Thermal Fatigue Life Prediction under Temperature Uncertainty for Shot Sleeve of Squeeze Casting Machine

Abstract

:1. Introduction

2. Methodology

- (1)

- Selection of uncertain parameters;

- (2)

- Sample acquisition by experiment or FE simulation;

- (3)

- Establishment of the surrogate model;

- (4)

- Accuracy testing and improvement of the surrogate model;

- (5)

- Calculation of the thermal fatigue life;

- (6)

- Statistical characteristics analysis and verification of the thermal fatigue life.

2.1. Kriging Surrogate Model

2.2. Monte Carlo Simulation

2.3. Prediction Method of Thermal Fatigue Life

2.4. Statistical Characteristic Analysis

3. Prediction of Thermal Fatigue Life of a Shot Sleeve Considering Temperature Uncertainty

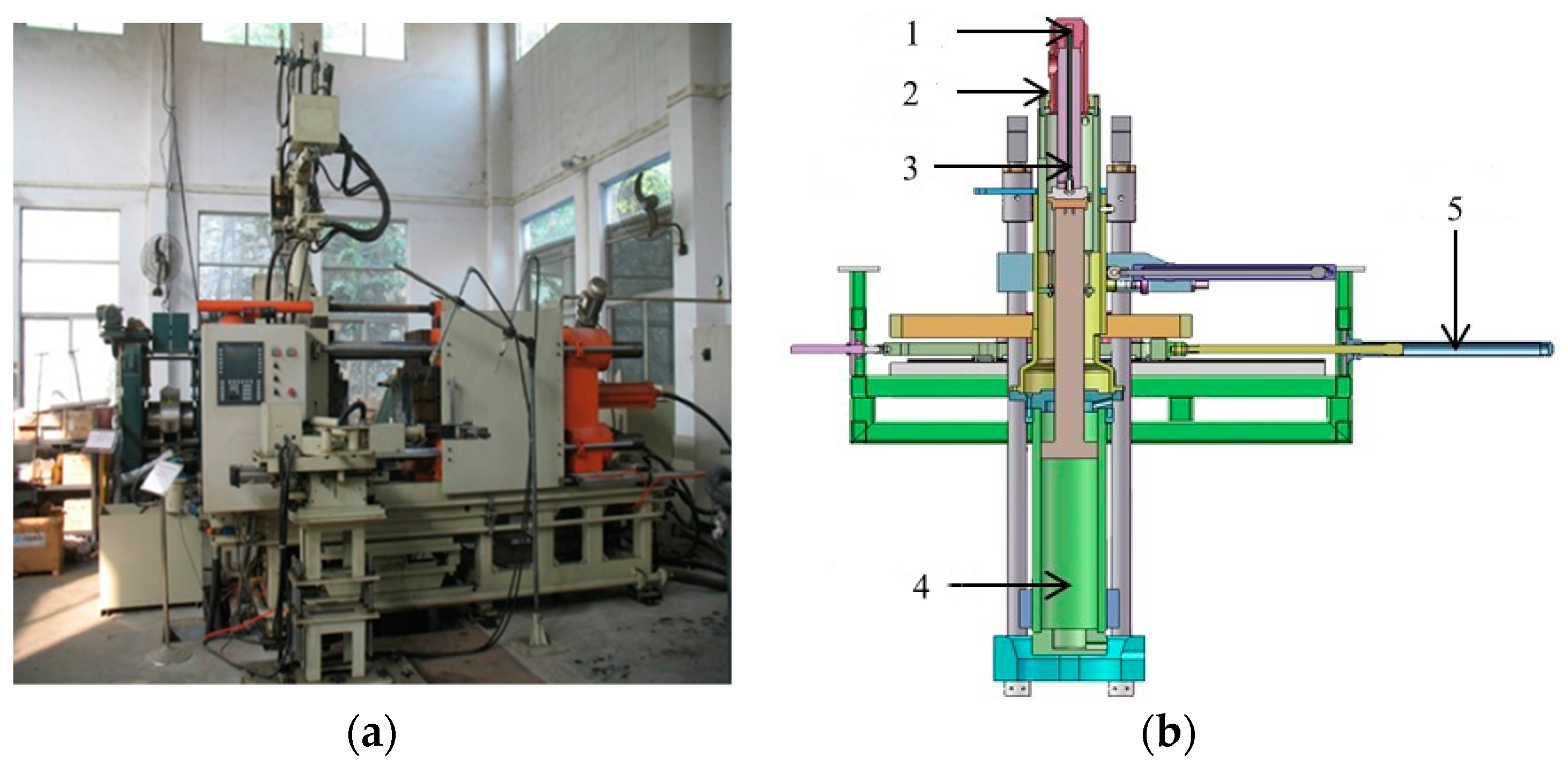

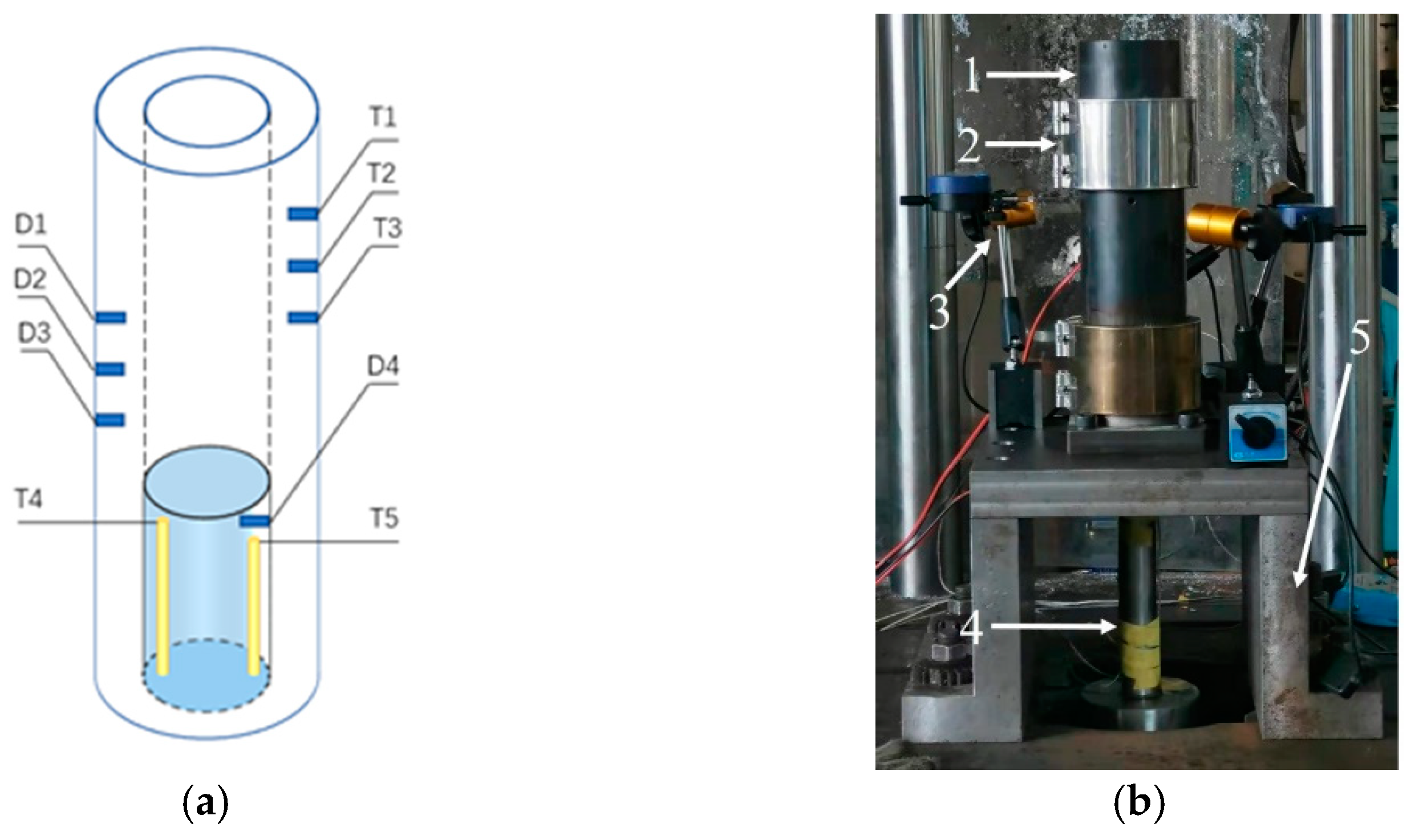

3.1. Experiment of Injection Mechanism

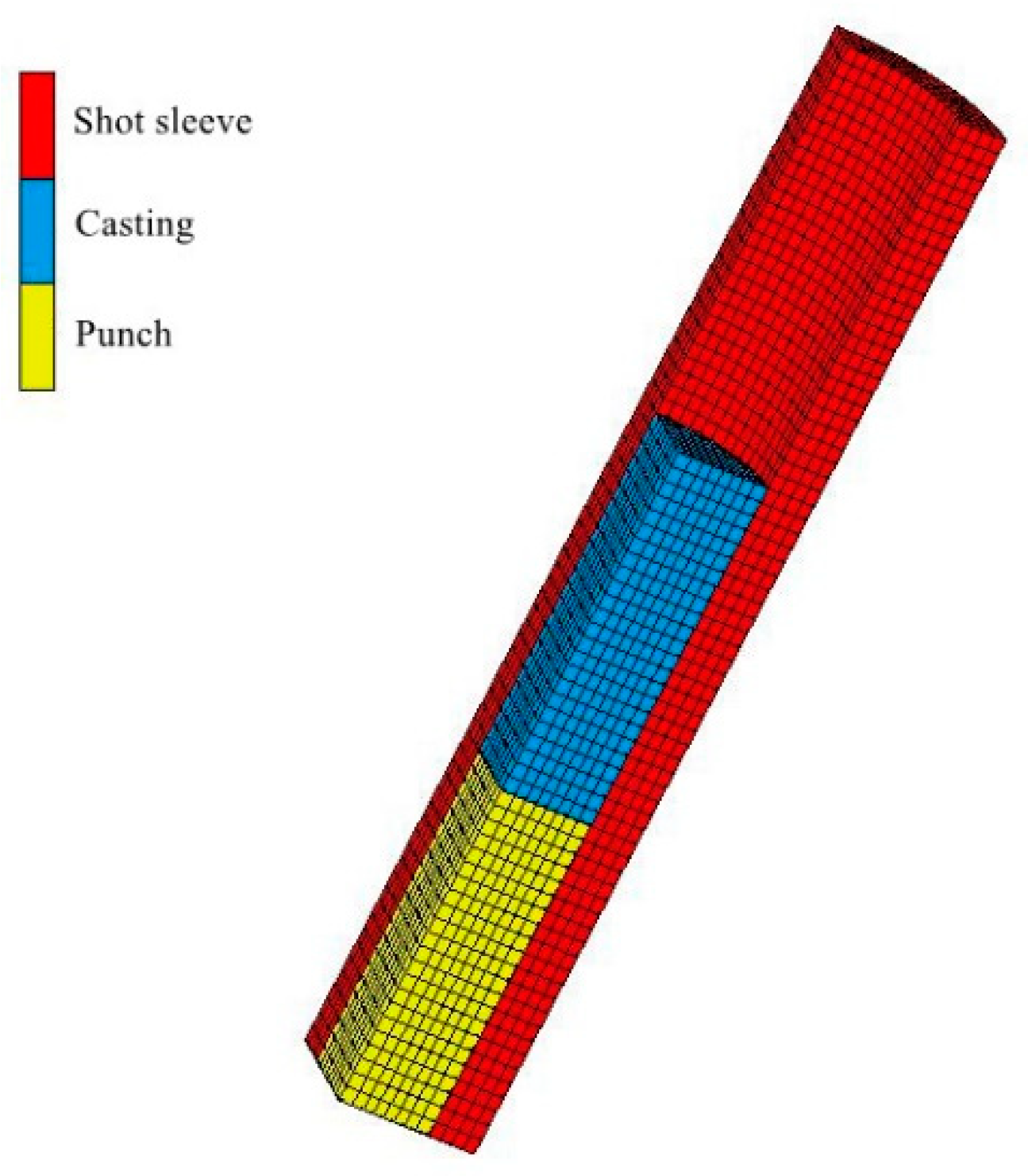

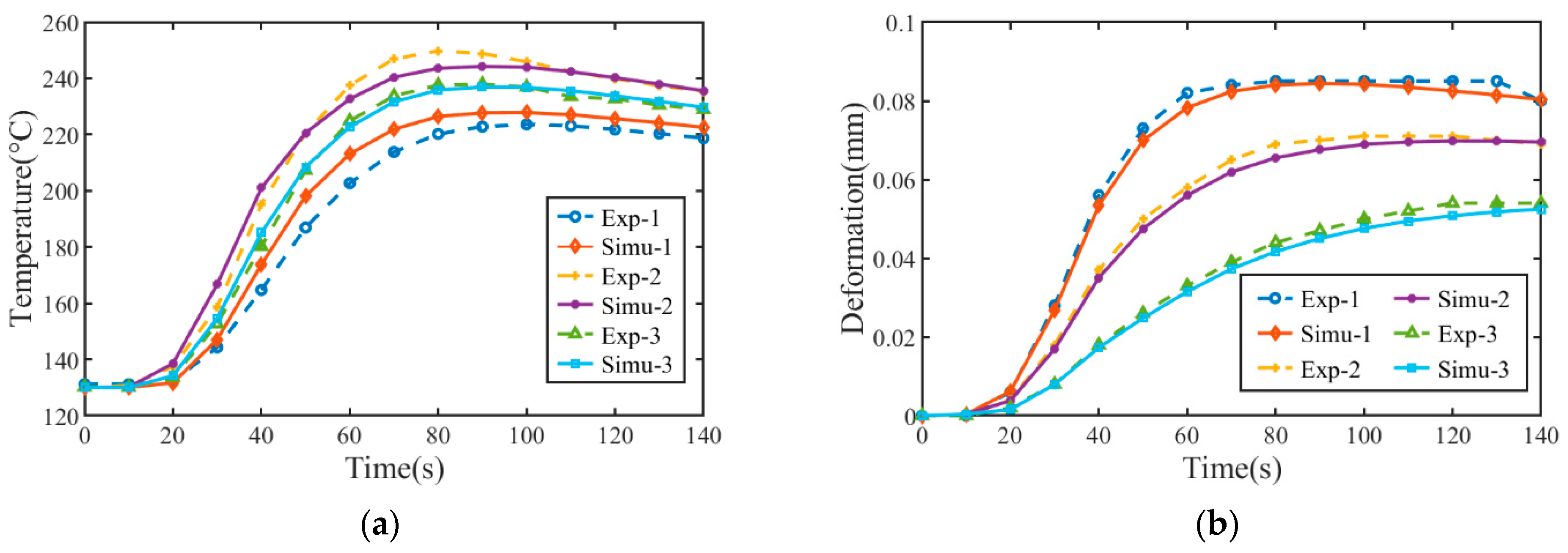

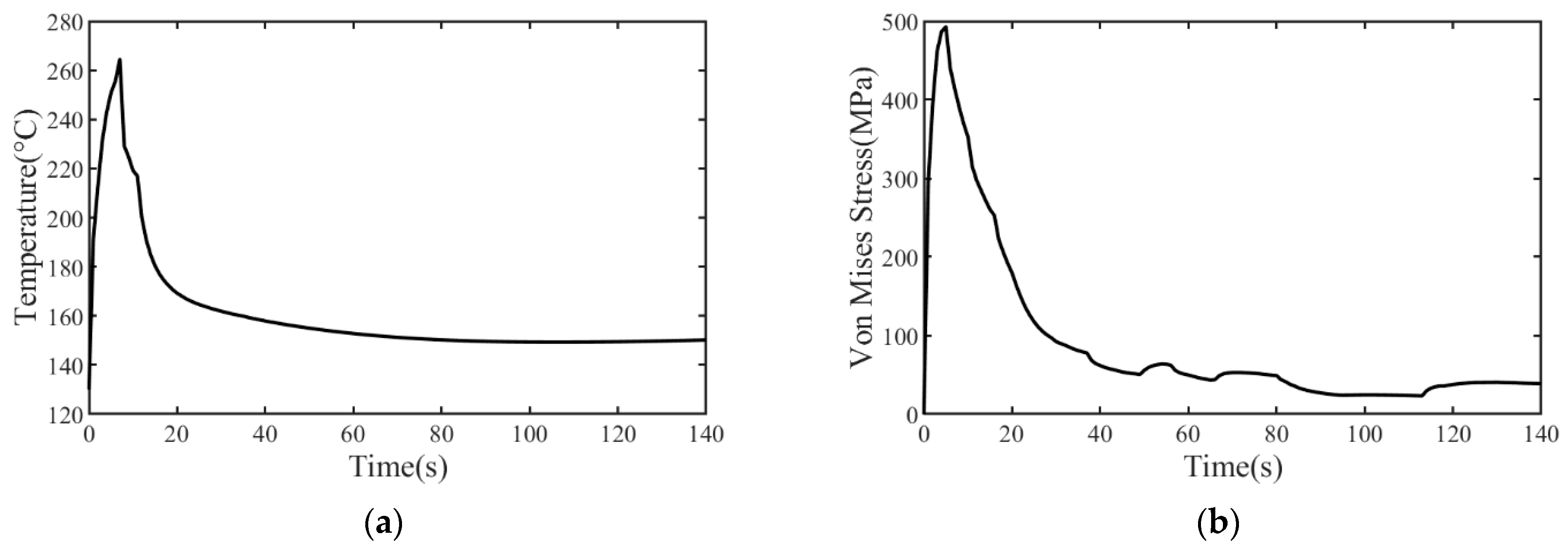

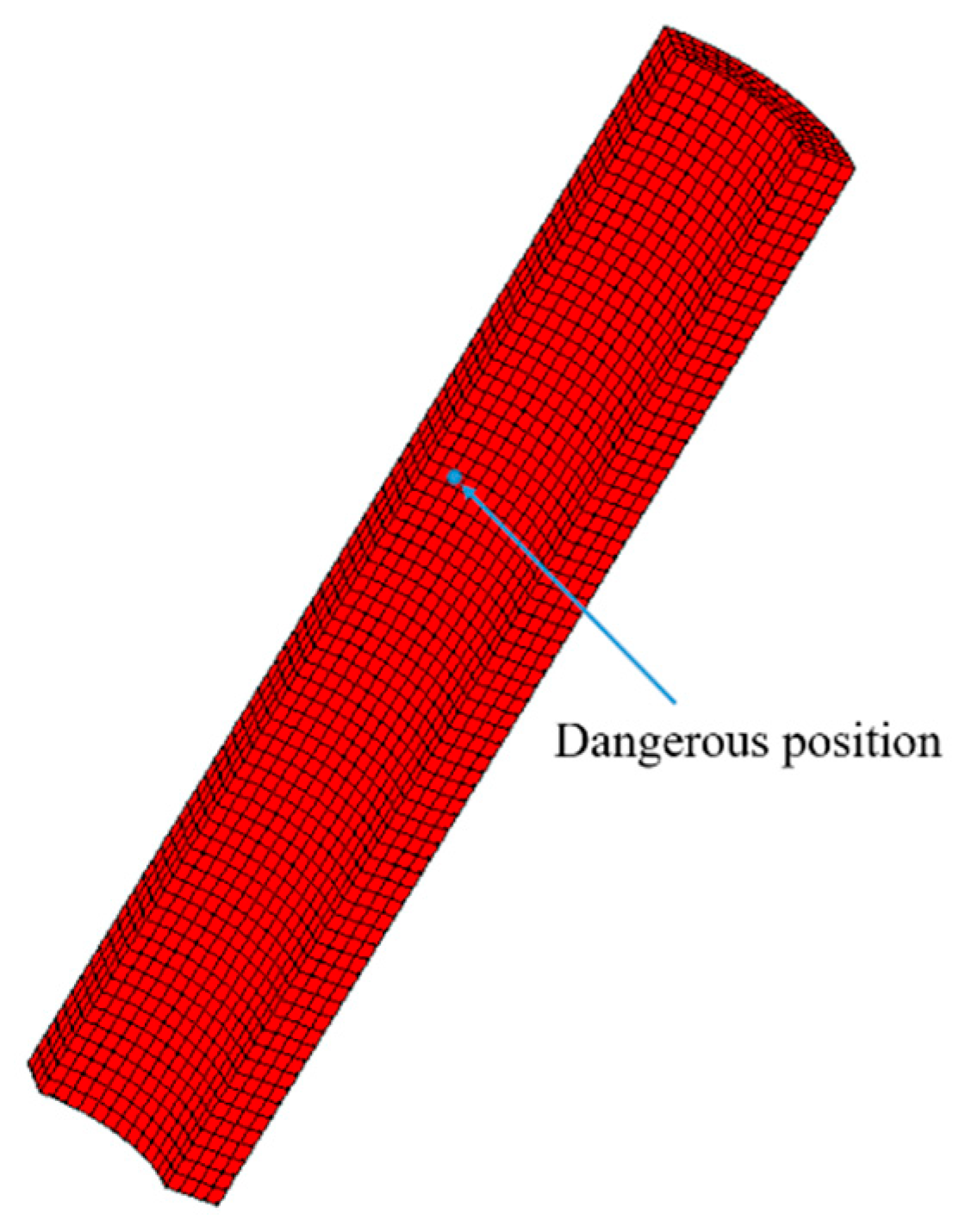

3.2. FE Simulation of Injection Mechanism

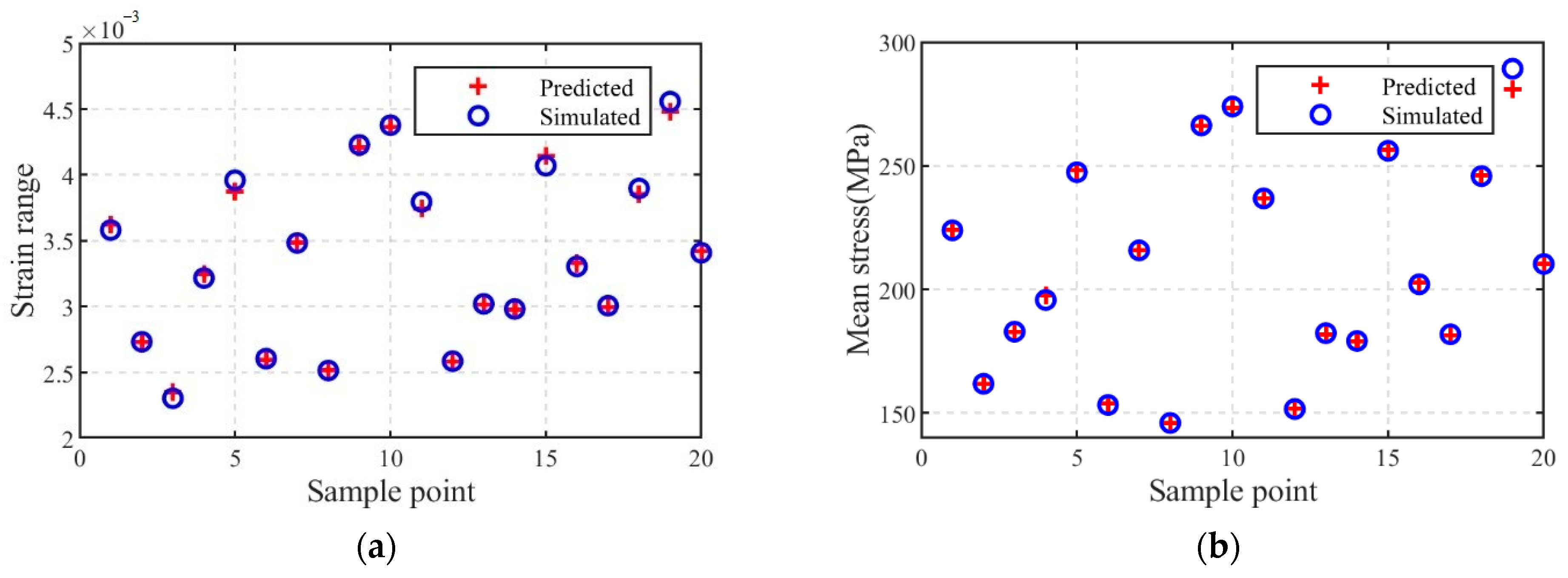

3.3. Data Acquisition and Kriging Model Building

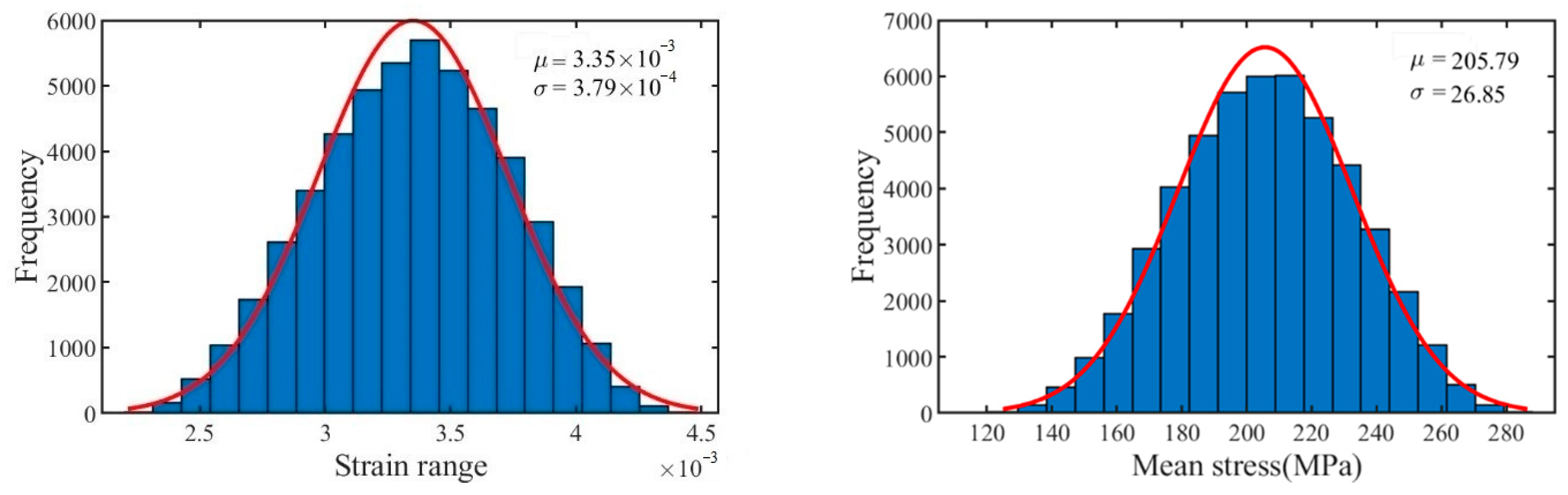

3.4. MCS and Thermal Fatigue Life Calculation

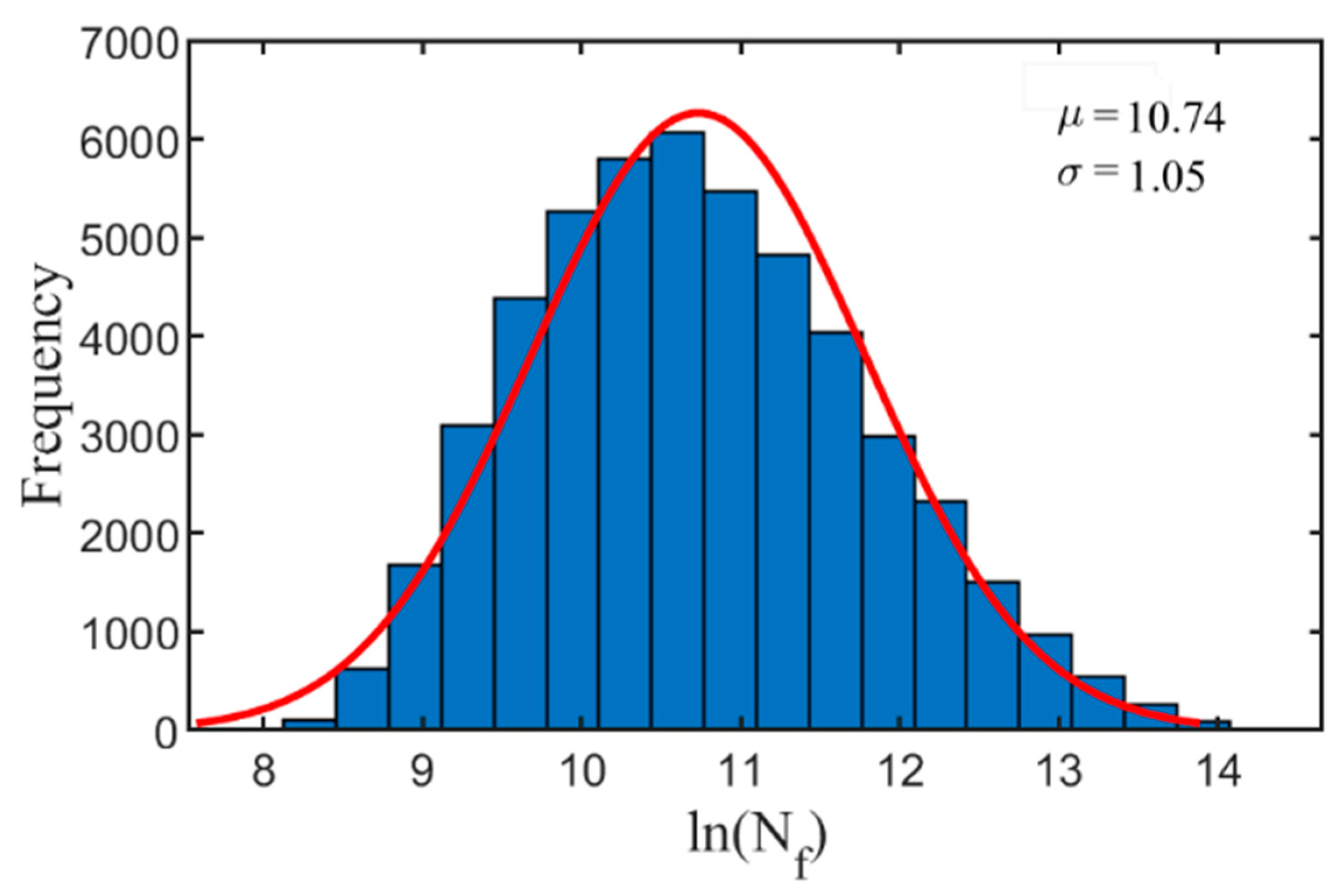

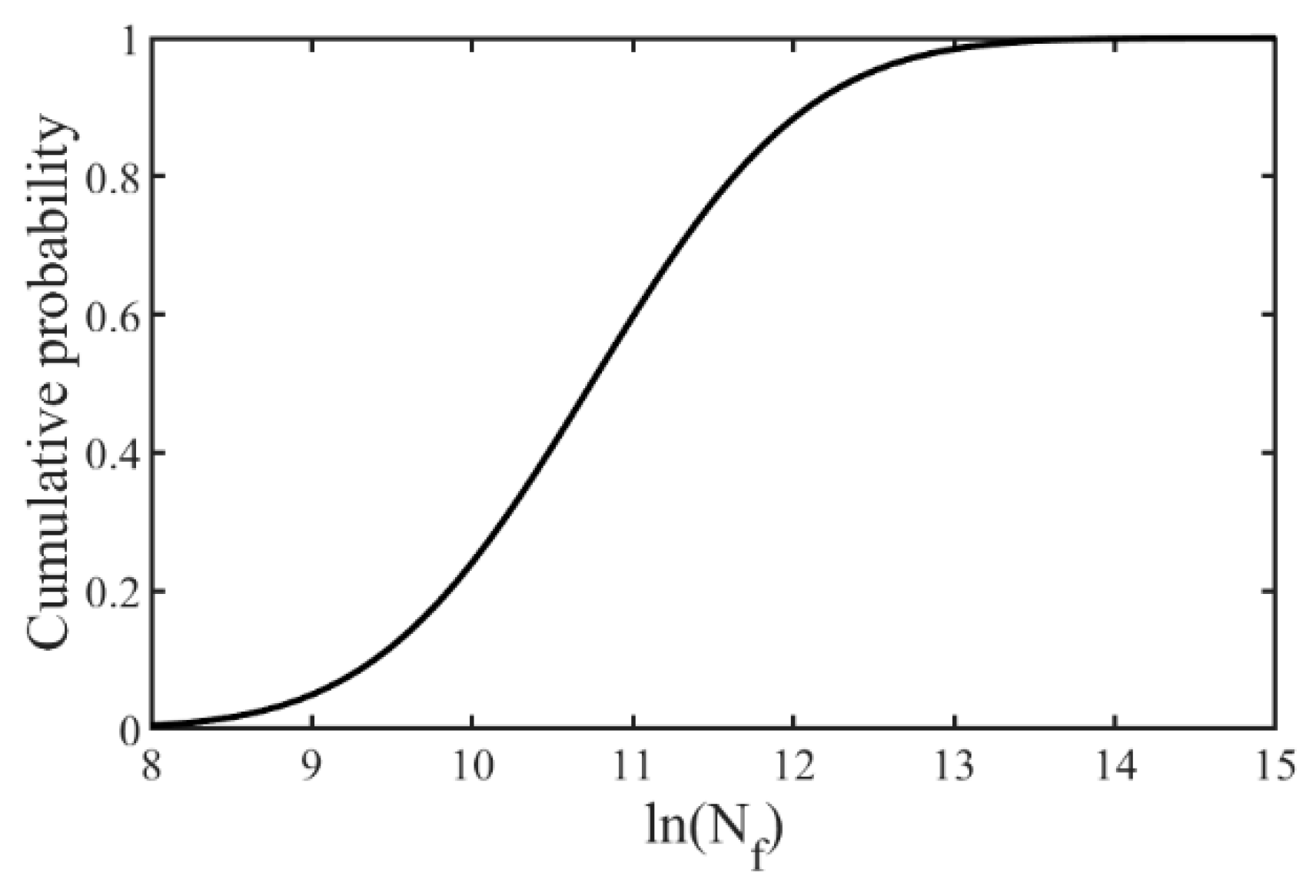

4. Results and Discussion

5. Conclusions

- Temperature uncertainty has an important influence on the prediction of the thermal fatigue life of shot sleeves, and considering temperature uncertainty can allow for realizing a more accurate and reliable life prediction for shot sleeves.

- When the pouring temperature ranges from 660 to 720 °C and the preheating temperature ranges from 100 to 200 °C, the predicted average thermal fatigue life of a shot sleeve is 36,975 to 38,109 cycles. The predicted results are close to those of others and are also consistent with the service life of commercial shot sleeves. In addition, reducing the difference between the pouring temperature and the preheating temperature is helpful to prolong the service life of the shot sleeve.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ghomashchi, M.R.; Vikhrov, A. Squeeze casting: An overview. J. Mater. Process. Technol. 2000, 101, 1–9. [Google Scholar] [CrossRef]

- Li, Y.Y.; Zhang, W.W.; Zhao, H.D.; You, D.D.; Zhang, D.T.; Shao, M.; Zhang, W. Research progress on squeeze casting in China. China Found. 2014, 11, 239–246. [Google Scholar]

- Fiorese, E.; Richiedei, D.; Bonollo, F. Improving the quality of die castings through optimal plunger motion planning: Analytical computation and experimental validation. Int. J. Adv. Manuf. Technol. 2017, 88, 1475–1484. [Google Scholar] [CrossRef]

- Wang, Q.-L.; Xiong, S.-M. Effect of multi-step slow shot speed on microstructure of vacuum die cast AZ91D magnesium alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 375–380. [Google Scholar] [CrossRef]

- Mitrović, D.; Terčelj, M.; Kastelic, S.; Primož, M. Analysis of degradation processes on shot sleeves made from new Si-Mo cast iron in aluminium high pressure die casting—A case study. Eng. Fail. Anal. 2020, 109, 104283. [Google Scholar] [CrossRef]

- Mellouli, D.; Haddar, N.; Köster, A.; Ayedi, H.F. Hardness effect on thermal fatigue damage of hot-working tool steel. Eng. Fail. Anal. 2014, 45, 85–95. [Google Scholar] [CrossRef]

- Klobčar, D.; Tušek, J. Thermal stresses in aluminium alloy die casting dies. Comput. Mater. Sci. 2008, 43, 1147–1154. [Google Scholar] [CrossRef]

- Shi, Q. Prediction of Thermal Distortion and Thermal Fatigue in Shot Sleeves. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2002. [Google Scholar]

- Lu, Y.; Ripplinger, K.; Huang, X.; Mao, Y.; Detwiler, D.; Luo, A.A. A new fatigue life model for thermally-induced cracking in H13 steel dies for die casting. J. Mater. Process. Technol. 2019, 271, 444–454. [Google Scholar] [CrossRef]

- Long, A.; Thornhill, D.; Armstrong, C.; Watson, D. Predicting die life from die temperature for high pressure dies casting aluminium alloy. Appl. Therm. Eng. 2012, 44, 100–107. [Google Scholar] [CrossRef]

- Long, A. Extending Life of High Pressure Die Casting Dies. Ph.D. Thesis, Queen’s University, Belfast, Northern Ireland, 2010. [Google Scholar]

- Broucaret, S.; Michrafy, A.; Dour, G. Heat transfer and thermo-mechanical stresses in a gravity casting die: Influence of process parameters. J. Mater. Process. Technol. 2001, 110, 211–217. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Thomas, B.G. Thermomechanical finite-element model of shell behavior in continuous casting of steel. Met. Mater. Trans. A 2004, 35, 1151–1172. [Google Scholar] [CrossRef]

- Koric, S.; Thomas, B.G.; Voller, V.R. Enhanced latent heat method to incorporate superheat effects into fixed-grid multiphysics simulations. Numer. Heat Tran. Part B Fundam. 2010, 57, 396–413. [Google Scholar] [CrossRef]

- Zappulla, M.L.S.; Cho, S.; Koric, S.; Lee, H.; Kim, S.; Thomas, B.G. Multiphysics modeling of continuous casting of stainless steel. J. Mater. Process. Technol. 2020, 278, 116469. [Google Scholar] [CrossRef]

- Jhavar, S.; Paul, C.; Jain, N.K. Causes of failure and repairing options for dies and molds: A review. Eng. Fail. Anal. 2013, 34, 519–535. [Google Scholar] [CrossRef]

- Bjorklund, A.E. Survey of approaches to improve reliability in lca. Int. J. Life Cycle Assess. 2002, 7, 64–72. [Google Scholar] [CrossRef]

- JCGM. Evaluation of Measurement Data-Supplement 1 to the “Guide to The Expression of Uncertainty in Measurement”—Propagation of Distributions Using a Monte Carlo Method; Joint Committee for Guides in Metrology: Geneva, Switzerland, 2008. [Google Scholar]

- Groen, E.; Heijungs, R.; Bokkers, E.; De Boer, I. Methods for uncertainty propagation in life cycle assessment. Environ. Model. Softw. 2014, 62, 316–325. [Google Scholar] [CrossRef]

- Han, Z.-H.; Görtz, S. Hierarchical Kriging Model for Variable-Fidelity Surrogate Modeling. AIAA J. 2012, 50, 1885–1896. [Google Scholar] [CrossRef]

- Sacks, J.; Welch, J.W.; Mitchell, T.J.; Henry, P.W. Design and Analysis of Computer Experiments. Stat. Sci. 1989, 4, 409–423. [Google Scholar] [CrossRef]

- Currin, C.; Mitchell, T.; Morris, M.; Ylvisaker, D. A Bayesian Approach to the Design and Analysis of Computer Experiments; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1988.

- Gao, L.M.; Cai, Y.T.; Xu, H.L.; Deng, W.M. Uncertainty analysis of machining error influence of compressor blade. J. Aerosp. Power 2017, 32, 2253–2259. [Google Scholar]

- Ma, J.; Han, X.Y.; Xu, Q.; Chen, S.Y.; Zhao, W.B.; Li, X.K. Reliability-based EDM process parameter optimization using kriging model and sequential sampling. Math. Biosci. Eng. 2019, 16, 7421–7432. [Google Scholar]

- Sun, D.Y.; Chen, G.P.; Wang, T.C.; Sun, R.J. Wear Prediction of a Mechanism with Joint Clearance Involving Aleatory and Epistemic Uncertainty. J. Tribol. Trans. 2014, 136, 41101. [Google Scholar] [CrossRef]

- You, D.D.; Jiang, X.M.; Cheng, X.Y.; Wang, X. Bayesian kriging modeling for spatiotemporal prediction in squeeze casting. Int. J. Adv. Manuf. Technol. 2017, 89, 355–369. [Google Scholar] [CrossRef]

- Coffin, L.F. A study of the effects of cyclic thermal stresses on a ductile metal. Trans. ASME 1954, 76, 931–950. [Google Scholar]

- Manson, S.S. Behavior of Materials under Conditions of Thermal Stress. NACA Rep. 1954, 7, 661–665. [Google Scholar]

- Muralidharan, U.; Manson, S.S. A Modified Universal Slopes Equation for Estimation of Fatigue Characteristics of Metals. J. Eng. Mater. Technol. 1988, 110, 55–58. [Google Scholar] [CrossRef]

- Hu, K.; Zhu, F.; Chen, J.; Noda, N.-A.; Han, W.; Sano, Y. Simulation of Thermal Stress and Fatigue Life Prediction of High Speed Steel Work Roll during Hot Rolling Considering the Initial Residual Stress. Metals 2019, 9, 966. [Google Scholar] [CrossRef] [Green Version]

- Socie, D.F.; Morrow, J. Review of Contemporary Approaches to Fatigue Damage Analysis. In Risk and Failure Analysis for Improved Performance and Reliability; Burke, J.J., Weiss, V., Eds.; Springer: Boston, MA, USA, 1980; pp. 141–194. [Google Scholar]

- Ince, A.; Glinka, G. A modification of Morrow and Smith-Watson-Topper mean stress correction models. Fatigue Fract. Eng. Mater. Struct. 2011, 34, 854–867. [Google Scholar] [CrossRef]

- Klobčar, D.; Tušek, J.; Taljat, B. Thermal fatigue of materials for die-casting tooling. Mater. Sci. Eng. A 2008, 472, 198–207. [Google Scholar] [CrossRef]

- Das, P.; Bhuniya, B.; Samanta, S.K.; Dutta, P. Studies on die filling of A356 Al alloy and development of a steering knuckle component using rheo pressure die casting system. J. Mater. Process. Technol. 2019, 271, 293–311. [Google Scholar] [CrossRef]

- Coates, B.; Argyropoulos, S.A. The Effects of Surface Roughness and Metal Temperature on the Heat-Transfer Coefficient at the Metal Mold Interface. Met. Mater. Trans. A 2007, 38, 243–255. [Google Scholar] [CrossRef]

- Helenius, R.; Lohne, O.; Arnberg, L.; Laukli, H.I. The heat transfer during filling of a high-pressure die-casting shot sleeve. Mater. Sci. Eng. A 2005, 413–414, 52–55. [Google Scholar] [CrossRef]

- Lophaven, S.N.; Søndergaard, J.; Nielsen, H.B. DACE-A Matlab Kriging Toolbox (Version 2.0): IMM-REP-2002-12; Technical University of Denmark: Kongens Lyngby, Denmark, 2002. [Google Scholar]

| Material Properties | Punch | Shot Sleeve | Casting |

|---|---|---|---|

| Density (kg/m3) | 7060 | 7800 | 2700 |

| Young’s modulus (GPa) | 169 | 210 | - |

| Poisson’s ratio | 0.257 | 0.3 | - |

| Thermal conductivity (W/m·K) | 24.5–32.2 | 25.0–34.2 | 60–160 |

| Specific heat (J/kg·K) | 560–856 | 460–520 | 963–1082 |

| Expansion coefficient (10−5/K) | 1.29 | 1.15 | - |

| Pouring Temperature (°C) | Preheating Temperature (°C) | Strain Range | Mean Stress (MPa) |

|---|---|---|---|

| 690 | 150 | 3.35 × 10−3 | 205.7 |

| 684 | 180 | 2.64 × 10−3 | 156.3 |

| 696 | 120 | 4.04 ×10−3 | 257.4 |

| 678 | 130 | 3.74 × 10−3 | 235.7 |

| 672 | 140 | 3.51 × 10−3 | 218.6 |

| 708 | 160 | 3.19 × 10−3 | 193.4 |

| 702 | 190 | 2.53 × 10−3 | 146.8 |

| 666 | 170 | 2.79 × 10−3 | 167.6 |

| 714 | 110 | 4.33 × 10−3 | 271.2 |

| 720 | 200 | 2.46 × 10−3 | 146.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, D.; Pang, W.; Cai, D. Thermal Fatigue Life Prediction under Temperature Uncertainty for Shot Sleeve of Squeeze Casting Machine. Metals 2021, 11, 1126. https://doi.org/10.3390/met11071126

You D, Pang W, Cai D. Thermal Fatigue Life Prediction under Temperature Uncertainty for Shot Sleeve of Squeeze Casting Machine. Metals. 2021; 11(7):1126. https://doi.org/10.3390/met11071126

Chicago/Turabian StyleYou, Dongdong, Wenbin Pang, and Dongqing Cai. 2021. "Thermal Fatigue Life Prediction under Temperature Uncertainty for Shot Sleeve of Squeeze Casting Machine" Metals 11, no. 7: 1126. https://doi.org/10.3390/met11071126

APA StyleYou, D., Pang, W., & Cai, D. (2021). Thermal Fatigue Life Prediction under Temperature Uncertainty for Shot Sleeve of Squeeze Casting Machine. Metals, 11(7), 1126. https://doi.org/10.3390/met11071126