RANS versus Scale Resolved Approach for Modeling Turbulent Flow in Continuous Casting of Steel

Abstract

:1. Introduction

2. Materials and Methods

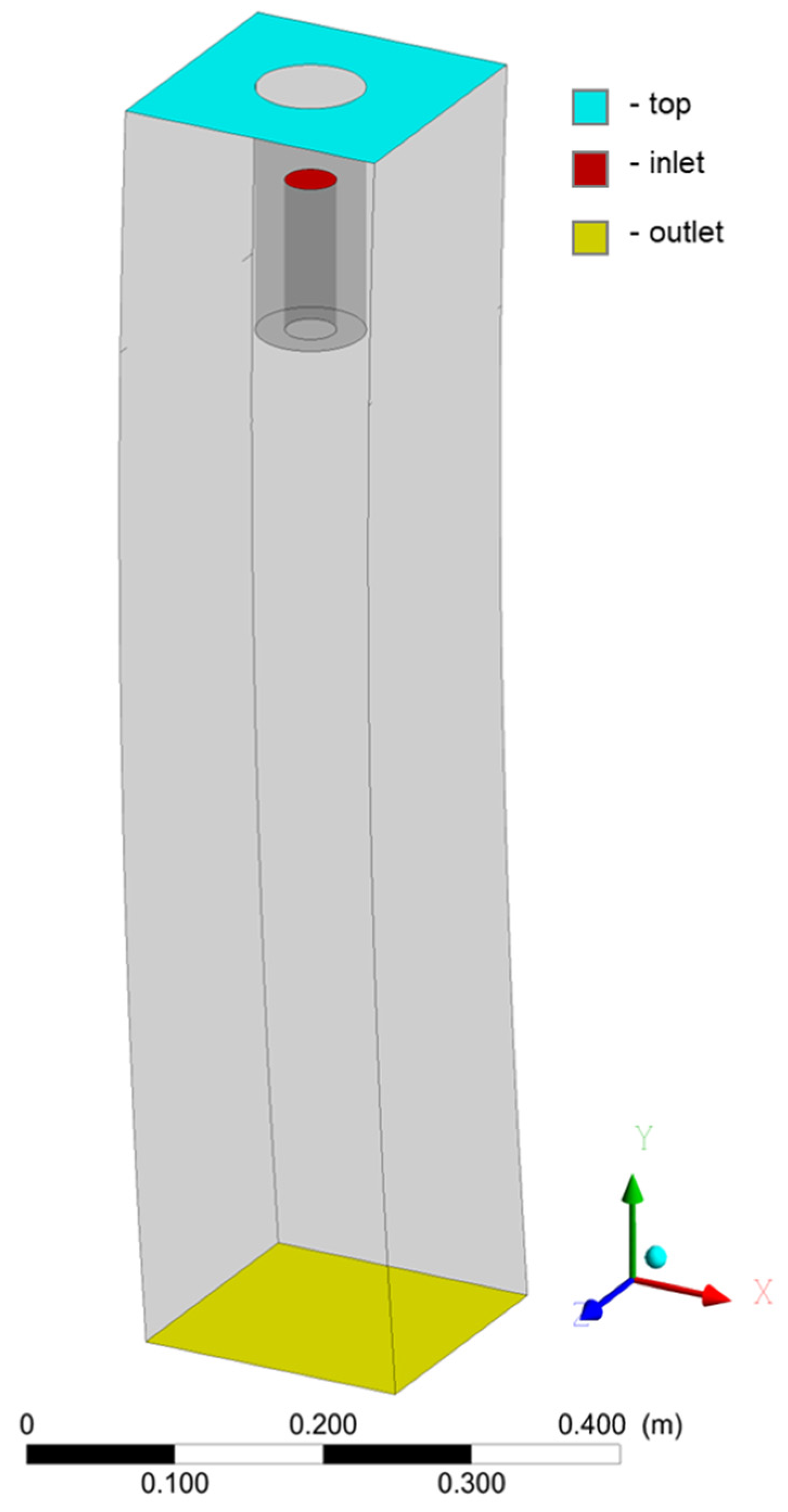

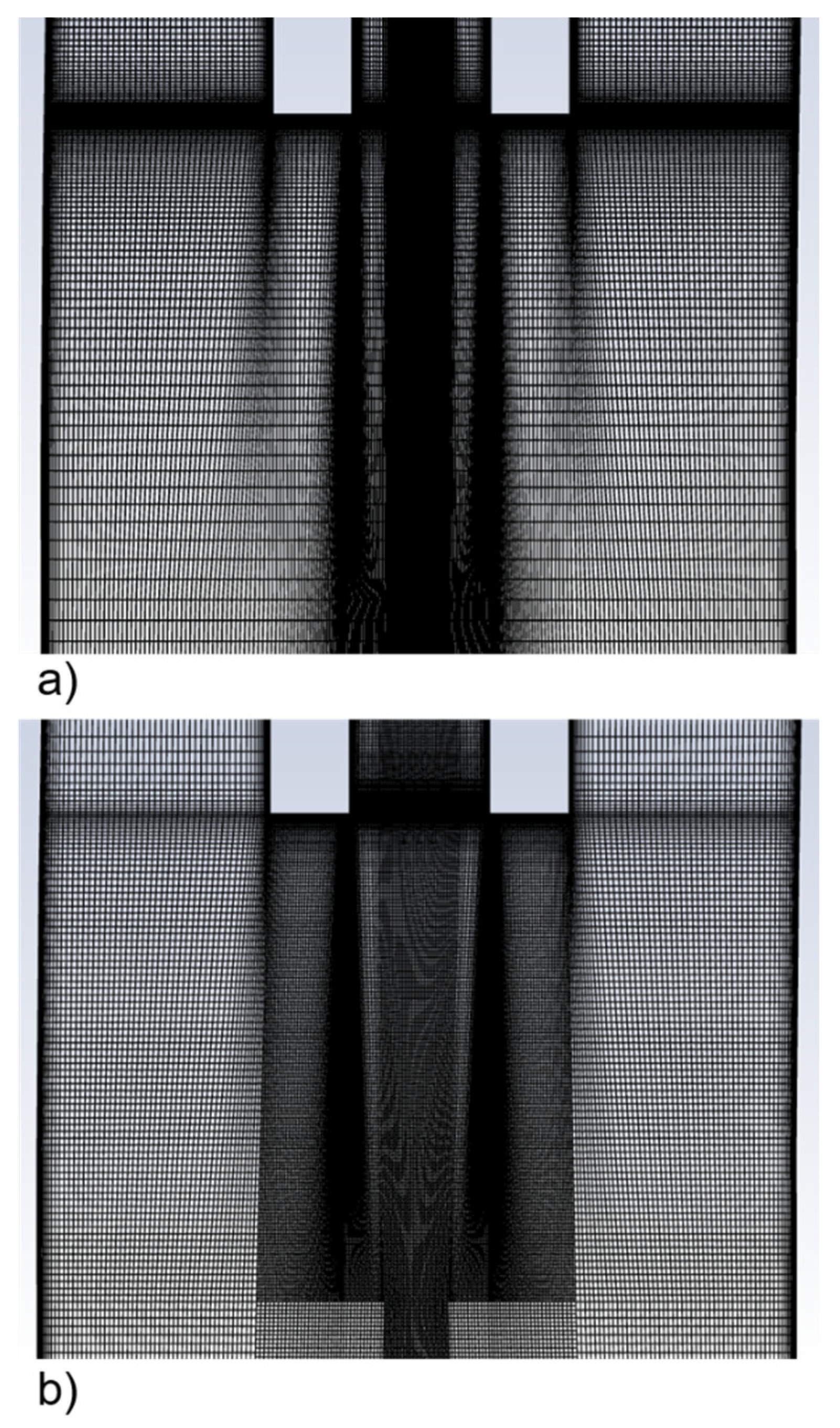

2.1. Numerical Setup and Procedure

2.1.1. Governing Equations

2.1.2. Turbulence Modelling

2.1.3. Discretization

2.1.4. Boundary Conditions and Solution Procedure

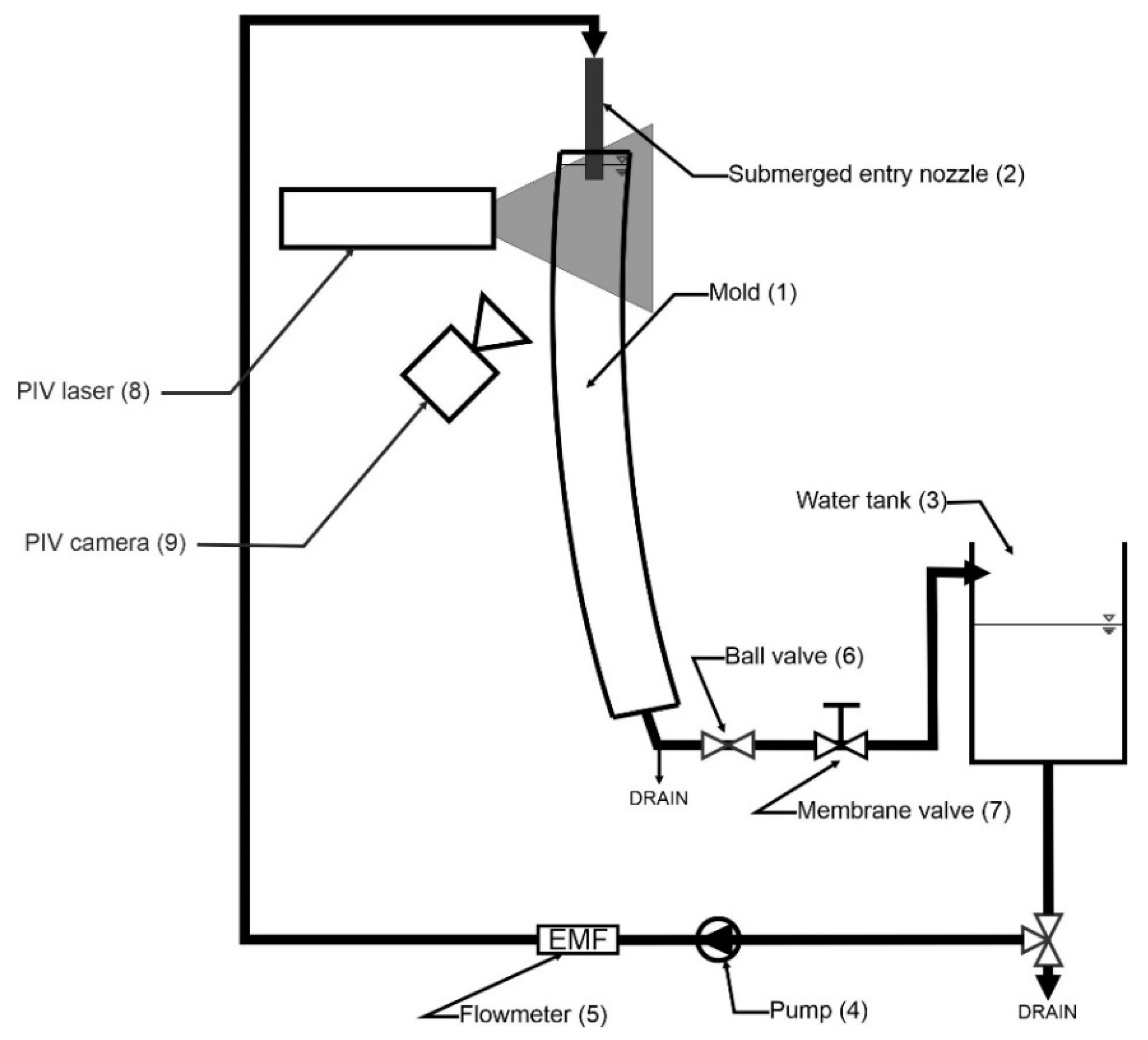

2.2. Experimental Setup and Methods

2.2.1. Experimental Conditions and Process Similarity

2.2.2. PIV Measurements

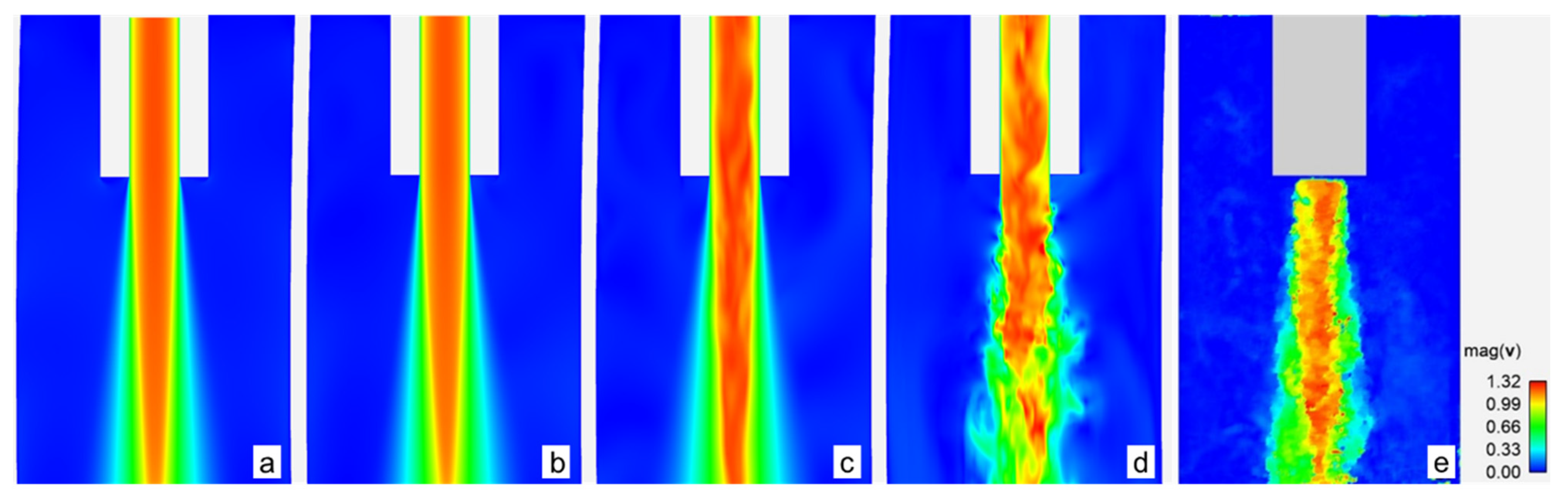

3. Results

4. Conclusions

- General flow features can be reasonably predicted using either of the models.

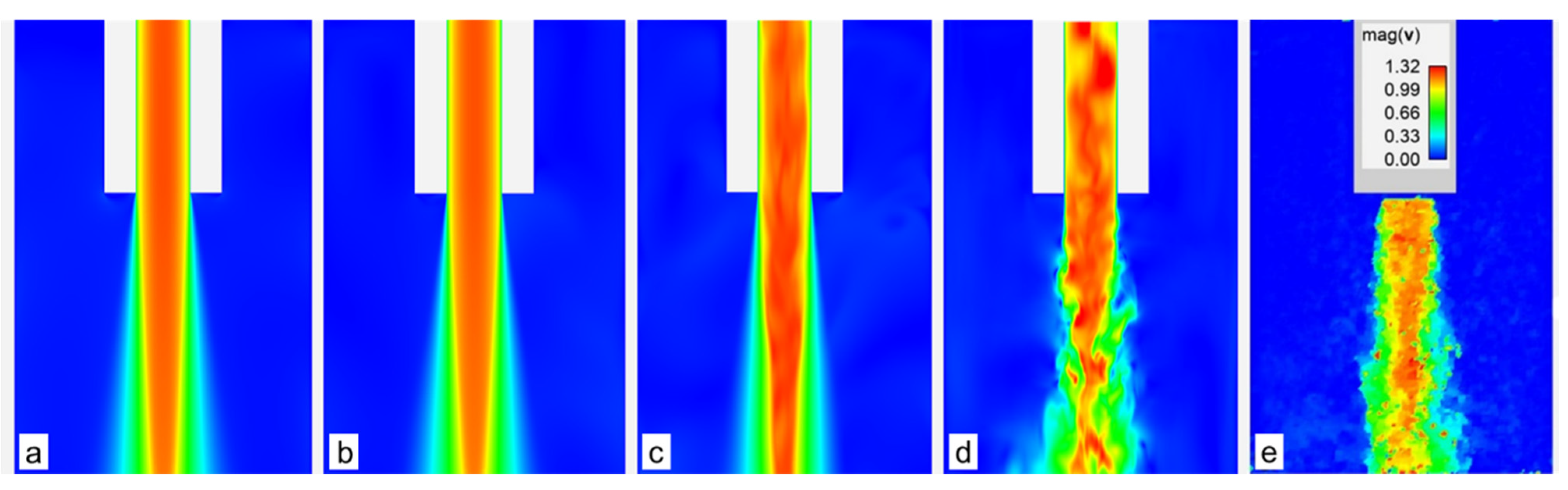

- In the case of typical RANS models (Realizable k-ε EWT and SST k-ω), the solution is more or less steady, even if the solving procedure is transient.

- With the SAS and LES models, a steady solution does not exist. Fluctuations in the primary jet are always present.

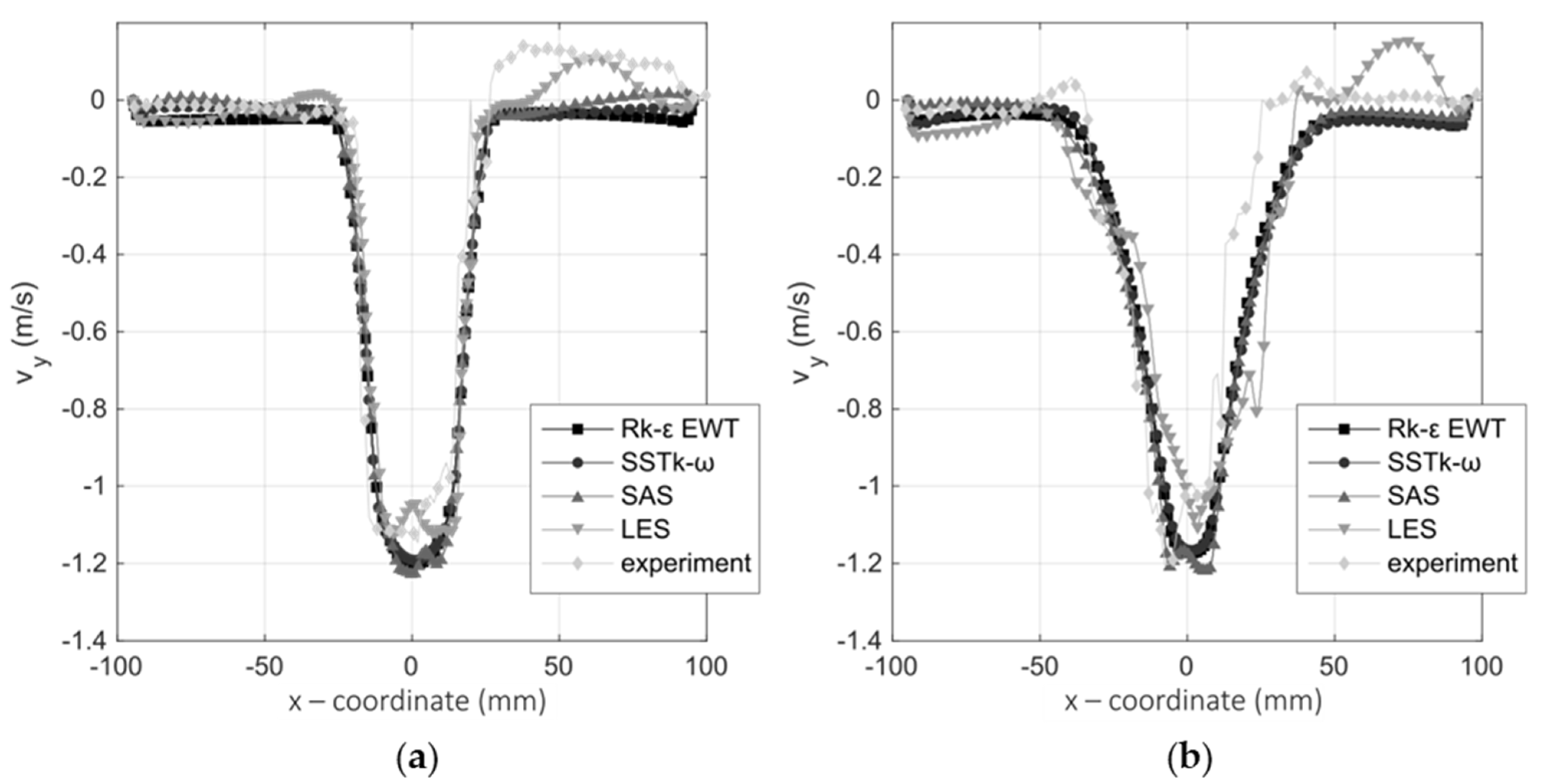

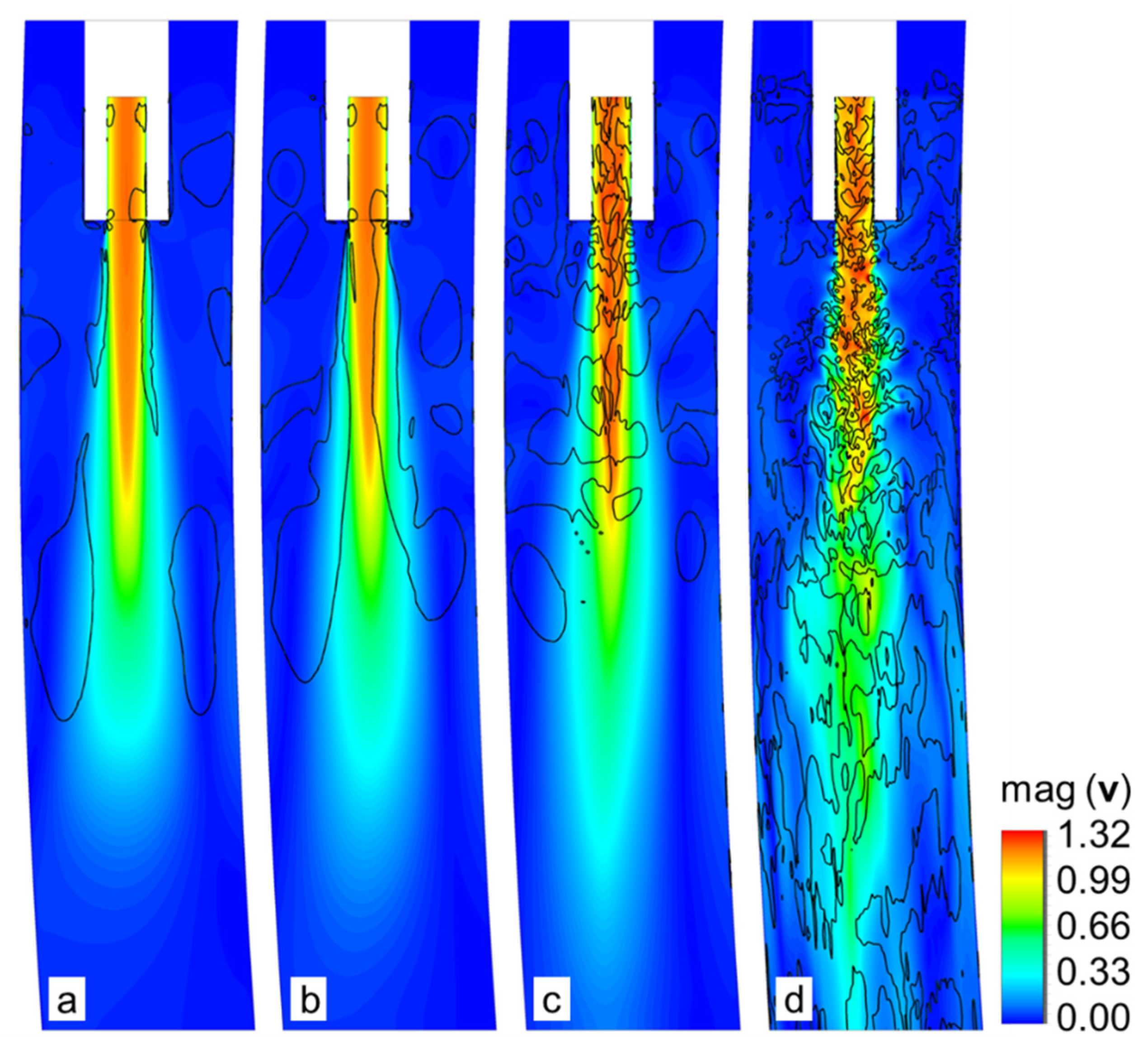

- LES model offers the closest prediction to experimental PIV data. It can also resolve secondary flow with a high degree of similarity to the experiment.

- Similar computational costs were observed for Realizable k-ε EWT and SST k-ω models. A significant increase is observed for the SAS model and even more in the case of the LES model. The computational times increase by a factor of 4, and the number of computational cells increases by a factor of 1.7 compared to the SAS model.

- An increase in computational cost is only feasible if a detailed description of the flow is needed, e.g., the study of inclusion paths.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Branca, T.A.; Fornai, B.; Colla, V.; Murri, M.M.; Streppa, E.; Schröder, A.J. The challenge of digitalization in the steel sector. Metals 2020, 10, 288. [Google Scholar] [CrossRef] [Green Version]

- Hardin, R.A.; Liu, K.; Kapoor, A.; Beckermann, C. A transient simulation and dynamic spray cooling control model for continuous steel casting. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2003. [Google Scholar] [CrossRef]

- Da Costa, E.; Silva, A.L.V. The effects of non-metallic inclusions on properties relevant to the performance of steel in structural and mechanical applications. J. Mater. Res. Technol. 2019, 8, 2408–2422. [Google Scholar] [CrossRef]

- Väyrynen, P.; Wang, S.; Louhenkilpi, S.; Holappa, L. Modeling and removal of inclusions in continuous casting. In Proceedings of the Materials Science and Technology 2009—International Symposium on Inclusions and Clean Steel, Pittsburg, PA, USA, 25–29 October 2009. [Google Scholar]

- Saeidy Pour, M.A.; Hassanpour, S. Steel Cleanliness Depends on Inflow Turbulence Intensity (in Tundishes and Molds). Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2020. [Google Scholar] [CrossRef]

- Chaudhary, R.; Rietow, B.T.; Thomas, B.G. Differences between physical water models and steel continuous casters: A theoretical evaluation. In Proceedings of the Materials Science and Technology 2009—International Symposium on Inclusions and Clean Steel, Pittsburg, PA, USA, 25–29 October 2009. [Google Scholar]

- Chaudhary, R.; Ji, C.; Thomas, B.G.; Vanka, S.P. Transient turbulent flow in a liquid-metal model of continuous casting, including comparison of six different methods. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2011. [Google Scholar] [CrossRef]

- Cho, S.M.; Thomas, B.G.; Kim, S.H. Effect of Nozzle Port Angle on Transient Flow and Surface Slag Behavior During Continuous Steel-Slab Casting. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2019, 50, 52–76. [Google Scholar] [CrossRef]

- Yuan, Q.; Sivaramakrishnan, S.; Vanka, S.P.; Thomas, B.G. Computational and experimental study of turbulent flow in a 0.4-scale water model of a continuous steel caster. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2004. [Google Scholar] [CrossRef]

- Ramos-Banderas, A.; Sánchez-Pérez, R.; Morales, R.D.; Palafox-Ramos, J.; Demedices-García, L.; Díaz-Cruz, M. Mathematical simulation and physical modeling of unsteady fluid flows in a water model of a slab mold. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2004, 35, 449–460. [Google Scholar] [CrossRef]

- Zhao, B.; Thomas, B.G.; Vanka, S.P.; O’Malley, R.J. Transient fluid flow and superheat transport in continuous casting of steel slabs. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2005, 36, 801. [Google Scholar] [CrossRef] [Green Version]

- Gregorc, J.; Kunavar, A.; Šarler, B. Performance of turbulence models for flow prediction in a mould of continuous steel caster. IOP Conf. Ser. Mater. Sci. Eng. 2020, 861, 012019. [Google Scholar] [CrossRef]

- Shih, T.H.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A new k-ϵ eddy viscosity model for high reynolds number turbulent flows. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef] [Green Version]

- Menter, F.R.; Egorov, Y. The scale-adaptive simulation method for unsteady turbulent flow predictions. part 1: Theory and model description. Flow Turbul. Combust. 2010, 85, 113–138. [Google Scholar] [CrossRef]

- Ducros, F.; Nicoud, F.; Poinsot, T. Wall-adapting local eddy-viscosity models for simulations in complex geometries. Conf. Numer. Methods Fluid Dyn. 1998, 6, 293–299. [Google Scholar]

- Ferziger, J.H.; Perić, M.; Street, R.L. Computational Methods for Fluid Dynamics, 4th ed.; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- ANSYS. User Guide for ANSYS 18.2; ANSYS Inc.: Cotonsburg, PA, USA, 2015. [Google Scholar]

| Material | Density (kg·m−3) | Dynamic Viscosity (kg·m−1·s−1) |

|---|---|---|

| Water (liquid) | 0.9982 × 10+3 | 1.003 × 10−3 |

| Air (gas) | 1.2250 × 10+3 | 1.820 × 10−5 |

| Steel (liquid) | 6.8839 × 10+3 | 5.318 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gregorc, J.; Kunavar, A.; Šarler, B. RANS versus Scale Resolved Approach for Modeling Turbulent Flow in Continuous Casting of Steel. Metals 2021, 11, 1140. https://doi.org/10.3390/met11071140

Gregorc J, Kunavar A, Šarler B. RANS versus Scale Resolved Approach for Modeling Turbulent Flow in Continuous Casting of Steel. Metals. 2021; 11(7):1140. https://doi.org/10.3390/met11071140

Chicago/Turabian StyleGregorc, Jurij, Ajda Kunavar, and Božidar Šarler. 2021. "RANS versus Scale Resolved Approach for Modeling Turbulent Flow in Continuous Casting of Steel" Metals 11, no. 7: 1140. https://doi.org/10.3390/met11071140

APA StyleGregorc, J., Kunavar, A., & Šarler, B. (2021). RANS versus Scale Resolved Approach for Modeling Turbulent Flow in Continuous Casting of Steel. Metals, 11(7), 1140. https://doi.org/10.3390/met11071140