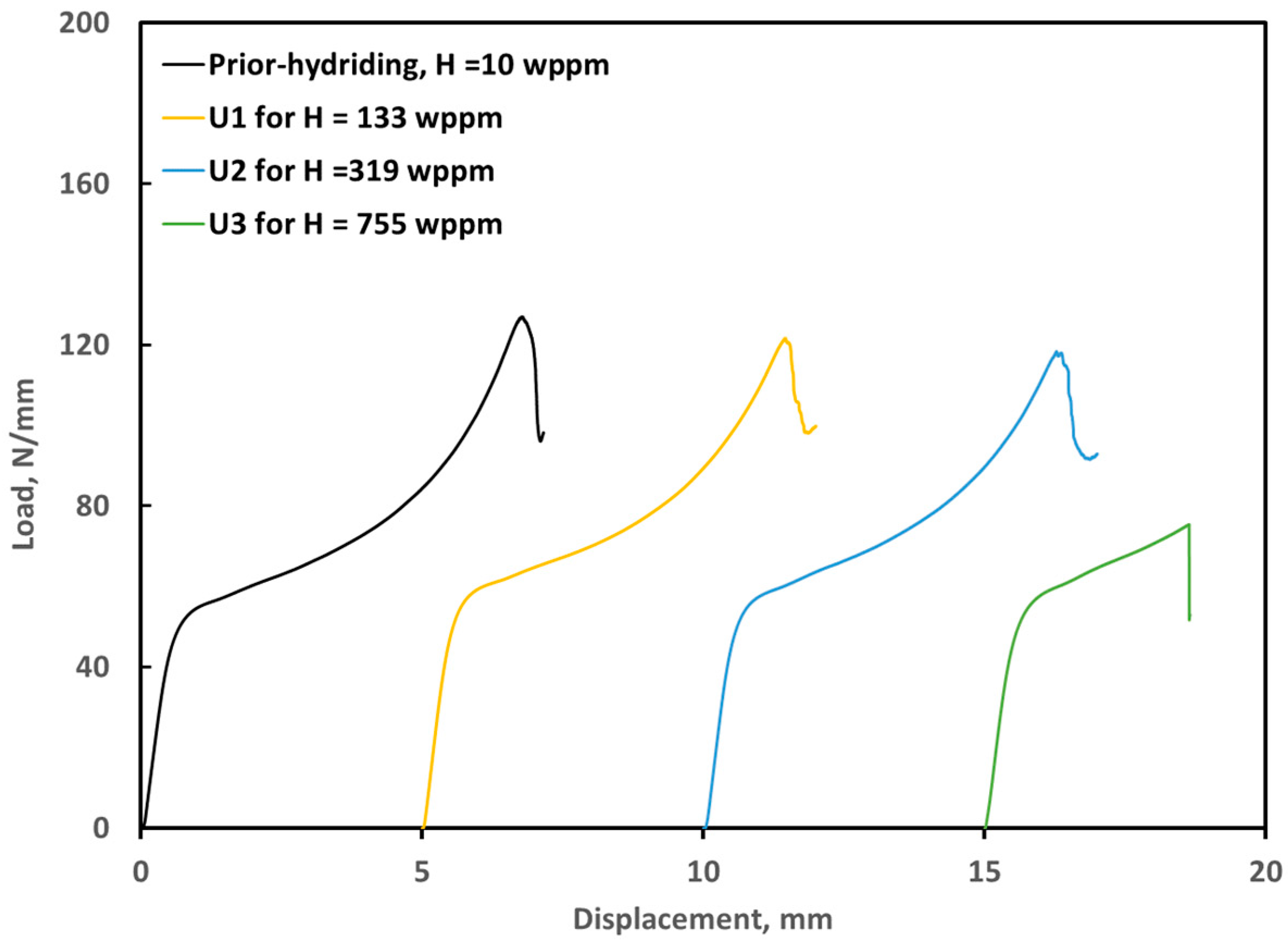

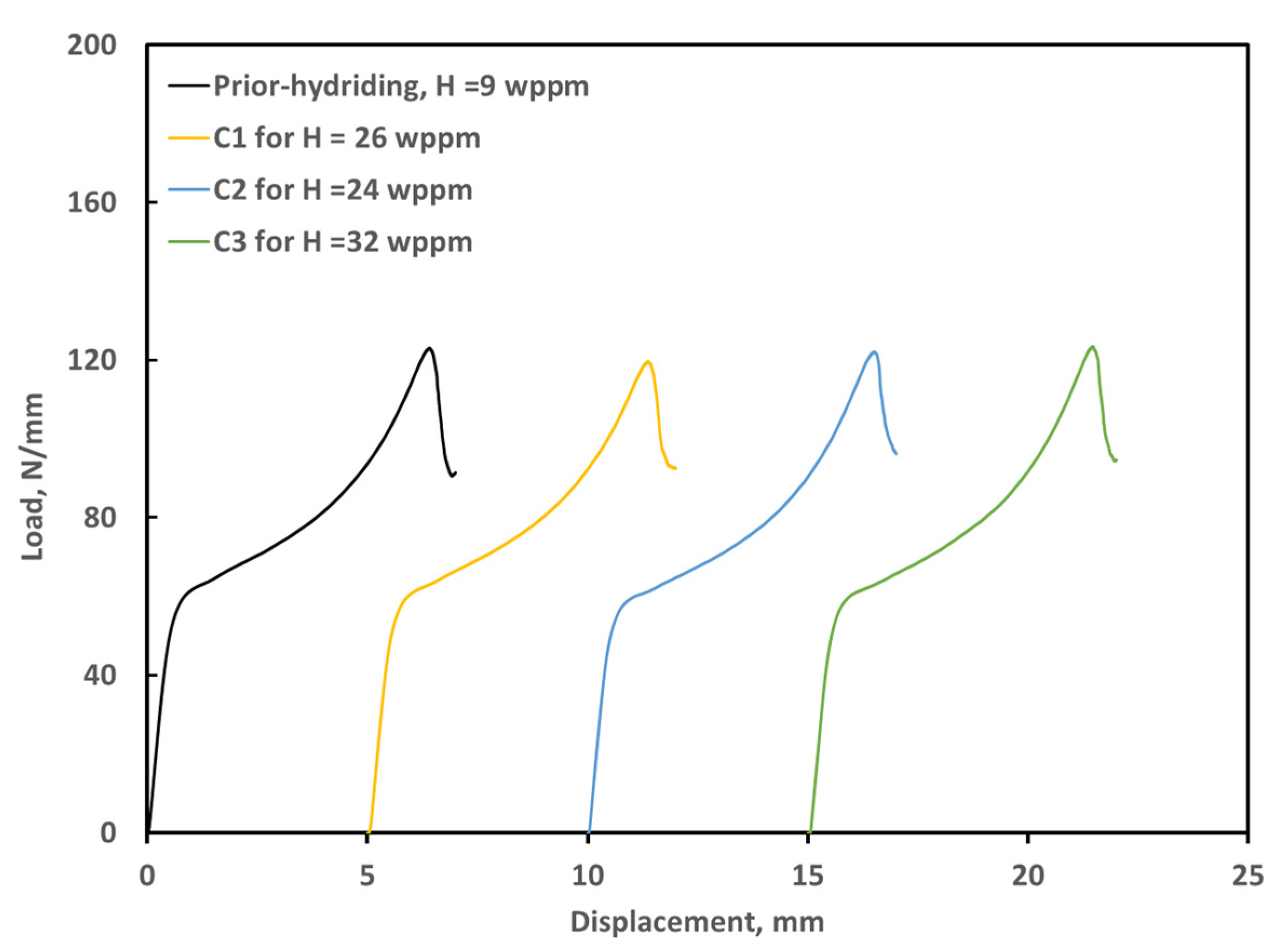

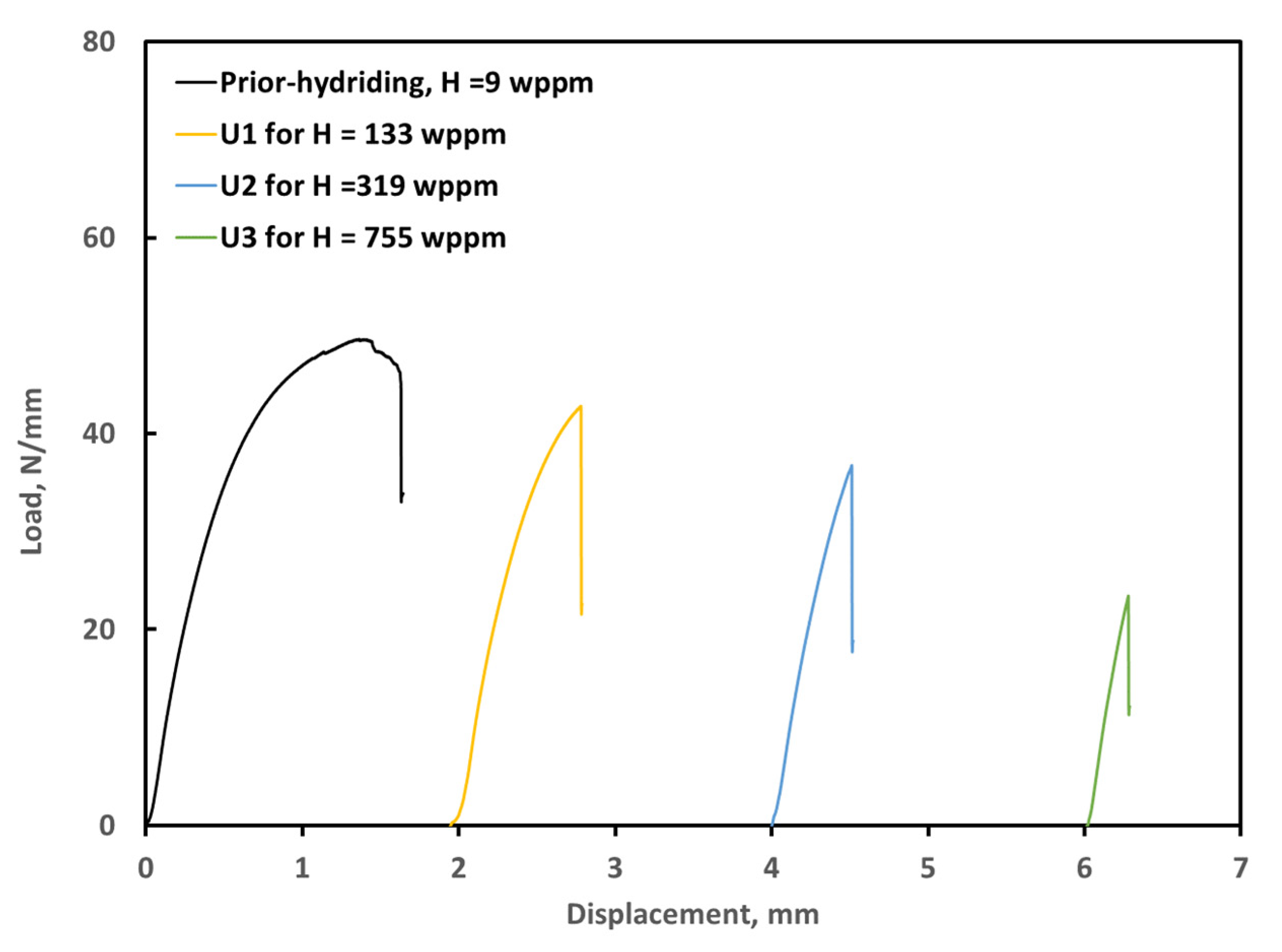

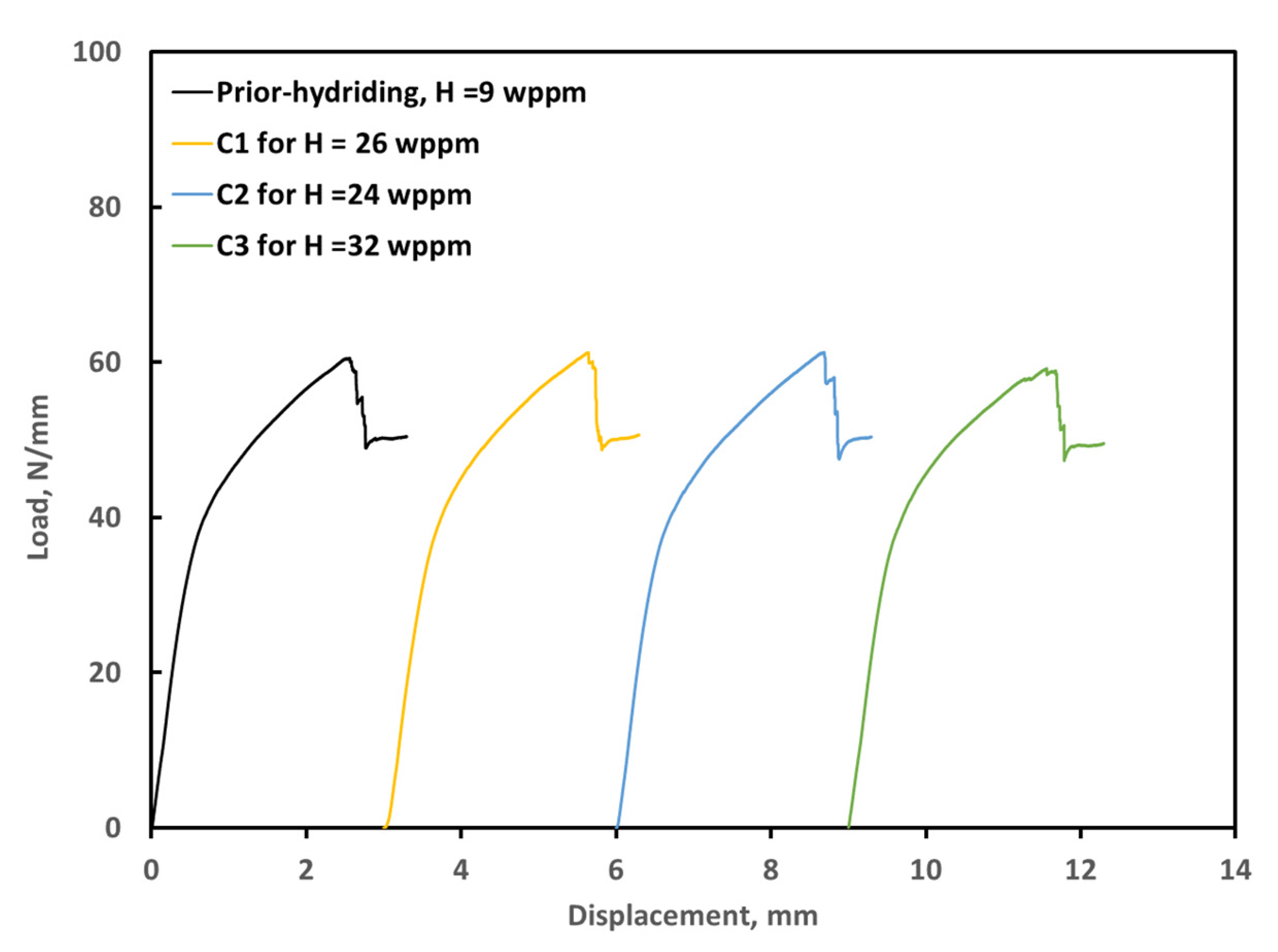

3.3. Ring Compression Testing of Hydrided and Oxidized Zircaloy-4 Specimens

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zinkle, S.J.; Terrani, K.A.; Gehin, J.C.; Ott, L.J.; Snead, L.L. Accident tolerant fuels for LWRs: A perspective. J. Nucl. Mater. 2014, 448, 374–379. [Google Scholar] [CrossRef]

- Kurata, M. Research and Development Methodology for Practical Use of Accident Tolerant Fuel in Light Water Reactors. Nucl. Eng. Technol. 2016, 48, 26–32. [Google Scholar] [CrossRef]

- Tang, C.; Stueber, M.; Seifert, H.J.; Steinbrueck, M. Protective coatings on zirconium-based alloys as accident-Tolerant fuel (ATF) claddings. Corros. Rev. 2017, 35, 141–165. [Google Scholar] [CrossRef]

- Terrani, K.A. Accident tolerant fuel cladding development: Promise, status, and challenges. J. Nucl. Mater. 2018, 501, 13–30. [Google Scholar] [CrossRef]

- Geelhood, K.G.; Luscher, W.G. Degradation and Failure Phenomena of Accident Tolerant Fuel Concepts; PNNL-28437; Pacific Northwest National Laboratory: Richland, WA, USA, 2019. [Google Scholar]

- Krejčí, J.; Ševeče, M.; Kabátová, J.; Manoch, F.; Kočí, J.; Cvrček, L.; Málek, J.; Krum, S.; Šutta, P.; Bublíková, P.; et al. Experimental Behavior of Chromium-Based Coatings. TopFuel 2018, 2018, A0233. [Google Scholar]

- Evans, A.K.; Kelly, P.J.; Goddard, D.T.; Cole-Baker, A.; Obasi, G.; Preuss, M.; Vernon, E.P. Fabrication, characterization, and testing of Cr-coated Zr alloy nuclear fuel rod cladding for enhanced accident tolerance. In Proceedings of the Light Water Reactor Fuel Performance Conference 2019, Seattle, WA, USA, 22–27 September 2019; pp. 864–872. [Google Scholar]

- Park, D.J.; Kim, H.G.; Jung, Y.I.; Park, J.H.; Yang, J.H.; Koo, Y.H. Behavior of an improved Zr fuel cladding with oxidation resistant coating under loss-of-coolant accident condition. J. Nucl. Mater. 2016, 482, 75–82. [Google Scholar] [CrossRef]

- Yeom, H.; Maier, B.; Johnson, G.; Dabney, T.; Lenling, M.; Sridharan, K. High temperature oxidation and microstructural evolution of cold spray chromium coatings on Zircaloy-4 in steam environments. J. Nucl. Mater. 2019, 526, 151737. [Google Scholar] [CrossRef]

- Yook, H.; Shirvan, K.; Phillips, B.; Lee, Y. Post-LOCA ductility of Cr-coated cladding and its embrittlement limit. J. Nucl. Mater. 2022, 558, 153354. [Google Scholar] [CrossRef]

- Malgin, A.; Sheleppov, I.; Markelov, V.; Eremin, I.; Vorobev, E.; Novikov, V.; Karpyuk, L. Corrosion and high teemperature oxidation resistance of chromium-coated zirconium based caldding for accident tolerant fuel. In Proceedings of the TopFuel 2021, Santander, Spain, 24–28 October 2021. [Google Scholar]

- Ma, H.; Yan, J.; Zhao, Y.; Liu, T.; Ren, Q.; Liao, Y.; Zuo, J.; Liu, G.; Yao, M. Oxidation behavior of Cr-coated zirconium alloy cladding in high-temperature steam above 1200 °C. Mater. Degrad. 2021, 5, 7. [Google Scholar] [CrossRef]

- Bell, S.B.; Graening, T.; Evans, A.; Kelly, P.; Pint, B.A.; Kane, K.A. Burst and oxidation behavior of Cr-coated Zirlo during simulated LOCA testing. J. Nucl. Mater. 2022, 564, 153679. [Google Scholar] [CrossRef]

- Yan, Y.; Qian, S.; Littrell, K.; Parish, C.M.; Plummer, L.K. Fast, Quantitative, and Nondestructive Evaluation of Hydrided LWR Fuel Cladding by Small Angle Incoherent Neutron Scattering of Hydrogen. J. Nucl. Mater. 2015, 460, 114–121. [Google Scholar] [CrossRef]

- US Nuclear Regulatroy Commission. NRC Draft Regulatory Guideline DG-1263: Establishing Analytical Limits for Zirconium-Based Alloy Cladding; US Nuclear Regulatroy Commission: Rockville, MD, USA, 2014.

- Yan, Y.; Garrison, B.E.; Howell, M.; Bell, G.L. High-Temperature Oxidation Kinetics of Sponge-Based E110 Cladding Alloy. J. Nucl. Mater. 2018, 499, 596. [Google Scholar] [CrossRef]

- Yan, Y.; Garrison, B.E.; Nelson, A.T.; Lutz, D. Correlations of the Steam Oxidation Rate Constant of BWR Alloy Zircaloy-2 at 800–1400 °C. Oxid. Met. 2022, 97, 227–239. [Google Scholar] [CrossRef]

- Billone, M.; Yan, Y.; Burtseva, T.; Daum, R. Cladding Embrittlement during Postulated Loss-of-Coolant Accidents; NUREG/CR-6967, ANL-07/04; Argonne National Lab. (ANL): Argonne, IL, USA, 2008. [Google Scholar]

- Cathcart, J.V.; Pawel, R.E.; McKee, R.A.; Druschel, R.E.; Yurek, G.J.; Cambell, J.J.; Jury, S.H. Zirconium Metal-Water Oxidation Kinetics IV; Reaction Rate Studies, ORNL/NUREG-17; Oak Ridge National Laboratory: Oak Riidge, TN, USA, 1977.

- Stein, F.; Leineweber, A. Laves phases: A review of their functional and structural applications and an improved fundamental understanding of stability and properties. J. Mater. Sci. 2021, 56, 5321–5427. [Google Scholar] [CrossRef]

- Jiang, J.; Du, M.; Pan, Z.; Yuan, M.; Ma, X.; Wang, B. Effects of oxidation and inter-diffusion on the fracture mechanisms of Cr-coated Zry-4 alloys: An in situ three-point bending study. Mater. Des. 2021, 212, 110168. [Google Scholar] [CrossRef]

- Hu, X.; Dong, C.; Wang, Q.; Chen, B.; Yang, H.; Wei, T.; Zhang, R.; Gu, W.; Chen, D. High-temperature oxidation of thick Cr coating prepared by arc deposition for accident tolerant fuel claddings. J. Nucl. Mater. 2019, 519, 145–156. [Google Scholar] [CrossRef]

- Han, X.; Chen, C.; Tan, Y.; Feng, W.; Peng, S.; Zhang, H. A systematic study of the oxidation behavior of Cr coatings on Zry4 substrates in high temperature steam environment. Corros. Sci. 2020, 174, 108826. [Google Scholar] [CrossRef]

| Parameter | ORNL Zircaloy-4 |

|---|---|

| Zr (wt %) | Balance |

| Sn (wt %) | 1.29–1.37 |

| Fe (wt %) | 0.30–0.34 |

| Cr (wt %) | 0.10 |

| Ni (wt %) | - |

| H (wppm) | 4–6 |

| Sample | Materials | Hydriding Temp. (°C) | Pressure (Torr) | Time (h) | Measured H (wppm) | Comments |

|---|---|---|---|---|---|---|

| U0 | Uncoated | N/A | N/A | N/A | 10 | As-polished |

| C0 | Coated | N/A | N/A | N/A | 9 | As-coated |

| U1 | Uncoated | 425 | 33 | 50 | 143 | Target: 150 wppm |

| C1 | Coated | 425 | 33 | 50 | 26 | Repeat Test U1 |

| U2 | Uncoated | 425 | 51 | 50 | 319 | Target: 300 wppm |

| C2 | Coated | 425 | 51 | 50 | 24 | Repeat Test U2 |

| U3 | Uncoated | 425 | 71 | 51 | 755 | Target: 750 wppm |

| C3 | Coated | 425 | 71 | 51 | 32 | Repeat Test U3 |

| Sample | Measured H * (wppm) | Oxidation Temp. (°C) | Hold Time at Target Temp. (s) | Measured Weight Gain (mg/cm2) | Comments |

|---|---|---|---|---|---|

| ox1205-U0 | 10 | 1205 | 100 | 8.7 | As-polished |

| ox1205-C0 | 9 | 1205 | 100 | 4.5 | As-coated |

| ox1205-U1 | 143 | 1205 | 100 | 8.6 | Hydrided for 50 h, Pi = 32.7 Torr |

| ox1205-C1 | 26 | 1205 | 100 | 4.5 | Hydrided for 50 h, Pi = 32.8 Torr |

| ox1205-U2 | 319 | 1205 | 100 | 8.9 | Hydrided for 50 h, Pi = 51.1 Torr |

| ox1205-C2 | 24 | 1205 | 100 | 4.6 | Hydrided for 50 h, Pi = 51.0 Torr |

| ox1205-U3 | 755 | 1205 | 100 | 8.6 | Hydrided for 51 h, Pi = 71.3 Torr |

| ox1205-C3 | 32 | 1205 | 100 | 4.5 | Hydrided for 51 h, Pi = 71.3 Torr |

| Sample | Measured H * (wppm) | Oxidation Temp. (°C) | Hold Time at Target Temp. (s) | Measured Weight Gain (mg/cm2) | Comments |

|---|---|---|---|---|---|

| ox1000-U0 | 10 | 1000 | 3000 | 12.0 | As-polished |

| ox1000-C0 | 9 | 1000 | 3000 | 5.9 | As-coated |

| ox1000-U1 | 143 | 1000 | 3000 | 11.8 | Hydrided for 50 h, Pi = 32.7 Torr |

| ox1000-C1 | 26 | 1000 | 100 | 5.9 | Hydrided for 50 h, Pi = 32.8 Torr |

| ox1000-U2 | 319 | 1000 | 3000 | 12.1 | Hydrided for 50 h, Pi = 51.1 Torr |

| ox1000-C2 | 24 | 1000 | 3000 | 6.1 | Hydrided for 50 h, Pi = 51.0 Torr |

| ox1000-U3 | 755 | 1000 | 3000 | 12.3 | Hydrided for 51 h, Pi = 71.3 Torr |

| ox1000-C3 | 32 | 1000 | 3000 | 6.0 | Hydrided for 51 h, Pi = 71.3 Torr |

| Sample | Measured H * (wppm) | Weight Gain (mg/cm2) | Offset Displacement(mm) | Offset Strain (%) | Comments |

|---|---|---|---|---|---|

| ox1205-U0 | 10 | 8.7 | 0.92 | 9.7 | As-polished |

| ox1205-C0 | 9 | 4.5 | 1.88 | 19.7 | As-coated |

| ox1205-U1 | 143 | 8.6 | 0.18 | 1.8 | Hydrided for 50 h, Pi = 32.7 Torr |

| ox1205-C1 | 26 | 4.5 | 1.85 | 19.5 | Hydrided for 50 h, Pi = 32.8 Torr |

| ox1205-U2 | 319 | 8.9 | 0.14 | 1.4 | Hydrided for 50 h, Pi = 51.1 Torr |

| ox1205-C2 | 24 | 4.6 | 1.88 | 19.7 | Hydrided for 50 h, Pi = 51.0 Torr |

| ox1205-U3 | 755 | 8.6 | 0.04 | 0.4 | Hydrided for 51 h, Pi = 71.3 Torr |

| ox1205-C3 | 32 | 4.5 | 1.86 | 19.6 | Hydrided for 51 h, Pi = 71.3 Torr |

| Sample | Measured H * (wppm) | Weight Gain (mg/cm2) | Offset Displacement (mm) | Offset Strain (%) | Comments |

|---|---|---|---|---|---|

| ox1000-U0 | 10 | 12.0 | 0.4 | 4.2 | As-polished |

| ox1000-C0 | 9 | 5.9 | 2.5 | 26.4 | As-coated |

| ox1000-U1 | 143 | 11.8 | 0.27 | 2.8 | Hydrided for 50 h, Pi = 32.7 Torr |

| ox1000-C1 | 26 | 5.9 | 2.43 | 25.6 | Hydrided for 50 h, Pi = 32.8 Torr |

| ox1000-U2 | 319 | 12.1 | 0.15 | 1.6 | Hydrided for 50 h, Pi = 51.1 Torr |

| ox1000-C2 | 24 | 6.1 | 2.28 | 24.0 | Hydrided for 50 h, Pi = 51.0 Torr |

| ox1000-U3 | 755 | 12.3 | 0.03 | 0.3 | Hydrided for 51 h, Pi = 71.3 Torr |

| ox1000-C3 | 32 | 6.0 | 2.51 | 26.4 | Hydrided for 51 h, Pi = 71.3 Torr |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Y.; Graening, T.; Nelson, A.T. Hydriding, Oxidation, and Ductility Evaluation of Cr-Coated Zircaloy-4 Tubing. Metals 2022, 12, 1998. https://doi.org/10.3390/met12121998

Yan Y, Graening T, Nelson AT. Hydriding, Oxidation, and Ductility Evaluation of Cr-Coated Zircaloy-4 Tubing. Metals. 2022; 12(12):1998. https://doi.org/10.3390/met12121998

Chicago/Turabian StyleYan, Yong, Tim Graening, and Andrew T. Nelson. 2022. "Hydriding, Oxidation, and Ductility Evaluation of Cr-Coated Zircaloy-4 Tubing" Metals 12, no. 12: 1998. https://doi.org/10.3390/met12121998

APA StyleYan, Y., Graening, T., & Nelson, A. T. (2022). Hydriding, Oxidation, and Ductility Evaluation of Cr-Coated Zircaloy-4 Tubing. Metals, 12(12), 1998. https://doi.org/10.3390/met12121998