Oversizing Thread Diagnosis in Tapping Operation

Abstract

:1. Introduction

2. Materials and Methods

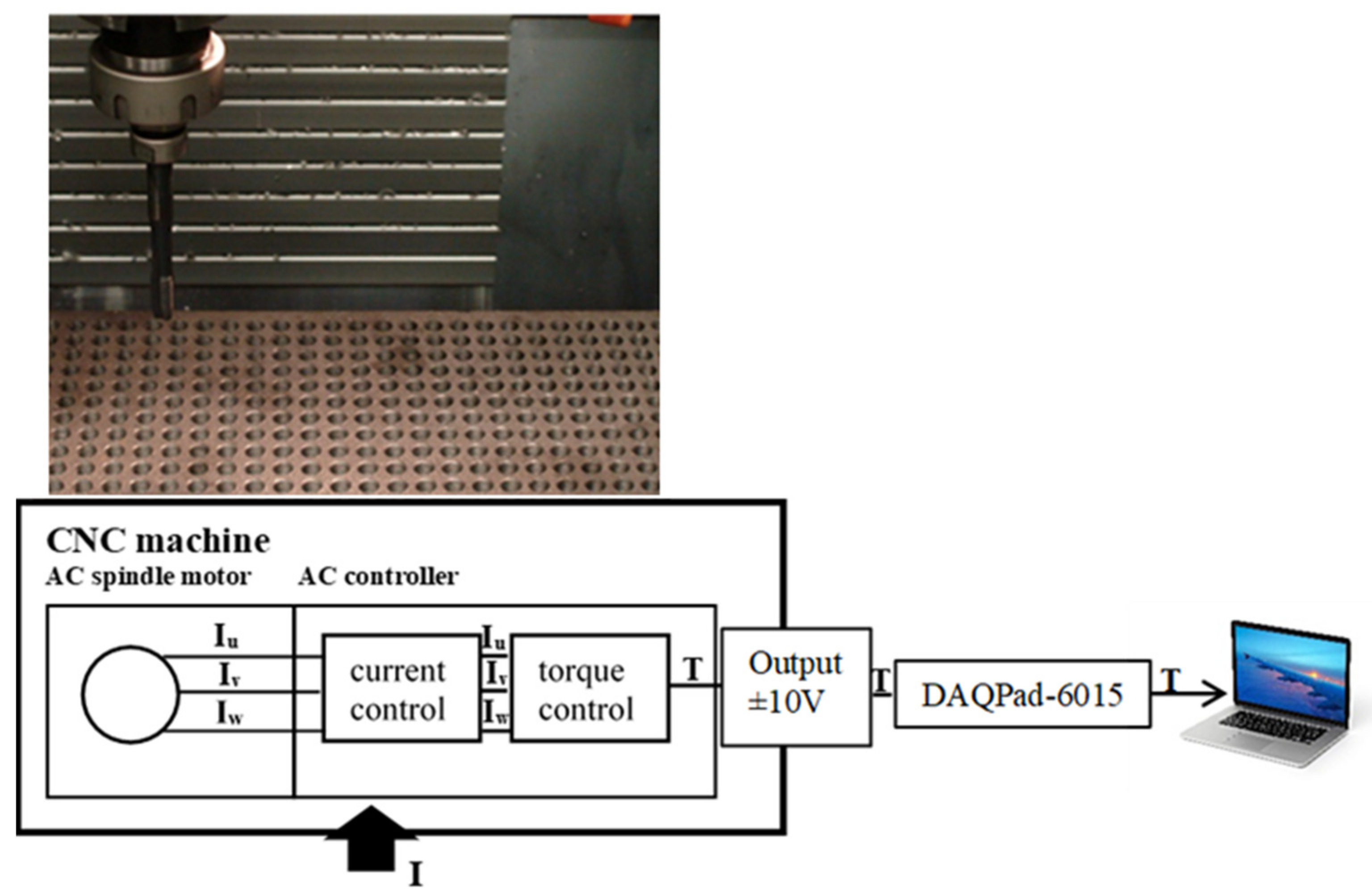

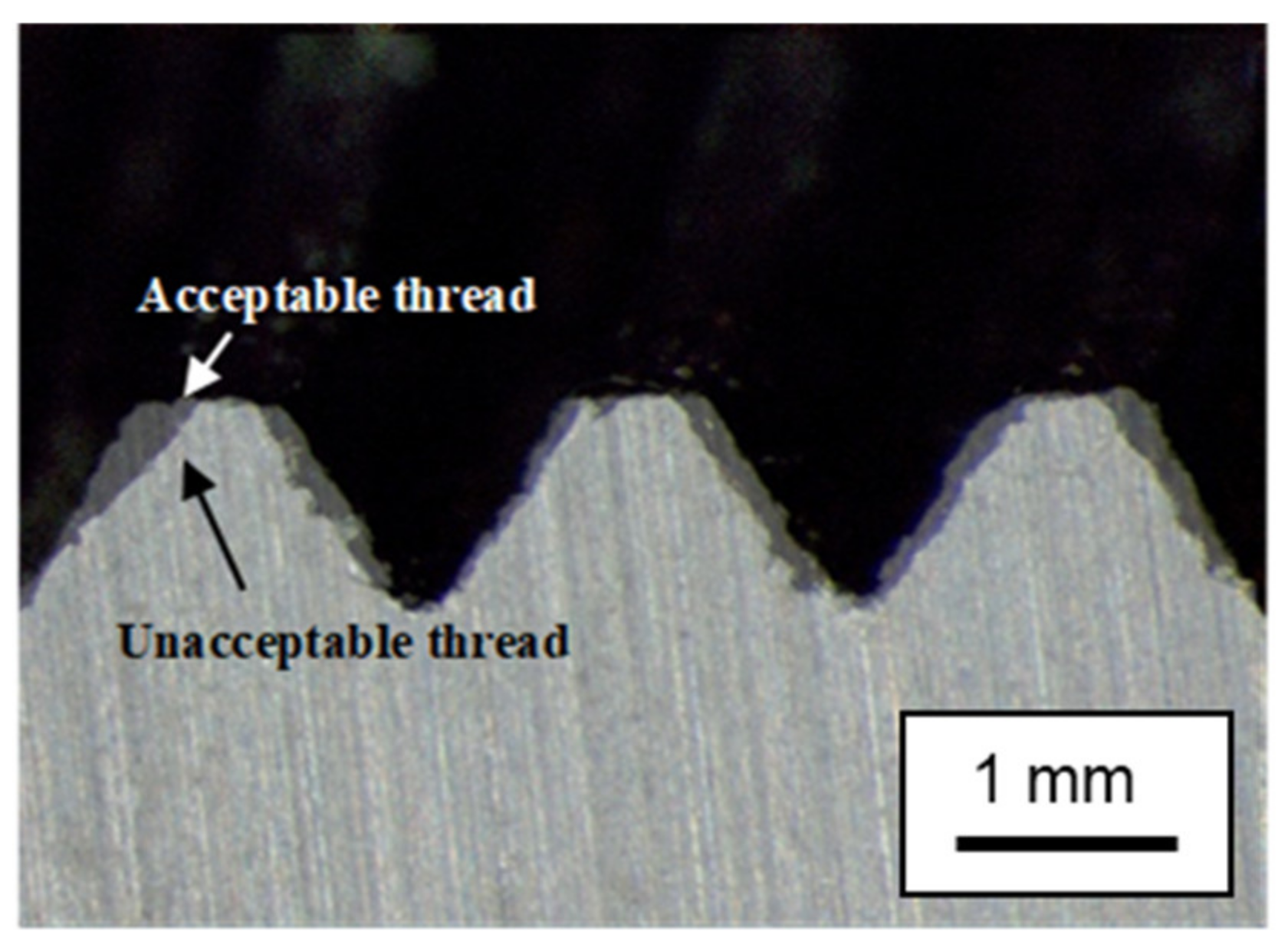

2.1. Measurement Configuration and Thread Quality

2.2. Torque Parameter Selection

3. Theoretical Background

3.1. Principal Component Analysis (PCA)

3.2. Statistical Process Control (SPC)

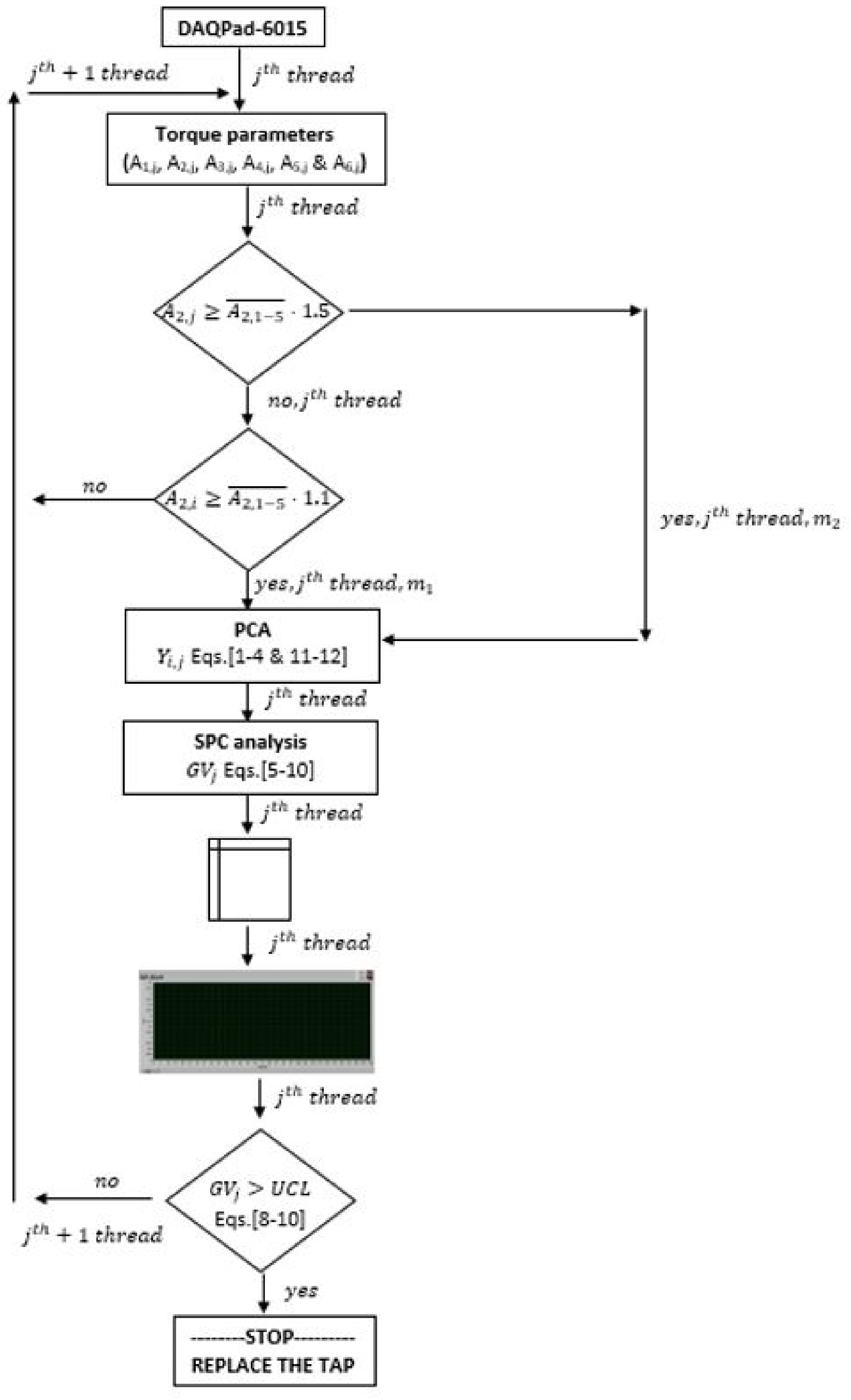

4. Diagnosis Strategy

5. Results

5.1. Measurement Results

5.2. PCA Results

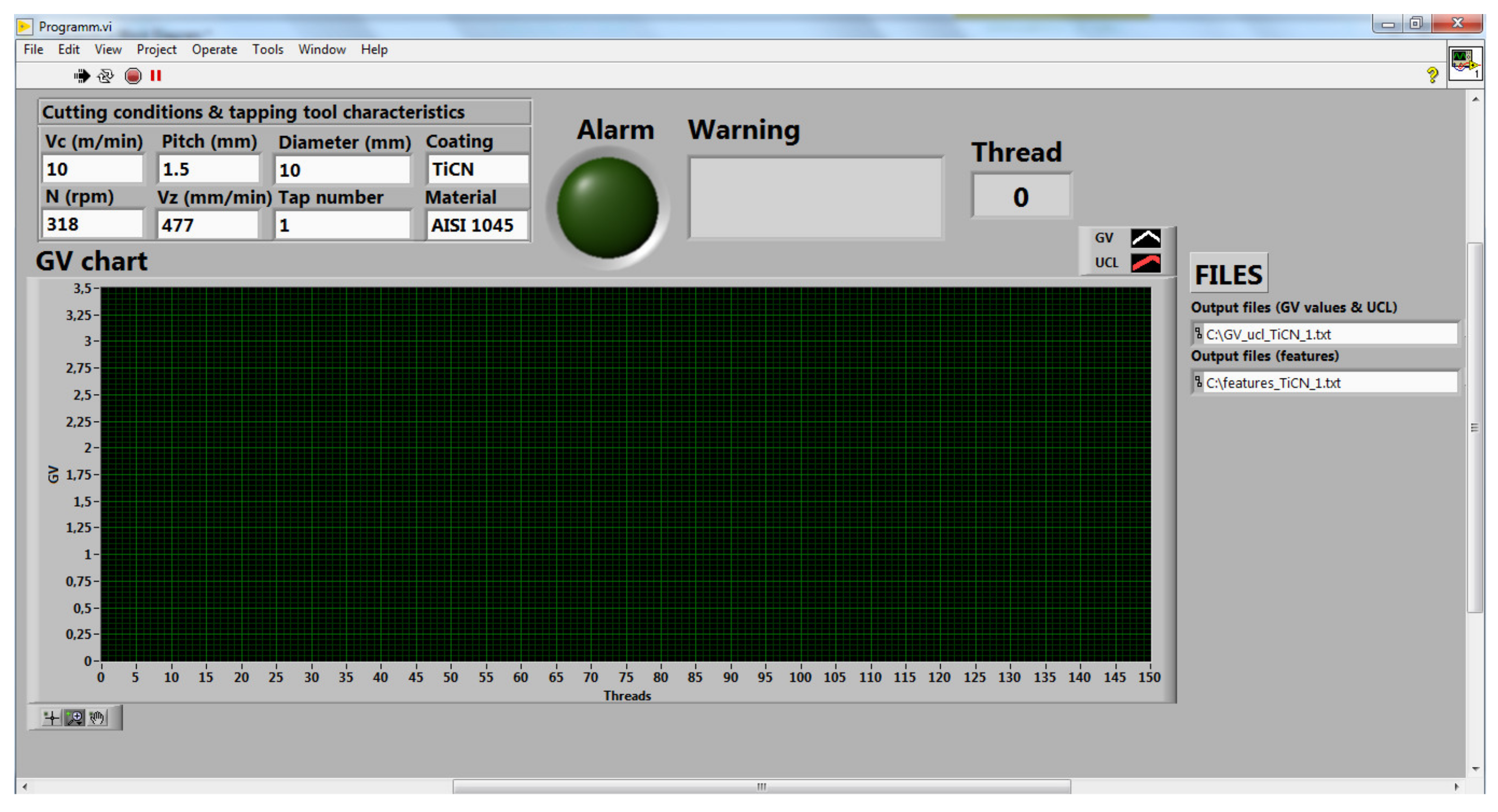

5.3. Results of Diagnosis System

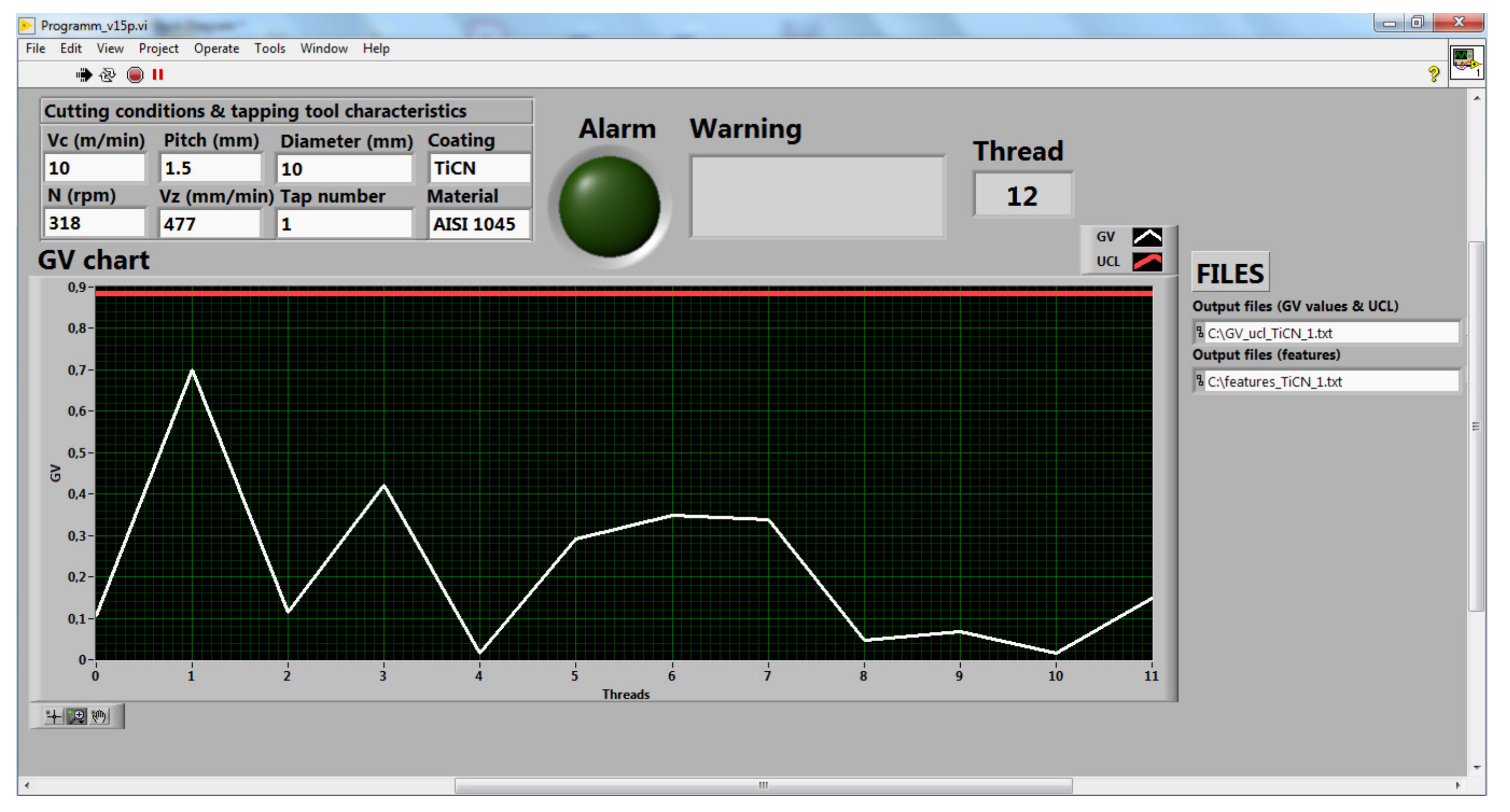

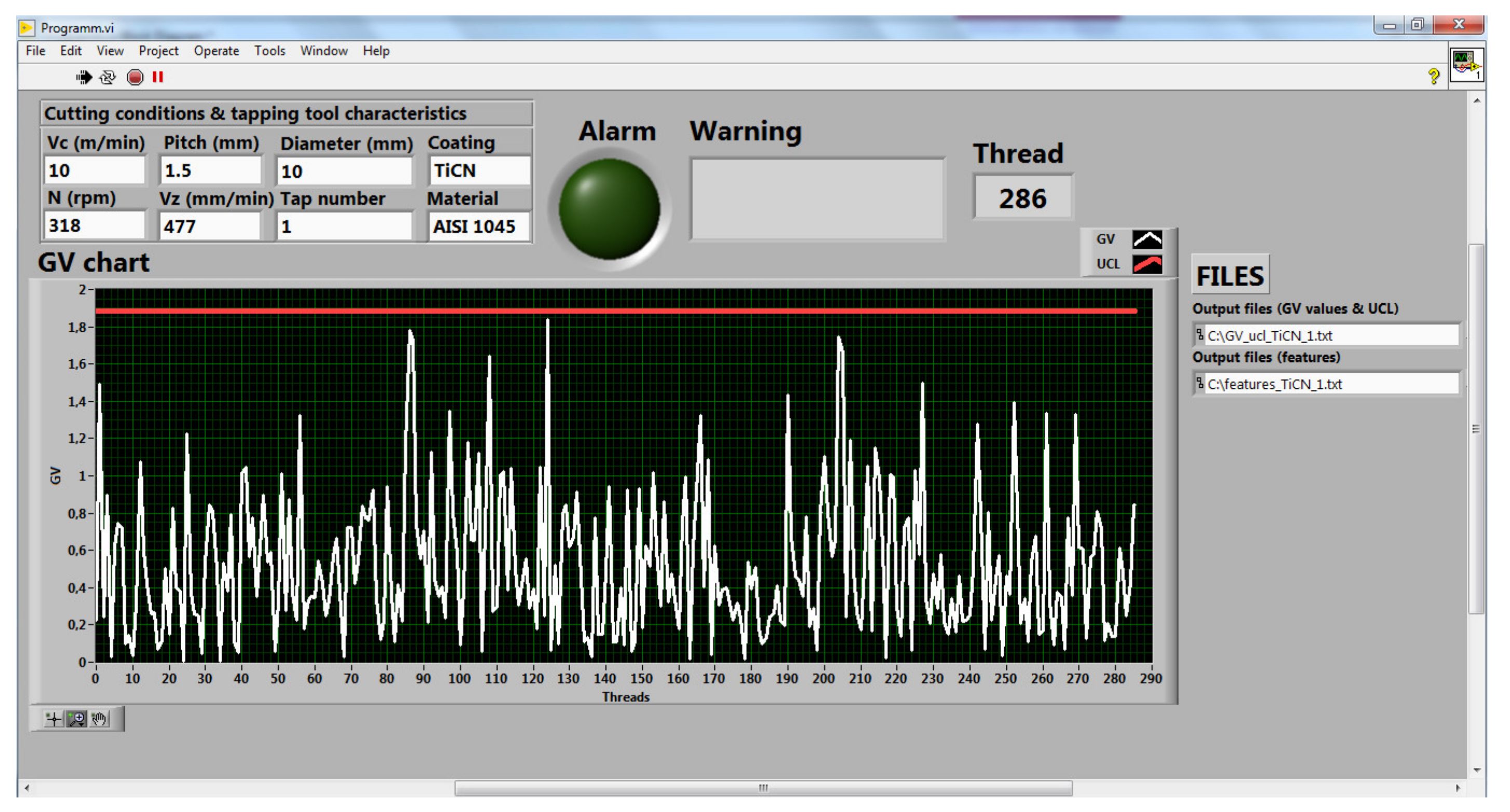

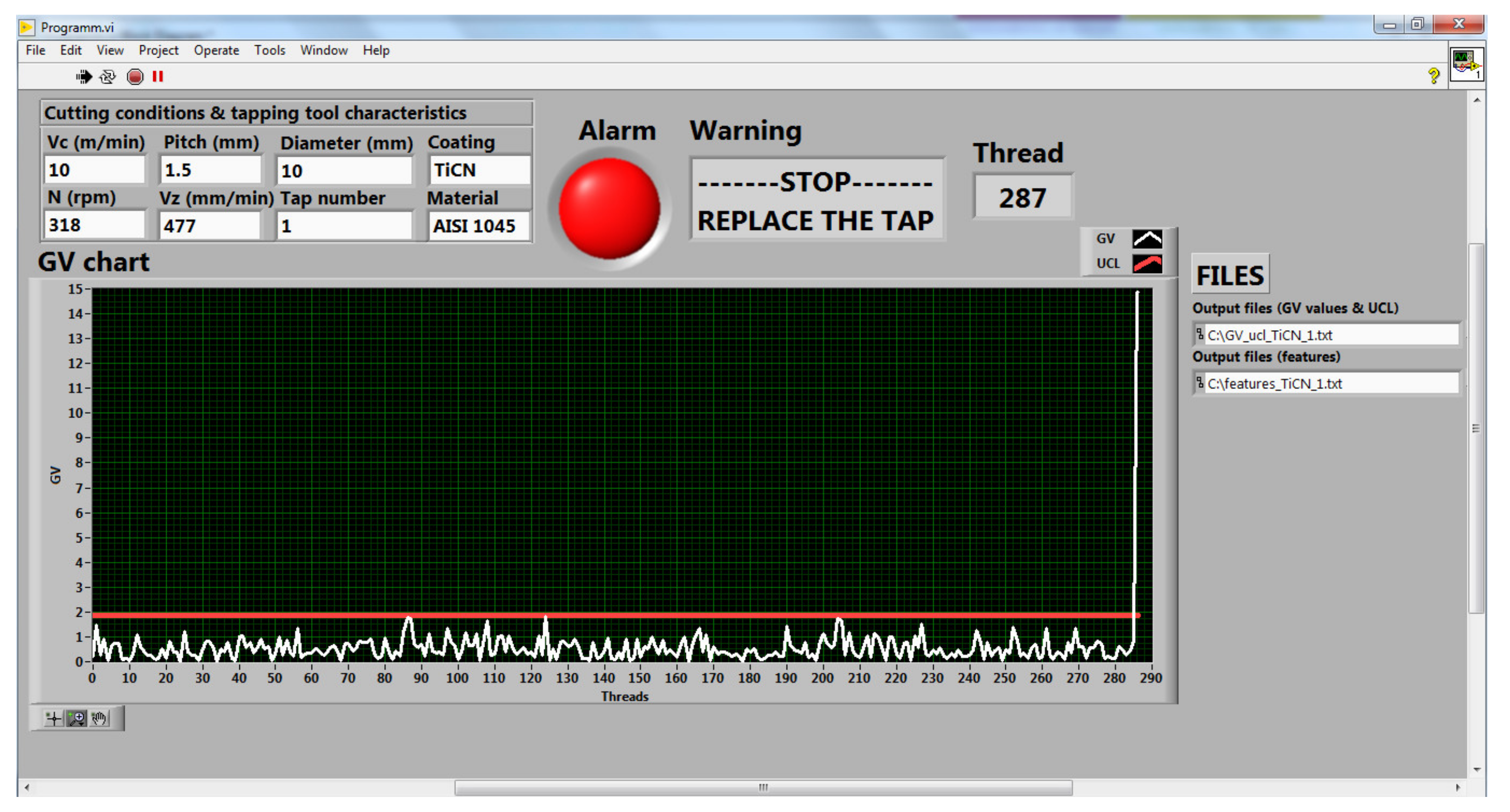

5.3.1. Multivariate Control Chart Tapping in AISI 1045

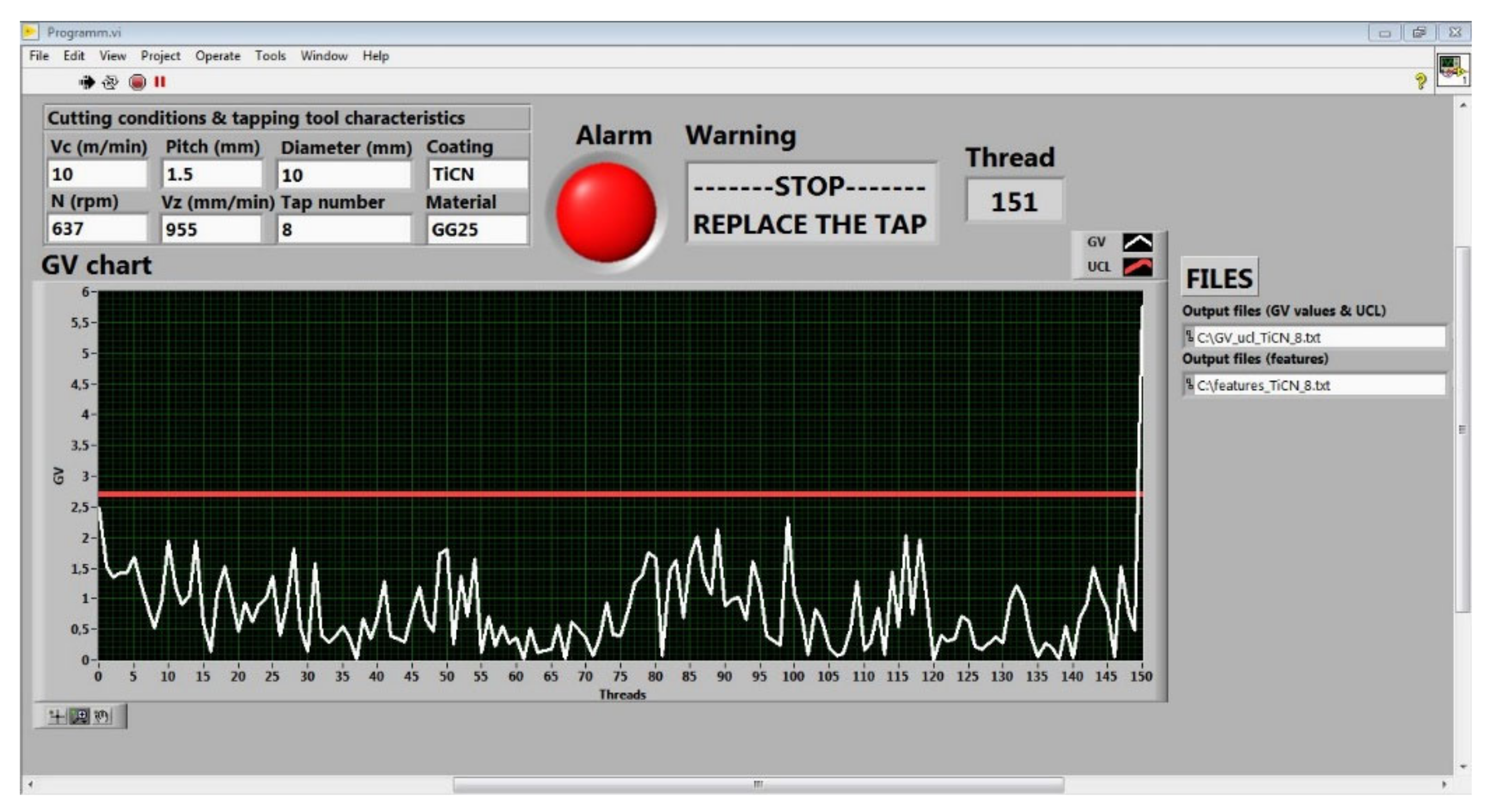

5.3.2. Multivariate Control Chart Tapping in Grey Cast Iron (GG25)

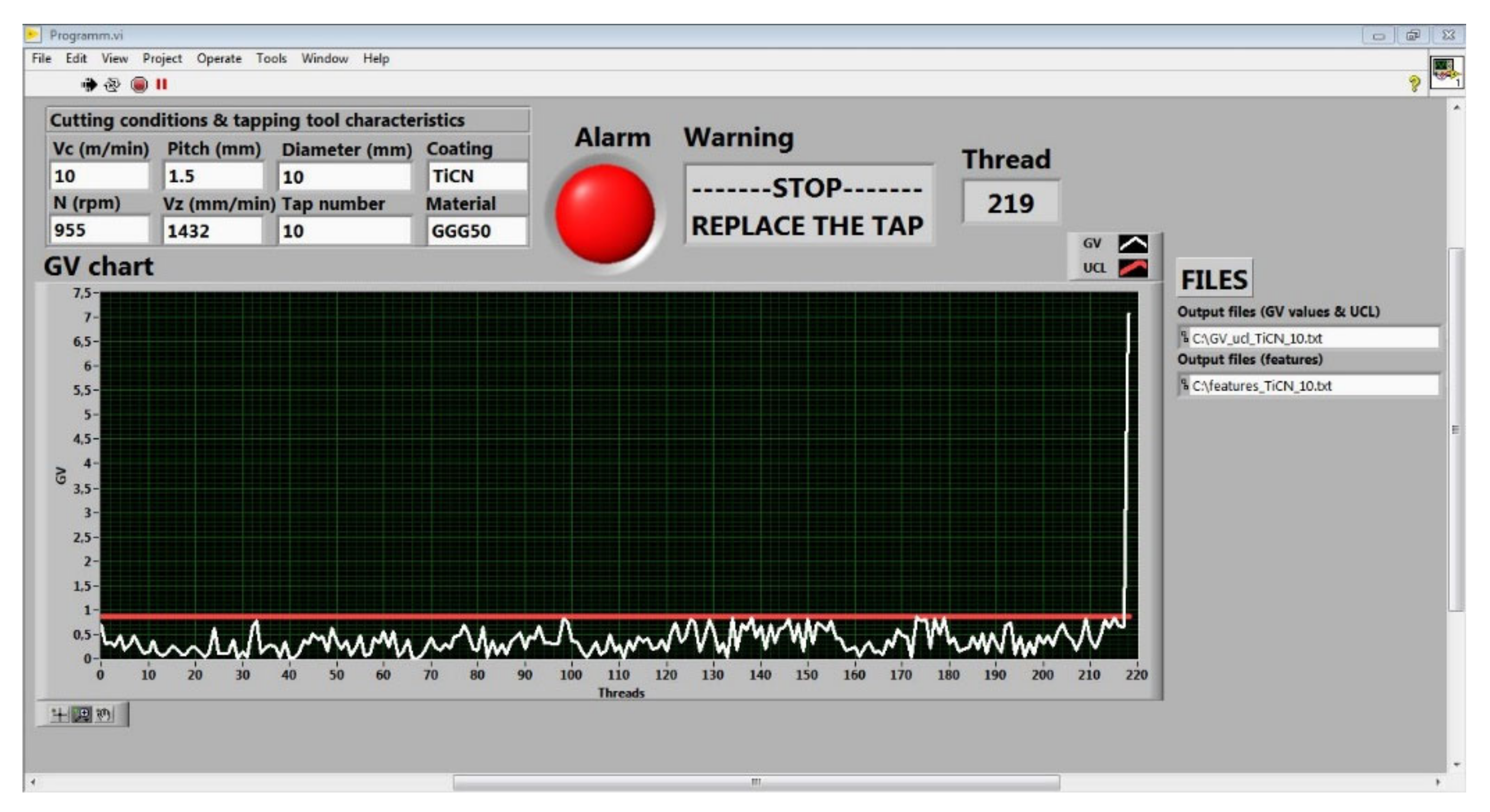

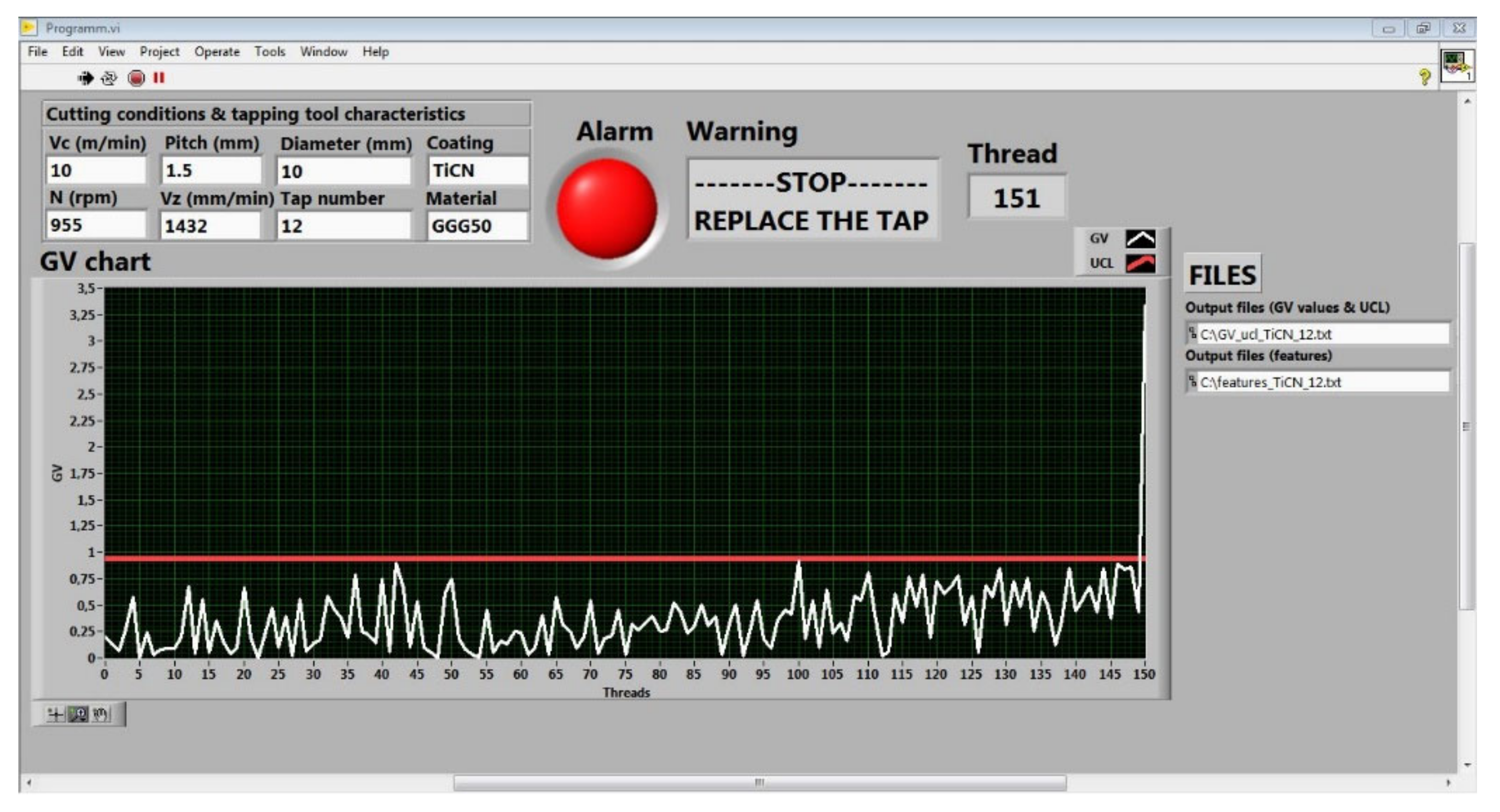

5.3.3. Multivariate Control Chart Tapping in Nodular Cast Iron (GGG50)

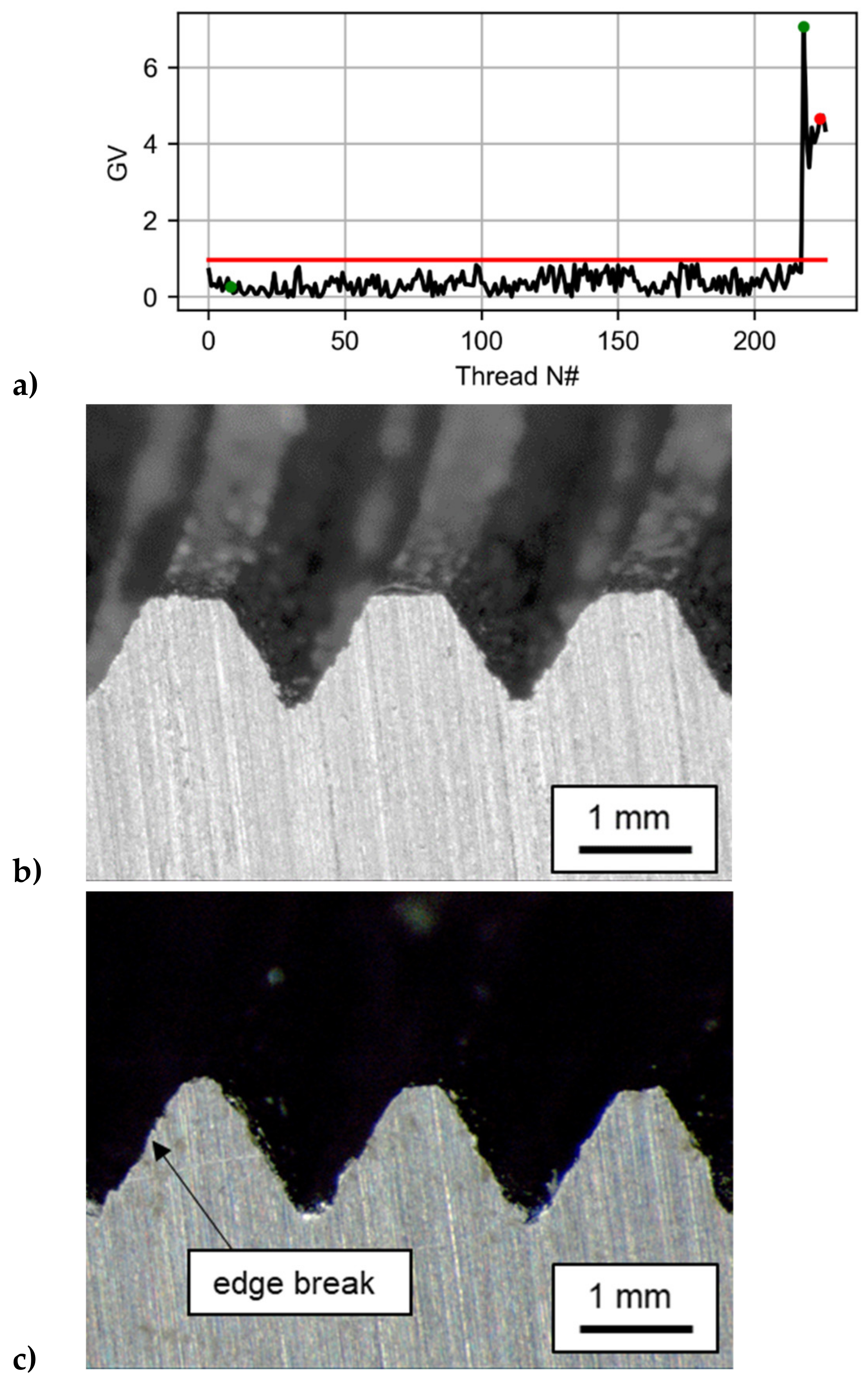

5.3.4. Discussion on Quality Loss: Thread Oversizing

5.3.5. Penalization Study of Diagnosis System

6. Conclusions

- The system warns to the worker when the tapping process is out of control. The system prevents to continue making threaded holes with the same tool, recommending its replacement.

- The out of control in tapping process means wear and faults (micro-chipping, micro-tooth breakage or material removing on the thread flanks) on the tap tool geometry. The system detects errors originating from an oversize of the threaded hole, which means that the no go gauge passes through the hole because the tooth geometry is not well sculpted.

- The strategy assures the thread quality along the tapping operation. The penalization average (5.5%) can be assumed because the tapping safety is guaranteed. Penalization is defined as the number of threaded holes that could have been made until the loss of thread quality.

- The strategy is independent of the tool life and each tap is monitored against its own threshold. Also, the diagnosis approach works with different cutting conditions and workpiece materials.

- The strategy can work as an automatic tapping manufacturing approach with total manufacturing security because it could stop the operation without operator inspection.

- The developed strategy is reliable and could be implemented in a manufacturing environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Urbikain, G.; Perez, J.M.; De Lacalle, L.N.L.; Andueza, A. Combination of friction drilling and form tapping processes on dissimilar materials for making nutless joints. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1007–1020. [Google Scholar] [CrossRef]

- Ahn, J.H.; Lee, D.J.; Kim, S.H.; Cho, K.K. Effects of synchronizing errors in cutting performance in the ultrahigh- speed tapping. Ann. CIRP 2003, 52, 53–56. [Google Scholar] [CrossRef]

- Elosegui, I.; Alonso, U.; De Lacalle, L.N.L. PVD coatings for thread tapping of austempered ductile iron. Int. J. Adv. Manuf. Technol. 2017, 91, 2663–2672. [Google Scholar] [CrossRef]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; De Lacalle, L.N.L.; Polvorosa, R. Enhanced Performance of Nanostructured Coatings for Drilling by Droplet Elimination. Mater. Manuf. Process. 2016, 31, 593–602. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO1502:1996 ISO General-Purpose Metric Screw Threads. Gauges and Gauging; International Organization for Standardization: Geneva, Switzerland, 1996. [Google Scholar]

- Corne, R.; Nath, C.; El Mansori, M.; Kurfess, T. Study of spindle power data with neural network for predicting real-time tool wear/breakage during inconel drilling. J. Manuf. Syst. 2017, 43, 287–295. [Google Scholar] [CrossRef]

- Yao, C.; Chien, Y. A diagnosis method of wear and tool life for an endmill by ultrasonic detection. J. Manuf. Syst. 2014, 33, 129–138. [Google Scholar] [CrossRef]

- Kan, C.; Yang, H.; Kumara, S. Parallel computing and network analytics for fast Industrial Internet-of-Things (IIoT) machine information processing and condition monitoring. J. Manuf. Syst. 2018, 46, 282–293. [Google Scholar] [CrossRef]

- Armarego, E.J.A.; Chen, M.N.P. Predictive models for the forces and torque in machine tapping with straight flute taps. CIRP Ann. 2002, 51, 75–78. [Google Scholar] [CrossRef]

- Oezkaya, E.; Biermann, D. Development of a geometrical torque prediction method (GTPM) to automatically determine the relative torque for different tapping tools and diameters. Int. J. Adv. Manuf. Technol. 2018, 97, 1465–1479. [Google Scholar] [CrossRef]

- Lenz, J.; Wuest, T.; Westkämper, E. Holistic approach to machine tool data analytics. J. Manuf. Syst. 2018, 48, 180–191. [Google Scholar] [CrossRef]

- Chen, Y.B.; Sha, J.L.; Wu, S.M. Diagnosis of tapping process by information measure and probability voting approach. J. Eng. Ind. 1990, 112, 319–325. [Google Scholar] [CrossRef]

- Liu, T.; Ko, E.J.; Sha, S.L. Diagnosis of tapping processes using an AI approach. J. Mater. Shap. Technol. 1991, 9, 39–46. [Google Scholar] [CrossRef]

- Li, W.; Li, D.; Ni, J. Diagnosis of tapping process using spindle motor current. Int. J. Mach. Tools Manuf. 2003, 43, 73–79. [Google Scholar] [CrossRef]

- Lorentz, G. Principal component analysis in technology. Ann. CIRP 1989, 38, 107–109. [Google Scholar] [CrossRef]

- Liu, T.-I.; Lee, J.; Liu, G.; Wu, Z. Monitoring and diagnosis of the tapping process for product quality and automated manufacturing. Int. J. Adv. Manuf. Technol. 2013, 64, 1169–1175. [Google Scholar] [CrossRef]

- Zawada-Tomkiewicz, A.; Wierucka, I. A case study in technological quality assurance of a metric screw thread. Measurement 2018, 114, 208–217. [Google Scholar] [CrossRef]

- De Freitas, S.A.; Vieira, J.T.; Filho, S.L.M.R.; Brandão, L.C. Experimental investigation of tapping in CFRP with analysis of torque-tension resistance. Int. J. Adv. Manuf. Technol. 2019, 104, 757–766. [Google Scholar] [CrossRef]

- Monka, P.; Monkova, K.; Modrak, V.; Hric, S.; Pastucha, P. Study of a tap failure at the internal threads machining. Eng. Fail. Anal. 2019, 100, 25–30. [Google Scholar] [CrossRef]

- Pereira, I.C.; Vianello, P.I.; Boing, D.; Guimarães, G.; Da Silva, M.B. An approach to torque and temperature thread by thread on tapping. Int. J. Adv. Manuf. Technol. 2020, 106, 4891–4901. [Google Scholar] [CrossRef]

- Polvorosa, R.; de Lacalle, L.L.; Egea, A.J.S.; Fernandez, A.; Esparta, M.; Zamakona, I. Cutting edge control by monitoring the tapping torque of new and resharpened tapping tools in Inconel 718. Int. J. Adv. Manuf. Technol. 2020, 106, 3799–3808. [Google Scholar] [CrossRef]

- Gil Del Val, A.; Veiga, F.; Pereira, O.; De Lacalle, L.N.L. Threading Performance of Different Coatings for High Speed Steel Tapping. Coatings 2020, 10, 464. [Google Scholar] [CrossRef]

- Brandão, G.L.; Silva, P.M.D.C.; De Freitas, S.A.; Pereira, R.B.D.; Lauro, C.H.; Brandão, L.C. State of the art on internal thread manufacturing: A review. Int. J. Adv. Manuf. Technol. 2020, 110, 3445–3465. [Google Scholar] [CrossRef]

- Gil Del Val, A.; Fernandez, J.R.; Del Castillo, E.; Arizmendi, M.; Veiga, F.G. Monitoring of thread quality when tapping nodular cast iron with TiN-coated HSS cutting taps. Int. J. Adv. Manuf. Technol. 2013, 69, 1273–1282. [Google Scholar] [CrossRef]

- Jackson, J.E.A. User´s Guide to Principal Components; John Wiley & Sons: New York, NY, USA, 1991. [Google Scholar] [CrossRef]

- Sullivan, J.H.; Woodall, W.H. A comparison of multivariate control chart for individual observations. J. Qual. Tecnol. 1996, 28, 398–408. [Google Scholar] [CrossRef]

- Montgomery, D.C. Introduction to Statistical Quality Control, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1996. [Google Scholar]

| Tap | Material | Coating | Vc (m/min) | Alarm |

|---|---|---|---|---|

| 1 | AISI 1045 | TiCN | 10 | 287 |

| 2 | AISI 1045 | TiCN | 10 | 297 |

| 3 | AISI 1045 | TiCN | 10 | 312 |

| 4 | AISI 1045 | TiCN | 10 | 281 |

| 5 | GG25 | TiCN | 20 | 197 |

| 6 | GG25 | TiCN | 20 | 172 |

| 7 | GG25 | TiCN | 20 | 177 |

| 8 | GG25 | TiCN | 20 | 151 |

| 9 | GGG50 | TiCN | 30 | 171 |

| 10 | GGG50 | TiCN | 30 | 219 |

| 11 | GGG50 | TiCN | 30 | 165 |

| 12 | GGG50 | TiCN | 30 | 151 |

| Tap | Alarm | Defected Thread | Thread Quality | Penalty (%) |

|---|---|---|---|---|

| 1 | 287 | 301 | Oversizing | 4.3 |

| 2 | 297 | 325 | Oversizing | 9.1 |

| 3 | 312 | 320 | Oversizing | 2.2 |

| 4 | 281 | 285 | Oversizing | 1.4 |

| 5 | 197 | 201 | Oversizing | 1.5 |

| 6 | 172 | 187 | Oversizing | 7.5 |

| 7 | 177 | 193 | Oversizing | 7.8 |

| 8 | 151 | 174 | Oversizing | 12.7 |

| 9 | 171 | 184 | Oversizing | 6.6 |

| 10 | 219 | 223 | Oversizing | 1.4 |

| 11 | 165 | 178 | Oversizing | 6.8 |

| 12 | 151 | 156 | Oversizing | 2.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gil Del Val, A.; Veiga, F.; Penalva, M.; Arizmendi, M. Oversizing Thread Diagnosis in Tapping Operation. Metals 2021, 11, 537. https://doi.org/10.3390/met11040537

Gil Del Val A, Veiga F, Penalva M, Arizmendi M. Oversizing Thread Diagnosis in Tapping Operation. Metals. 2021; 11(4):537. https://doi.org/10.3390/met11040537

Chicago/Turabian StyleGil Del Val, Alain, Fernando Veiga, Mariluz Penalva, and Miguel Arizmendi. 2021. "Oversizing Thread Diagnosis in Tapping Operation" Metals 11, no. 4: 537. https://doi.org/10.3390/met11040537

APA StyleGil Del Val, A., Veiga, F., Penalva, M., & Arizmendi, M. (2021). Oversizing Thread Diagnosis in Tapping Operation. Metals, 11(4), 537. https://doi.org/10.3390/met11040537