A Comprehensive Study of Dynamic Recrystallization Behavior of Mg Alloy with 3 wt.% Bi Addition

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

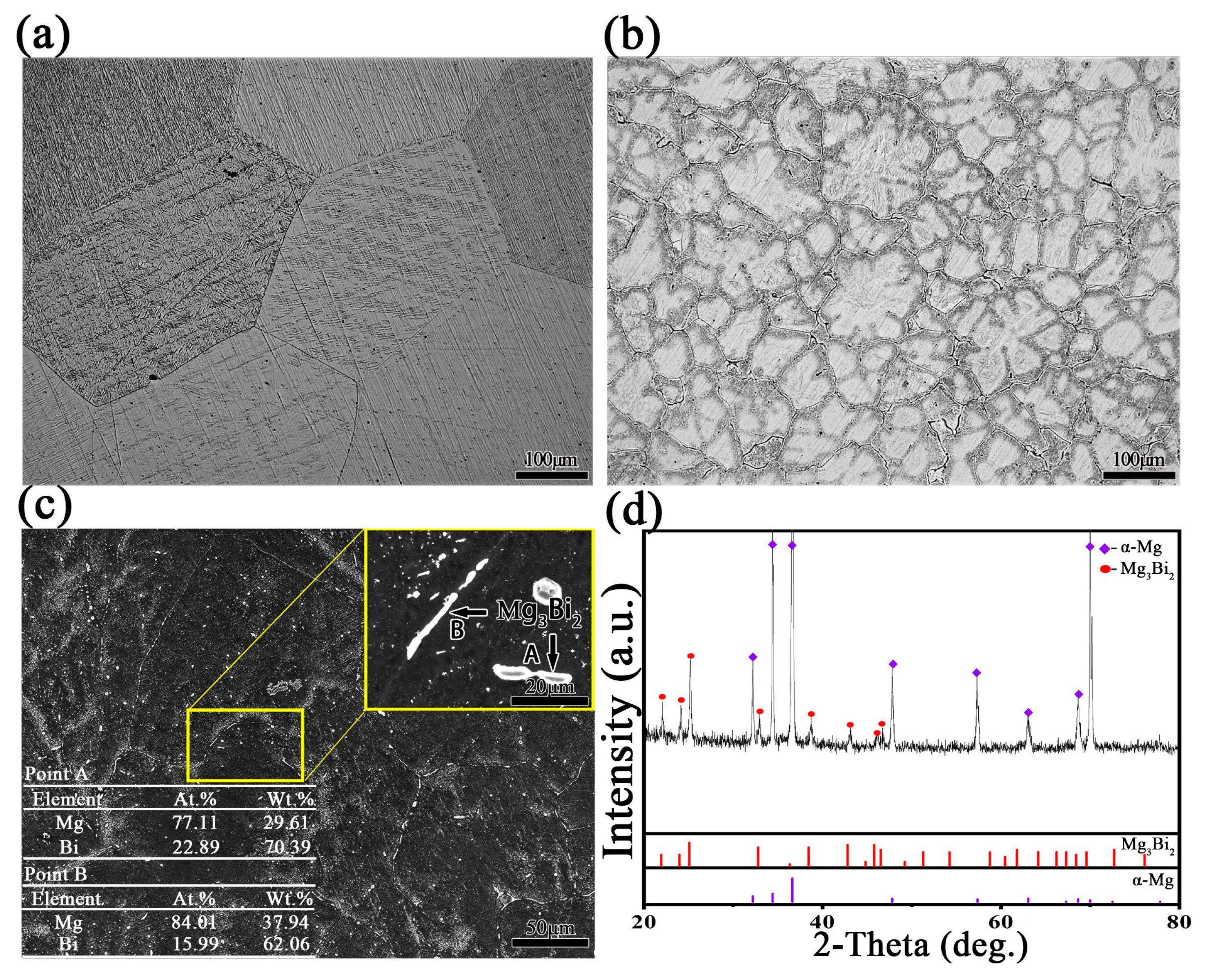

3.1. The Initial Microstructure of Pure Mg and Mg-3Bi Alloy

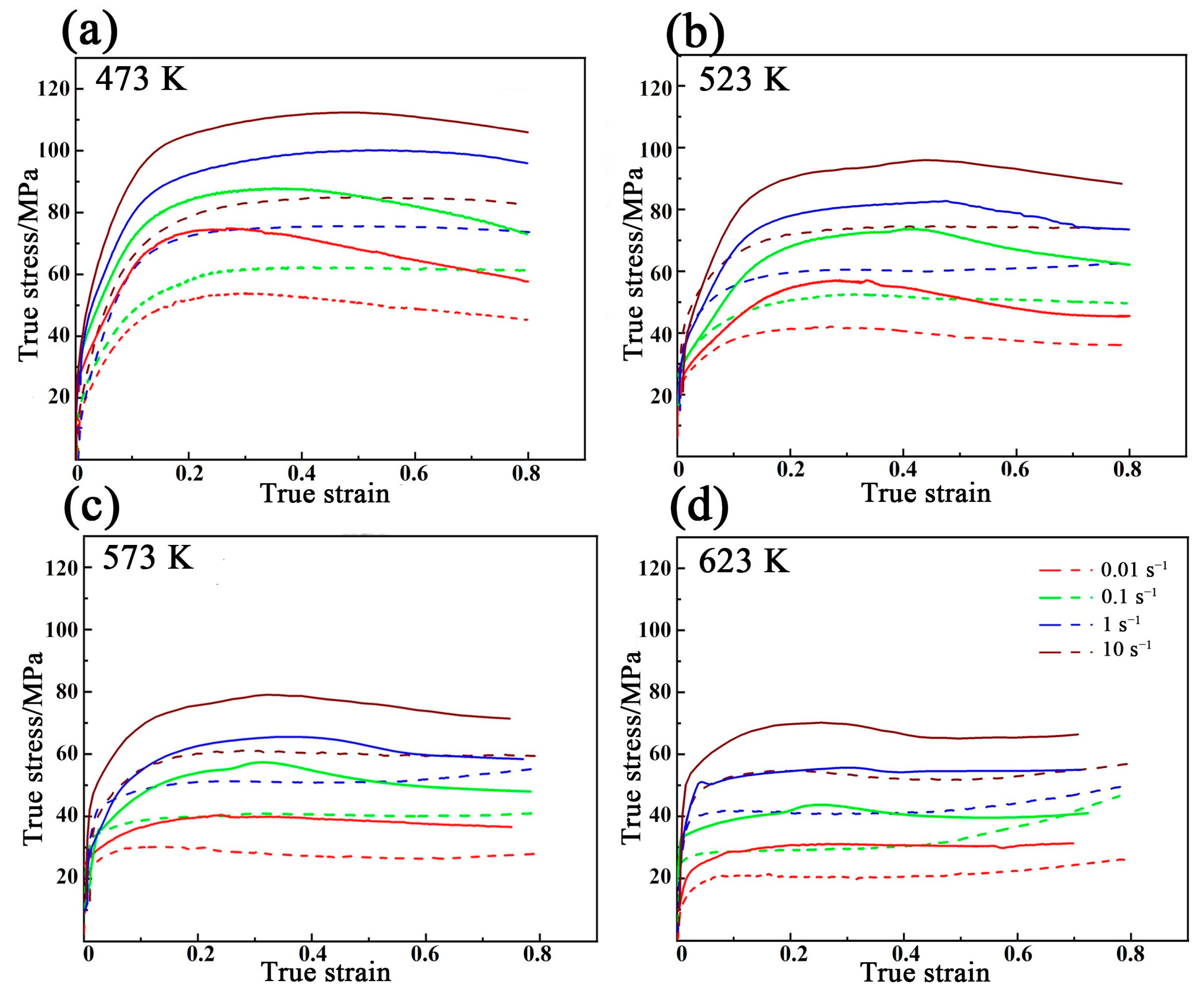

3.2. Flow Stress−Strain Behavior

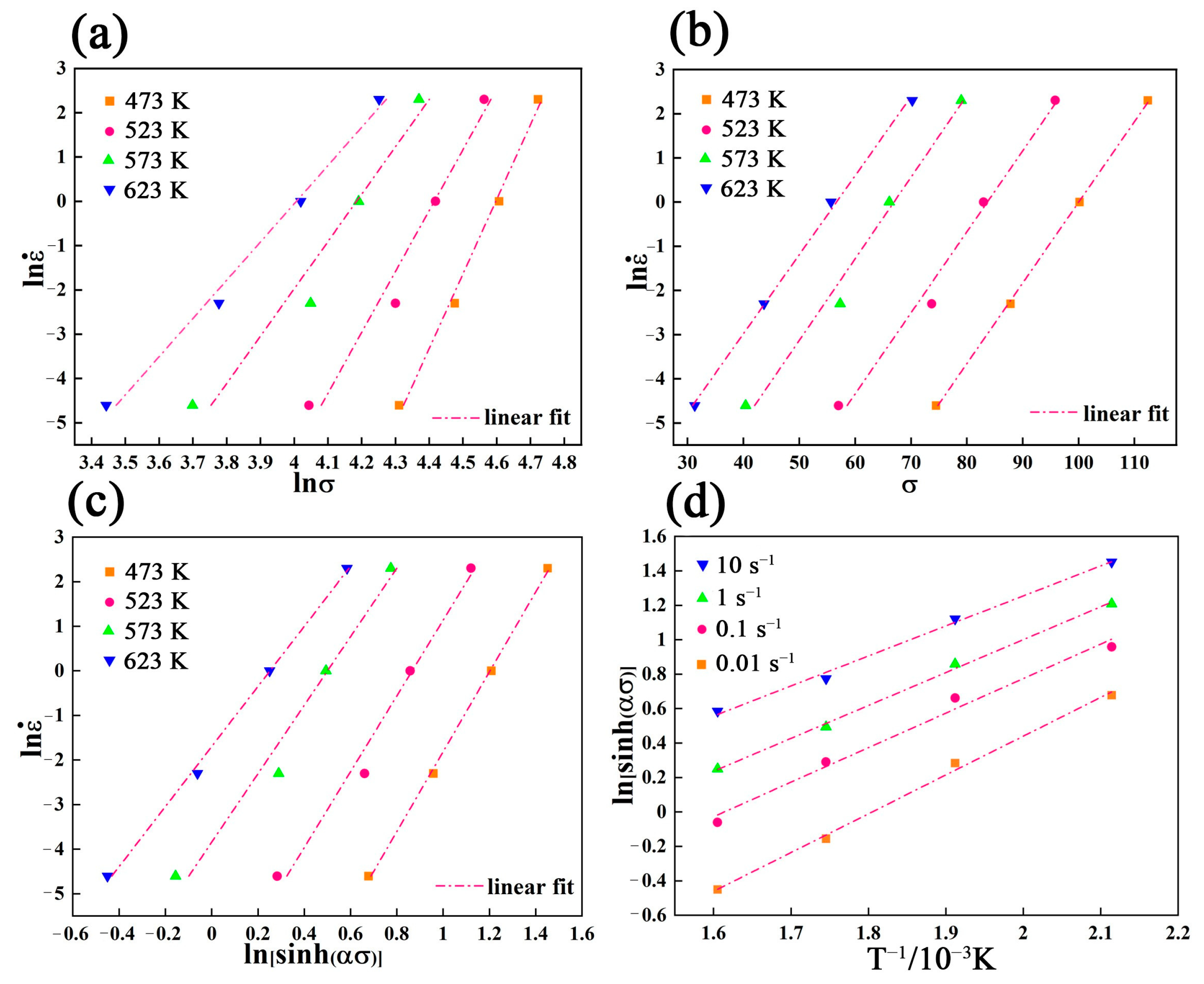

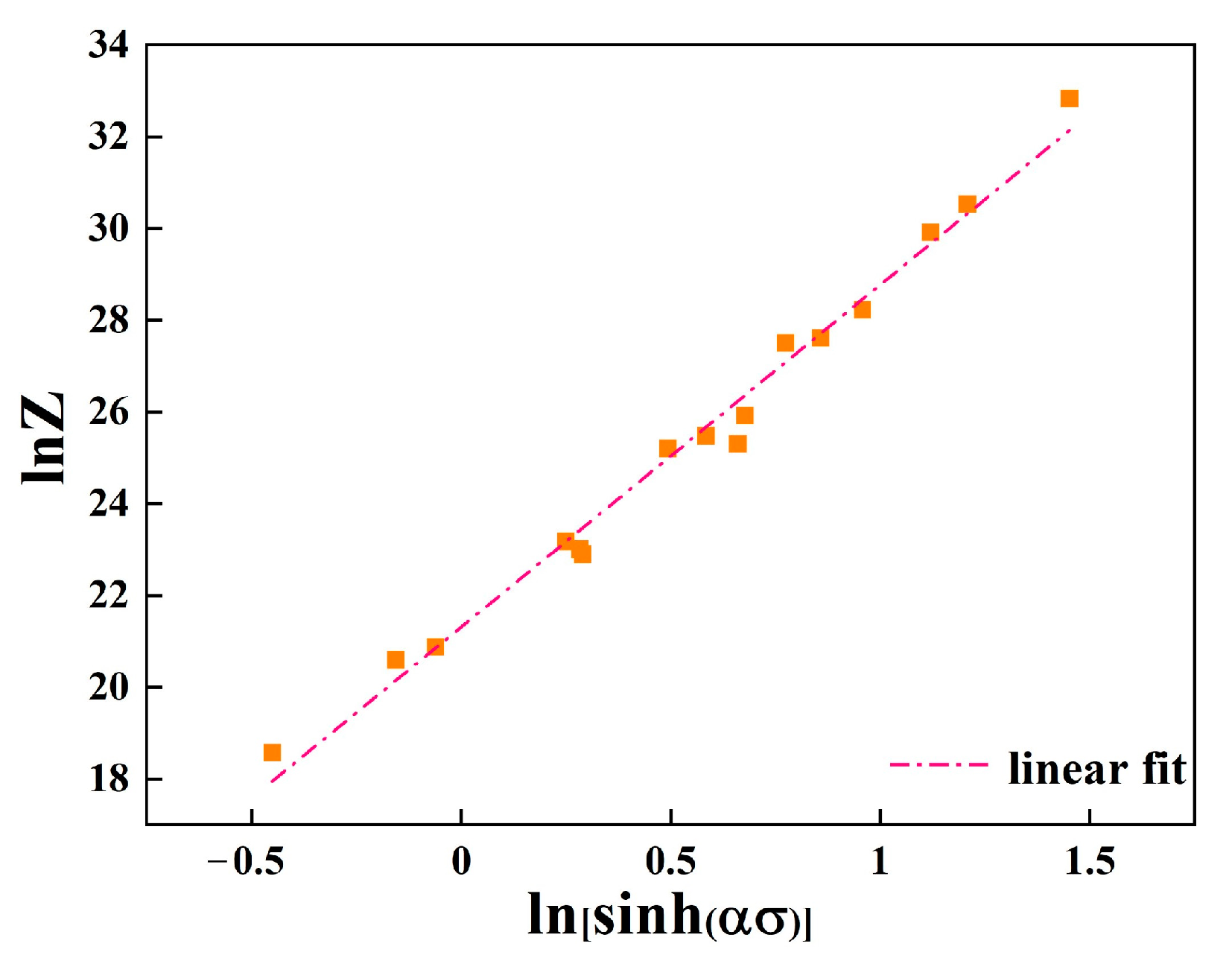

3.3. The Constitutive Equation of Mg-3Bi Alloy

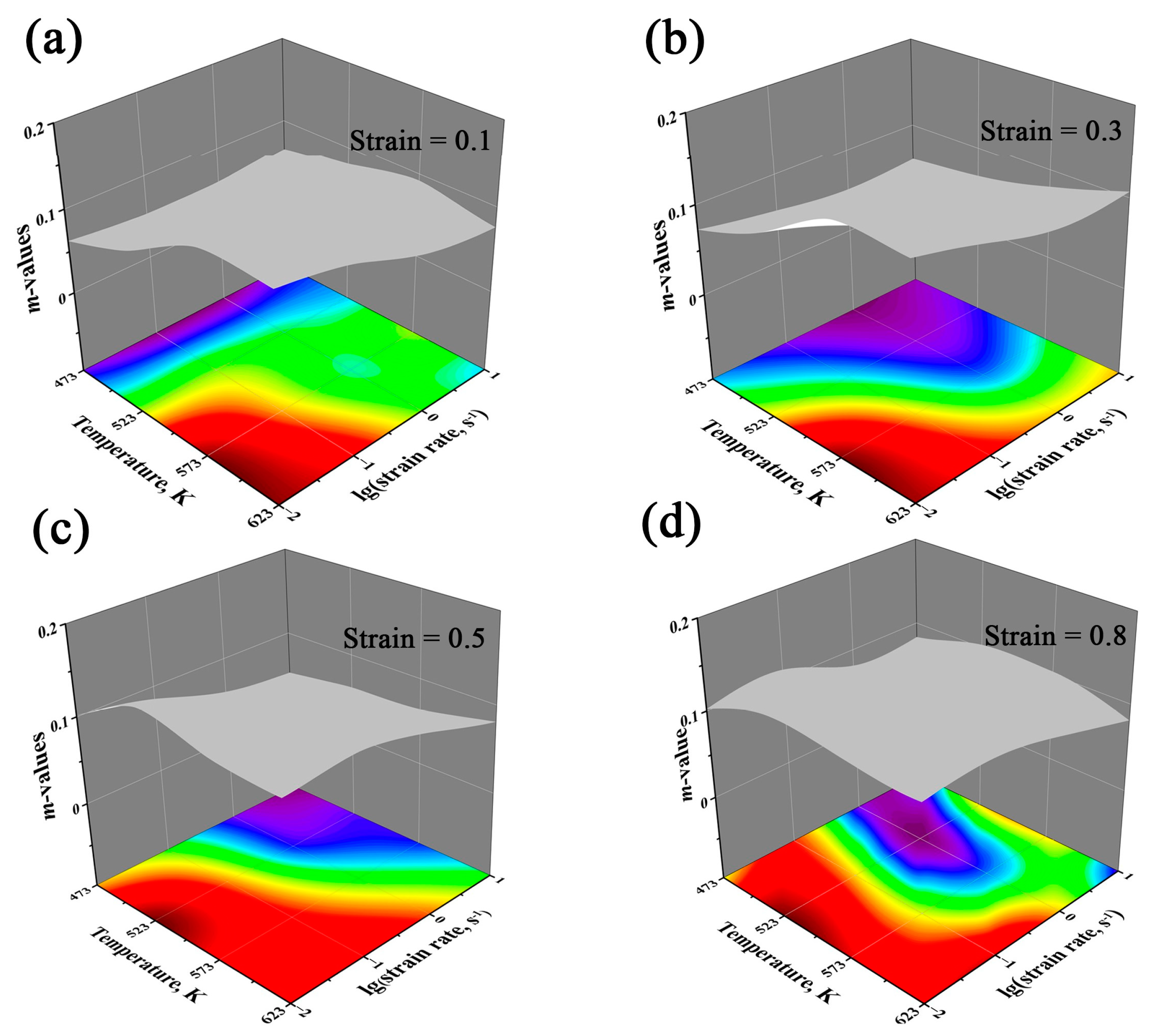

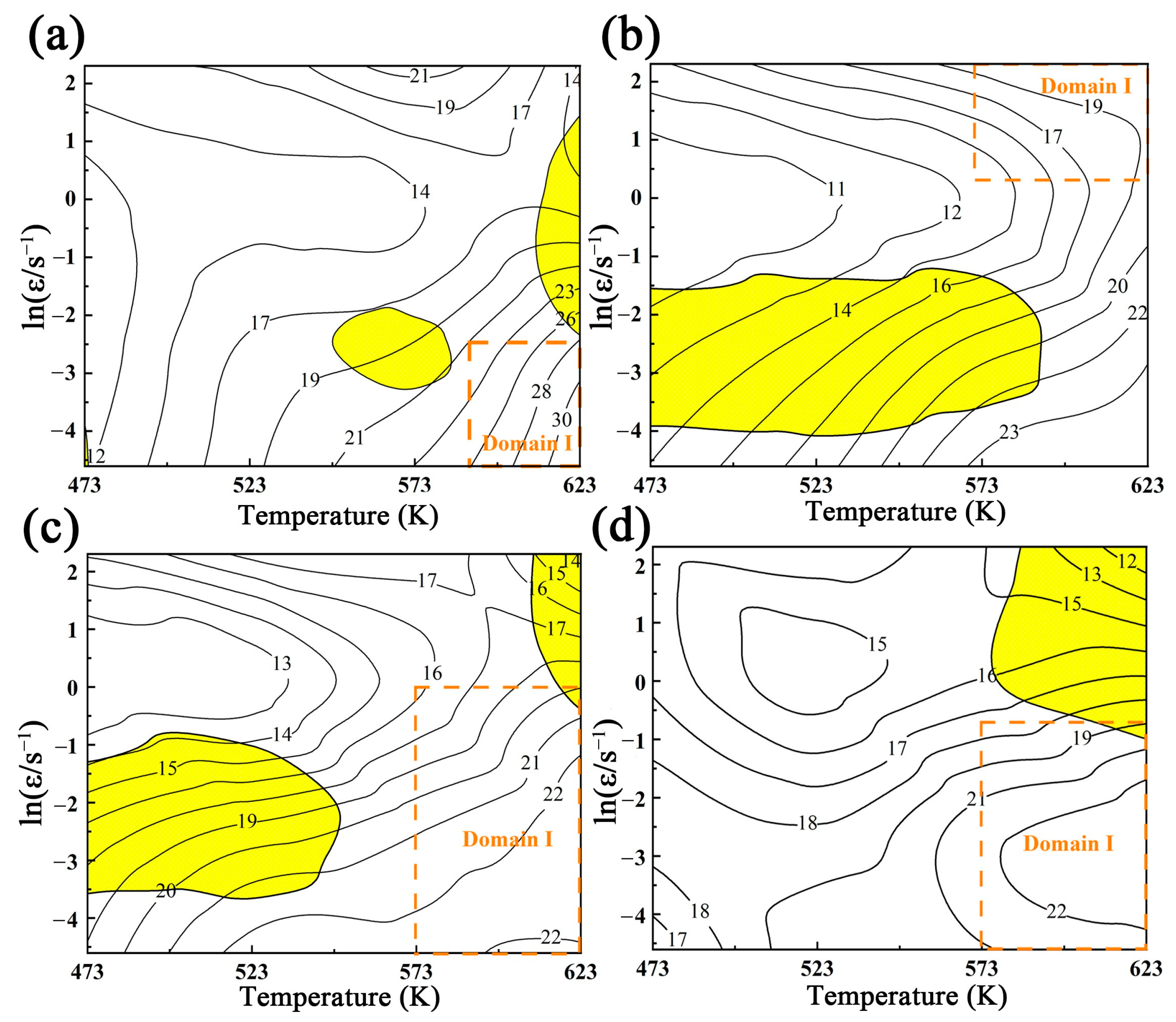

3.4. Construction of the Hot Processing Map for Mg Containing Bi

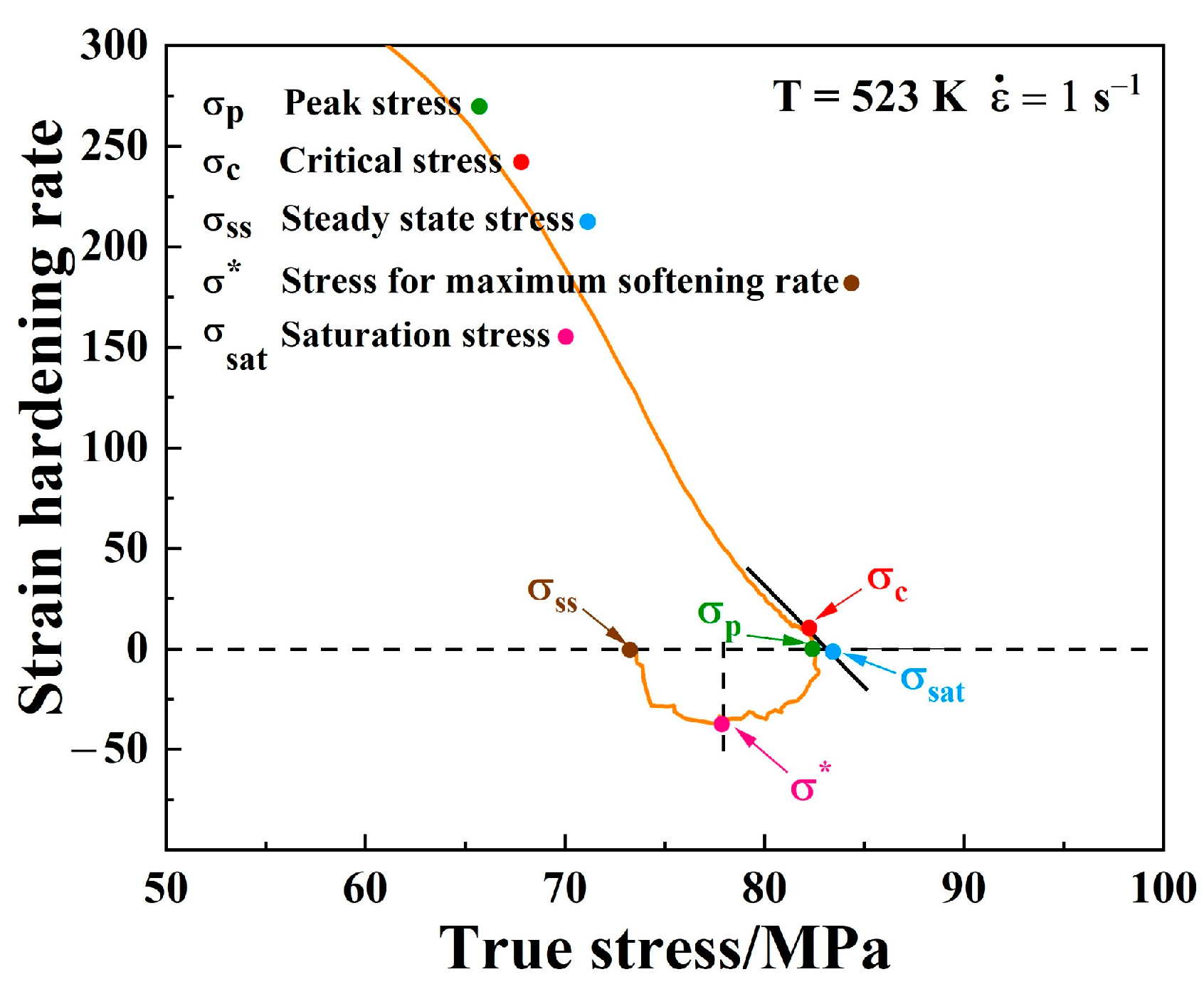

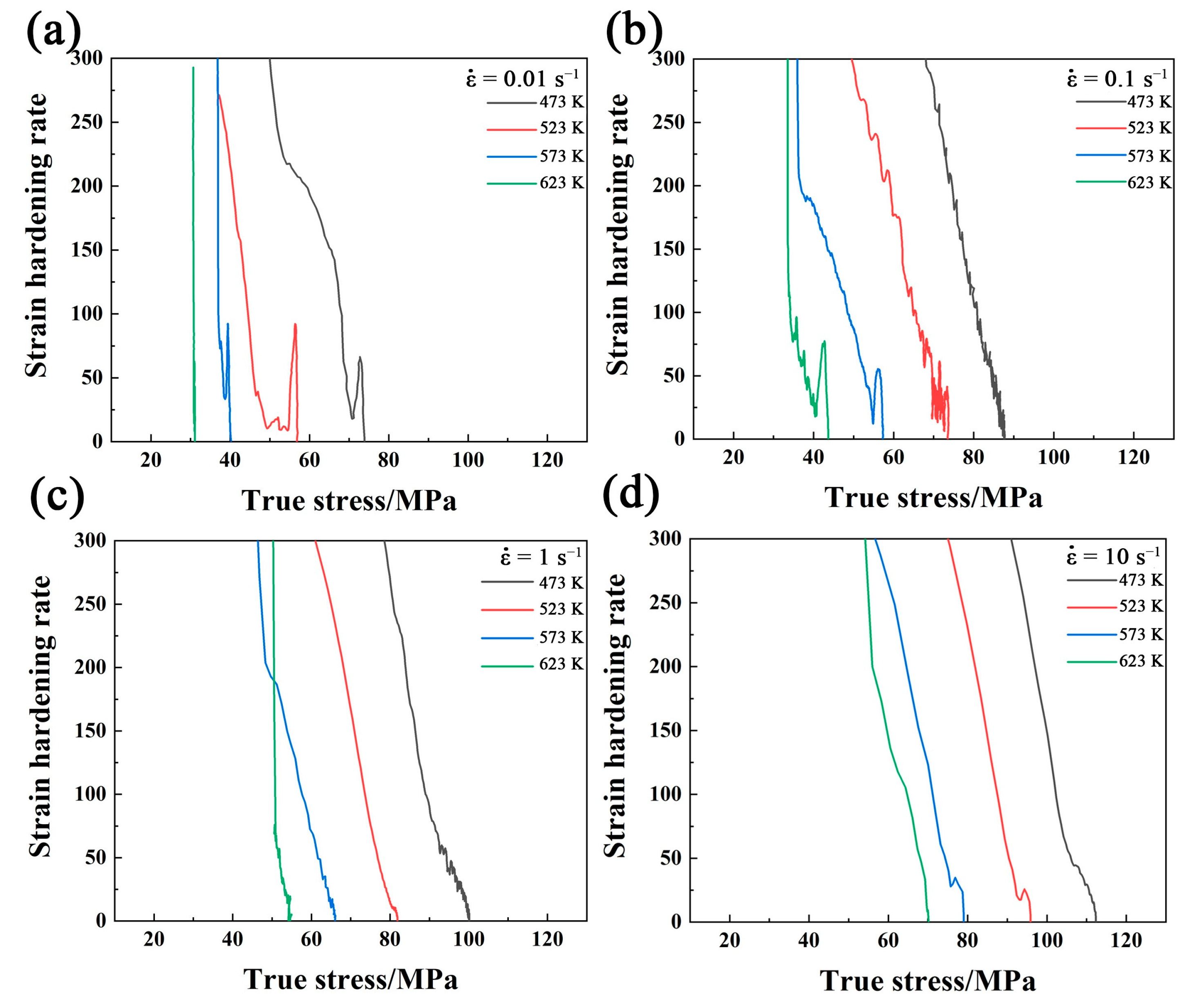

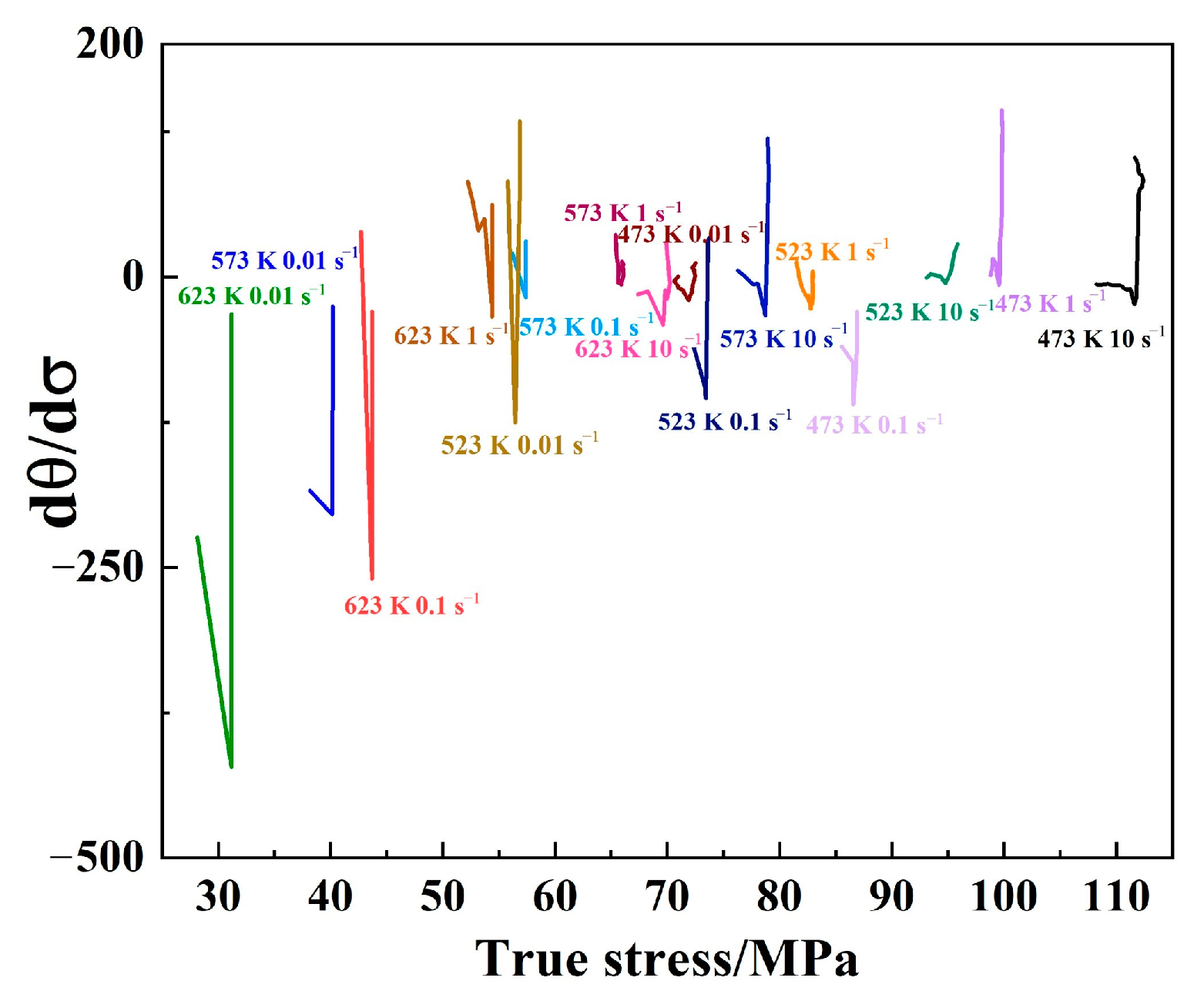

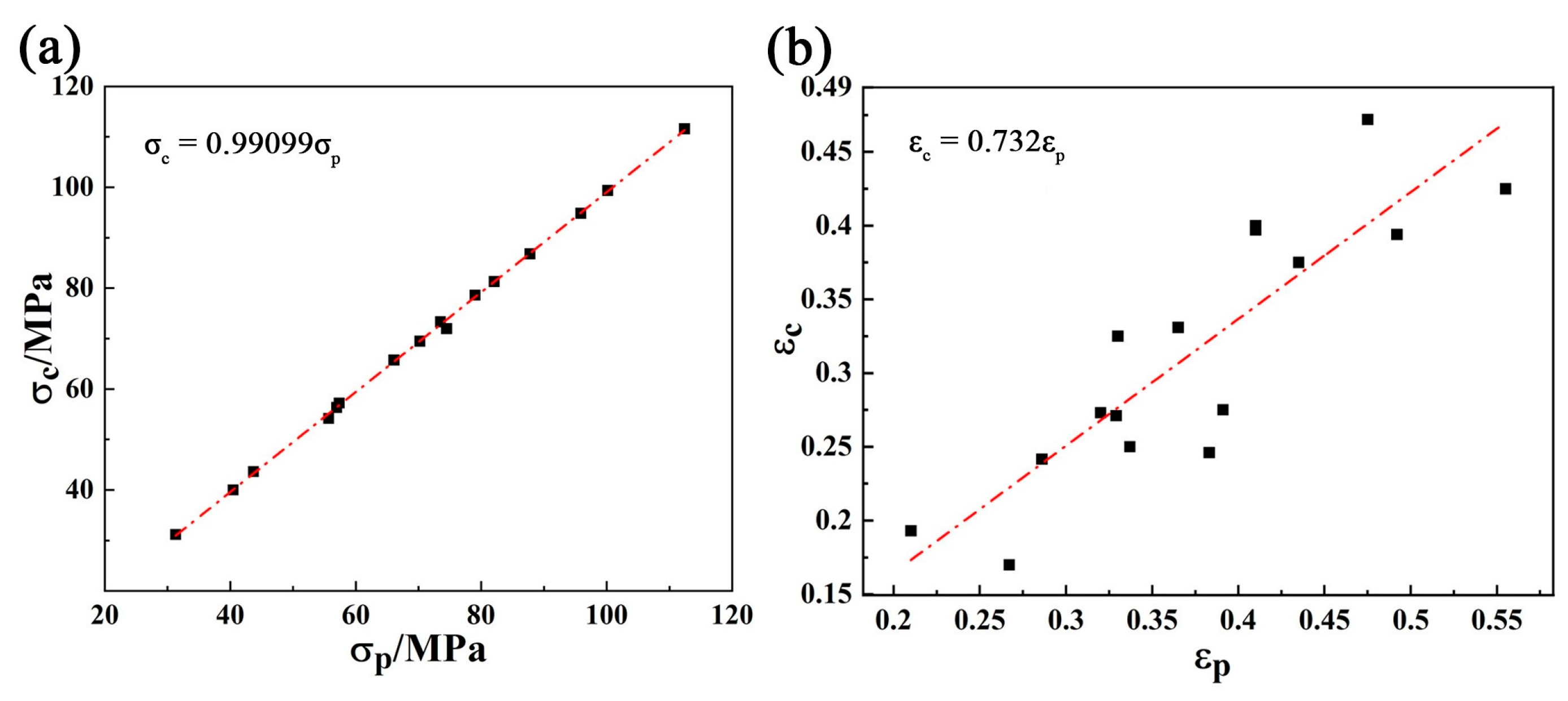

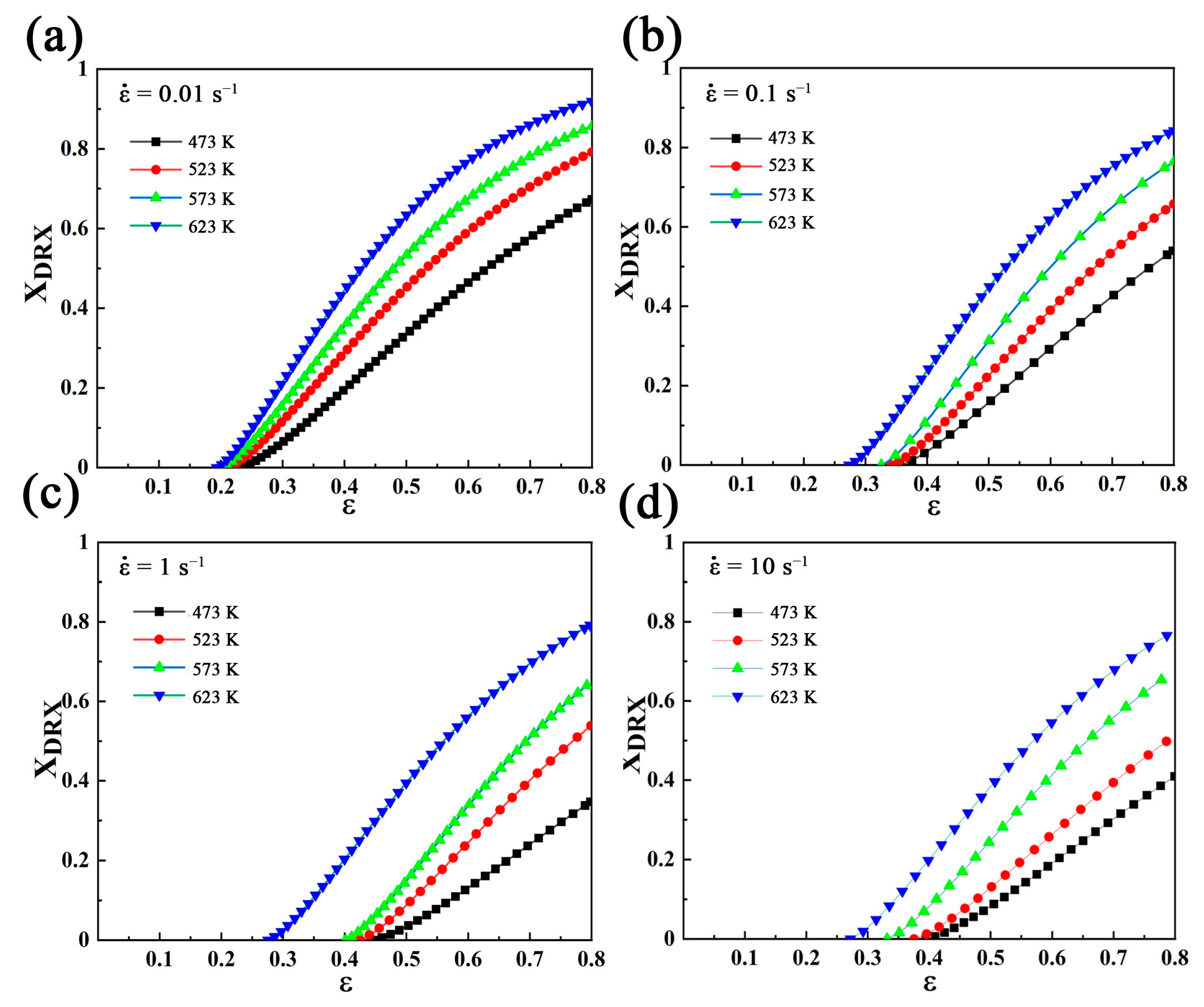

3.5. DRX Kinetics in Case of Mg-3Bi Alloy

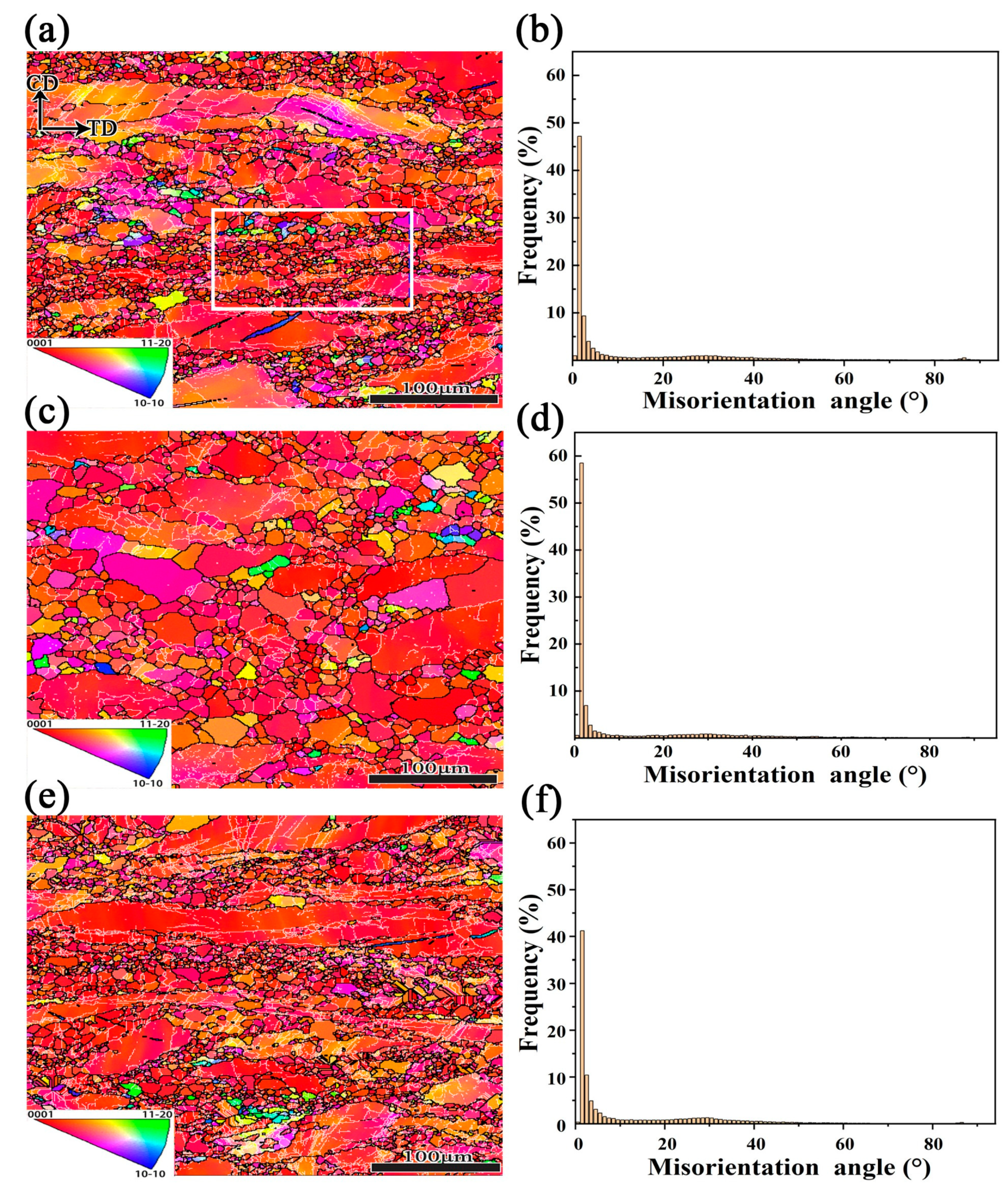

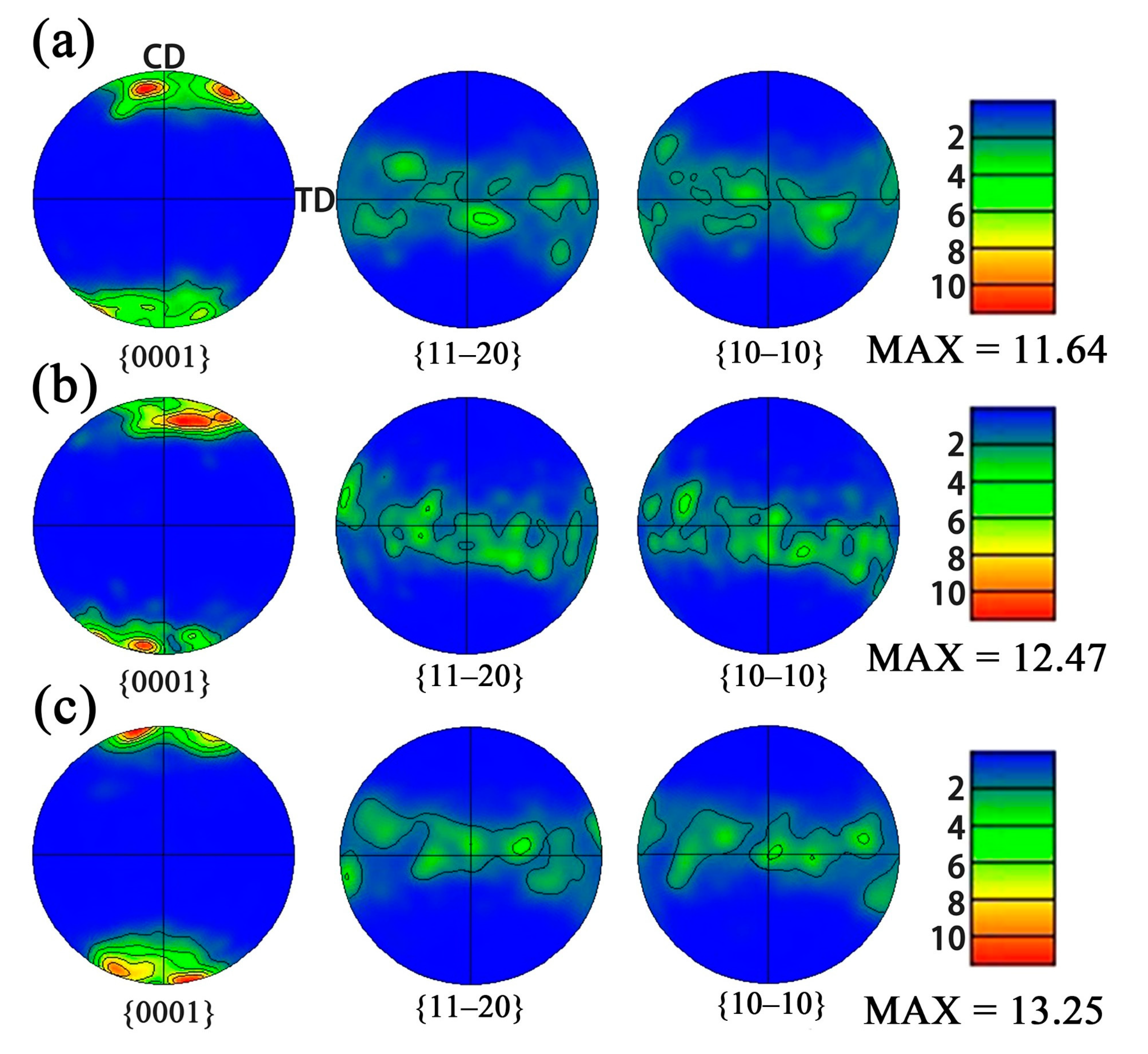

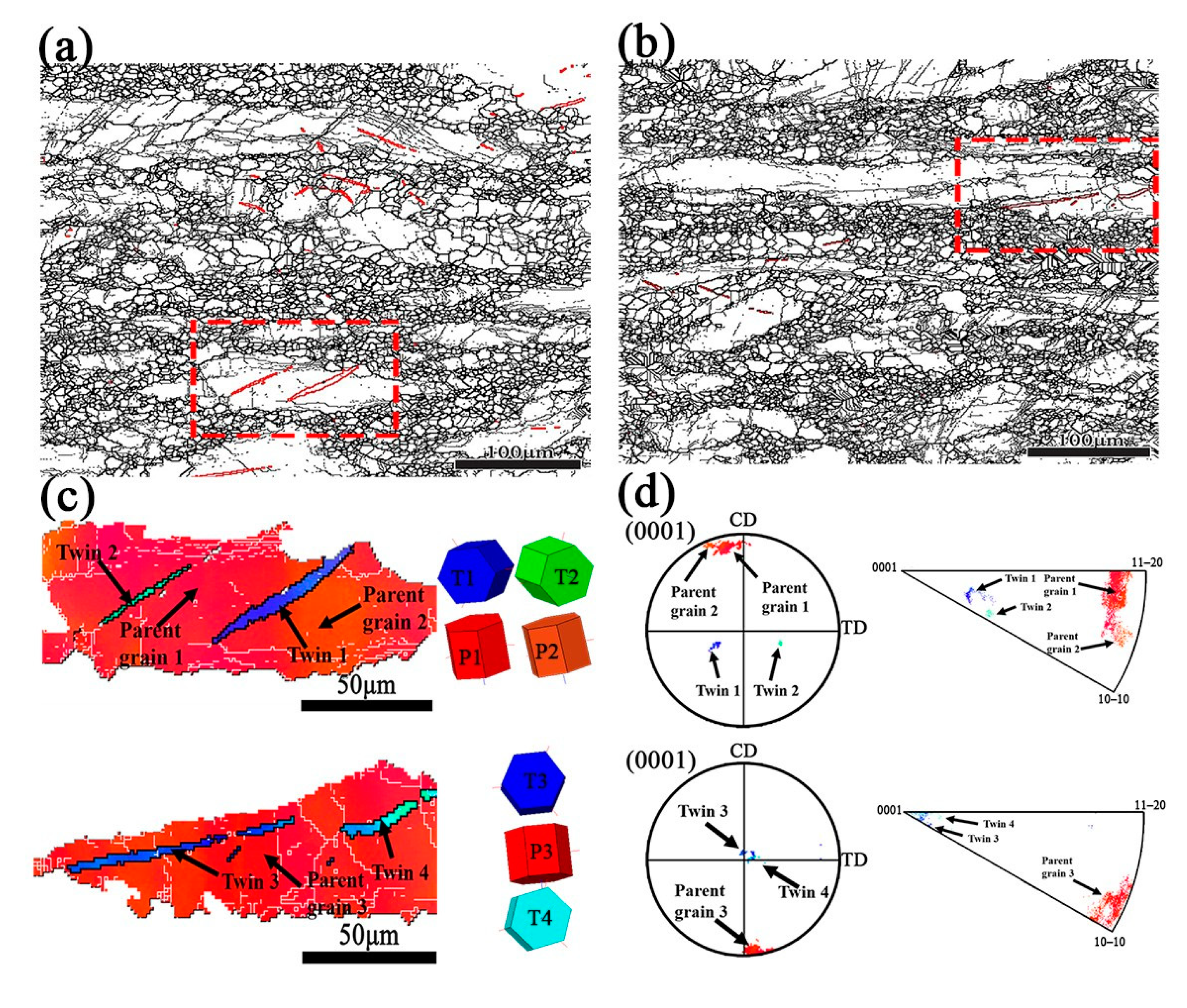

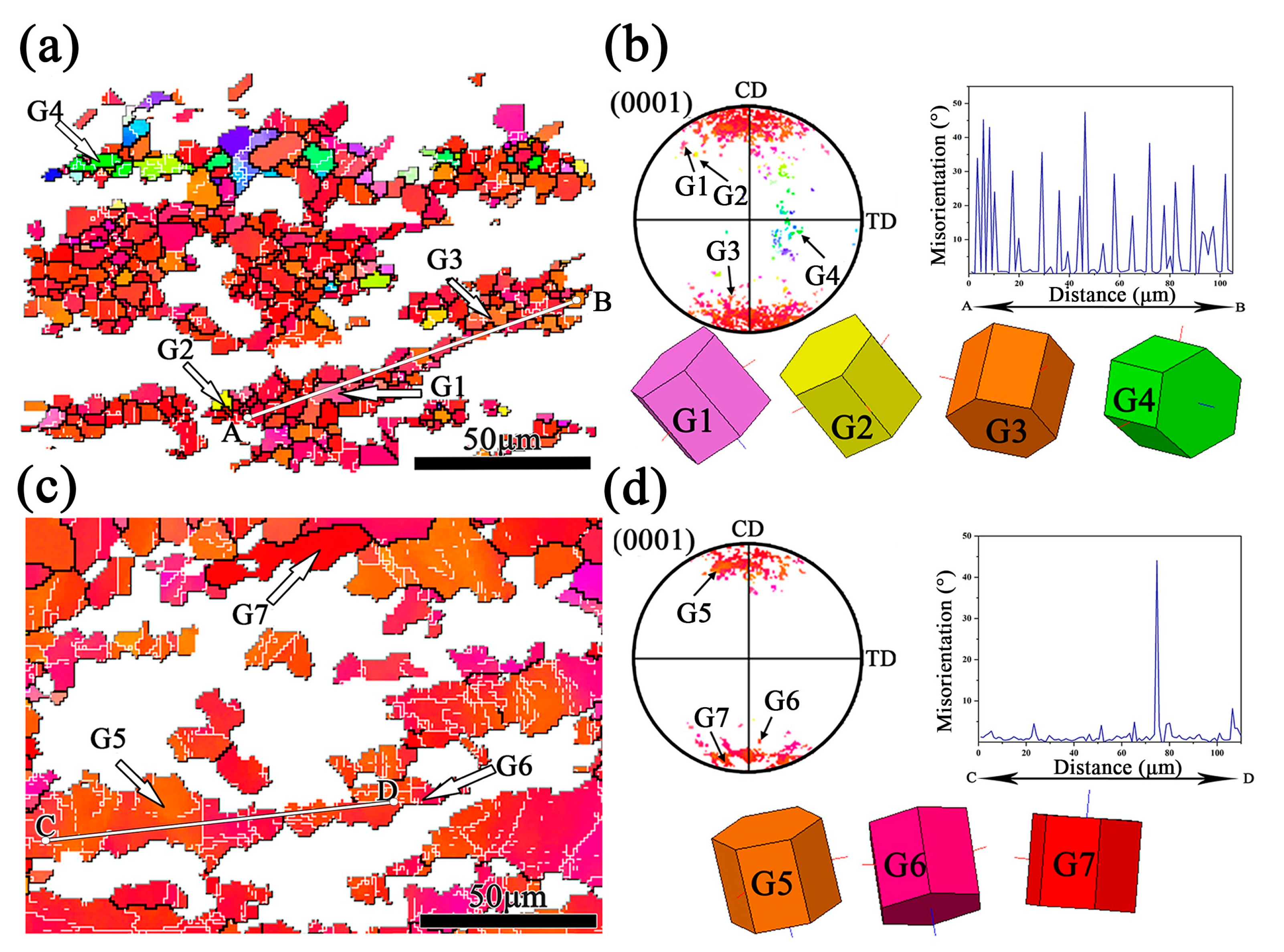

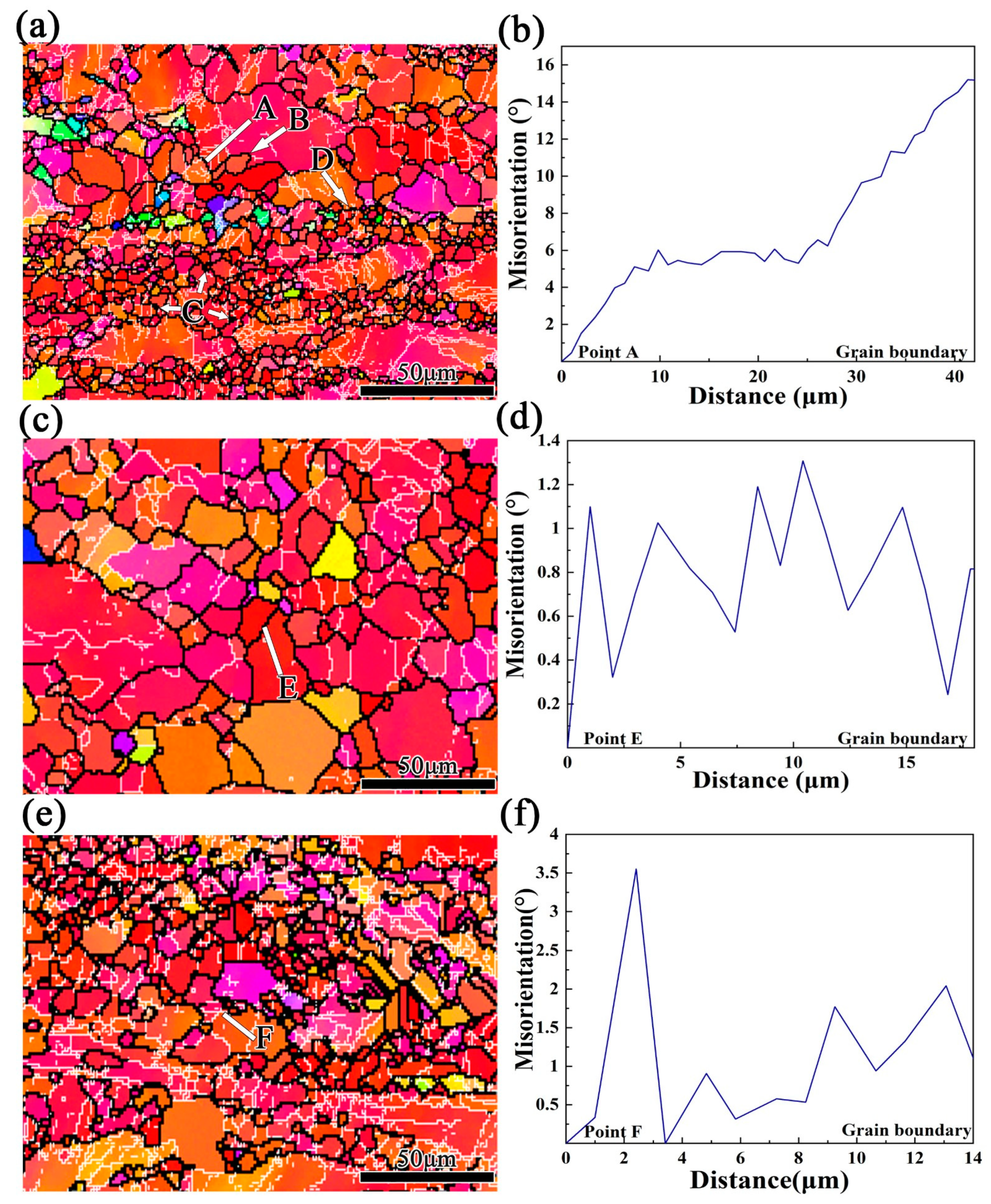

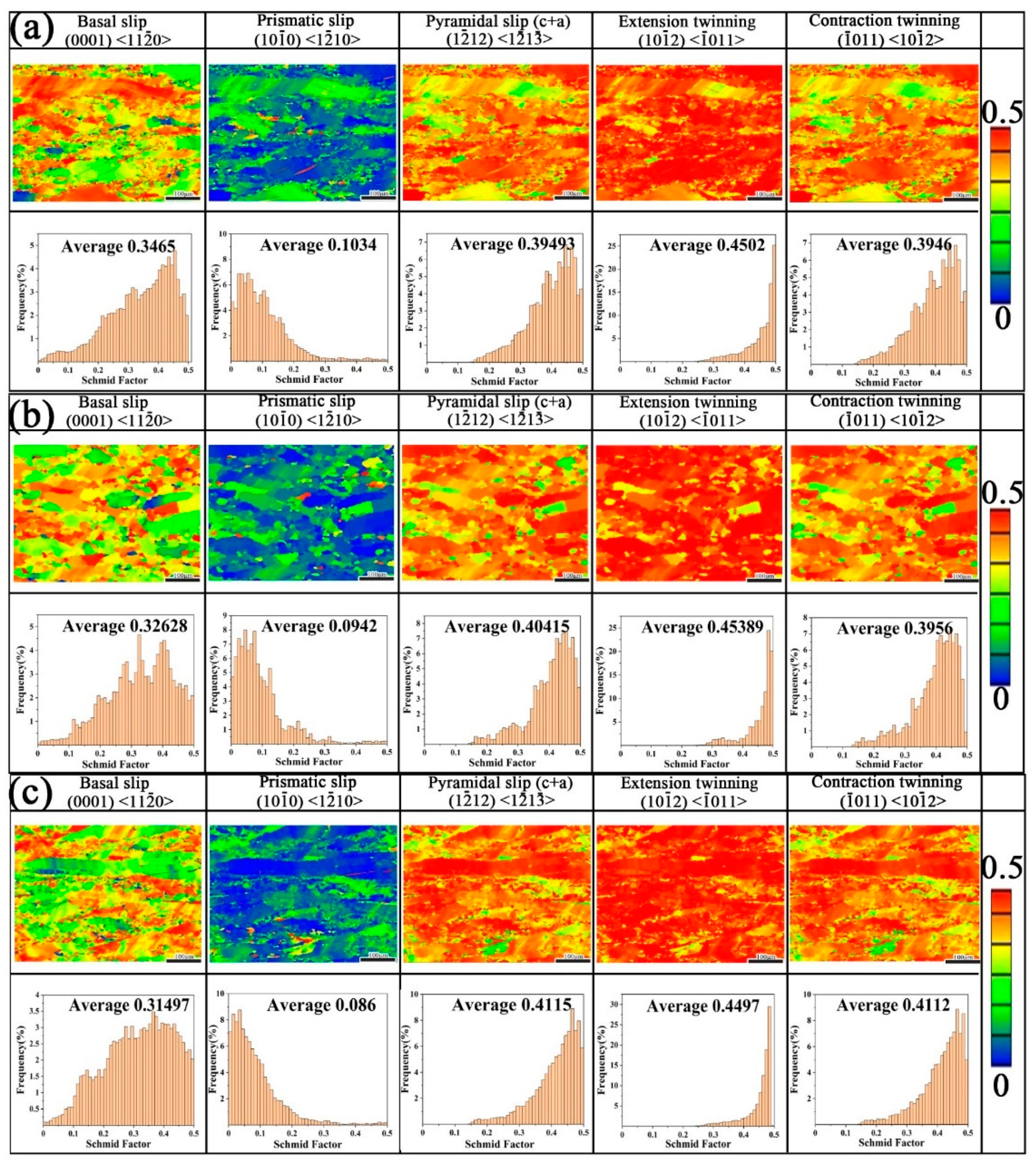

3.6. Microstructure Evolution and Interpretation of the DRX Mechanism

4. Conclusions

- The true stress–strain curves of coarse grain Mg alloy showed typical DRX features. The addition of 3 wt.% Bi in pure Mg results in higher flow stress and a faster recrystallization under lower strain.

- The constitutive equation of Mg-3Bi alloy was established, with average Q and n being 130.501 kJ/mol and 8.92. The constitutive equation for the hot deformation of the as-cast Mg-3Bi alloy is: .

- The optimum hot deformation domains were also given, based on the processing maps. The range of the better stability domain was concentrated in 573 K/0.01 s−1–0.1 s−1 and 623 K/0.01 s−1. The DRX, more dependent on deformation temperature, and the kinetics were discussed.

- According to extensive EBSD analysis, CDRX and DDRX mechanisms occurred simultaneously at 573 K/0.01 s−1. The dominant mechanism changed to DDRX when the deformation temperature and strain rate increased in the Mg-3Bi alloy. The PSN effect also partially contributed to DRX of this RE-free Mg alloy.

Author Contributions

Funding

Conflicts of Interest

References

- Kulekci, M.K. Magnesium and its alloys applications in automotive industry. Int. J. Adv. Manuf. Technol. 2007, 39, 851–865. [Google Scholar] [CrossRef]

- Joost, W.J. Reducing Vehicle Weight and Improving U.S. Energy Efficiency Using Integrated Computational Materials Engineering. JOM 2012, 64, 1032–1038. [Google Scholar] [CrossRef]

- Wu, X.L.; Youssef, K.M.; Koch, C.C.; Mathaudhu, S.N.; Kecskés, L.J.; Zhu, Y.T. Deformation twinning in a nanocrystalline hcp Mg alloy. Scr. Mater. 2011, 64, 213–216. [Google Scholar] [CrossRef]

- Askariani, S.A.; Hasan Pishbin, S.M. Hot deformation behavior of Mg-4Li-1Al alloy via hot compression tests. J. Alloys Compd. 2016, 688, 1058–1065. [Google Scholar] [CrossRef]

- Hoseini-Athar, M.M.; Mahmudi, R.; Prasath Babu, R.; Hedström, P. Microstructural evolution and superplastic behavior of a fine-grained Mg–Gd alloy processed by constrained groove pressing. Mater. Sci. Eng. A 2019, 754, 390–399. [Google Scholar] [CrossRef]

- Nie, J.F.; Zhu, Y.M.; Liu, J.Z.; Fang, X.Y. Periodic segregation of solute atoms in fully coherent twin boundaries. Science 2013, 340, 957–960. [Google Scholar] [CrossRef] [PubMed]

- Pan, H.; Ren, Y.; Fu, H.; Zhao, H.; Wang, L.; Meng, X.; Qin, G. Recent developments in rare-earth free wrought magnesium alloys having high strength: A review. J. Alloys Compd. 2016, 663, 321–331. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Ohkubo, T.; Hono, K. Precipitation hardenable Mg–Bi–Zn alloys with prismatic plate precipitates. Scr. Mater. 2009, 61, 72–75. [Google Scholar] [CrossRef]

- Zhou, D.W.; Liu, J.S.; Xu, S.H.; Peng, P. Thermal stability and elastic properties of Mg3Sb2 and Mg3Bi2 phases from first-principles calculations. Phys. B 2010, 405, 2863–2868. [Google Scholar] [CrossRef]

- Go, J.; Lee, J.U.; Yu, H.; Park, S.H. Influence of Bi addition on dynamic recrystallization and precipitation behaviors during hot extrusion of pure Mg. J. Mater. Sci. Technol. 2020, 44, 62–75. [Google Scholar] [CrossRef]

- Go, J.; Jin, S.-C.; Kim, H.; Yu, H.; Park, S.H. Novel Mg–Bi–Al alloy with extraordinary extrudability and high strength. J. Alloys Compd. 2020, 843, 156026. [Google Scholar] [CrossRef]

- Meng, S.J.; Yu, H.; Fan, S.D.; Kim, Y.M.; Park, S.H.; Zhao, W.M.; You, B.S.; Shin, K.S. A high-ductility extruded Mg-Bi-Ca alloy. Mater. Lett. 2020, 261, 127066. [Google Scholar] [CrossRef]

- He, C.; Zhang, Y.; Liu, C.Q.; Yue, Y.; Chen, H.W.; Nie, J.F. Unexpected partial dislocations within stacking faults in a cold deformed Mg−Bi alloy. Acta Mater. 2020, 188, 328–343. [Google Scholar] [CrossRef]

- He, C.; Li, Z.; Chen, H.; Wilson, N.; Nie, J.-F. Unusual solute segregation phenomenon in coherent twin boundaries. Nat. Commun. 2021, 12, 722. [Google Scholar] [CrossRef]

- Ion, S.E.; Humphreys, F.J.; White, S.H. Dynamic recrystallisation and the development of microstructure during the high temperature deformation of magnesium. Acta Metall. 1982, 30, 1909–1919. [Google Scholar] [CrossRef]

- Hoseini-Athar, M.M.; Mahmudi, R. Effect of Zn content on hot deformation behavior of extruded Mg–Gd–Zn alloys. Mater. Sci. Eng. A 2019, 759, 745–753. [Google Scholar] [CrossRef]

- Meng, S.; Yu, H.; Li, L.; Qin, J.; Woo, S.K.; Go, Y.; Kim, Y.M.; Park, S.H.; Zhao, W.; Yin, F.; et al. Effects of Ca addition on the microstructures and mechanical properties of as-extruded Mg–Bi alloys. J. Alloys Compd. 2020, 834, 155216. [Google Scholar] [CrossRef]

- Ali, Y.; Qiu, D.; Jiang, B.; Pan, F.; Zhang, M.-X. Current research progress in grain refinement of cast magnesium alloys: A review article. J. Alloys Compd. 2015, 619, 639–651. [Google Scholar] [CrossRef]

- Yu, H.; Fan, S.; Meng, S.; Choi, J.O.; Li, Z.; Go, Y.; Kim, Y.M.; Zhao, W.; You, B.S.; Shin, K.S. Microstructural evolution and mechanical properties of binary Mg–xBi (x = 2, 5, and 8 wt%) alloys. J. Magnes. Alloys. 2020, 8, 959–967. [Google Scholar] [CrossRef]

- Yang, Y.; Peng, X.; Ren, F.; Wen, H.; Su, J.; Xie, W. Constitutive Modeling and Hot Deformation Behavior of Duplex Structured Mg–Li–Al–Sr Alloy. J. Mater. Sci. Technol. 2016, 32, 1289–1296. [Google Scholar] [CrossRef]

- Xia, X.; Chen, Q.; Huang, S.; Lin, J.; Hu, C.; Zhao, Z. Hot deformation behavior of extruded Mg–Zn–Y–Zr alloy. J. Alloys Compd. 2015, 644, 308–316. [Google Scholar] [CrossRef]

- Liu, S.; Pan, Q.; Li, M.; Wang, X.; He, X.; Li, X.; Peng, Z.; Lai, J. Microstructure evolution and physical-based diffusion constitutive analysis of Al-Mg-Si alloy during hot deformation. Mater. Des. 2019, 184, 108181. [Google Scholar] [CrossRef]

- Cheng, W.; Bai, Y.; Ma, S.; Wang, L.; Wang, H.; Yu, H. Hot deformation behavior and workability characteristic of a fine-grained Mg‒8Sn‒2Zn‒2Al alloy with processing map. J. Mater. Sci. Technol. 2019, 35, 1198–1209. [Google Scholar] [CrossRef]

- Zheng, T.; Li, D.; Zeng, X.; Ding, W. Hot compressive deformation behaviors of Mg–10Gd–3Y–0.5Zr alloy. Prog. Nat. Sci. Mater. Int. 2016, 26, 78–84. [Google Scholar] [CrossRef]

- Sellars, C.M.; Mctegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Cai, J.; Li, F.; Liu, T.; Chen, B.; He, M. Constitutive equations for elevated temperature flow stress of Ti–6Al–4V alloy considering the effect of strain. Mater. Des. 2011, 32, 1144–1151. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.-M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- McQueen, H.J.; Ryan, N.D. Constitutive analysis in hot working. Mater. Sci. Eng. A 2002, 322, 43–63. [Google Scholar] [CrossRef]

- Zhou, Z.; Fan, Q.; Xia, Z.; Hao, A.; Yang, W.; Ji, W.; Cao, H. Constitutive Relationship and Hot Processing Maps of Mg-Gd-Y-Nb-Zr Alloy. J. Mater. Sci. Technol. 2017, 33, 637–644. [Google Scholar] [CrossRef]

- Ansari, N.; Tran, B.; Poole, W.J.; Singh, S.S.; Krishnaswamy, H.; Jain, J. High temperature deformation behavior of Mg-5wt.%Y binary alloy: Constitutive analysis and processing maps. Mater. Sci. Eng. A 2020, 777, 139051. [Google Scholar] [CrossRef]

- Karami, M.; Mahmudi, R. Hot shear deformation constitutive analysis of an extruded Mg–6Li–1Zn alloy. Mater. Lett. 2012, 81, 235–238. [Google Scholar] [CrossRef]

- Svsn, M.; Bn, R. On the development of instability criteria during hotworking with reference to IN 718. Mater. Sci. Eng. A 1998, 254, 76–82. [Google Scholar] [CrossRef]

- Farabi, E.; Zarei-Hanzaki, A.; Abedi, H.R. Processing Map Development through Elaborating Phenomenological and Physical Constitutive Based Models. Adv. Eng. Mater. 2016, 18, 572–581. [Google Scholar] [CrossRef]

- Niu, Y.; Hou, J.; Ning, F.; Chen, X.; Jia, Y.; Le, Q. Hot deformation behavior and processing map of Mg-2Zn-1Al-0.2RE alloy. J. Rare Earths 2020, 38, 665–675. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K. Processing maps: A status report. J. Mater. Eng. Perform. 2003, 12, 638–645. [Google Scholar] [CrossRef]

- Tahreen, N.; Zhang, D.F.; Pan, F.S.; Jiang, X.Q.; Li, D.Y.; Chen, D.L. Hot deformation and processing map of an as-extruded Mg–Zn–Mn–Y alloy containing I and W phases. Mater. Des. 2015, 87, 245–255. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Phaniraj, C.; Bhaduri, A.K. Flow behavior and microstructural evolution during hot deformation of AISI Type 316 L(N) austenitic stainless steel. Mater. Sci. Eng. A 2011, 528, 8565–8572. [Google Scholar] [CrossRef]

- Lv, B.-J.; Peng, J.; Wang, Y.-J.; An, X.-Q.; Zhong, L.-P.; Tang, A.-T.; Pan, F.-S. Dynamic recrystallization behavior and hot workability of Mg–2.0Zn–0.3Zr–0.9Y alloy by using hot compression test. Mater. Des. 2014, 53, 357–365. [Google Scholar] [CrossRef]

- Zhang, B.P.; Geng, L.; Huang, L.J.; Zhang, X.X.; Dong, C.C. Enhanced mechanical properties in fine-grained Mg–1.0Zn–0.5Ca alloys prepared by extrusion at different temperatures. Scr. Mater. 2010, 63, 1024–1027. [Google Scholar] [CrossRef]

- Cai, Z.; Chen, F.; Ma, F.; Guo, J. Dynamic recrystallization behavior and hot workability of AZ41M magnesium alloy during hot deformation. J. Alloys Compd. 2016, 670, 55–63. [Google Scholar] [CrossRef]

- Sadananda, K.; Marcinkowski, M.J. Mutual annihilation of unlike dislocations by cross slip in ordered and disordered alloys. J. Appl. Phys. 1973, 44, 4445–4454. [Google Scholar] [CrossRef]

- Jain, J.; Poole, W.J.; Sinclair, C.W.; Gharghouri, M.A. Reducing the tension–compression yield asymmetry in a Mg–8Al–0.5Zn alloy via precipitation. Scr. Mater. 2010, 62, 301–304. [Google Scholar] [CrossRef]

- Guan, D.; Rainforth, W.M.; Ma, L.; Wynne, B.; Gao, J. Twin recrystallization mechanisms and exceptional contribution to texture evolution during annealing in a magnesium alloy. Acta Mater. 2017, 126, 132–144. [Google Scholar] [CrossRef]

- Dudamell, N.V.; Ulacia, I.; Gálvez, F.; Yi, S.; Bohlen, J.; Letzig, D.; Hurtado, I.; Pérez-Prado, M.T. Twinning and grain subdivision during dynamic deformation of a Mg AZ31 sheet alloy at room temperature. Acta Mater. 2011, 59, 6949–6962. [Google Scholar] [CrossRef]

- McQueen, H.J. Development of dynamic recrystallization theory. Mater. Sci. Eng. A 2004, 387–389, 203–208. [Google Scholar] [CrossRef]

- Mwembela, A.; Konopleva, E.B. Microstructural development in Mg alloy AZ31 during hot working. Scr. Mater. 1997, 37, 1789–1795. [Google Scholar] [CrossRef]

- Jia, J.; Yang, Y.; Xu, Y.; Xu, B.; Luo, J.; Zhang, K. Microstructure evolution and dynamic recrystallization behavior of a powder metallurgy Ti-22Al-25Nb alloy during hot compression. Mater. Charact. 2017, 123, 198–206. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.; Liu, H.; Jiang, B.; Yu, W.; Kang, S.; Cheng, W.; Park, S.; Chen, D.; Yin, F.; Shin, K.; et al. A Comprehensive Study of Dynamic Recrystallization Behavior of Mg Alloy with 3 wt.% Bi Addition. Metals 2021, 11, 838. https://doi.org/10.3390/met11050838

Yu H, Liu H, Jiang B, Yu W, Kang S, Cheng W, Park S, Chen D, Yin F, Shin K, et al. A Comprehensive Study of Dynamic Recrystallization Behavior of Mg Alloy with 3 wt.% Bi Addition. Metals. 2021; 11(5):838. https://doi.org/10.3390/met11050838

Chicago/Turabian StyleYu, Hui, Hao Liu, Binan Jiang, Wei Yu, Shaoming Kang, Weili Cheng, Sunghyuk Park, Dong Chen, Fuxing Yin, Kwangseon Shin, and et al. 2021. "A Comprehensive Study of Dynamic Recrystallization Behavior of Mg Alloy with 3 wt.% Bi Addition" Metals 11, no. 5: 838. https://doi.org/10.3390/met11050838

APA StyleYu, H., Liu, H., Jiang, B., Yu, W., Kang, S., Cheng, W., Park, S., Chen, D., Yin, F., Shin, K., Mu, J., Cui, X., & Li, J. (2021). A Comprehensive Study of Dynamic Recrystallization Behavior of Mg Alloy with 3 wt.% Bi Addition. Metals, 11(5), 838. https://doi.org/10.3390/met11050838