Perforated Plate for Ballistic Protection—A Review

Abstract

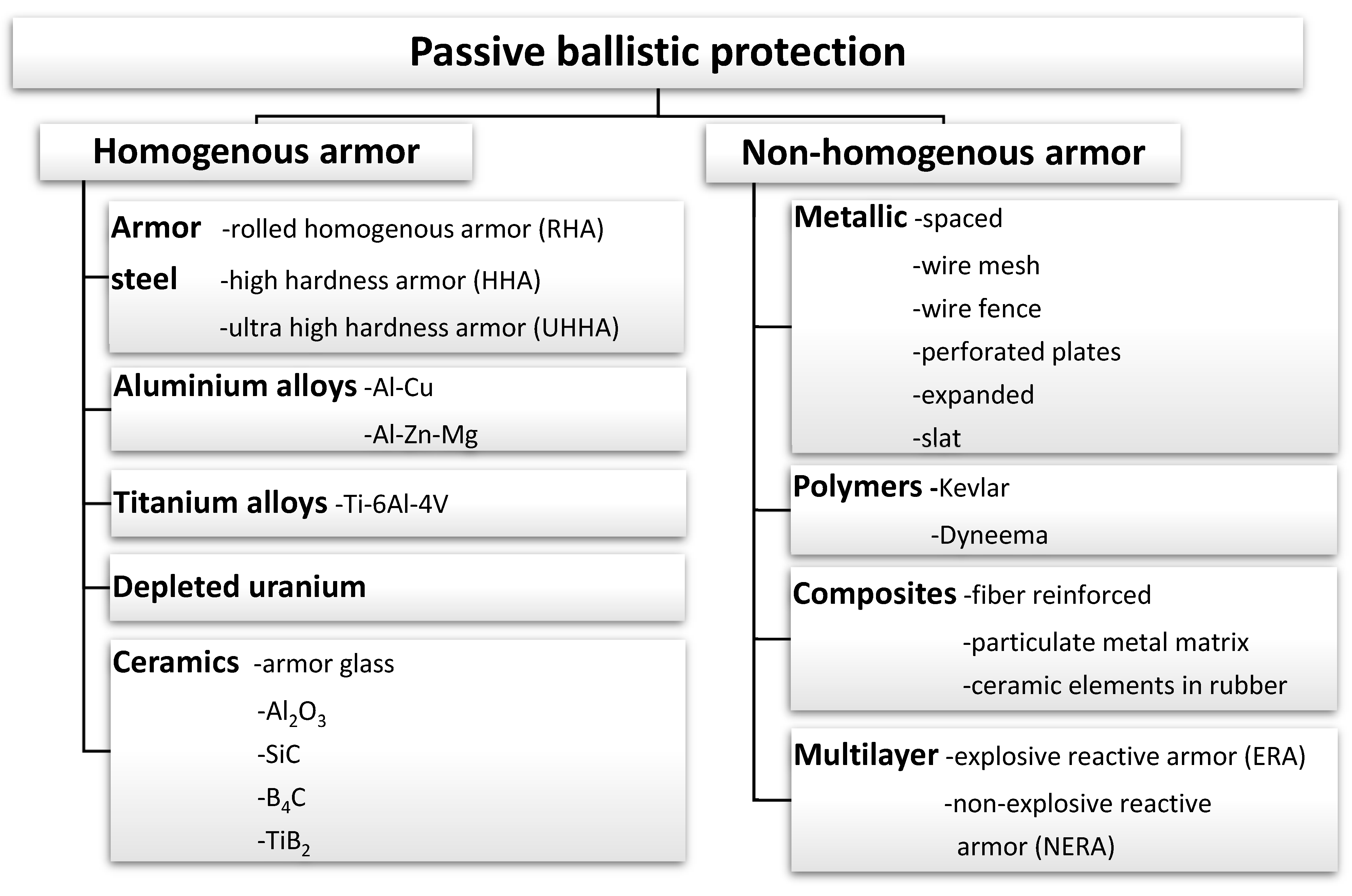

1. Introduction

2. Perforated Plates in Armoured Vehicles

3. Basic Principle

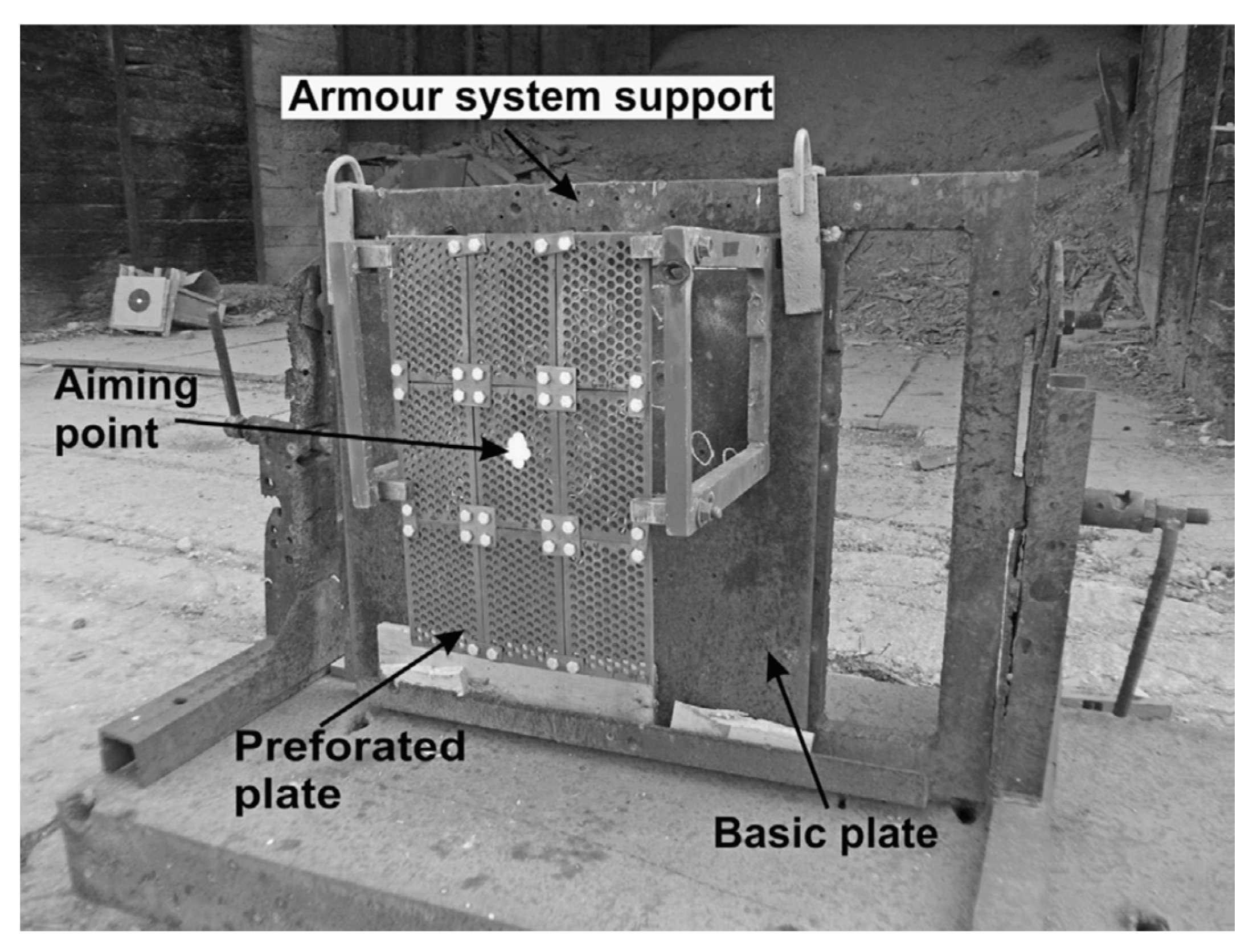

4. Perforated Plate Geometry and Materials

5. Finite Modelling and Ballistic Testing

6. Blast Passive Mitigation

7. Concluding Remarks

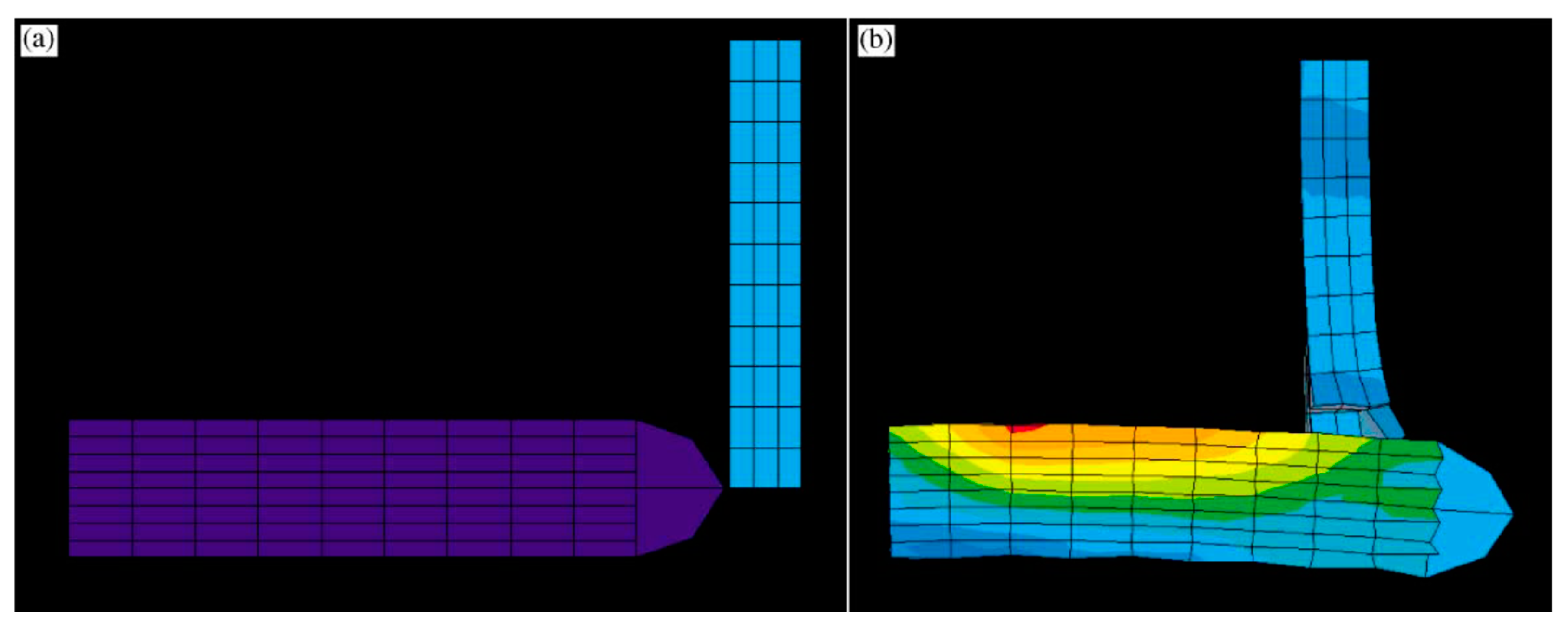

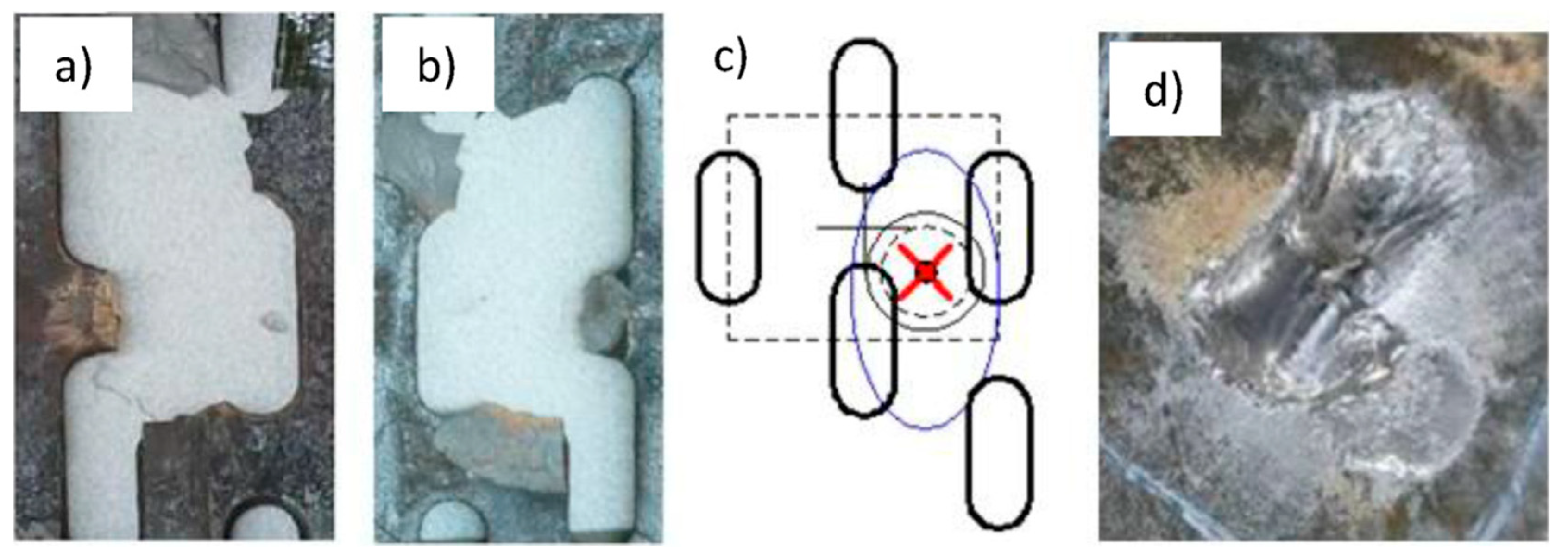

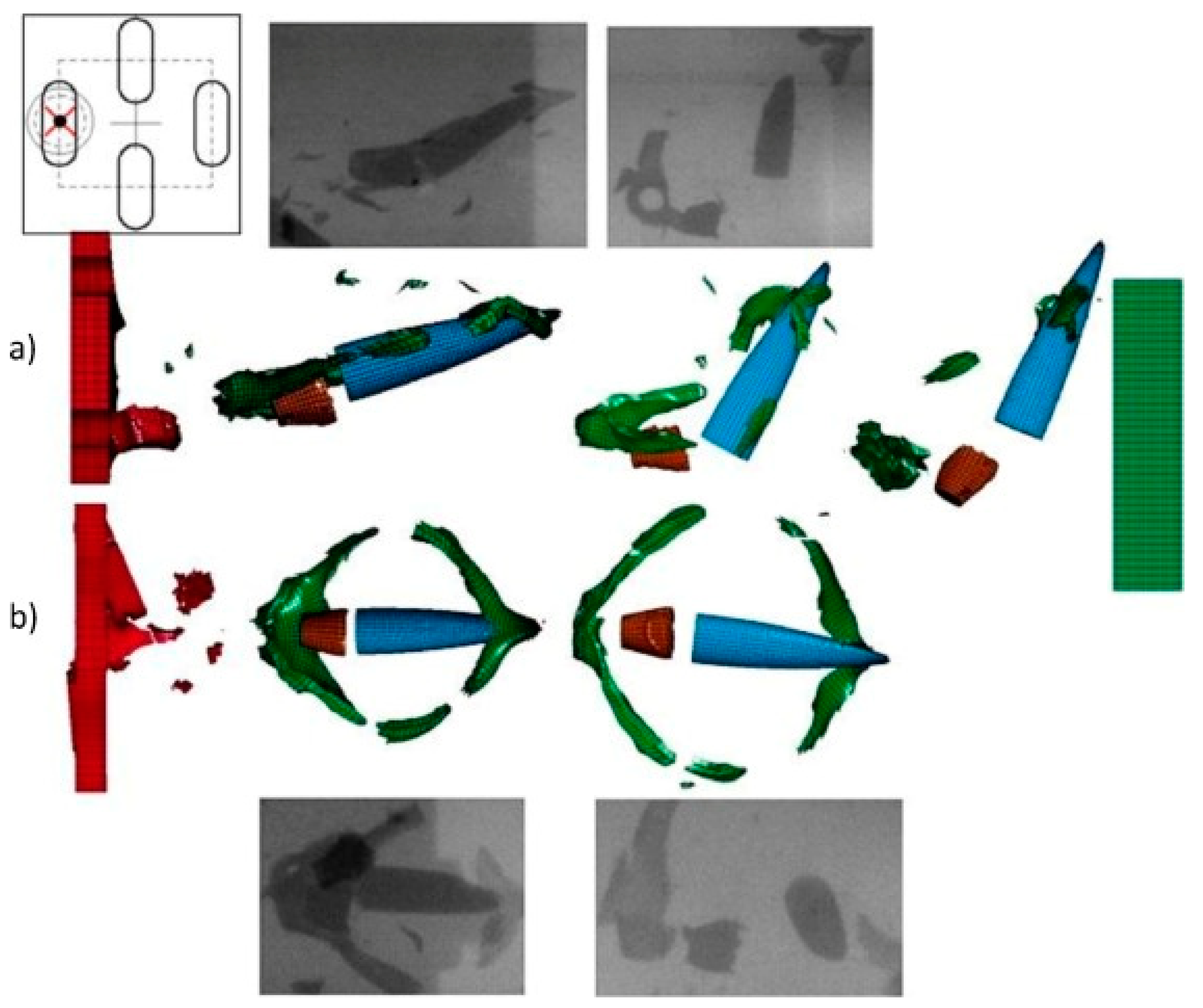

- Perforated plates work mainly through stress induction in the projectile, causing fractures of the penetrating core of armor-piercing ammunition. Penetrating core fracture occurs as strains above 2%. Besides penetrating core fracture, which is the optimal case, perforated plates work through inducing yaw and penetrating core tip damage and erosion.

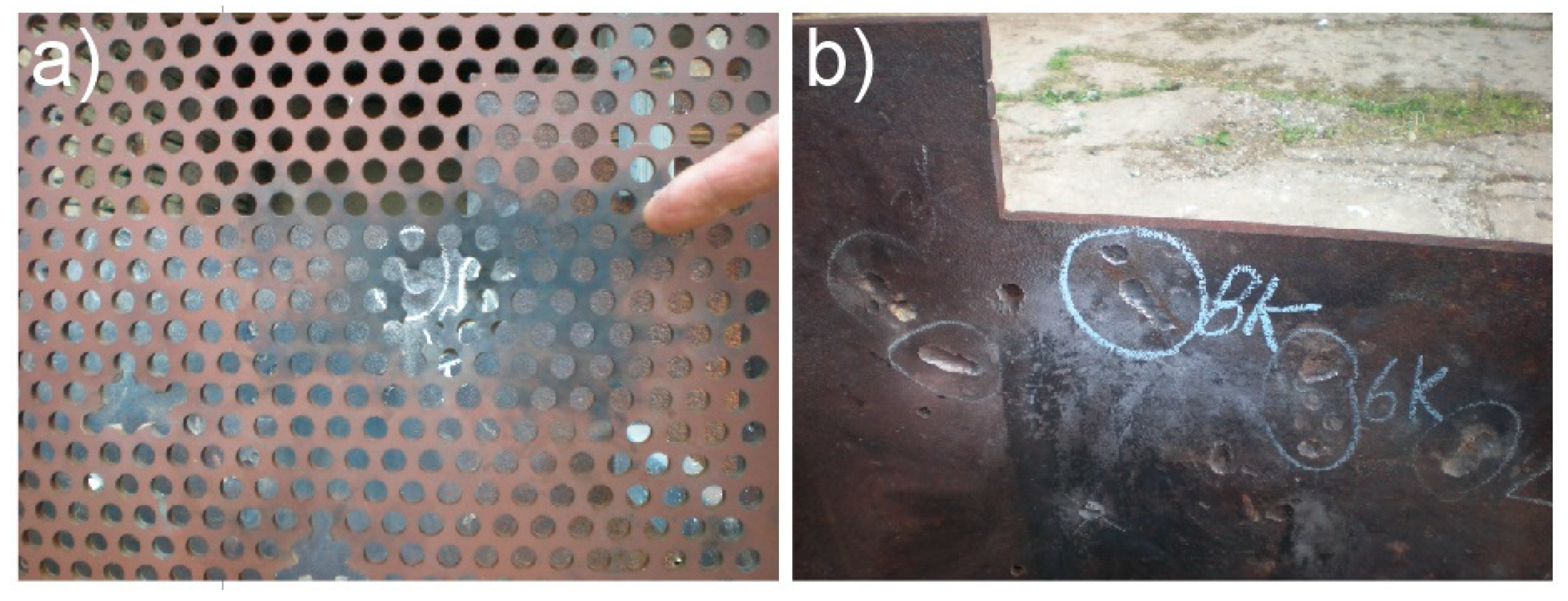

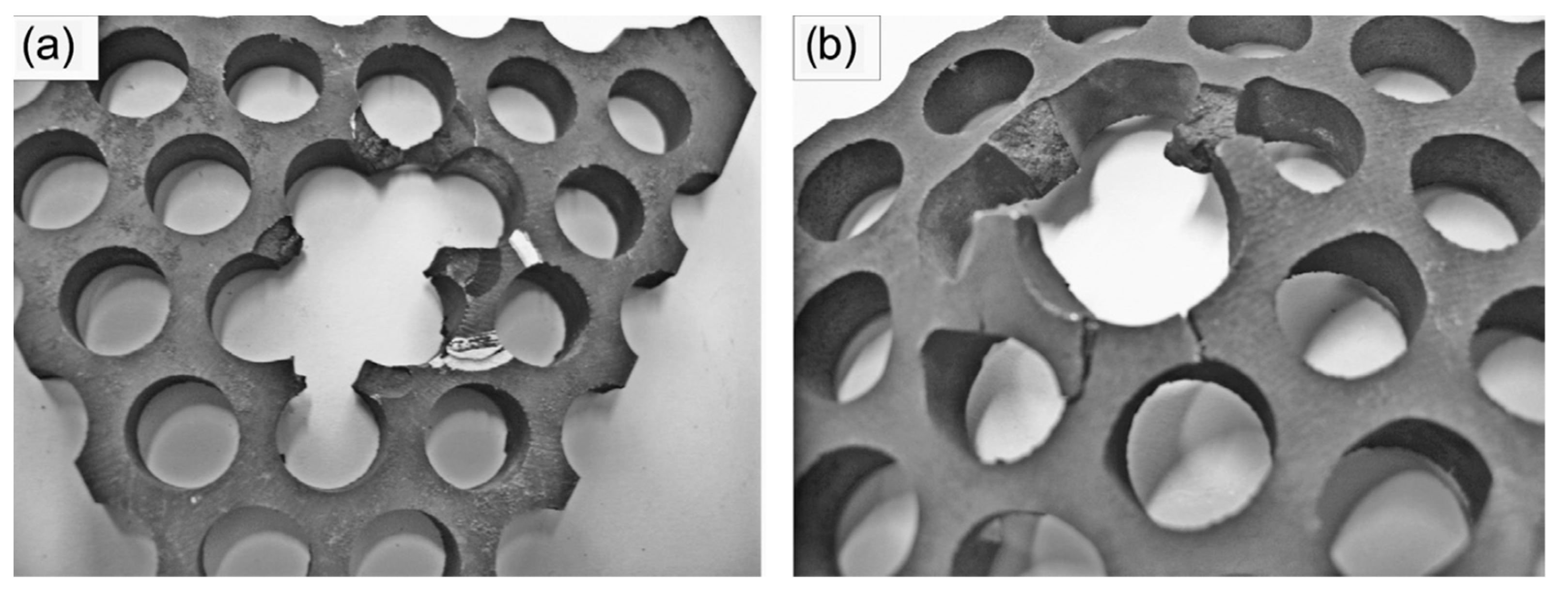

- The perforated plate-based armor system has an exceptional multi-hit resistance due to crack arrest by the nearest perforation. For further crack initiation and propagation, another impact is required in the damaged region. ASB-induced crack formation can be partially inhibited due to the presence of perforations, making the perforated plate material more resistant to multiple impacts compared to homogenous steel.

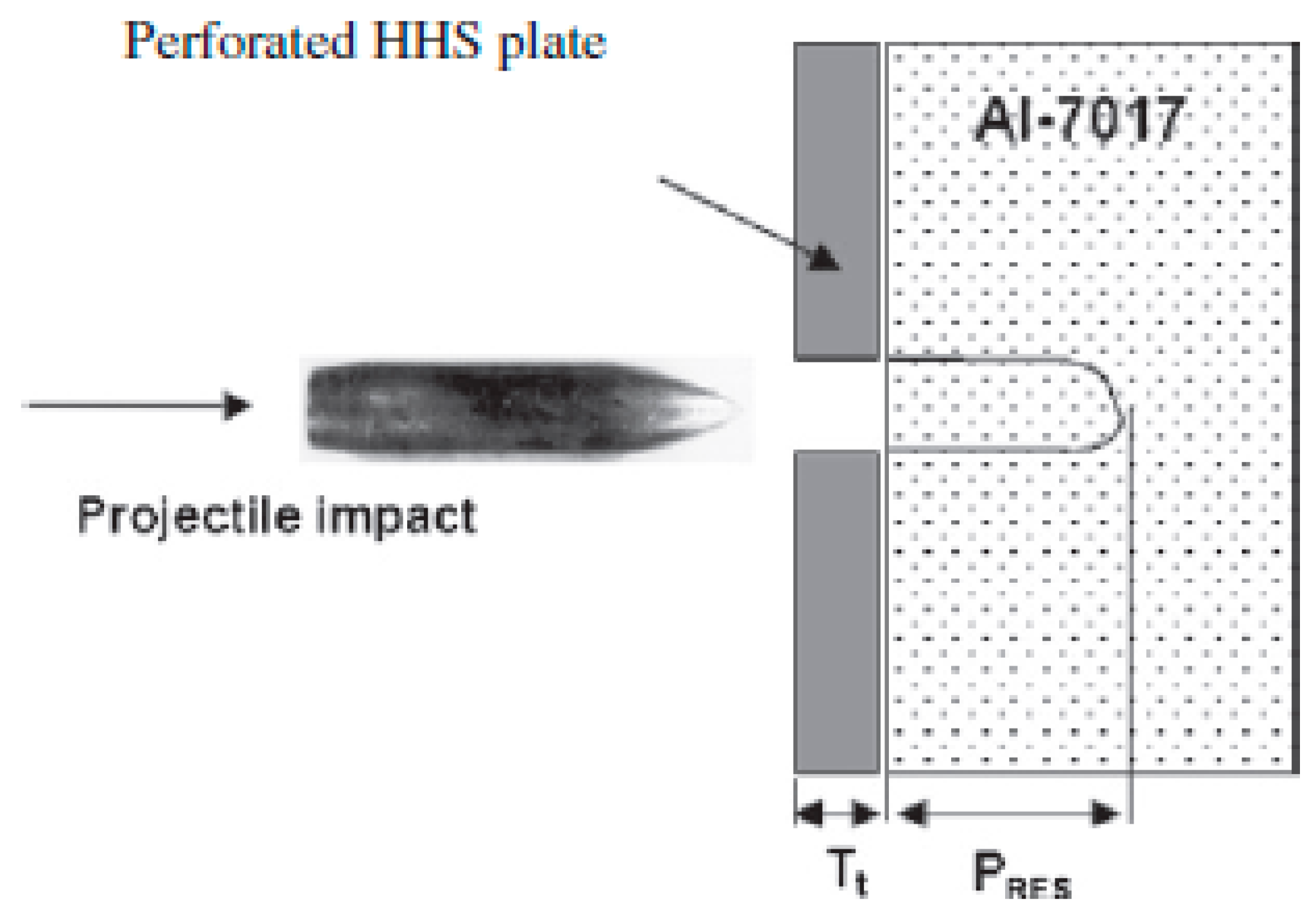

- Perforated plates placed directly on the basic armor also induce bend stresses in the penetrating core, but as the projectile tip becomes embedded in the base plate, fracture potential might be reduced, rendering the need to increase the thickness of the perforated plate.

- Besides heat-treated steels, commercial and armor steels, nanostructured bainitic steels and austempered ductile and compacted graphite irons can be used, essentially enabling a wide variety of materials and fabrication processes to manufacture perforated plates.

- Considerable potential exists for applying amorphous metals to reinforce the crystalline base structure of the perforated plate, but this remains to be proved experimentally, as only simulations proved its merit. Simulations proved the potential of using high-strength aluminium alloys.

- If spaced, perforated plates inevitably increase the footprint and weight of the vehicle, which is a major deficiency. However, a perforated plate placed directly on the base plate deserves more attention from the point of view of defeating kinetic energy rounds, while optimizing parasitic weight and volume. A perforated plate placed directly at the base armor will have a negligible effect against shaped charges and IEDs.

- Even relatively thin perforated plates placed at some distance from the base plate significantly mitigate the effects of a blast from IEDs, providing higher survivability of the vehicle in the contemporary battlefield.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miller, D.; Foss, C. Modern Land Combat; Salamander: London, UK, 1987. [Google Scholar]

- Hilmes, R. Brassey’s Multilingual Military Dictionary; Brassey’s Defence Publishers: London, UK, 1987; pp. 71–79. [Google Scholar]

- Djordjevic, M. Tenkovi 1945-2005; NIU Vojska: Belgrade, Serbia, 1997. [Google Scholar]

- Djordjevic, M. Future Armoured Troop Carrying Vehicles. Odbrana, 76; Arsenal, 23 2009, 9–24. [Google Scholar]

- Djordjevic, M.; Arsic, S. Oklopni Transporteri 1945–2005; NIU Vojska: Belgrade, Serbia, 2001. [Google Scholar]

- Odanović, Z.; Bobić, B. Ballistic Protection Efficiency of Composite Ceramics/Metal Armours. Sci. Rev. 2003, 53, 30–37. [Google Scholar]

- Ogorkiewitz, R. Armor for Light Combat Vehicles–Advances in Armour Materials. Int. Def. Rev. 2002, 35, 41–45. [Google Scholar]

- Phelps, W.; Schoeters, R. Panzer Survivors: Panzerkampfwagen IV Ausf. A-J; Masalai Press: Oakland, CA, USA, 2005. [Google Scholar]

- Jenz, T.; Doyle, D. Drachtgeflectschuerzen. AFV News 2002, 37, 6–8. [Google Scholar]

- Balos, S. Non-Homogenous Spaced Metallic Armour for Armoured Vehicles; University of Novi Sad: Novi Sad, Serbia, 2010. [Google Scholar]

- Grove, E. World War II–Tanks; Orbis Publishing: London, UK, 1976. [Google Scholar]

- Ogorkiewitz, R. Technology of Tanks; Jane’s Information Group: Coulsdon, Surrey, UK, 1991. [Google Scholar]

- Balos, S.; Grabulov, V.; Sidjanin, L.; Pantic, M. Wire Fence as Applique Armour. Mater. Des. 2010, 31, 1293–1301. [Google Scholar] [CrossRef]

- Balos, S.; Pecanac, M.; Trivkovic, M.; Sidjanin, L. Ballistic Behavior of Multilayer Wire Mesh Application Armor. Adv. Technol. Mater. 2019, 44, 7–11. [Google Scholar] [CrossRef]

- Balos, S. Unpublished Material. Personal Collection. 2009. [Google Scholar]

- Ogorkiewitz, R. Advances in Armour Materials. Int. Def. Rev. 1991, 4, 349–352. [Google Scholar]

- Radetic, M. Pravci Daljeg Razvoja Borbenih Vozila Pesadije. Vojn. Glas. 2001, 1, 83–100. [Google Scholar] [CrossRef]

- Howell, R.A.; Montgomery, J.S.; Van Aken, D.C. Advancements in Steel for Weight Reduction of P900 Armor Plate. Iron Steel Technol. 2009, 6, 168–176. [Google Scholar]

- Auyer, R.; Buccellato, R.; Gidynski, A. Perforated Plate Armor. U.S. Patent No. 5,014,593, 14 April 1991. [Google Scholar]

- Ogorkiewicz, R.M. Shifting Focus: Armored Vehicle Protection Adapts to New Threats. Janes Int. Def. Rev. 2007, 40, 35–43. [Google Scholar]

- Arcelor Mittal MARS 300 brochure. Available online: https://industeel.arcelormittal.com/wp-content/uploads/2018/06/DS-PROTECTION-MARS300-GB.pdf (accessed on 22 February 2021).

- Atabaki, M.M.; Nikodinovski, M.; Chenier, P.; Ma, J.; Harooni, M.; Kovacevic, R. Welding of Aluminum Alloys to Steels: An Overview. J. Manuf. Sci. Prod. 2014, 14, 59–78. [Google Scholar] [CrossRef]

- Potesser, M.; Schoeberl, T.; Antrekowitsch, H.; Bruckner, J. The Characterization of the Intermetallic Fe-Al Layer of Steel-aluminum Weldings. In Proceedings of the EPD Congress, The Minerals, Metals & Materials Society, San Antonio, TX, USA, 12–16 March 2006; pp. 167–176. [Google Scholar]

- Haidara, F.; Record, M.C.; Duployer, B.; Mangelinck, D. Phase Formation in Al-Fe Thin Film Systems. Intermetallics 2012, 23, 143–147. [Google Scholar] [CrossRef]

- Bruckner, J. Considering Thermal Processes for Dissimilar Metals–Joining Steel to Aluminum in Heat-intensive Applications. Fabricator, 28 August 2003. [Google Scholar]

- Chocron, S.; Anderson, C.E.; Grosch, D.J.; Popelar, C.H. Impact of the 7.62-mm APM2 Projectile against the Edge of a Metallic Target. Int. J. Impact Eng. 2001, 25, 423–437. [Google Scholar] [CrossRef]

- Mubashar, A.; Uddin, E.; Anwar, S.; Arif, N.; Waheed Ul Haq, S.; Chowdhury, M.A.K. Ballistic Response of 12.7 mm Armour Piercing Projectile against Perforated Armour Developed from Structural Steel. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1993–2005. [Google Scholar] [CrossRef]

- Smallman, R.E.; Bishop, R.J. Modern Physical Metallurgy & Materials Engineering, 6th ed.; Butterworth Heinemann: Woburn, MA, USA, 1999. [Google Scholar]

- Agudo, L.; Eyidi, D.; Schmaranzer, C.H.; Arenholz, E.; Jank, N.; Bruckner, J.; Pyzalla, A.R. Intermetallic Fe x Al y-phases in a Steel/Al-alloy Fusion Weld. J. Mater. Sci. 2007, 42, 4205–4214. [Google Scholar] [CrossRef]

- Mendez, P.; Eagar, T. New Trends in Welding in the Aeronautic Industry Bilboa, Spain. In Proceedings of the 2nd Conference of New Manufacturing Trends, San Sebastian, Spain, 24–25 May 2000; pp. 1–15. [Google Scholar]

- Gullino, A.; Matteis, P.; Aiuto, F.D. Review of Aluminum-to-steel Welding Technologies for Car-body Applications. Metals 2019, 9, 315. [Google Scholar] [CrossRef]

- Balos, S.; Grabulov, V.; Sidjanin, L.; Pantic, M.; Radisavljevic, I. Geometry, Mechanical Properties and Mounting of Perforated Plates for Ballistic Application. Mater. Des. 2010, 31, 2916–2924. [Google Scholar] [CrossRef]

- Radisavljevic, I.; Balos, S.; Nikacevic, M.; Sidjanin, L. Optimization of Geometrical Characteristics of Perforated Plates. Mater. Des. 2013, 49, 81–89. [Google Scholar] [CrossRef]

- Diederen, A.; Broos, J.; Peijen, M. Modern Armour Configurations against 14.5 mm AP. In Lightweight Armour Systems Symposium, Shrivenham, Proceedings of the Lightweight Armour Systems Symposium, Shrivenham, UK, 28–30 June 1995; Royal Military College of Science, Shrivenham: Shrivenham, UK, 2006; paper no. 131193. [Google Scholar]

- Balos, S. Perforirane Ploče za Balističku Zaštitu; Faculty of Technical Sciences: Novi Sad, Serbia, 2015. [Google Scholar]

- Hazell, P.J.; Roberson, C.J.; Moutinho, M. The Design of Mosaic Armour: The Influence of Tile Size on Ballistic Performance. Mater. Des. 2008, 29, 1497–1503. [Google Scholar] [CrossRef]

- Balos, S.; Radisavljevic, I.; Rajnovic, D.; Dramicanin, M.; Tabakovic, S.; Eric-Cekic, O.; Sidjanin, L. Geometry, Mechanical and Ballistic Properties of ADI Material Perforated Plates. Mater. Des. 2015, 83, 66–74. [Google Scholar] [CrossRef]

- Balos, S.; Radisavljevic, I.; Rajnovic, D.; Janjatovic, P.; Dramicanin, M.; Eric-Cekic, O.; Sidjanin, L. Ballistic Behaviour of Austempered Compacted Graphite Iron Perforated Plates. Def. Sci. J. 2019, 69, 571–576. [Google Scholar] [CrossRef]

- Balos, S.; Sidjanin, L.; Rajnovic, D. ADI Materials for Ballistic Protection. In Proceedings of the 34th International Conference on Production Engineering, Nis, Serbia, 28–30 September 2011; pp. 91–94. [Google Scholar]

- Thomas, D.J. Laser Cut Hole Matrices in Novel Armour Plate Steel for Appliqué Battlefield Vehicle Protection. Def. Technol. 2016, 12, 351–359. [Google Scholar] [CrossRef]

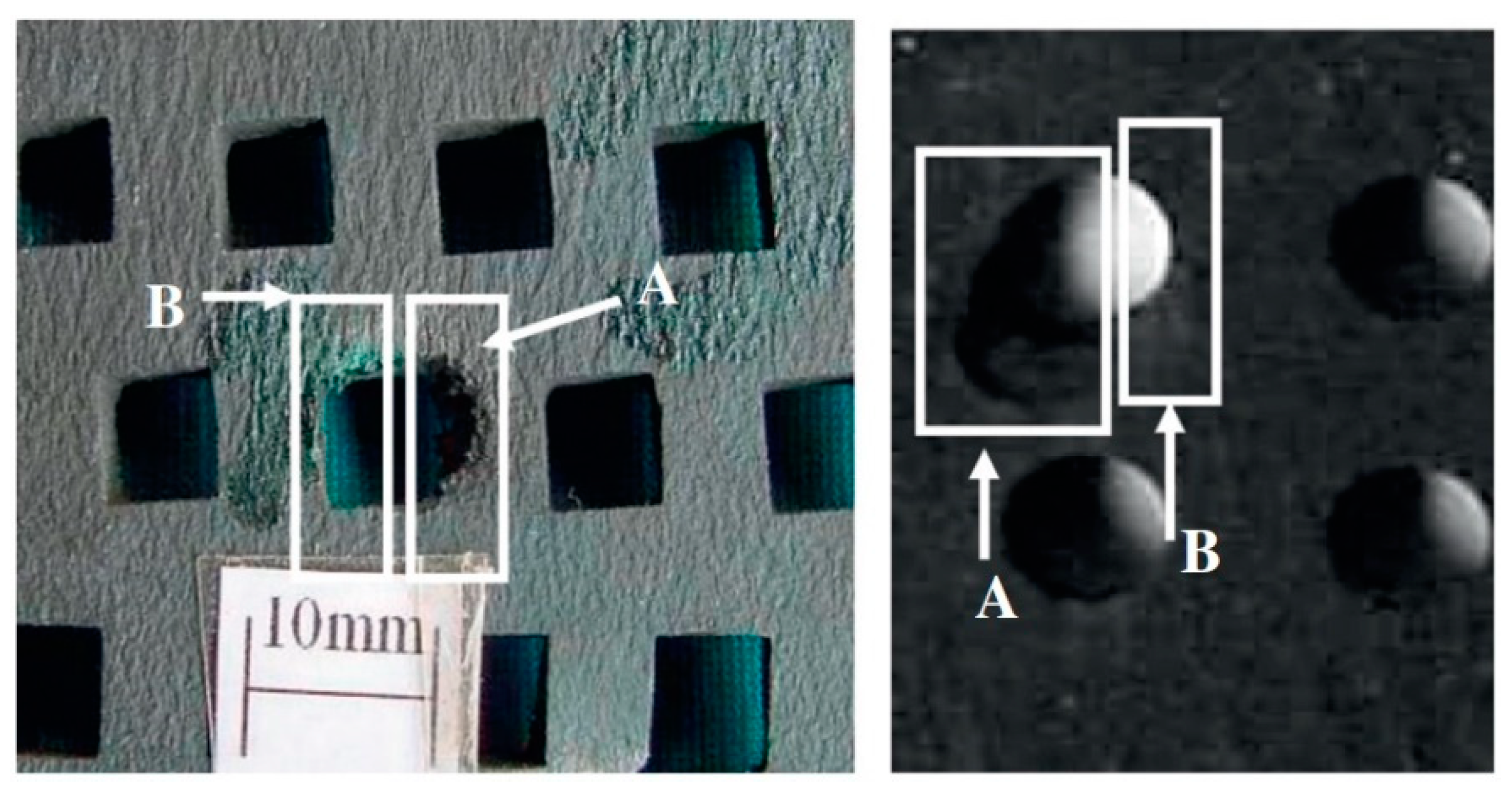

- Balos, S.; Sidjanin, L. Metallographic Study of Non-homogenous Armour Impacted by Armour-piercing Incendiary Ammunition. Mater. Des. 2011, 32, 4022–4029. [Google Scholar] [CrossRef]

- Fras, T.; Faderl, N. Influence of Add-On Perforated Plates on the Protective Performance of Light-Weight Armour Systems. Probl. Mechatron. Armament Aviat. Saf. Eng. 2018, 9, 31–48. [Google Scholar] [CrossRef]

- Fras, T.; Murzyn, A.; Pawlowski, P. Defeat Mechanisms Provided by Slotted Add-on Bainitic Plates against Small-calibre 7.62 mm × 51 AP Projectiles. Int. J. Impact Eng. 2017, 103, 241–253. [Google Scholar] [CrossRef]

- Kiliç, N.; Bedir, S.; Erdik, A.; Ekici, B.; Taşdemirci, A.; Güden, M. Ballistic Behavior of High Hardness Perforated Armor Plates against 7.62mm Armor Piercing Projectile. Mater. Des. 2014, 63, 427–438. [Google Scholar] [CrossRef]

- Kılıç, N.; Ekici, B.; Bedir, S. Optimization of High Hardness Perforated Steel Armor Plates using Finite Element and Response Surface Methods. Mech. Adv. Mater. Struct. 2017, 24, 615–624. [Google Scholar] [CrossRef]

- Mishra, B.; Jena, P.K.; Ramakrishna, B.; Madhu, V.; Bhat, T.B.; Gupta, N.K. Effect of Tempering Temperature, Plate Thickness and Presence of Holes on Ballistic Impact Behavior and ASB Formation of a High Strength Steel. Int. J. Impact Eng. 2012, 44, 17–28. [Google Scholar] [CrossRef]

- Mishra, B.; Ramakrishna, B.; Jena, P.K.; Siva Kumar, K.; Madhu, V.; Gupta, N.K. Experimental Studies on the Effect of Size and Shape of Holes on Damage and Microstructure of High Hardness Armour Steel Plates under Ballistic Impact. Mater. Des. 2013, 43, 17–24. [Google Scholar] [CrossRef]

- Burian, W.; Żochowski, P.; Gmitrzuk, M.; Marcisz, J.; Starczewski, L.; Juszczyk, B.; Magier, M. Protection Effectiveness of Perforated Plates Made of High Strength Steel. Int. J. Impact Eng. 2019, 126, 27–39. [Google Scholar] [CrossRef]

- Cui, T.; Qin, Q.; Yan, W.; Wang, T.; Zhang, J. Ballistic Resistance of Novel Amorphous-Alloy-Reinforced Perforated Armor. Acta Mech. Solida Sin. 2021, 34, 12–26. [Google Scholar] [CrossRef]

- Wang, W.; Dong, C.; Shek, C. Bulk Metallic Glasses. Mater. Sci. Eng. R Rep. 2004, 44, 45–89. [Google Scholar] [CrossRef]

- Schuh, C.A.; Hufnagel, T.C.; Ramamurty, U. Mechanical Behavior of Amorphous Alloys. Acta Mater. 2007, 55, 4067–4109. [Google Scholar] [CrossRef]

- Dai, L.H.; Bai, Y.L. Basic Mechanical Behaviors and Mechanics of Shear Banding in BMGs. Int. J. Impact Eng. 2008, 35, 704–716. [Google Scholar] [CrossRef]

- Johnson, W.L. Bulk Glass-forming Metallic Alloys: Science and Technology. MRS Bull. 1999, 24, 42–56. [Google Scholar] [CrossRef]

- Chao, L.; Kun, L.; Guo, X.J.; Yuan, L.X. Experimental Study on Ballistic Performance for Multi-hole Armor Steel Plates Against the 7.62mm Armor Piercing Projectile. IOP Conf. Ser. Mater. Sci. Eng. 2018, 382. [Google Scholar] [CrossRef]

- Madhu, V.; Bhat, T.B. Armour Protection and Affordable Protection for Futuristic Combat Vehicles. Def. Sci. J. 2011, 61, 394–402. [Google Scholar] [CrossRef]

- Langdon, G.S.; Nurick, G.N.; Balden, V.H.; Timmis, R.B. Perforated Plates as Passive Mitigation Systems. Def. Sci. J. 2008, 58, 238–247. [Google Scholar] [CrossRef]

- Langdon, G.; Nurick, G.; Du Plessis, N.; Rossiter, I. Using Perforated Plates as a Blast Wave Shielding Technique for Application to Tunnels. Appl. Mech. Mater. 2011, 82, 467–472. [Google Scholar] [CrossRef]

- Ciortan, I.F.; Giurgiu, I.T.; Pupəža, C. Passive Mitigation Solutions using Explicit Dynamics Simulation. Proc. Rom. Acad. Ser. A Math. Phys. Tech. Sci. Inf. Sci. 2014, 15, 262–271. [Google Scholar]

| Thickness [mm] | Areal Density [kg/m2] | Mass Effectiveness | |

|---|---|---|---|

| 380 BHN* rolled homogenous armour (RHA) | 41 | 322 | 1.00 |

| 500 BHN* high hardness armour (HHA) | 36 | 283 | 1.14 |

| Aluminium alloy 5083 | 134 | 356 | 0.90 |

| Aluminium alloy 7019 | 97 | 270 | 1.19 |

| Aluminium alloy 7039 | 91 | 253 | 1.27 |

| Titanium alloy Ti-6Al-4V | 45 | 199 | 1.62 |

| 500 BHN* HHA and aluminium alloy 5083 500 BHN* HHA and titanium alloy Ti-6Al-4V | - | 192 167 | 1.68 1.93 |

| High hardness perforated plates and aluminium alloy 5083 | - | 168 | 1.92 |

| Al2O3 ceramics and 500 BHN* HHA Al2O3 ceramics and aluminium alloy5083 Al2O3 ceramic composite reinforced with glass fibers | - | 152 146 141 | 2.12 2.19 2.28 |

| Performances | Perforated Plate Material | |||||

|---|---|---|---|---|---|---|

| 50CrV4 | H9-6-0 | H10-6-0 | H11-6-0 | ADI-275 | ACGI-275 | |

| Thickness [mm] | 6 | 6 | 6 | 6 | 7 | 7 |

| Perforation diameter [mm] | 9 | 9 | 10 | 11 | 11 | 11 |

| Ligament length [mm] | 4.5 | 4.5 | 3.5 | 3.5 | 3.5 | 3.5 |

| Inclination [o] | 20 | 0 | 0 | 0 | 0 | 0 |

| Maximal number of fractured parts | 2 | 5 | 3 | 6 | 3 | 3 |

| Average no. of interconnected perforations | 6 | 6.4 | 6.2 | 5.8 | 7.2 | 7.8 |

| Damaged area [mm2] | 448 | 483 | 487 | 551 | 2076 | 2214 |

| Perforated plate areal density [kg/m2] | 30 | 28 | 24 | 23 | 24 | 24 |

| Armour system areal density (perforated + base plate) [kg/m2] | 132 | 130 | 126 | 125 | 126 | 126 |

| Mass effectiveness of the perforated plate vs. 380 BHN RHA | 3.93 | 4.21 | 4.92 | 5.13 | 4.92 | 4.92 |

| Mass effectiveness of armour system vs. 380 BHN RHA | 1.67 | 1.69 | 1.75 | 1.76 | 1.75 | 1.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balos, S.; Howard, D.; Brezulianu, A.; Labus Zlatanović, D. Perforated Plate for Ballistic Protection—A Review. Metals 2021, 11, 526. https://doi.org/10.3390/met11040526

Balos S, Howard D, Brezulianu A, Labus Zlatanović D. Perforated Plate for Ballistic Protection—A Review. Metals. 2021; 11(4):526. https://doi.org/10.3390/met11040526

Chicago/Turabian StyleBalos, Sebastian, Daniel Howard, Adrian Brezulianu, and Danka Labus Zlatanović. 2021. "Perforated Plate for Ballistic Protection—A Review" Metals 11, no. 4: 526. https://doi.org/10.3390/met11040526

APA StyleBalos, S., Howard, D., Brezulianu, A., & Labus Zlatanović, D. (2021). Perforated Plate for Ballistic Protection—A Review. Metals, 11(4), 526. https://doi.org/10.3390/met11040526