Effect of the γ→ε Phase Transition on Transformation-Induced Plasticity (TRIP) of Nickel-Free High Nitrogen Steel at Low Temperatures

Abstract

1. Introduction

2. Materials and Methods

3. Results

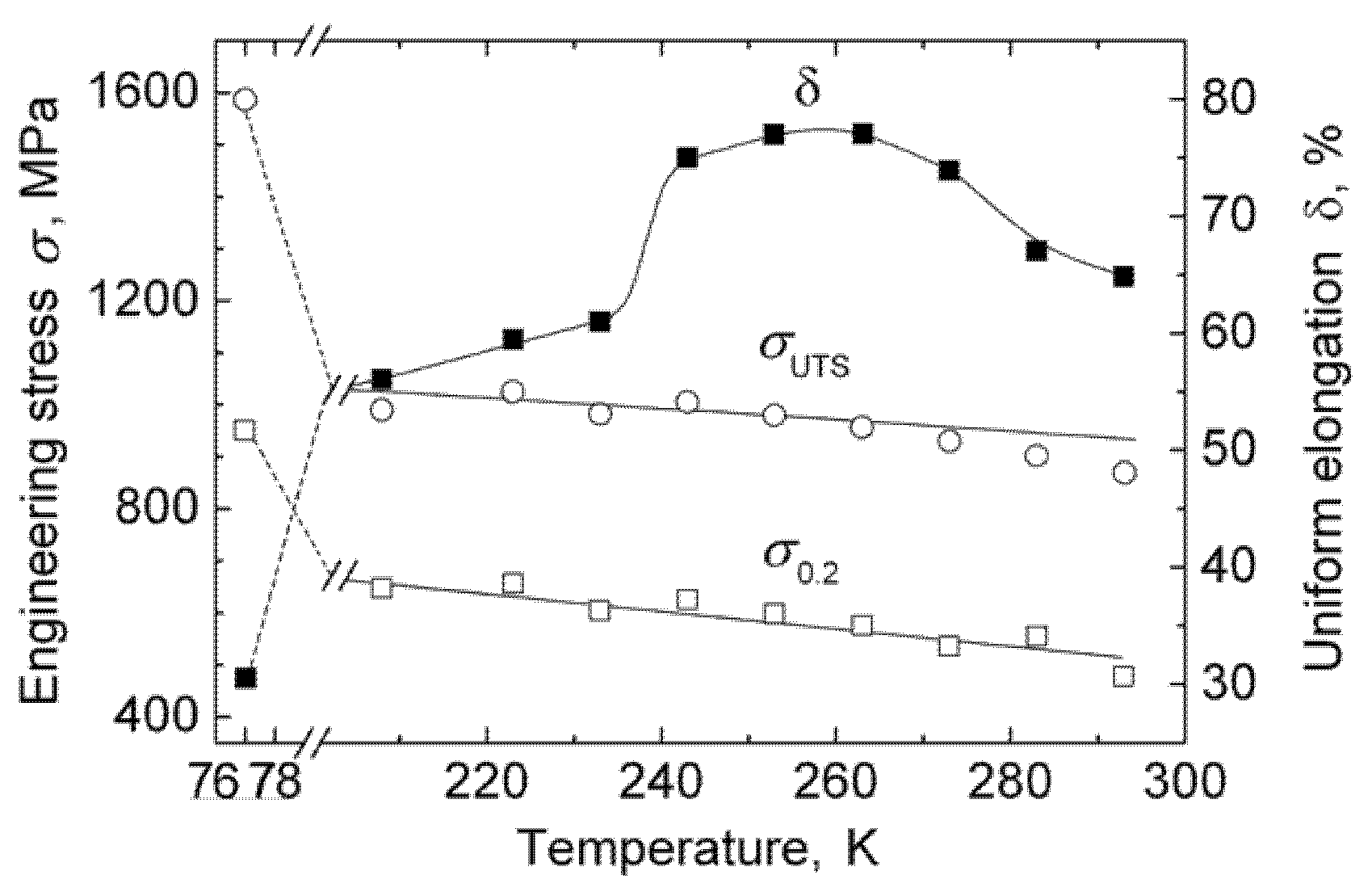

3.1. Tensile Properties

3.2. The Microstructural Studies of the Deformed Samples

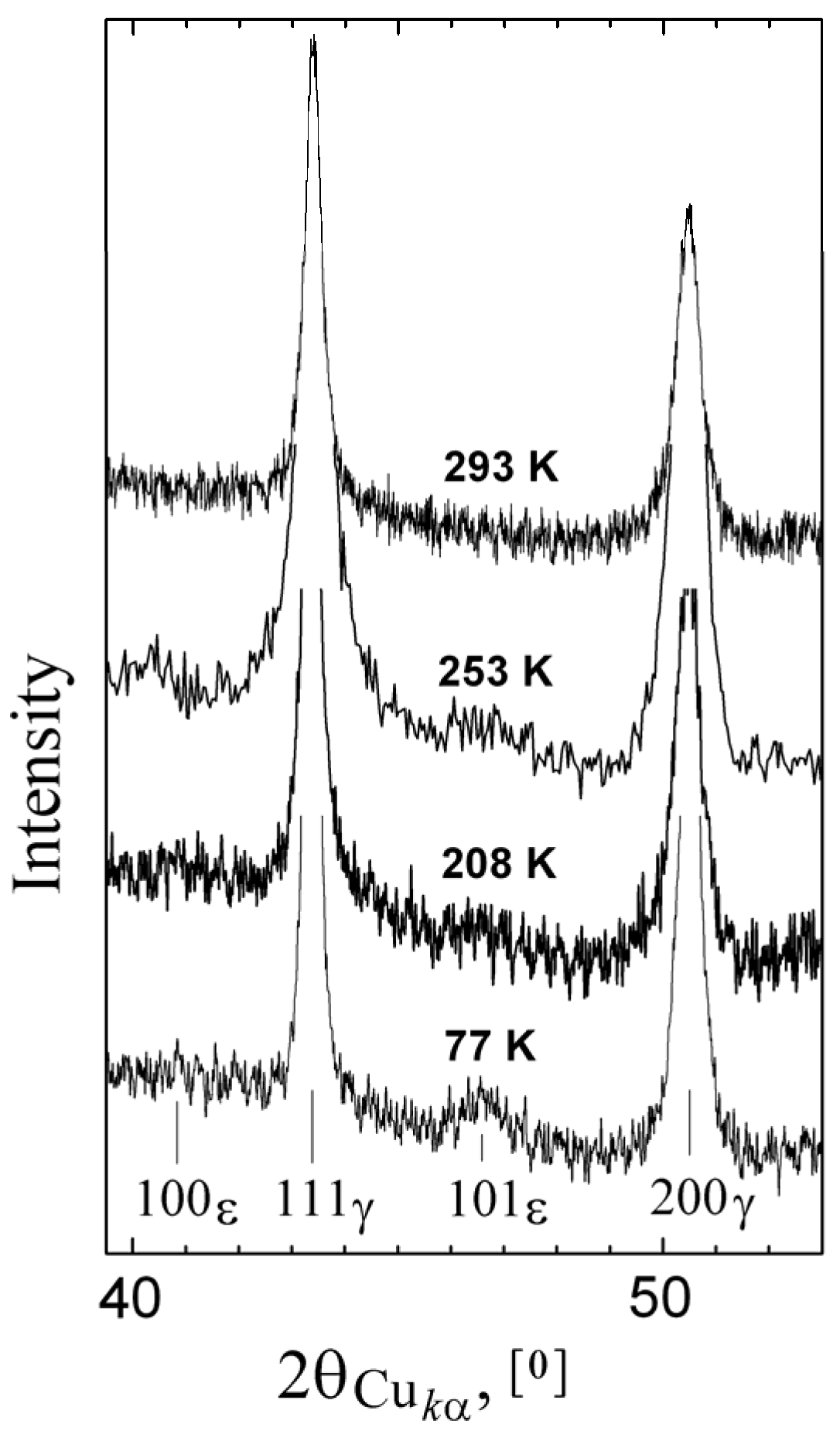

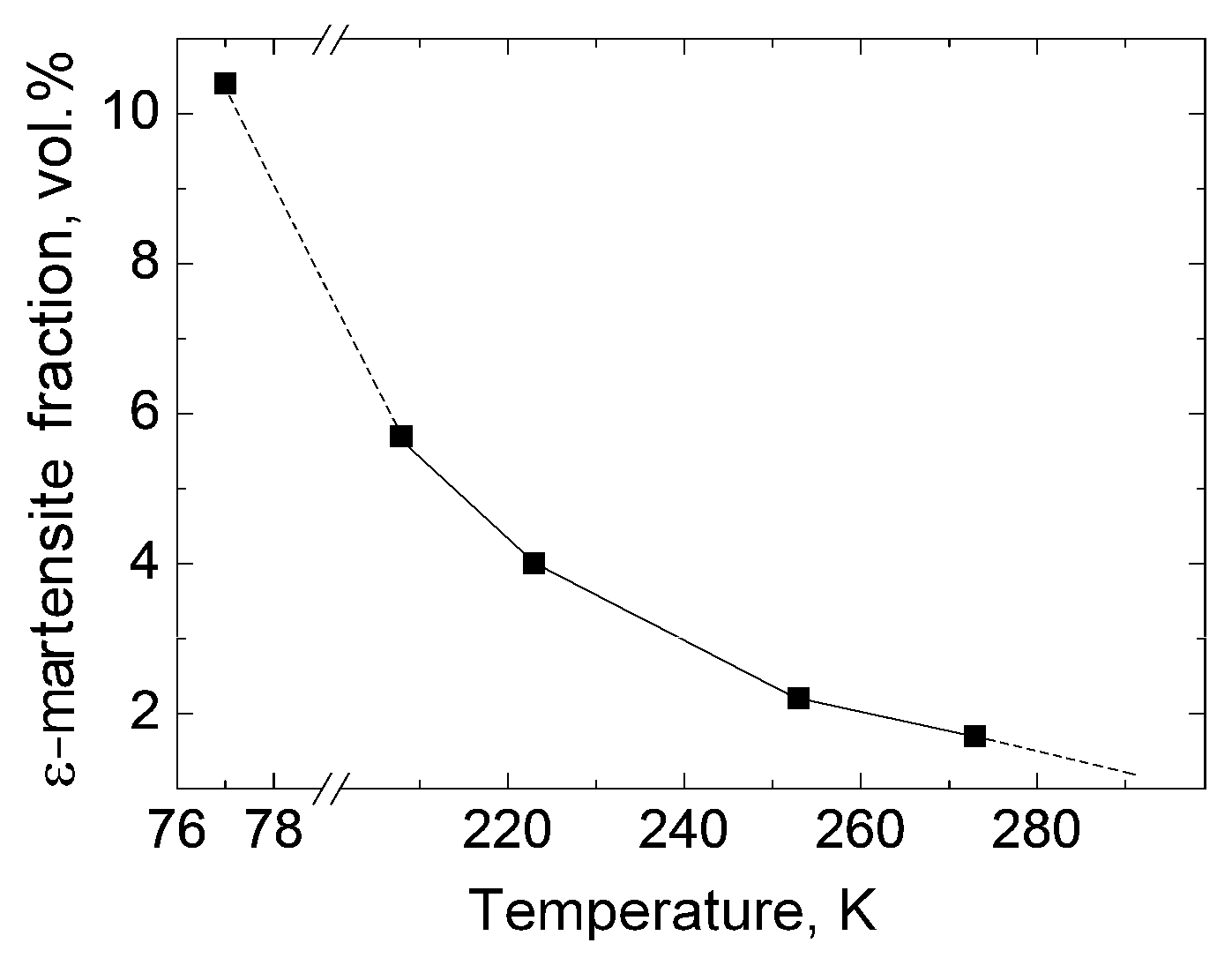

3.2.1. The Phase Composition

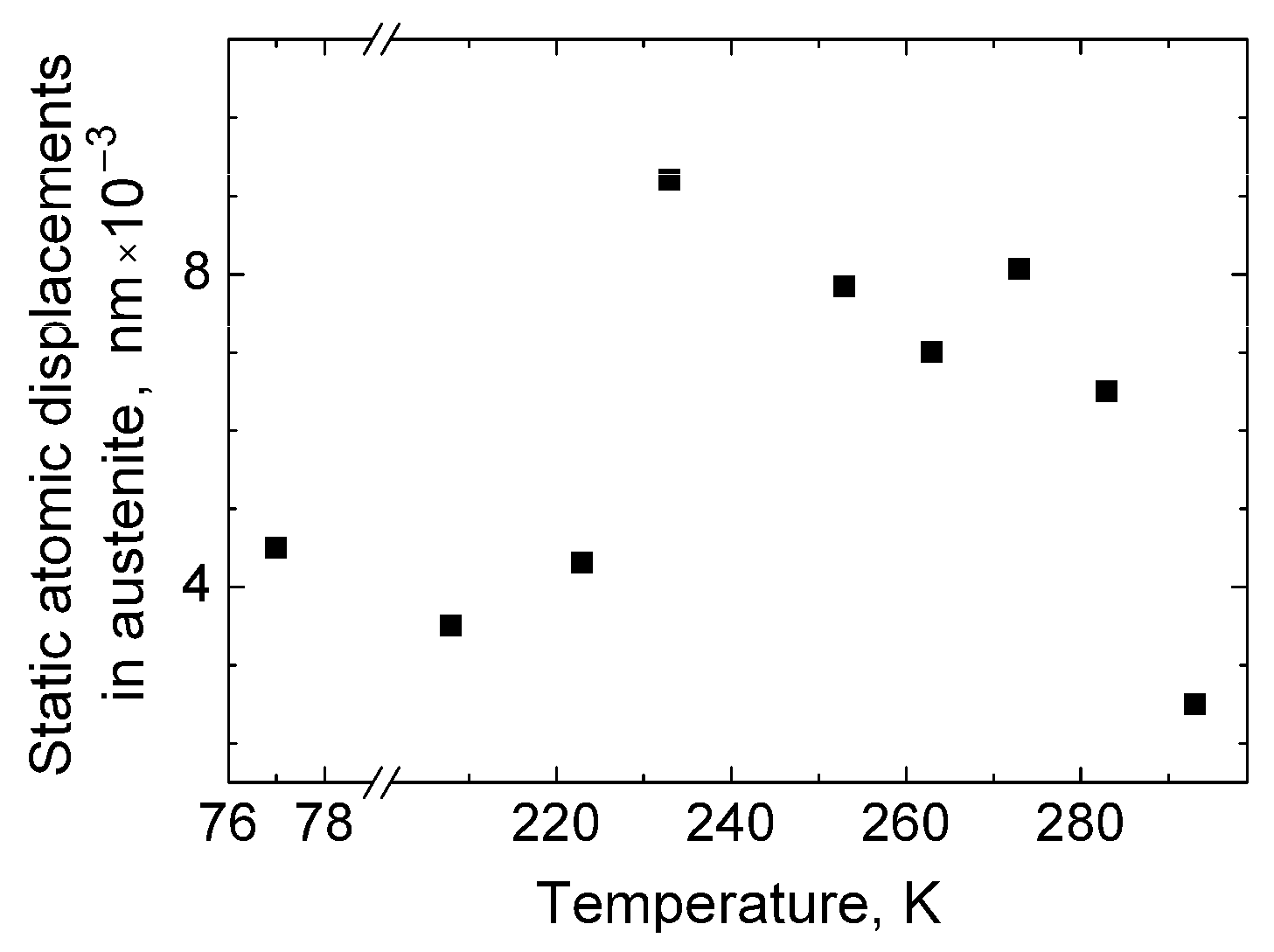

3.2.2. RMS Atom Displacements in the Fcc Lattice

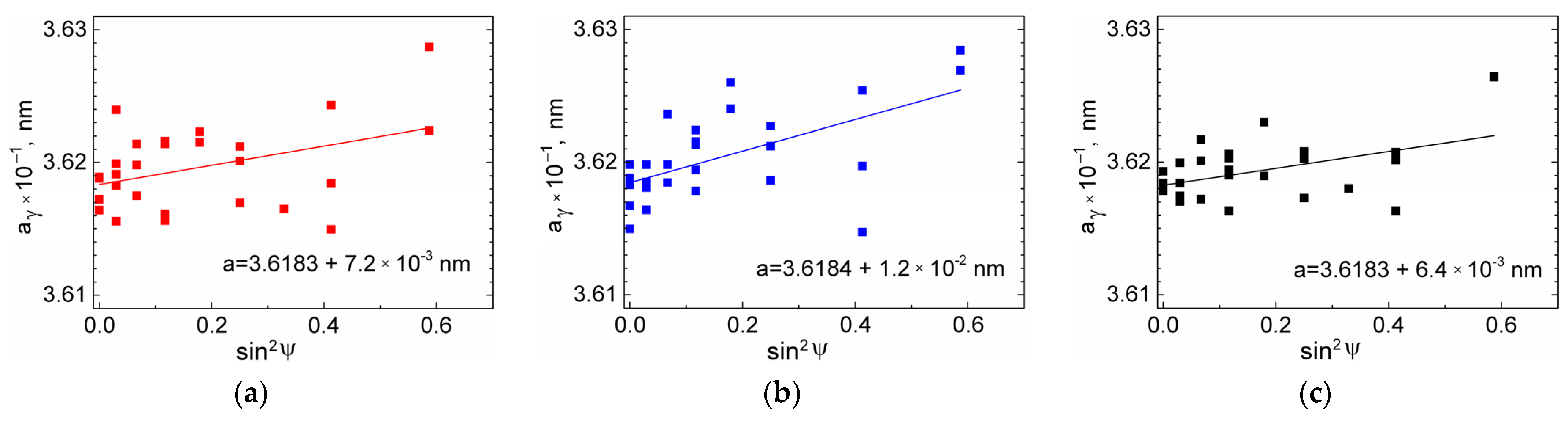

3.2.3. Residual Stresses

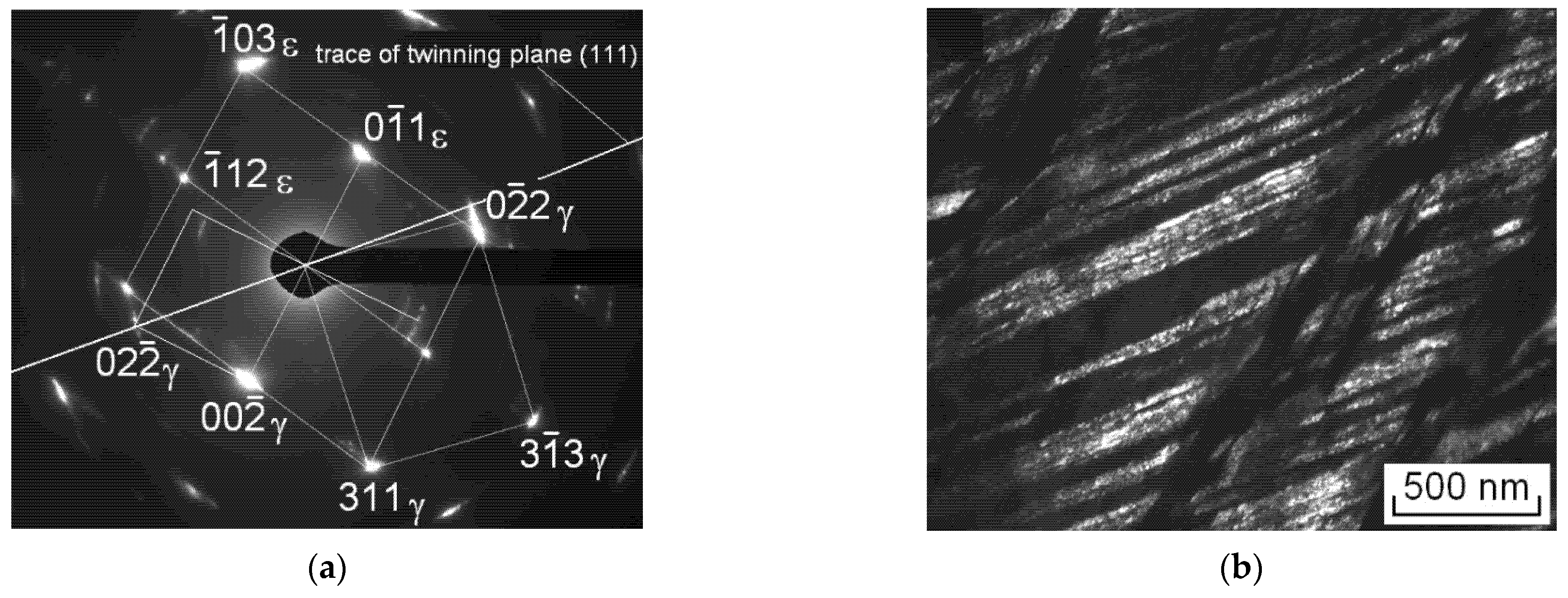

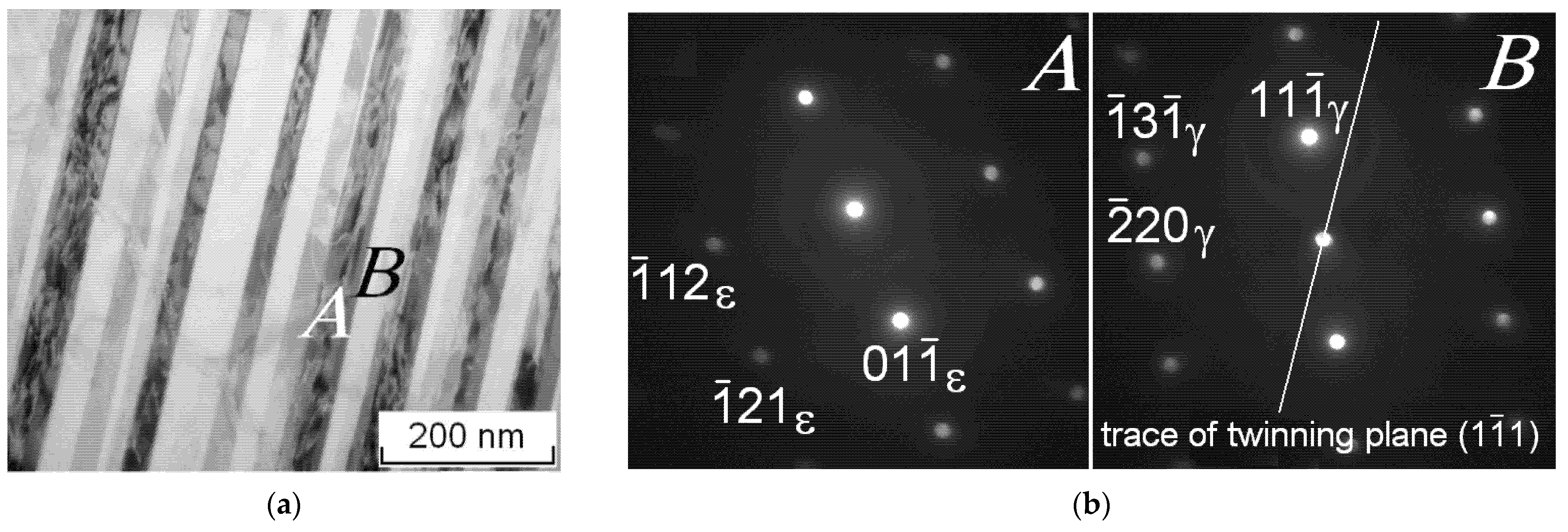

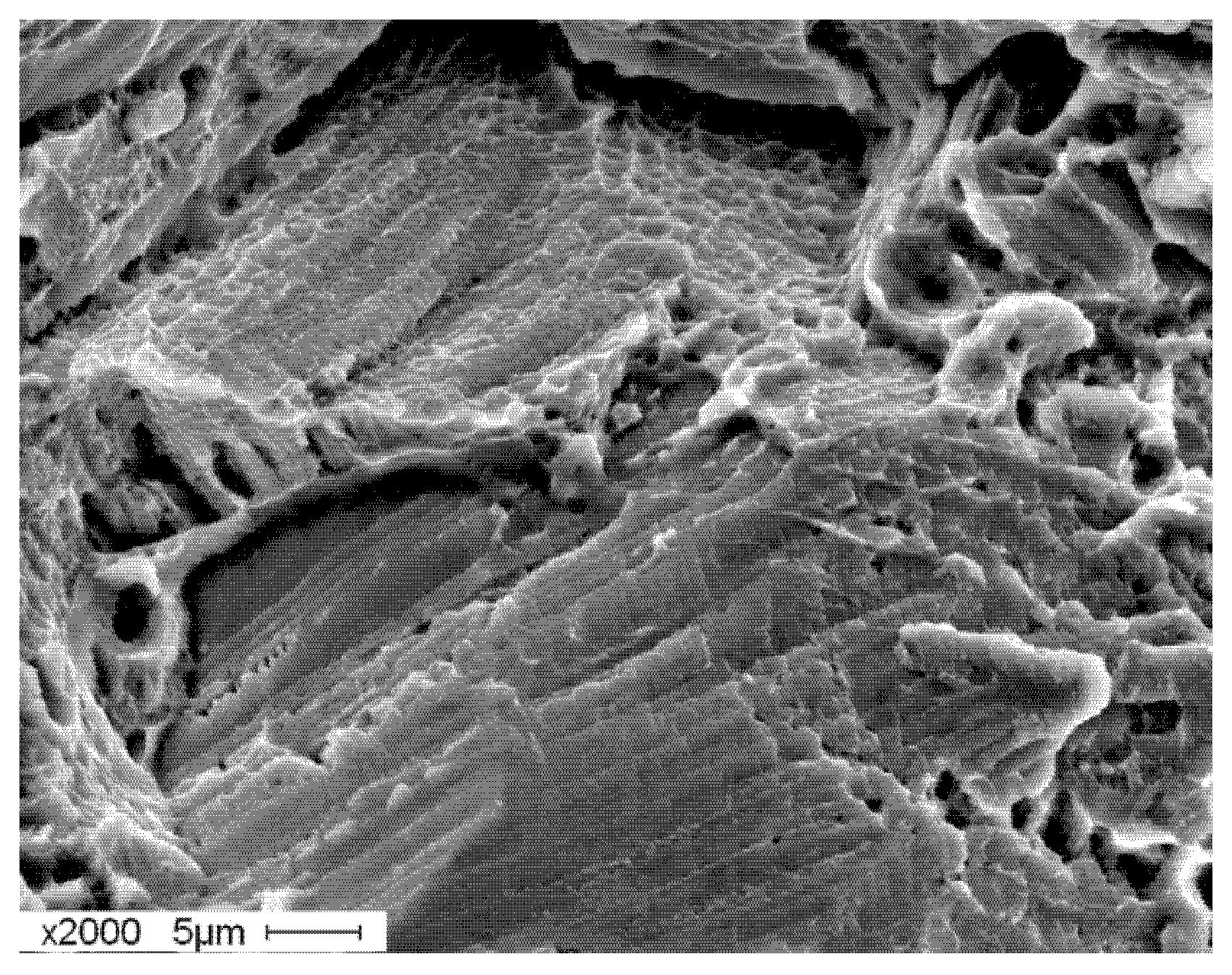

3.2.4. TEM Investigations

4. Discussion

5. Conclusions

- Upon tensile testing of Fe-Cr-Mn-0.53%N steel at low temperatures, the γ→ε martensitic transformation was initiated. It started at the true stress level of about 1040 ± 50 MPa.

- Elongation increased with the decrease in the tensile test temperature from 293 down to 260 K and remained at a high level down to 240 K due to the stress-induced γ→ε transformation, which ensured prolonged plastic deformation of the steel. With reductions in the tensile test temperature below 240 K, elongation reduced from the maximum values due to the plastic deformation of the hcp ε-martensite lattice.

- Mechanical twinning and the increase in the SF density during low-temperature deformation enhanced static atom displacements from their equilibrium positions in the fcc lattice, destabilized it, and promoted the formation of stress-induced ε-martensite. However, this effect was reduced by the increase in the volume fraction of ε-martensite.

- Stress-induced ε-martensite formed residual stresses in austenite. Their level was maximal at the stage of the ε-martensite formation and its elastic deformation but decreased with the beginning of the hcp lattice plastic deformation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Defilippi, J.D.; Brickner, K.G.; Gilbert, E.M. Ductile-to-brittle transition in austenitic chromium-manganese-nitrogen stainless steels. Trans. Metall. Soc. AIME 1969, 245, 2141–2148. [Google Scholar]

- Milititsky, M.; Matlock, D.; Regully, A.; de Wispelaere, N.; Penning, J.; Hдnninen, H. Impact toughness properties of nickel-free austenitic stainless steels. Mater. Sci. Eng. A 2008, 496, 189–199. [Google Scholar] [CrossRef]

- Wang, S.; Yang, K.; Shan, Y.; Li, L. Plastic deformation and fracture behaviors of nitrogen-alloyed austenitic stainless steels. Mater. Sci. Eng. A 2008, 490, 95–104. [Google Scholar] [CrossRef]

- Byun, T.; Hashimoto, N.; Farrell, K. Temperature dependence of strain hardening and plastic instability behaviors in austenitic stainless steels. Acta Mater. 2004, 52, 3889–3899. [Google Scholar] [CrossRef]

- Balachandran, G. High Nitrogen Steels and Stainless Steels—Manufacturing Properties and Applications; Alpha Science International: Pangbourne, UK, 2004; pp. 40–93. [Google Scholar]

- Berns, H.; Gavriljuk, V.; Riedner, S.; Tyshchenko, A. High Strength Stainless Austenitic CrMnCN Steels—Part I: Alloy Design and Properties. Steel Res. Int. 2007, 78, 714–719. [Google Scholar] [CrossRef]

- Lee, T.-H.; Shin, E.; Oh, C.-S.; Ha, H.-Y.; Kim, S.-J. Correlation between stacking fault energy and deformation microstructure in high-interstitial-alloyed austenitic steels. Acta Mater. 2010, 58, 3173–3186. [Google Scholar] [CrossRef]

- Bazaleeva, K.O. Mechanisms of the Influence of Nitrogen on the Structure and Properties of Steels (A Review). Met. Sci. Heat Treat. 2005, 47, 455–461. [Google Scholar] [CrossRef]

- Lenel, U.R.; Knott, B.R. Microstructure-composition relationships and Ms temperatures in Fe-Cr-Mn-N alloys. Met. Mater. Trans. A 1987, 18, 767–775. [Google Scholar] [CrossRef]

- Dai, Q.-X.; Wang, A.-D.; Cheng, X.-N.; Luo, X.-M. Stacking fault energy of cryogenic austenitic steels. Chin. Phys. 2002, 11, 596–600. [Google Scholar] [CrossRef]

- Gavriljuk, V.; Sozinov, A.; Foct, J.; Petrov, J.; Polushkin, Y. Effect of nitrogen on the temperature dependence of the yield strength of austenitic steels. Acta Mater. 1998, 46, 1157–1163. [Google Scholar] [CrossRef]

- Martin, S.; Wolf, S.; Martin, U.; Krьger, L.; Rafaja, D. Deformation Mechanisms in Austenitic TRIP/TWIP Steel as a Function of Temperature. Met. Mater. Trans. A 2016, 47, 49–58. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, W.; Liu, X.; Liu, Z.; Wang, G. Development of TRIP-Aided Lean Duplex Stainless Steel by Twin-Roll Strip Casting and Its Deformation Mechanism. Met. Mater. Trans. A 2016, 47, 6292–6303. [Google Scholar] [CrossRef]

- Lee, T.-H.; Oh, C.-S.; Kim, S.-J. Effects of nitrogen on deformation-induced martensitic transformation in metastable austenitic Fe–18Cr–10Mn–N steels. Scr. Mater. 2008, 58, 110–113. [Google Scholar] [CrossRef]

- Narkevich, N.A.; Surikova, N.S. Deformation Behavior and Structural Evolution of Stainless Cr–Mn–N Steel during Low-Temperature Tension. Phys. Met. Met. 2020, 121, 1175–1181. [Google Scholar] [CrossRef]

- Lee, T.-H.; Oh, C.-S.; Kim, S.-J.; Takaki, S. Deformation twinning in high-nitrogen austenitic stainless steel. Acta Mater. 2007, 55, 3649–3662. [Google Scholar] [CrossRef]

- Lee, T.-H.; Ha, H.-Y.; Hwang, B.; Kim, S.-J.; Shin, E. Effect of Carbon Fraction on Stacking Fault Energy of Austenitic Stainless Steels. Met. Mater. Trans. A 2012, 43, 4455–4459. [Google Scholar] [CrossRef]

- Narkevich, N.A.; Shulepov, I.A.; Mironov, Y.P. Structure, mechanical, and tribotechnical properties of an austenitic nitrogen steel after frictional treatment. Phys. Met. Met. 2017, 118, 399–406. [Google Scholar] [CrossRef]

- Narkevich, N.A.; Tolmachev, A.I.; Vlasov, I.V.; Surikova, N.S. Structure and Mechanical Properties of Nitrogen Austenitic Steel after Ultrasonic Forging. Phys. Met. Met. 2016, 117, 288–294. [Google Scholar] [CrossRef]

- Perevalova, O.B.; Konovalova, E.V.; Koneva, N.A.; Kozlov, E.V. Influence of Atomic Ordering on Grain-Boundary Ensembles of Fcc solid Solutions; NTL: Tomsk, Russia, 2014; pp. 43–57. [Google Scholar]

- Drozdov, A.N.; Vus, A.S.; Pukha, V.E.; Pugachev, A.T. Specific features of the formation of diffraction patterns of metallofullerene crystals. Phys. Solid State 2010, 52, 1999–2004. [Google Scholar] [CrossRef]

- Sangal, S.K.; Sharma, P.K. Mean square displacements of atoms in cubic metals at melting point. Czechoslov. J. Phys. 1968, 18, 1413–1415. [Google Scholar] [CrossRef]

- Nagy, E.; Mertinger, V.; Tranta, F.; Sylyom, J. Deformation induced martensitic transformation in stainless steels. Mater. Sci. Eng. A 2004, 378, 308–313. [Google Scholar] [CrossRef]

- Karthik, D.; Kalainathan, S.; Swaroop, S.; Dhandapani, K. Surface modification of 17-4 PH stainless steel by laser peening without protective coating process. Surf. Coat. Technol. 2015, 278, 138–145. [Google Scholar] [CrossRef]

- Warren, B. X-ray studies of deformed metals. Prog. Met. Phys. 1959, 8, 147–202. [Google Scholar] [CrossRef]

- Guler, S.; Fischer, A. Fatigue Behavior of Cold-Worked High-Interstitial Steels. Metals 2018, 8, 442. [Google Scholar] [CrossRef]

- Asgari, S.; El-Danaf, E.; Kalidindi, S.R.; Doherty, R.D. Strain hardening regimes and microstructural evolution during large strain compression of low stacking fault energy fcc alloys that form deformation twins. Met. Mater. Trans. A 1997, 28, 1781–1795. [Google Scholar] [CrossRef]

- Rasouli, D.; Kermanpur, A.; Ghassemali, E.; Najafizadeh, A. On the Reversion and Recrystallization of Austenite in the Interstitially Alloyed Ni-Free Nano/Ultrafine Grained Austenitic Stainless Steels. Met. Mater. Int. 2019, 25, 846–859. [Google Scholar] [CrossRef]

- Ojima, M.; Adachi, Y.; Tomota, Y.; Ikeda, K.; Kamiyama, T.; Katada, Y. Work hardening mechanism in high nitrogen austenitic steel studied by in situ neutron diffraction and in situ electron backscattering diffraction. Mater. Sci. Eng. A 2009, 527, 16–24. [Google Scholar] [CrossRef]

- Clausen, B.; Lorentzen, T.; Leffers, T. Self-consistent modelling of the plastic deformation of f.c.c. polycrystals and its implications for diffraction measurements of internal stresses. Acta Mater. 1998, 46, 3087–3098. [Google Scholar] [CrossRef]

- Byrnes, M.; Grujicic, M.; Owen, W. Nitrogen strengthening of a stable austenitic stainless steel. Acta Met. 1987, 35, 1853–1862. [Google Scholar] [CrossRef]

- Volynova, T.F. High Manganese Steels and Alloys; Metallurgia: Moscow, Russia, 1988; pp. 876–892. [Google Scholar]

- Astafurova, E.G.; Moskvina, V.A.; Maier, G.G.; Gordienko, A.I.; Burlachenko, A.G.; Smirnov, A.I.; Bataev, V.A.; Galchenko, N.K.; Astafurov, S.V. Low-temperature tensile ductility by V-alloying of high-nitrogen CrMn and CrNiMn steels: Characterization of deformation microstructure and fracture micromechanisms. Mater. Sci. Eng. A 2019, 745, 265–278. [Google Scholar] [CrossRef]

- Frommeyer, G.; Brьx, U.; Neumann, P. Supra-Ductile and High-Strength Manganese-TRIP/TWIP Steels for High Energy Absorption Purposes. ISIJ Int. 2003, 43, 438–446. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.-P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe–Mn–C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

- Talonen, J.; Taulavuori, T.; Hanninen, H. Effect of temperature on tensile behaviour and microstructural evolution of nitrogen alloyed austenitic stainless steel. In Proceedings of the International Conference on High Nitrogen Steels, Espoo, Finland, 24–26 May 2006; Dong, H., Speidel, M.O., Eds.; Metallurgical Industry Press: Beijing, China, 2006; pp. 52–58. [Google Scholar]

- Yang, J.; Wayman, C. On secondary variants formed at intersections of ϵ martensite variants. Acta Met. Mater. 1992, 40, 2011–2023. [Google Scholar] [CrossRef]

| Element | Cr | Mn | C | N | Si | Fe |

|---|---|---|---|---|---|---|

| Content, wt.% | 16.5 | 18.8 | 0.07 | 0.53 | 0.52 | balance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narkevich, N.; Deryugin, Y.; Mironov, Y. Effect of the γ→ε Phase Transition on Transformation-Induced Plasticity (TRIP) of Nickel-Free High Nitrogen Steel at Low Temperatures. Metals 2021, 11, 710. https://doi.org/10.3390/met11050710

Narkevich N, Deryugin Y, Mironov Y. Effect of the γ→ε Phase Transition on Transformation-Induced Plasticity (TRIP) of Nickel-Free High Nitrogen Steel at Low Temperatures. Metals. 2021; 11(5):710. https://doi.org/10.3390/met11050710

Chicago/Turabian StyleNarkevich, Natalia, Yevgeny Deryugin, and Yury Mironov. 2021. "Effect of the γ→ε Phase Transition on Transformation-Induced Plasticity (TRIP) of Nickel-Free High Nitrogen Steel at Low Temperatures" Metals 11, no. 5: 710. https://doi.org/10.3390/met11050710

APA StyleNarkevich, N., Deryugin, Y., & Mironov, Y. (2021). Effect of the γ→ε Phase Transition on Transformation-Induced Plasticity (TRIP) of Nickel-Free High Nitrogen Steel at Low Temperatures. Metals, 11(5), 710. https://doi.org/10.3390/met11050710