Analysis of Non-Symmetrical Heat Transfers during the Casting of Steel Billets and Slabs

Abstract

:1. Introduction

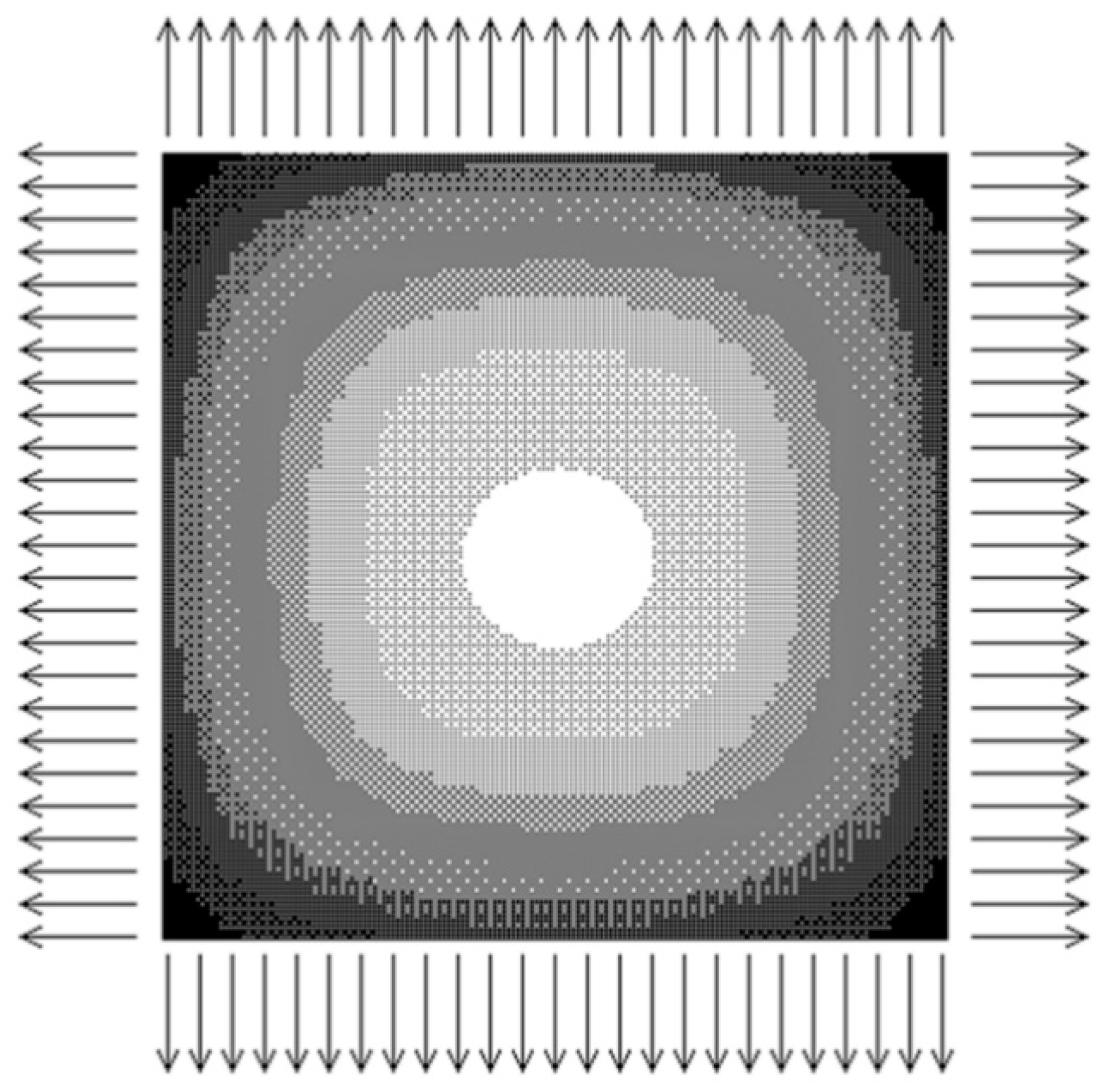

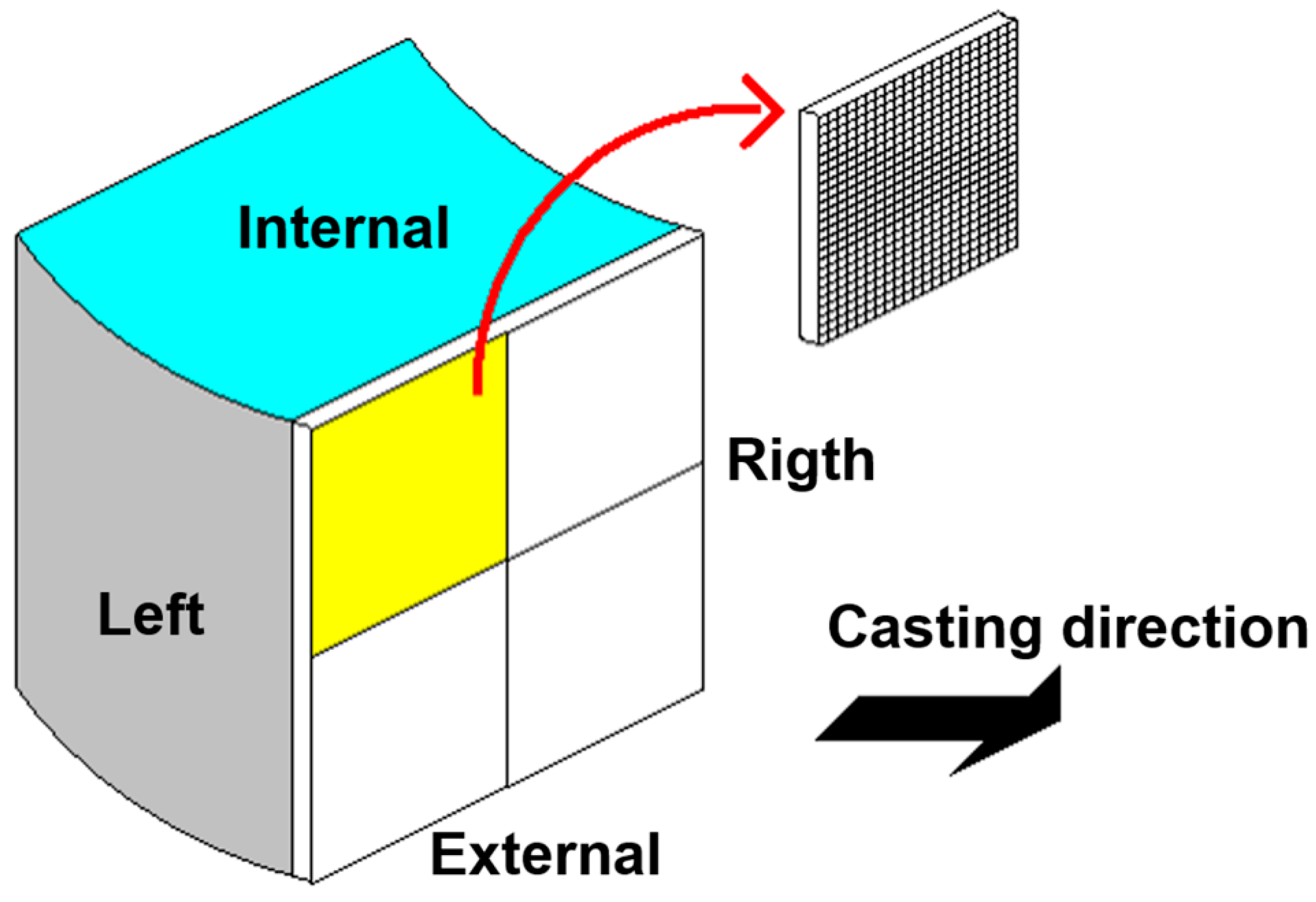

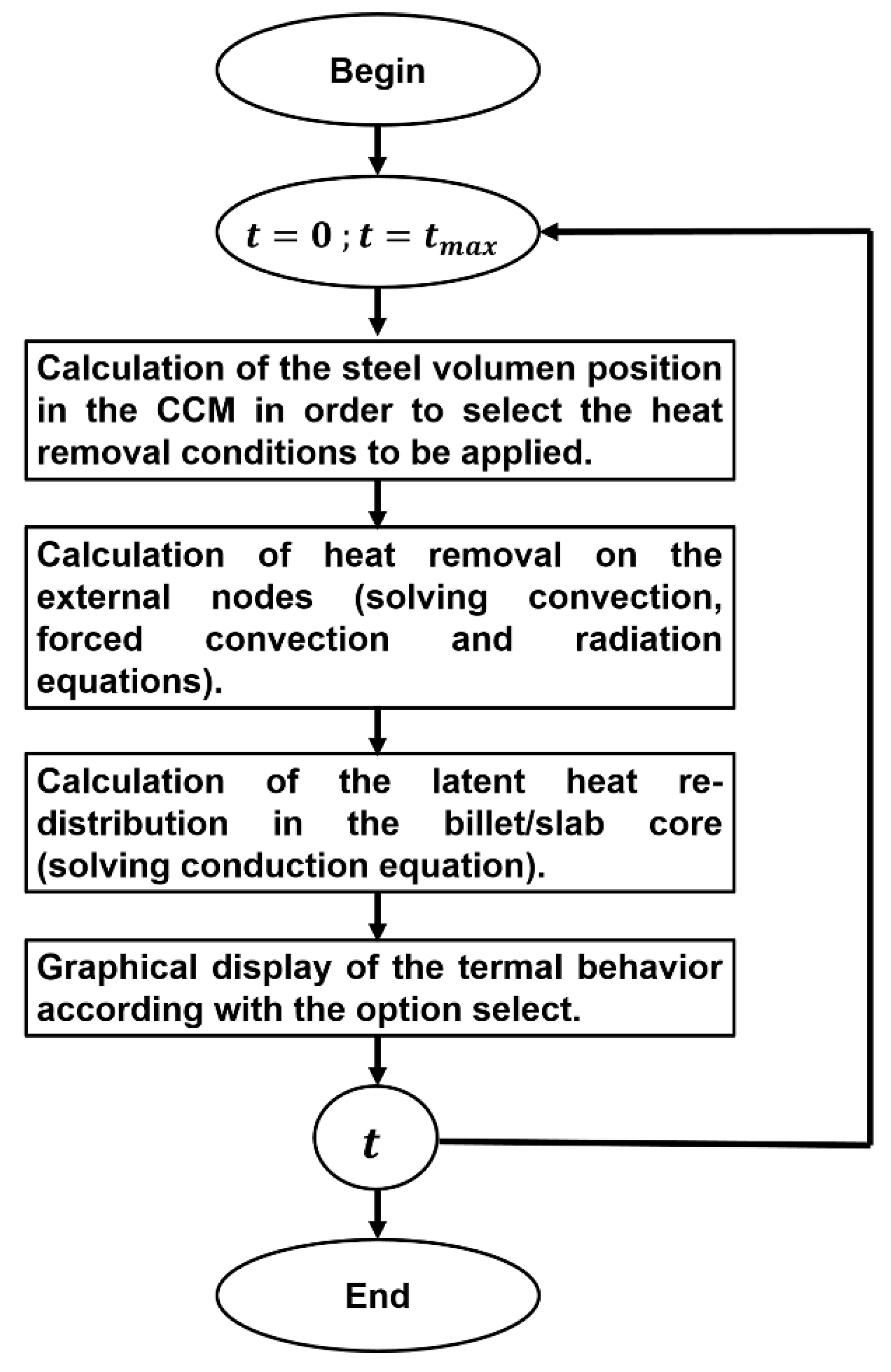

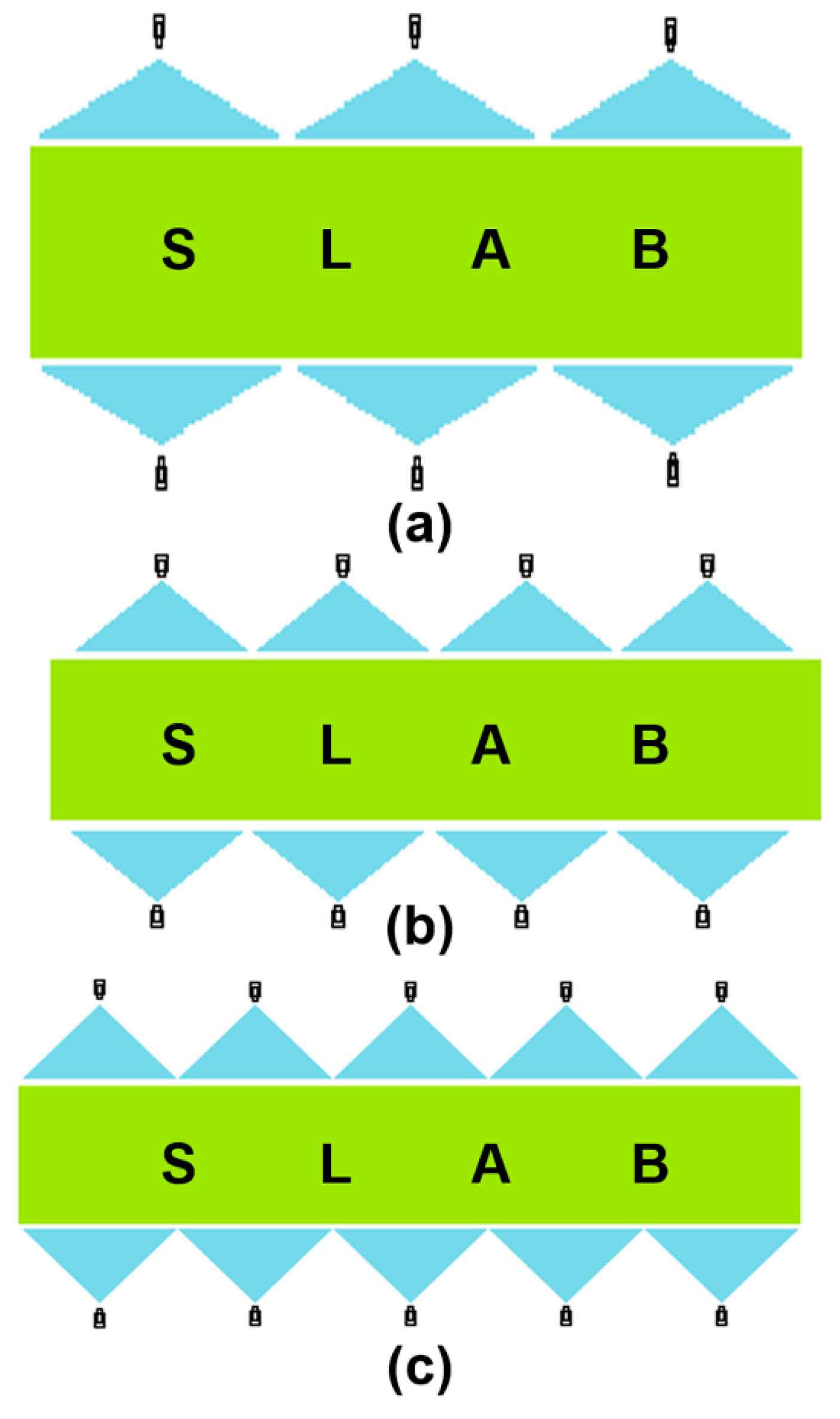

2. Computational Representation of Steel Casting

- The casting temperature (TCO) is the same for all the nodes. Thus, the assignment of the energy required to define the casting temperature is for all nodes.

- Only one single steel volume is in the casting plant for the simulation. In consequence, there is no heat inter-change in the longitudinal direction of the machine. Thus, the heat removal in the cast direction is negligible. This assumption simplifies the problem and reduces the calculation time; the problem is a 2D type as the longitudinal heat transfer is negligible. Therefore, the treatment of the problem uses 2D computational arrays; one for enthalpies and one for both the latest and previous calculations of enthalpy ( and ) and ( and ), reducing the computer’s memory requirements.

- The simulation begins at the meniscus level inside the mold. Then, the simulation time is (t = 0).

- The step time (Δt) is calculated as a function of the billet dimensions (lx) and (ly) using (Nx) and (Ny) nodes, and the steel thermal diffusivity (α) is given in Equation (1) where k is the thermal conductivity, ρ is density, and Cp is heat capacity.

3. Heat Transfer and Conduction inside the Billet Core

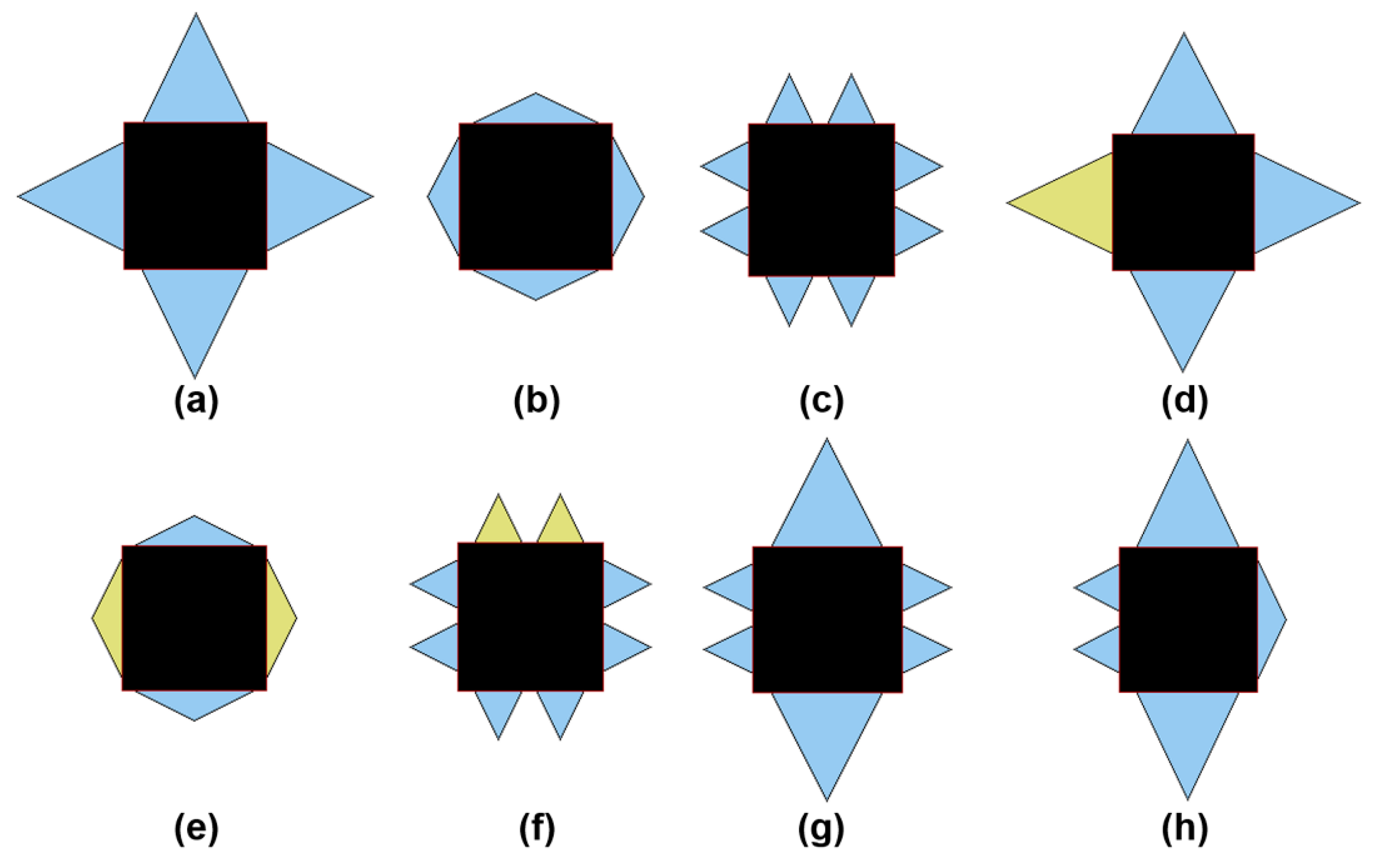

4. Process Simulation

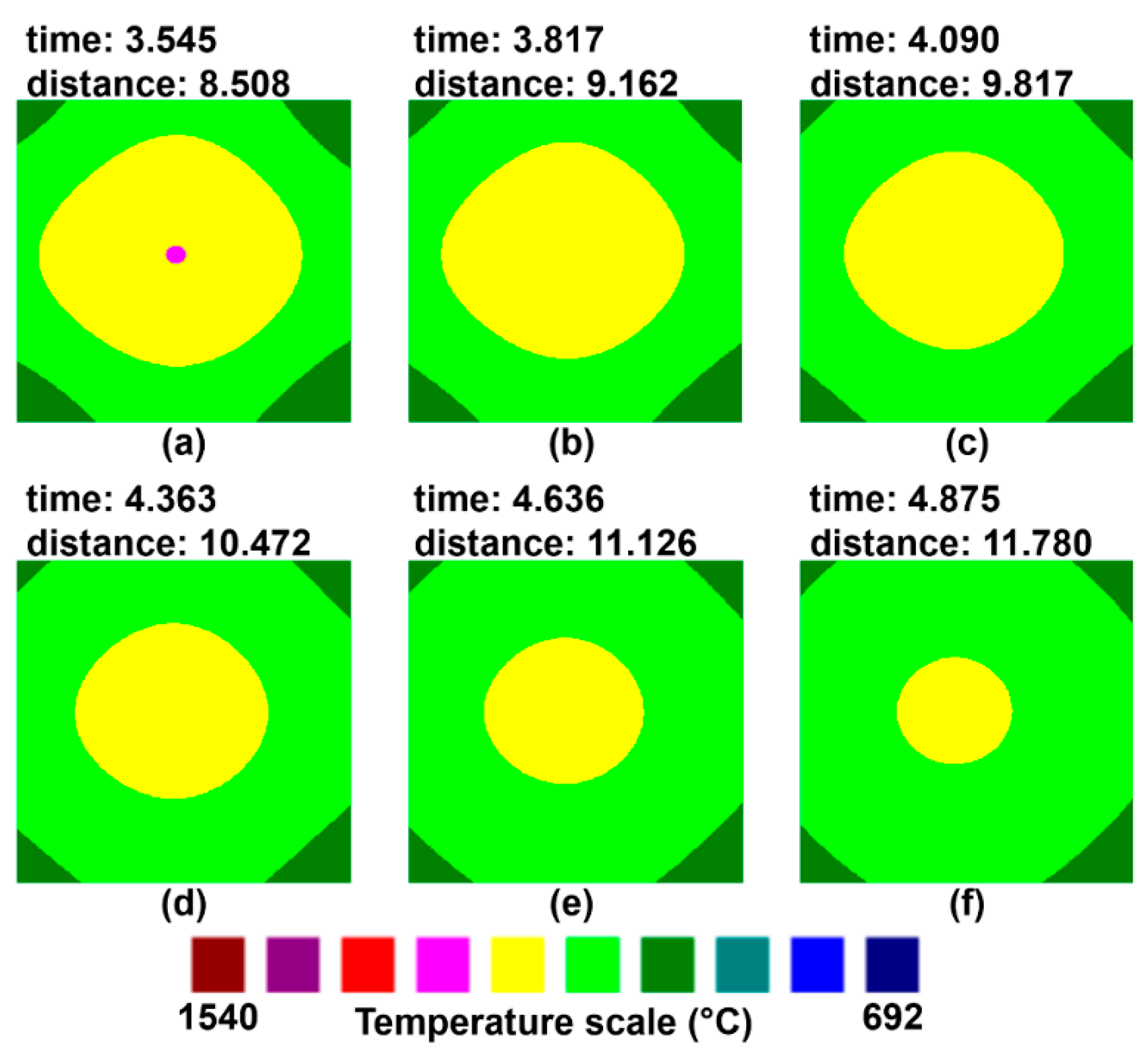

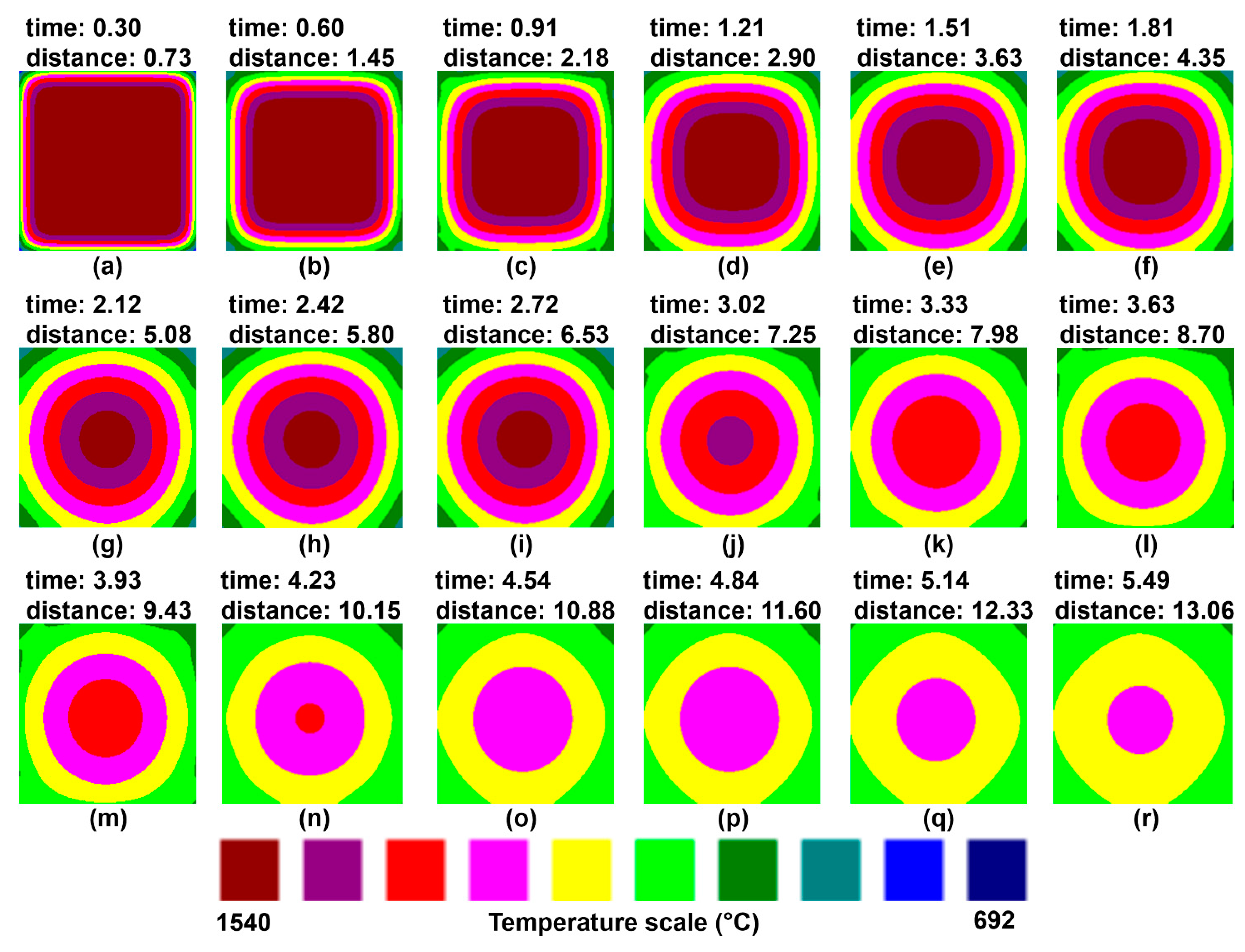

4.1. Case 1

4.1.1. Operating Conditions and Assumptions

- The steel composition is homogeneous.

- The cast speed is constant during the simulation.

- The heat removal inside the mold is constant and equal on each side of the billet.

- The operating and quenching conditions are constant during the casting operation.

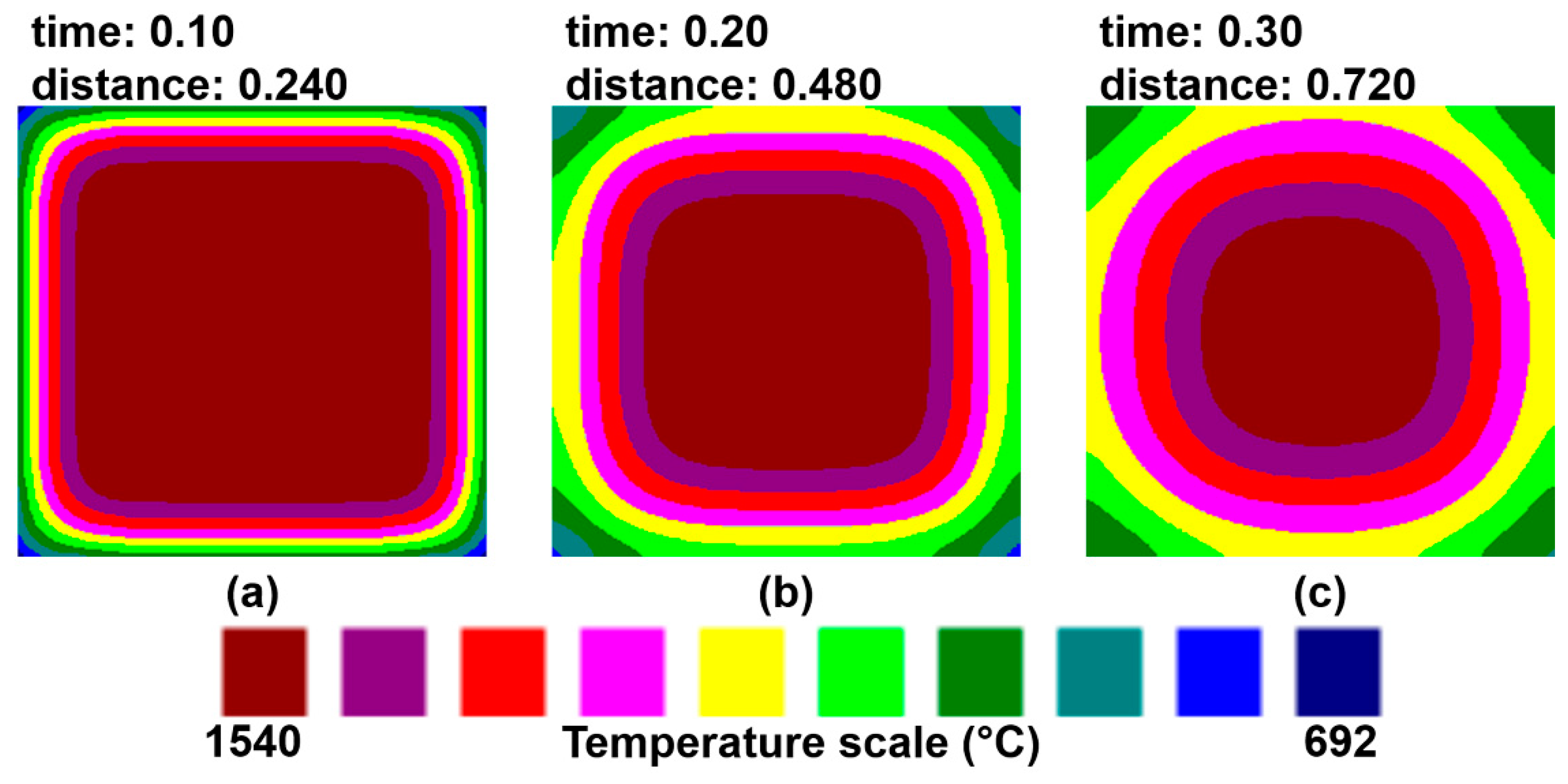

4.1.2. Simulations and Results

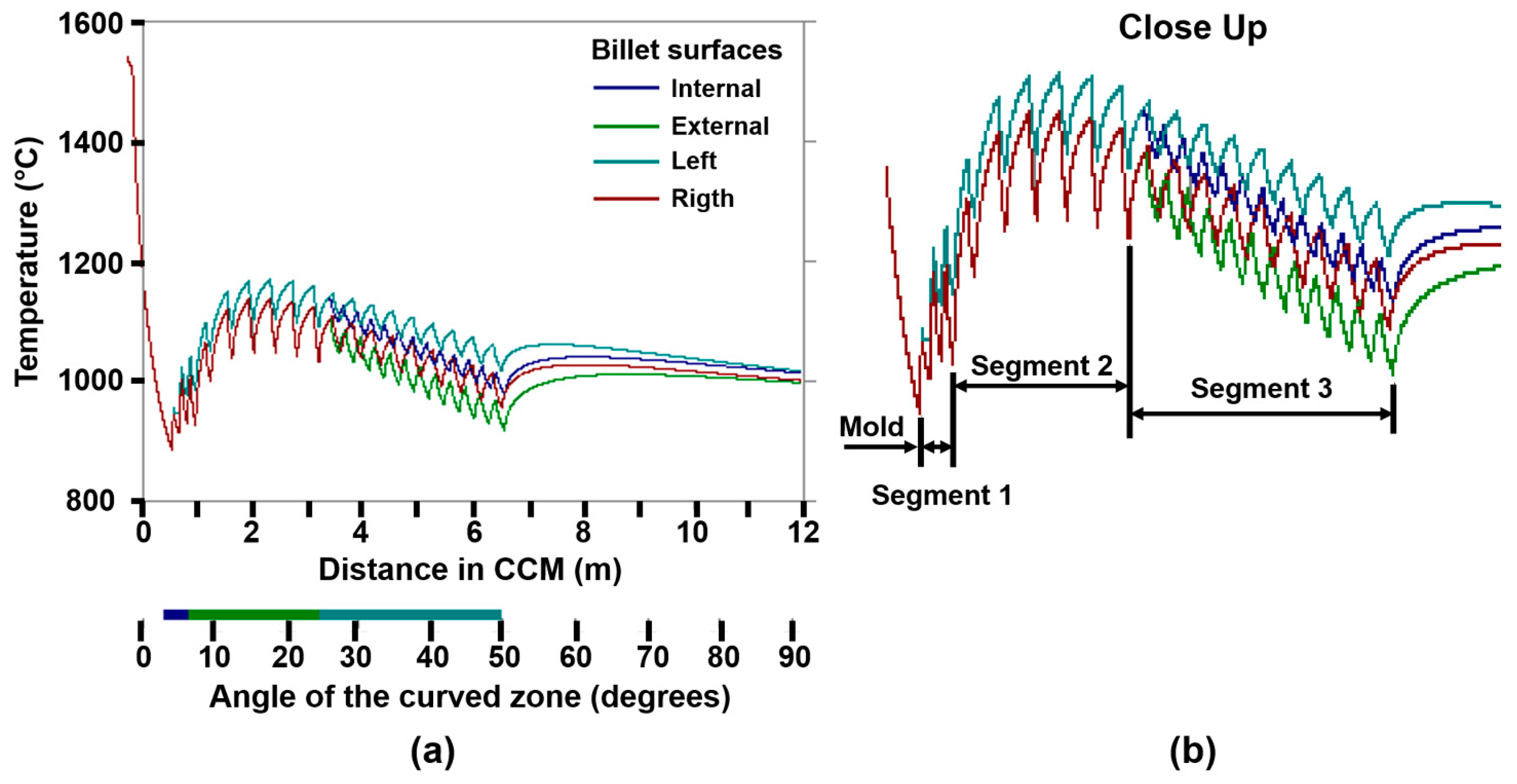

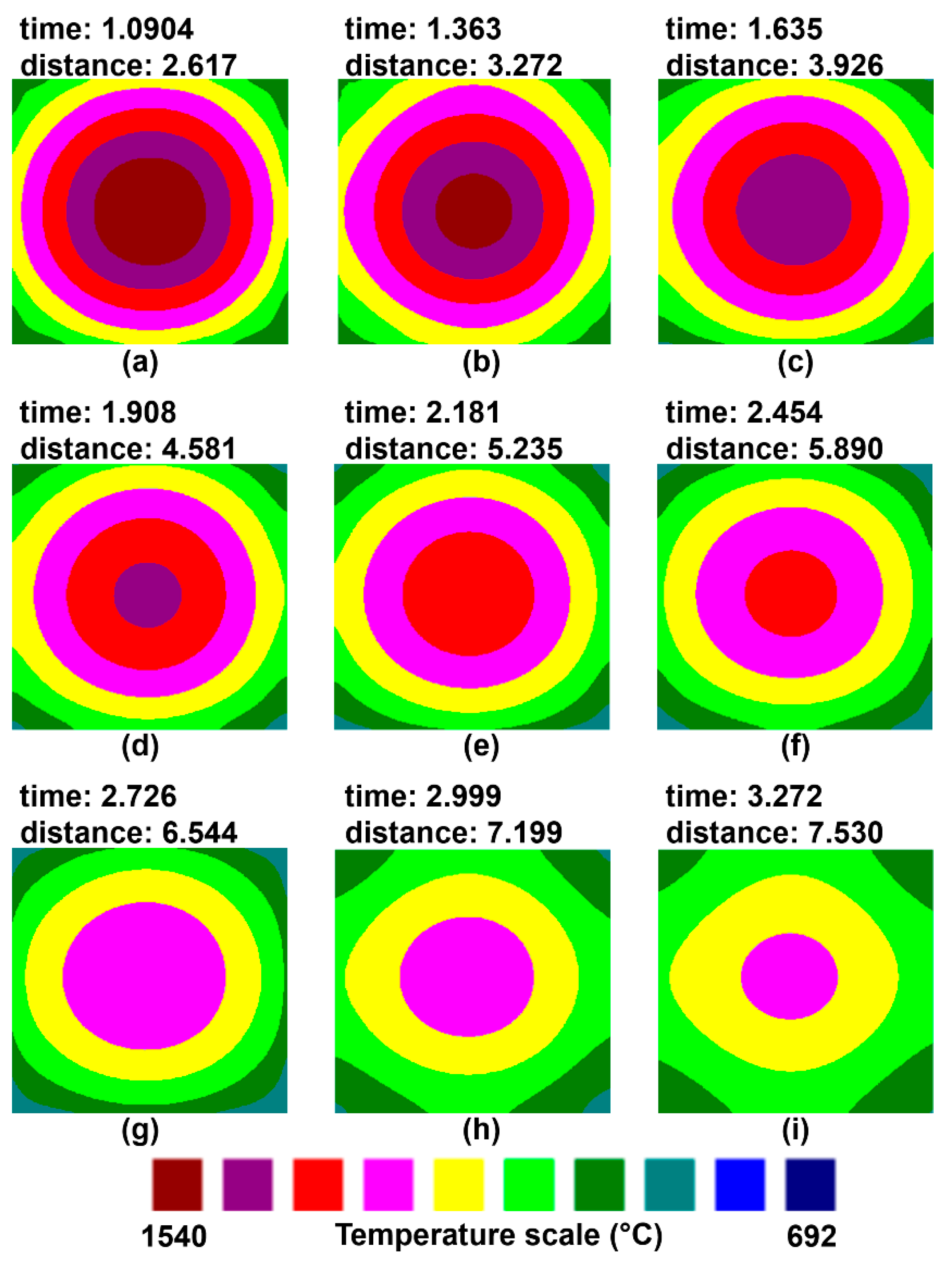

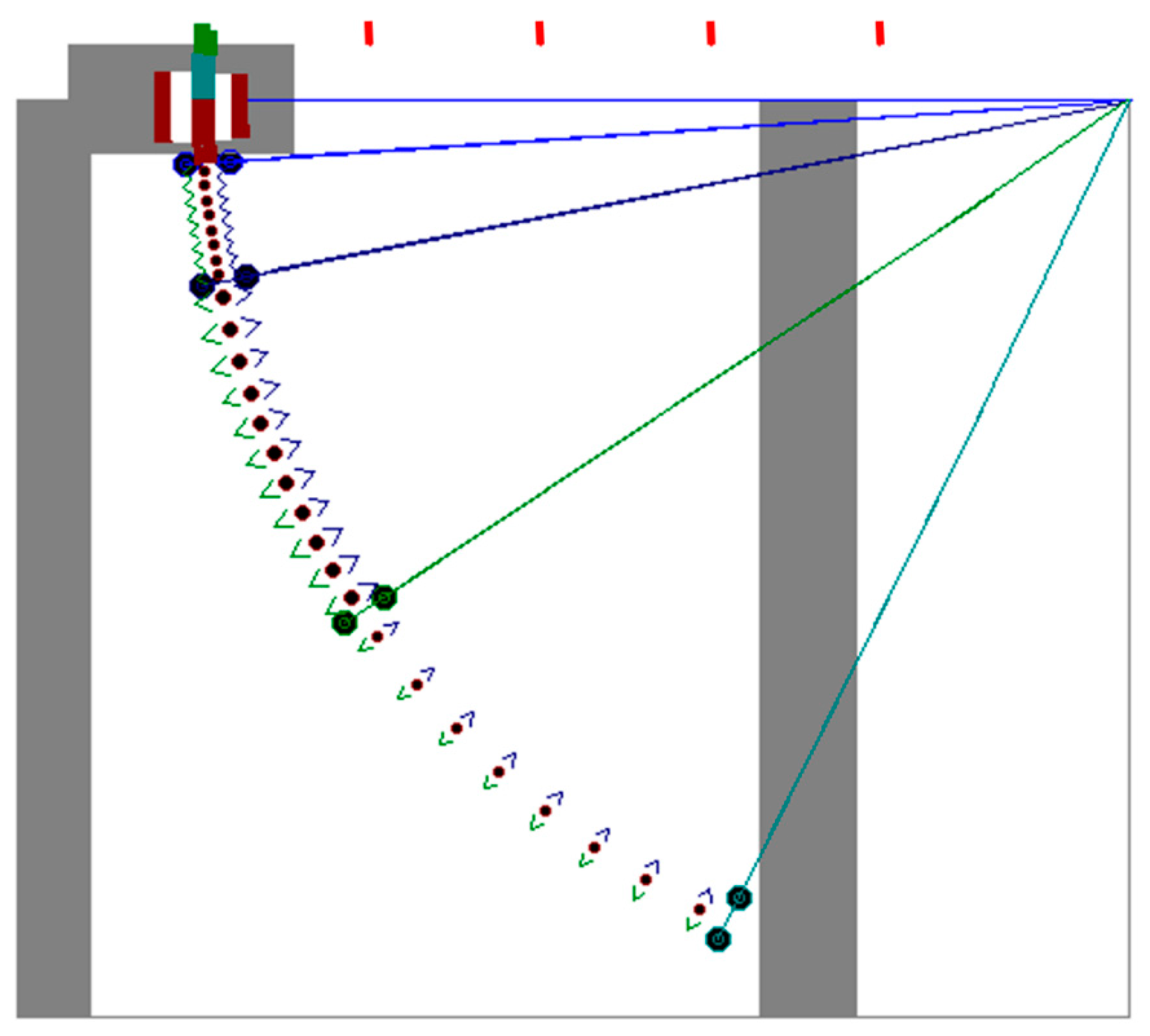

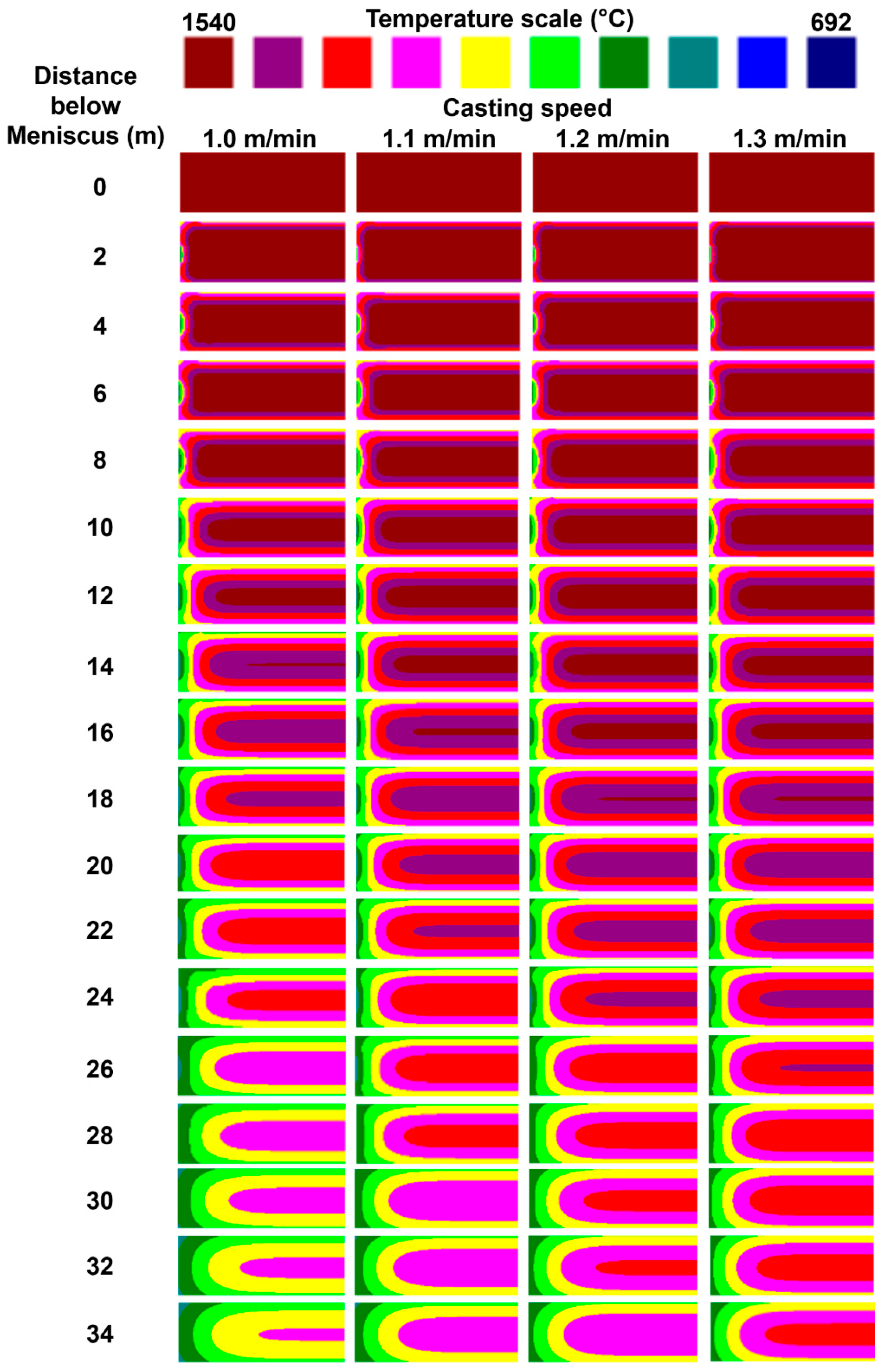

4.2. Case 2

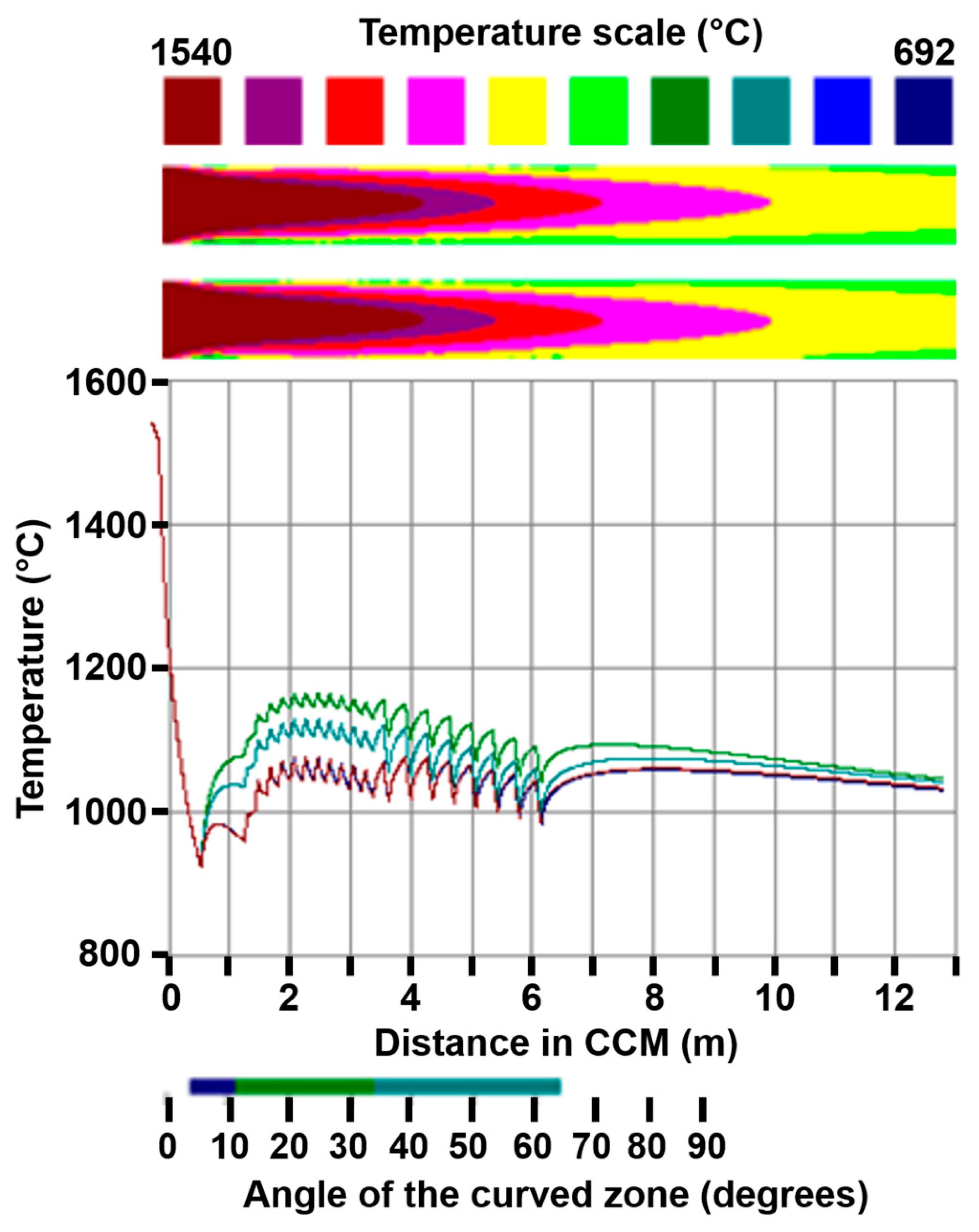

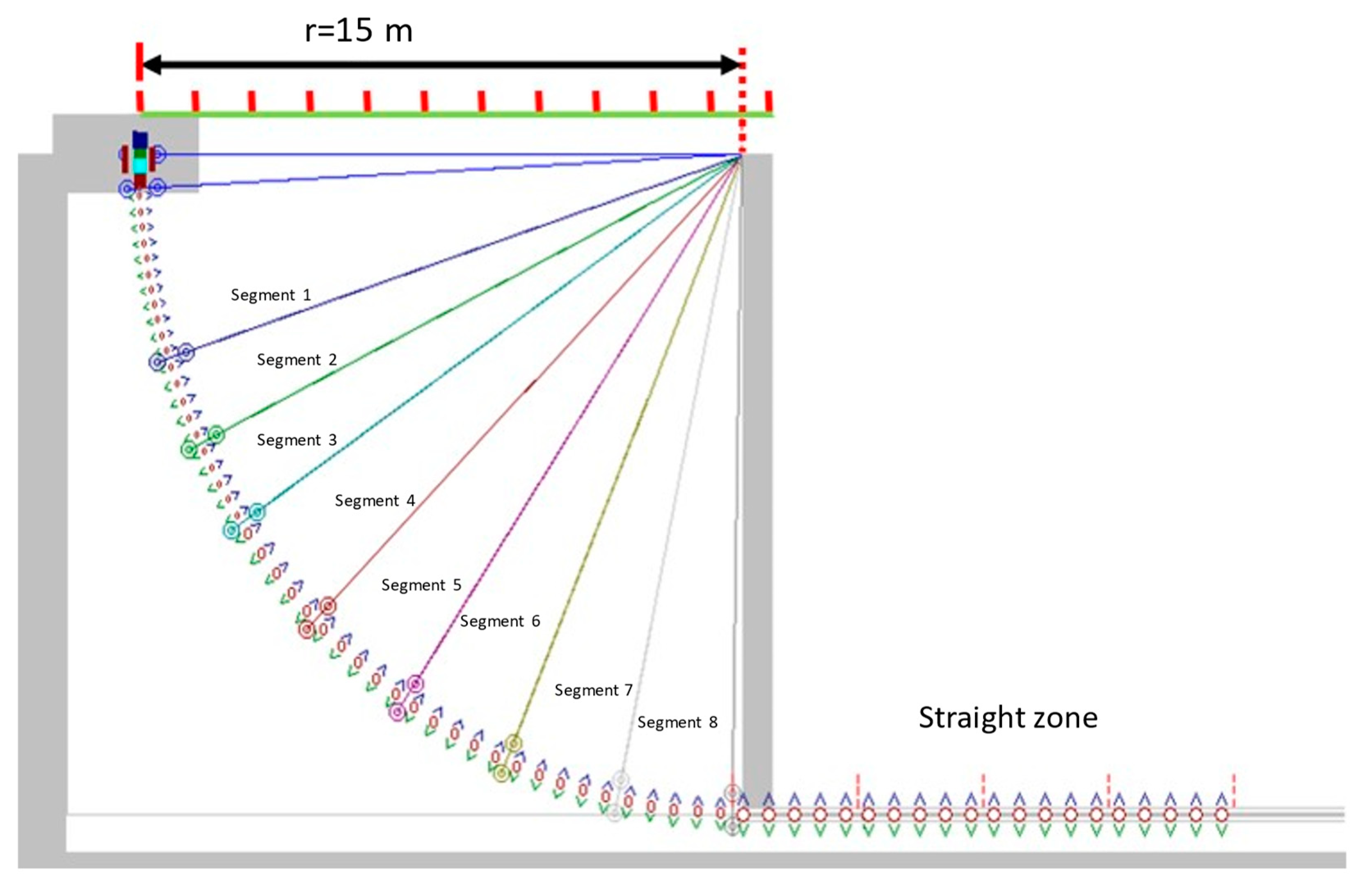

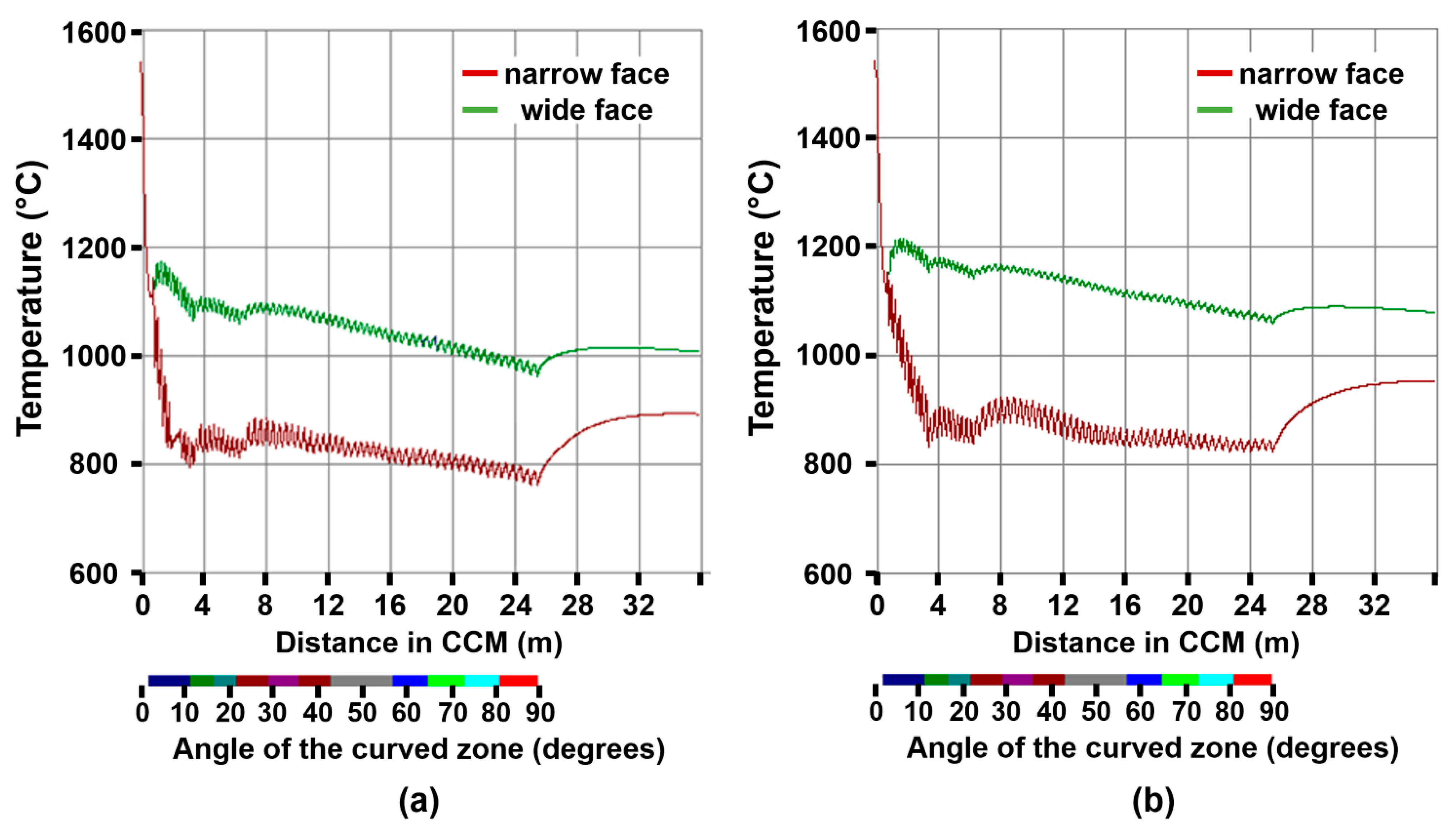

4.3. Case 3

5. Conclusions

- The direct approach of calculating the heat transfer coefficients through the appropriate dimensionless numbers, rather than through other reported empirical correlations, is suitable to predict the temperature fields in slab and billet machines.

- The surface temperatures along the casting length of slabs and billets using this algorithm match acceptably well the temperature measurements.

- The matching between the measured temperatures and those simulated indicate that the mesh size of 200 × 200 nodes is large enough to obtain reliable thermal predictions.

- The algorithm is versatile as it permits the friendly changes of different casting machines, including the use of different types of water spray nozzles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AR1 | upper austenite-ferrite transformation temperature |

| AR3 | lower austenite-peralite transformation temperature |

| Cp | heat capacity |

| D | diameter |

| h | heat transfer coefficient |

| H | enthalpy |

| k | thermal conductivity |

| l | billet side length |

| Nu | Nusselt number |

| q | heat flux |

| Pr | Prandtl number |

| Re | Reynolds number |

| T | temperature |

| t | time |

| W | mass of steel |

| Greek symbols: | |

| α | thermal diffusivity |

| Δx, Δy, and Δz | increments of distance and time |

| μ | viscosity |

| Ω | shooting angle of every spray |

| ρ | density |

| the first angle of the secondary colling system | |

| Subindexes: | |

| bs | length of billet side cooled by the spray |

| i,j | nodes in the computational mesh |

| Liq | liquidus temperature |

| m | mold |

| mushy | two-phase region of solidification depending on the steel chemistry |

| n and side | indexes to indicate that these values can differ for every segment of the SCS and every billet side |

| s | water spray |

| sol | solidus temperature |

| w | water |

| Acronyms: | |

| CCP | continuous casting process |

| PCS | primary cooling system, i.e., the mold |

| SCS | secondary cooling system, i.e., the water spray segments of a machine |

| CCM | continuous casting machine |

| TCO | casting temperature at the meniscus level |

| RC | machine radius |

References

- Blase, T.A.; Guo, Z.X.; Shi, Z.; Long, K.; Hopkins, W.G. A 3D conjugated heat transfer model for continuous wire casting. Mater. Sci. Eng. A 2004, 365, 318–324. [Google Scholar] [CrossRef]

- Brimacombe, J.K. Design of continuous casting machine based on a heat-flow analysis: State-of-the-art review. Can. Metall. Q. 1976, 15, 163–175. [Google Scholar] [CrossRef]

- Choudhary, S.K.; Mazumdar, D.; Ghosg, A. Mathematical modeling of heat transfer phenomena in continuous casting of steel. ISIJ Int. 1993, 33, 764–774. [Google Scholar] [CrossRef]

- Choudhary, S.K.; Mazumdar, D. Mathematical modeling of transport phenomena in continuous casting of steel. ISIJ Int. 1994, 34, 548–592. [Google Scholar] [CrossRef]

- Choudhary, S.K.; Mazumdar, D. Mathematical modeling of fluid flow, heat transfer and solidification phenomena in continuous casting of steel. Steel Res. Int. 1995, 66, 199–205. [Google Scholar] [CrossRef]

- Crank, J.; Nicholson, P. A practical method for numerical evaluation of partial differential equations of the heat conduction type. Proc. Camb. Philos. Soc. 1947, 43, 50–67. [Google Scholar] [CrossRef]

- Das, S.K. Evaluation of solid-liquid interface profile during continuous casting by a spline-based formalism. Bull. Mater. Sci. 2001, 24, 373–378. [Google Scholar] [CrossRef] [Green Version]

- Fachinotti, V.D.; Cardona, A. Constitutive models for steel under continuous casting conditions. J. Mater. Process. Technol. 2003, 135, 30–43. [Google Scholar] [CrossRef]

- Gerald, C.F.; Wheatley, P.O. Applied Numerical Analysis; Addison Wesley Publishing: Boston, MA, USA, 1994; pp. 6116–6158. [Google Scholar]

- Hibbins, S.G. Characterization of Heat Transfer in the Secondary Cooling System of a Continuous Slab Caster. Master’s Thesis, Materials Engineering, University of British Columbia, Vancouver, BC, Canada, 1982. [Google Scholar]

- Janik, M.; Dyja, H. Modeling of three-dimensional temperature field inside the mold during continuous casting of steel. J. Mater. Process. Technol. 2004, 157–158, 177–182. [Google Scholar] [CrossRef]

- Kulkarni, M.S.; Subash Babu, A. Manging quality in continuous casting process using product quality model and simulated anneling. J. Mater. Process. Technol. 2005, 166, 294–306. [Google Scholar] [CrossRef]

- Lait, J.; Brimacombe, J.K.; Weinberg, F. Mathamatical modelling of heat flow in the continuous casting of steel. Ironmak. Steelmak. 1974, 2, 90–98. [Google Scholar]

- Li, B.Q. Numerical simulation of flow and temperature evolution during the initial phase of steady-state solidification. J. Mater. Process. Technol. 1997, 71, 402–413. [Google Scholar] [CrossRef]

- Louhenkilpi, S.; Laitinen, E.; Nienminen, R. Real-time simulation of heat transfer in continuous casting. Metall. Mater. Trans. B 1993, 24, 685–693. [Google Scholar] [CrossRef]

- Louhenkilpi, S. Simulation and Control of Heat Transfer in Continuous Casting of Steel; Acta Polytechnica Scandinavica, Chemical Tech. Series No. 230; The Finish Academy of Technology: Espoo, Finland, 1995. [Google Scholar]

- Oliveira, M.J.; Malheiros, L.F.; Silva Ribeiro, C.A. Evaluation of the heat of solidification of cast irons from continuous cooling curves. J. Mater. Process. Technol. 1999, 92–93, 25–30. [Google Scholar] [CrossRef]

- British Iron and Steel Research Association. Physical Constant of Some Commercial Steels at Elevated Temperatures; Butteworths Scientific Publations: London, UK, 1978; pp. 1–38. [Google Scholar]

- Ruhul Amin, M.; Mahajan, A. Modeling of turbulent heat transfer during the solidification process of continuous castings. J. Mater. Process. Technol. 2006, 174, 155–166. [Google Scholar] [CrossRef]

- Savage, J.; Pritchard, W.H. The problem of rupture of the billet in the continuous casting of steel. J. Iron Steel Inst. 1954, 178, 269–277. [Google Scholar]

- Zhang, L.; Rong, Y.M.; Shen, H.F.; Huang, T.Y. Solidification modeling in continuous casting by finite point method. J. Mater. Process. Technol. 2007, 192–193, 511–517. [Google Scholar] [CrossRef]

- Thomas, B.G.; Samarasekera, I.V.; Brimacombe, J.K. Comparison of numerical modeling techniques for complex, two-dimensional, transient heat-conduction problems. Met. Mater. Trans. B 1984, 15, 307–318. [Google Scholar] [CrossRef] [Green Version]

- Ramírez-López, A.; Aguilar-López, R.; Palomar-Pardavé, M.; Romero-Romo, M.A.; Muñóz-Negrón, D. Simulation of heat transfer in steel billets during continuous casting. Int. J. Miner. Metall. Mater. 2010, 17, 403–416. [Google Scholar] [CrossRef]

- Ramírez-López, A.; Aguilar-López, A.; Kunold-Bello, A.; González-Trejo, J.; Palomar-Pardavé, M. Simulation factors of steel continuous casting. Int. J. Miner. Metall. Mater. 2010, 17, 267–275. [Google Scholar] [CrossRef]

- Dauby, P.H.; Assar, M.B.; Lawson, G.D. PIV and MFC measurements in a continuous caster mould. New tools to penetrate the caster black box. La Rev. Metall.-CIT 2001, 98, 353–366. [Google Scholar] [CrossRef]

- Thomas, B.G. Chapter 14. Fluid Flow in the Mold. In Making, Shaping and Treating of Steel: Continuous Casting; Cramb, A., Ed.; AISE Steel Foundation: Pittsburgh, PA, USA, 2003; pp. 14.1–14.41. [Google Scholar]

- Thomas, B.G. Modeling of Continuous Casting Defects Related to Mold Fluid Flow. Iron Steel Technol. 2006, 3, 128–143. [Google Scholar]

- Yuan, Q.; Zhao, B.; Vanka, S.P.; Thomas, B.G. Study of computational issues in simulation of transient flow in continuous casting. Steel Res. Int. 2005, 76, 33–43. [Google Scholar] [CrossRef]

- Emling, W.H.; Waugaman, T.A.; Feldbauer, S.L.; Cramb, A.W. Subsurface mold slag entrainment in ultra-low carbon steels. In Steelmaking Conference Proceedings; The Iron and Steel Society: Warrendale, PA, USA, 1994; pp. 371–379. [Google Scholar]

- Zhao, B.; Thomas, B.G.; Vanka, S.P.; O’Malley, R.J. Transint fluid flow and superheat transport in continuous casting of steel slabs. Metall. Mater. Trans. B 2005, 36, 801–823. [Google Scholar] [CrossRef] [Green Version]

- Thomas, B.G.; O’Malley, R.; Shi, T.; Meng, Y.; Creech, D.; Stone, D. Validation of fluid flow and solidification simulation of a continuous thin slab caster. In Proceedings of the Ninth International Conference on Modeling of Casting, Welding and Advanced Solidification Processes, Aachen, Germany, 20–25 August 2000; pp. 769–776. [Google Scholar]

- Su, W.; Wang, W.; Luo, S.; Jiang, D.; Zhu, M. Heat transfer and central segregation of continuous cast high carbon steel billets. J. Iron Steel Res. Int. 2014, 21, 565–574. [Google Scholar] [CrossRef]

- Yu, Y.; Luo, X. Identification of heat transfer coefficients of steel billet in continuous casting by weight least square and improved difference evolution method. Appl. Therm. Eng. 2017, 114, 36–43. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, D.F.; Zhang, C.Q.; Wang, S.G.; Hwang, W.S. Dynamic spray cooling control model based on the tracking of velocity and superheat for the continuous casting steel. J. Mater. Process. Technol. 2016, 229, 651–658. [Google Scholar] [CrossRef]

- Ramírez-López, A.; Muñoz-Negrón, D.; Palomar-Pardavé, M.; Romero-Romo, A.; Cruz-Morales, V. Using finite-difference to solve heat removal in metallic sections industrially produced. AIP Conf. Proc. 2012, 1479, 2302. [Google Scholar]

- Ramírez-López, A.; Muñoz-Negrón, D.; Palomar-Pardavé, M.; Romero-Romo, M.A.; Gonzalez-Trejo, J. Heat removal analysis on steel billets and slabs produced by continuous casting using numerical simulation. Int. J. Adv. Manuf. Technol. 2017, 93, 1545–1565. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Chen, D.F.; Zhang, C.Q.; Wang, S.G.; Hwang, W.S.; Han, M.R. Effects of an even secondary cooling mode on the temperature and stress fields of round billet continuous casting steel. J. Mater. Process. Technol. 2015, 222, 315–326. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, M.; Wang, X.; Zhang, X.; Yang, L.; Lu, H.; Wang, X. Inverse problem-coupled heat transfer model for steel continuous casting. J. Mater. Process. Technol. 2014, 214, 44–49. [Google Scholar] [CrossRef]

- Lally, B.; Biegler, L.; Henein, H. Finite difference heat-transfer modeling for continuous casting. Metall. Mater. Trans. B 1990, 21, 761–770. [Google Scholar] [CrossRef]

- Chen, Y.; Peng, Z.; Wu, L.; Zhao, L.; Wang, M.; Bao, Y. High-precision numerical simulation for the effect of casting speed on solidification of 40Cr during continuous billet casting. La Metall. Ital. 2015, 1, 47–51. [Google Scholar]

- O’Connor, T.G.; Dantzing, J.A. Modeling the thin-slab continuous-casting mold. Metall. Mater. Trans. B 1994, 25, 443–457. [Google Scholar] [CrossRef]

- Ramírez-López, A.; Muñoz-Negrón, D.; Romero-Hernández, S.; Cruz-Morales, V.; Escalera-Pérez, R. Thermal behavior of cast steel industrially produced. Adv. Mater. Res. 2012, 628, 179–182. [Google Scholar] [CrossRef]

- Ramírez, A.; Mosqueda, A.; Sauce, V.; Morales, R.; Ramos, A.; Solorio, G. Desarrollo de simuladores para procesos industriales. Parte II (colada continua). Rev. Metal. 2006, 42, 209–215. [Google Scholar]

| Cast Speed (m/min) | Casting Temperature (°C) | RC (m) | |||

|---|---|---|---|---|---|

| 2.40 | 1535 | 7.45 | 5.8 | 130 | 130 |

| Tariq (°C) | Tsol (°C) | TAR3 (°C) | TAR1 (°C) |

|---|---|---|---|

| 1524.38 | 1507.85 | 844.07 | 721.04 |

| C | Al | Cr | Cu | Mn | Nb | Mo |

| 0.380 | 0.003 | 0.05 | 0.040 | 1.050 | 0.002 | 0.002 |

| Ni | P | Ti | S | Si | Sn | V |

| 0.006 | 0.014 | 0.002 | 0.018 | 0.200 | 0.001 | 0.002 |

| Segment | 1 | 2 | 3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Surface | Internal | External | Left | Right | Internal | External | Left | Right | Internal | External | Left | Right |

| Water flow rate (L/min) | 7 | 10 | 7 | 10 | 7 | 10 | 7 | 10 | 7 | 10 | 7 | 10 |

| Sprays on cast direction | 3 | 3 | 3 | 3 | 6 | 6 | 6 | 6 | 13 | 12 | 9 | 9 |

| Sprays on the lateral direction | 2 | 2 | 2 | 2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Nozzle diameter (m) | 0.003 | 0.003 | 0.003 | |||||||||

| 50 | 60 | 60 | ||||||||||

| 60 | 50 | 50 | ||||||||||

| (m) | 0.083 | 0.100 | 0.100 | |||||||||

| 3 | 17 | 25 | ||||||||||

| Segment | 1 | 2 | 3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Surface | Internal | External | Left | Right | Internal | External | Left | Right | Internal | External | Left | Right |

| Water flow rate (L/min) | 15 | 15 | 25 | 22 | 12 | 12 | 17 | 15 | 9 | 9 | 12 | 10 |

| Sprays on cast direction | 8 | 11 | 8 | |||||||||

| Sprays on the lateral direction | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Nozzle diameter (m) | 0.003 | |||||||||||

| 7.50 | 22.5 | 30 | ||||||||||

| 80 | 60 | 60 | ||||||||||

| (m) | 0.060 | 0.110 | 0.075 | |||||||||

| Cast Temperature (°C) | RC (m) | θ0 | Narrow Side Dx (mm) | Broad Side Dy (mm) | Mold Length (m) | Meniscus Level (%) |

|---|---|---|---|---|---|---|

| 1545 | 10.5 | 23.5 | 200 | 1100 | 1.10 | 82 |

| Zone | θ | Σθ | Rd (m) | Ω | Sprays on Casting Direction | ds′ZN (mm) | dw′ZN (mm) | dnw′ZN (mm) |

|---|---|---|---|---|---|---|---|---|

| Curved Zone | ||||||||

| 1 | 12 | 18 | 3.29 | 60 | 11 | 500 | 329 | 171 |

| 2 | 8 | 26 | 4.76 | 55 | 5 | 500 | 467 | 33 |

| 3 | 8 | 34 | 6.23 | 50 | 5 | 500 | 467 | 33 |

| 4 | 11 | 45 | 8.24 | 50 | 5 | 750 | 660.5 | 89.5 |

| 5 | 11 | 56 | 10.26 | 50 | 5 | 750 | 660.5 | 89.5 |

| 6 | 11 | 67 | 12.28 | 50 | 5 | 750 | 660.5 | 89.5 |

| 7 | 11 | 78 | 14.29 | 50 | 5 | 750 | 660.5 | 89.5 |

| 8 | 10 | 88 | 16.30 | 50 | 5 | 750 | 660.5 | 89.5 |

| Straight Zone | ||||||||

| Zone | Rd (m) | Ω | Sprays | ds′ZN (mm) | dw′ZN (mm) | dnw′ZN (mm) | ||

| 9 | 18.61 | 55 | 5 | 750 | 630.4 | 119.6 | ||

| 10 | 20.92 | 55 | 5 | 750 | 630.4 | 119.6 | ||

| 11 | 23.22 | 55 | 5 | 750 | 630.4 | 119.6 | ||

| 12 | 25.52 | 55 | 5 | 750 | 630.4 | 119.6 | ||

| Zone | Sprays on the Lateral Direction | Nozzle Diameter (mm) | Ω | Dbs (mm) |

|---|---|---|---|---|

| 1 | 5 | 2.5 | 40 | 180 |

| 2 | 5 | 2.5 | 40 | 180 |

| 3 | 4 | 2.5 | 45 | 150 |

| 4 | 4 | 2.5 | 45 | 150 |

| 5 | 3 | 3 | 30 | 120 |

| 6 | 3 | 3 | 30 | 120 |

| 7 | 3 | 3 | 30 | 120 |

| 8 | 3 | 3 | 30 | 120 |

| 9 | 3 | 3 | 30 | 120 |

| 10 | 3 | 3 | 30 | 120 |

| 11 | 3 | 3 | 30 | 120 |

| 12 | 3 | 3 | 30 | 120 |

| Distance below Meniscus (m) | Temperature Measured (°C) | Temperature Simulated (Lowest) 200 × 200 Mesh (°C) | ΔT (°C) | Temperature Simulated (Highest) 200 × 200 Mesh (°C) | ΔT (°C) |

|---|---|---|---|---|---|

| 2.25 | 1072 | 1065 | −7 | 1080 | 8 |

| 3.75 | 1111 | 1070 | −41 | 1125 | 14 |

| 4.8 | 1080 | 1050 | −30 | 1098 | 18 |

| 5.0 | 1054 | 1017 | −37 | 1089 | 35 |

| 5.4 | 1050 | 1020 | −30 | 1075 | 25 |

| 7.0 | 1035 | 995 | −40 | 1052 | 17 |

| 7.5 | 1033 | 1002 | −31 | 1045 | 12 |

| 8.0 | 1024 | 1010 | −14 | 1037 | 13 |

| 8.5 | 1024 | 1012 | −12 | 1031 | 7 |

| 9.0 | 1022 | 1012 | −10 | 1025 | 3 |

| 9.5 | 1025 | 1010 | −15 | 1022 | −3 |

| 10 | 1015 | 1006 | −9 | 1017 | 2 |

| 10.5 | 1010 | 1004 | −6 | 1014 | 4 |

| Distance Below Meniscus (m) | Temperature Measured (°C) | Temperature Simulated (Lowest) 200 × 200 Mesh (°C) | ΔT (°C) | Temperature Simulated (Highest) 200 × 200 Mesh (°C) | ΔT (°C) |

|---|---|---|---|---|---|

| 1 | 975 | 920 | −55 | 1040 | 65 |

| 2.5 | 1095 | 1040 | −55 | 1140 | 45 |

| 3.0 | 1095 | 1030 | −65 | 1135 | 40 |

| 4.1 | 1090 | 1025 | −65 | 1120 | 30 |

| 4.9 | 1056 | 1001 | −55 | 1108 | 52 |

| 5.5 | 1045 | 980 | −65 | 1099 | 54 |

| 6.0 | 1035 | 976 | −59 | 1084 | 49 |

| 6.5 | 1031 | 970 | −61 | 1068 | 37 |

| 7.0 | 1035 | 980 | −55 | 1095 | 60 |

| 7.5 | 1030 | 962 | −68 | 1072 | 42 |

| 8.0 | 1048 | 995 | −53 | 1051 | 3 |

| 8.5 | 1025 | 1001 | −24 | 1047 | 22 |

| 9.0 | 1025 | 1003 | −22 | 1041 | 16 |

| 9.5 | 1020 | 1002 | −18 | 1034 | 14 |

| 10 | 1021 | 999 | −22 | 1028 | 7 |

| Distance below Meniscus (m) | Temperature Measured (°C) | Temperature Simulated 550 × 100 Mesh (°C) | ΔT (°C) |

|---|---|---|---|

| 24 | 800 | 810 | 10 |

| 26 | 795 | 807 | 12 |

| 28 | 850 | 842 | −8 |

| 30 | 860 | 851 | −9 |

| 32 | 882 | 874 | −8 |

| 34 | 890 | 883 | −7 |

| 36 | 886 | 881 | −5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramírez-López, A.; Dávila-Maldonado, O.; Nájera-Bastida, A.; Morales, R.D.; Rodríguez-Ávila, J.; Muñiz-Valdés, C.R. Analysis of Non-Symmetrical Heat Transfers during the Casting of Steel Billets and Slabs. Metals 2021, 11, 1380. https://doi.org/10.3390/met11091380

Ramírez-López A, Dávila-Maldonado O, Nájera-Bastida A, Morales RD, Rodríguez-Ávila J, Muñiz-Valdés CR. Analysis of Non-Symmetrical Heat Transfers during the Casting of Steel Billets and Slabs. Metals. 2021; 11(9):1380. https://doi.org/10.3390/met11091380

Chicago/Turabian StyleRamírez-López, Adán, Omar Dávila-Maldonado, Alfonso Nájera-Bastida, Rodolfo D. Morales, Jafeth Rodríguez-Ávila, and Carlos Rodrigo Muñiz-Valdés. 2021. "Analysis of Non-Symmetrical Heat Transfers during the Casting of Steel Billets and Slabs" Metals 11, no. 9: 1380. https://doi.org/10.3390/met11091380

APA StyleRamírez-López, A., Dávila-Maldonado, O., Nájera-Bastida, A., Morales, R. D., Rodríguez-Ávila, J., & Muñiz-Valdés, C. R. (2021). Analysis of Non-Symmetrical Heat Transfers during the Casting of Steel Billets and Slabs. Metals, 11(9), 1380. https://doi.org/10.3390/met11091380