Full Variation of Site Substitution in Ni-Mn-Ga by Ferromagnetic Transition Metals

Abstract

1. Introduction

2. Materials and Methods

3. Results

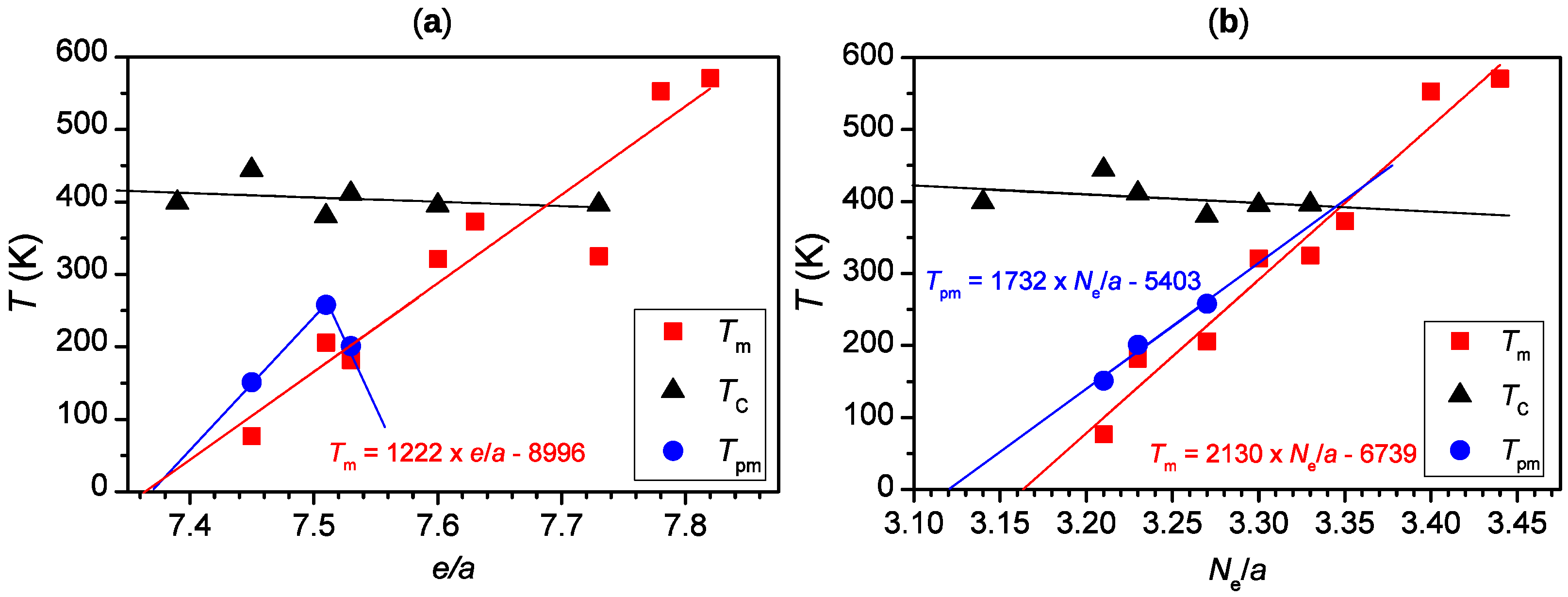

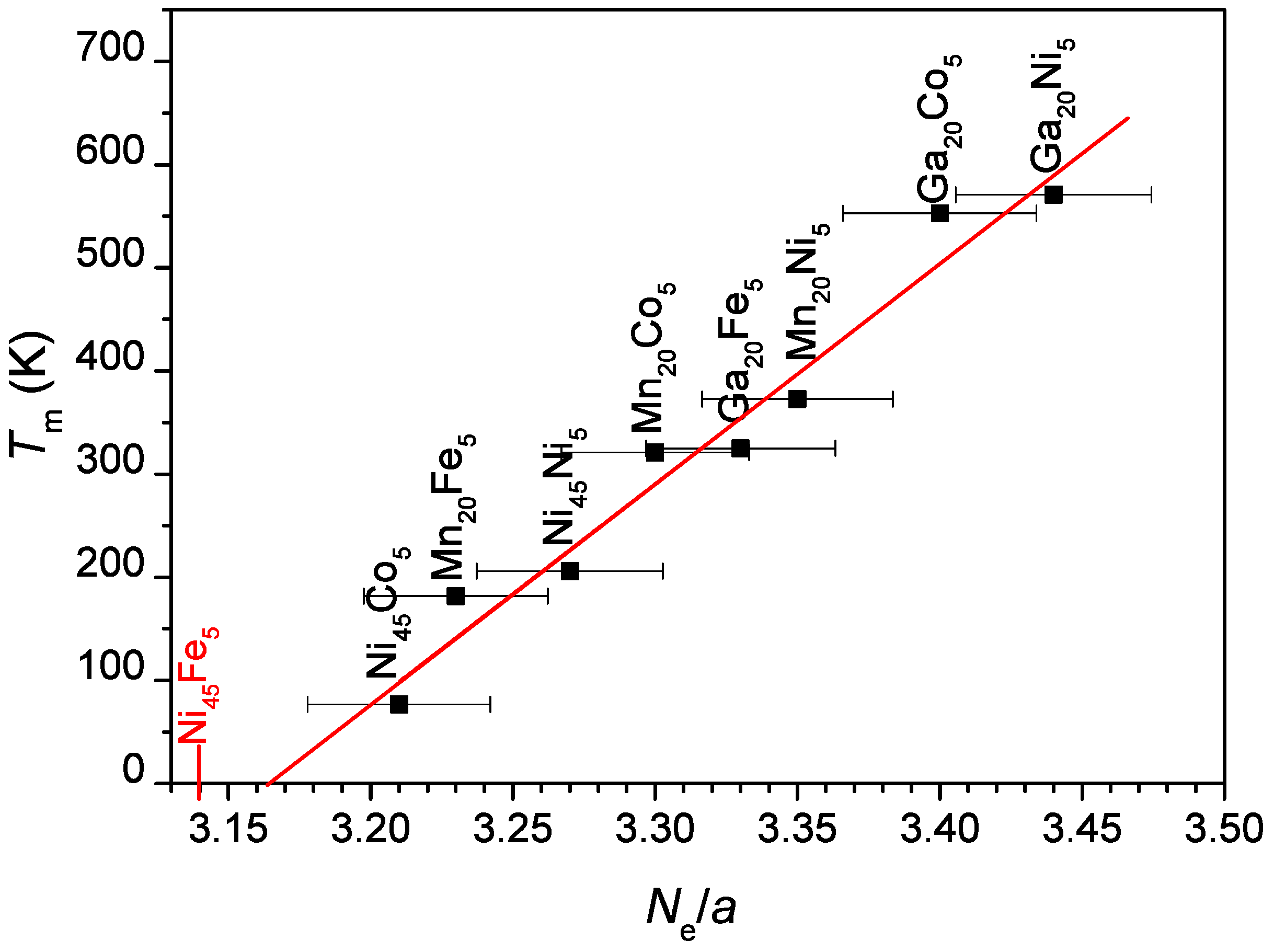

3.1. Transformation Temperatures and Magnetic Properties

3.2. Fe Substitution

3.2.1. Ni45Fe5

3.2.2. Mn20Fe5

3.2.3. Ga20Fe5

3.3. Co-Substitution

3.3.1. Ni45Co5

3.3.2. Mn20Co5

3.3.3. Ga20Co5

3.4. Ni Substitution

3.4.1. Ni45Ni5

3.4.2. Mn20Ni5

3.4.3. Ga20Ni5

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MSM | magnetic shape memory |

| MT | martensitic transformation |

| FM | ferromagnetic |

| AFM | antiferromagnetic |

References

- Sozinov, A.; Lanska, N.; Soroka, A.; Zou, W. 12% magnetic field-induced strain in Ni-Mn-Ga-based non-modulated martensite. Appl. Phys. Lett. 2013, 102, 21902. [Google Scholar] [CrossRef]

- Heczko, O.; Sozinov, A.; Ullakko, K. Giant field-induced reversible strain in magnetic shape memory NiMnGa alloy. IEEE Trans. Magn. 2000, 36, 3266–3268. [Google Scholar] [CrossRef]

- Heczko, O.; Scheerbaum, N.; Gutfleisch, O. Magnetic shape memory phenomena. In Nanoscale Magnetic Materials and Applications; Liu, J.P., Fullerton, E., Gutfleisch, O., Sellmyer, D.J., Eds.; Springer: New York, NY, USA, 2009; Chapter 14; pp. 399–439. [Google Scholar] [CrossRef]

- Sozinov, A.; Lanska, N.; Soroka, A.; Straka, L. Highly mobile type II twin boundary in Ni-Mn-Ga five-layered martensite. Appl. Phys. Lett. 2011, 99, 124103. [Google Scholar] [CrossRef]

- Straka, L.; Soroka, A.; Seiner, H.; Hänninen, H.; Sozinov, A. Temperature dependence of twinning stress of Type I and Type II twins in 10 M modulated Ni-Mn-Ga martensite. Scr. Mater. 2012, 67, 25–28. [Google Scholar] [CrossRef]

- Straka, L.; Hänninen, H.; Soroka, A.; Sozinov, A. Ni-Mn-Ga single crystals with very low twinning stress. J. Phys. Conf. Ser. 2011, 303, 12079. [Google Scholar] [CrossRef]

- Kopecký, V.; Perevertov, O.; Straka, L.; Ševčík, M.; Heczko, O. Equivalence of mechanical and magnetic force in magnetic shape memory effect. Acta Phys. Pol. A 2015, 128, 754–757. [Google Scholar] [CrossRef]

- Lanska, N.; Söderberg, O.; Sozinov, A.; Ge, Y.; Ullakko, K.; Lindroos, V.K. Composition and temperature dependence of the crystal structure of Ni-Mn-Ga alloys. J. Appl. Phys. 2004, 95, 8074–8078. [Google Scholar] [CrossRef]

- Castán, T.; Vives, E.; Mañosa, L.; Planes, A.; Saxena, A. Disorder in Magnetic and Structural Transitions: Pretransitional Phenomena and Kinetics. In Magnetism and Structure in Functional Materials, 1st ed.; Planes, A., Mañosa, L., Saxena, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; Volume 79, Chapter 3; pp. 27–48. ISBN 978-3-540-23672-6. [Google Scholar] [CrossRef]

- Entel, P.; Buchelnikov, V.D.; Khovailo, V.V.; Zayak, A.T.; Adeagbo, W.A.; Gruner, M.E.; Herper, H.C.; Wassermann, E.F. Modelling the phase diagram of magnetic shape memory Heusler alloys. J. Phys. D Appl. Phys. 2006, 39, 865. [Google Scholar] [CrossRef]

- Vasil’ev, A.N.; Buchel’nikov, V.D.; Takagi, T.; Khovailo, V.V.; Estrin, E.I. Shape memory ferromagnets. Phys-Usp+ 2003, 46, 559. [Google Scholar] [CrossRef]

- Xu, X.; Nagasako, M.; Ito, W.; Umetsu, R.Y.; Kanomata, T.; Kainuma, R. Magnetic properties and phase diagram of Ni50Mn50−xGax ferromagnetic shape memory alloys. Acta Mater. 2013, 61, 6712–6723. [Google Scholar] [CrossRef]

- Jin, X.; Marioni, M.; Bono, D.; Allen, S.C.; O’Handley, R.; Hsu, T.Y. Empirical Mapping of Ni-Mn-Ga Properties with Composition and Valence Electron Concentration. J. Appl. Phys. 2002, 91, 8222–8224. [Google Scholar] [CrossRef]

- Pagounis, E.; Chulist, R.; Szczerba, M.; Laufenberg, M. High-temperature magnetic shape memory actuation in a Ni–Mn–Ga single crystal. Scr. Mater. 2014, 83, 29–32. [Google Scholar] [CrossRef]

- Soto-Parra, D.; Moya, X.; Mañosa, L.; Planes, A.; Flores-Zúñiga, H.; Alvarado-Hernández, F.; Ochoa-Gamboa, R.; Matutes-Aquino, J.; Ríos-Jara, D. Fe and Co selective substitution in Ni2MnGa: Effect of magnetism on relative phase stability. Philos. Mag. 2010, 90, 2771–2792. [Google Scholar] [CrossRef]

- Kanomata, T.; Kitsunai, Y.; Sano, K.; Furutani, Y.; Nishihara, H.; Umetsu, R.Y.; Kainuma, R.; Miura, Y.; Shirai, M. Magnetic properties of quaternary Heusler alloys Ni2−xCoxMnGa. Phys. Rev. B 2009, 80, 214402. [Google Scholar] [CrossRef]

- Sakon, T.; Fujimoto, N.; Kanomata, T.; Adachi, Y. Magnetostriction of Ni2Mn1−xCrxGa Heusler Alloys. Metals 2017, 7, 410. [Google Scholar] [CrossRef]

- Gomes, A.M.; Khan, M.; Stadler, S.; Ali, N.; Dubenko, I.; Takeuchi, A.Y.; Guimarães, A.P. Magnetocaloric properties of the Ni2Mn1−x(Cu,Co)xGa Heusler alloys. J. Appl. Phys. 2006, 99, 08Q106. [Google Scholar] [CrossRef]

- Adachi, Y.; Kouta, R.; Fujio, M.; Kanomata, T.; Umetsu, R.Y.; Xu, X.; Kainuma, R. Magnetic Phase Diagram of Heusler Alloy System Ni2Mn1−xCrxGa. Phys. Proc. 2015, 75, 1187–1191. [Google Scholar] [CrossRef]

- Xu, X.; Yoshida, Y.; Omori, T.; Kanomata, T.; Kainuma, R. Magnetic Properties and Phase Diagram of Ni50Mn50−xGax/2Inx/2 Magnetic Shape Memory Alloys. Shape Mem. Superelasticity 2016, 2, 371–379. [Google Scholar] [CrossRef]

- Kanomata, T.; Shirakawa, K.; Kaneko, T. Effect of hydrostatic pressure on the Curie temperature of the Heusler alloys Ni2MnZ (Z = Al, Ga, In, Sn and Sb). J. Magn. Magn. Mater. 1987, 65, 76–82. [Google Scholar] [CrossRef]

- Chatterjee, S.; Giri, S.; De, S.; Majumdar, S. Giant magneto-caloric effect near room temperature in Ni–Mn–Sn–Ga alloys. J. Alloys Compd. 2010, 503, 273–276. [Google Scholar] [CrossRef]

- Chatterjee, S.; Giri, S.; Majumdar, S.; De, S.; Koledov, V. Effect of Sn doping on the martensitic and premartensitic transitions in Ni2MnGa. J. Magn. Magn. Mater. 2012, 324, 1891–1896. [Google Scholar] [CrossRef]

- Armstrong, A.; Nilsén, F.; Rameš, M.; Colman, R.H.; Veřtát, P.; Kmječ, T.; Straka, L.; Müllner, P.; Heczko, O. Systematic Trends of Transformation Temperatures and Crystal Structure of Ni-Mn-Ga-Fe-Cu Alloys. Shape Mem. Superelasticity 2020, 6, 97–106. [Google Scholar] [CrossRef]

- Kratochvílová, M.; Král, D.; Dušek, M.; Valenta, J.; Colman, R.; Heczko, O.; Veis, M. Fe2MnSn—Experimental quest for predicted Heusler alloy. J. Magn. Magn. Mater. 2020, 501, 166426. [Google Scholar] [CrossRef]

- Kratochvílová, M.; Klicpera, M.; Malý, F.; Valenta, J.; Veis, M.; Colman, R.; Heczko, O. Systematic experimental search for Fe2YZ Heusler compounds predicted by ab-initio calculation. Intermetallics 2021, 131, 107073. [Google Scholar] [CrossRef]

- Criss, J.W.; Birks, L.S. Calculation methods for fluorescent X-ray spectrometry. Empirical coefficients versus fundamental parameters. Anal. Chem. 1968, 40, 1080–1086. [Google Scholar] [CrossRef]

- Rousseau, R. How to Apply the Fundamental Parameters Method to the Quantitative X-ray Fluorescence Analysis of Geological Materials. J. Geosci. Geomat. 2013, 1, 1–7. [Google Scholar] [CrossRef]

- Haschke, M. Quantification. In Laboratory Micro-X-ray Fluorescence Spectroscopy; Springer International Publishing: Cham, Swizterland, 2014; Chapter 4; pp. 157–199. [Google Scholar] [CrossRef]

- Kanomata, T.; Nunoki, S.; Endo, K.; Kataoka, M.; Nishihara, H.; Khovaylo, V.V.; Umetsu, R.Y.; Shishido, T.; Nagasako, M.; Kainuma, R.; et al. Phase diagram of the ferromagnetic shape memory alloys Ni2MnGa1−xCox. Phys. Rev. B 2012, 85, 134421. [Google Scholar] [CrossRef]

- Straka, L.; Sozinov, A.; Drahokoupil, J.; Kopecký, V.; Hänninen, H.; Heczko, O. Effect of intermartensite transformation on twinning stress in Ni-Mn-Ga 10 M martensite. J. Appl. Phys. 2013, 114, 63504. [Google Scholar] [CrossRef]

- Arrott, A. Criterion for Ferromagnetism from Observations of Magnetic Isotherms. Phys. Rev. 1957, 108, 1394–1396. [Google Scholar] [CrossRef]

- Heczko, O.; Fähler, S.; Vasilchikova, T.M.; Voloshok, T.N.; Klimov, K.V.; Chumlyakov, Y.I.; Vasiliev, A.N. Thermodynamic, kinetic, and magnetic properties of a Ni54Fe19Ga27 magnetic shape-memory single crystal. Phys. Rev. B 2008, 77, 174402. [Google Scholar] [CrossRef]

- Graf, T.; Felser, C.; Parkin, S.S.P. Simple rules for the understanding of Heusler compounds. Prog. Solid. State Chem. 2011, 39, 1–50. [Google Scholar] [CrossRef]

- Ramudu, M.; Kumar, A.S.; Seshubai, V.; Rajasekharan, T. Correlation of martensitic transformation temperatures of Ni- Mn-Ga/Al-X alloys to non-bonding electron concentration. IOP Conf. Ser. Mater. Sci. Eng. 2015, 73, 012074. [Google Scholar] [CrossRef]

- Miedema, A.; de Châtel, P.; de Boer, F. Cohesion in alloys—Fundamentals of a semi-empirical model. Physic B 1980, 100, 1–28. [Google Scholar] [CrossRef]

- Miedema, A.R.; de Boer, F.R.; de Chatel, P.F. Empirical description of the role of electronegativity in alloy formation. J. Phys. F Met. Phys. 1973, 3, 1558–1576. [Google Scholar] [CrossRef]

- Nespoli, A.; Villa, E.; Passaretti, F.; Albertini, F.; Cabassi, R.; Pasquale, M.; Sasso, C.P.; Coïsson, M. Non-Conventional Techniques for the Study of Phase Transitions in NiTi-Based Alloys. J. Mater. Eng. Perform. 2014, 23, 2491–2497. [Google Scholar] [CrossRef]

- Heczko, O.; Vronka, M.; Veřtát, P.; Rameš, M.; Onderková, K.; Kopecký, V.; Krátká, P.; Ge, Y. Mechanical Stabilization of Martensite in Cu–Ni–Al Single Crystal and Unconventional Way to Detect It. Shape Mem. Superelasticity 2018, 4, 77–84. [Google Scholar] [CrossRef]

- O’Handley, R.C. Modern Magnetic Materials: Principles and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2000; ISBN 0-471-15566-7. [Google Scholar]

- Straka, L.; Fekete, L.; Rameš, M.; Belas, E.; Heczko, O. Magnetic coercivity control by heat treatment in Heusler Ni–Mn–Ga(–B) single crystals. Acta Mater. 2019, 169, 109–121. [Google Scholar] [CrossRef]

- Webster, P.J.; Ziebeck, K.R.A.; Town, S.L.; Peak, M.S. Magnetic order and phase transformation in Ni2MnGa. Phil. Mag. B 1984, 49, 295–310. [Google Scholar] [CrossRef]

- Vasil’ev, A.N.; Bozhko, A.D.; Khovailo, V.V.; Dikshtein, I.E.; Shavrov, V.G.; Buchelnikov, V.D.; Matsumoto, M.; Suzuki, S.; Takagi, T.; Tani, J. Structural and magnetic phase transitions in shape-memory alloys Ni2+xMn1−xGa. Phys. Rev. B 1999, 59, 1113–1120. [Google Scholar] [CrossRef]

- Enkovaara, J.; Heczko, O.; Ayuela, A.; Nieminen, R.M. Coexistence of ferromagnetic and antiferromagnetic order in Mn-doped Ni2MnGa. Phys. Rev. B 2003, 67, 212405. [Google Scholar] [CrossRef]

- Kainuma, R.; Imano, Y.; Ito, W.; Sutou, Y.; Morito, H.; Okamoto, S.; Kitakami, O.; Oikawa, K.; Fujita, A.; Kanomata, T.; et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 2006, 439, 957–960. [Google Scholar] [CrossRef]

- Kainuma, R.; Oikawa, K.; Ito, W.; Sutou, Y.; Kanomata, T.; Ishida, K. Metamagnetic shape memory effect in NiMn-based Heusler-type alloys. J. Mater. Chem. 2008, 18, 1837–1842. [Google Scholar] [CrossRef]

- Rameš, M.; Heczko, O.; Sozinov, A.; Ullakko, K.; Straka, L. Magnetic properties of Ni-Mn-Ga-Co-Cu tetragonal martensites exhibiting magnetic shape memory effect. Scr. Mater. 2018, 142, 61–65. [Google Scholar] [CrossRef]

- Pushin, V.G.; Kourov, N.I.; Korolev, A.V.; Marchenkov, V.V.; Marchenkova, E.B.; Kazantsev, V.A.; Kuranova, N.N.; Popov, A.G. Effect of cobalt doping on thermoelastic martensitic transformations and physical properties of magnetic shape memory alloys Ni50−xCoxMn29Ga21. Phys. Solid State 2013, 55, 2413–2421. [Google Scholar] [CrossRef]

- Söderberg, O.; Koho, K.; Sammi, T.; Liu, X.; Sozinov, A.; Lanska, N.; Lindroos, V. Effect of the selected alloying on Ni-Mn-Ga alloys. Mater. Sci. Eng. A 2004, 378, 389–393. [Google Scholar] [CrossRef]

- Cherechukin, A.; Khovailo, V.; Koposov, R.; Krasnoperov, E.; Takagi, T.; Tani, J. Training of the Ni-Mn-Fe-Ga ferromagnetic shape-memory alloys due cycling in high magnetic field. J. Magn. Magn. Mater. 2003, 258–259, 523–525. [Google Scholar] [CrossRef][Green Version]

- Kumar, A.S.; Ramudu, M.; Seshubai, V. Effect of selective substitution of Co for Ni or Mn on the superstructure and microstructural properties of Ni50Mn29Ga21. J. Alloys Compd. 2011, 509, 8215–8222. [Google Scholar] [CrossRef]

- Soto, D.; Hernández, F.A.; Flores-Zúñiga, H.; Moya, X.; Mañosa, L.; Planes, A.; Aksoy, S.; Acet, M.; Krenke, T. Phase diagram of Fe-doped Ni-Mn-Ga ferromagnetic shape-memory alloys. Phys. Rev. B 2008, 77, 184103. [Google Scholar] [CrossRef]

- Chen, X.Q.; Lu, X.; Wang, D.Y.; Qin, Z.X. The effect of Co-doping on martensitic transformation temperatures in Ni–Mn–Ga Heusler alloys. Smart Mater. Struct. 2008, 17, 065030. [Google Scholar] [CrossRef]

- Belosludtseva, E.S.; Kuranova, N.N.; Marchenkova, E.B.; Popov, A.G.; Pushin, V.G. Effect of gallium alloying on the structure, the phase composition, and the thermoelastic martensitic transformations in ternary Ni–Mn–Ga alloys. Tech. Phys. 2016, 61, 547–553. [Google Scholar] [CrossRef]

- Yang, S.; Wang, C.; Liu, X. Phase equilibria and composition dependence of martensitic transformation in Ni–Mn–Ga ternary system. Intermetallics 2012, 25, 101–108. [Google Scholar] [CrossRef]

- Ingale, B.; Gopalan, R.; Rajasekhar, M.; Ram, S. Studies on ordering temperature and martensite stabilization in Ni55Mn20−xGa25+x alloys. J. Alloys Compd. 2009, 475, 276–280. [Google Scholar] [CrossRef]

- Pushin, V.; Kuranova, N.; Marchenkova, E.; Pushin, A. Design and Development of Ti–Ni, Ni–Mn–Ga and Cu–Al–Ni-based Alloys with High and Low Temperature Shape Memory Effects. Materials 2019, 12, 2616. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Z.; He, X.; Huang, Y.; Xu, K.; Jing, C. Evolution of phase transformation and magnetic properties with Fe content in Ni55−xFexMn20Ga25 Heusler alloys. J. Phys. D Appl. Phys. 2018, 51, 075004. [Google Scholar] [CrossRef]

- Khan, M.; Dubenko, I.; Stadler, S.; Ali, N. The structural and magnetic properties of Ni2Mn1−xMxGa (M=Co, Cu). J. Appl. Phys. 2005, 97, 10M304. [Google Scholar] [CrossRef]

- Richard, M.L.; Feuchtwanger, J.; Allen, S.M.; O’handley, R.C.; Lázpita, P.; Barandiaran, J.M.; Gutierrez, J.; Ouladdiaf, B.; Mondelli, C.; Lograsso, T.; et al. Chemical order in off-stoichiometric Ni-Mn-Ga ferromagnetic shape-memory alloys studied with neutron diffraction. Philos. Mag. 2007, 87, 3437–3447. [Google Scholar] [CrossRef]

- Porro-Azpiazu, J.M.; Barandiaran, J.M.; Chernenko, V.; Feuchtwanger, J.; Lazpita, P.; Perez-checa, A.; Velamazan, R.; Alberto, J. Role of Fe and Co Addition in NiMnGa Shape Memory Alloys: Site Occupancy and Structural Stabilization of Crystallographic Phases; Technical Report; Institut Laue-Langevin (ILL): Grenoble, France, 2018. [Google Scholar] [CrossRef]

- Lazpita, P.; Barandiaran, J.M.; Chernenko, V.; Feuchtwanger, J.; Gutierrez, J.; Hansen, T.; Martinez, C.F.J.; Mondelli, C.; Perez-Checa, A.; Sozinov, A.; et al. Influence Fe Addition on Structural and Magnetic Properties of Ni45Co5Mn25−xFexGa20Cu5 (x = 0, 1, 2, 4, 5, 6 and 8) Heusler Alloys; Technical Report; Institut Laue-Langevin (ILL): Grenoble, France, 2018. [Google Scholar] [CrossRef]

- Perez-Checa, A.; Lazpita, P.; Porro-Azpiazu, J.M.; Feuchtwanger, J.; Velamazan, J.A.R. Site occupancy study of Fe doped Ni45Co5Mn25−xFexGa20Cu5 (x = 4 and 5) Heusler single crystals; Technical Report; Institut Laue-Langevin (ILL): Grenoble, France, 2018. [Google Scholar] [CrossRef]

- Li, C.M.; Luo, H.B.; Hu, Q.M.; Yang, R.; Johansson, B.; Vitos, L. Site preference and elastic properties of Fe-, Co-, and Cu-doped Ni2MnGa shape memory alloys from first principles. Phys. Rev. B 2011, 84, 024206. [Google Scholar] [CrossRef]

- Jie, C.; Yan, L.; Jia-Xiang, S.; Hui-Bin, X. Site Preference and Alloying Effect of Excess Ni in Ni-Mn-Ga Shape Memory Alloys. Chin. Phys. Lett. 2009, 26, 047101. [Google Scholar] [CrossRef]

- Ayila, S.K.; Machavarapu, R.; Vummethala, S. Site preference of magnetic atoms in Ni-Mn-Ga-M (M = Co, Fe) ferromagnetic shape memory alloys. Phys. Status Solidi B 2011, 249, 620–626. [Google Scholar] [CrossRef]

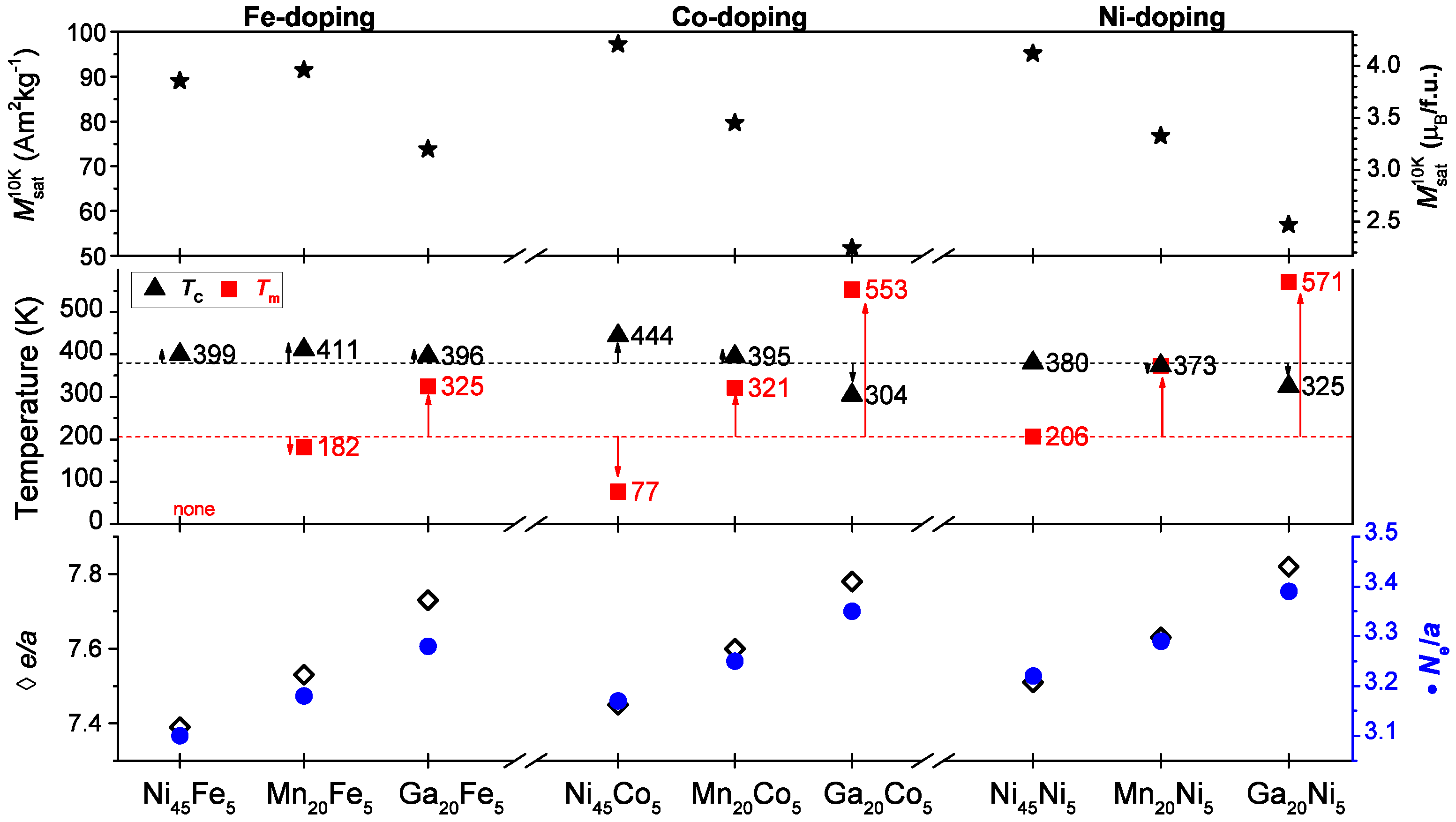

| Identifier | Composition by XRF | e/a | Ne/a | Structure |

|---|---|---|---|---|

| Ni45Fe5 | (Ni45.3Fe5.3)Mn23.8Ga25.6 | 7.39 | 3.10 | A |

| Mn20Fe5 | Ni49.2(Mn20.5Fe5.3)Ga25.0 | 7.53 | 3.18 | A |

| Ga20Fe5 | Ni49.0Mn25.5(Ga20.0Fe5.5) | 7.73 | 3.28 | 14 M |

| Ni45Co5 | (Ni44.9Co5.1)Mn25.1Ga24.9 | 7.45 | 3.17 | A |

| Mn20Co5 | Ni49.9(Mn20.1Co5.0)Ga25.0 | 7.60 | 3.25 | NM |

| Ga20Co5 | Ni49.9Mn24.6(Ga20.4Co5.1) | 7.78 | 3.35 | NM |

| Ni45Ni5 | (Ni45.0Ni5.4)Mn24.6Ga25.0 | 7.51 | 3.22 | A |

| Mn20Ni5 | Ni50.0(Mn20.5Ni4.4)Ga25.1 | 7.63 | 3.29 | NM |

| Ga20Ni5 | Ni50.0Mn25.4(Ga20.3Ni4.3) | 7.82 | 3.39 | NM |

| Identifier | a0 | a | b | c | c/a | Structure | |

|---|---|---|---|---|---|---|---|

| Ni45Fe5 | 0.5827(1) | – | – | – | 90 | – | A |

| Mn20Fe5 | 0.5814(1) | – | – | – | 90 | – | A |

| Ga20Fe5 | – | 0.6200(2) | 0.5764(2) | 0.5506(2) | 90.4(2) | 0.89 | 14M |

| Ni45Co5 | 0.5822(1) | – | – | – | 90 | – | A |

| Mn20Co5 | – | 0.5535(2) | – | 0.6384(2) | 90 | 1.15 | NM |

| Ga20Co5 | – | 0.5424(2) | – | 0.6630(2) | 90 | 1.22 | NM |

| Ni45Ni5 | 0.5818(5) | – | – | – | 90 | – | A |

| Mn20Ni5 | – | 0.5469(4) | – | 0.6515(5) | 90 | 1.19 | NM |

| Ga20Ni5 | – | 0.5392(2) | – | 0.6701(1) | 90 | 1.24 | NM |

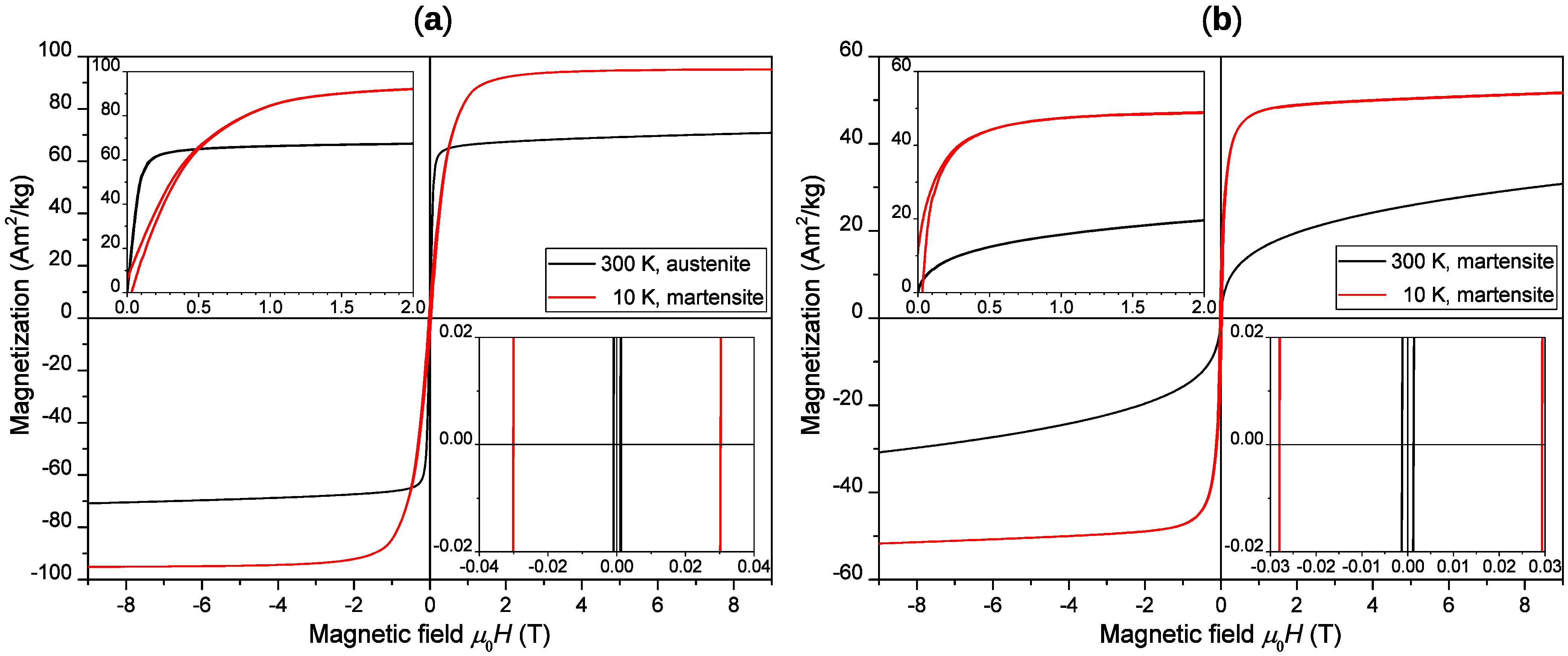

| Identifier | |||||

|---|---|---|---|---|---|

| Am/kg | /f.u. | mT | Am/kg | mT | |

| Ni45Fe5 | |||||

| Mn20Fe5 | 91.4 | 3.96 | 12.2 | ||

| Ga20Fe5 | 73.8 | 3.16 | 43.4 | 64.4 | 29.3 |

| Ni45Co5 | 97.2 | 4.21 | 0.8 | ||

| Mn20Co5 | 79.6 | 3.46 | 10.9 | 63.4 | 7.3 |

| Ga20Co5 | 51.7 | 2.22 | 28.7 | 30.8 | 1.3 |

| Ni45Ni5 | 95.1 | 4.12 | 30.2 | ||

| Mn20Ni5 | 76.7 | 3.33 | 28.2 | 57.0 | 14.6 |

| Ga20Ni5 | 56.9 | 2.44 | 48.5 | 34.1 | 0.9 |

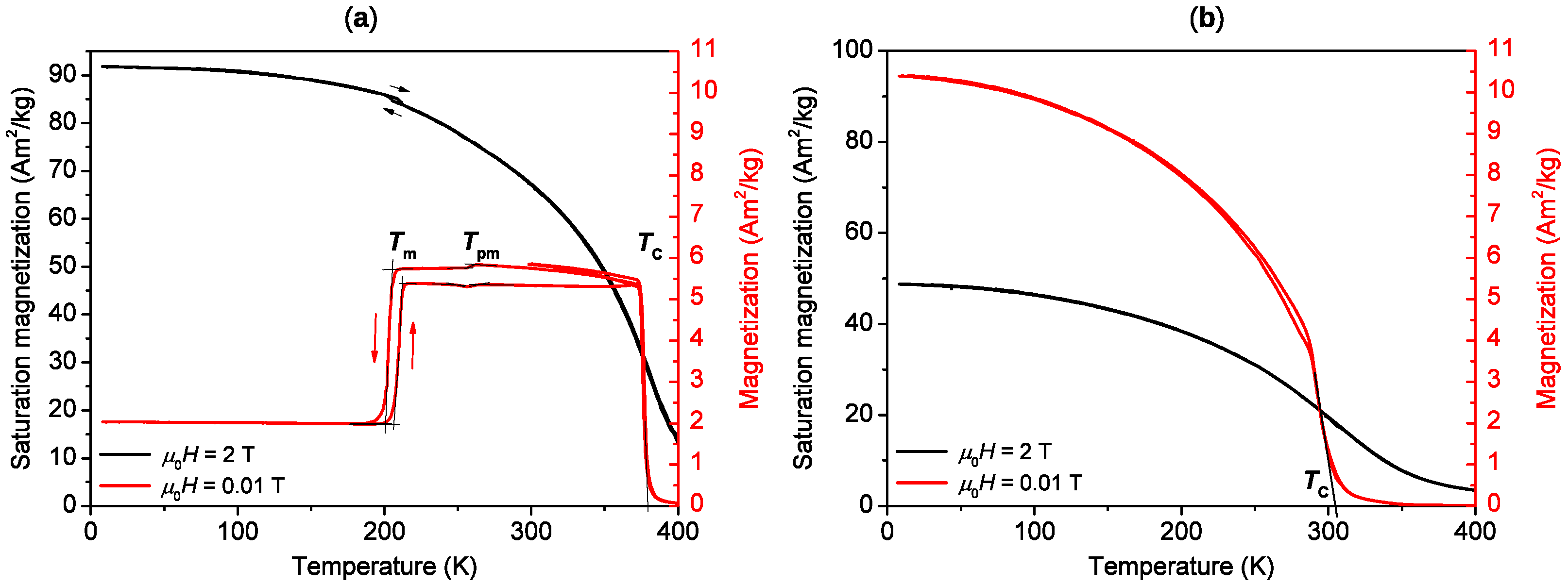

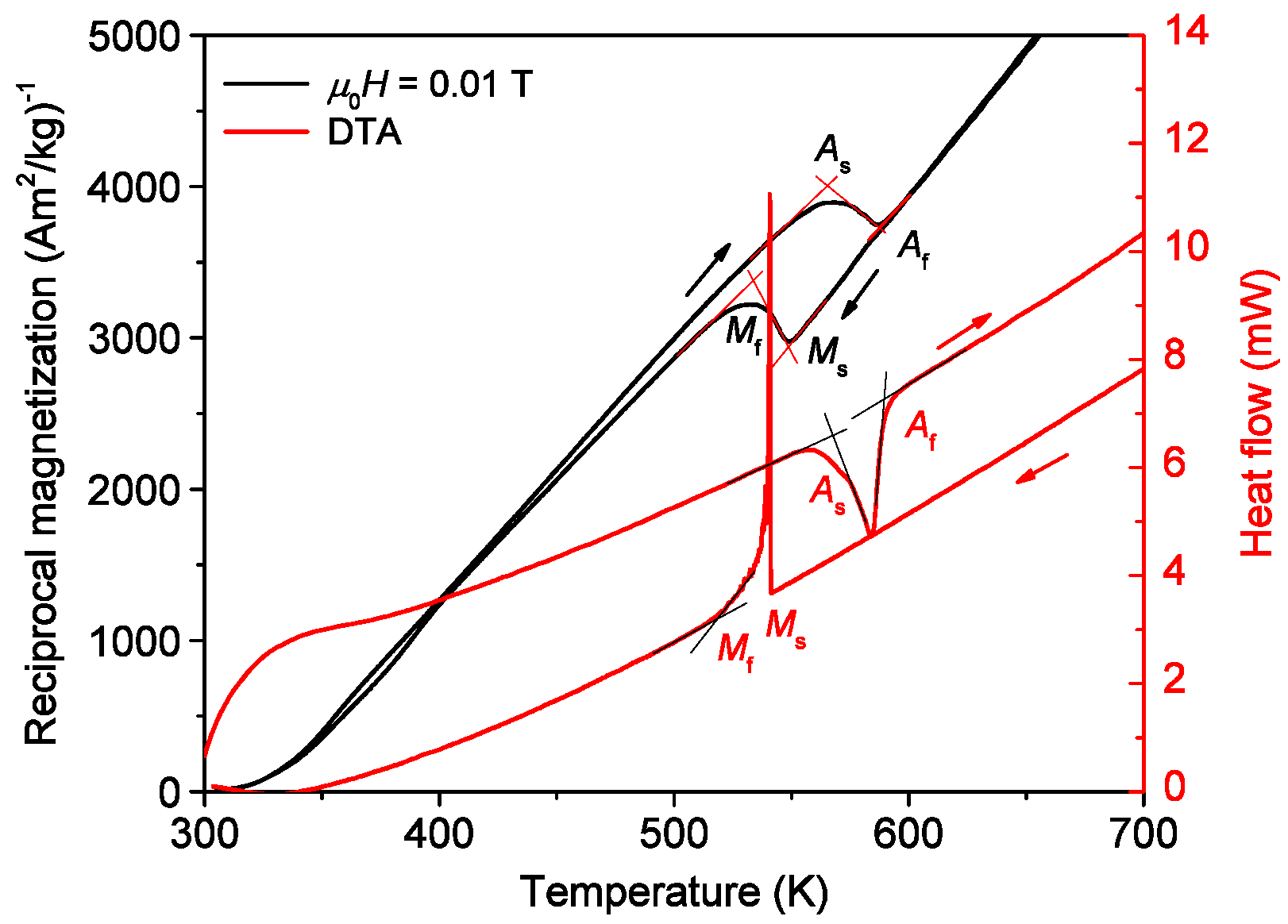

| Identifier | Ms | Mf | As | Af | Tm | TC | Tpm |

|---|---|---|---|---|---|---|---|

| Ni45Fe5 | – | – | – | – | – | 399 | – |

| Mn20Fe5 | 187 | 170 | 177 | 195 | 182 | 411 | 201 |

| Ga20Fe5 | 325 | 318 | 325 | 333 | 325 | 396 | – |

| Ni45Co5 | 104 | 100 | 43 | 61 | 77 | 444 | 151 |

| Mn20Co5 | 322 | 309 | 319 | 330 | 321 | 395 | – |

| Ga20Co5 | 541 | 520 | 553 | 597 | 553 | 304 * | – |

| Ni45Ni5 | 205 | 200 | 206 | 212 | 206 | 380 | 258 |

| Mn20Ni5 | 382 | 358 | 366 | 384 | 373 | 373 ** | – |

| Ga20Ni5 | 564 | 497 | 603 | 621 | 571 | 325 * | – |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kopecký, V.; Rameš, M.; Veřtát, P.; Colman, R.H.; Heczko, O. Full Variation of Site Substitution in Ni-Mn-Ga by Ferromagnetic Transition Metals. Metals 2021, 11, 850. https://doi.org/10.3390/met11060850

Kopecký V, Rameš M, Veřtát P, Colman RH, Heczko O. Full Variation of Site Substitution in Ni-Mn-Ga by Ferromagnetic Transition Metals. Metals. 2021; 11(6):850. https://doi.org/10.3390/met11060850

Chicago/Turabian StyleKopecký, Vít, Michal Rameš, Petr Veřtát, Ross H. Colman, and Oleg Heczko. 2021. "Full Variation of Site Substitution in Ni-Mn-Ga by Ferromagnetic Transition Metals" Metals 11, no. 6: 850. https://doi.org/10.3390/met11060850

APA StyleKopecký, V., Rameš, M., Veřtát, P., Colman, R. H., & Heczko, O. (2021). Full Variation of Site Substitution in Ni-Mn-Ga by Ferromagnetic Transition Metals. Metals, 11(6), 850. https://doi.org/10.3390/met11060850