Development of a Fast Modeling Approach for the Prediction of Scrap Preheating in Continuously Charged Metallurgical Recycling Processes

Abstract

1. Introduction

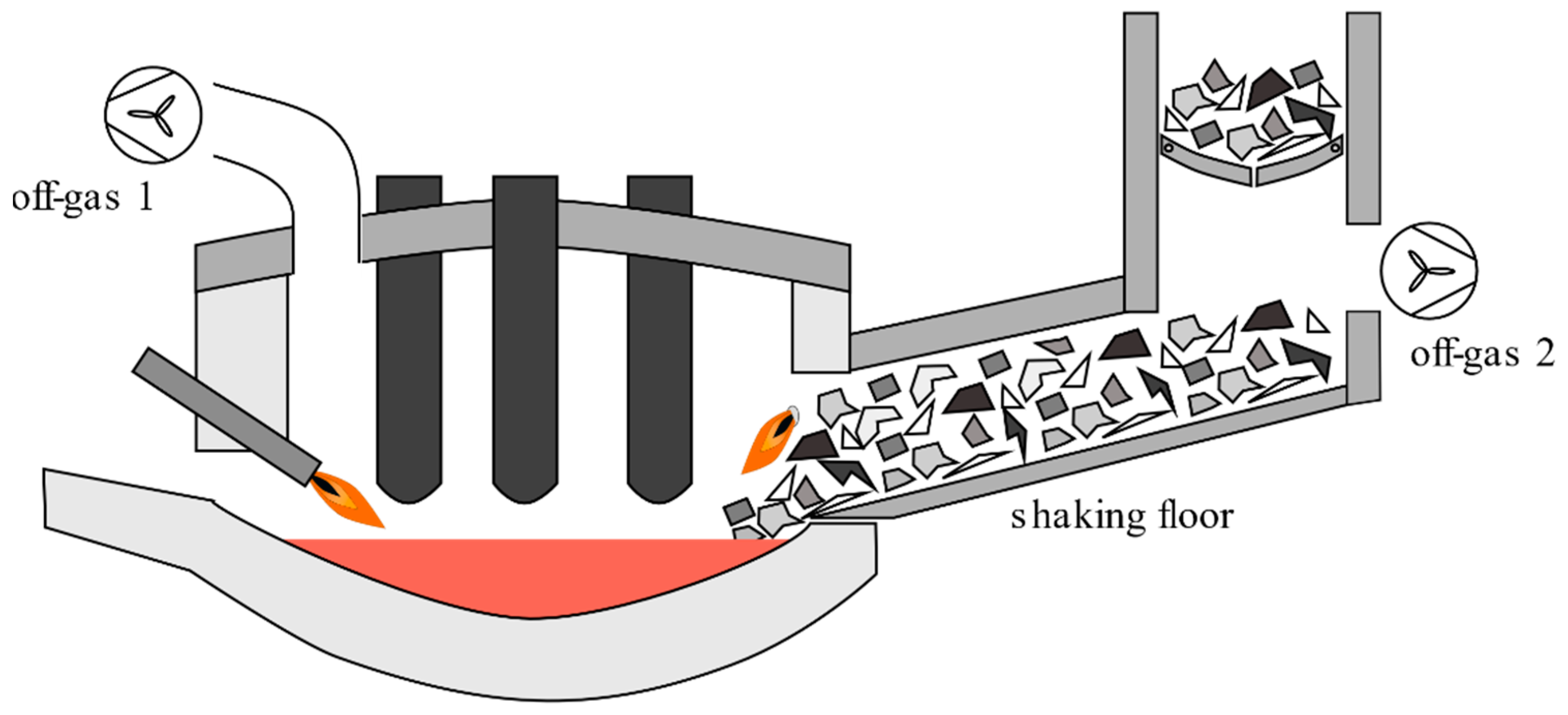

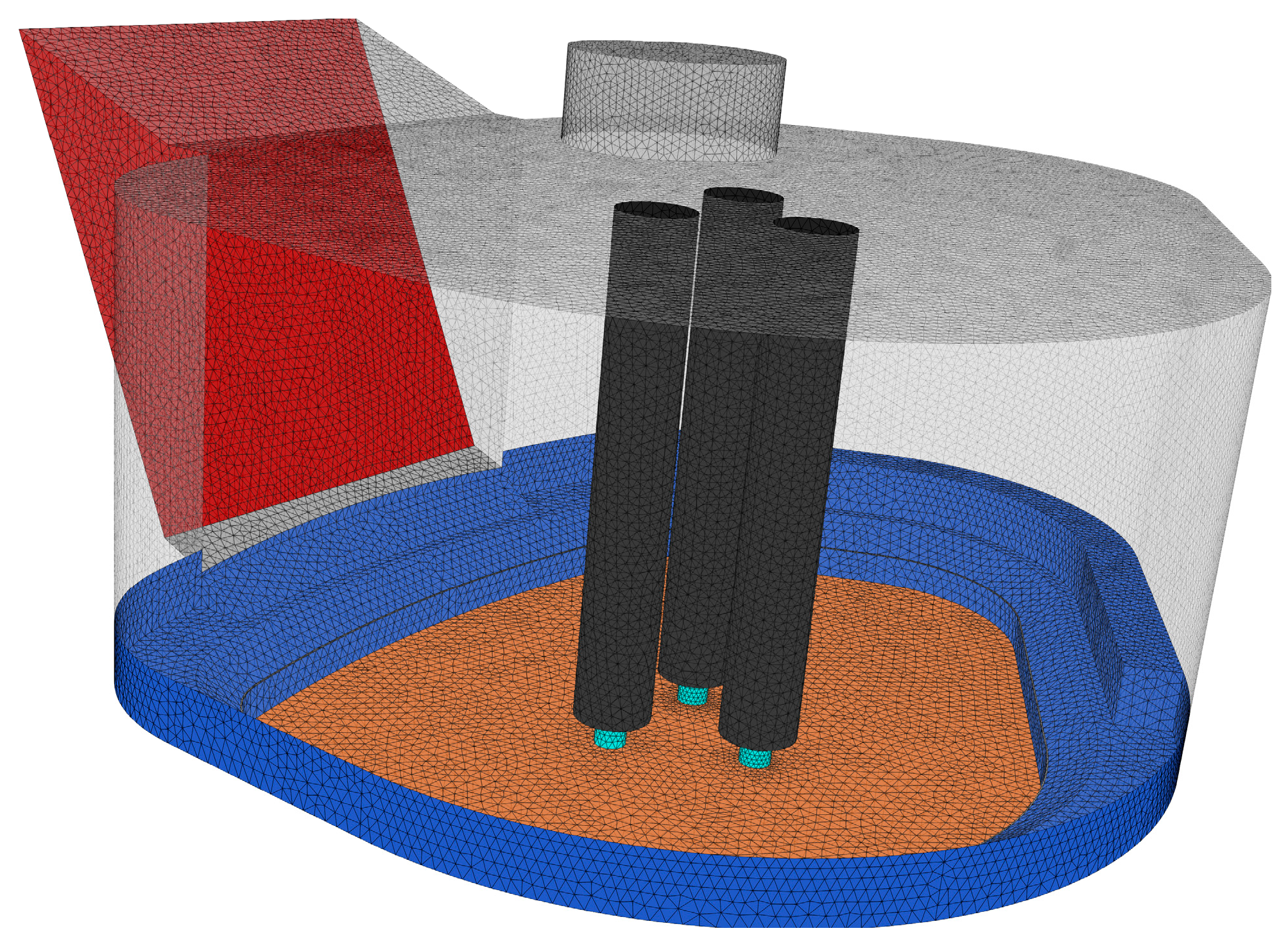

Description of the Modeled Process

- Flat-bath melting phase model (phase 1): Here, a continuous scrap flow to the melt is modeled. The off-gas temperature and flow rate is assumed to be constant.

- Refining phase (phase 2): No off-gas or scrap flow through the shaking floor tunnel, heat transfer inside the scrap bulk is mainly driven by surface to surface (s2s) radiation effects.

2. Materials and Modeling Approach

2.1. Materials

2.1.1. Scrap

- Scrap composition (steel grades and alloying elements);

- Scrap contamination in terms of adherent organic materials;

- Distribution of the geometrical characteristics of the scrap speaking of the mean scrap part thickness and the surface to volume ratio.

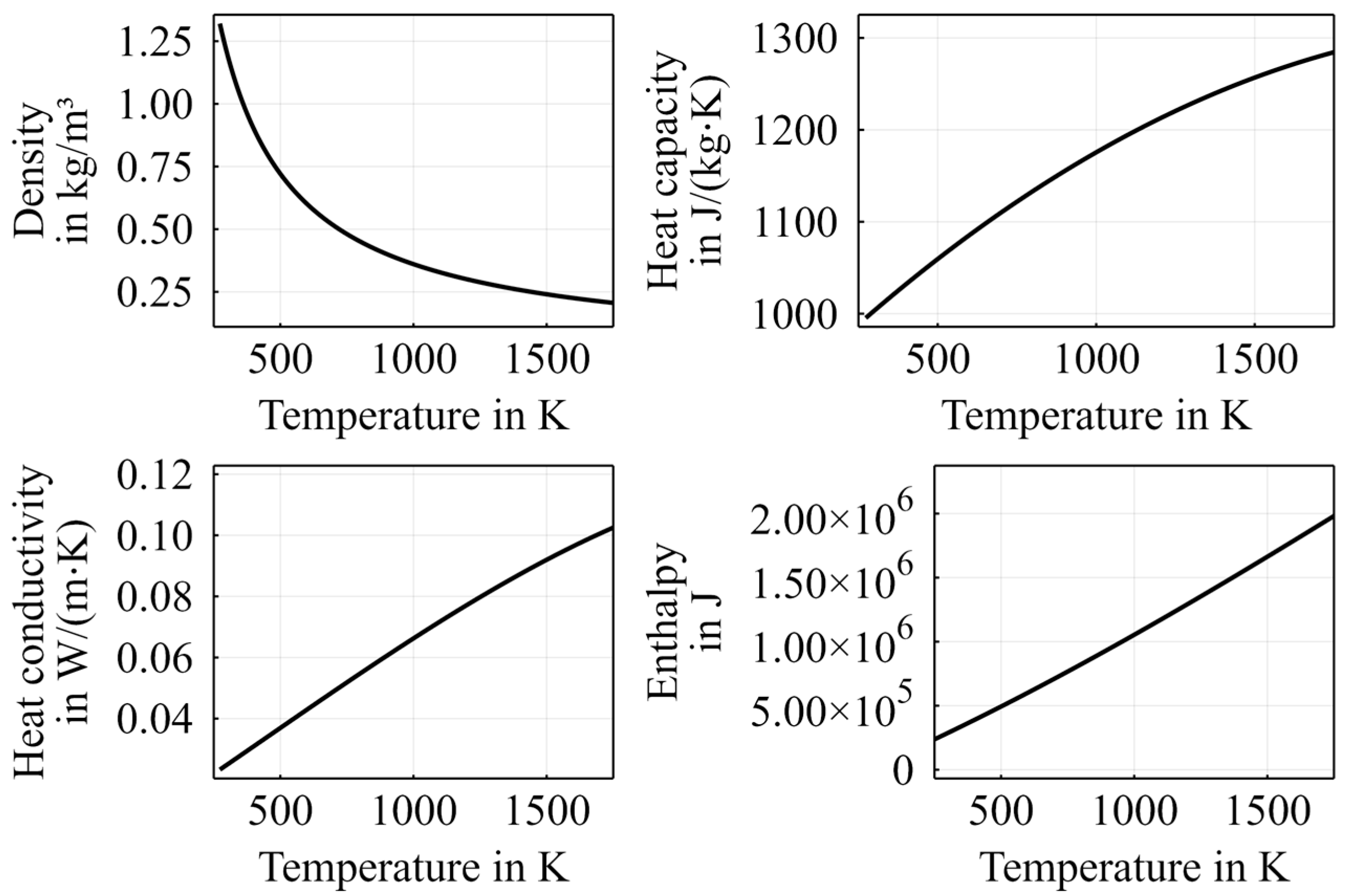

2.1.2. Off-Gas

2.2. Modeling Parameters

2.3. Modeling Approach

2.3.1. Modeling Simplifications

- Scrap consisting of small flat stripes of metal with a characteristic thickness (which should translate to the fact that they have only one direction where thermal conduction will matter the most) and a representative surface area;

- All scrap parts are composed of the same material;

- Scrap pieces are shaped approximately equal and distributed evenly over the scrap bulk;

- The scrap bulk has uniform scrap thicknesses and constant surface to volume ratio;

- There is a uniform scrap movement in direction of the shaking floor;

- Neglection of gas radiation (the usual distance between different parts) is estimated to be in between 1 and 15 cm, and the gray gas emissivity for the given gas composition (over a temperature range from 300 K to 1500 K at 1 atm) varies between 0.01 and 0.08, calculated according to Alberti et al. [25]; therefore, its influence will be neglected for now);

- The emissivity of all surfaces (scrap and furnace walls) will be assumed to be 0.8;

- Assuming temperatures listed in Table 3 for modeling of scrap bulk incident radiation for the refining phase (2);

- Neglecting dissipation and compressible pressure effects in the off-gas flow;

- Constant gas composition over whole process time;

- Constant heat transfer coefficient between scrap and off-gas over the length of the shaft;

- Symmetry assumption over the individual scrap part’s thicknesses;

- Neglecting the contact of scrap with the surrounding walls;

- No modeling of thermal conduction between the individual scrap parts in the bulk (convective and/or radiative heating is assumed to dominate the heat distribution of the scrap bulk);

- Homogeneous temperature and mass flow of the off-gas in each bulk layer cell.

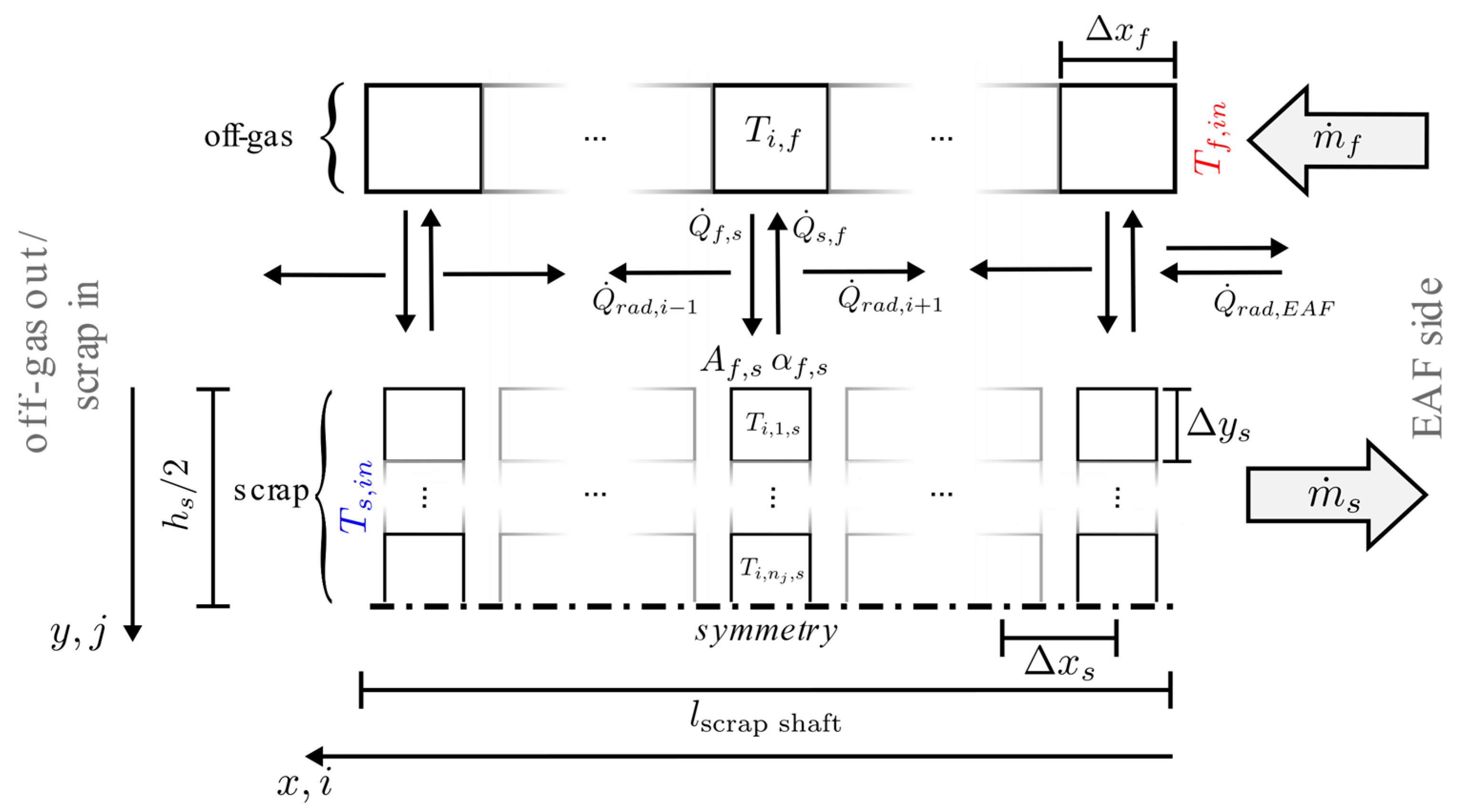

2.3.2. Heat Conduction over Characteristic Scrap Thickness

2.3.3. Heat Conduction in the Off-Gas

2.3.4. Convective Heat Exchange between Scrap and Off-Gas

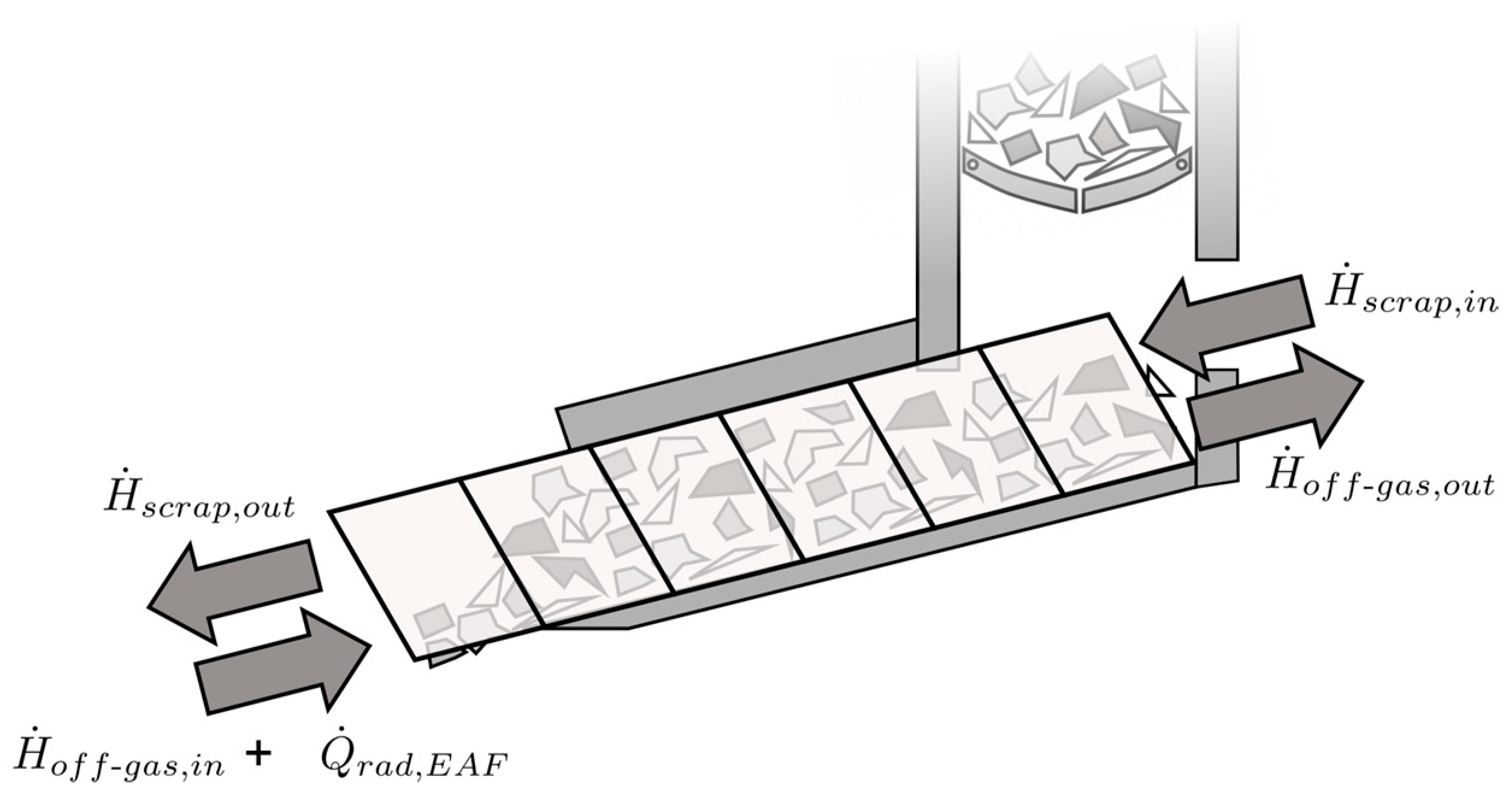

2.3.5. Balancing

2.3.6. Radiation Modeling—Bulk Incident Radiation

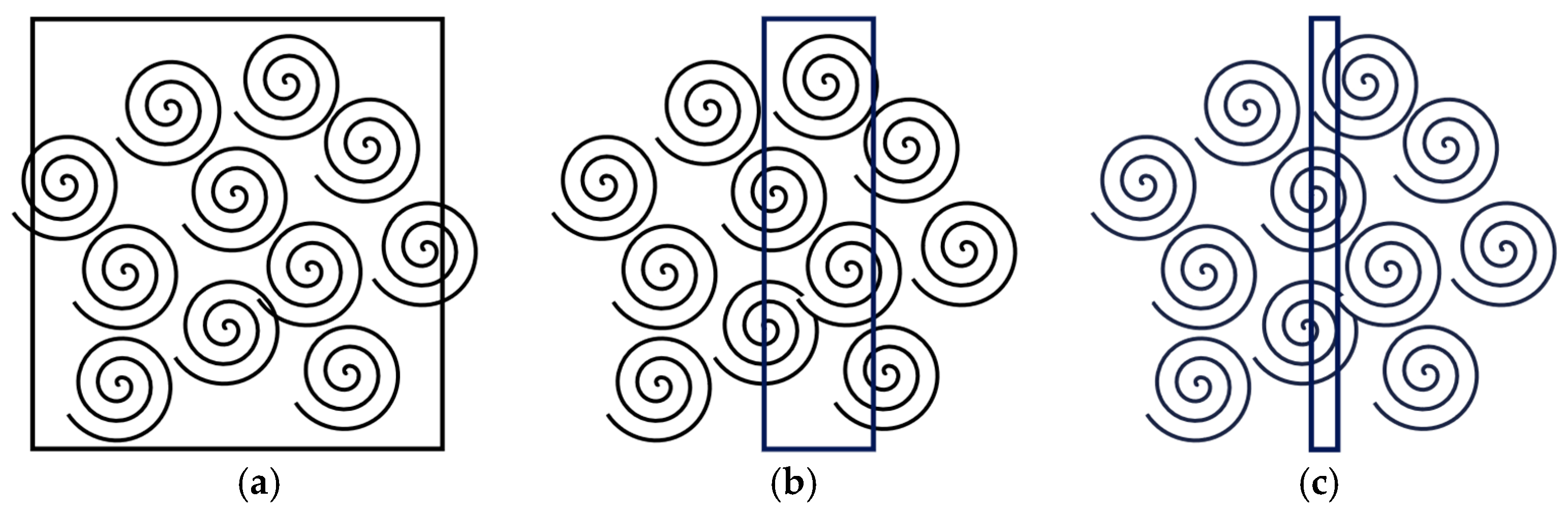

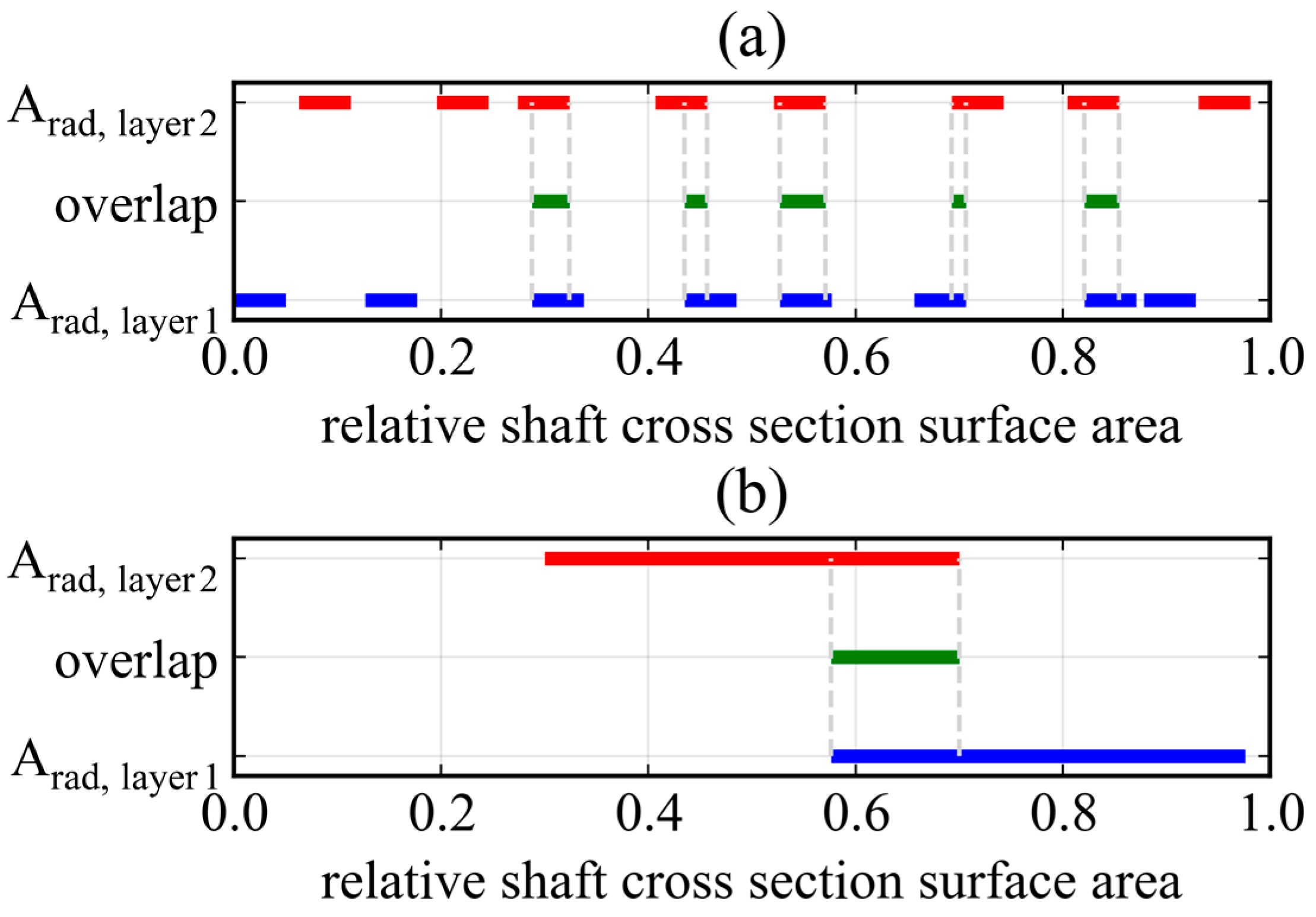

2.3.7. Radiation Modeling—Inside of the Scrap Bulk

3. Results

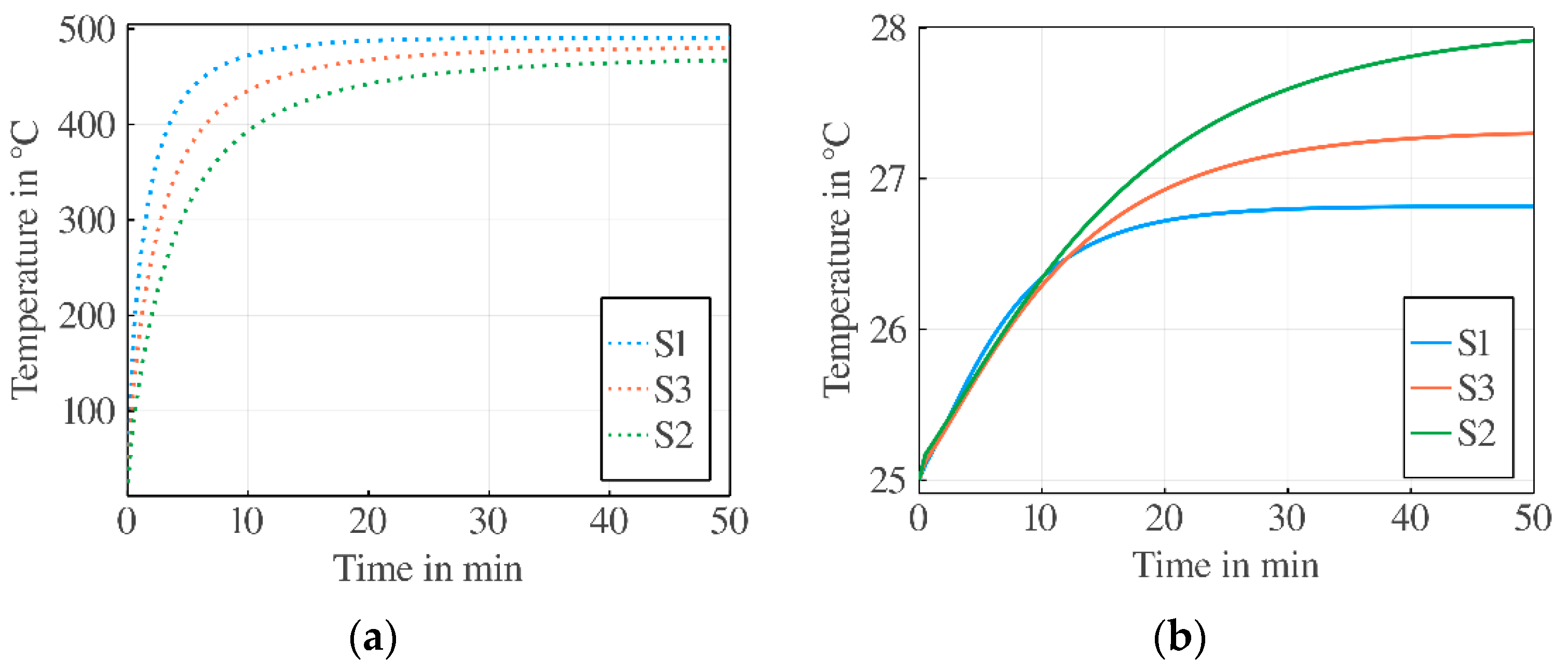

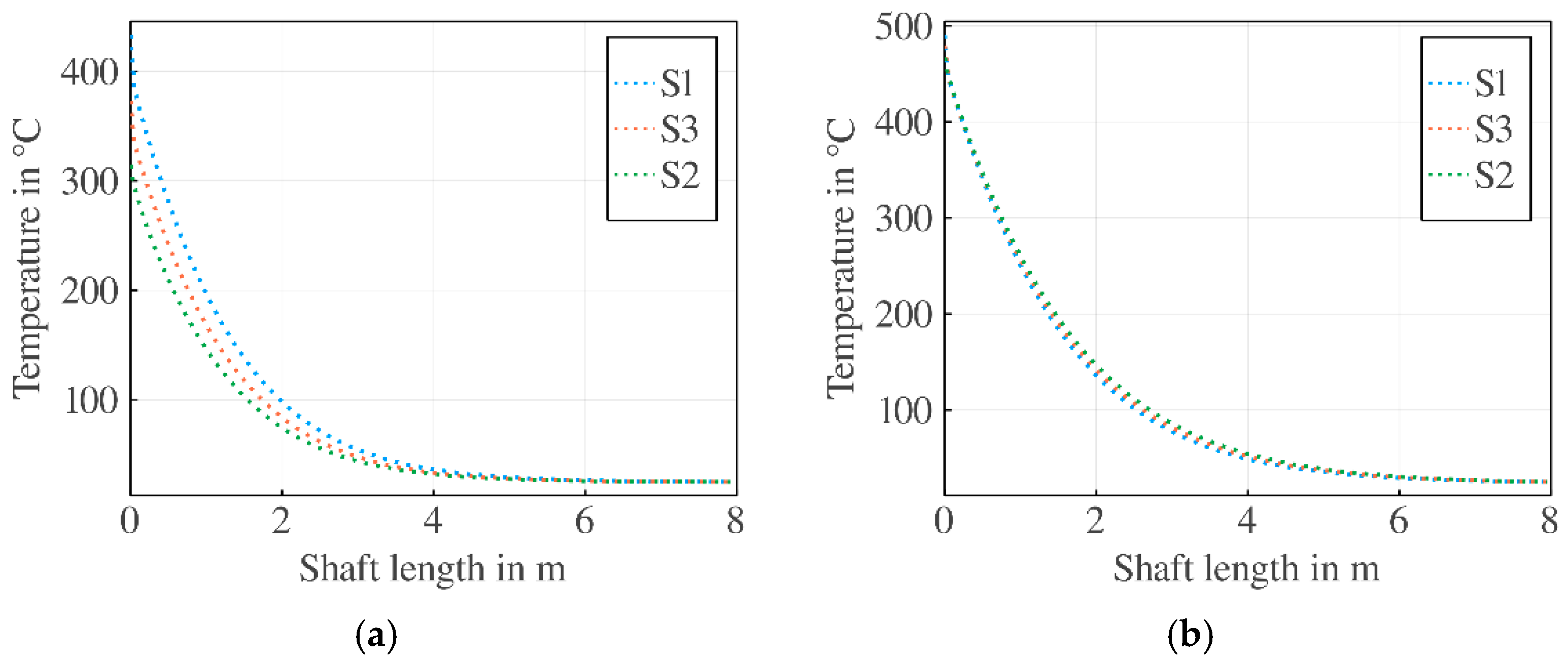

3.1. Model Sensitivity to Different Scrap Types

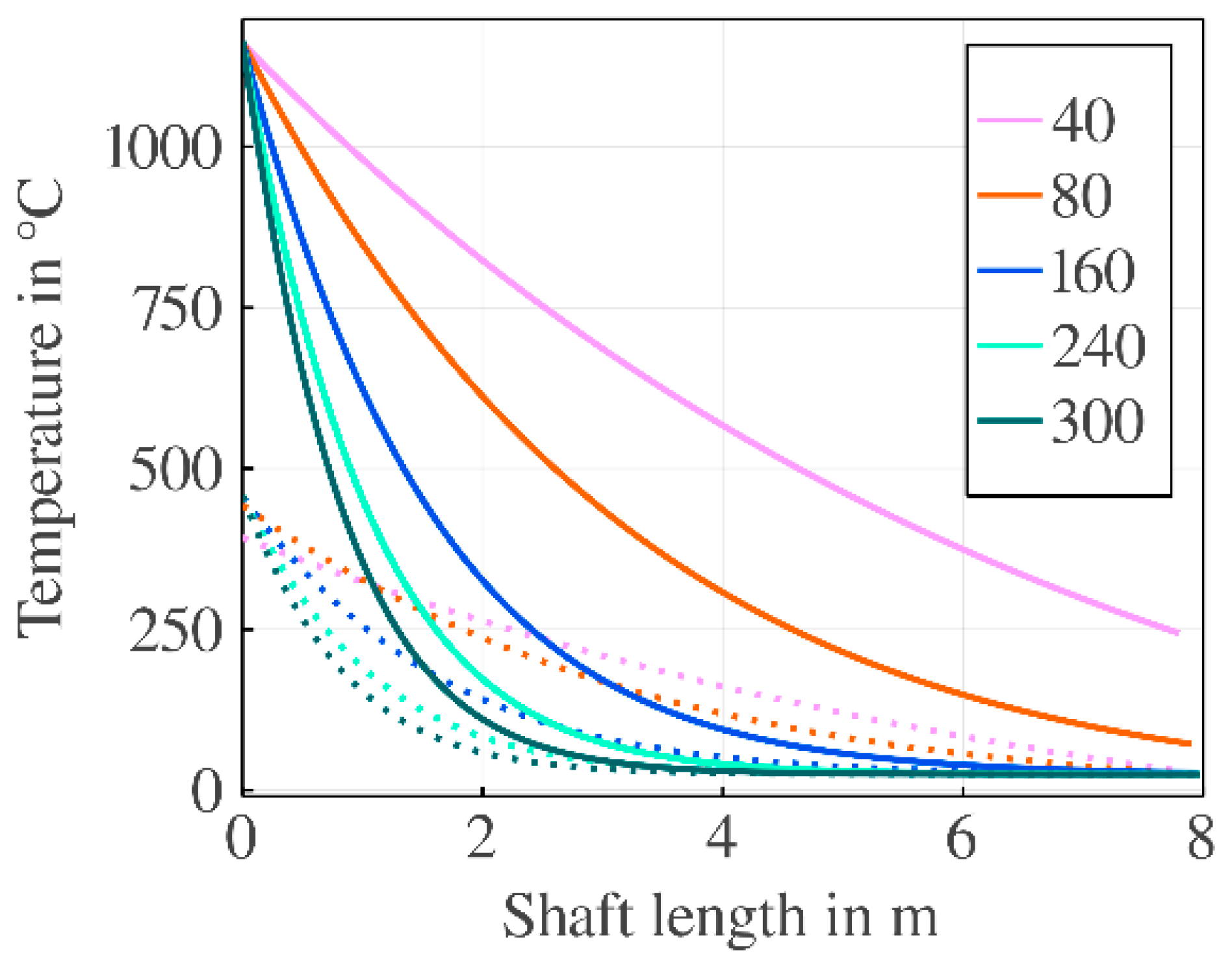

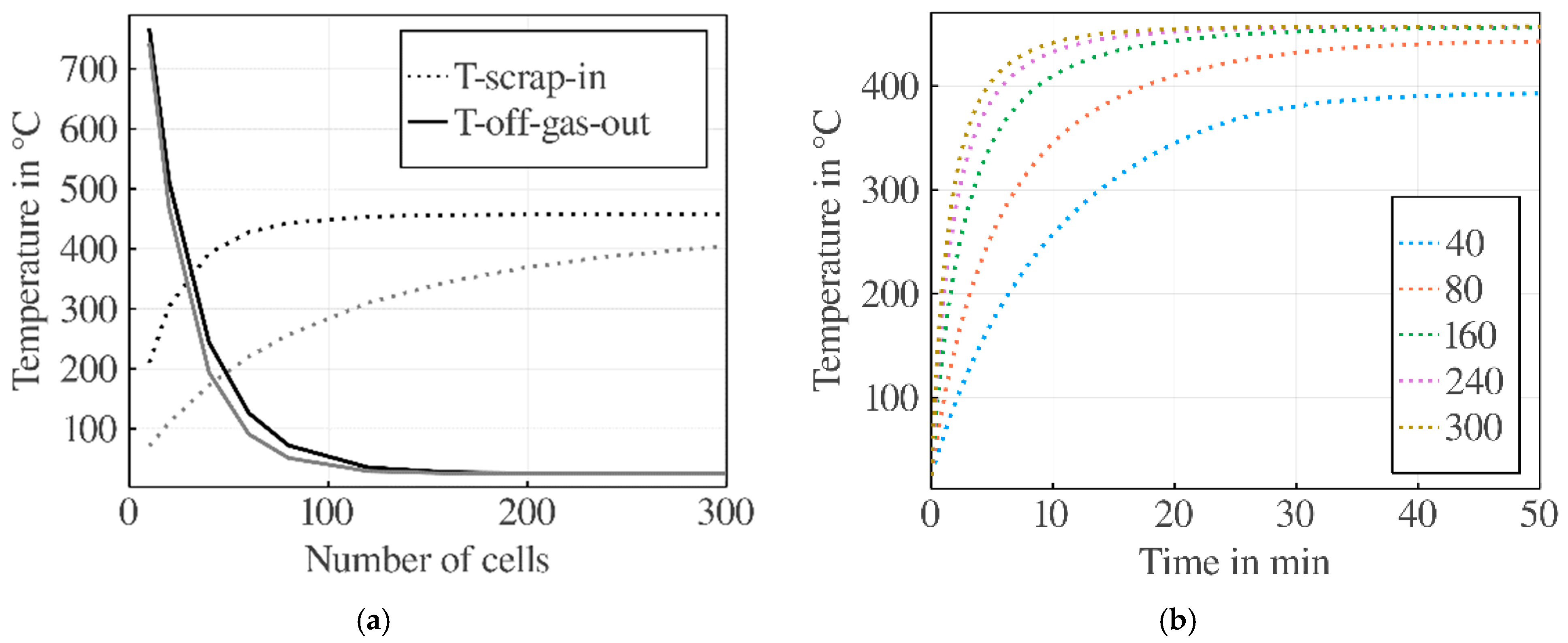

3.2. Mesh Size Implications on the Modeled Process

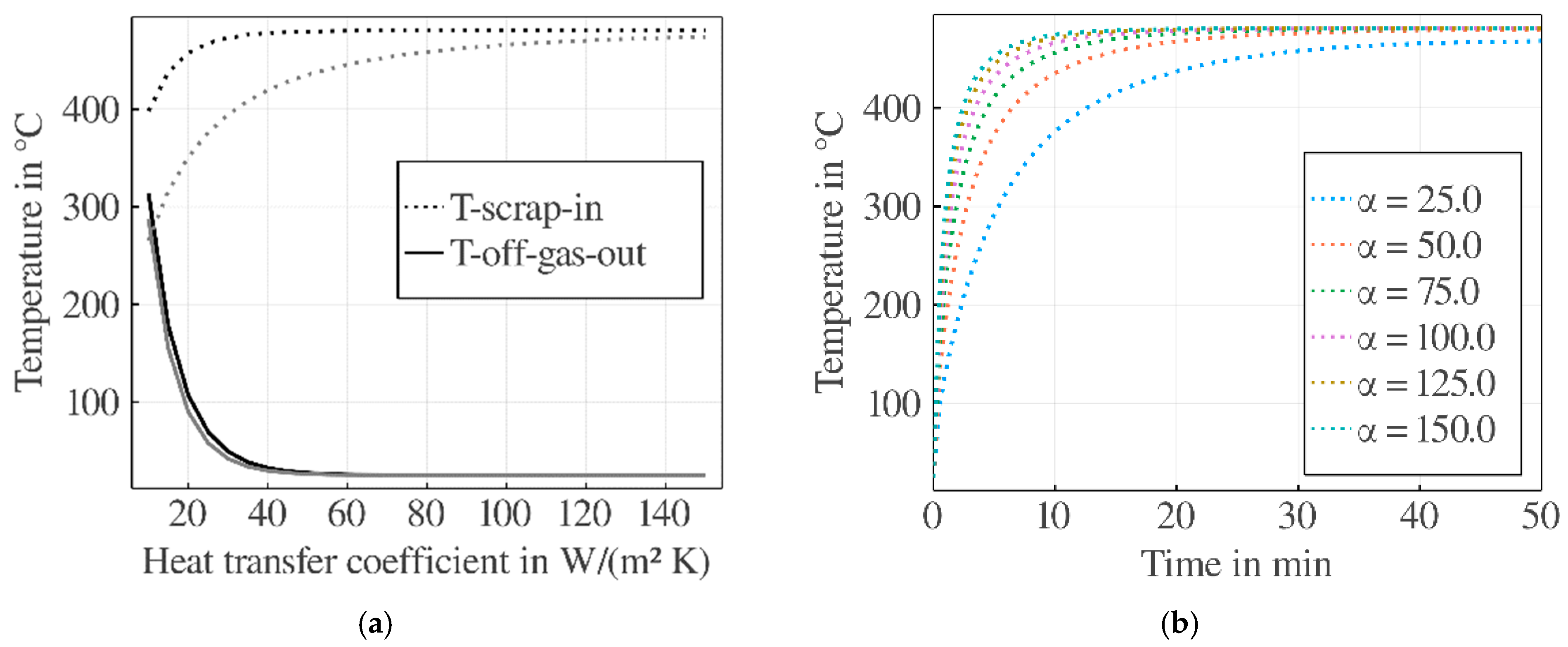

3.3. Influence of Convective Heat Transfer Assumptions

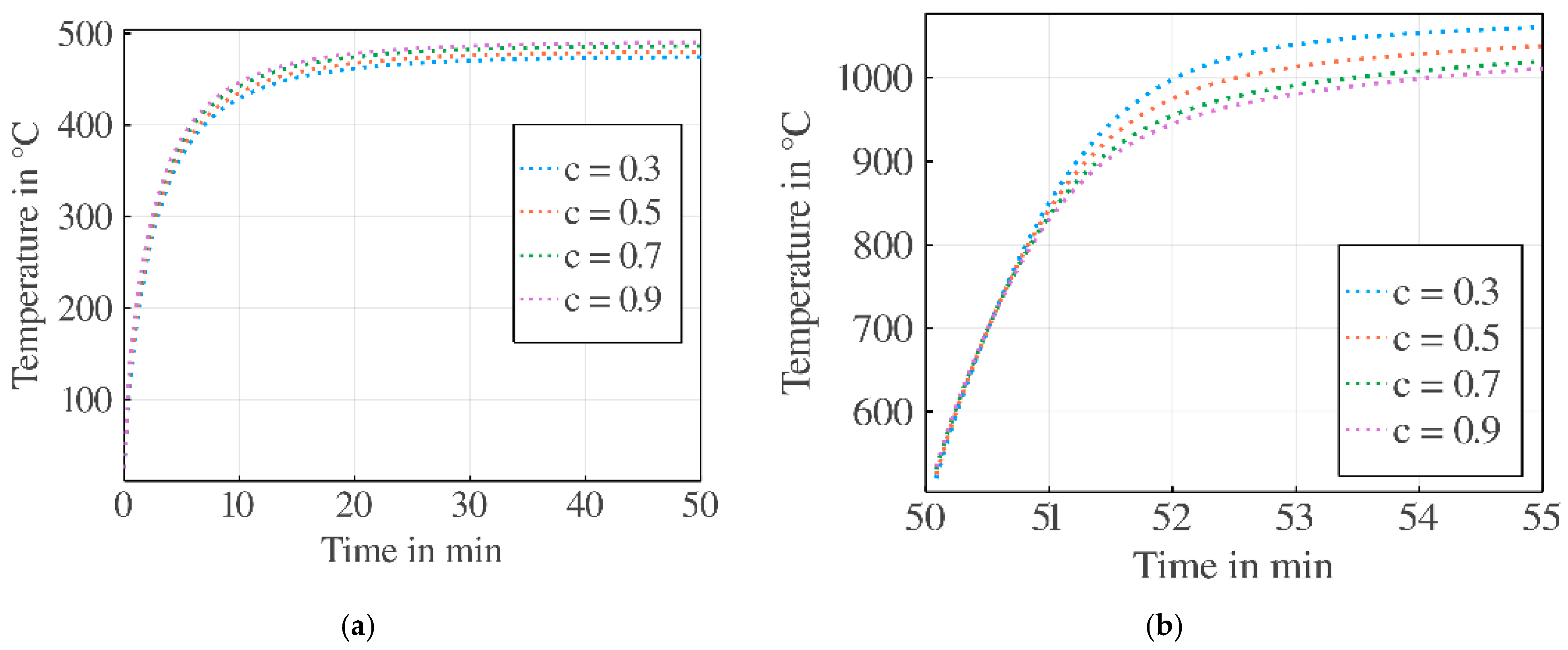

3.4. Influence of Factor on Modeled Radiative Heat Transfer

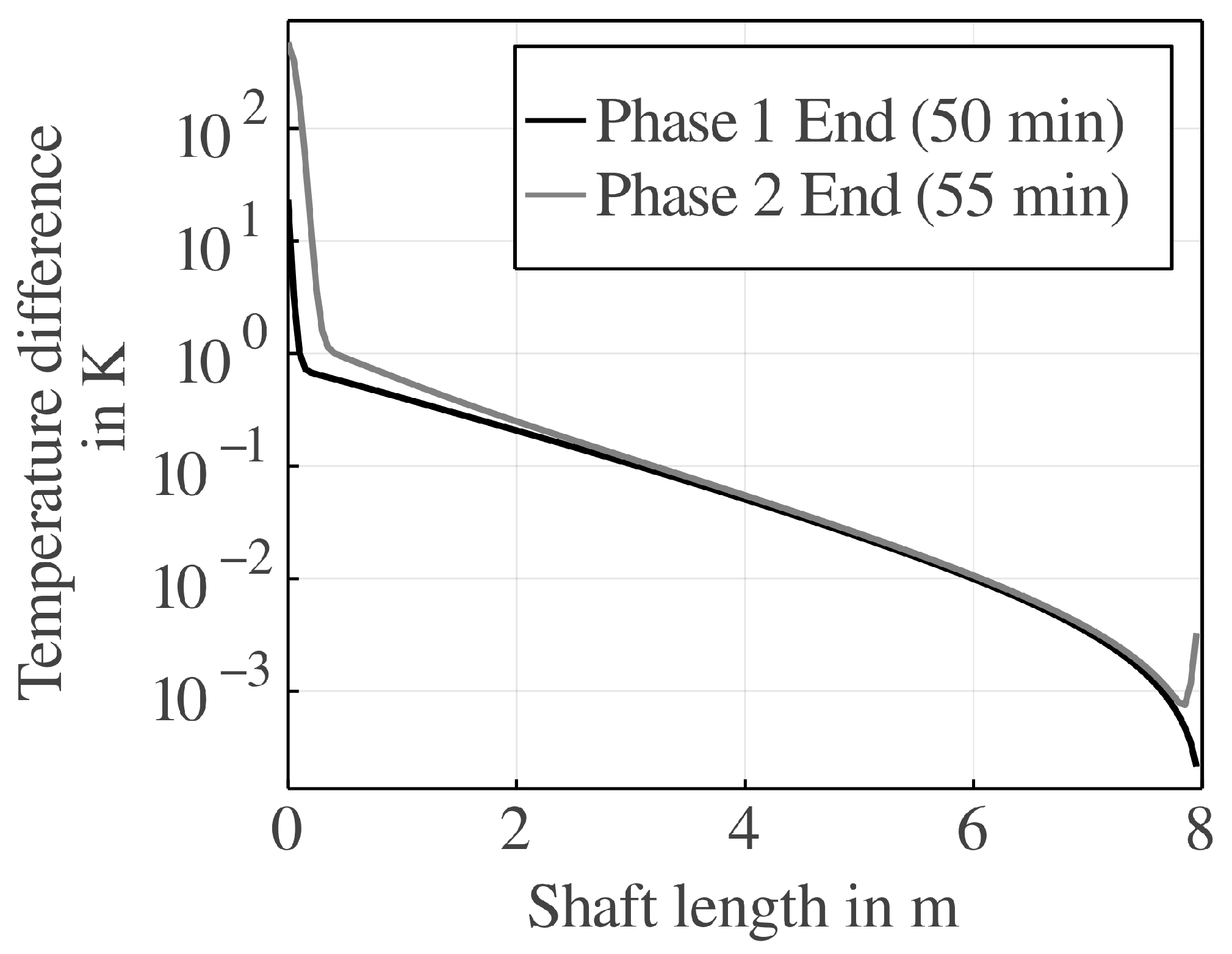

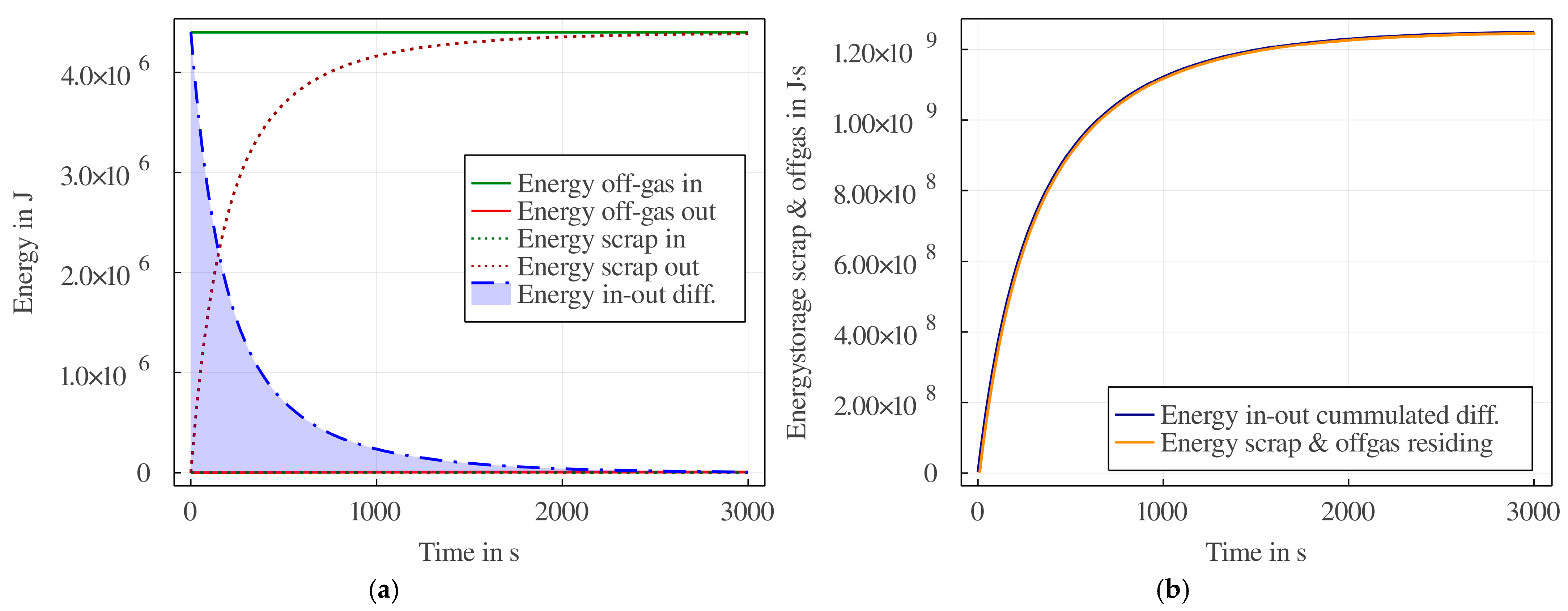

3.5. Verification of the Model’s Heat Balance

4. Conclusions

5. Summary

- Simplified modeling of conduction heat transfer between individual scrap parts, for applications where this becomes relevant;

- Validation and parameterization of the blocking modeling;

- Estimation strategies for the factor and the heat transfer coefficient ;

- Modeling of more complex scrap bulks with mixed materials;

- Finding suitable optimization factors to fit the model to various experimental cases.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Coenen, L. Steel—The Surprising Recycling Champion. Available online: https://www.worldsteel.org/media-centre/blog/2018/blog-steel-surprising-recycling-champion.html (accessed on 20 February 2019).

- Nardin, G.; Ciotti, G.; Dal Magro, F.; Meneghetti, A.; Simeoni, P. Waste Heat Recovery in the Steel Industry: Better Internal Use or External Integration?, XXIII Summer School “Francesco Turco”—Industrial Systems Engineering A New Model Proposal for Occupational Health and Safety Management in Small and Medium Enterprises; Summer School Francesco Turco: Palermo, Italy, 2018. [Google Scholar]

- Toulouevski, Y.N.; Zinurov, I.Y. Electric Arc Furnace with Flat Bath—Achievements and Prospects; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-319-15886-0. [Google Scholar]

- Yang, Q.; Yang, L.; Shen, J.; Yang, Y.; Wang, M.; Liu, X.; Shen, X.; Li, C.; Xu, J.; Li, F.; et al. Polychlorinated Dibenzo-p-Dioxins and Dibenzofurans (PCDD/Fs) Emissions from Electric Arc Furnaces for Steelmaking. Emerg. Contam. 2020, 6, 330–336. [Google Scholar] [CrossRef]

- Yang, L.; Jiang, T.; Li, G.; Guo, Y.; Chen, F. Present Situation and Prospect of EAF Gas Waste Heat Utilization Technology. High Temp. Mater. Process. 2018, 37, 357–363. [Google Scholar] [CrossRef]

- Lehner, J.; Friedacher, A.; Gould, L.; Fingerhut, W. Low-Cost Solutions for the Removal of Dioxin from EAF Offgas. Rev. Met. Paris 2004, 101, 49–56. [Google Scholar] [CrossRef][Green Version]

- Dicion, A. Innovative Energy Conservation through Scrap Pre-Heating in an Electric Arc Furnace; ACEEE Summer Study on Energy Efficiency in Industry: 2013; p. 5. Available online: https://oaktrust.library.tamu.edu/handle/1969.1/149172?show=full (accessed on 1 July 2021).

- SMS Group. Metallurgical Plant and Technology; Maenken Kommunikation GmbH: Köln, Germany, 2016; pp. 52–57. [Google Scholar]

- CISDI Engineering Co. Ltd. (54). Steel Scrap Preheating-Type Electric arc Furnace and Method for Improving Heating Cold Area of Side Wall Charging Electric Arc Furnace. 2018. Available online: https://patents.google.com/patent/US10928136B2/en (accessed on 1 July 2021).

- Manazzone, M.; Valoppi, A. ISMELT—Inteco Scrap MELting Technology Evolution. Available online: https://www.eases.rwth-aachen.de/dl/AOTK-2021/Manazzone_ISMELT%20%E2%80%93%20Inteco%20Scrap%20MELting%20Technology%20evolution.pdf (accessed on 18 June 2021).

- Tang, G. Modeling of Steel Heating and Melting Processes in Industrial Steelmaking Furnaces. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2019. [Google Scholar]

- Mandai, K. Modelling of Scrap Heating by Burners. Ph.D. Thesis, McMaster University, Hamilton, ON, Canada, 2010. [Google Scholar]

- Arink, T.; Hassan, M.I. Metal Scrap Preheating Using Flue Gas Waste Heat. Energy Procedia 2017, 105, 4788–4795. [Google Scholar] [CrossRef]

- Ioana, A.; Preda, A.; Be, L.; Moldovan, P.; Constantin, N. Improving Electric arc Furnace (eaf) Operation through Mathematical Modelling. UPB Sci. Bull. Ser. B 2016, 78, 185–194. [Google Scholar]

- Schubert, C.; Eickhoff, M.; Pfeifer, H. Modelling of Continuous Scrap Preheating. In Proceedings of the 2019 STEELSIM Conference Proceedings, Toronto, ON, Canada, 13–15 August 2019; p. 8. [Google Scholar]

- Zhang, L.; Oeters, F. Possibilities of Counter-Current Scrap Pre-Heating with Melting by Use of 100% Fossil Energy. Steel Res. 1999, 70, 296–308. [Google Scholar] [CrossRef]

- Hay, T.; Visuri, V.-V.; Aula, M.; Echterhof, T. A Review of Mathematical Process Models for the Electric Arc Furnace Process. Steel Res. Int. 2020, 92, 2000395. [Google Scholar] [CrossRef]

- Bezanson, J.; Edelman, A.; Karpinski, S.; Shah, V.B. Julia: A Fresh Approach to Numerical Computing. SIAM Rev. 2017, 59, 65–98. [Google Scholar] [CrossRef]

- Bezanson, J.; Bolewski, J.; Chen, J. Fast Flexible Function Dispatch in Julia. arXiv 2018, arXiv:1808.03370v1. [Google Scholar]

- StahlDat SX Professional: Register of European Steels. Available online: https://www.stahldaten.de/en/pub/home (accessed on 1 July 2021).

- GERDAU Midlothian. Ferrous Raw Materials Manual—Part 3—Ferrous Raw Materialspecifications; GERDAU Midlothian Grade Specs: 2018. Available online: https://www2.gerdau.com/sites/gln_gerdau/files/downloadable_files/Midlothian%20Ferrous%20Raw%20Material%20Specifications.pdf (accessed on 1 July 2021).

- Goodwin, D.G.; Speth, R.L.; Moffat, H.K.; Weber, B.W. Cantera: An Object-Oriented Software Toolkit for Chemical Kinetics, Thermodynamics, and Transport Processes. 2021. Available online: https://www.cantera.org (accessed on 30 May 2018).

- Smith, G.P.; Golden, D.M.; Frenklach, M.; Moriarty, N.W.; Eiteneer, B.; Goldenberg, M.; Bowman, C.T.; Hanson, R.K.; Song, S.; Gardiner, W.C., Jr.; et al. GRI-Mech. Available online: http://www.me.berkeley.edu/gri_mech/ (accessed on 30 June 2020).

- Rackauckas, C.; Nie, Q. DifferentialEquations.Jl—A Performant and Feature-Rich Ecosystem for Solving Differential Equations in Julia. J. Open Res. Softw. 2017, 5, 15. [Google Scholar] [CrossRef]

- Alberti, M.; Weber, R.; Mancini, M. Gray Gas Emissivities for H2O-CO2-CO-N2 Mixtures. J. Quant. Spectrosc. Radiat. Transf. 2018, 219, 274–291. [Google Scholar] [CrossRef]

- Hottel, H.C.; Sarofim, A.F. Radiative Transfer; McGraw-Hill: New York, NY, USA, 1967. [Google Scholar]

- Howell, J.R.; Menguc, M.P.; Siegel, R. Thermal Radiation Heat Transfer; CRC Press: Boca Raton, FL, USA, 2015; ISBN 1-4987-5774-X. [Google Scholar]

- Odenthal, H.-J.; Kemminger, A.; Krause, F.; Sankowski, L.; Uebber, N.; Vogl, N. Review on Modeling and Simulation of the Electric Arc Furnace (EAF). Steel Res. Int. 2018, 89, 1700098. [Google Scholar] [CrossRef]

- Gruber, J.C.; Echterhof, T.; Pfeifer, H. Investigation on the Influence of the Arc Region on Heat and Mass Transport in an EAF Freeboard Using Numerical Modeling. Steel Res. Int. 2016, 87, 15–28. [Google Scholar] [CrossRef]

- Coskun, G.; Yigit, C.; Buyukkaya, E. CFD Modelling of a Complete Electric Arc Furnace Energy Sources. Innovations 2016, 4, 22–24. [Google Scholar]

| Name | Label | Density in kg/m³ | Dimensions (Length × Width × Thickness) in m | Source |

|---|---|---|---|---|

| Turning chips | S1 | 500 | 0.25 × 0.03 × 0.001 | Measurements from CNC scrap of our workshop |

| Rail crops scrap | S2 | 1121 | 1.21 × 0.45 × 0.0127 | Datasheet [21] |

| Plate Scrap | S3 | 801 | 0.92 × 0.61 × 0.003175 | Datasheet [21] |

| Property | Value | Unit |

|---|---|---|

| Input temperature scrap | 25 | °C |

| Mass flow scrap | 38.6 | kg/s |

| Mass flow off-gas (through scrap bulk) | 6.64 | kg/s |

| Floor length | 8 | m |

| Floor cross section area | 2.9 × 3.2 | m² |

| Color | Red | Blue | Cyan | Orange | Gray |

| Temperature in °C | Modeled | 1500 | 4500 | 1650 | 900 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schubert, C.; Büschgens, D.; Eickhoff, M.; Echterhof, T.; Pfeifer, H. Development of a Fast Modeling Approach for the Prediction of Scrap Preheating in Continuously Charged Metallurgical Recycling Processes. Metals 2021, 11, 1280. https://doi.org/10.3390/met11081280

Schubert C, Büschgens D, Eickhoff M, Echterhof T, Pfeifer H. Development of a Fast Modeling Approach for the Prediction of Scrap Preheating in Continuously Charged Metallurgical Recycling Processes. Metals. 2021; 11(8):1280. https://doi.org/10.3390/met11081280

Chicago/Turabian StyleSchubert, Christian, Dominik Büschgens, Moritz Eickhoff, Thomas Echterhof, and Herbert Pfeifer. 2021. "Development of a Fast Modeling Approach for the Prediction of Scrap Preheating in Continuously Charged Metallurgical Recycling Processes" Metals 11, no. 8: 1280. https://doi.org/10.3390/met11081280

APA StyleSchubert, C., Büschgens, D., Eickhoff, M., Echterhof, T., & Pfeifer, H. (2021). Development of a Fast Modeling Approach for the Prediction of Scrap Preheating in Continuously Charged Metallurgical Recycling Processes. Metals, 11(8), 1280. https://doi.org/10.3390/met11081280