Influence of Chromium Concentration on the Abrasive Wear of Ni-Cr-B-Si Coatings Applied by Supersonic Flame Jet (HVOF)

Abstract

1. Introduction

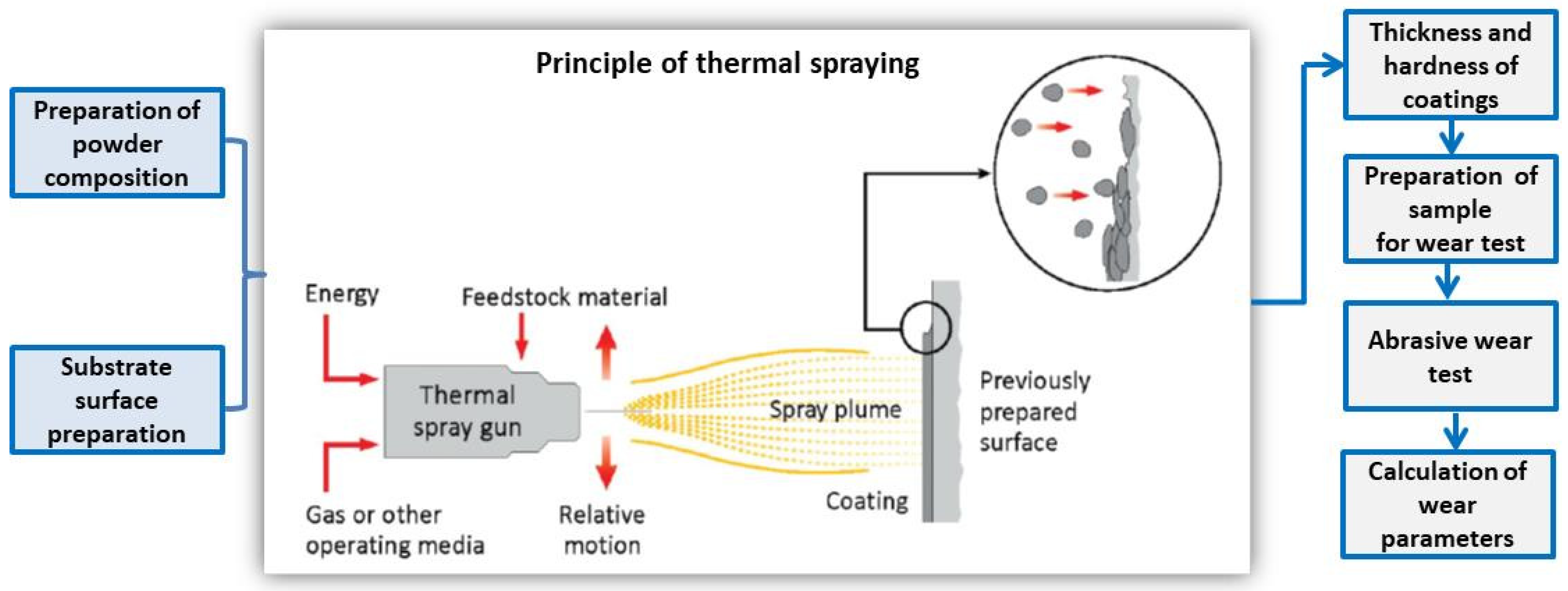

2. Materials and Technology

3. Experimental Procedures

4. Experimental Results and Discussion

5. Regression Models

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings; John Wiley&Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Holmberg, K.; Matthews, A. Coatings Tribology: Properties, Mechanisms, Techniques and Applications in Surface Engineering; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Bhushan, B. Nanortibology, Nanomechanics and Materials Characterization Studies and Application to Bio/Nanotechnology and Biomimetics. In Proceedings of the Serbiatrib’11, Kragujevac, Serbia, 11–13 May 2011. [Google Scholar]

- Stachowiak, G.; Batchelor, A.W. Engineering Tribology; Butterworth-Heinemann: Boston, MA, USA, 2000. [Google Scholar]

- Vencl, A. Optimization of the Deposition Parameters of Thick Atmospheric Plasma Spray Coatings. J. Balk. Tribol. Assoc. 2012, 18, 405–414. [Google Scholar]

- Kandeva, M.; Peichev, I.; Kostova, N.; Stoichkov, K. Complex Study of Surface layers and Coatings. J. Balk. Tribol. Assoc. 2011, 17, 387–393. [Google Scholar]

- Petrov, T.; Tashev, P.; Kandeva, M. Wear Resistance of Surface Layers Modified with AL2O3 and TiCN Nanopowders Weld Overlaid Using TIG and ITIG Methods. J. Balk. Tribol. Assoc. 2016, 22, 304–315. [Google Scholar]

- Tashev, P.; Lazarova, R.; Kandeva, M.; Petrov, R.; Manolov, V. Tungsten Inert Gas Weld Overlay Using Nano-Sized Tin Powder. J. Balk. Tribol. Assoc. 2016, 22, 2916–2932. [Google Scholar]

- Dimitrova, R.; Kandeva, M.; Kamburov, V.; Jordanov, M. Mechanical and Tribological Characteristics of Hardfaced Dispersive Reinforced Aluminium Metal Matrix Layers. J. Balk. Tribol. Assoc. 2017, 23, 641–652. [Google Scholar]

- Kandeva, M.; Penyashki, T.; Kostadinov, G.; Kalitchin, Z.; Kaleicheva, J. Wear of Electroless Nickel-Phosphorus Composite Coatings with Nanodiamond Particles. J. Environ. Prot. Ecol. 2018, 19, 1200–1214. [Google Scholar]

- Kandeva, M.; Kamburov, V.; Zadorozhnaya, E.; Kalitchin, Z. Abrasion Wear of Electroless Nickel Composite Coatings Modified with Boron Nitride Nanoparticles. J. Environ. Prot. Ecol. 2018, 19, 1690–1703. [Google Scholar]

- Kovac, P.; Jesic, D.; Sovilj-Nikic, S.; Kandeva, M.; Kalitchin, Z.; Gostimirovic, M.; Savkovic, B. Energy Aspects of Tribological Behaviour of Nodular Cast Iron. J. Environ. Prot. Ecol. 2018, 19, 163–172. [Google Scholar]

- Kandeva, M.; Grozdanova, T.; Karastoyanov, D.; Assenova, E. Wear Resistance of WC/Co HVOF-Coatings and Galvanic Cr Coatings Modified by Diamond Nanoparticles. In Proceedings of the 13th International Conference on Tribology ROTRIB’16, Galați, Romania, 22–24 September 2016; IOP Conference Series: Materials Science and Engineering. 2017; Volume 174, p. 012060. [Google Scholar] [CrossRef]

- Kandeva, M.; Balabanov, V.; Zadorozhnaya, E.; Kalitchin, Z.; Svoboda, P. Environmental Protection by Self-Organisation of Tribosystems with Self-Lubricating Materials in Dry Friction: Part I. Investigations at different loads. J. Environ. Prot. Ecol. 2017, 18, 1050–1069. [Google Scholar]

- Kandeva, M.; Balabanov, V.; Zadorozhnaya, E.; Kalitchin, Z.; Svoboda, P.; Levanov, I. Environmental Protection by Self-Organisation of Tribosystems with Self-Lubricating Materials in Dry Friction. Part II: IInvestigations at Different Dry Sliding Rates. J. Environ. Prot. Ecol. 2017, 18, 1581–1592. [Google Scholar]

- Kandeva, M.; Svoboda, P.; Nikolov, N.; Todorov, T.; Sofronov, Y.; Pokusová, M.; Vencl, A. Effect of Silicon Carbide Nanoparticles Size on Friction Properties of Electroless Nickel Coatings. J. Environ. Prot. Ecol. 2020, 21, 1314–1325. [Google Scholar]

- Kandeva, M.; Kamburov, V.; Nikolov, K.; Dimitrov, L. Abrasive Wear of Ultra-High-Molecular-Weight Polyethylene Modified with Carbon Nanotubes. J. Balk. Tribol. Assoc. 2020, 26, 272. [Google Scholar]

- Kandeva, M.; Stoimenov, N.; Popov, B.; Kalitchin, Z.; Pozhidaeva, V. Abrasive Wear Resistance of Micro- and Nano-Diamond Particles. J. Balk. Tribol. Assoc. 2020, 26, 181. [Google Scholar]

- Dyakova, V.; Tashev, P.; Kandeva, M. Study on the Effect of Nanosized Particles of Tin and SiC on the Wear Resistance, Microstructure and Corrosion Behavior of Overlay Weld Metal. J. Balk. Tribol. Assoc. 2020, 26, 56–65. [Google Scholar]

- Alaci, S.; Irimescu, L.; Ciornei, F.; Kandeva, M. Device and Method for Simultaneous Determination of Rolling and Spinning Friction in a Concentrated Contact. J. Balk. Tribol. Assoc. 2020, 26, 1–10. [Google Scholar]

- Kandeva, M.; Rozhdestvensky, Y.; Svoboda, P.; Kalitchin, Z.; Zadorozhnaya, E. Influence of the Size of Silicon Carbide Nanoparticles on the Abrasive Wear of Electroless Nickel Coatings. Part 1. J. Environ. Prot. Ecol. 2019, 20, 1889–1903. [Google Scholar]

- Kandeva, M.; Rozhdestvensky, Y.; Svoboda, P.; Kalitchin, Z.; Zadorozhnaya, E. Influence of the Size of Silicon Carbide Nanoparticles on the Abrasive Wear of Electroless Nickel Coatings. Part 2. J. Environ. Prot. Ecol. 2020, 21, 222–233. [Google Scholar]

- Kandeva, M.; Kalitchin, Z.H.; Svoboda, P.; Sovilj-Nikic, S. General Methodology for Studying the Tribological Processes on the Basis of the Communicative Potential. J. Balk. Tribol. Assoc. 2019, 25, 432–442. [Google Scholar]

- Oksa, M.; Turunen, E.; Suhonen, T.; Varis, T.; Hannula, S. Optimization and Characterization of High Velocity Oxy-Fuel Sprayed Coatings, Techniques, Materials and Applications. Coatings 2011, 1, 17–52. [Google Scholar] [CrossRef]

- Mrdak, M.R.; Vencl, A.; Nedeljković, B.D.; Stanković, M. Influence of Plasma Spraying Parameters on Properties of the Thermal Barrier Coatings. Mater.Sci. Technol. 2013, 29, 559–567. [Google Scholar] [CrossRef]

- Wood, R.J.K.; Roy, M. Tribology of Thermal—Sprayed Coatings (Surface Engineering for Enhanced Performance against Wear); Roy, M., Ed.; Springer: Wien, Austria, 2013; pp. 1–43. [Google Scholar]

- Cabral-Miramontes, J.A.; Gaona-Tiburcio, C.; Almeraya-Calderón, F.; Estupiñan-Lopez, F.H.; Pedraza-Basulto, G.K.; Poblano-Salas, C.A. Parameter studies on high-velocity oxy-fuel spraying of CoNiCrAlY coatings used in theater on autical industry. Int. J. Corros. 2014, 2014, 703806. [Google Scholar] [CrossRef]

- Chivavibul, P.; Watanabe, M.; Kuroda, S.; Kawakita, J.; Komatsu, M.; Sato, K.; Kitamura, J. Effect of powder characteristics on properties of warm-sprayed WC-Co coatings. J. Therm. Spray Technol. 2003, 19, 81–88. [Google Scholar] [CrossRef]

- Liu, Y.; Fischer, T.E.; Dent, A. Comparison of HVOF and Plasma-sprayed Alumina/titania coatings—Microstructure, Mechanical Properties and Abrasion Behaviour. Surf. Coat. Technol. 2013, 167, 68–76. [Google Scholar] [CrossRef]

- Kandeva, M.; Grozdanova, T.; Karastoyanov, D.; Ivanov, P.; Kalitchin, Z. Tribology Study of High-Technological Composite Coatings Applied Using High Velocity Oxy-Fuel. In Proceedings of the 9th International Conference on Tribology (Balkantrib 2017), Nevsehir, Turkey, 13–15 September 2017; IOP Conference Series: Materials Science and Engineering. 2018; Volume 295, p. 012025. [Google Scholar]

- Kandeva, M.; Ivanova, B.; Karastoyanov, D.; Grozdanova, T.; Assenova, E. Abrasive Wear of High Velocity Oxygen Fuel (HVOF) Superalloy Coatings under Vibration Load. In Proceedings of the 13th International Conference on Tribology ROTRIB’16, Galați, Romania, 22–24 September 2016; IOP Conference Series: Materials Science and Engineering. 2017; Volume 174, p. 012010. [Google Scholar] [CrossRef]

- Kandeva, M.; Zadorozhnaya, E.; Kalitchin, Z.; Svoboda, P. Tribological Studies Of High Velocity Oxy-Fuel (HVOF) Superalloy Coatings. J. Balk. Tribol. Assoc. 2018, 24, 411–428. [Google Scholar]

- Kandeva, M.; Svoboda, P.; Kalitchin, Z.; Penyashki, T.; Kostadinov, G. Wear of Gas-Flame Composite Coatings with Tungsten and Nickel Matrix. Part, I. Abrasive Wear. J. Environ. Prot. Ecol. 2019, 20, 811–822. [Google Scholar]

- Penyashki, T.; Kostadinov, G.; Radev, D.; Kandeva, M. Comparative Studies of Tribological Characteristics of Carbon Steels with Gas Flame Coatings from New Multi-component Carbide Composite Materials. Oxid. Commun. 2019, 42, 74–89. [Google Scholar]

- Czupryński, A. Properties of Al2O3/TiO2 and ZrO2/CaO flame sprayed coatings. Spajanie Mater. Konstr. 2017, 2, 32–39. [Google Scholar]

- Czupryński, A.; Górka, J.; Adamiak, M.; Tomiczek, B. Testing of Flame Sprayed Al2O3 Matrix Coatings Containing TiO2. Arch. Metall. Mater. 2016, 61, 1363–1370. [Google Scholar] [CrossRef]

- Czupryński, A. Flame spraying of aluminum coatings reinforced with particles of carbonaceous materials as an alternative for laser cladding technologies. Materials 2019, 12, 3467. [Google Scholar] [CrossRef]

- Liao, H.; Normand, B.; Coddet, C. Influence of coating microstructure on the abrasive wear resistance of WC/Co cermet coatings. Surf. Coat. Technol. 2000, 124, 235–242. [Google Scholar] [CrossRef]

- Magnani, M.; Suegama, P.H.; Espallargas, N.; Dosta, S.; Fugivara, C.S.; Guilemany, J.M.; Benedetti, A.V. Influence of HVOF parameters on the corrosion and wear resistance of WC-Co coatings sprayed on AA7050 T7. Surf. Coat. Technol. 2008, 202, 4746–4757. [Google Scholar] [CrossRef]

- Janka, L.; Norpoth, J.; Trache, R.; Thiele, S.; Berger, L.-M. HVOF- and HVAF-Sprayed Cr3C2-NiCr Coatings Deposited from Feedstock Powders of Spherical Morphology: Microstructure Formation and High-Stress Abrasive Wear Resistance Up to 800 °C. J. Therm. Spray Technol. 2017, 26, 1720–1731. [Google Scholar] [CrossRef]

- Poirier, D.; Legoux, J.-G.; Lima, R.S. Engineering HVOF-Sprayed Cr3C2-NiCr Coatings: The Effect of Particle Morphology and Spraying Parameters on the Microstructure, Properties, and High Temperature Wear Performance. J. Therm. Spray Technol. 2013, 22, 280–289. [Google Scholar] [CrossRef]

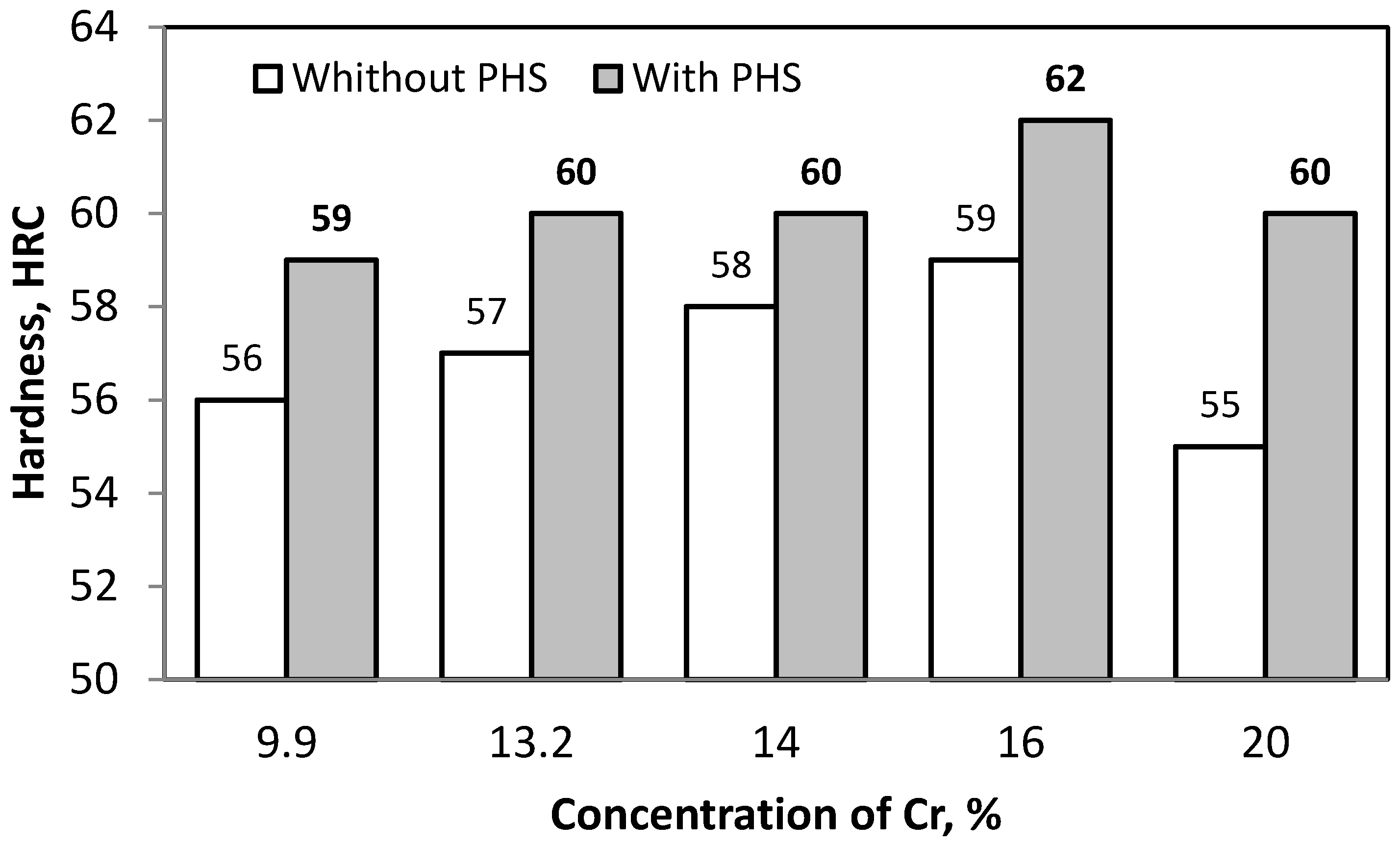

| Series | Sample | Coating Designation | Description | Chemical Composition, wt. % | Hardness HRC | Thickness µm |

|---|---|---|---|---|---|---|

| A | 1 | NiBSi-9.9Cr | Coatings without heat treatment of the substrate | Cr: 9.9; Si:3.1; B:1.7; Fe:3.2; C: 0.35; Mo: 3; Cu:3; Ni Balance | 55–56 | 410–415 |

| 2 | NiBSi-9.9Cr:PHS | Coatings with heat treatment of the substrate | 58–59 | 400–412 | ||

| B | 3 | NiBSi-13.2Cr | Coatings without heat treatment of the substrate | Cr: 13.2; Si: 3.98; B: 2.79; Fe: 4.6; Co: 0.03; C: 0.63; Ni: Balance | 56–57 | 395–400 |

| 4 | NiBSi-13.2Cr:PHS | Coatings with heat treatment of the substrate | 59–60 | 408–414 | ||

| C | 5 | NiBSi-14Cr | Coatings without heat treatment of the substrate | Cr: 14; Si:4.2; B:2,9; Fe:4,6; C:0.6; Mo:2,5; Cu:2,4; Ni: Balance | 57–58 | 395–406 |

| 6 | NiBSi-14Cr:PHS | Coatings with heat treatment of the substrate | 59–60 | 400–405 | ||

| D | 7 | NiBSi-16Cr | Coatings without heat treatment of the substrate | Cr:16; Si:4; B:3.4; Fe:2.7; C:0.6; Mo:3; Cu:3; Ni: Balance | 58–59 | 394–405 |

| 8 | NiBSi-16Cr:PHS | Coatings with heat treatment of the substrate | 61–62 | 404–410 | ||

| E | 9 | Ni80-20Cr | Coatings without heat treatment of the substrate | Cr: 20; Ni: 80 | 54–55 | 400–408 |

| 10 | Ni80-20Cr:PHS | Coatings with heat treatment of the substrate | 57–60 | 393–403 |

| Parameter | Technological Regime |

|---|---|

| Propylene/oxygen ratio | 55/100% |

| Particle velocity | 1000 m/s |

| Spraying distance | 100 mm |

| Impact angle | 90° |

| Air pressure from compressor | 5 bar |

| N2 pressure in the proportioning device | 4 bar |

| Powder feed rate | 22 g/min |

| Sample | Coating Designation | Number of Cycles | |||

|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | ||

| Sliding Distance, m | |||||

| 20 | 40 | 60 | 80 | ||

| Mass Wear, [mg]//Wear Rate, [mg/Nm] | |||||

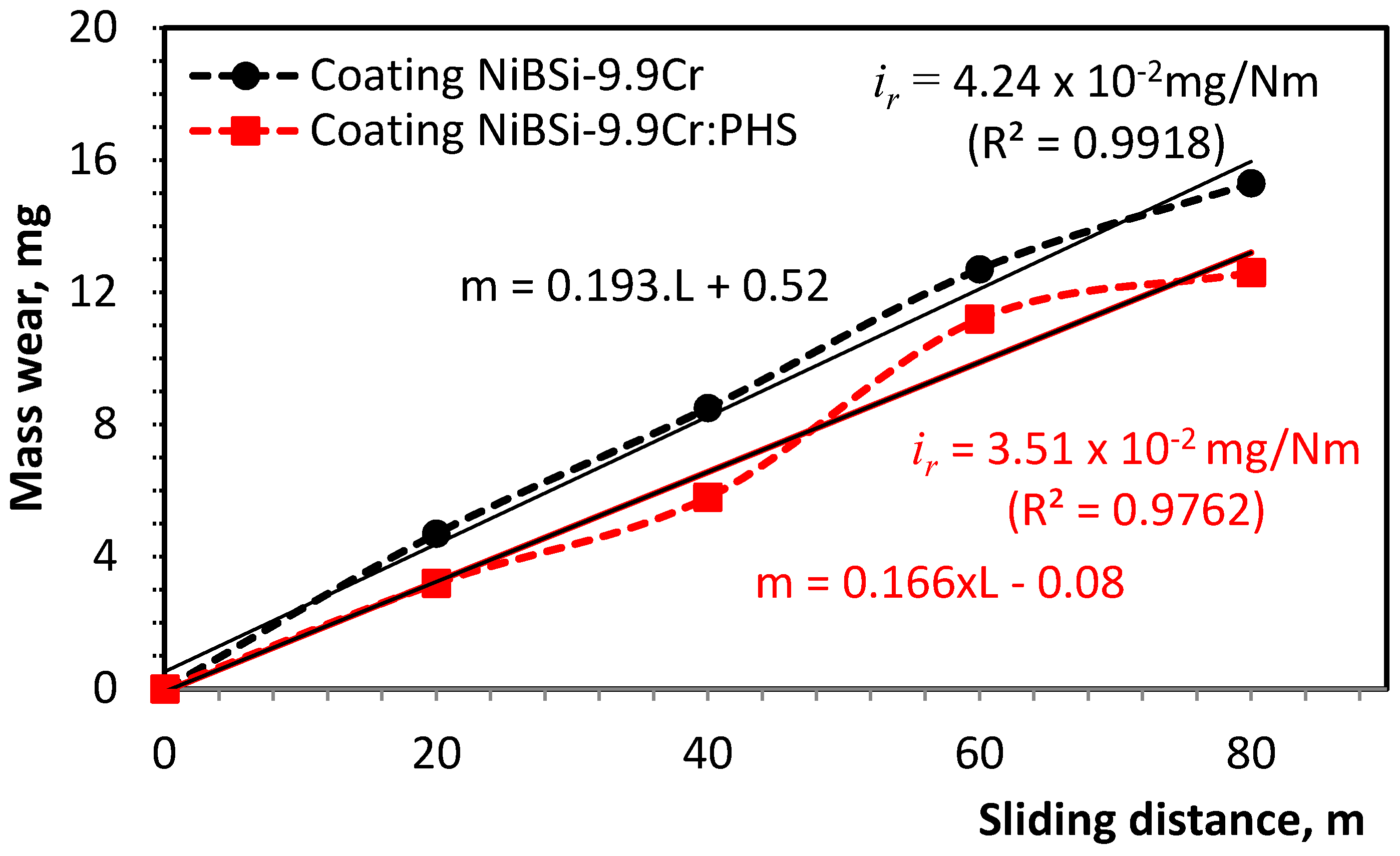

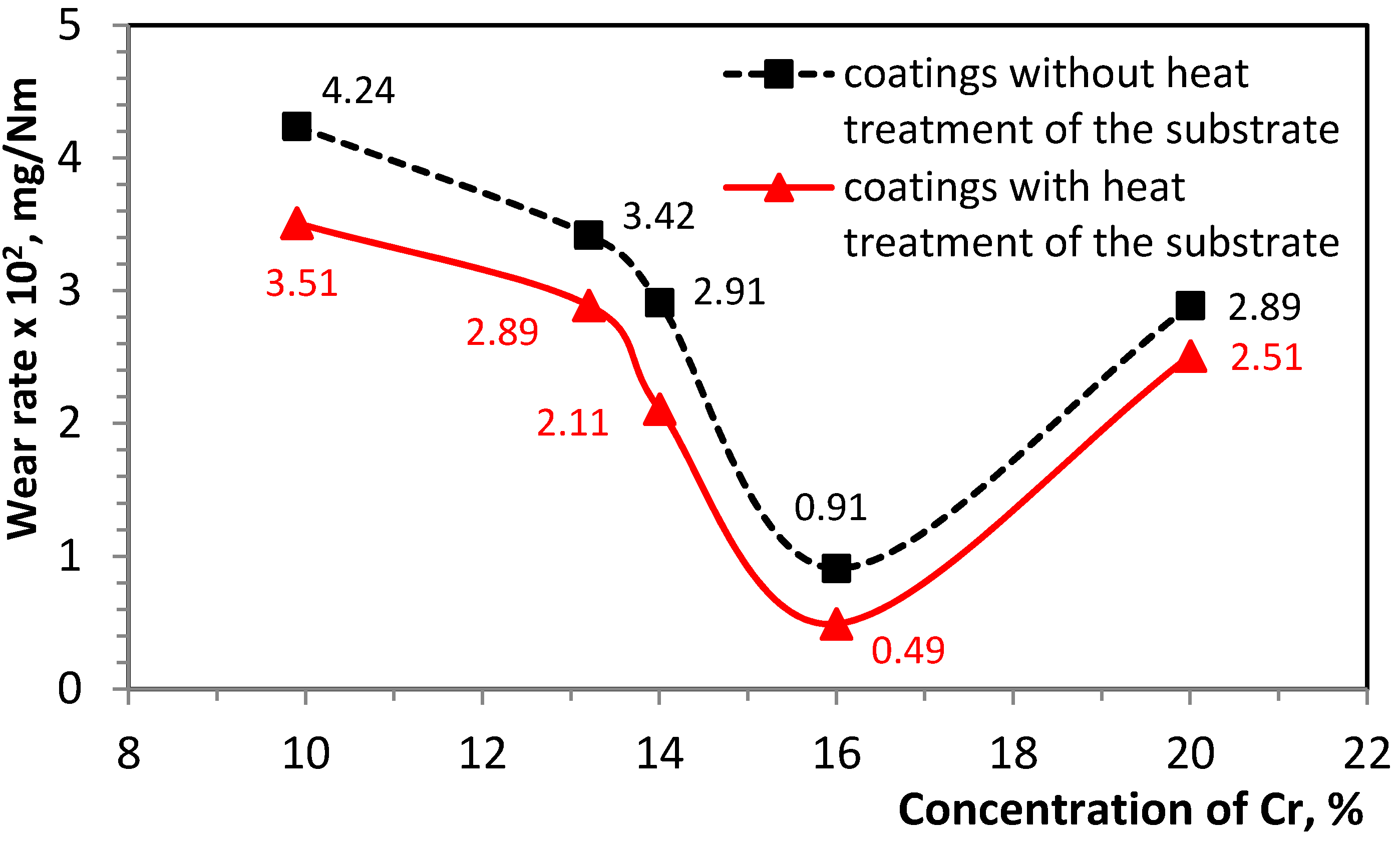

| 1 | NiBSi-9.9Cr | 4.7 5.22 × 10−2 | 8.5 4.71 × 10−2 | 12.7 4.71 × 10−2 | 15.3 4.24 × 10−2 |

| 2 | NiBSi-9.9Cr:PHS | 3.2 3.56 × 10−2 | 5.8 3.22 × 10−2 | 11.2 4.15 × 10−2 | 12.6 3.51 × 10−2 |

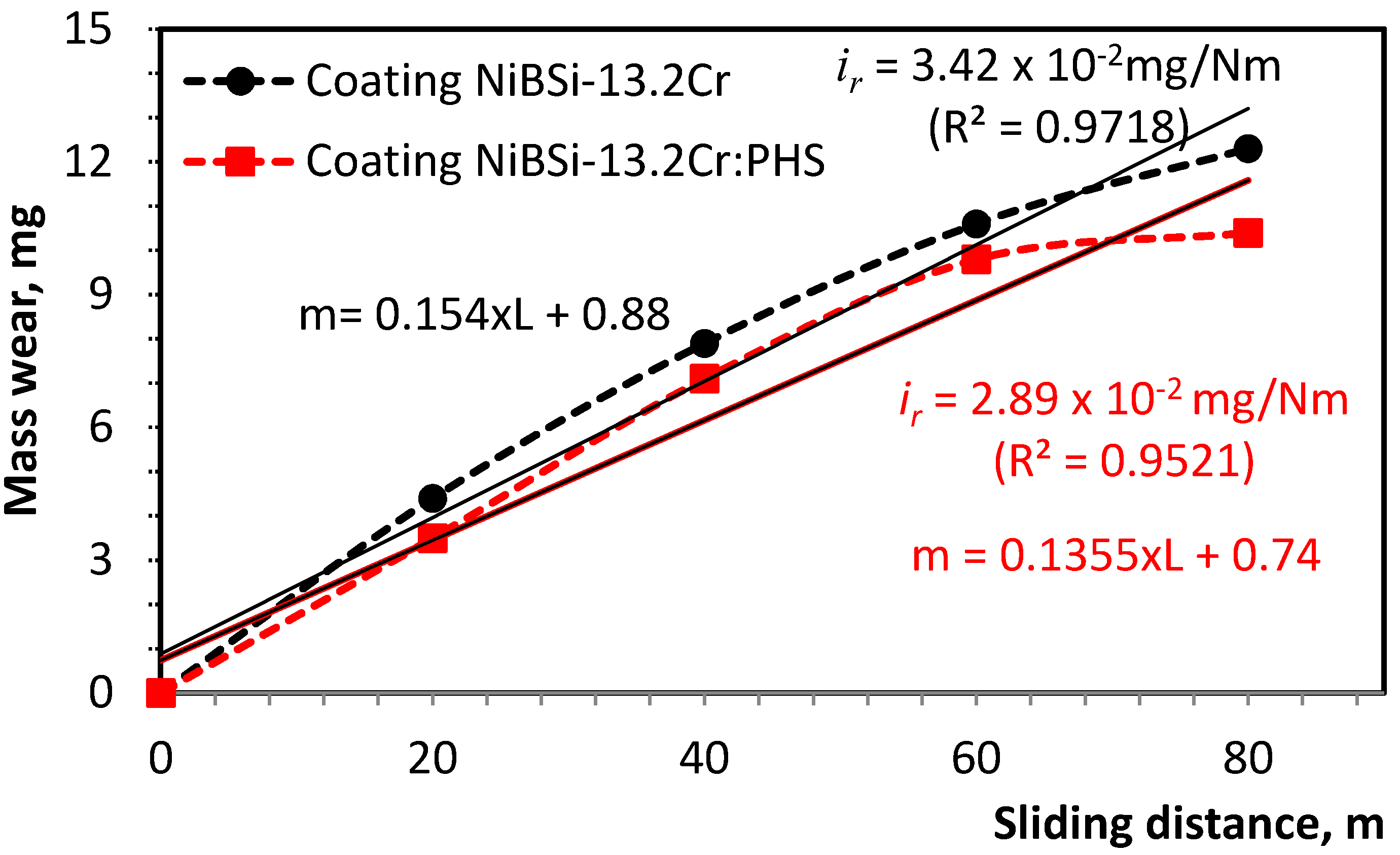

| 3 | NiBSi-13.2Cr | 4.4 4.89 × 10−2 | 7.9 4.4 × 10−2 | 10.6 3.93 × 10−2 | 12.3 3.42 × 10−2 |

| 4 | NiBSi-13.2Cr:PHS | 3.5 3.89 × 10−2 | 7.1 3.96 × 10−2 | 9.8 3.62 × 10−2 | 10.4 2.89 × 10−2 |

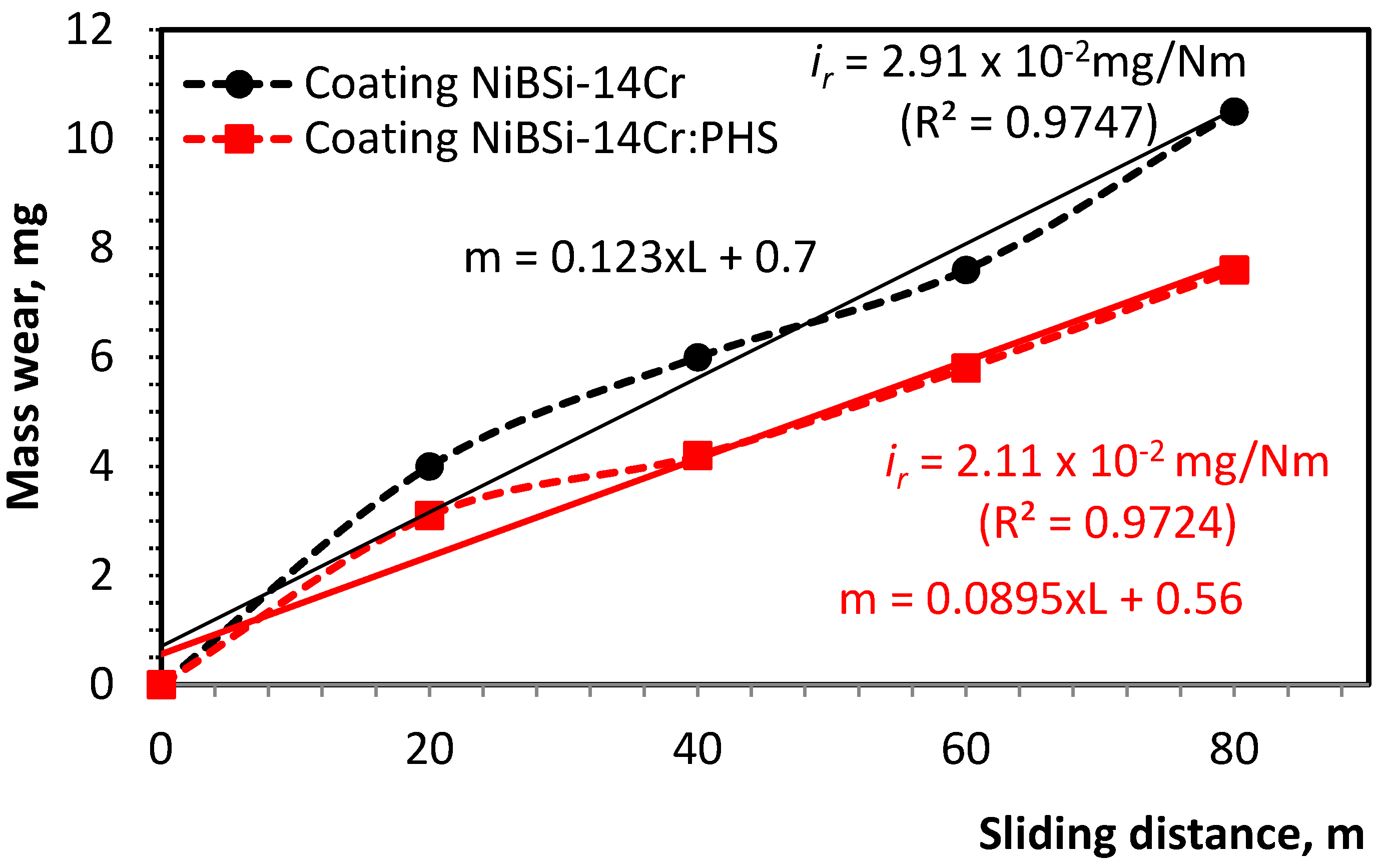

| 5 | NiBSi-14Cr | 4.0 4.44 × 10−2 | 6.0 3.33 × 10−2 | 7.6 2.82 × 10−2 | 10.5 2.91 × 10−2 |

| 6 | NiBSi-14Cr:PHS | 3.1 3.44 × 10−2 | 4.2 2.33 × 10−2 | 5.8 2.16 × 10−2 | 7.6 2.11 × 10−2 |

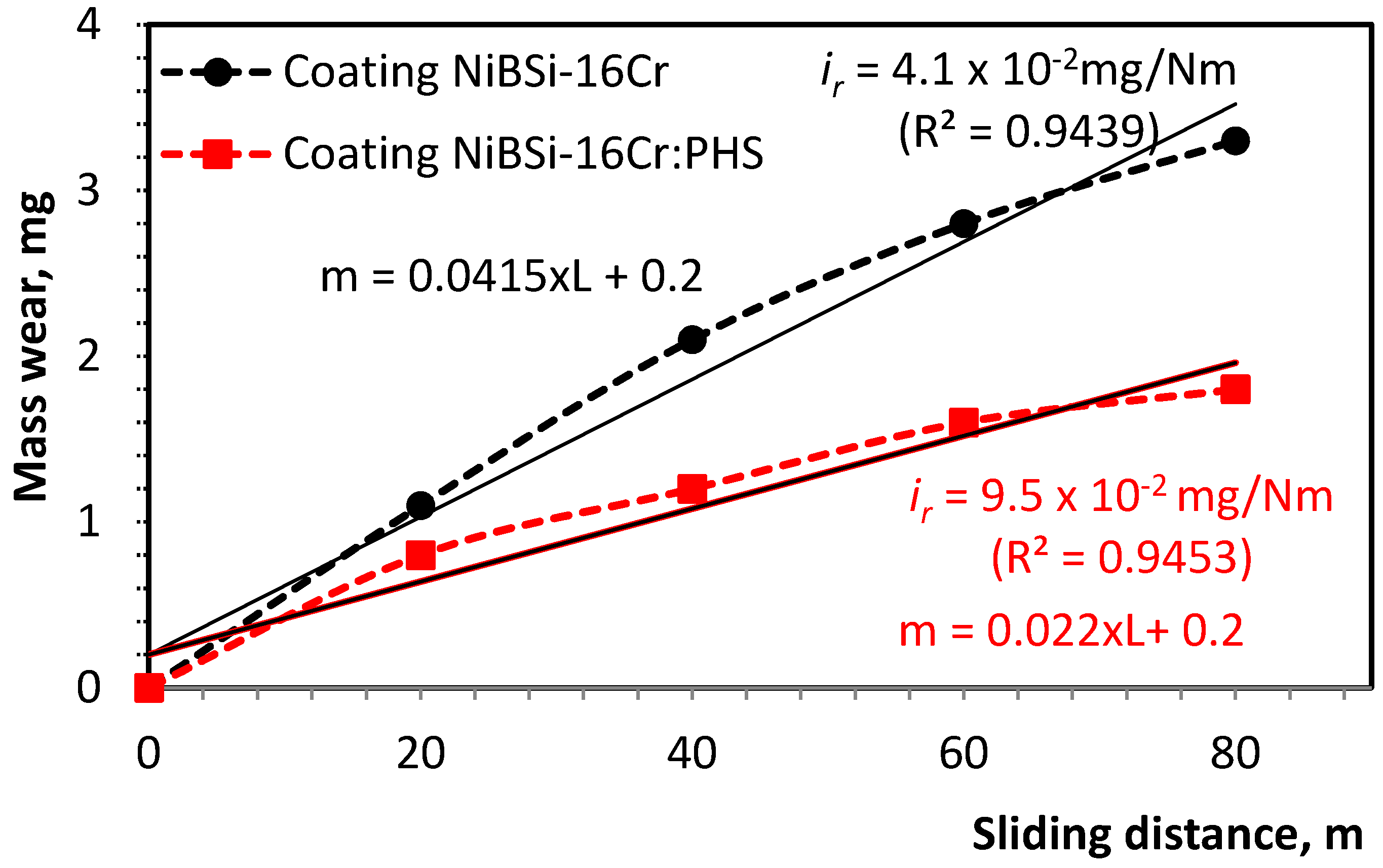

| 7 | NiBSi-16Cr | 1.5 1.67 × 10−2 | 2.2 1.22 × 10−2 | 2.8 1.04 × 10−2 | 3.3 0.91 × 10−2 |

| 8 | NiBSi-16Cr:PHS | 0.9 1.0 × 10−2 | 1.2 0.67 × 10−2 | 1.6 0.58 × 10−2 | 1.8 0.49 × 10−2 |

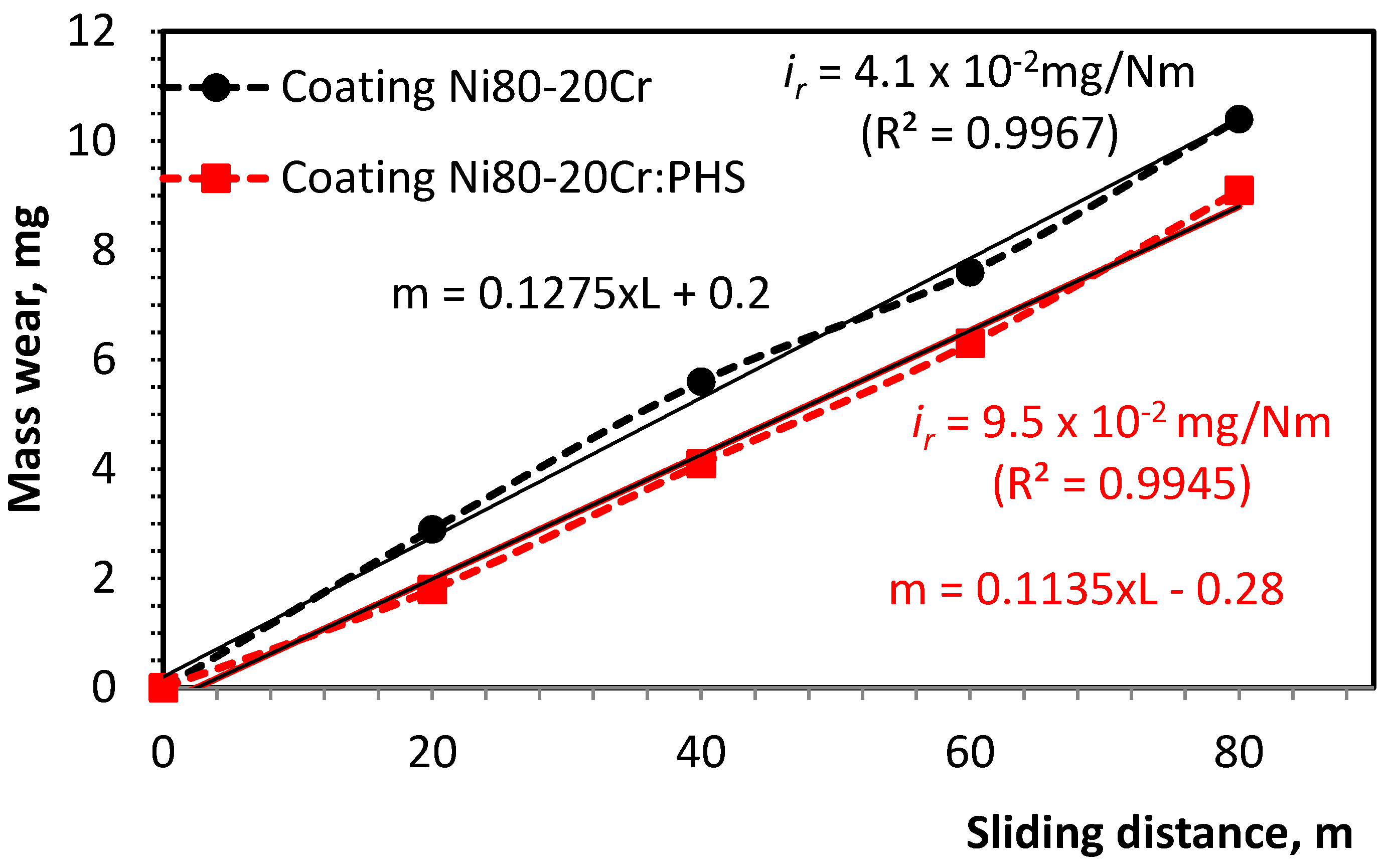

| 9 | Ni80-20Cr | 2.9 3.22 × 10−2 | 5.6 3.11 × 10−2 | 7.6 2.82 × 10−2 | 10.4 2.89 × 10−2 |

| 10 | Ni80-20Cr:PHS | 1.8 2.0 × 10−2 | 4.1 2.22 × 10−2 | 6.3 2.33 × 10−2 | 9.1 2.51 × 10−2 |

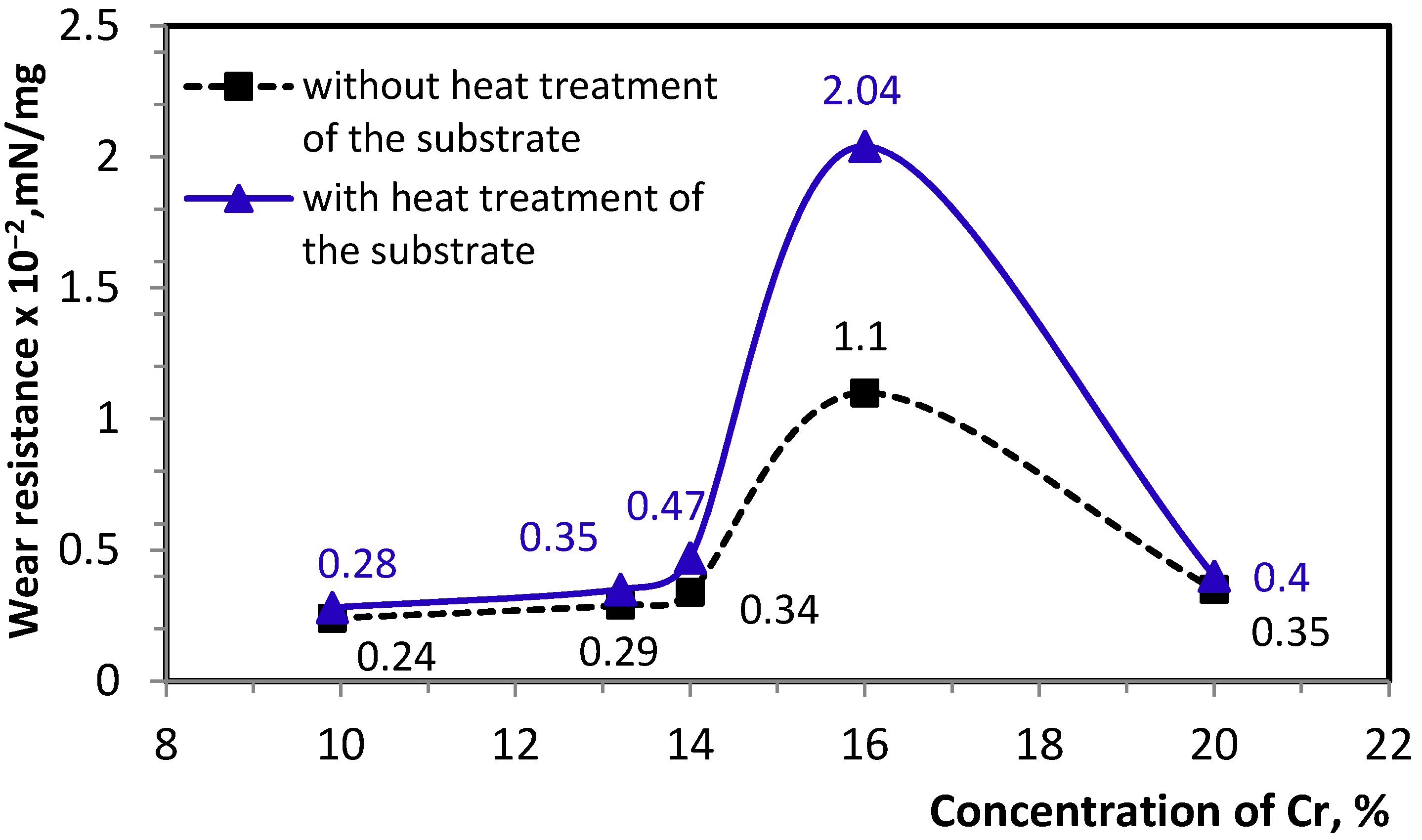

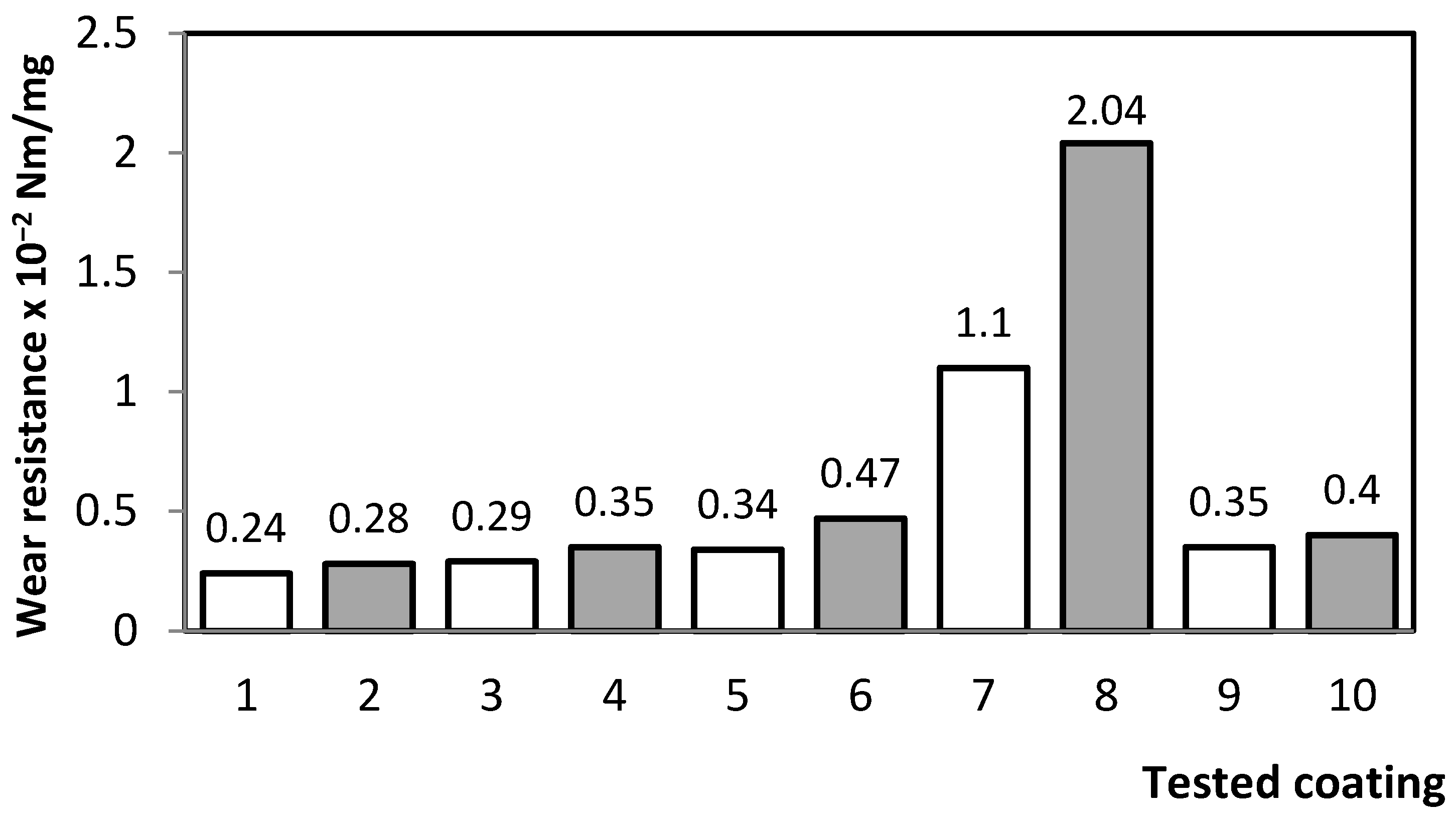

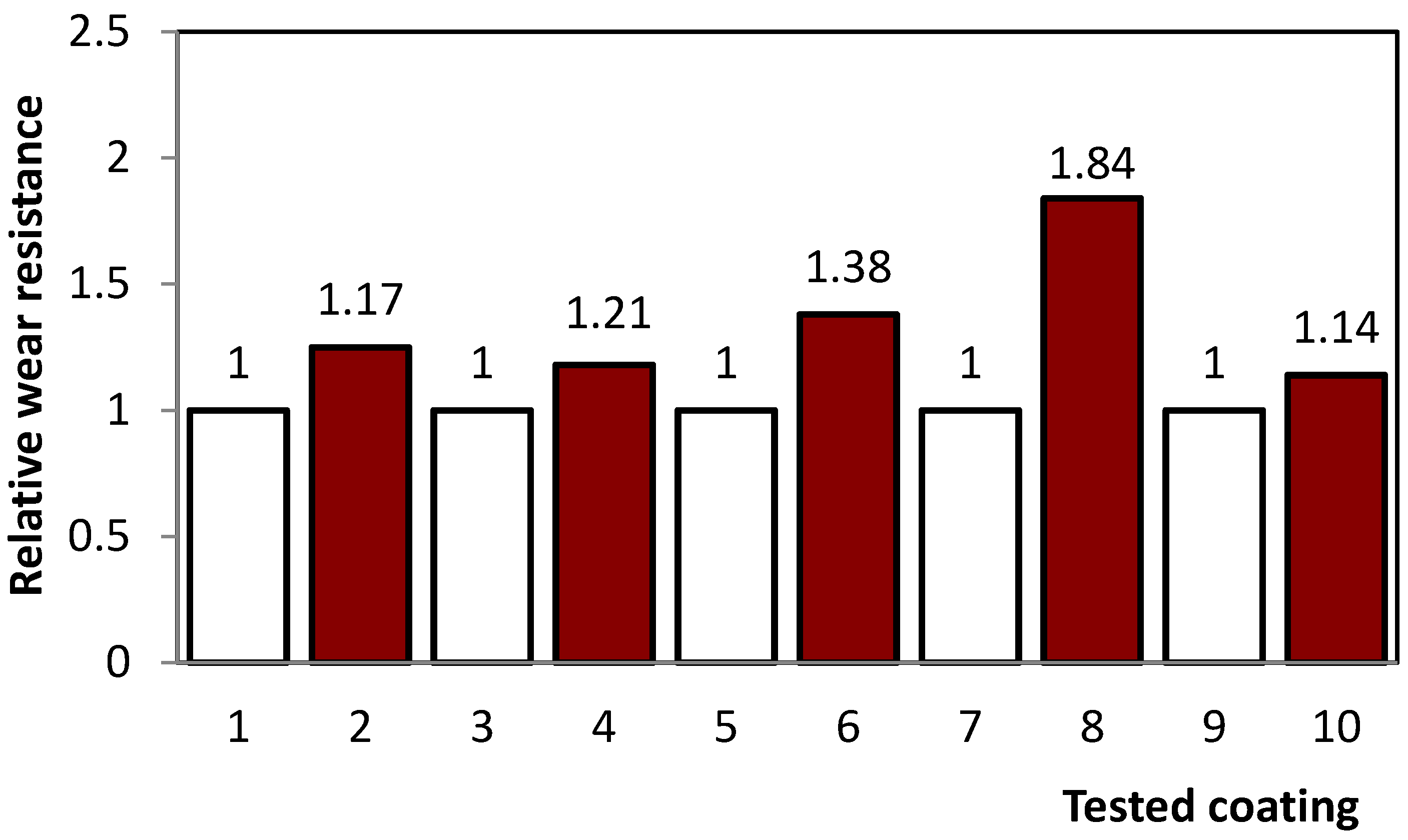

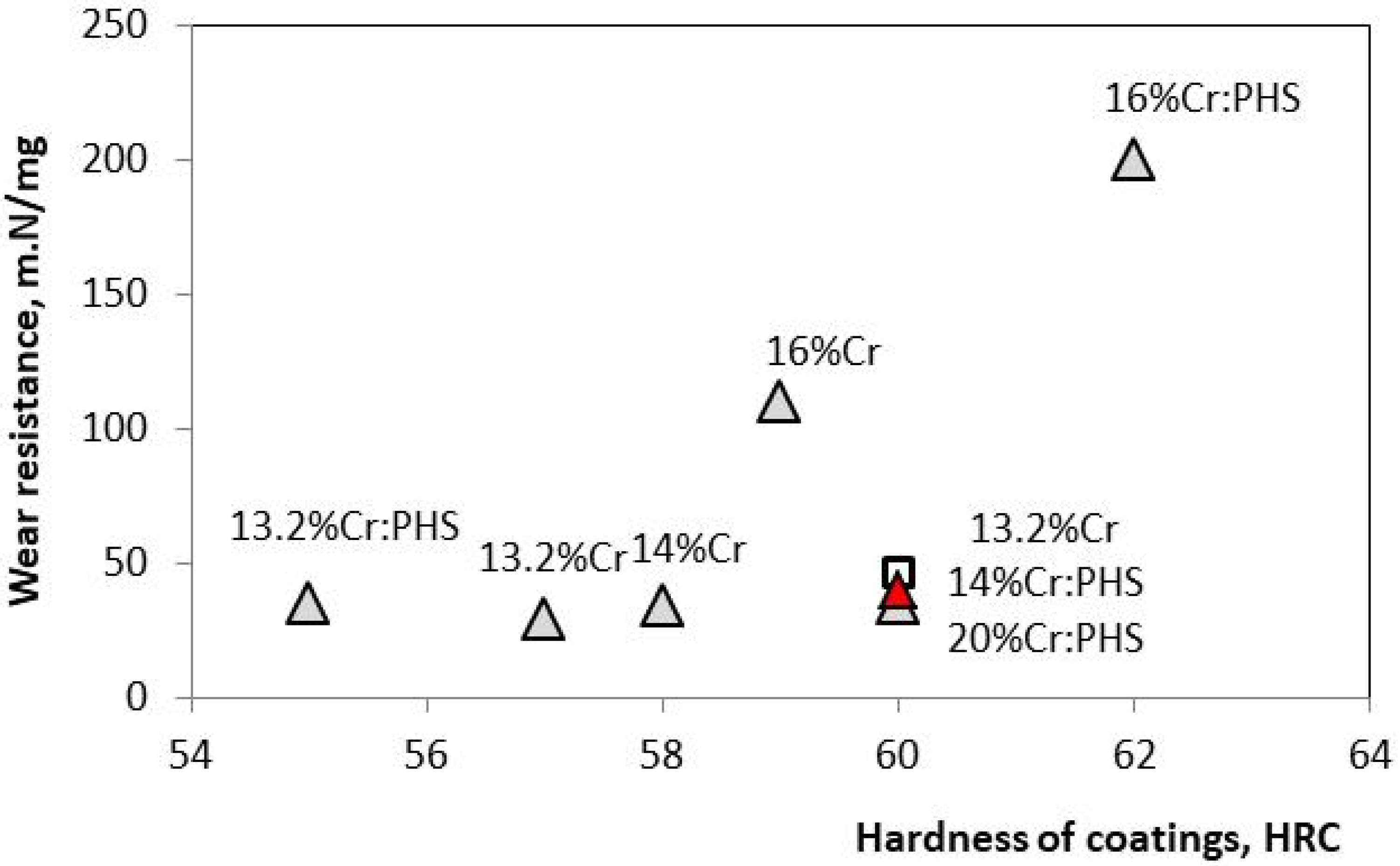

| Series | Sample | Coating Designation | Wear Resistance, mN/mg in the Sliding Distance 80 m | Relative Abrasive Wear Resistance | |

|---|---|---|---|---|---|

| Influence of Heat Treatment of the Substrate | Influence of the Concentration of Cr, % | ||||

| A | 1 | NiBSi-9.9Cr | 0.24 × 102 | R1,1 = 1 | R1,1 = 1 |

| 2 | NiBSi-9.9Cr:PHS | 0.28 × 102 | R2,1 = 1.17 | R2,2 = 1 | |

| B | 3 | NiBSi-13.2Cr | 0.29 × 102 | R3,3 = 1 | R3,1 = 1.21 |

| 4 | NiBSi-13.2Cr:PHS | 0.35 × 102 | R4,3 = 1.21 | R4,2 = 1.25 | |

| C | 5 | NiBSi-14Cr | 0.34 × 102 | R5,5 = 1 | R5,1 = 1.42 |

| 6 | NiBSi-14Cr:PHS | 0.47 × 102 | R6,5 = 1.38 | R6,2 = 1.68 | |

| D | 7 | NiBSi-16Cr | 1.10 × 102 | R7,7 = 1 | R7,1 = 4.58 |

| 8 | NiBSi-16Cr:PHS | 2.04 × 102 | R8,7 = 1.84 | R8,2 = 7.29 | |

| E | 9 | Ni80-20Cr | 0.35 × 102 | R9,9 = 1 | R9,1 = 1.46 |

| 10 | Ni80-20Cr:PHS | 0.40 × 102 | R10,9 = 1.14 | R10.2 = 1.67 | |

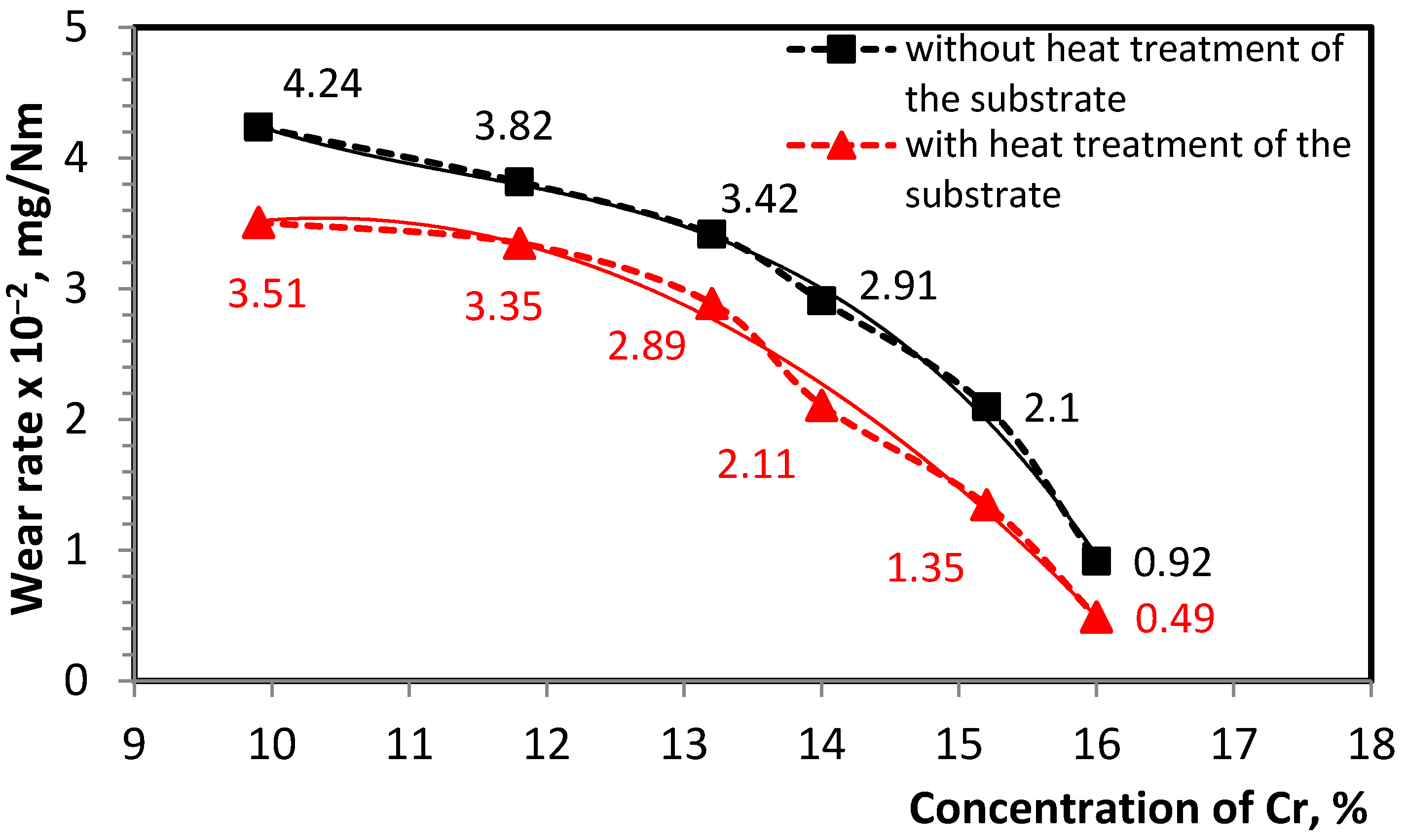

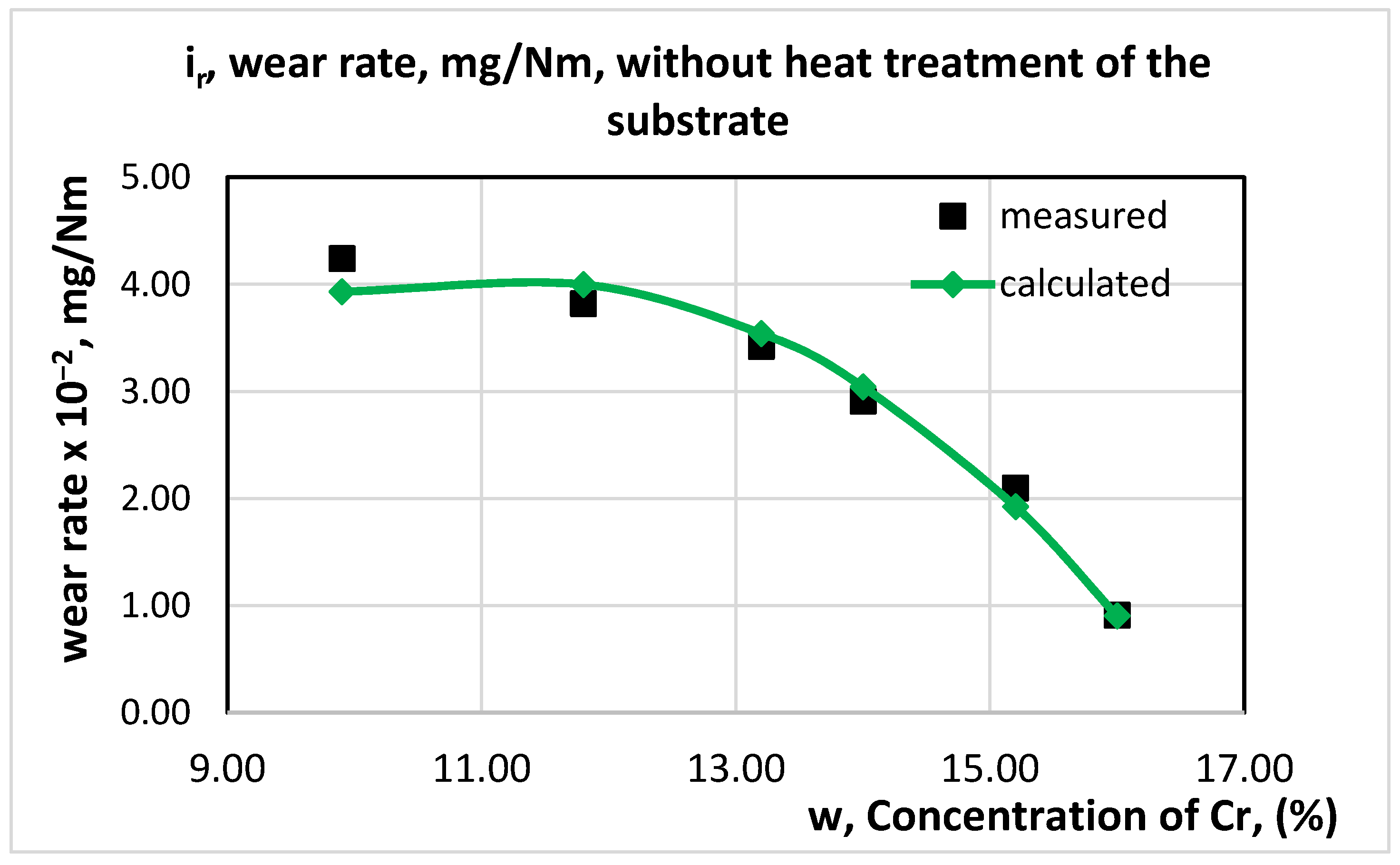

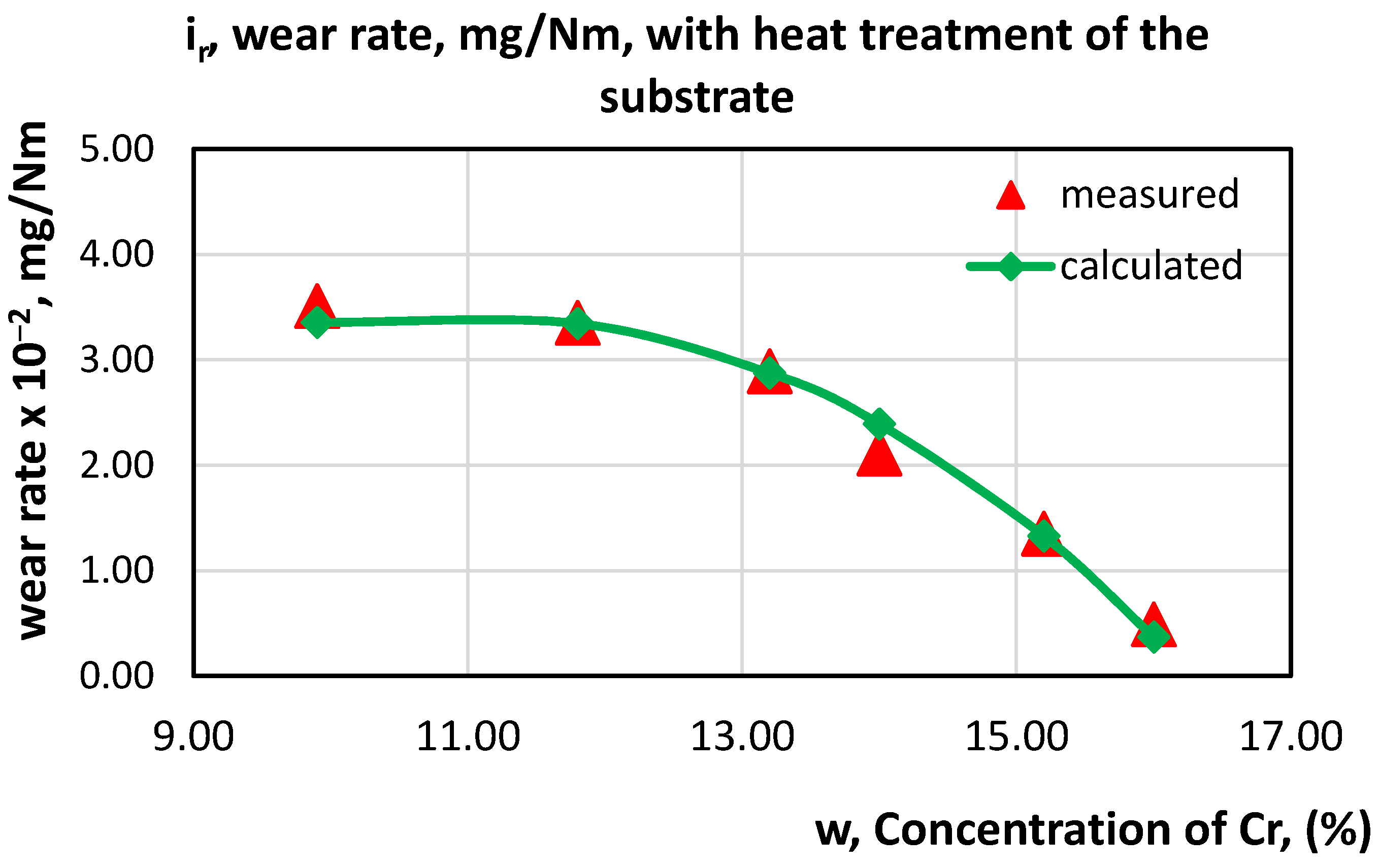

| w, Concentration of Cr, (%) | 9.9 | 11.8 | 13.2 | 14.0 | 15.2 | 16.0 |

| , wear rate, mg/Nm, without heat treatment of the substrate | 4.24 | 3.82 | 3.42 | 2.91 | 2.1 | 0.91 |

| , wear rate, mg/Nm, with heat treatment of the substrate | 3.51 | 3.35 | 2.89 | 2.11 | 1.35 | 0.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kandeva, M.; Kalitchin, Z.; Stoyanova, Y. Influence of Chromium Concentration on the Abrasive Wear of Ni-Cr-B-Si Coatings Applied by Supersonic Flame Jet (HVOF). Metals 2021, 11, 915. https://doi.org/10.3390/met11060915

Kandeva M, Kalitchin Z, Stoyanova Y. Influence of Chromium Concentration on the Abrasive Wear of Ni-Cr-B-Si Coatings Applied by Supersonic Flame Jet (HVOF). Metals. 2021; 11(6):915. https://doi.org/10.3390/met11060915

Chicago/Turabian StyleKandeva, Mara, Zhetcho Kalitchin, and Yana Stoyanova. 2021. "Influence of Chromium Concentration on the Abrasive Wear of Ni-Cr-B-Si Coatings Applied by Supersonic Flame Jet (HVOF)" Metals 11, no. 6: 915. https://doi.org/10.3390/met11060915

APA StyleKandeva, M., Kalitchin, Z., & Stoyanova, Y. (2021). Influence of Chromium Concentration on the Abrasive Wear of Ni-Cr-B-Si Coatings Applied by Supersonic Flame Jet (HVOF). Metals, 11(6), 915. https://doi.org/10.3390/met11060915