Ti Interlayer Mediated Uniform NiGe Formation under Low-Temperature Microwave Annealing

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

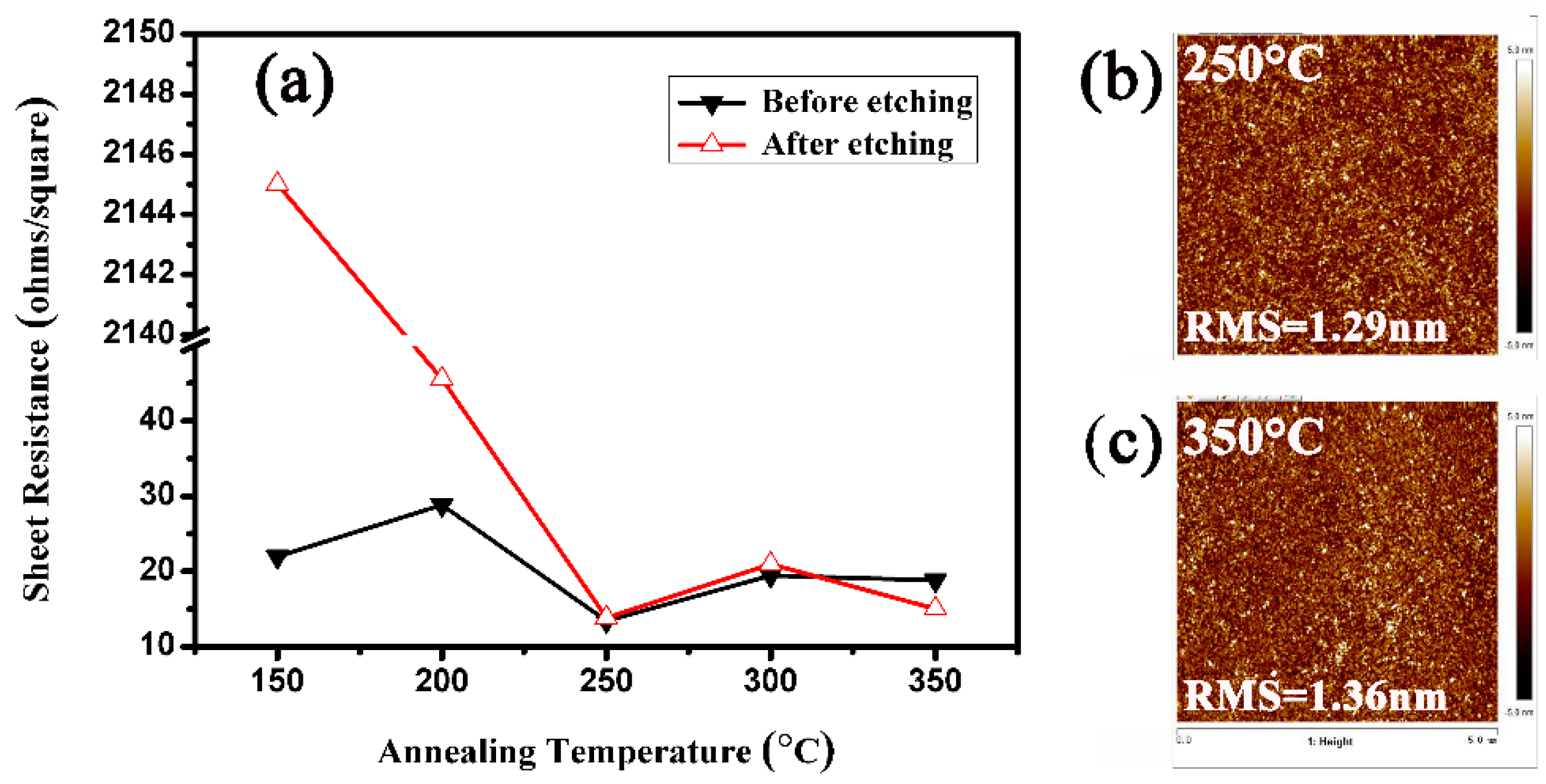

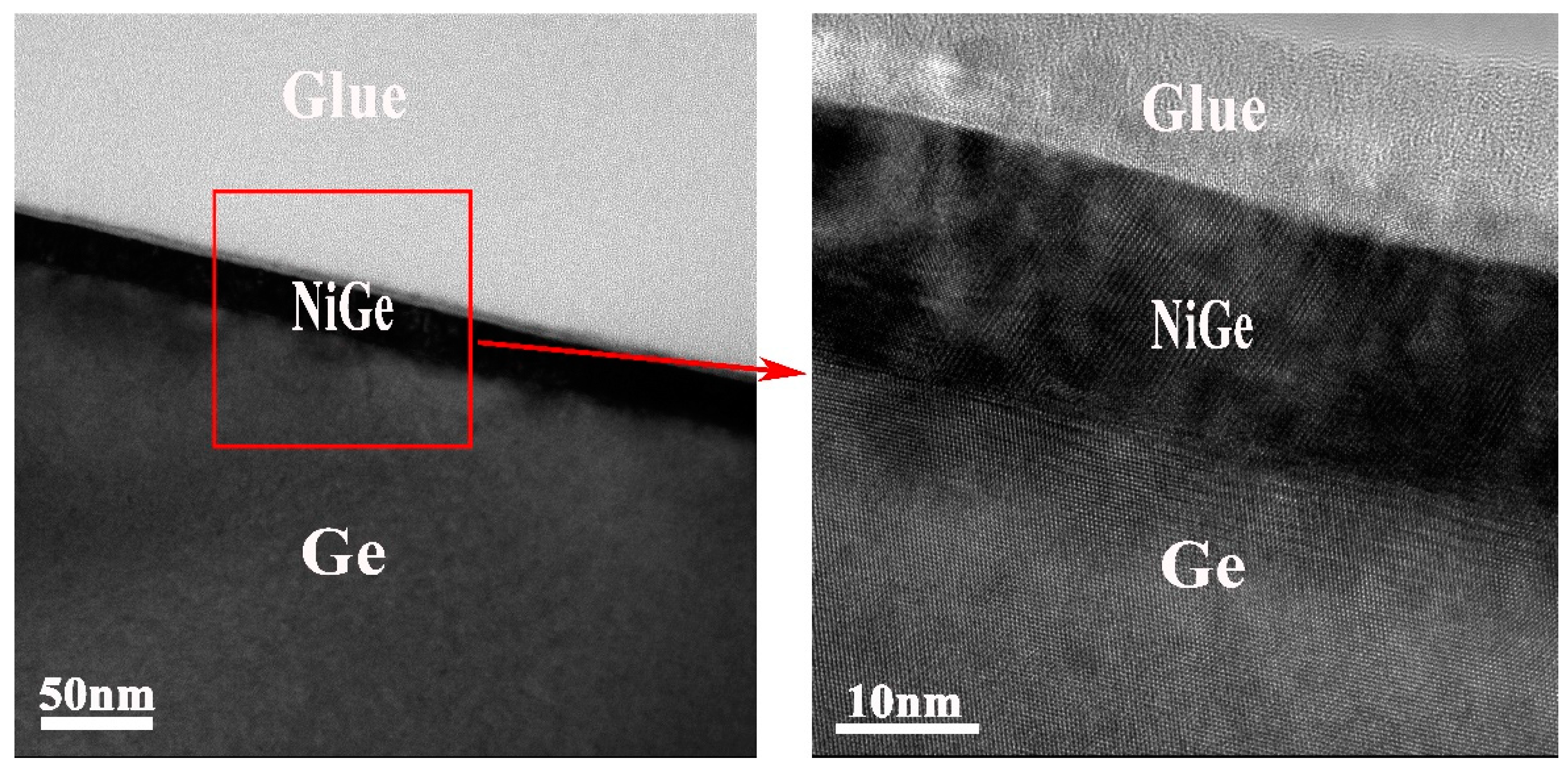

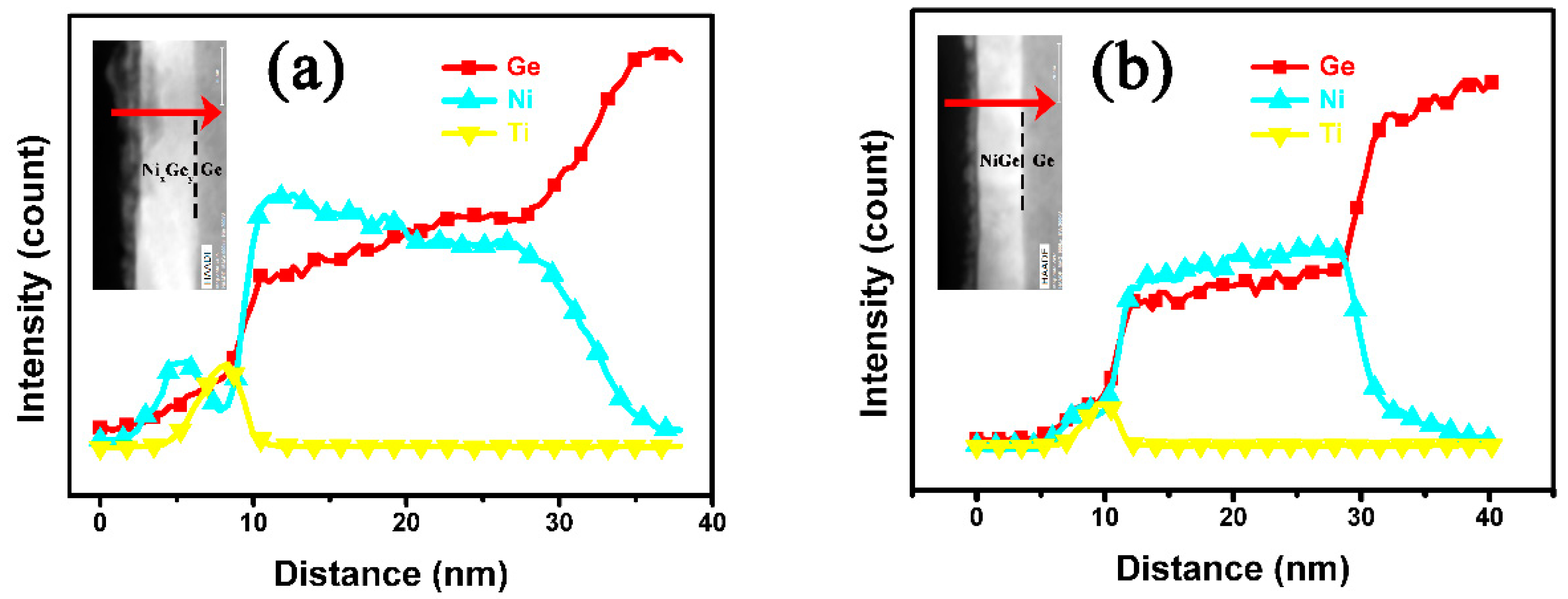

3.1. Characterization of the NixGey Layers

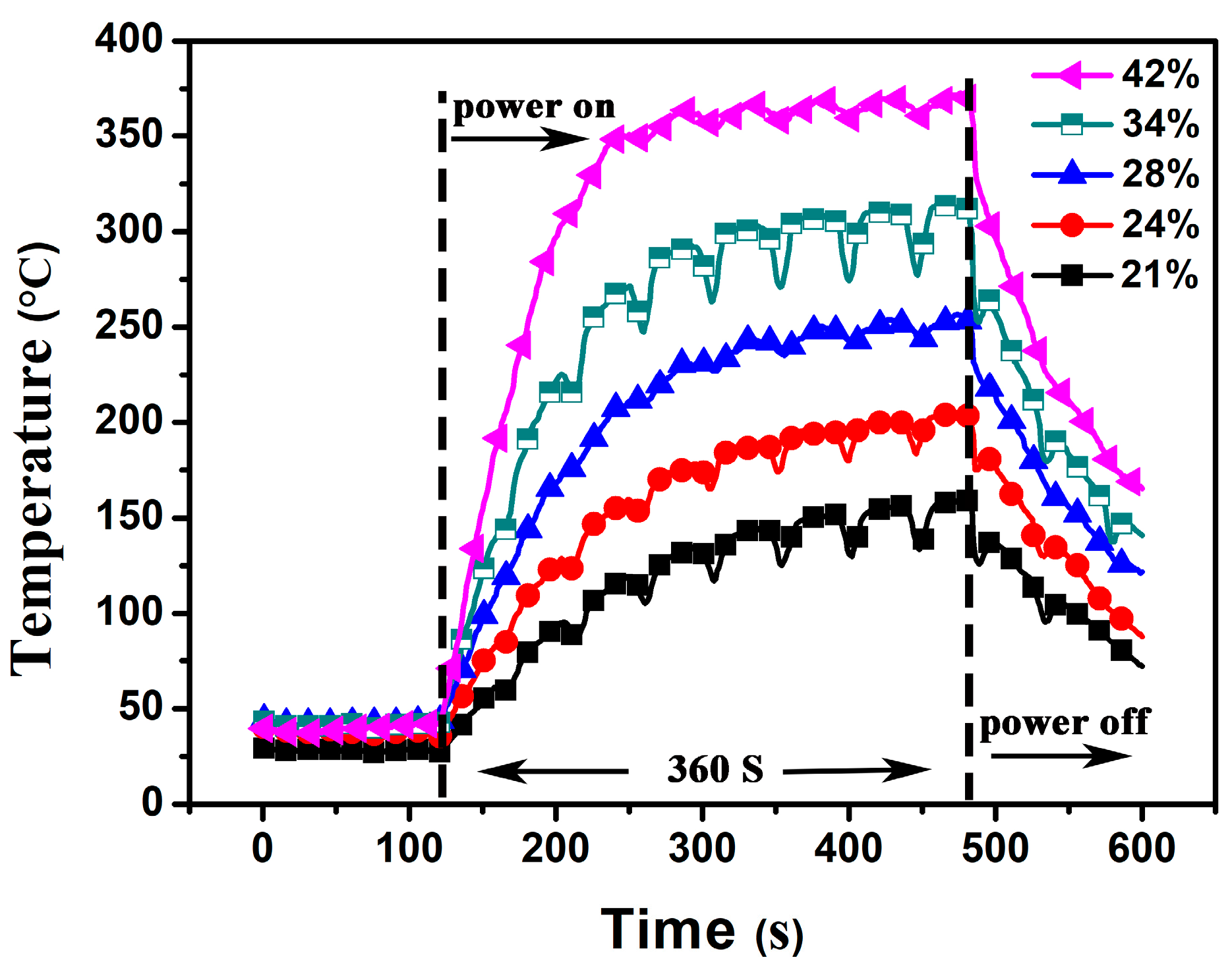

3.2. Mechanism Analysis of MWA

3.3. The Benefits of MWA

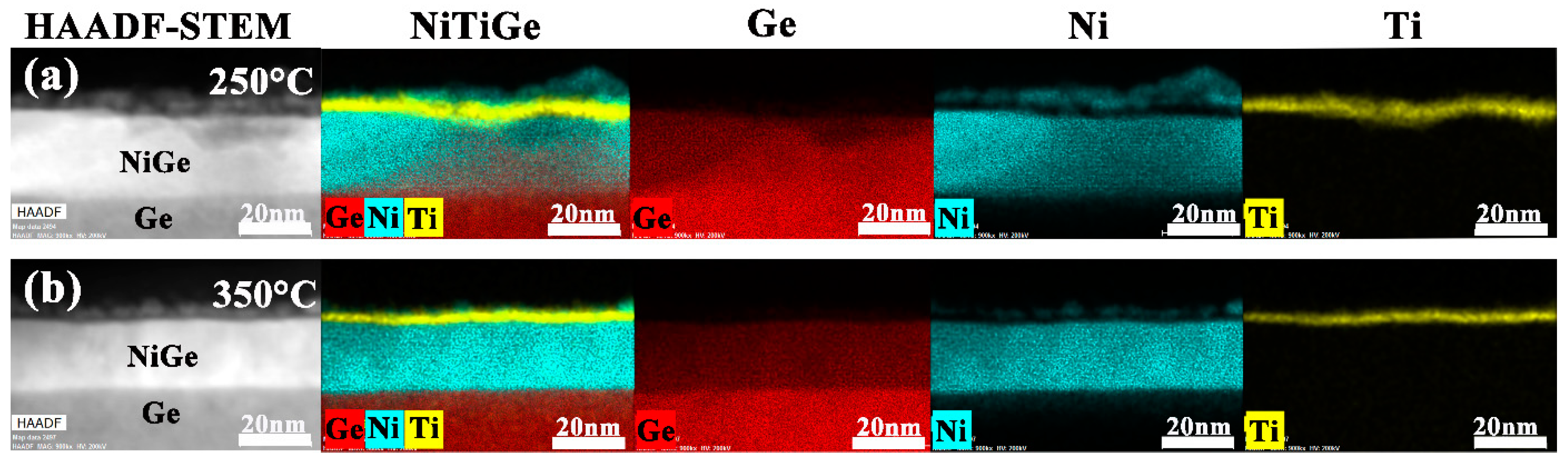

3.4. The Effect of Ti Mediation under MWA

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Microwave Annealing Temperature (°C) | Minimum Temperature (°C) | Maximum Temperature (°C) |

|---|---|---|

| 150 | 130 | 160 |

| 200 | 173 | 202 |

| 250 | 233 | 257 |

| 300 | 277 | 314 |

| 350 | 342 | 366 |

References

- Chi On, C.; Hyoungsub, K.; Chi, D.; Triplett, B.B.; McIntyre, P.C.; Saraswat, K.C. A sub-400/spl deg/C germanium MOSFET technology with high-/spl kappa/dielectric and metal gate, Digest. In Proceedings of the International Electron Devices Meeting, San Francisco, CA, USA, 8–11 December 2002; IEEE: New York, NY, USA, 2002; pp. 437–440. [Google Scholar] [CrossRef]

- Huiling, S.; Okorn-Schmidt, H.; Chan, K.K.; Copel, M.; Ott, J.A.; Kozlowski, P.M.; Steen, S.E.; Cordes, S.A.; Wong, H.P.; Jones, E.C.; et al. High mobility p-channel germanium MOSFETs with a thin Ge oxynitride gate dielectric, Digest. In Proceedings of the International Electron Devices Meeting, San Francisco, CA, USA, 8–11 December 2002; IEEE: New York, NY, USA, 2002; pp. 441–444. [Google Scholar] [CrossRef]

- Zhu, S.; Li, R.; Lee, S.J.; Li, M.F.; Du, A.; Singh, J.; Zhu, C.; Chin, A.; Kwong, D.L. Germanium pMOSFETs with Schottky-barrier germanide S/D, high-/spl kappa/gate dielectric and metal gate. IEEE Electron Device Lett. 2005, 26, 81–83. [Google Scholar] [CrossRef]

- Hsu, S.-L.; Chien, C.-H.; Yang, M.-J.; Huang, R.-H.; Leu, C.-C.; Shen, S.-W.; Yang, T.-H. Study of thermal stability of nickel monogermanide on single- and polycrystalline germanium substrates. Appl. Phys. Lett. 2005, 86, 251906. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, N.; Osipowicz, T.; Bera, L.K.; Zhu, C. Formation and Thermal Stability of Nickel Germanide on Germanium Substrate. Jpn. J. Appl. Phys. 2005, 44, L1389–L1391. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, J.; Liu, J.; Wang, G.; Luo, X.; Zhang, D.; Mao, S.; Li, Y.; Li, J.; Zhao, C.; et al. Role of Carbon Pre-Germanidation Implantation on Enhancing the Thermal Stability of NiGe Films Below 10 nm Thickness. ECS J. Solid State Sci. Technol. 2020, 9, 054006. [Google Scholar] [CrossRef]

- Duan, N.; Wang, G.; Xu, J.; Mao, S.; Luo, X.; Zhang, D.; Wang, W.; Chen, D.; Li, J.; Liu, S.; et al. Enhancing the thermal stability of NiGe by prior-germanidation fluorine implantation into Ge substrate. Jpn. J. Appl. Phys. 2018, 57, 07MA03. [Google Scholar] [CrossRef]

- Chen, Z.; Yuan, S.; Li, J.; Zhang, R. Thermal Stability Enhancement of NiGe Metal Source/Drain and Ge pMOSFETs by Dopant Segregation. IEEE Trans. Electron Devices 2019, 66, 5284–5288. [Google Scholar] [CrossRef]

- Zhu, S.; Yu, M.B.; Lo, G.Q.; Kwong, D.L. Enhanced thermal stability of nickel germanide on thin epitaxial germanium by adding an ultrathin titanium layer. Appl. Phys. Lett. 2007, 91, 051905. [Google Scholar] [CrossRef]

- Nakatsuka, O.; Suzuki, A.; Sakai, A.; Ogawa, M.; Zaima, S. Impact of Pt Incorporation on Thermal Stability of NiGe Layers on Ge(001) Substrates. In Proceedings of the 2007 International Workshop on Junction Technology, Kyoto, Japan, 8–9 June 2007; IEEE: New York, NY, USA, 2007; pp. 87–88. [Google Scholar] [CrossRef]

- Jablonka, L.; Kubart, T.; Gustavsson, F.; Descoins, M.; Mangelinck, D.; Zhang, S.L.; Zhang, Z. Improving the morphological stability of nickel germanide by tantalum and tungsten additions. Appl. Phys. Lett. 2018, 112, 103102. [Google Scholar] [CrossRef]

- Lee, J.W.; Kim, H.K.; Bae, J.H.; Park, M.H.; Kim, H.; Ryu, J.; Yang, C.W. Enhanced morphological and thermal stabilities of nickel germanide with an ultrathin tantalum layer studied by ex situ and in situ transmission electron microscopy. Microsc. Microanal. 2013, 19, 114–118. [Google Scholar] [CrossRef]

- Shin, G.-H.; Kim, J.; Li, M.; Lee, J.; Lee, G.-W.; Oh, J.; Lee, H.-D. A Study on Thermal Stability Improvement in Ni Germanide/p-Ge using Co interlayer for Ge MOSFETs. J. Semicond. Technol. Sci. 2017, 17, 277–282. [Google Scholar] [CrossRef]

- Zhang, Y.-Y.; Oh, J.; Li, S.-G.; Jung, S.-Y.; Park, K.-Y.; Shin, H.-S.; Lee, G.-W.; Wang, J.-S.; Majhi, P.; Tseng, H.-H.; et al. Ni Germanide Utilizing Ytterbium Interlayer for High-Performance Ge MOSFETs. Electrochem. Solid-State Lett. 2009, 12, H18–H20. [Google Scholar] [CrossRef]

- Lee, K.Y.; Liew, S.L.; Chua, S.J.; Chi, D.Z.; Sun, H.P.; Pan, X.Q. Formation and Morphology Evolution of Nickel Germanides on Ge (100) under Rapid Thermal Annealing. MRS Proceed. 2004, 810, C2.4. [Google Scholar] [CrossRef]

- Lim, P.S.Y.; Chi, D.Z.; Lim, P.C.; Wang, X.C.; Chan, T.K.; Osipowicz, T.; Yeo, Y.-C. Formation of epitaxial metastable NiGe2 thin film on Ge(100) by pulsed excimer laser anneal. Appl. Phys. Lett. 2010, 97, 182104. [Google Scholar] [CrossRef]

- Kappe, C.O. Controlled microwave heating in modern organic synthesis. Angew. Chem. Int. Ed. 2004, 43, 6250–6285. [Google Scholar] [CrossRef]

- Lee, Y.J.; Hsueh, F.K.; Current, M.I.; Wu, C.Y.; Chao, T.S. Susceptor coupling for the uniformity and dopant activation efficiency in implanted Si under fixed-frequency microwave anneal. IEEE Electron Device Lett. 2012, 33, 248–250. [Google Scholar] [CrossRef]

- Alford, T.L.; Thompson, D.C.; Mayer, J.W.; Theodore, N.D. Dopant activation in ion implanted silicon by microwave annealing. J. Appl. Phys. 2009, 106. [Google Scholar] [CrossRef]

- Oghbaei, M.; Mirzaee, O. Microwave versus conventional sintering: A review of fundamentals, advantages and applications. J. Alloys Compd. 2010, 494, 175–189. [Google Scholar] [CrossRef]

- Hu, C.; Xu, P.; Fu, C.; Zhu, Z.; Gao, X.; Jamshidi, A.; Noroozi, M.; Radamson, H.; Wu, D.; Zhang, S.-L. Characterization of Ni(Si,Ge) films on epitaxial SiGe(100) formed by microwave annealing. Appl. Phys. Lett. 2012, 101, 092101. [Google Scholar] [CrossRef]

- Hsu, C.-C.; Lin, K.-L.; Chi, W.-C.; Chou, C.-H.; Luo, G.-L.; Lee, Y.-J.; Chien, C.-H. Phase-separation phenomenon of NiGePt alloy on n-Ge by microwave annealing. J. Alloys Compd. 2018, 743, 262–267. [Google Scholar] [CrossRef]

- De Schutter, B.; Van Stiphout, K.; Santos, N.M.; Bladt, E.; Jordan-Sweet, J.; Bals, S.; Lavoie, C.; Comrie, C.M.; Vantomme, A.; Detavernier, C. Phase formation and texture of thin nickel germanides on Ge(001) and Ge(111). J. Appl. Phys. 2016, 119, 135305. [Google Scholar] [CrossRef]

- Jablonka, L.; Kubart, T.; Primetzhofer, D.; Abedin, A.; Hellström, P.-E.; Östling, M.; Jordan-Sweet, J.; Lavoie, C.; Zhang, S.-L.; Zhang, Z. Formation of nickel germanides from Ni layers with thickness below 10 nm. J. Vac. Sci. Technol. B 2017, 35, 020602. [Google Scholar] [CrossRef]

- Begeza, V.; Mehner, E.; Stocker, H.; Xie, Y.; Garcia, A.; Hubner, R.; Erb, D.; Zhou, S.; Rebohle, L. Formation of Thin NiGe Films by Magnetron Sputtering and Flash Lamp Annealing. Nanomaterials 2020, 10, 648. [Google Scholar] [CrossRef]

- Guo, Y.; An, X.; Huang, R.; Fan, C.; Zhang, X. Tuning of the Schottky barrier height in NiGe/n-Ge using ion-implantation after germanidation technique. Appl. Phys. Lett. 2010, 96, 143502. [Google Scholar] [CrossRef]

- Uddin, W.; Saleem Pasha, M.; Dhyani, V.; Maity, S.; Das, S. Temperature dependent current transport behavior of improved low noise NiGe schottky diodes for low leakage Ge-MOSFET. Semicond. Sci. Technol. 2019, 34, 035026. [Google Scholar] [CrossRef]

- Ping, Y.; Hou, C.; Zhang, C.; Yu, W.; Xue, Z.; Wei, X.; Peng, W.; Di, Z.; Zhang, M.; Zhang, B. Ti mediated highly oriented growth of uniform and smooth Ni(Si0.8Ge0.2) layer for advanced contact metallization. J. Alloys Compd. 2017, 693, 527–533. [Google Scholar] [CrossRef]

- Tamura, H. Microwave dielectric losses caused by lattice defects. J. Eur. Ceram. Soc. 2006, 26, 1775. [Google Scholar] [CrossRef]

- Shen, L.C.; Kong, J.A. Applied Electromagnetism; PWS Publishing: Boston, MA, USA, 1995; p. 552. [Google Scholar]

- Wang, T.; Dai, Y.; Dai, Q.; Ng RM, Y.; Chan, W.T.; Lee, P.; Chan, M. Microwave plasma anneal to fabricate silicides and restrain the formation of unstable phases. In Proceedings of the 2007 IEEE Conference on Electron Devices and Solid-State Circuits, Tainan, Taiwan, 20–22 December 2007; IEEE: New York, NY, USA, 2007; pp. 609–612. [Google Scholar] [CrossRef]

- Moulder, J.C.; Uzal, E.; Rose, J.H. Thickness and conductivity of metallic layers from eddy current measurements. Rev. Sci. Instrum. 1992, 63, 3455–3465. [Google Scholar] [CrossRef]

- Gaudet, S.; Detavernier, C.; Kellock, A.J.; Desjardins, P.; Lavoie, C. Thin film reaction of transition metals with germanium. J. Vac. Sci. Technol. 2006, 24, 474–485. [Google Scholar] [CrossRef]

- Nakatsuka, O.; Okubo, K.; Tsuchiya, Y.; Sakai, A.; Zaima, S.; Yasuda, Y. Low-Temperature Formation of Epitaxial NiSi2 Layers with Solid-Phase Reaction in Ni/Ti/Si(001) Systems. Jpn. J. Appl. Phys. 2005, 44, 2945–2947. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Ping, Y.; Liu, W.; Yu, W.; Xue, Z.; Wei, X.; Wu, A.; Zhang, B. Ti Interlayer Mediated Uniform NiGe Formation under Low-Temperature Microwave Annealing. Metals 2021, 11, 488. https://doi.org/10.3390/met11030488

Yang J, Ping Y, Liu W, Yu W, Xue Z, Wei X, Wu A, Zhang B. Ti Interlayer Mediated Uniform NiGe Formation under Low-Temperature Microwave Annealing. Metals. 2021; 11(3):488. https://doi.org/10.3390/met11030488

Chicago/Turabian StyleYang, Jun, Yunxia Ping, Wei Liu, Wenjie Yu, Zhongying Xue, Xing Wei, Aimin Wu, and Bo Zhang. 2021. "Ti Interlayer Mediated Uniform NiGe Formation under Low-Temperature Microwave Annealing" Metals 11, no. 3: 488. https://doi.org/10.3390/met11030488

APA StyleYang, J., Ping, Y., Liu, W., Yu, W., Xue, Z., Wei, X., Wu, A., & Zhang, B. (2021). Ti Interlayer Mediated Uniform NiGe Formation under Low-Temperature Microwave Annealing. Metals, 11(3), 488. https://doi.org/10.3390/met11030488