Casting Microstructure Inspection Using Computer Vision: Dendrite Spacing in Aluminum Alloys

Abstract

1. Introduction

2. Related Work

3. Materials and Models

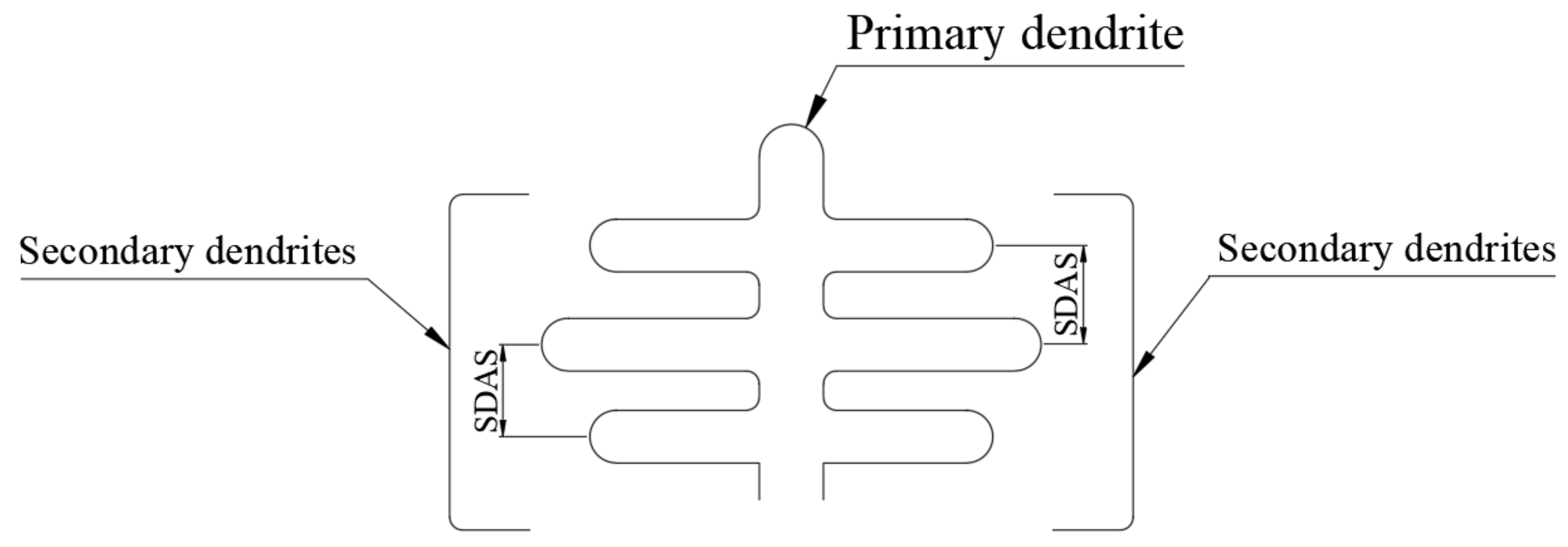

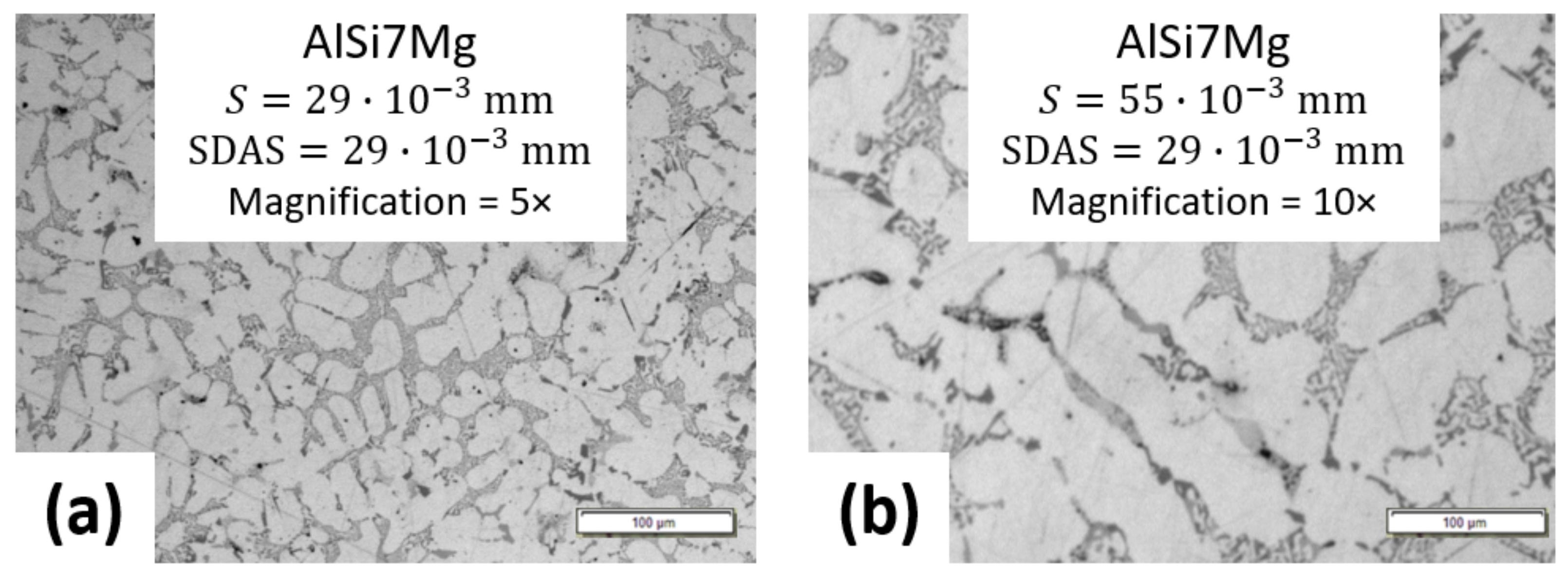

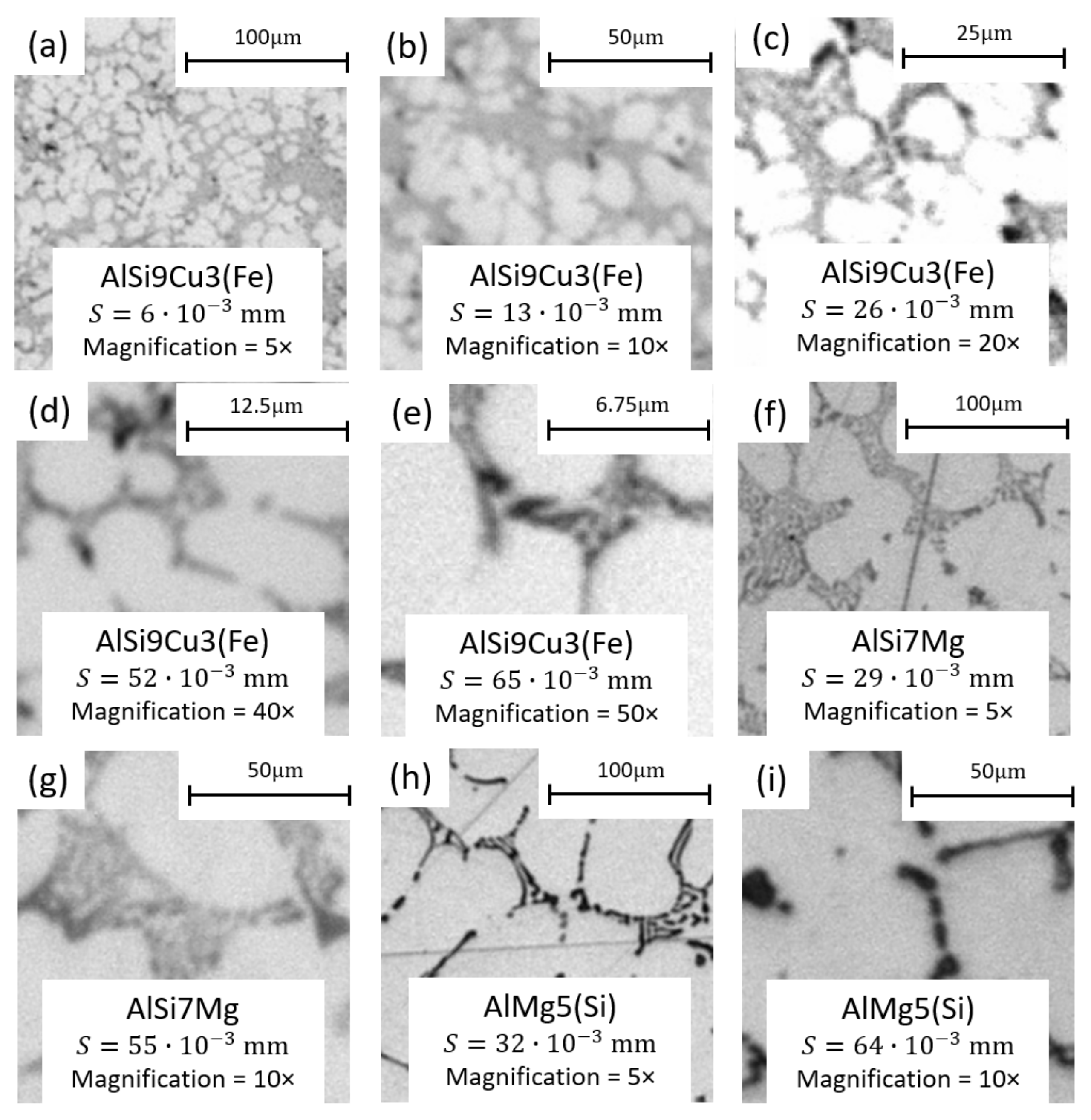

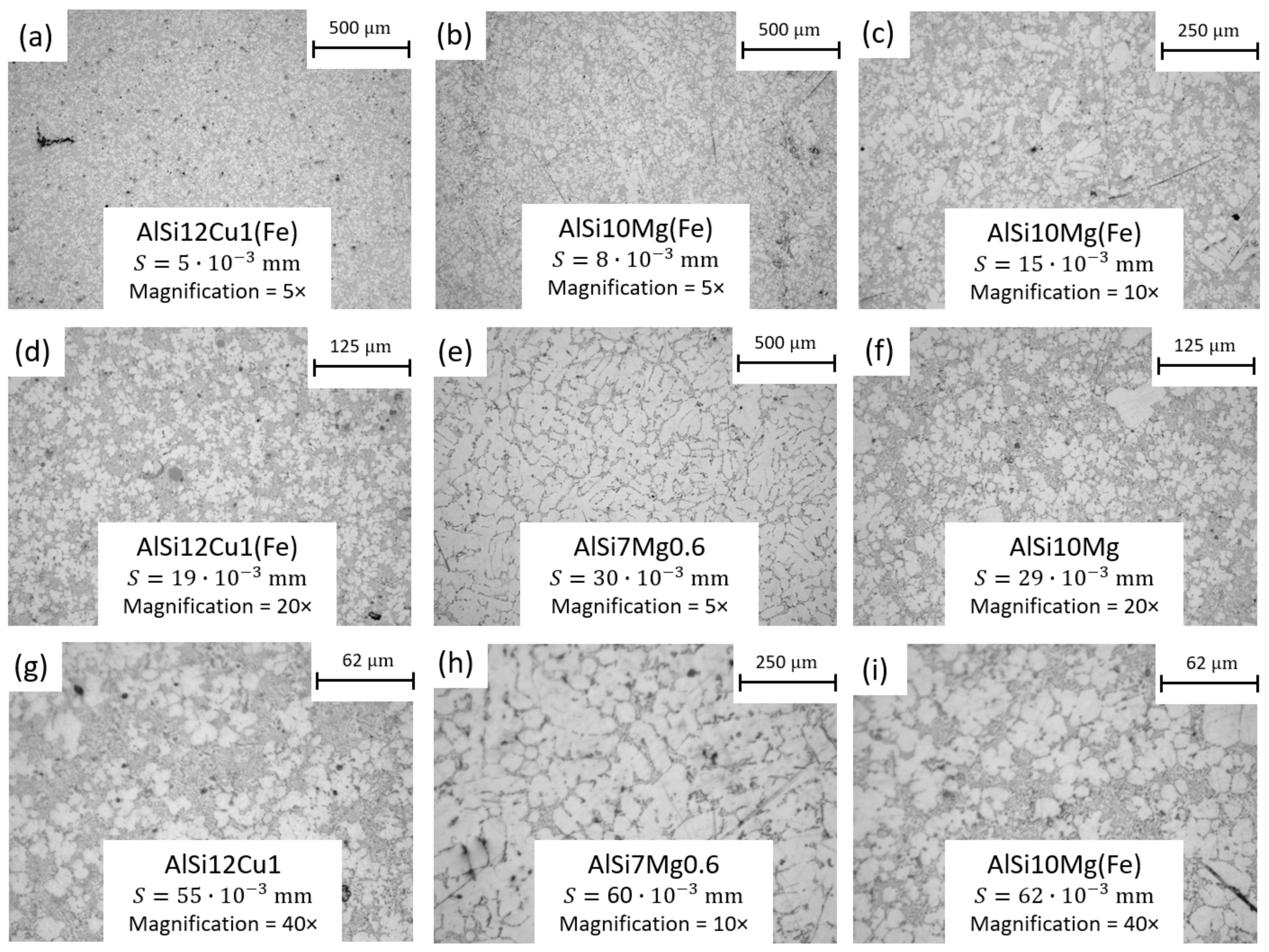

3.1. Aluminum Alloy Samples

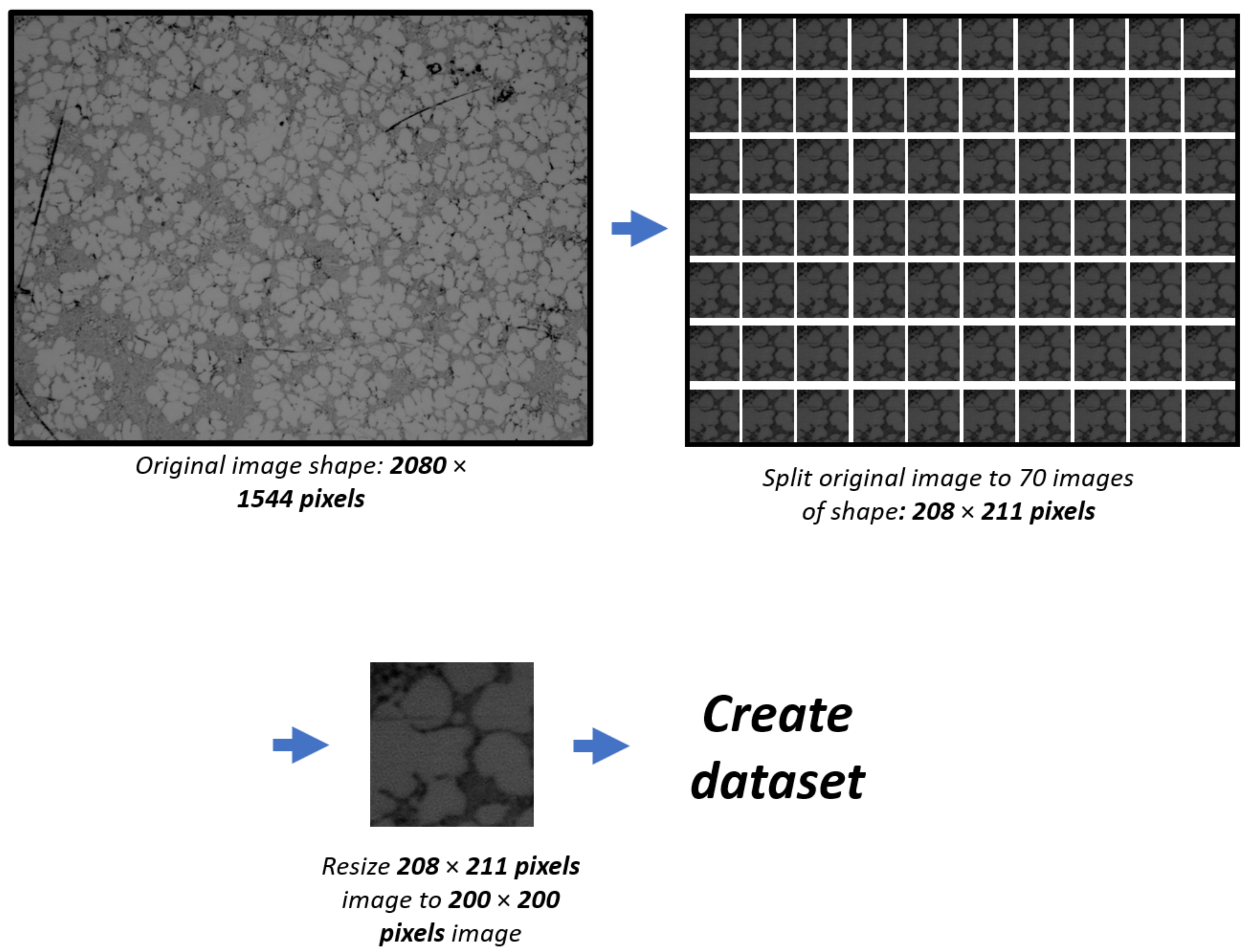

3.2. Dataset and Image Preprocessing

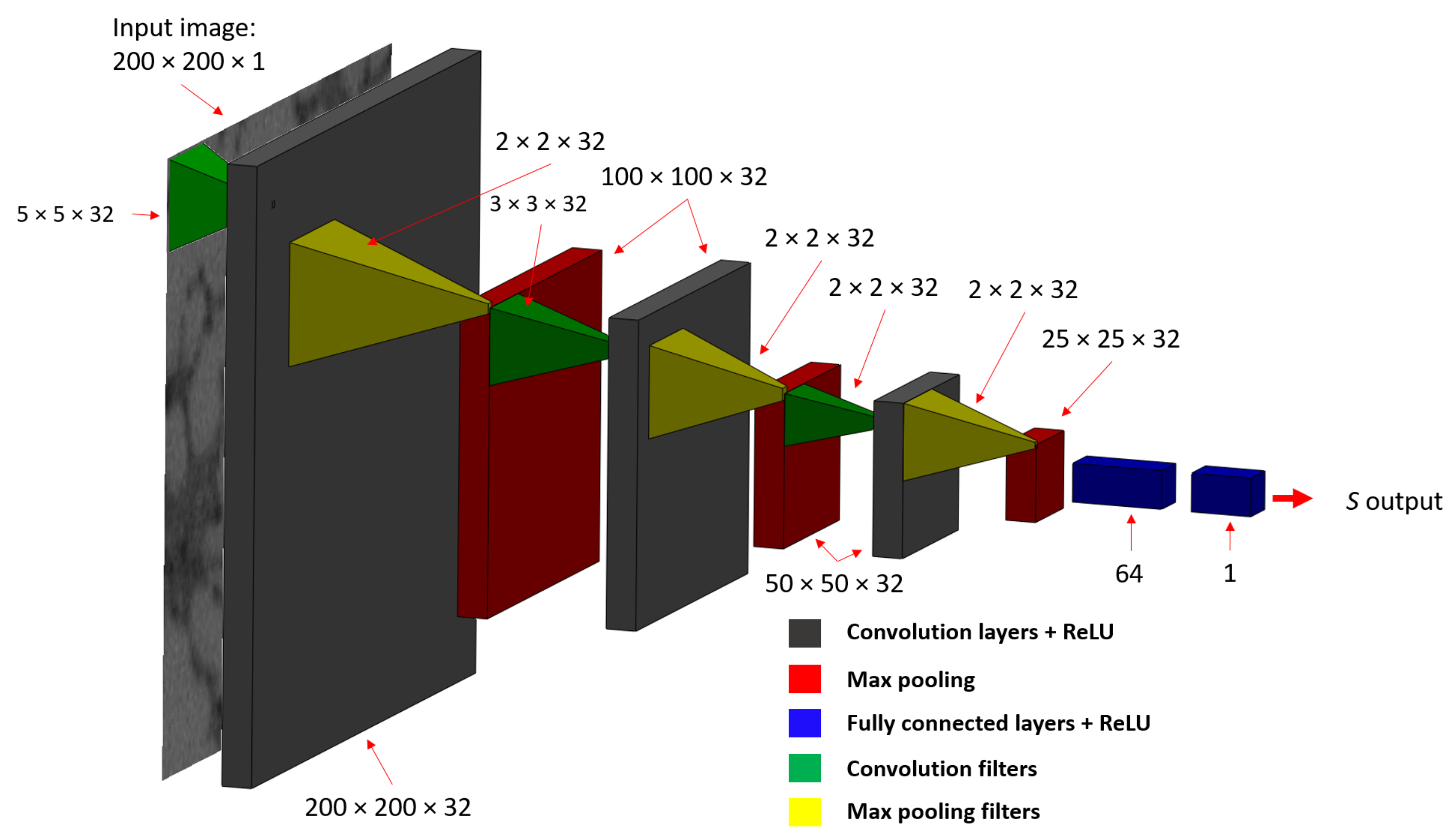

3.3. Overview of the CNN Model

4. Results and Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vandersluis, E.; Ravindran, C. Relationships between solidification parameters in A319 aluminum alloy. J. Mater. Eng. Perform. 2018, 27, 1109–1121. [Google Scholar] [CrossRef]

- Vandersluis, E.; Ravindran, C. Influence of solidification rate on the microstructure, mechanical properties, and thermal conductivity of cast A319 Al alloy. J. Mater. Sci. 2019, 54, 4325–4339. [Google Scholar] [CrossRef]

- Djurdjevič, M.; Grzinčič, M. The effect of major alloying elements on the size of the secondary dendrite arm spacing in the as-cast Al-Si-Cu alloys. Arch. Foundry Eng. 2012, 12, 19–24. [Google Scholar] [CrossRef]

- Brusethaug, S.; Langsrud, Y. Aluminum properties, a model for calculating mechanical properties in AlSiMgFe-foundry alloys. Metall. Sci. Tecnol. 2000, 18, 3–7. [Google Scholar]

- Shabestari, S.; Shahri, F. Influence of modification, solidification conditions and heat treatment on the microstructure and mechanical properties of A356 aluminum alloy. J. Mater. Sci. 2004, 39, 2023–2032. [Google Scholar] [CrossRef]

- Kabir, M.S.; Ashrafi, A.; Minhaj, T.I.; Islam, M.M. Effect of foundry variables on the casting quality of as-cast LM25 aluminium alloy. Int. J. Eng. Adv. Technol. 2014, 3, 115–120. [Google Scholar]

- Seifeddine, S.; Wessen, M.; Svensson, I. Use of simulation to predict microstructure and mechanical properties in an as-cast aluminium cylinder head comparison-with experiments. Metall. Sci. Tecnol. 2006, 24, 7. [Google Scholar]

- Morri, A. Empirical models of mechanical behaviour of Al-Si-Mg cast alloys for high performance engine applications. Metall. Sci. Technol. 2010, 28, 25–32. [Google Scholar]

- Grosselle, F.; Timelli, G.; Bonollo, F.; Della Corte, E. Correlation between microstructure and mechanical properties of Al-Si cast alloys. La Metallurgia Italiana 2009, 27, 25–32. [Google Scholar]

- Qi, M.; Li, J.; Kang, Y. Correlation between segregation behavior and wall thickness in a rheological high pressure die-casting AC46000 aluminum alloy. J. Mater. Res. Technol. 2019, 8, 3565–3579. [Google Scholar] [CrossRef]

- Singh, S.; Bhadeshia, H.; MacKay, D.; Carey, H.; Martin, I. Neural network analysis of steel plate processing. Ironmak. Steelmak. 1998, 25, 355–365. [Google Scholar]

- Hancheng, Q.; Bocai, X.; Shangzheng, L.; Fagen, W. Fuzzy neural network modeling of material properties. J. Mater. Process. Technol. 2002, 122, 196–200. [Google Scholar] [CrossRef]

- Agrawal, A.; Deshpande, P.D.; Cecen, A.; Basavarsu, G.P.; Choudhary, A.N.; Kalidindi, S.R. Exploration of data science techniques to predict fatigue strength of steel from composition and processing parameters. Integr. Mater. Manuf. Innov. 2014, 3, 8. [Google Scholar] [CrossRef]

- Liu, R.; Kumar, A.; Chen, Z.; Agrawal, A.; Sundararaghavan, V.; Choudhary, A. A predictive machine learning approach for microstructure optimization and materials design. Sci. Rep. 2015, 5, 11551. [Google Scholar] [CrossRef]

- Yang, X.W.; Zhu, J.C.; Nong, Z.S.; Dong, H.; Lai, Z.H.; Ying, L.; Liu, F.W. Prediction of mechanical properties of A357 alloy using artificial neural network. Trans. Nonferrous Met. Soc. China 2013, 23, 788–795. [Google Scholar] [CrossRef]

- Santos, I.; Nieves, J.; Penya, Y.K.; Bringas, P.G. Machine-learning-based mechanical properties prediction in foundry production. In Proceedings of the 2009 ICCAS-SICE, Fukuoka City, Japan, 18–21 August 2009; pp. 4536–4541. [Google Scholar]

- Liao, H.; Zhao, B.; Suo, X.; Wang, Q. Prediction models for macro shrinkage of aluminum alloys based on machine learning algorithms. Mater. Today Commun. 2019, 21, 100715. [Google Scholar] [CrossRef]

- Agrawal, A.; Choudhary, A. Deep materials informatics: Applications of deep learning in materials science. MRS Commun. 2019, 9, 779–792. [Google Scholar] [CrossRef]

- Herriott, C.; Spear, A.D. Predicting microstructure-dependent mechanical properties in additively manufactured metals with machine-and deep-learning methods. Comput. Mater. Sci. 2020, 175, 109599. [Google Scholar] [CrossRef]

- Ferguson, M.K.; Ronay, A.; Lee, Y.T.T.; Law, K.H. Detection and segmentation of manufacturing defects with convolutional neural networks and transfer learning. Smart Sustain. Manuf. Syst. 2018, 2, 1–42. [Google Scholar] [CrossRef]

- Hanumantha Rao, D.; Tagore, G.; Ranga Janardhana, G. Evolution of Artificial Neural Network (ANN) model for predicting secondary dendrite arm spacing in aluminium alloy casting. J. Braz. Soc. Mech. Sci. Eng. 2010, 32, 276–281. [Google Scholar] [CrossRef]

- Wei, J.; Chu, X.; Sun, X.Y.; Xu, K.; Deng, H.X.; Chen, J.; Wei, Z.; Lei, M. Machine learning in materials science. InfoMat 2019, 1, 338–358. [Google Scholar] [CrossRef]

- Azimi, S.M.; Britz, D.; Engstler, M.; Fritz, M.; Mücklich, F. Advanced steel microstructural classification by deep learning methods. Sci. Rep. 2018, 8, 2128. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.; Zhao, H.; Burkhart, C.; Brinson, L.C.; Chen, W. A transfer learning approach for microstructure reconstruction and structure-property predictions. Sci. Rep. 2018, 8, 13461. [Google Scholar] [CrossRef]

- Mery, D. Aluminum Casting Inspection Using Deep Learning: A Method Based on Convolutional Neural Networks. J. Nondestruct. Eval. 2020, 39, 12. [Google Scholar] [CrossRef]

- DeCost, B.L.; Lei, B.; Francis, T.; Holm, E.A. High throughput quantitative metallography for complex microstructures using deep learning: A case study in ultrahigh carbon steel. arXiv 2018, arXiv:1805.08693. [Google Scholar] [CrossRef]

- Chowdhury, A.; Kautz, E.; Yener, B.; Lewis, D. Image driven machine learning methods for microstructure recognition. Comput. Mater. Sci. 2016, 123, 176–187. [Google Scholar] [CrossRef]

- Exl, L.; Fischbacher, J.; Kovacs, A.; Oezelt, H.; Gusenbauer, M.; Yokota, K.; Shoji, T.; Hrkac, G.; Schrefl, T. Magnetic microstructure machine learning analysis. J. Phys. Mater. 2018, 2, 014001. [Google Scholar] [CrossRef]

- Yucel, B.; Yucel, S.; Ray, A.; Duprez, L.; Kalidindi, S.R. Mining the Correlations Between Optical Micrographs and Mechanical Properties of Cold-Rolled HSLA Steels Using Machine Learning Approaches. Integr. Mater. Manuf. Innov. 2020, 9, 240–256. [Google Scholar] [CrossRef]

- Pokuri, B.S.S.; Ghosal, S.; Kokate, A.; Sarkar, S.; Ganapathysubramanian, B. Interpretable deep learning for guided microstructure-property explorations in photovoltaics. NPJ Comput. Mater. 2019, 5, 95. [Google Scholar] [CrossRef]

- DeCost, B.L.; Holm, E.A. A computer vision approach for automated analysis and classification of microstructural image data. Comput. Mater. Sci. 2015, 110, 126–133. [Google Scholar] [CrossRef]

- DIN EN 1706: Aluminium und Aluminiumlegierungen-Gussstücke-Chemische Zusammensetzung und mechanische Eigenschaften; Beuth: Berlin, Germany, 1998.

- Vandersluis, E.; Ravindran, C. Comparison of measurement methods for secondary dendrite arm spacing. Metallogr. Microstruct. Anal. 2017, 6, 89–94. [Google Scholar] [CrossRef]

- Nikolic, F.; Štajduhar, I.; Čanađija, M. Aluminum microstructure inspection using deep learning: A convolutional neural network approach toward secondary dendrite arm spacing determination. In 4th Edition of My First Conference; University of Rijeka, Faculty of Engineering: Rijeka, Croatia, 2020. [Google Scholar]

- Alexander Mordvintsev, A.K.R. Image Processing in OpenCV. 2013. Available online: https://opencv-python-tutroals.readthedocs.io/en/latest/py_tutorials/py_imgproc/py_table_of_contents_imgproc/py_table_of_contents_imgproc.html (accessed on 5 September 2020).

| F | Magnification | Pixel/ mm |

|---|---|---|

| 1 | 5× | 1.36 |

| 0.5 | 10× | 2.72 |

| 0.25 | 20× | 5.44 |

| 0.125 | 40× | 10.88 |

| 0.1 | 50× | 13.60 |

| Alloy | Magnification | S | F | S-SDAS/F | Images Count |

|---|---|---|---|---|---|

| AlSi9Cu3(Fe) | 5× | 6 mm | 1 | 0 | 1076 |

| AlSi9Cu3(Fe) | 10× | 13 mm | 0.5 | 1 | 6820 |

| AlSi9Cu3(Fe) | 20× | 26 mm | 0.25 | 2 | 815 |

| AlSi9Cu3(Fe) | 40× | 52 mm | 0.125 | 4 | 1236 |

| AlSi9Cu3(Fe) | 50× | 65 mm | 0.1 | 5 | 1128 |

| AlSi7Mg | 5× | 29 mm | 1 | 0 | 1216 |

| AlSi7Mg | 10× | 55 mm | 0.5 | 3 | 1176 |

| AlMg5(Si) | 5× | 32 mm | 1 | 0 | 1032 |

| AlMg5(Si) | 10× | 64 mm | 0.5 | 0 | 1174 |

| Material | S | Pred. S | Pred. Dev. | Pred. Err. | Magnification |

|---|---|---|---|---|---|

| µm | µm | µm | % | ||

| AlSi9Cu3(Fe) | 6 | 4.8 | 1.2 | 20 | 5× |

| AlSi9Cu3(Fe) | 13 | 13.6 | 0.6 | 4.6 | 10× |

| AlSi9Cu3(Fe) | 27 | 27.7 | 0.7 | 2.6 | 20× |

| AlSi9Cu3(Fe) | 52 | 52.9 | 0.9 | 1.7 | 40× |

| AlSi9Cu3(Fe) | 65 | 64.9 | 0.1 | 0.15 | 50× |

| AlMg5(Si) | 32 | 29.8 | 2.2 | 6.9 | 5× |

| AlMg5(Si) | 64 | 62.6 | 1.4 | 2.2 | 10× |

| AlSi7Mg | 29 | 23.0 | 6.0 | 20.7 | 5× |

| AlSi7Mg | 55 | 55.9 | 0.9 | 1.6 | 10× |

| Average prediction deviation on 10× magnification: 0.76 µm | |||||

| Average prediction error on 10× magnification: 2.15% | |||||

| Material | S | Pred. S | Pred. Dev. | Pred. Err. | Magnification |

|---|---|---|---|---|---|

| µm | µm | µm | % | ||

| AlSi7Mg0.6 | 30 | 28.1 | 1.9 | 6.3 | 5× |

| AlSi7Mg0.6 | 60 | 58.1 | 1.9 | 3.1 | 10× |

| AlSi10Mg(Fe) | 8 | 11.1 | 3.1 | 38.8 | 5× |

| AlSi10Mg(Fe) | 15 | 23.9 | 8.9 | 59.3 | 10× |

| AlSi10Mg(Fe) | 31 | 35.8 | 4.8 | 15.5 | 20× |

| AlSi10Mg(Fe) | 62 | 52.7 | 9.3 | 15.0 | 40× |

| AlSi12Cu1(Fe) | 5 | 13.9 | 8.9 | 178 | 5× |

| AlSi12Cu1(Fe) | 19 | 26.1 | 7.1 | 37.4 | 20× |

| AlSi12Cu1(Fe) | 40 | 41.4 | 1.4 | 3.5 | 40× |

| Average prediction deviation on max. mag.: 4.60 µm | |||||

| Average prediction error on max. mag.: 7.2% | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikolić, F.; Štajduhar, I.; Čanađija, M. Casting Microstructure Inspection Using Computer Vision: Dendrite Spacing in Aluminum Alloys. Metals 2021, 11, 756. https://doi.org/10.3390/met11050756

Nikolić F, Štajduhar I, Čanađija M. Casting Microstructure Inspection Using Computer Vision: Dendrite Spacing in Aluminum Alloys. Metals. 2021; 11(5):756. https://doi.org/10.3390/met11050756

Chicago/Turabian StyleNikolić, Filip, Ivan Štajduhar, and Marko Čanađija. 2021. "Casting Microstructure Inspection Using Computer Vision: Dendrite Spacing in Aluminum Alloys" Metals 11, no. 5: 756. https://doi.org/10.3390/met11050756

APA StyleNikolić, F., Štajduhar, I., & Čanađija, M. (2021). Casting Microstructure Inspection Using Computer Vision: Dendrite Spacing in Aluminum Alloys. Metals, 11(5), 756. https://doi.org/10.3390/met11050756