Abstract

Downsizing energy consumption during the machining of metals is vital for sustainable manufacturing. As a prerequisite, energy consumption should be determined, through direct or indirect measurement. The manufacturing process of interest is the finish turning which has been explored to generate (near) net shapes, particularly for hardened steels. In this paper, we propose using measured cutting forces to calculate the electrical energy consumption during the finish turning process of metals where typically the depth of cut is lower than the cutting tool nose radius. In this approach, the resultant cutting force should be used for calculating the energy consumption, instead of only the main (tangential) cutting force as used in the conventional approach. A case study was carried out where a hardened stainless steel (AISI 420, hardness of 47–48 HRC) was turned using a coated carbide tool, with a nose radius of 0.8 mm, without cutting fluid, and at 0.4 mm depth of cut. The experimental design varied the cutting speed (100, 130, and 170 m/min) and feed (0.10, 0.125, and 0.16 mm) while other parameters were kept constant. The results indicate that the electrical energy consumption during the particular dry turning of hardened steel can be calculated using cutting force data as proposed. This generally means machining studies that measure cutting forces can also present energy consumption during the finish or hard turning of metals, without specifically measuring the power consumption of the machining process. For this particular dry turning of hardened stainless steel, cutting parameters optimization in terms of machining responses (i.e., low surface roughness, long tool life, low cutting force, and low energy consumption) was also determined to provide an insight on how energy consumption can be integrated with other machining responses towards sustainable machining process of metals.

1. Introduction

With sustainable manufacturing in mind, a product’s manufacture should minimize energy consumption and negative environmental impact [1]. From the sustainable manufacturing point of view, machining is a material removal process using machine tools, where it is wasteful in its use of both material and energy [2]. Yet, given that machining can produce shapes, sizes, and surface finishes with simplicity and accuracy, it is still the most widely used manufacturing process [1,3].

Researchers have introduced models to assess the environmental impact and energy consumption of machining. Munoz et al. [4] developed modeling approaches specifically to the environmental issues of machining processes. Later on, they presented a methodology for considering environmental factors in machining facilities which used analytical process models embedded as the attributes of systems resources to determine energy use and mass flow based on process time and volume of material removed. Choi et al. [5] developed the assessment methodology to measure the amount of the generated solid waste, the consumed energy, the incurred wastewater, and the noise level for machining processes. For energy consumption, the analytical models proposed in previous works differentiate the machine tool’s energy consumption between constant and variable energy consumptions. An empirical approach was presented by Kara and Li [6] in building models for machining processes in predicting their consumed energy for each unit process. They showed that the machining process’s energy consumption could be predicted using the empirical models within the set cutting parameters for the selected machine tools. Their model can calculate the energy requirement for turning or milling processes to machine a product. An on-line approach proposed by Hu et al. [7] was developed based on an energy consumption model of a machine tool for energy efficiency monitoring. Another model was proposed by He et al. [8], seeing machining in a manufacturing system, by categorizing the machine tool’s energy consumption based on the task. They found that the task flow’s flexibility and variability influence the machining’s energy consumption in a particular manufacturing system. These models were developed to reduce environmental impact and energy consumption when machining metals.

Reducing energy consumption requires the capability of monitoring the machining process’s energy consumption [9]. To better calculate the energy consumption, we need to incorporate the machining conditions into energy consumption. However, this is challenging considering the complexity of manufacturing systems and a large amount of data. Previous studies on this include automated monitoring and analysis of energy consumption in manufacturing systems using event stream processing techniques [10]. Another work by Rajemi et al. [11] includes optimization of the energy footprint of a machined product in developing the energy consumption model. As a case study, they machined a part by turning and analyzed the total consumed energy of the process. Afterward, the minimum energy footprint was determined during the optimization of the total energy consumption concerning the machine tool’s tool life.

The turning process of hardened steels is gaining ground with empirical evidence that it can be done, to a certain extent, as a finishing process to get net shapes or near-net shapes of cylindrical or conical parts [12]. As a finishing process, hard turning is typically done at a low depth of cut, lower than the nose radius of the cutting tool. We identified that many works on hard turning reported the effect of machining parameters (e.g., cutting speed, depth of cut, and feed) to quantitative machining responses like cutting forces, tool life, surface roughness, and cutting temperatures. There is only a limited number of studies that are addressing the electrical energy consumption as a machining response in turning of steels, even more for hard turning. Among the few are the works of Astakhov and Xiao [13] and Li and Kara [14] in the turning of steels. These works calculated the machining energy through the measured electrical power consumption and the machining time. These works also acknowledge that power consumption can also be obtained from the multiplication of the main cutting force (i.e., tangential cutting force) and the cutting speed. The only work related to hard turning is by Chudy et al. [15] which also indirectly measured the energy as the product of the tangential cutting force, the cutting speed, and cutting time.

The simplification in calculating the machining power consumption through the use of the main cutting force only is derived from an established theory, with the assumption that the main force contributes the most to the resultant cutting force. However, we observed that the other force components other than the main cutting force are not negligible in finish hard turning. This is also true for the work on hard turning above [15], where the cutting force in the radial direction was higher than the main cutting force for some cutting parameters.

Based on these observations, in this study, we propose the use of resultant cutting force to approximate the electrical energy consumption in the hard turning of steels. As a case study, hardened stainless steel was turned under varying cutting speed and feed conditions, using a carbide tool without cutting fluid. We calculated the energy consumption and further determined the optimum machining parameters region based on the machining responses specified, which also include machining energy.

2. Cutting Forces and Energy Consumption Calculation in Finish Turning Process

The information on cutting forces during various machining processes is essential for determining machinability. Some uses of measuring cutting forces during the machining process include machining economics analysis, adaptive control applications, and numerical modeling of the machining process. As machining responses, cutting forces are studied in various machining processes. Models of cutting forces are formulated to correlate between the machining parameters to cutting forces. The empirical models are based on the established machining theory.

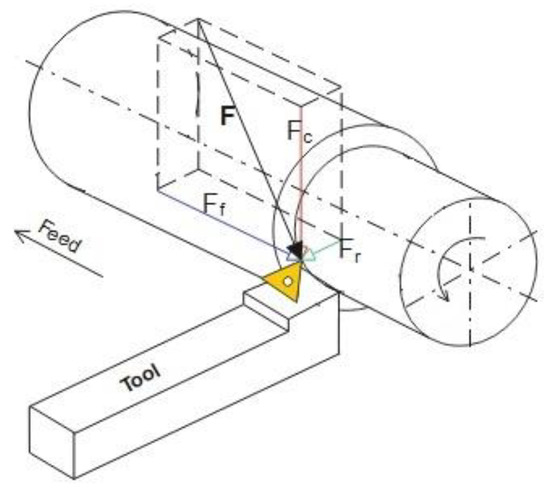

There are three cutting force components of the cutting force (F) in a turning process, which are designated according to the direction of the cutting tool’s relative movement to the workpiece (Figure 1). The cutting force components are tangential force (Fc) in the direction of the main cutting action, radial force (Fr) in the direction toward the axis of the workpiece, and feed force (Ff) in a parallel direction to the workpiece axis [16,17].

Figure 1.

Cutting force components in the turning process, where F is resultant cutting force, Fc tangential force, Fr radial force, and Ff feed force.

During the turning process, power consumption can be an indicator of tool conditions and as a design criterion of the machining input. To determine the power consumption, which is calculated as the product of the cutting force and the cutting speed, only the tangential cutting force is considered for the former. This simplification was rooted in the use of orthogonal cutting theory in the relationship between machining power and cutting force. It is a common practice that tangential cutting force is used to represent the cutting force considering it makes the majority among the three force components [13,18,19].

However, we observed that for finish turning processes of steels, where the depth of cut is low—at times even lower than the nose radius of the cutting tool—the radial and feed forces are not negligible [16,17,18]. The feed force is indeed the lowest among the three, but its value is not that small. In some works, the radial force is even higher than the tangential cutting force for some cutting parameters [15,18]. Hence, in this study, the cutting force (F) which is the resultant of all three force components is used. It can be calculated by Equation (1),

where Pc is the power consumption (W), vc is the cutting speed (m/min), and F is the resultant cutting force (Newton).

Pc = vc·F

Studies on determining the machining process’s energy consumption commonly differentiate the electrical energy consumption in the idle, run-time, and production modes [10,11]. Idle mode is when the machine is ready for or in between machining. Although no material removal action is performed, there is still constant energy consumption in standby mode (for example, for the operation panel and fans). Run-time mode is when the auxiliaries are on (e.g., motor for the spindle and pump for the cutting fluid) but there is no material removal action. This consumes constant energy. Production mode is when the material removal action occurs. It varies and depends on the applied load towards the machine.

Factors that affect energy consumption include cutting parameters, cutting tools, and workpiece material [16,17,18,19,20]. Studies found that compared to the total energy consumption, the energy consumption during production mode where material removal action occurs is small [21,22] Considering this, efforts to lower energy consumption are focused more on reducing the constant energy. Some approaches include specific components improvement or overall cycle time reduction [5,23].

We agree with the approach proposed in a previous study [6] that the total energy consumption (E) for the turning process is a summation of the energy consumption during setup (E1), when performing material removal (E2), for tool change (E3), to fabricate the cutting tool (with all its cutting edges) (E4) and in the manufacture of the workpiece material (E5). Considering that the workpiece material is given depending on the product and the machine shop has limited control over the energy contained in the particular workpiece material, this factor can be omitted during the machining process itself.

From the above, for the turning process, the total energy can be calculated as Equation (2),

where E1 is the energy used during machine setup. It can be calculated as a product of the setup time and the corresponding power consumption, as shown in Equation (3),

where P0 is the power (W) in idle and run-time modes and t1 is the time (s) required for machine setup.

E = E1 + E2 + E3 + E4

E1 = P0·t1

E2 is the machining energy consumption. It is calculated by multiplying the actual machining time by the corresponding power consumption (Equation (4)) [21],

E2 = (Po + Pc)·tc.

Thus, the Equation for machining energy consumption becomes Equation (6),

E2 = (Po + F·vc)·t2.

E3 is the energy used during the replacement of a tool and is calculated as a product of the time required for tool changes and the associated power. In the turning process, tool replacement is conducted manually or using an automated tool changer, both of which occur when the tool is retracted away from the workpiece. Thus, it can be assumed that the energy used during the replacement of the tool is as much as the power when the machine is in a no-load position, which is Equation (7).

E4 can be calculated as the sum of energy consumed to fabricate each cutting edge (yE) on a cutting tool. Note that cutting tools in the form of indexable inserts usually have multiple cutting edges. So, this energy should be divided by the number of edges needed to perform the turning process (Equation (8)),

where yE can be obtained from the total energy per insert (MJ) for material and manufacturing process and that refer to [24].

Based on the description above, the Equation to calculate the energy consumed in a turning process can be written as Equation (9),

or as Equation (10),

E = P0·t1 + (Po + Fc·vc)·t2 + P0·t3+ yE

Based on both Equations (9) and (10), the total energy consumption is only distinguished in the calculation of energy during the actual cutting process (E2), which is categorized as the variable factor. Other factors, i.e., E1, E3, and E4 are the same for both Equations (9) and (10) and are considered as constant factors in energy consumption calculation [6].

3. Case Study

3.1. Experimental

As a case study, a previous experiment [25] is referred to. Briefly, it is a hard turning process of stainless steel using a coated carbide tool in a two-axis CNC lathe machine rated at 5.5 kW with a varied cutting speed of 100, 130, and 170 m/min, with a varied feed of 0.1, 0.125, and 0.16 mm, and with a constant depth of cut of 0.4 mm. In determining the lower and upper values of the cutting parameters, the recommendation by the cutting tool manufacturer for finish turning a stainless steel workpiece with a hardness of up to 48 HRC was considered (ASSAB Steel, Shah Alam, Malaysia). As the depth of cut was 0.4 mm, the selected lower and upper limit values for cutting speed were 100 and 170 m/min, respectively, and for feed were 0.1 and 0.16 mm, respectively. The middle values were 130 m/min for cutting speed and 0.125 mm for feed. The turning process was performed dry (without any cutting fluid). The workpiece material was an AISI 420 martensitic stainless steel, with a chemical composition of 0.38% C, 13.6% Cr, 0.3% V, 0.9% Si, 0.5% Mn, and balance Fe (ASSAB Steel, Shah Alam, Malaysia). The stainless steel was expected to have corrosion resistance, stability at a hardened state, and to result in a fine surface finish for plastic mold applications. The stainless steel was hardened throughout by heat treatment to reach a hardness value of 47–48 HRC. Before the machining trial, the workpiece surface was finish turned using the last set of cutting parameters. The cutting tool used for the experiment was a TiAlN coated carbide tool (Kennametal, Shah Alam, Malaysia) that is designated as CNMG 120408. The cutting tool was a fine-grained WC-6% Co substrate coated with 3.0 to 35 m thick TiAlN through physical vapor deposition. The cutting tool was mounted on a holder with an ISO designation of MCLNL 1616-H12, giving the 10° rake angle, −5° side cutting edge angle, and 5° relief angle. The positive rake angle—commonly hard turning sets negative rake angle—was due to the tool has a 15° chip breaker profile, despite the tool holder actually positions the cutting tool at −5° angle. The tool wear was measured according to ANSI/ASME B94.55M-1985 standard, subjected to the maximum flank wear width (VBmax) within the nose radius of the tool (zone C). An optical microscope (Stemi 200-C, Carl Zeiss, Petaling Jaya, Malaysia) with an image analyzer was used for this purpose. Surface roughness (Ra) was measured by a surface profilometer (Accretech Handysurf, Tokyo Seimitsu, Tokyo, Japan) at 0.8 mm cut off length and 4 mm sampling length in each measurement. The tool life criteria were at a maximum of 0.14 mm of flank wear width, at the machined surface roughness Ra beyond 1.6 μm, or severely damaged cutting tool.

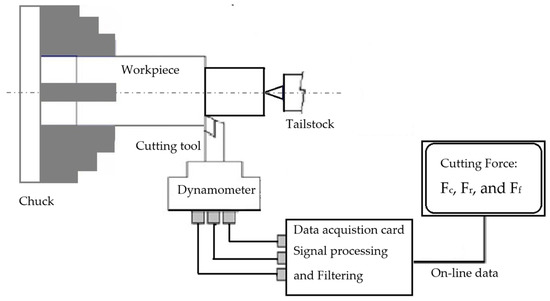

The experiments measured the cutting force elements in all three directions (Fc, Fr, and Ff is the schematic layout below (Figure 2). A three-component turning dynamometer (Kistler, Type 9265B, Singapore) with data acquisition software was used for this purpose. For measuring the electrical power consumption of the turning process, three portable power monitors (Omron ZN-CTX21, Johor Bahru, Malaysia) with three clamp meters (Omron ZNCTM11, Johor Bahru, Malaysia) were used. One power monitor was used to measure the main power while the other two to the spindle and axis drives. The measured power data was acquired and visualized using Wave Inspire ES (Omron, Johor Bahru, Malaysia) software.

Figure 2.

Schematic layout of cutting force measurement setup.

3.2. Experimental Design

Response Surface Methodology (RSM) was chosen for the design of experiments. A commercial software (Design Expert, StatEase, Minneapolis, MN, USA) was used for this purpose. For the RSM, regression is used to approximate the machining response based on the relationship between one or more factors (input variable) and the estimated response, yest. The fitting of the model Equation was using the least square technique through residual error minimization. The model Equation and its coefficients were tested for statistical significance. Analysis of variance (ANOVA) was used for this purpose. For the case at hand, a three-level factorial design having two input factors and 2 center points was applied, making 11 runs in total (Table 1). The type 1 error (α) value was set at 0.05 for the models and its coefficients to be considered significant.

Table 1.

Factor and levels for the experiments.

4. Results and Discussion

4.1. Surface Roughness and Tool Life

The experimental results for surface roughness and tool life for all eleven trials are summarized in Table 2 [25].

Table 2.

Experimental results for surface roughness and tool life. (Note: vc is cutting speed, f feed, Ra surface roughness, and T tool life).

Based on the results of surface roughness and tool life, a selection of models using regression calculations were made [26]. The linear model was chosen for modeling the surface roughness while the quadratic model was most suitable for the tool life. The backward elimination procedure was selected to automatically reduce the terms that are not significant and the resulting ANOVA table for the reduced linear model for surface roughness and the reduced quadratic model for tool life is displayed in Table 3 [25]. The ANOVA table shows the statistics used to test the hypotheses about the population means.

Table 3.

Result of ANOVA table for tool life and surface roughness.

In an analysis of variance, the total variation in the response measurements, in this case, the surface roughness and tool life values, are partitioned into variation which can be explained by the independent variables or factor effects (Model) and the variation which is not explained by the independent variables (Residual which is also called Error). In the case of surface roughness, the model is made up of the main effects of cutting speed, x1, and feed, x2. Thus, the Sum of Squares for the independent variables, x1 and x2, add up to become the Sum of Squares for Model. Whilst the Sum of Squares for Model and Residual add up to the Total Variance.

Degrees of freedom are associated with the sources of variance. The total variance has N-1 degrees of freedom, where N is the total number of experiments. In this case, there were N = 11 experiments, so the degrees of freedom for total is 10. The degrees of freedom for the model is the sum degrees of freedom of the independent variables or factor effects which explains the variation. In the case of independent variables or factor effects, the degrees of freedom for each independent variable or factor effect is the number of levels −1. Thus, for cutting speed, the degrees of freedom is 2 − 1 = 1 and this is similar to the degrees of freedom for feed. The degrees of freedom for the model is therefore 1 + 1 = 2. The degrees of freedom residual is the degrees of freedom total minus the degrees of freedom model, which is 10 − 2 = 8. The respective Mean squares are computed by dividing the respective Sum of squares by their respective degrees of freedom. The respective F ratios are computed by dividing the respective Mean squares by the Mean square residual or error and these are used to test the significance of the predictors in the model. The p-value associated with these F values are small, 0.031 or less. The p value is compared to the alpha level (typically 0.05) and, if it is smaller, then the independent variable or factor effects is statistically significant. Therefore, the null hypothesis is rejected and the alternative hypothesis is accepted thus indicating differences in the mean values of the respective independent variables or factor effects.

The final equation, in terms of actual factors, acquired from the model for surface roughness is as in Equation (11),

where Ra is surface roughness (µm), vc is cutting speed (m/min), and f is feed (mm/rev).

Ra = 0.4793 − 0.0031·vc + 4.6513·f

For tool life, the logarithmic transformation is recommended based on the best lambda value found at the minimum point of the Box–Cox curve generated by the natural log of the sum of squares of the residuals. The final equation, in terms of actual factors, achieved from the model for tool life can be expressed as in Equation (12),

where T is tool life (min) and the other variables were as defined previously.

Ln T = 13.4177 − 0.1297·vc − 9.8739·f + 0.0004·vc2

4.2. Cutting Force

The experimental results for cutting force and the respective calculated machining energy for all trials are summarized in Table 4. The machining time t2 is the tool life in second. F is the resultant cutting force calculated from the measured tangential force Fc, radial force Fr, and feed force Ff. The trend in cutting force values where the feed force is the lowest among the three force components and where the radial force is higher than the tangential force at some cutting parameters is in agreement with previous work on the hard turning of AISI 5140 (55 ± 1 HRC hardness) using CBN (cubic boron nitride) tool at 150–300 m/min cutting speed, 0.05–0.2 mm feed, and 0.2 mm depth of cut [15].

Table 4.

Experimental results for cutting force and machining energy. (Note: vc is cutting speed, f feed, t2 tool life (in second), Fc tangential force, Fr radial force, Ff feed force, F resultant cutting force, E2 calculated machining energy based on Equation (6), and E2# calculated machining energy based on Equation (4)).

The model selection and its subsequent reduction as well as the empirical Equation development for cutting force were performed in the same manner as those for surface roughness and tool life [25]. The resulting ANOVA is as shown in Table 5.

Table 5.

Result of ANOVA for cutting force F.

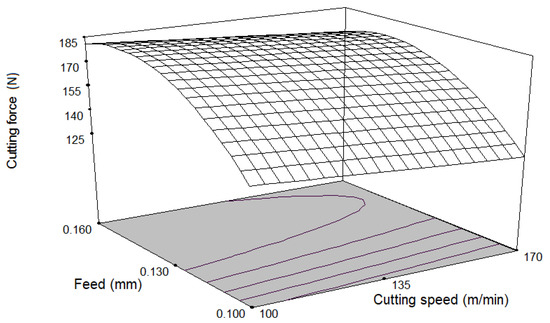

The final Equation obtained from the model for cutting force can be expressed in terms of actual factors as in Equation (13),

where F is the resultant cutting force (N).

F = −299.88 − 0.17·vc + 6895.59·f − 23667.19·f2

The final model Equation for cutting force can be shown as a 3D contour graph (Figure 3). From Equation (13) and Figure 3, it can be observed that the cutting force is affected significantly first by the feed and second by the cutting speed. Generally, the feed is proportional to the cutting force while the cutting speed is inversely proportional to the cutting force. The proportionality relation between feed and cutting force is as expected since feed increase means the higher surface area of the workpiece to machine by the cutting tool [25]. The finding on cutting speed effect to cutting force was analyzed to be due to the higher cutting temperature at high cutting speed softened the workpiece and there was a transition from low to high cutting speed indicated by the change in chip type from continuous to segmented [25].

Figure 3.

Response surface graph of 3D surface for F.

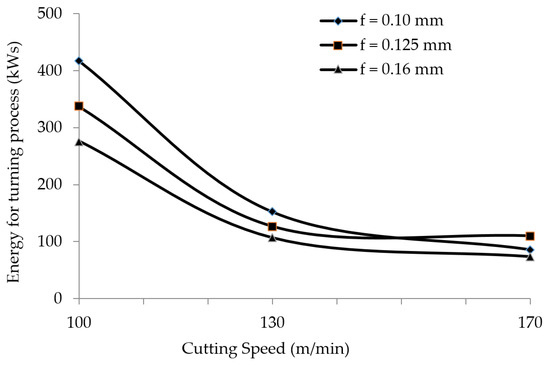

4.3. Energy Consumption

The maximum energy for the turning process (E2) was calculated using cutting force data, as in Equation (6). The power consumption in idle and run-time modes P0 was measured to be 1925 W. The maximum energy for the turning process, E2, of 417.11 kWs was shown by the lowest of cutting speed and feed, while the minimum energy for the machining process (73.8 kWs) for cutting speed and feed rate is high (Figure 4). We calculated that E1, E3, and E4 were 3.85 kWs, 5.58 kWs, and 1325 kWs, respectively. Compared to the total machining energy, the actual machining energy E2 is low (5–20% of total energy), in agreement with a previous study [21,22].

Figure 4.

Energy for turning process (E2) at various cutting speeds and feed.

For comparison, we also calculated E2 using Equation (4), with specific machining energy k 3.5 Ws/mm3 and material removal rate (in mm3/s) calculated by multiplying cutting speed, feed, and depth of cut. We found that the values are comparable with the machining energy E2 calculated using resultant cutting force as proposed in this study. Had the tangential cutting force was used like in the conventional approach instead of resultant cutting force, the calculated machining energy E2 will be 57–70% of the calculated values in this study.

The quadratic model was chosen to represent the data of E2 because it has the least probabilistic value. ANOVA of the selected regression model and its coefficients was performed (Table 6).

Table 6.

ANOVA for machining energy consumption (E2).

The final Equation obtained from the machining energy consumption can be expressed in terms of actual factors as in Equation (14),

where E2 is machining energy consumption (kWs).

E2 = 2949.55 – 33.00·vc – 4851.99·f + 0.0954·vc2 + 28.26·vc·f

Equation (14) shows that the lower machining energy (E2) can be obtained by choosing higher feed and cutting speed. This result is in agreement with the previous work on the hard turning of steel that also resulted in the highest machining energy was at the lowest cutting speed and feed while the lowest machining energy was at the highest cutting speed and feed [15]. In addition, for the turning of unhardened steel (AISI 1045), it was reported that lower feed and depth of cut increases the machining energy [14].

It should be noted that the results of machining energy calculation proposed for finish hard turning of steel in this study have not been tested extensively. Nevertheless, for this particular case study where an AISI 420 martensitic stainless steel (47–48 HRC hardness), turned using a TiAlN coated carbide mounted on a particular tool holder, with parameters set at a constant depth of cut and cutting speed and feed within their particular ranges, without cutting fluid, the results are encouraging. The machining energy can be calculated and an empirical model can be developed based on the results, within the cutting speed and feed range. In addition to the cutting speed and feed themselves, the interaction between cutting speed and feed was found to affect the machining energy. This indicates that when any of the machining conditions change, the trend showed by the modified model of machining energy might change as well.

4.4. Optimum Cutting Parameters for the Case Study

Having all empirical models for surface roughness, tool life, cutting force, and machining energy consumption; optimization can be performed to determine the suitable cutting parameters that result in preferred machining responses. Some things to consider related to machining responses are:

- hard turning as a final operation must produce a smooth surface finish to meet customer demand for the geometric accuracy of machined components

- the machine shop would prefer the cutting tools to last longer

- cutting force should be low to minimize damage on the machined surface, and

- energy consumption should be minimized for each workpiece volume removed.

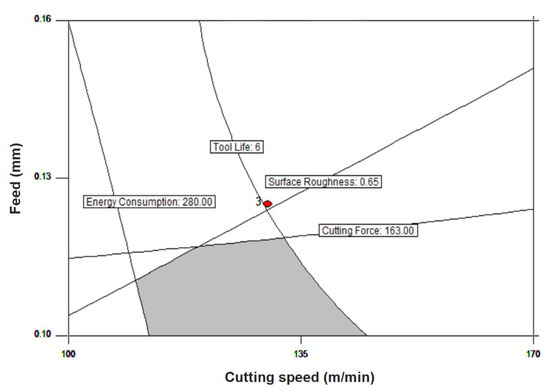

As mentioned above, some machining responses require contradicting cutting parameter settings. Therefore, a compromise solution is necessary to select the cutting parameters. A relatively straightforward approach that is used to optimize several responses is to overlay or superimpose the contour plots for each response. This can be performed using the Graphical Optimization function of the statistical software. Based on this approach and using Equations (11)–(14), the overlay plot as shown in Figure 5 is obtained. The criteria for optimizing the responses are then specified and incorporated into the overlay plot. As an example, if it was preferred that the surface roughness produced should be less than 0.65 μm, the coated carbide tools should last at least six minutes, the cutting force should be less than 163 N, and the machining energy consumption should be less than 280 kWs, then, the shaded, grey region represents the combinations of cutting speed and feed fulfilling the criteria specified. This region can be visually examined further to determine the appropriate operating conditions to be utilized.

Figure 5.

Overlay plot of the predetermined response criteria of T not less than 6 min, and Ra, FC, and E2 of not more than 0.65 μm, 163 N, and 280 kWs, respectively.

Derringer and Suich [27] proposed another approach to optimizing several responses using the simultaneous optimization technique which makes use of the desirability functions [28]. Here, each response yi is first converted into an individual desirability function di that varies over the range 0 ≤ di ≤ 1. If the objective or target T for the response y is a maximum value then (Equation (15))

where L is the lower limit. On the other hand, if the objective or target T for the response y is a minimum value then (Equation (16))

where U is the upper limit. The design variables are chosen to maximize the overall desirability D (Equation (17))

where there are m responses. The overall desirability will be zero if any of the individual responses is undesirable.

The Numerical Optimization function of the statistical software can be utilized to solve the previous example using the desirability function approach. The optimization criteria for the responses are set to minimize E2, subject to Ra ≤ 0.65 μm, T ≥ 6 min, and F ≤ 163 N. Based on these criteria, the optimum cutting speed is 132.42 m/min and feed is 0.12 mm, at the desirability of 0.93. At this optimum cutting parameters, the surface roughness Ra is predicted to be 0.62 μm, tool life T is 6 min, resultant cutting force F is 163 N, and the machining energy E2 will be 121 kWs.

5. Conclusions

This study proposes the use of the resultant cutting force (instead of the tangential cutting force in the conventional approach) for calculating the machining energy consumption in the finish turning process of hardened steels where typically the depth of cut is lower than the cutting tool nose radius. A case study was carried out where a hardened AISI 420 stainless steel (47–48 HRC hardness) was turned using a coated carbide tool, with a nose radius of 0.8 mm, without cutting fluid, and at 0.4 mm depth of cut, 100, 130, and 170 m/min cutting speed, and 0.10, 0.125, and 0.16 mm feed. Machining responses in addition to the machining energy E2 were surface roughness Ra, tool life T, and resultant cutting force F. Empirical models of the machining responses were developed using response surface methodology. The following were obtained.

- For the cutting forces, the tangential force was lower than the radial force at some cutting parameters and the feed force is the lowest among the three force components. This is typical for finish turning.

- The cutting speed is inversely proportional to the cutting force while the feed is proportional to the cutting force.

- Machining energy is inversely proportional to the cutting speed and the feed. There was also an effect of the interaction between cutting speed and feed to the machining energy.

- Comparison with another machining energy calculation approach using specific machining energy and material removal rate found the calculated machining energy using resultant cutting force proposed in this study to be similar. When the conventional approach was used where the tangential cutting force was used, the calculated machining energy will be much lower (57–70%) than the proposed approach’s values.

- Through optimization to minimize E2, subject to Ra ≤ 0.65 μm, T ≥ 6 min, and F ≤ 163 N, it was found that for the particular finish hard turning, the optimum cutting parameters were cutting speed is 132.42 m/min and feed is 0.12 mm.

Author Contributions

Conceptualization, R.N., N.M.Y., I.S., and D.K.; methodology, R.N., N.M.Y., I.S., and D.K.; formal analysis, R.N., N.M.Y., I.S., and D.K.; writing—original draft preparation, R.N., N.M.Y., and D.K.; writing—review and editing, R.N., N.M.Y., I.S., F.M.N., and D.K.; supervision, N.M.Y., I.S., and D.K.; funding acquisition, N.M.Y. and F.M.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Higher Education, Malaysia. The APC was funded by the State Government of Sarawak, Malaysia through the Sarawak Convention Bureau.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jawahir, I.S.; Schoop, J.; Kaynak, Y.; Balaji, A.K.; Ghosh, R.; Lu, T. Progress toward modeling and optimization of sustainable machining processes. J. Manuf. Sci. Eng. 2020, 142, 110811. [Google Scholar] [CrossRef]

- Dahmus, J.B.; Gutowski, T.G. An environmental analysis of machining. ASME Int. Mech. Eng. Congr. Expo. 2004, 47136, 643–652. [Google Scholar]

- Grzesik, W. Advanced Machining Processes of Metallic Materials: Theory, Modelling and Applications; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Munoz, A.A.; Sheng, P. An analytical approach for determining the environmental impact of machining processes. J. Mater. Proc. Technol. 1995, 53, 736–758. [Google Scholar] [CrossRef]

- Choi, A.C.K.; Kaebernick, H.; Lai, W.H. Manufacturing processes modelling for environmental impact assessment. J. Mater. Proc. Technol. 1997, 70, 231–238. [Google Scholar] [CrossRef]

- Kara, S.; Li, W. Unit process energy consumption models for material removal processes. CIRP Ann. Manuf. Technol. 2011, 60, 37–40. [Google Scholar] [CrossRef]

- Hu, S.; Liu, F.; He, Y.; Hu, T. An on-line approach for energy efficiency monitoring of machine tools. J. Clean. Prod. 2012, 27, 133–140. [Google Scholar] [CrossRef]

- He, Y.; Liu, B.; Zhang, X.; Gao, H.; Liu, X. A modeling method of task-oriented energy consumption for machining manufacturing system. J. Clean. Prod. 2012, 23, 167–174. [Google Scholar] [CrossRef]

- Sihag, N.; Sangwan, K.S. A systematic literature review on machine tool energy consumption. J. Clean. Prod. 2020, 275, 123125. [Google Scholar] [CrossRef]

- Vijayaraghavan, A.; Dornfeld, D. Automated energy monitoring of machine tools. CIRP Ann. Manuf. Technol. 2010, 59, 21–24. [Google Scholar] [CrossRef]

- Rajemi, M.F.; Mativenga, P.T.; Aramcharoen, A. Sustainable machining: Selection of optimum turning conditions based on minimum energy considerations. J. Clean. Prod. 2010, 18, 1059–1065. [Google Scholar] [CrossRef]

- Bartarya, G.; Choudhury, S.K. State of the art in hard turning. Int. J. Mach. Tools Manuf. 2012, 53, 1–14. [Google Scholar] [CrossRef]

- Astakhov, V.P.; Xiao, X. A methodology for practical cutting force evaluation based on the energy spent in the cutting system. Mach. Sci. Technol. 2008, 12, 325–347. [Google Scholar] [CrossRef]

- Li, W.; Kara, S. An empirical model for predicting energy consumption of manufacturing processes: A case of turning process. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2011, 225, 1636–1646. [Google Scholar] [CrossRef]

- Chudy, R.; Grzesik, W.; Zak, K. Influence of machining conditions on the energy consumption and productivity in finish hard turning. In Advances in Manufacturing; Springer: Cham, Switzerland, 2018; pp. 697–705. [Google Scholar]

- Elmunafi, M.H.S.; Noordin, M.Y.; Kurniawan, D. Effect of cutting speed and feed in turning hardened stainless steel using coated carbide cutting tool under minimum quantity lubrication using castor oil. Adv. Mech. Eng. 2015, 7, 1–7. [Google Scholar] [CrossRef]

- Huang, Y.; Liang, S.Y. Cutting forces modeling considering the effect of tool thermal property—application to CBN hard turning. Int. J. Mach. Tool Manuf. 2003, 43, 307–315. [Google Scholar] [CrossRef]

- Grzesik, W.; Denkena, B.; Żak, K.; Grove, T.; Bergmann, B. Energy consumption characterization in precision hard machining using CBN cutting tools. Int. J. Adv. Manuf. Technol. 2016, 85, 2839–2845. [Google Scholar] [CrossRef][Green Version]

- Zorev, N.N. (Ed.) Metal Cutting Mechanics; Pergamon Press: Oxford, UK, 1966. [Google Scholar]

- Nur, R.; Noordin, M.Y.; Izman, S.; Kurniawan, D. Machining parameters effect in dry turning of AISI 316L stainless steel using coated carbide tools. Proc. Inst. Mech. Eng. E J. Process. Mech. Eng. 2017, 231, 676–683. [Google Scholar] [CrossRef]

- Gutowski, T.; Dahmus, J.; Thiriez, A. Electrical energy requirements for manufacturing processes. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belgium, 31 May–2 June 2006; Volume 31, pp. 623–638. [Google Scholar]

- Li, W.; Zein, A.; Kara, S.; Herrmann, C. An investigation into fixed energy consumption of machine tools. In Glocalized Solutions for Sustainability in Manufacturing; Springer: Berlin, Germany, 2011; pp. 268–273. [Google Scholar]

- Mori, M.; Fujishima, M.; Inamasu, Y.; Oda, Y. A study on energy efficiency improvement for machine tools. CIRP Ann. Manuf. Technol. 2011, 60, 145–148. [Google Scholar] [CrossRef]

- Walsh, R.A. Handbook of Machining and Metalworking Calculations; McGraw-Hill Education: New York, NY, USA, 2001. [Google Scholar]

- Noordin, M.Y.; Kurniawan, D.; Tang, Y.C.; Muniswaran, K. Feasibility of mild hard turning of stainless steel using coated carbide tool. Int. J. Adv. Manuf. Technol. 2012, 60, 853–863. [Google Scholar] [CrossRef]

- Ambhore, N.; Kamble, D. Experimental investigation of tool wear and induced vibration in turning high hardness AISI52100 steel using cutting parameters and tool acceleration. Facta Univ. Mech. Eng. 2020, 18, 623–637. [Google Scholar]

- Derringer, G.; Suich, R. Simultaneous optimization of several response variables. J. Qual. Technol. 1980, 12, 214–219. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).