Effect of Pre-Strain on Microstructure and Tensile Properties of Ti-6Al-4V at Elevated Temperature

Abstract

:1. Introduction

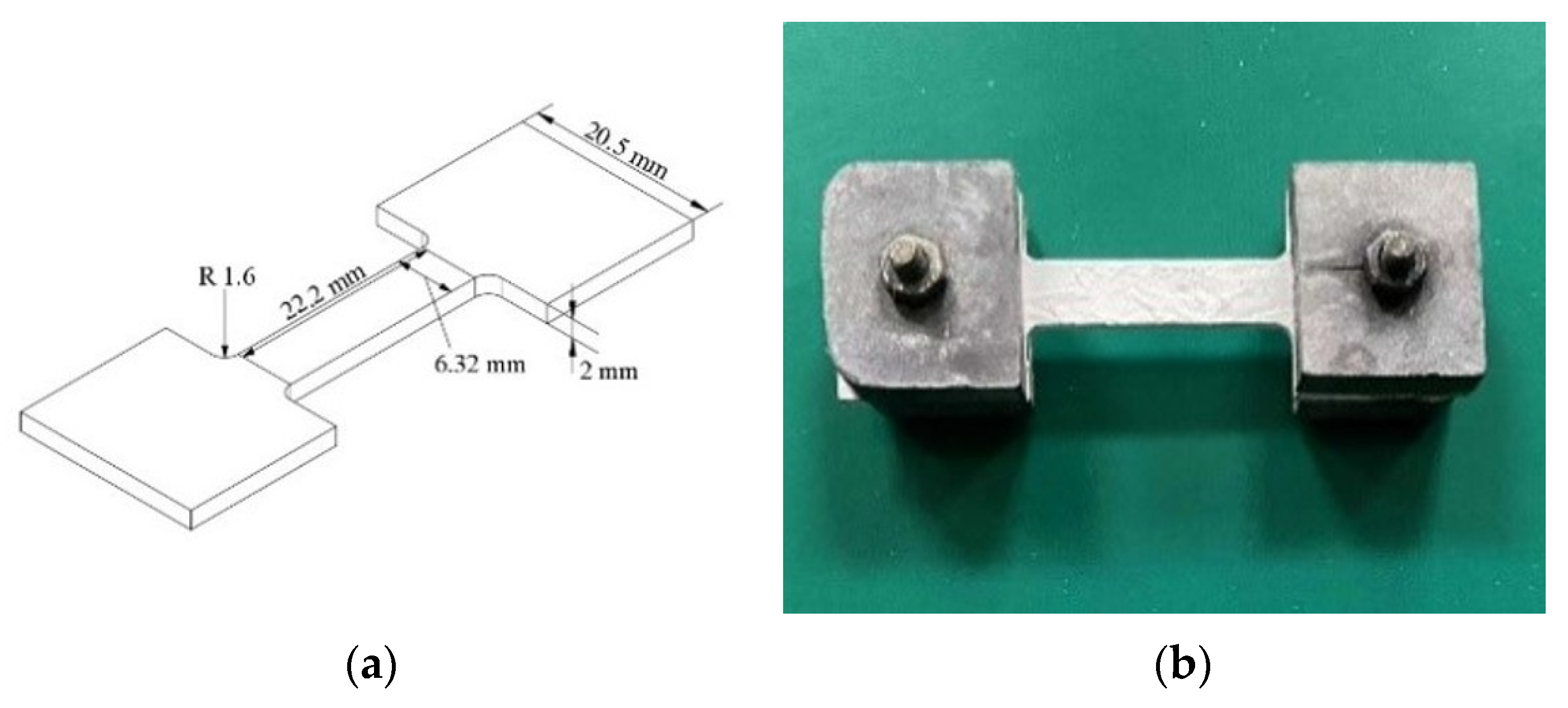

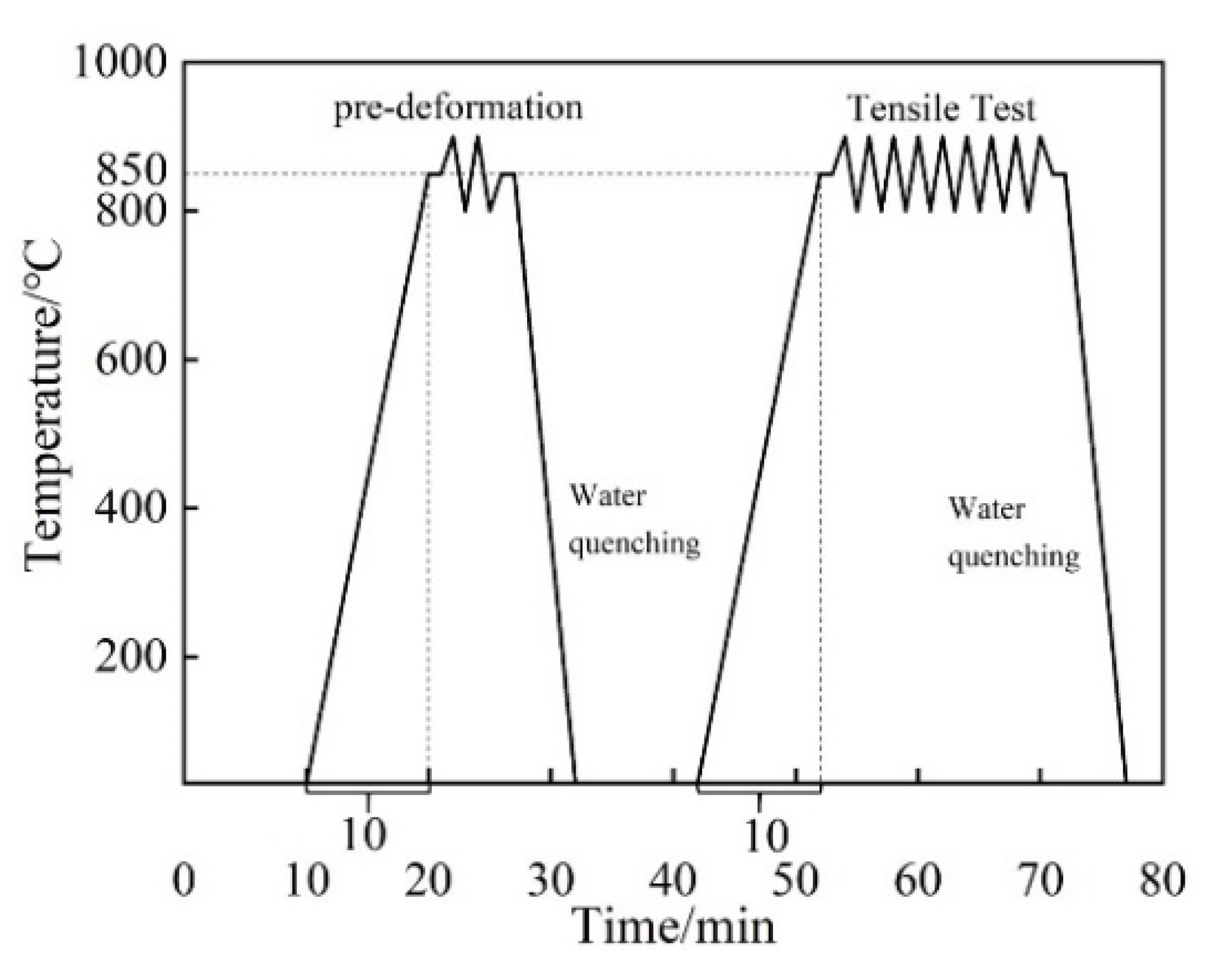

2. Materials and Methods

3. Results and Discussion

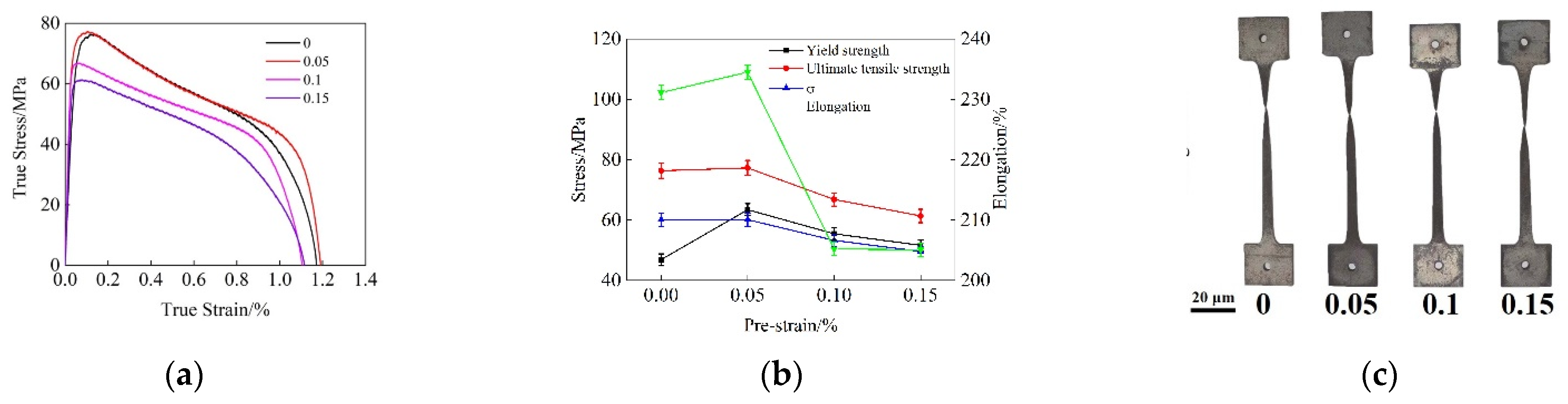

3.1. Hot Tensile Properties of Specimens with Pre-Strain

3.2. Microstructure Evolution during Hot Tensile Test

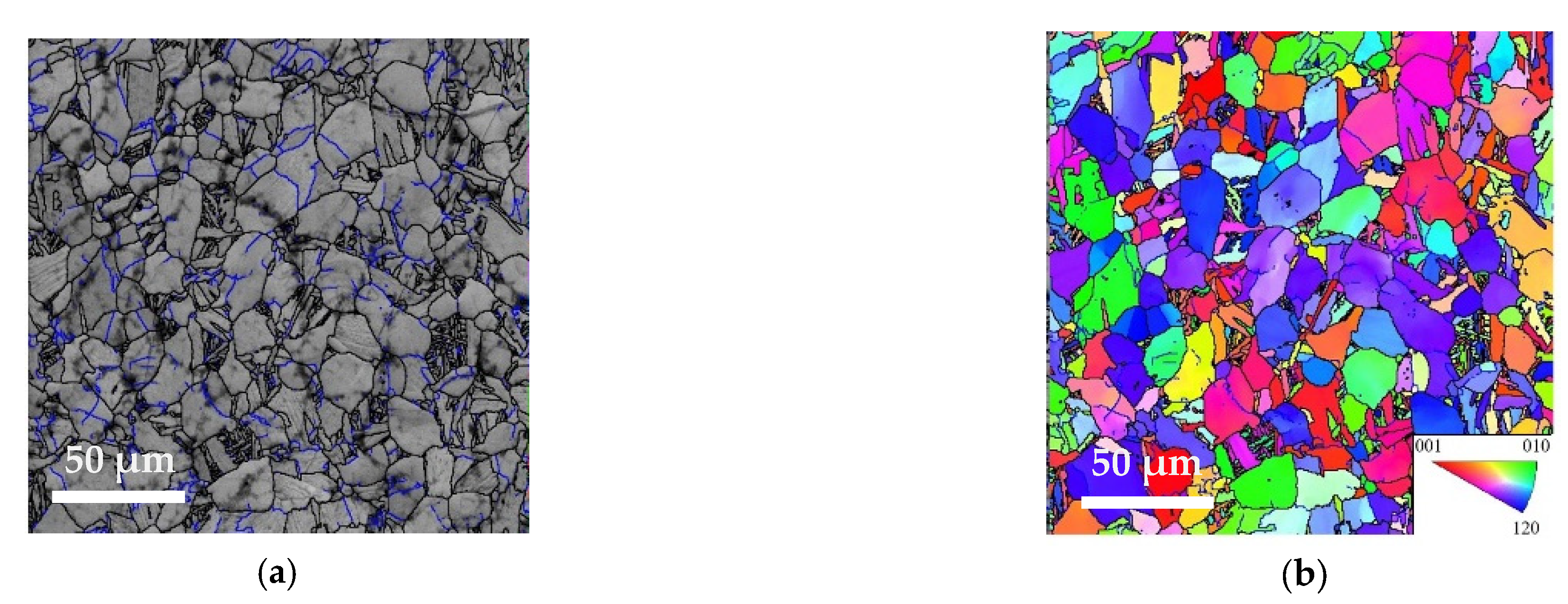

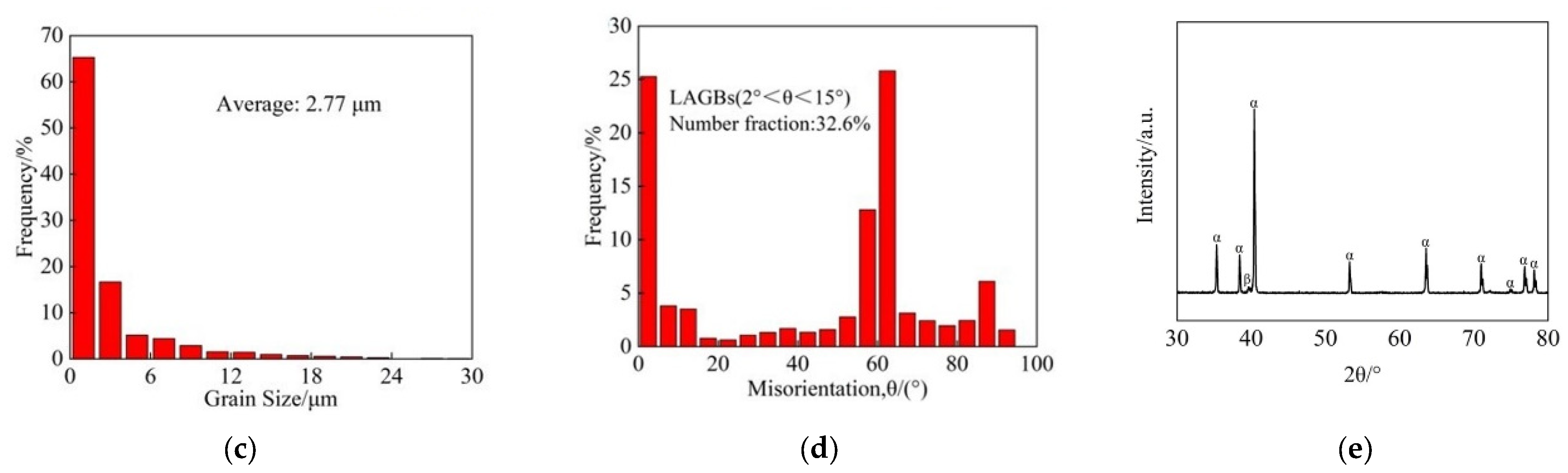

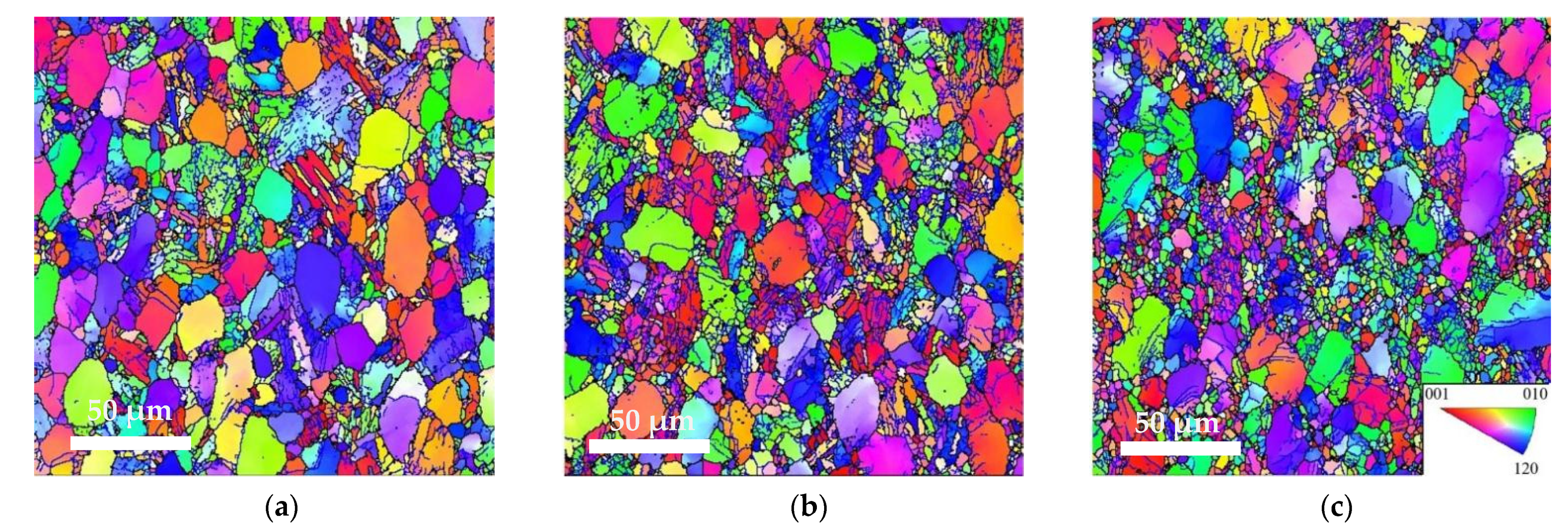

3.2.1. Initial Microstructure

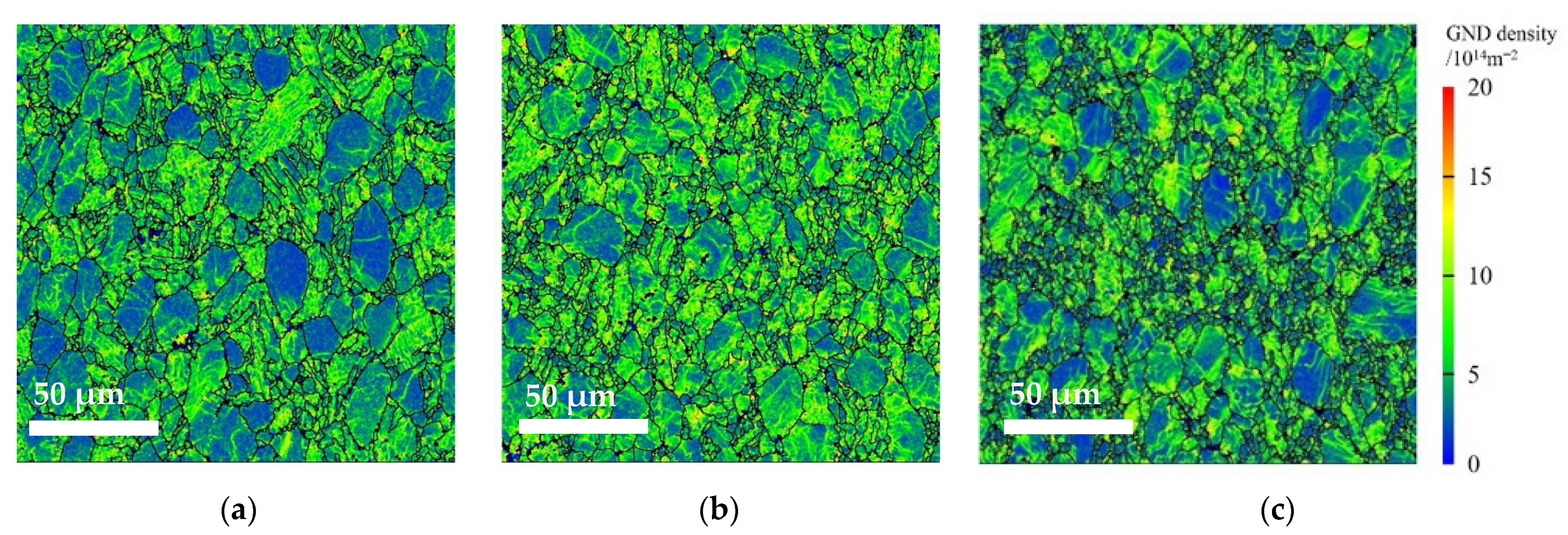

3.2.2. Microstructures of Specimens without Pre-Strain

3.2.3. Microstructure of Specimens with Pre-Strain

4. Conclusions

- The deformation behavior of Ti-6Al-4V titanium alloys with different pre-deformation was studied. When the pre-strain was 0.05, the elongation of the specimen was the highest: 234.5%. When the pre-strain reached 0.15, the ultimate tensile strength was the lowest: 66.8 MPa. The hot-forming performance of Ti-6Al-4V increased first and then decreased with the increase in pre-strain;

- During the hot tensile deformation, the deformation mechanism of Ti-6Al-4V was dominated by high-angle grain boundaries sliding. Dislocation movement also played an important role in the hot deformation process, which could be considered as the adjustment process of grain boundary sliding. In the non-pre-deformed specimen, the recrystallized grains all appeared at the grain boundary, indicating that the dynamic recrystallization was dominated by discontinuous dynamic recrystallization;

- Pre-deformation provides more deformation substructures for subsequent deformation and promotes dynamic recrystallization of the material in the subsequent deformation process. Recrystallized grains appeared at the grain boundaries and inside the grains during the hot tensile process. The pre-deformation promoted both continuous dynamic recrystallization and discontinuous dynamic recrystallization, which caused major changes in mechanical properties during the hot deformation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, Z.B.; Wang, Q.J.; Liu, J.R.; Yang, R. Effect of heat treatment on the crystallographic orientation evolution in a near-α titanium alloy Ti60. Acta Mater. 2017, 131, 305–314. [Google Scholar] [CrossRef]

- Ma, L.X.; Wan, M.; Li, W.D.; Shao, J.; Bai, X.P. Constitutive modeling and processing map for hot deformation of Ti-15Mo-3Al-2.7Nb-0.2Si. J. Alloys Compd. 2019, 808, 151759. [Google Scholar] [CrossRef]

- Cui, C.X.; Hu, B.M.; Zhao, L.C.; Liu, S.J. Titanium alloy production technology, market prospects and industry development. Mater. Des. 2011, 32, 1684–1691. [Google Scholar] [CrossRef]

- Wang, Q.Q.; Liu, Z.Q. Plastic deformation induced nano-scale twins in Ti-6Al-4V machined surface with high speed machining. Mater. Sci. Eng. A 2016, 675, 271–279. [Google Scholar] [CrossRef]

- Momeni, A.; Abbasi, S.M.; Sadeghpour, S. A comparative study on the hot deformation behavior of Ti-5Al-5Mo-5V-3Cr and newly developed Ti-4Al-7Mo-3V-3Cr alloys. Vaccum 2019, 161, 401–408. [Google Scholar] [CrossRef]

- Li, W.S.; Yamasaki, S.; Mitsuhara, M.; Hakashima, H. In situ EBSD study of deformation behavior of primary α phase in a bimodal Ti-6Al-4V alloy during uniaxial tensile tests. Mater. Charact. 2020, 163, 110282. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Chown, L.H.; Merwe, J.W.; Alaneme, K.K. Hot working of Ti-6Al-4V with a complex initial microstructure. Int. J. Mater. Form. 2018, 12, 857–874. [Google Scholar] [CrossRef]

- Cui, J.H.; Yang, H.; Sun, Z.C.; Li, H.W.; Li, Z.J.; Shen, W.C. Flow behavior and constitutive model using piecewise function of strain for TC11 alloy. Rare Met. Mater. Eng. 2012, 41, 397–401. [Google Scholar]

- Liu, Z.G.; Li, P.J.; Xiong, L.T.; Liu, T.Y.; He, L.J. High-temperature deformation behavior and microstructure evolution of Ti55 titanium alloy. Mater. Sci. Eng: A 2016, 680, 259–269. [Google Scholar] [CrossRef]

- Ma, T.F.; Zhou, X.; Du, Y.; Li, L.; Zhang, L.C.; Zhang, Y.S.; Zhang, P.X. High temperature deformation and microstructure evolution of core-shell structured titanium alloy. J. Alloys Compd. 2019, 775, 316–321. [Google Scholar] [CrossRef]

- Wang, H.F.; Ban, C.Y.; Zhao, N.N.; Kang, Y.Y.; Qin, T.P.; Liu, S.T.; Cui, J.Z. Enhance strength and ductility of nano-grain titanium processed by two-step severe plastic deformation. Mater. Lett. 2020, 266, 127485. [Google Scholar] [CrossRef]

- Hajizadeh, K.; Eghbali, B. Effect of two-step severe plastic deformation on the microstructure and mechanical properties of commercial purity titanium. Met. Mater. Int. 2014, 20, 343–350. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zeipper, L.; Mingler, B.; Zehetbauer, M. Influence of post-deformation on CP-Ti processed by equal channel angular pressing. Mater. Sci. Eng. A 2008, 476, 98–105. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.T.; Raab, G.I.; Zharikov, A.I.; Valiev, R.Z. Effect of initial microstructure on the microstructural evolution and mechanical properties of Ti during cold rolling. Mater. Sci. Eng. A 2004, 385, 309–313. [Google Scholar] [CrossRef]

- Zhu, T.; Huang, J.Y.; Gubicza, J.; Ungar, T.; Wang, Y.M.; Ma, E.; Valiev, R.Z. Nanostructures in Ti processed by severe plastic deformation. J. Mater. Res. 2003, 18, 1908–1917. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.H.; Liu, C.H.; Chen, J.H.; Li, X.L.; Zhu, D.H.; Tao, G.H. Hierarchical nanostructures strengthen Al–Mg–Si alloys processed by deformation and aging. Mater. Sci. Eng. A 2013, 585, 233–242. [Google Scholar] [CrossRef]

- Sachtleber, M.; Raabe, D.; Weiland, H. Surface roughening and color changes of coated aluminum sheets during plastic straining. J. Mater. Process. Technol. 2004, 148, 68–76. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Frazier, W.G.; Prasad, Y.V.R.K. Hot Working of Commercial Ti–6Al–4V with an Equiaxed α–β Microstructure: Materials Modeling Considerations. Mater. Sci. Eng. A 2000, 284, 184–194. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, H.; Ding, H.; Fujii, H. Superplastic Deformation Mechanism of the Friction Stir Processed Fully Lamellar Ti-6Al-4V Alloy. Mater. Sci. Eng. A 2020, 785, 139390. [Google Scholar] [CrossRef]

- Belyakov, A.; Sakai, T.; Miura, H.; Kaibyshev, R.; Tsuzaki, K. Continuous recrystallization in austenitic stainless steel after large strain deformation. Acta Mater. 2002, 50, 1547–1557. [Google Scholar] [CrossRef]

- Sheppard, T.; Norley, J. Deformation Characteristics of Ti–6Al–4V. Mater. Sci. Technol. 1988, 4, 903–908. [Google Scholar] [CrossRef]

- Park, N.-K.; Yeom, J.-T.; Na, Y.-S. Characterization of Deformation Stability in Hot Forging of Conventional Ti–6Al–4V Using Processing Maps. J. Mater. Process. Technol. 2002, 130–131, 540–545. [Google Scholar] [CrossRef]

- Kumar, S.; Pavithra, B.; Singh, V.; Ghosal, P.; Raghu, T. Tensile anisotropy associated microstructural and microtextural evolution in a metastable beta titanium alloy. Mater. Sci. Eng. A 2019, 747, 1–16. [Google Scholar] [CrossRef]

- Moussa, C.; Bernacki, M.; Besnard, R.; Bozzolo, N. Statistical analysis of dislocations and dislocation boundaries from EBSD data. Ultramicroscopy 2017, 179, 63–72. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yi, Z.X.; Li, X.Q.; Pan, C. Dynamic Recrystallization Behavior and Model Study of Equiaxed Fine Grain Structure TC4. J. Phys. Conf. Ser. 2020, 1676, 012159. [Google Scholar] [CrossRef]

- Sun, Y.G.; Zhang, C.J.; Feng, H.; Zhang, S.Z.; Han, J.C.; Zhang, W.G.; Zhao, E.; Wang, H.W. Dynamic recrystallization mechanism and improved mechanical properties of a near α high temperature titanium alloy processed by severe plastic deformation. Mater. Charact. 2020, 163, 110281. [Google Scholar] [CrossRef]

- Weiss, Y.; Semiatin, S.L. Thermomechanical processing of alpha titanium alloys—An overview. Mater. Sci. Eng. A 1999, 263, 243–256. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Murzinova, M.; Salishchev, G.; Semiatin, S.L. Spheroidization of the lamellar microstructure in Ti–6Al–4V alloy during warm deformation and annealing. Acta Mater. 2011, 59, 4138–4150. [Google Scholar] [CrossRef]

- Matsumoto, H.; Velay, V. Mesoscale modeling of dynamic recrystallization behavior, grain size evolution, dislocation density, processing map characteristic, and room temperature strength of Ti-6Al-4V alloy forged in the (α+β) region. J. Alloys Compd. 2017, 708, 404–413. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Wang, K.H.; Huang, K.; Liu, G. Recrystallization behavior during hot tensile deformation of TA15 titanium alloy sheet with substantial prior deformed substructures. Mater. Charact. 2019, 151, 429–435. [Google Scholar] [CrossRef]

| Test No. | Pre-Strain | Tensile Test Parameter | Final Strains |

|---|---|---|---|

| Test-0 | 0 | 850 °C, 0.001 s−1 | 0.3 |

| 0.5 | |||

| 0.7 | |||

| fracture | |||

| Test-1 | 0.05 | 850 °C, 0.001 s−1 | 0.3 |

| 0.5 | |||

| 0.7 | |||

| fracture | |||

| Test-2 | 0.1 | 850 °C, 0.001 s−1 | 0.3 |

| 0.5 | |||

| 0.7 | |||

| fracture | |||

| Test-3 | 0.15 | 850 °C, 0.001 s−1 | 0.3 |

| 0.5 | |||

| 0.7 | |||

| fracture |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, T.; Wang, N.; Chen, M.; Zuo, D.; Xie, L.; Shi, W. Effect of Pre-Strain on Microstructure and Tensile Properties of Ti-6Al-4V at Elevated Temperature. Metals 2021, 11, 1321. https://doi.org/10.3390/met11081321

Wu T, Wang N, Chen M, Zuo D, Xie L, Shi W. Effect of Pre-Strain on Microstructure and Tensile Properties of Ti-6Al-4V at Elevated Temperature. Metals. 2021; 11(8):1321. https://doi.org/10.3390/met11081321

Chicago/Turabian StyleWu, Taowen, Ning Wang, Minghe Chen, Dunwen Zuo, Lansheng Xie, and Wenxiang Shi. 2021. "Effect of Pre-Strain on Microstructure and Tensile Properties of Ti-6Al-4V at Elevated Temperature" Metals 11, no. 8: 1321. https://doi.org/10.3390/met11081321

APA StyleWu, T., Wang, N., Chen, M., Zuo, D., Xie, L., & Shi, W. (2021). Effect of Pre-Strain on Microstructure and Tensile Properties of Ti-6Al-4V at Elevated Temperature. Metals, 11(8), 1321. https://doi.org/10.3390/met11081321