Multiphasic Study of Fluid-Dynamics and the Thermal Behavior of a Steel Ladle during Bottom Gas Injection Using the Eulerian Model

Abstract

:1. Introduction

2. Materials and Methods

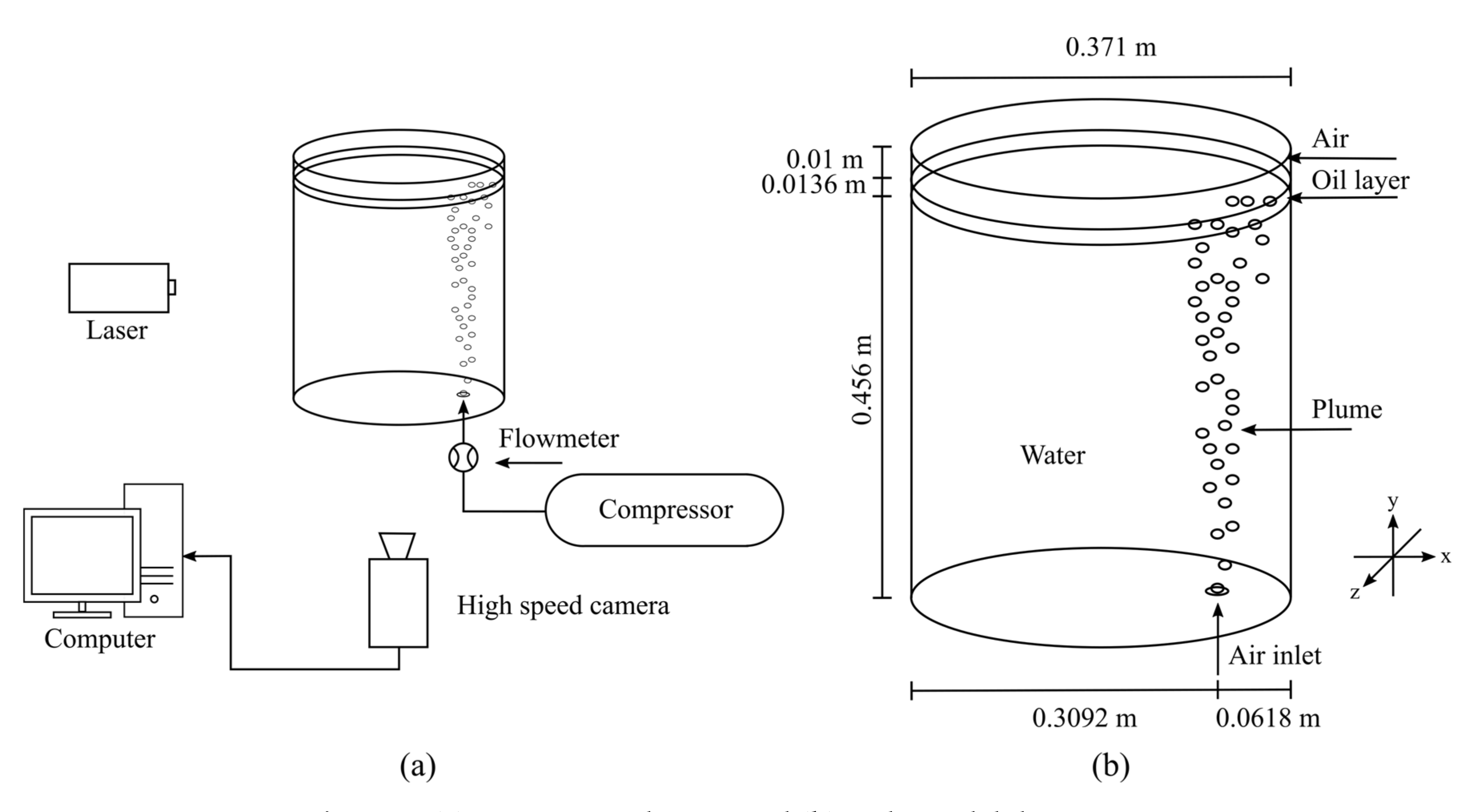

2.1. Physical Modeling

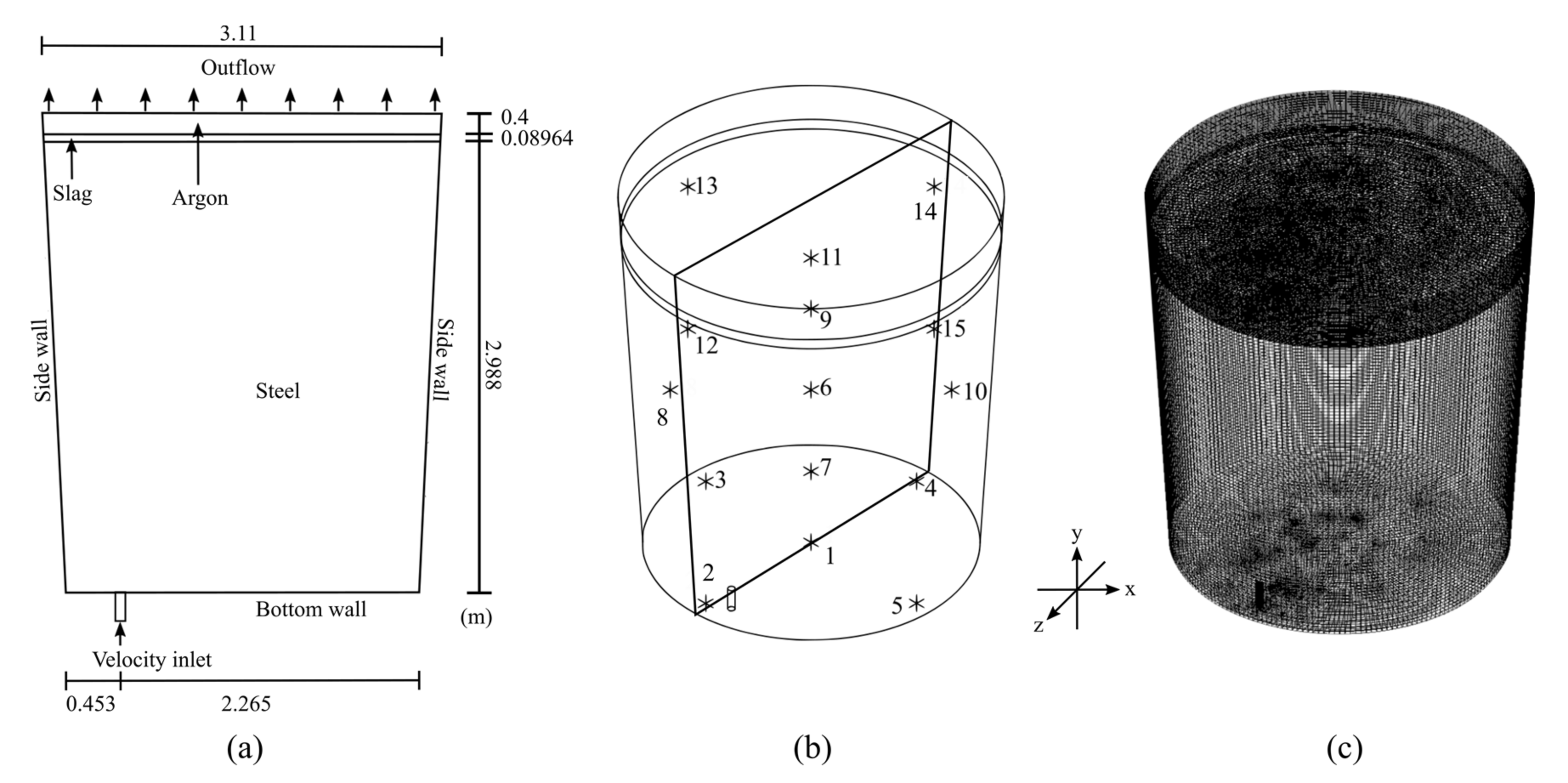

2.2. Mathematical Modeling

2.2.1. Boundary Conditions and Material Properties

2.2.2. Continuity Equation

2.2.3. Momentum Equation

2.2.4. k- Realizable Turbulence Model

2.2.5. Troshko–Hassan Turbulence Interaction

2.2.6. Symmetric Drag Model

2.2.7. Lift Model

2.2.8. Virtual Mass

2.2.9. Turbulent Dispersion Force

2.2.10. Energy Conservation

2.2.11. Heat Exchange Coefficient

2.2.12. Discrete Ordinates Radiation Model

3. Results and Discussion

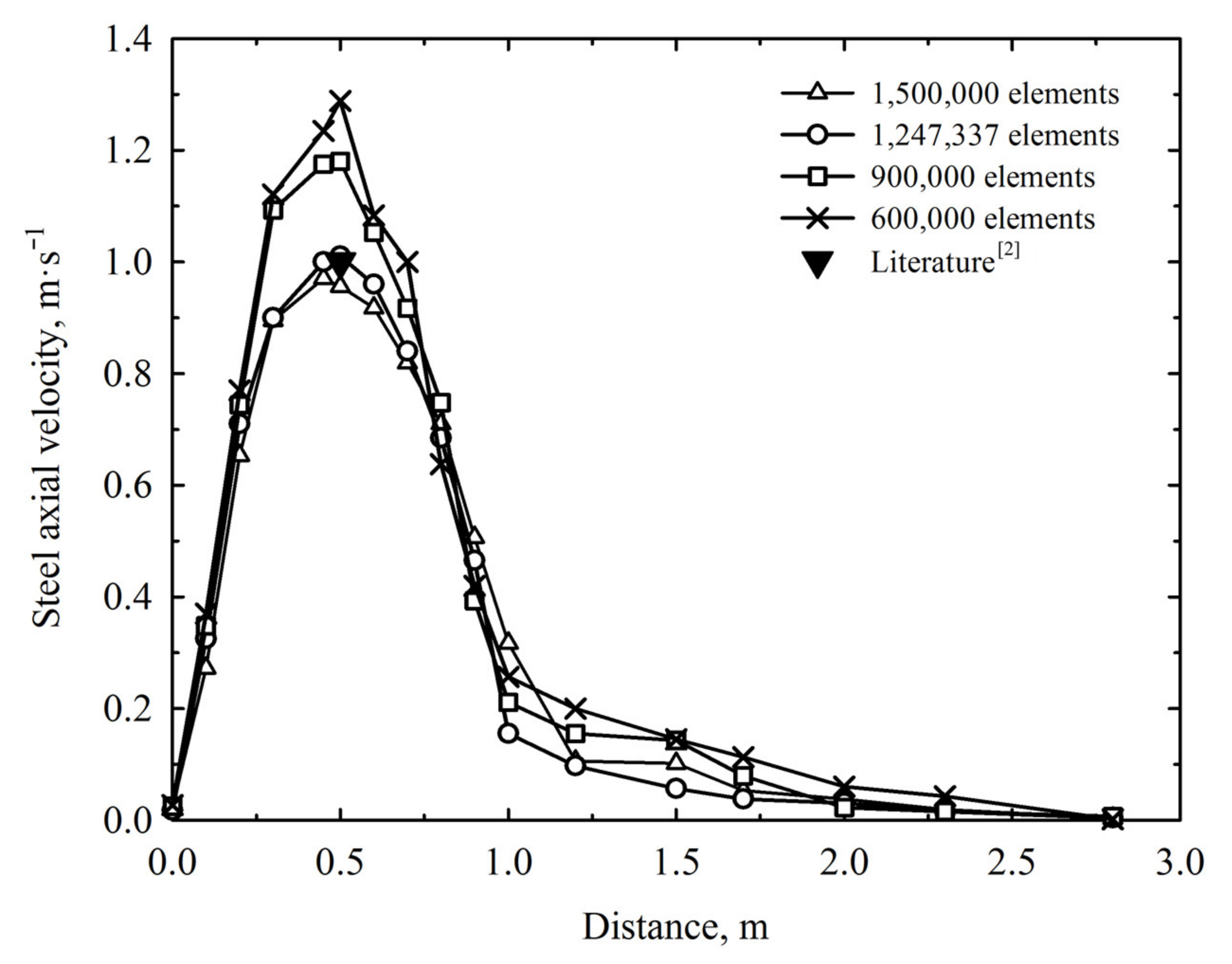

3.1. Fluid Dynamics Validation

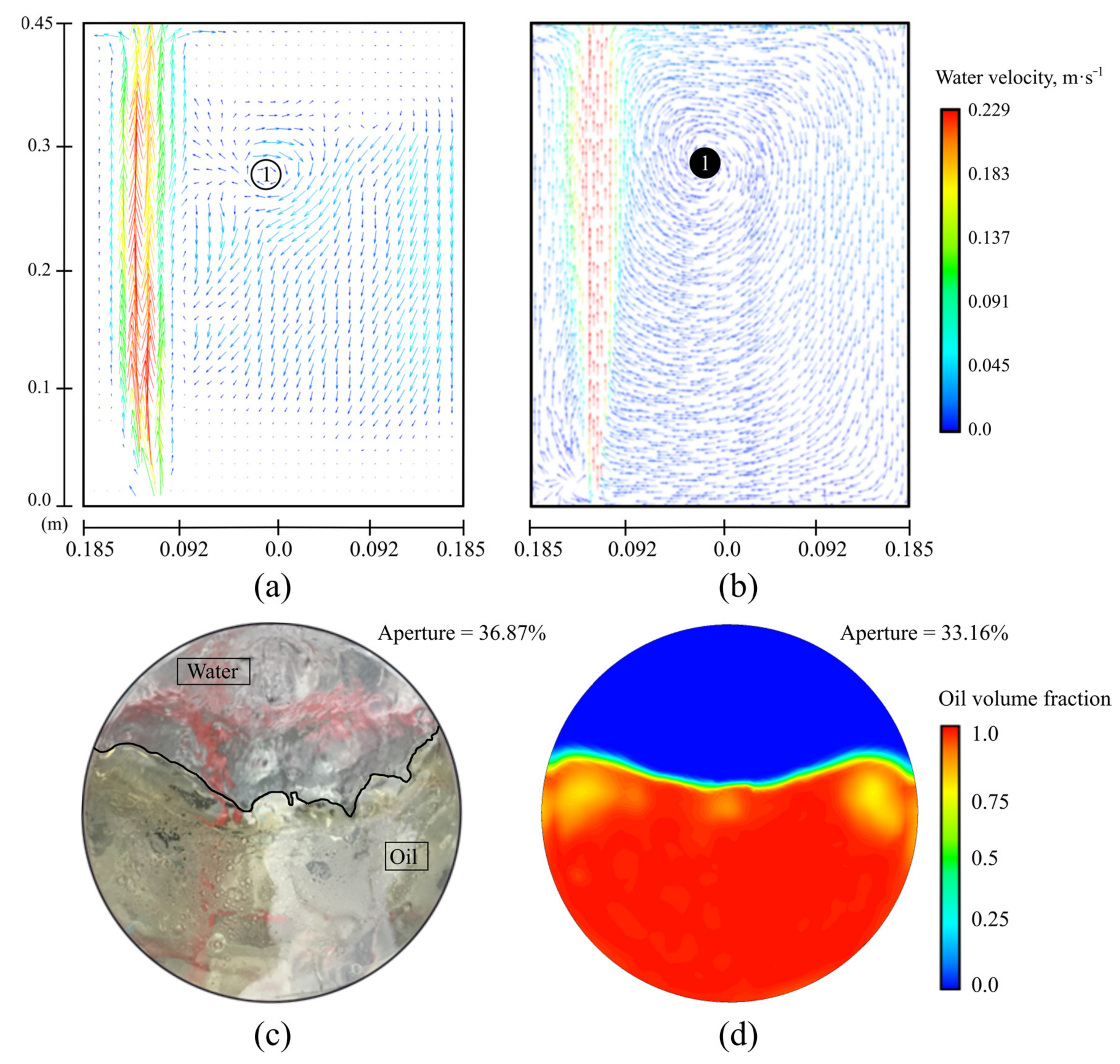

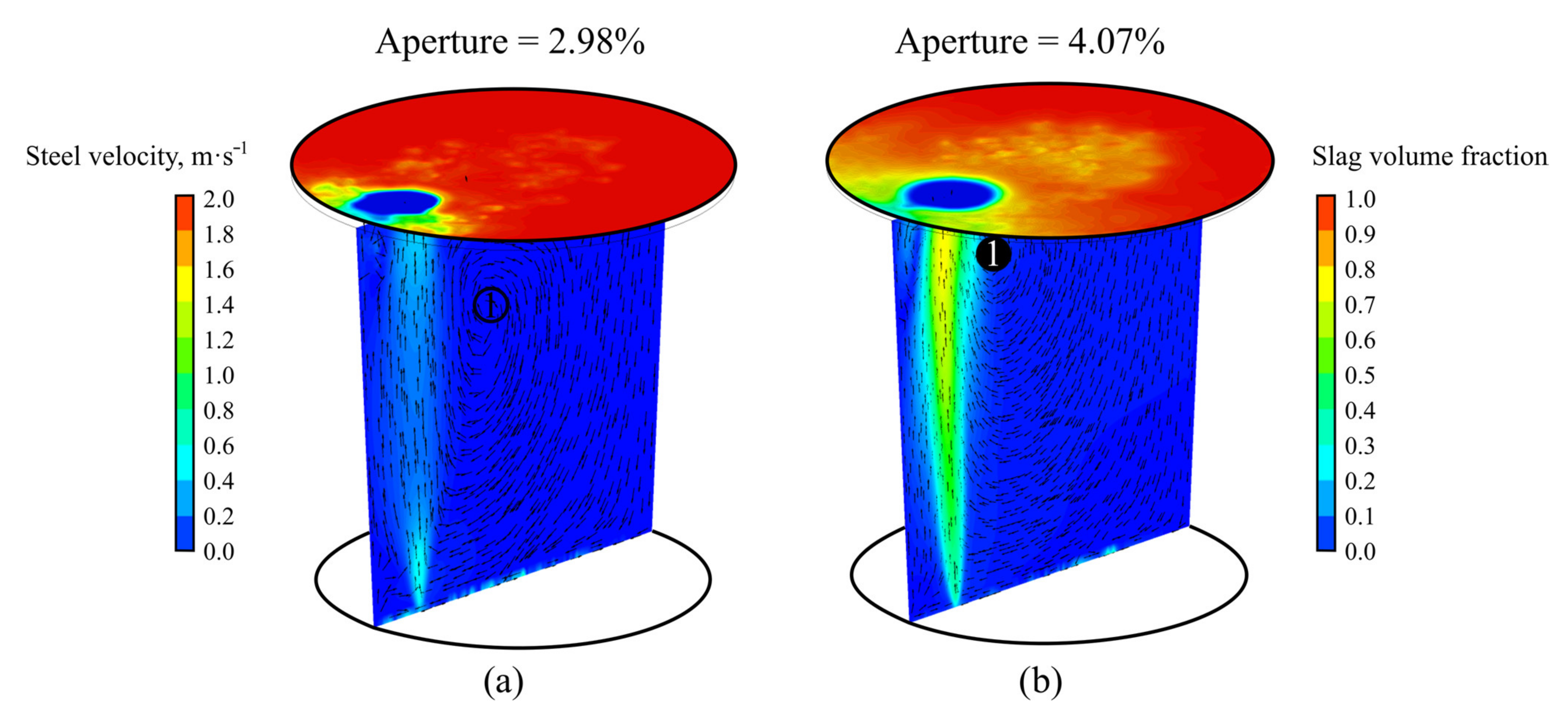

3.2. Behavior of the Gas Flow Rate and the Slag Eye Aperture

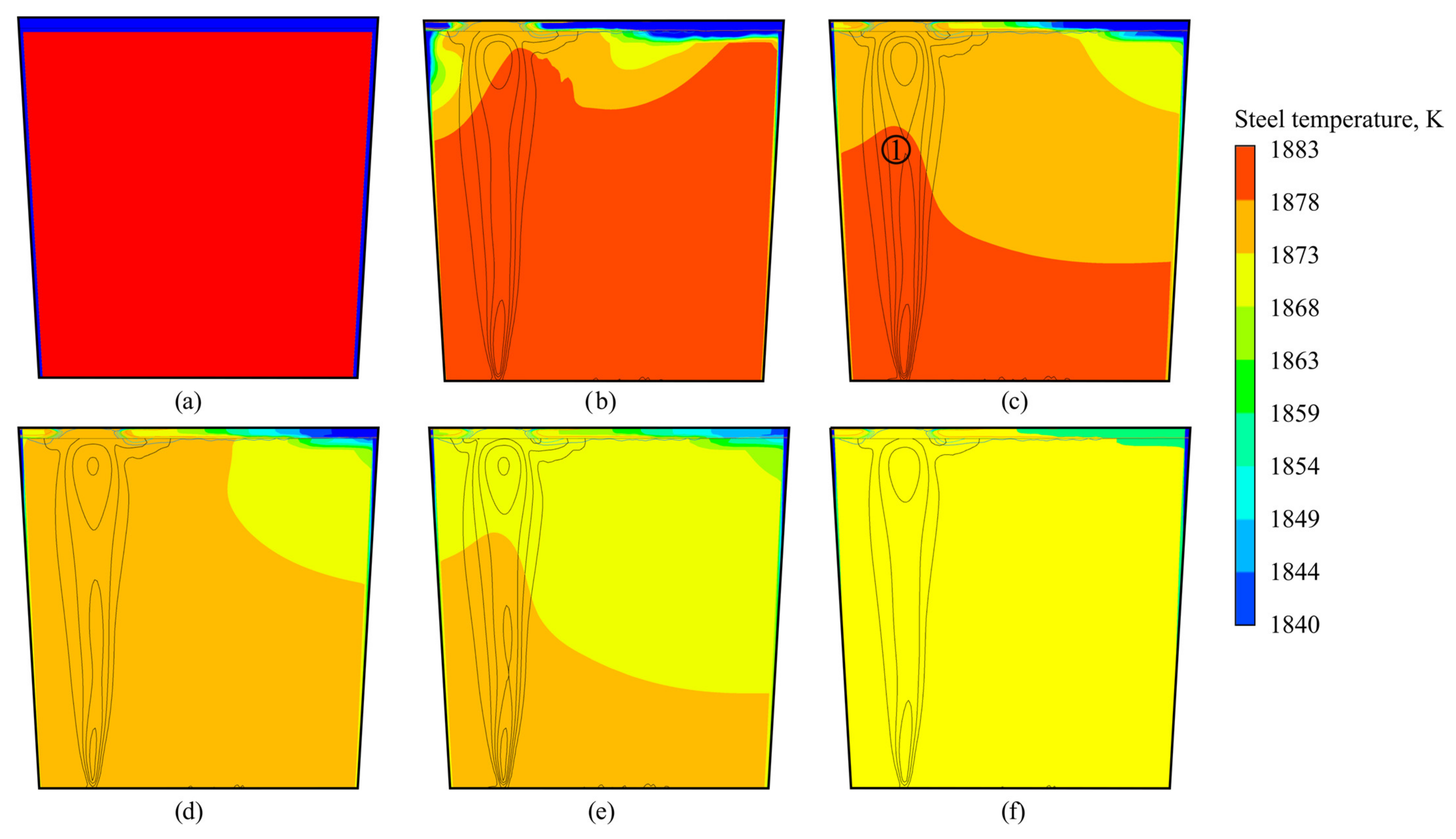

3.3. Thermal Behavior of Steel in the Ladle

4. Conclusions

- The selected multiphase models correctly predicted the fluid dynamics of a three-phase system (water-oil-air). The velocity of the water and the shape and area of the opening of the oil layer predicted mathematically had good agreement with the experimental data, through the PIV technique.

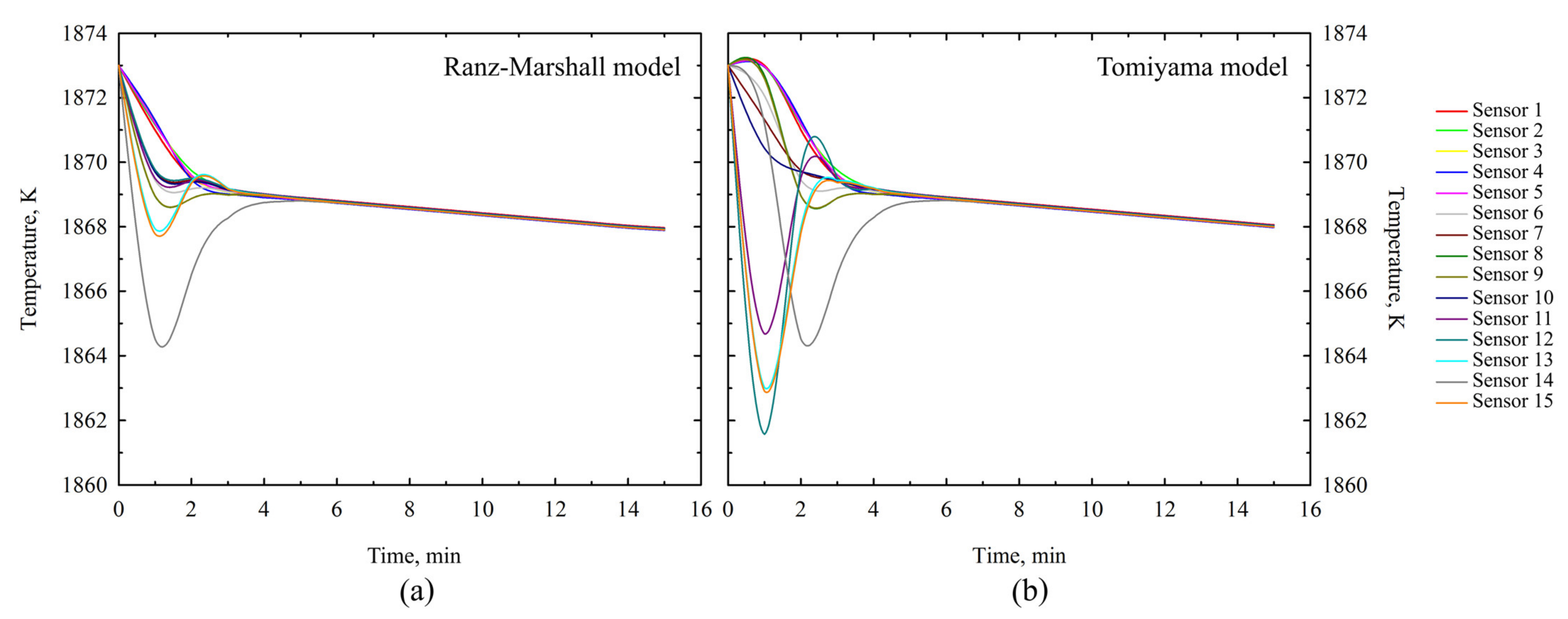

- It was observed that there were no significant differences between the results calculated for the coefficients of heat exchange between the Ranz-Mạrshall and Tomiyama models. However, the Tomiyama model was chosen because of its affinity with the lift model for fluid dynamics simulation.

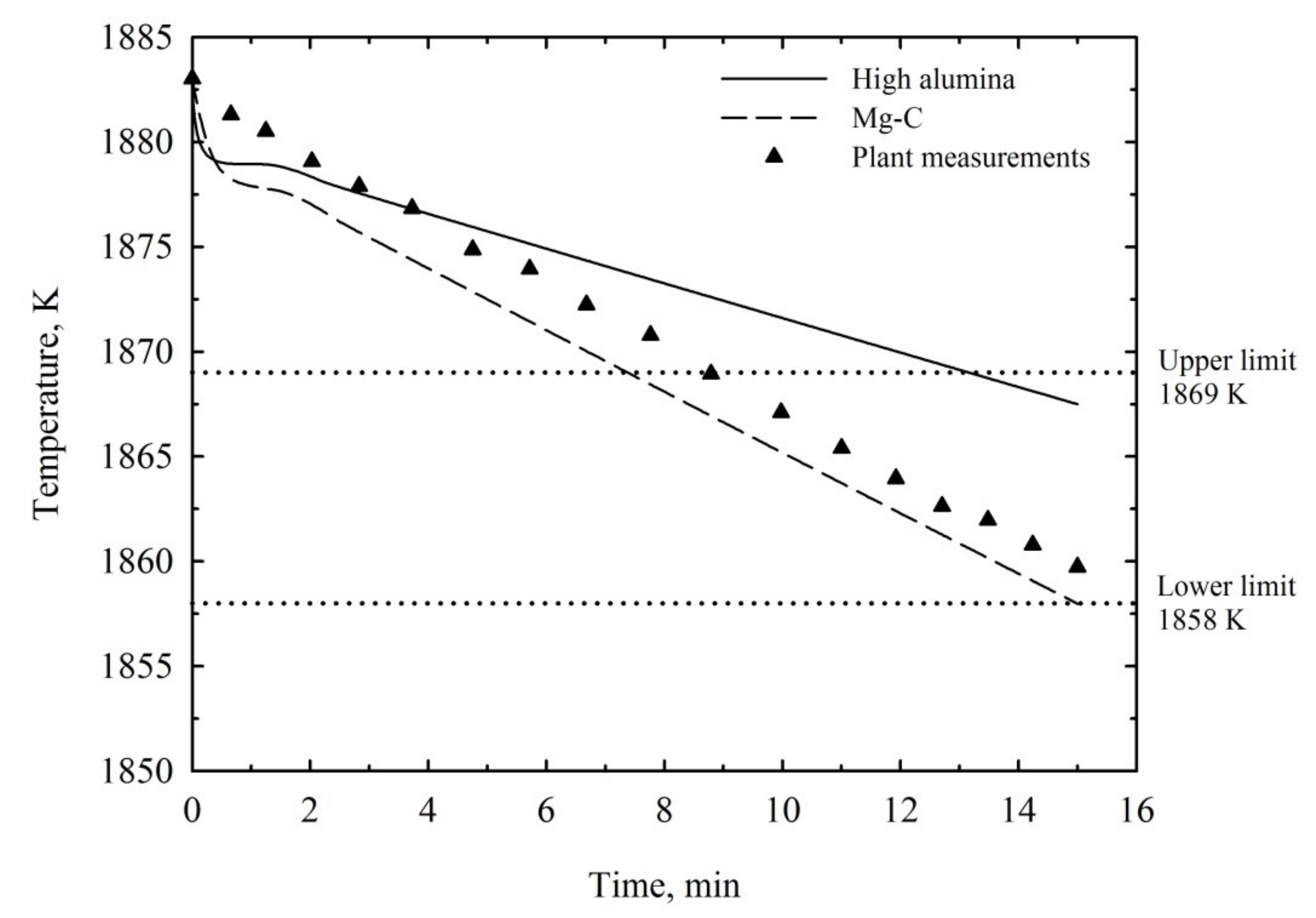

- Despite both refractories retaining enough heat to keep the steel temperature within industrial limits, the Al2O3 one had better heat retention, which would favor refining operations. However, for the desulfurization process, the use of basic refractories such as Mg-C is recommended to favor the reactions involved, and the operational cost is lower.

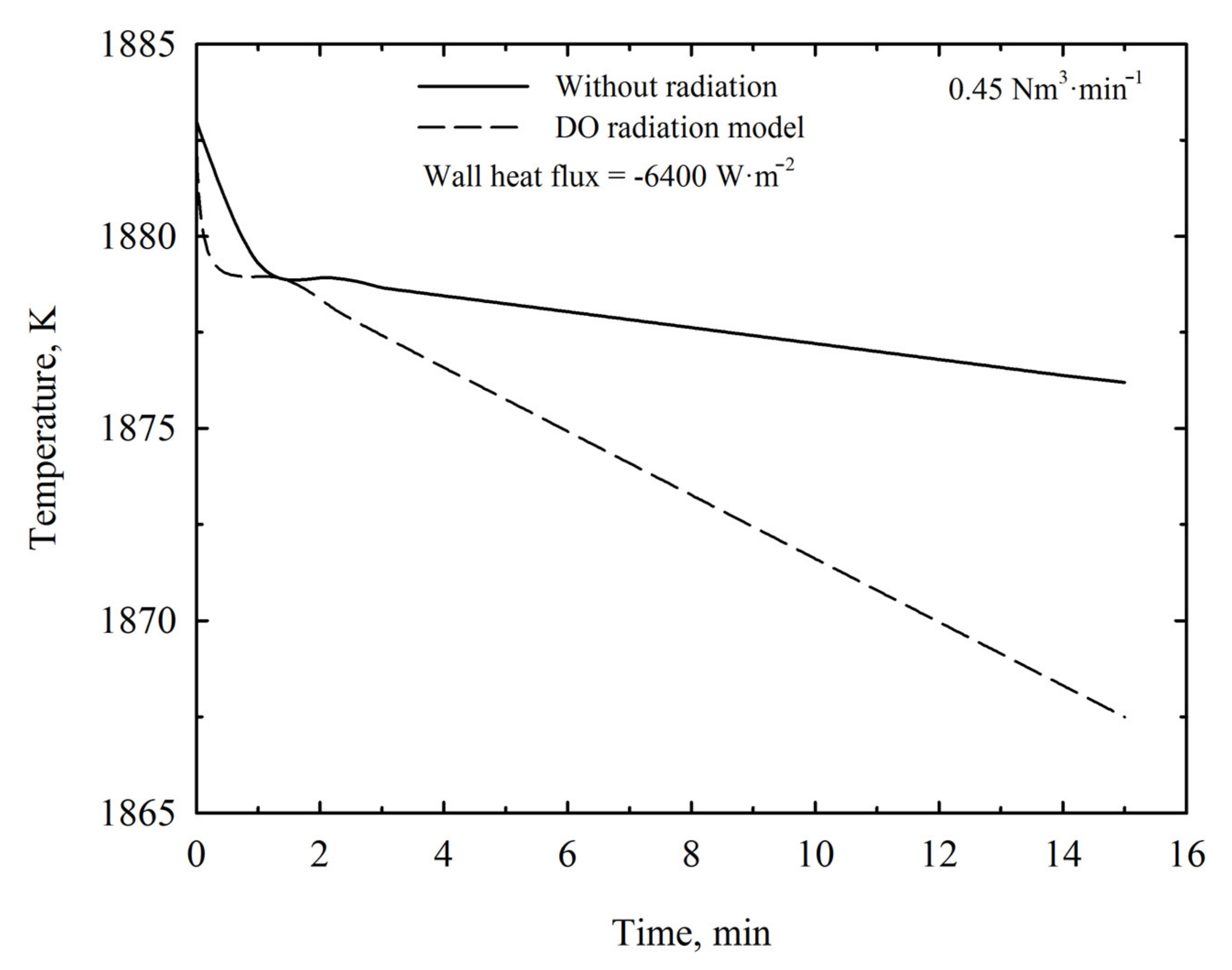

- The inclusion of the radiation mechanism contributes to the precision of the simulation of the thermal evolution of the steel into the ladle furnace. The DO radiation model correctly predicted heat loss through the free surface, reaching steel thermal homogenization at 2.5 min.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | Description |

| Interphase area, m2 | |

| Constants | |

| Drag coefficient, dimensionless | |

| Virtual mass coefficient | |

| d | Plug diameter, m |

| Dispersion scalar | |

| Bubble diameter of phase p, m | |

| Eötvos number, dimensionless | |

| Force, N | |

| Gravity acceleration, m·s−2 | |

| Generation of turbulence by bouyancy and velocity gradients | |

| H | Liquid height, m |

| Heat transfer coefficient, W·m−2·K−1 | |

| Turbulent kinetic energy, J·kg−1 | |

| Interphase momentum exchange coefficient | |

| Nu | Nusselt number, dimensionless |

| p | Pressure, Pa |

| Pr | Prandtl number, dimensionless |

| Gas flow rate, Nm3·min−1 | |

| Volumetric energy transfer rate, W | |

| Interaction force between phases, N | |

| Re | Reynolds number, dimensionless |

| T | Temperature, K |

| Unitary vector u-velocity, m·s−1 | |

| Velocity, m·s−1 | |

| Greek symbols | |

| Volume fraction, dimensionless | |

| Rate of dissipation of turbulent kinetic energy | |

| Thermal conductivity, W·m−1·K−1 | |

| Bulk viscosity, Pa·s | |

| Dynamic viscosity, Pa.s | |

| Density of phase q, kg·m−3 | |

| Surface tension, N·m−1 | |

| Time scale, s | |

| Solid angle, rad | |

| ω | Angular velocity, s−1 |

References

- Cao, Q.; Pitts, A.; Nastac, L. Numerical modelling of fluid flow and desulphurisation kinetics in an argon-stirred ladle furnace. Ironmak. Steelmak. 2016, 45, 280–287. [Google Scholar] [CrossRef]

- Singh, U.; Anapagaddi, R.; Mangal, S.; Padmanabhan, K.A.; Singh, A.K. Multiphase modeling of bottom-stirred ladle for prediction of slag–steel interface and estimation of desulfurization behavior. Metall. Mater. Trans. B 2016, 47, 1804–1816. [Google Scholar] [CrossRef]

- Liu, Z.; Li, L.; Li, B. Modeling of gas-steel-slag three phase flow in ladle metallurgy: Part, I. Physical modeling. ISIJ Int. 2017, 57, 1971–1979. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Li, B.; Liu, Z. Modeling of gas-steel-slag three phase flow in ladle metallurgy: Part II. Multi-scale Mathematical model. ISIJ Int. 2017, 57, 1980–1989. [Google Scholar]

- Jonsson, L.; Jönsson, P. Modeling of fluid flow conditions around the slag/metal interface in a gas-stirred ladle. ISIJ Int. 1996, 36, 1127–1134. [Google Scholar] [CrossRef] [Green Version]

- Lou, W.; Zhu, M. Numerical simulation of gas and liquid two-phase flow in gas-stirred systems based on euler–euler approach. Metall. Mater. Trans. B 2013, 44, 1251–1263. [Google Scholar] [CrossRef]

- Villela-Aguilar, J.J.; Ramos-Banderas, J.A.; Hernández-Bocanegra, C.A.; Urióstegui-Hernández, A.; Solorio-Díaz, G. Optimization of the mixing time using asymmetrical arrays in both gas flow and injection positions in a dual-plug ladle. ISIJ Int. 2020, 60, 1172–1178. [Google Scholar] [CrossRef] [Green Version]

- Senguttuvan, A.; Irons, G.A. Modeling of slag entrainment and interfacial mass transfer in gas stirred ladles. ISIJ Int. 2017, 57, 1962–1970. [Google Scholar] [CrossRef] [Green Version]

- Cao, Q.; Nastac, L. Mathematical investigation of fluid flow, mass transfer, and slag-steel interfacial behavior in gas-stirred ladles. Metall. Mater. Trans. B 2018, 49, 1138–1404. [Google Scholar] [CrossRef] [Green Version]

- Jönsson, P.; Jonsson, T. The use of fundamental process models in studying ladle refining operations. ISIJ Int. 2001, 41, 1289–1302. [Google Scholar] [CrossRef] [Green Version]

- Xia, J.L.; Ahokainen, T. Homogenization of temperature field in a steelmaking ladle with gas injection. Scand. J. Metall. 2003, 32, 211–217. [Google Scholar] [CrossRef]

- Mohammadi, D.; Seyedein, S.; Aboutalebi, M. Numerical simulation of thermal stratification and destratification in secondary steelmaking ladle. Ironmak. Steelmak. 2013, 40, 342–349. [Google Scholar] [CrossRef]

- GOSH. Secondary Steelmaking Principles and Applications; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Farrera-Buenrostro, J.E.; Hernández-Bocanegra, C.A.; Ramos-Banderas, J.A.; Torres-Alonso, E.; López-Granados, N.M.; Ramírez-Argáez, M.A. Analysis of temperature losses of the liquid steel in a ladle furnace during desulfurization stage. Trans. Indian Inst. Met. 2019, 72, 899–909. [Google Scholar] [CrossRef]

- Xia, J.L.; Ahokainen, T. Transient flow and heat transfer in a steelmaking ladle during the holding period. Metall. Mater. Trans. B 2001, 32, 733–741. [Google Scholar] [CrossRef]

- Ganguly, S.; Chakraborty, S. Numerical investigation on role of bottom gas stirring in controlling thermal stratification in steel ladles. ISIJ Int. 2004, 44, 537–546. [Google Scholar] [CrossRef]

- Gonzalez, H.; Ramos-Banderas, J.A.; Torres-Alonso, E.; Solorio-Diaz, G.; Hernández-Bocanegra, C.A. Multiphase modeling of fluid dynamic in ladle steel operations under non-isothermal conditions. J. Iron Steel Res. Int. 2017, 24, 888–900. [Google Scholar] [CrossRef]

- Chen, Y.C.; Bao, Y.; Wang, M.; Zhao, L.; Peng, Z. A mathematical model for the dynamic desulfurization process of ultra-low-sulfur steel in the LF refining process. Metall. Res. Technol. 2014, 111, 37–43. [Google Scholar] [CrossRef]

- Volkova, O.; Janke, D. Modelling of temperature distribution in refractory ladle lining for steelmaking. ISIJ Int. 2003, 43, 1185–1190. [Google Scholar] [CrossRef]

- Ilegbusi, O.; Szekely, J. Melt stratification in ladles. ISIJ Int. 1987, 27, 563–569. [Google Scholar] [CrossRef]

- Grip, C.E.; Jonsson, L.; Jönsson, P.; Jonsson, K.O. Numerical prediction and experimental verification of thermal stratification during holding in pilot plant and production ladles. ISIJ Int. 1999, 39, 715–721. [Google Scholar] [CrossRef]

- Pan, Y.; Björkman, B. Physical and mathematical modelling of thermal stratification phenomena in steel ladles. ISIJ Int. 2002, 42, 614–623. [Google Scholar] [CrossRef] [Green Version]

- Pan, Y.; Grip, C.E.; Björkman, B. Numerical studies on the parameters influencing steel ladle heat loss rate, thermal stratification during holding and steel stream temperature during teeming. Scand. J. Metall. 2003, 32, 71–85. [Google Scholar] [CrossRef]

- Austin, P.; Camplin, J.; Herbertson, J.; Taggart, I. Mathematical modelling of thermal stratification and drainage of steel ladle. ISIJ Int. 1992, 32, 196–202. [Google Scholar] [CrossRef] [Green Version]

- Chakraborty, S.; Sahai, Y. Effect of slag cover on heat loss and liquid steel flow in ladle before and during teeming to a continuous casting tundish. Metall. Mater. Trans. B 1992, 23, 135–151. [Google Scholar] [CrossRef]

- Maldonado-Parra, F.D.; Ramírez-Argáez, M.A.; Nava-Conejo, A.; González, C. Effect of both radial position and number of porous plugs on chemical and thermal mixing in an industrial ladle involving two phase flow. ISIJ Int. 2011, 51, 1110–1118. [Google Scholar] [CrossRef] [Green Version]

- Castillejos, A.H.; Salcudean, M.E.; Brimacombe, J.K. Fluid flow and bath temperatura destratification in gas stirred ladles. Metall. Mater. Trans. B 1989, 20, 603–611. [Google Scholar] [CrossRef]

- Ranz, W.E.; Marshall, W.R. Evaporation from drops. Chem. Eng. Prog. 1952, 48, 141–146. [Google Scholar]

- Tomiyama, A. Struggle with computational bubble dynamics. Multiph. Sci. Technol. 1998, 10, 369–405. [Google Scholar]

- Krishnapisharody, K.; Irons, G.A. A critical review of the modified froude number in ladle metallurgy. Metall. Mater. Trans. B 2013, 44, 1486–1498. [Google Scholar] [CrossRef]

- Jönsson, P.G.; Jonsson, L.; Sichen, D. Viscosities of LF slags and their impact on ladle refining. ISIJ Int. 1997, 37, 484–491. [Google Scholar] [CrossRef] [Green Version]

- ANSYS, Inc. Fluent Theory Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2013. [Google Scholar]

- Shih, T.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A new k-ε eddy viscosity model for high Reynolds number turbulent flows. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Troshko, A.A.; Hassan, Y.A. A two-equation turbulence model of turbulent bubbly flows. Int. J. Multiph. Flow 2001, 27, 1965–2000. [Google Scholar] [CrossRef]

- Drew, D.A.; Lahey, R.T. The virtual mass and lift force on a sphere in rotating and straining invisid flow. Int. J. Multiph. Flow 1987, 13, 113–121. [Google Scholar] [CrossRef]

- Burns, A.D.; Frank, T.; Hamill, I.; Shi, J. The Favre averaged drag model for turbulent dispersion in Eulerian multi-phase flows. In Proceedings of the 5th International Conference on Multiphase Flow, Yokohama, Japan, 30 May–4 June 2004. [Google Scholar]

- Chui, E.H.; Raithby, G.D. Computation of radiant heat transfer on a nonorthogonal mesh using the finite-volume method. Numer. Heat Transf. Part B 1993, 23, 269–288. [Google Scholar] [CrossRef]

- Mathur, S.R.; Murthy, J.Y. Coupled ordinates method for multigrid acceleration of radiation calculations. J. Thermophys. Heat Transf. 1999, 13, 467–473. [Google Scholar] [CrossRef]

- Raithby, G.D.; Chui, E.H. A finite-volume method for predicting a radiant heat transfer in enclosures with participating media. J. Heat Transf. 1990, 112, 415–423. [Google Scholar] [CrossRef]

- Tripathi, A.; Saha, J.K.; Singh, J.B.; Ajmani, S.K. Numerical simulation of heat transfer phenomenon in steel making ladle. ISIJ Int. 2012, 52, 1591–1600. [Google Scholar] [CrossRef] [Green Version]

- Méndez, C.G.; Nigro, N.; Cardona, A. Drag and non-drag forces influences in numerical simulations of metalurgical ladles, J. Mater. Process. Technol. 2005, 160, 296–305. [Google Scholar] [CrossRef]

| Material | Density (kg·m−3) | Viscosity (kg·m−1·s−1) | Surface Tension (N·m−1) | Heat Capacity (J·kg−1·K−1) | Thermal Conductivity (W·m−1·K−1) |

|---|---|---|---|---|---|

| Water | 998.2 [14] | 0.001003 [14] | - | - | - |

| Oil | 871 | 0.027872 | - | - | - |

| Air | 1.227 | 1.7 × 10−5 | - | - | - |

| Water-air | * | * | 0.072 | - | - |

| Water-oil | * | * | 0.021 | - | - |

| Oil-air | * | * | 0.04 | - | - |

| Steel | [5] | [5] | - | [5] | 41 [14] |

| Slag | 2800 [14] | [31] | - | [5] | 0.48 [14] |

| Argon | 1.6228 [14] | 2.125 × 10−5 [14] | - | 520.64 [14] | 0.0158 [14] |

| Steel-slag | * | * | 1.15 [14] | - | - |

| Steel-argon | * | * | 1.82 [14] | - | - |

| Slag-argon | * | * | 0.58 [14] | - | - |

| Sensor | Coordinates | ||

|---|---|---|---|

| r (m) | z (m) | θ (°) | |

| 1 | 0 | 0 | 0 |

| 2 | 1.2 | 0 | 180 |

| 3 | 1.2 | 0 | 90 |

| 4 | 1.2 | 0 | 0 |

| 5 | 1.2 | 0 | 270 |

| 6 | 0 | 1.5 | 0 |

| 7 | 1.13 | 1.5 | 135 |

| 8 | 1.13 | 1.5 | 45 |

| 9 | 1.13 | 1.5 | 315 |

| 10 | 1.13 | 1.5 | 225 |

| 11 | 0 | 2.8 | 0 |

| 12 | 1.98 | 2.8 | 180 |

| 13 | 1.98 | 2.8 | 90 |

| 14 | 1.98 | 2.8 | 0 |

| 15 | 1.98 | 2.8 | 270 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urióstegui-Hernández, A.; Garnica-González, P.; Ramos-Banderas, J.Á.; Hernández-Bocanegra, C.A.; Solorio-Díaz, G. Multiphasic Study of Fluid-Dynamics and the Thermal Behavior of a Steel Ladle during Bottom Gas Injection Using the Eulerian Model. Metals 2021, 11, 1082. https://doi.org/10.3390/met11071082

Urióstegui-Hernández A, Garnica-González P, Ramos-Banderas JÁ, Hernández-Bocanegra CA, Solorio-Díaz G. Multiphasic Study of Fluid-Dynamics and the Thermal Behavior of a Steel Ladle during Bottom Gas Injection Using the Eulerian Model. Metals. 2021; 11(7):1082. https://doi.org/10.3390/met11071082

Chicago/Turabian StyleUrióstegui-Hernández, Antonio, Pedro Garnica-González, José Ángel Ramos-Banderas, Constantin Alberto Hernández-Bocanegra, and Gildardo Solorio-Díaz. 2021. "Multiphasic Study of Fluid-Dynamics and the Thermal Behavior of a Steel Ladle during Bottom Gas Injection Using the Eulerian Model" Metals 11, no. 7: 1082. https://doi.org/10.3390/met11071082

APA StyleUrióstegui-Hernández, A., Garnica-González, P., Ramos-Banderas, J. Á., Hernández-Bocanegra, C. A., & Solorio-Díaz, G. (2021). Multiphasic Study of Fluid-Dynamics and the Thermal Behavior of a Steel Ladle during Bottom Gas Injection Using the Eulerian Model. Metals, 11(7), 1082. https://doi.org/10.3390/met11071082