Fatigue Crack Growth Analysis with Extended Finite Element for 3D Linear Elastic Material

Abstract

1. Introduction

2. Mixed-Mode Fatigue Life Evaluation Procedure Using ANSYS

3. Numerical Results and Discussion

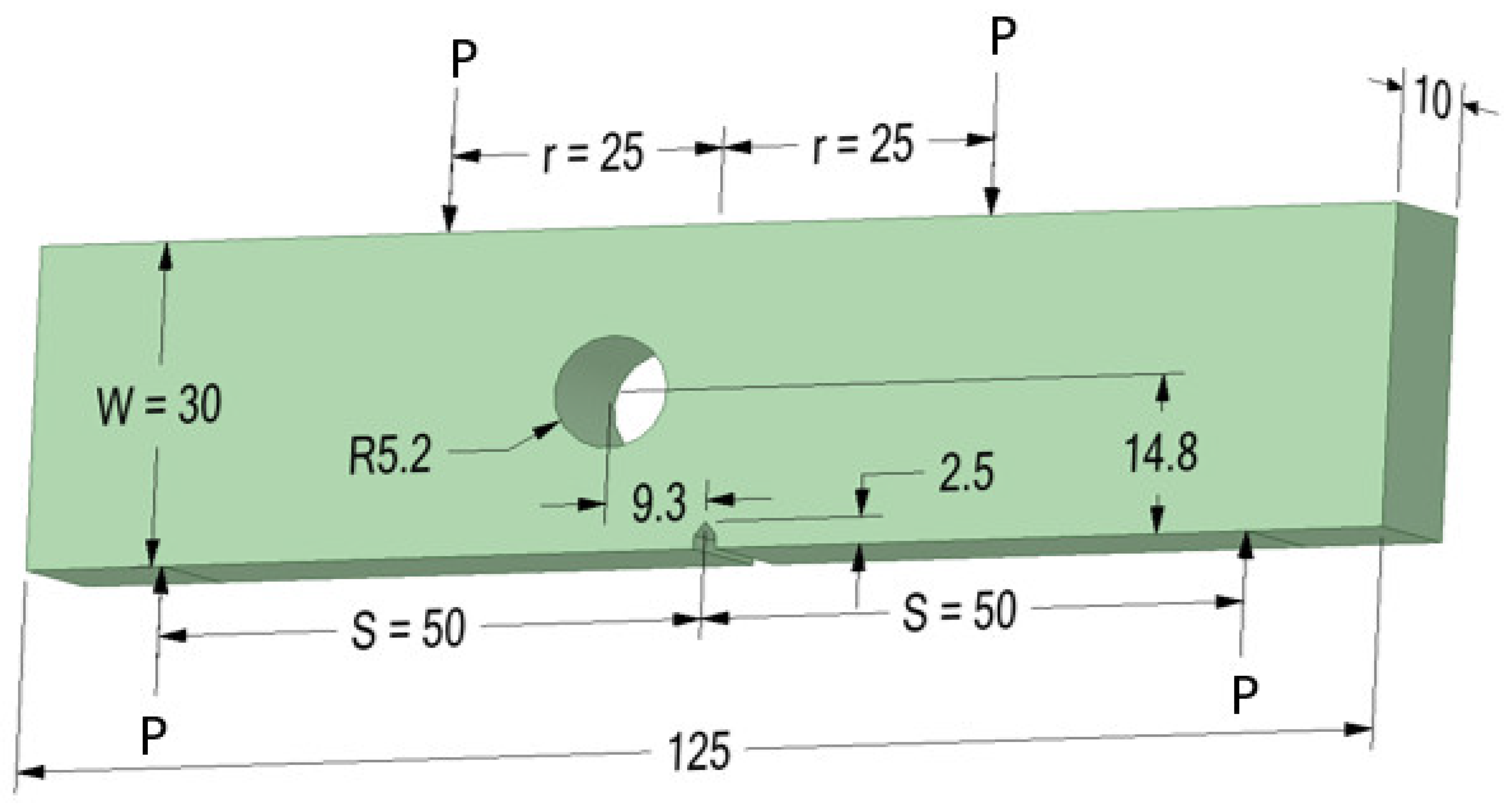

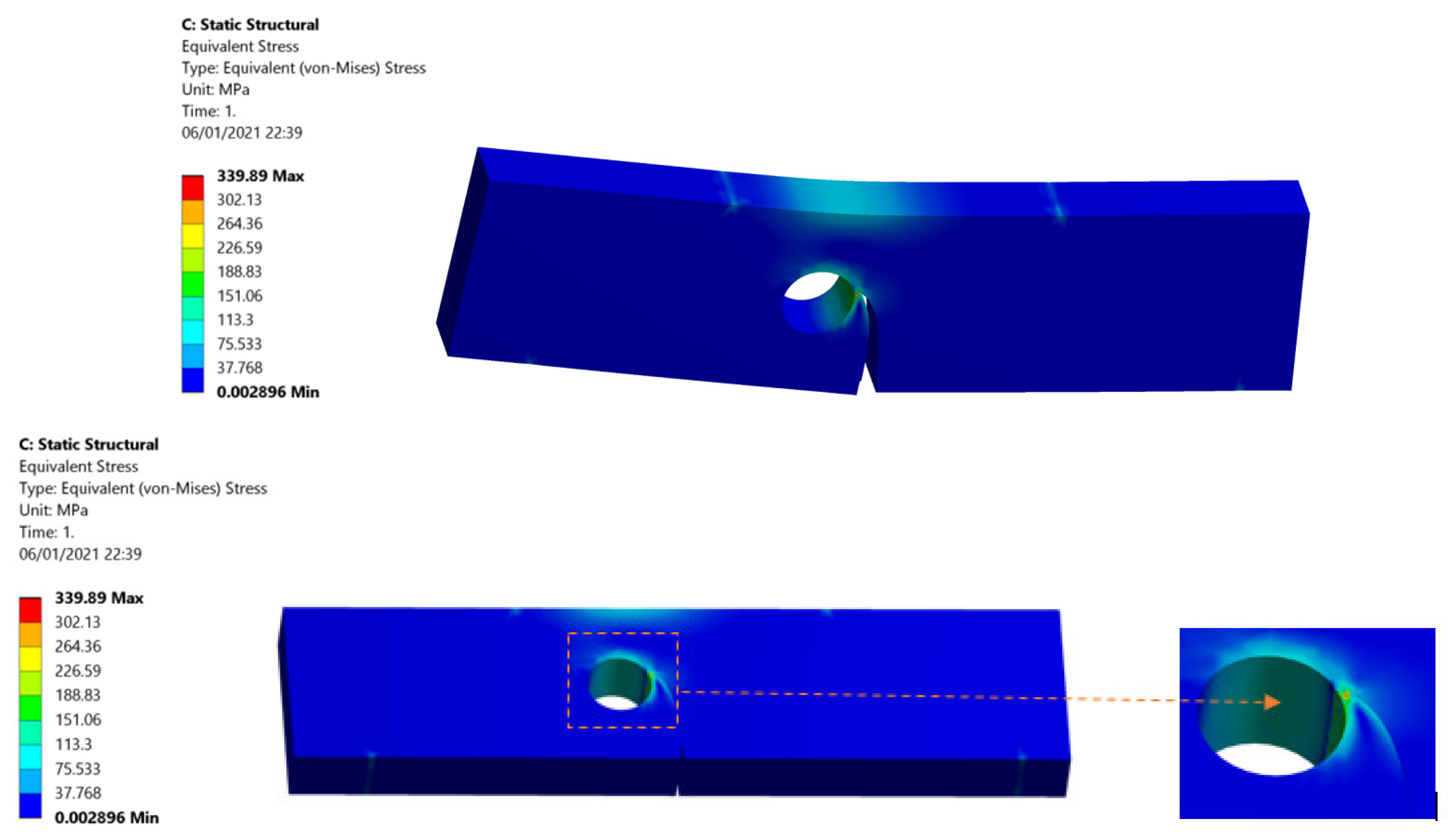

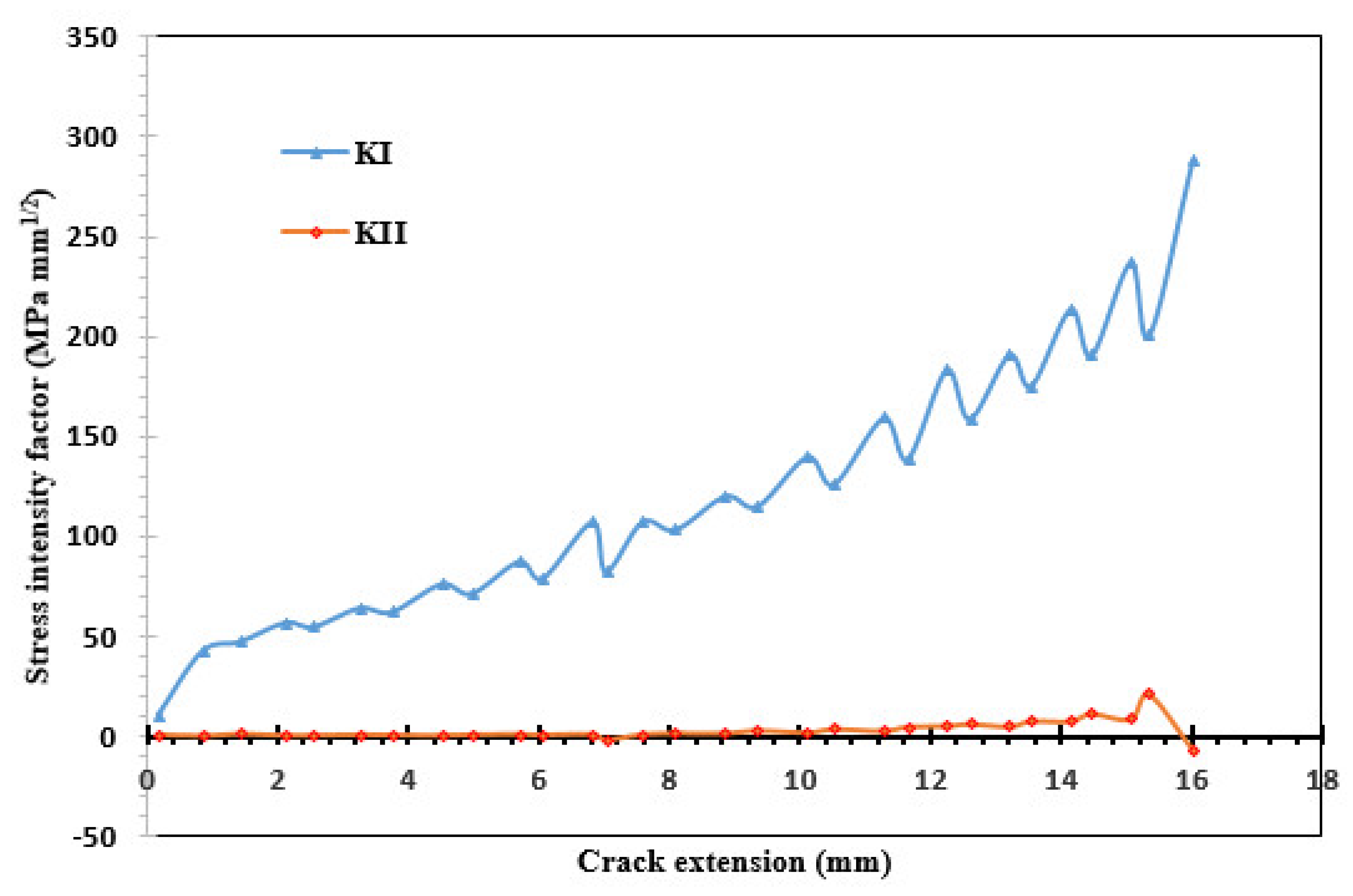

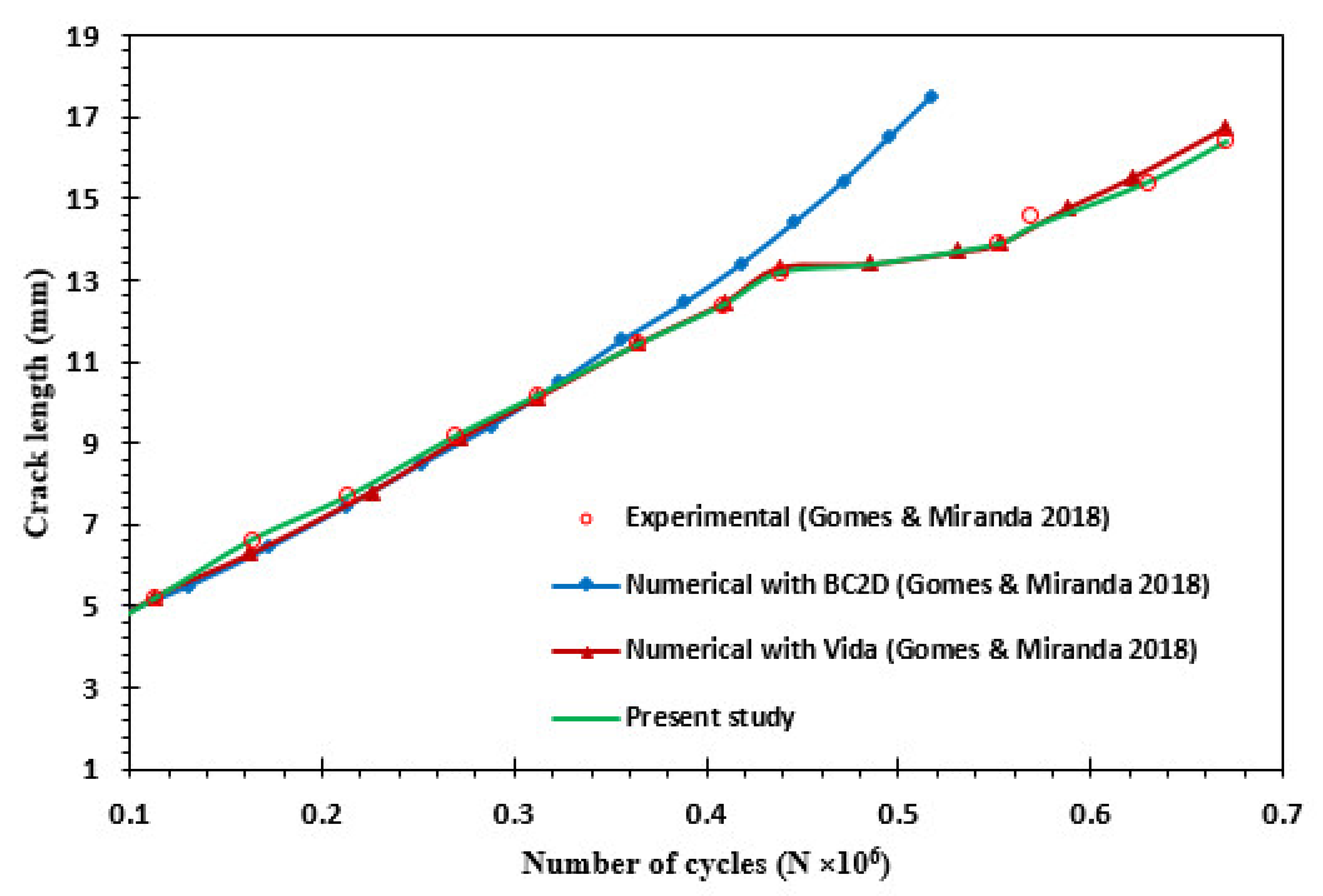

3.1. Modified Four-Point Bending Beam

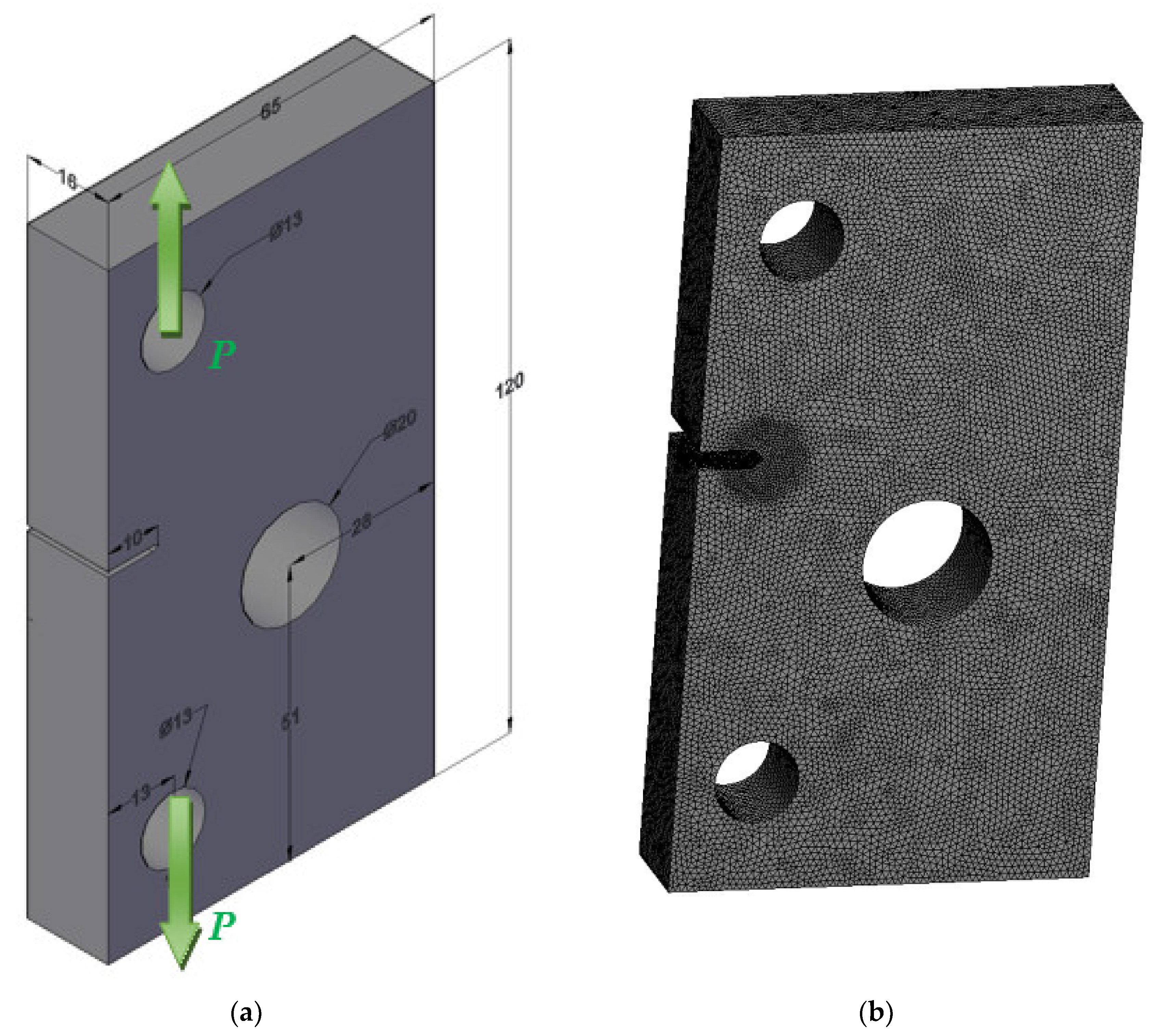

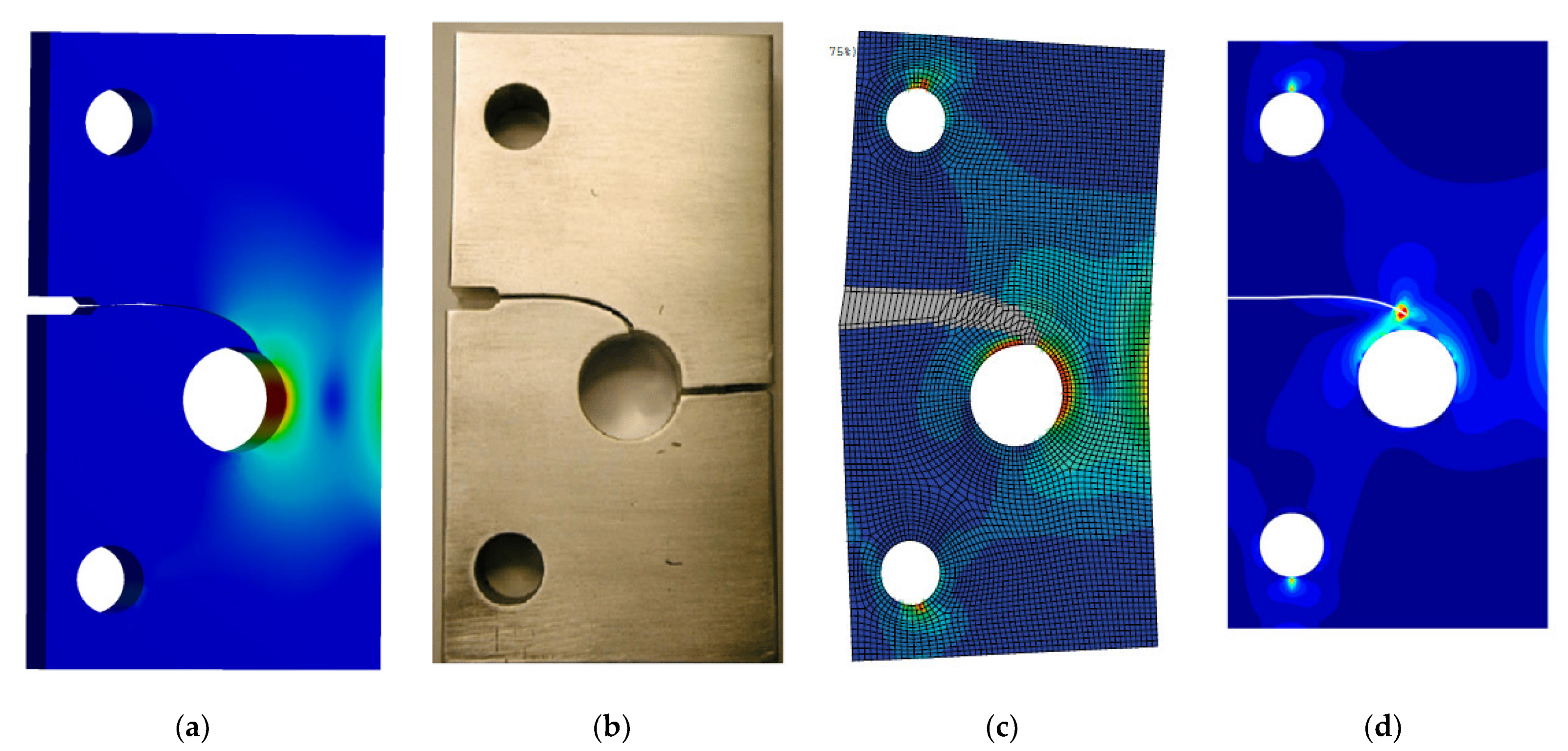

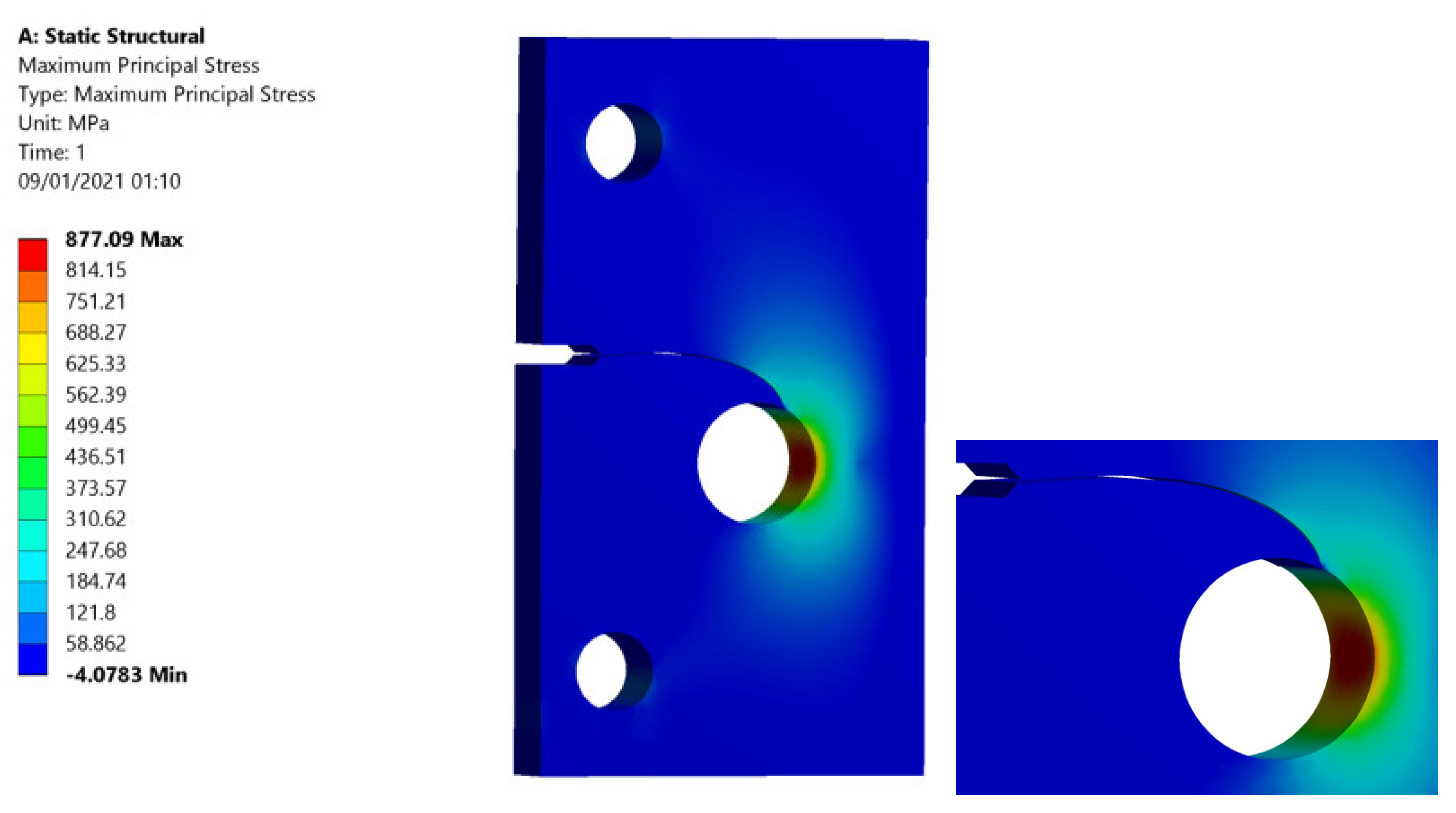

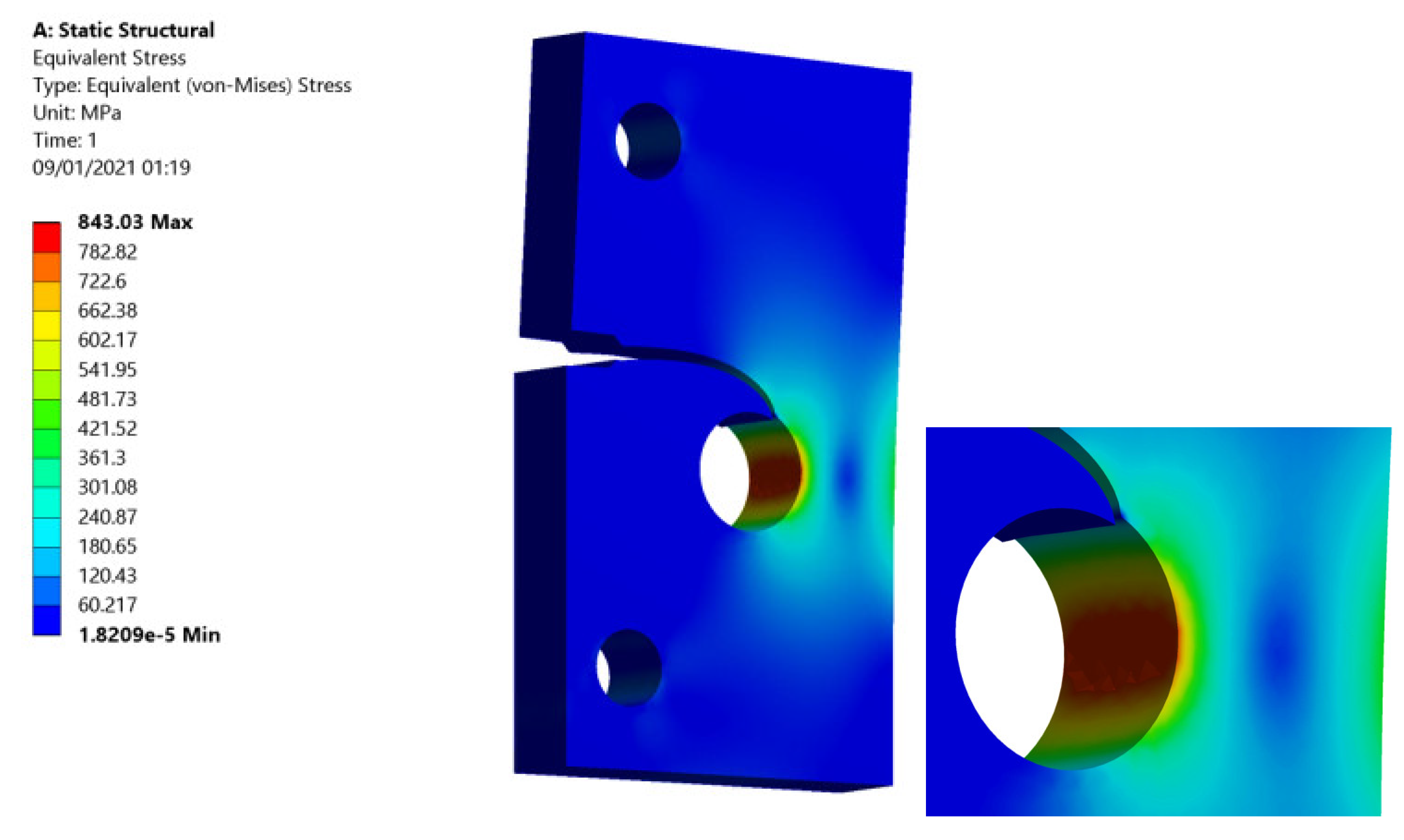

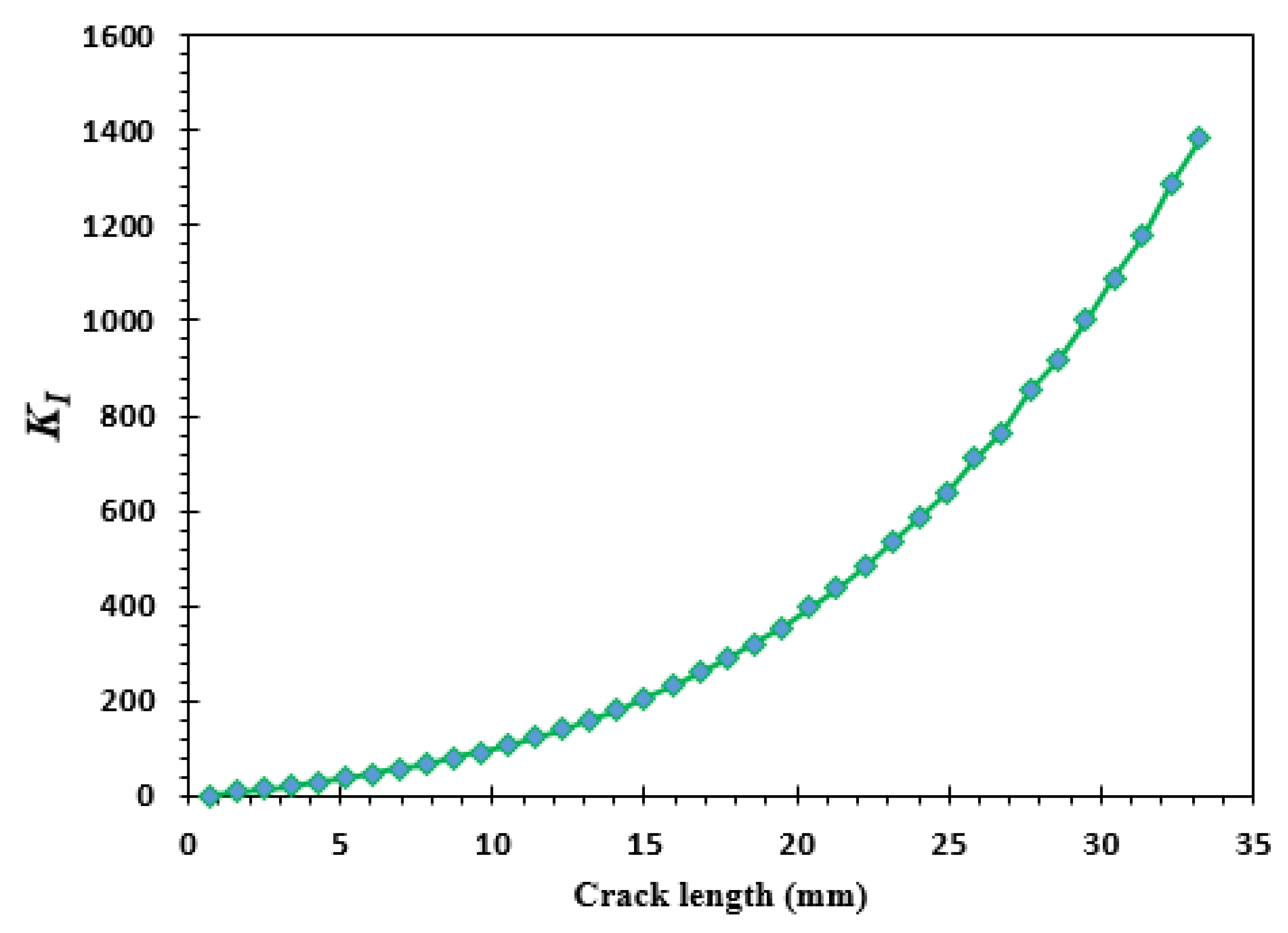

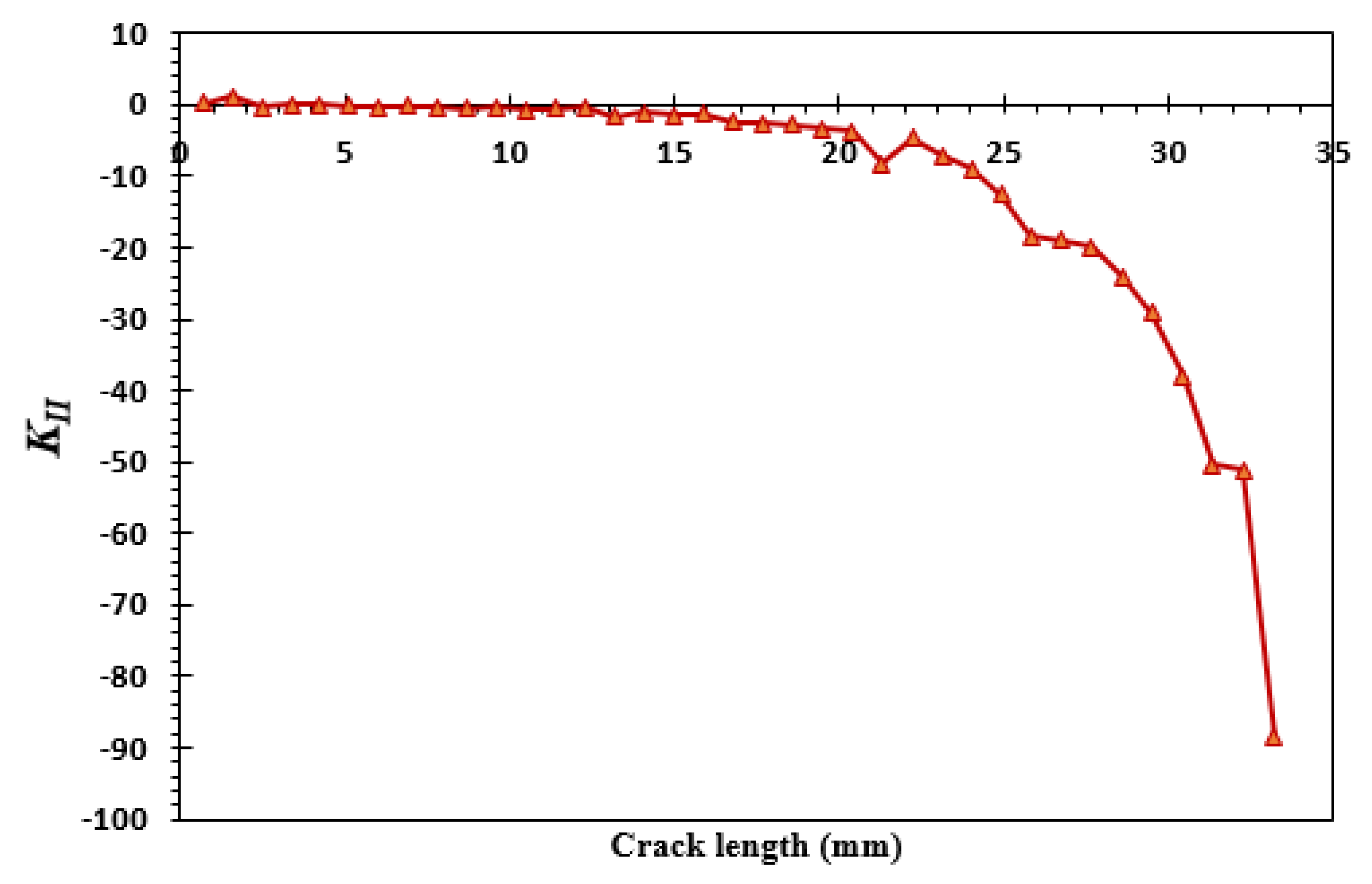

3.2. Cracked Plate with Three Holes

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Frost, N.; Pook, L.; Denton, K. A fracture mechanics analysis of fatigue crack growth data for various materials. Eng. Fract. Mech. 1971, 3, 109–126. [Google Scholar] [CrossRef]

- Dirik, H.; Yalçinkaya, T. Crack path and life prediction under mixed mode cyclic variable amplitude loading through XFEM. Int. J. Fatigue 2018, 114, 34–50. [Google Scholar] [CrossRef]

- Sih, G.; Liebowitz, H. Mathematical Fundamentals in Fracture; Academic Press: New York, NY, USA, 1968; pp. 67–190. [Google Scholar]

- Hellan, K. Introduction to Fracture Mechanics; McGraw-Hill: New York, NY, USA, 1985. [Google Scholar]

- Barsom, J.; Rolfe, S. Fracture and Fatigue in Structure: Application of Fracture Mechanics; American Society for Testing and Materials: Philadelphia, PA, USA, 1999. [Google Scholar]

- Broek, D. Elementary Engineering Fracture Mechanics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Belytschko, T.; Black, T. Elastic crack growth in finite elements with minimal remeshing. Int. J. Numer. Methods Eng. 1999, 45, 601–620. [Google Scholar] [CrossRef]

- Bergara, A.; Dorado, J.I.; Martin-Meizoso, A.; Martínez-Esnaola, J.M. Fatigue crack propagation in complex stress fields: Experiments and numerical simulations using the Extended Finite Element Method (XFEM). Int. J. Fatigue 2017, 103, 112–121. [Google Scholar] [CrossRef]

- Alshoaibi, A.M. Finite element procedures for the numerical simulation of fatigue crack propagation under mixed mode loading. Struct. Eng. Mech. 2010, 35, 283–299. [Google Scholar] [CrossRef]

- Alshoaibi, A.M. Comprehensive Comparisons of Two and Three Dimensional Numerical Estimation of Stress Intensity Factors and Crack propagation in Linear Elastic Analysis. Int. J. Integr. Eng. 2019, 11, 45–52. [Google Scholar] [CrossRef]

- Alshoaibi, A.M.; Fageehi, Y.A. 2D finite element simulation of mixed mode fatigue crack propagation for CTS specimen. J. Mater. Res. Technol. 2020, 9, 7850–7861. [Google Scholar] [CrossRef]

- Fageehi, Y.A.; Alshoaibi, A.M. Numerical Simulation of Mixed-Mode Fatigue Crack Growth for Compact Tension Shear Specimen. Adv. Mater. Sci. Eng. 2020. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Q.; Zeng, W.; Liu, G.R.; Sun, J.; He, L.; Bui, T.Q. Dynamic brittle crack propagation modeling using singular edge-based smoothed finite element method with local mesh rezoning. Eur. J. Mech. A/Solids 2019, 76, 208–223. [Google Scholar] [CrossRef]

- Gomes, G.; Miranda, A.C. Analysis of crack growth problems using the object-oriented program bemcracker2D. Frat. Ed Integrità Strutt. 2018, 12, 67–85. [Google Scholar] [CrossRef]

- Fageehi, Y.A.; Alshoaibi, A.M. Nonplanar Crack Growth Simulation of Multiple Cracks Using Finite Element Method. Adv. Mater. Sci. Eng. 2020. [Google Scholar] [CrossRef]

- Paris, P.; Erdogan, F. A critical analysis of crack propagation laws. J. Basic Eng. 1963, 85, 528–533. [Google Scholar] [CrossRef]

- Coffin, L. Fatigue and Endurance of Metals. In Cyclic Deformation and Fatigue of Metals (Russian Translation); USSR: Moscow, Russia, 1963; pp. 257–272. [Google Scholar]

- Wöhler, A. Versuche zur Ermittlung der auf die Eisenbahnwagenachsen einwirkenden Kräfte und die Widerstandsfähigkeit der Wagen-Achsen. Z. Bauwes. 1860, 10, 583–614. [Google Scholar]

- Bjørheim, F. Practical Comparison of Crack Meshing in ANSYS Mechanical APDL 19.2. Master’s Thesis, University of Stavanger, Stavanger, Norway, 2019. [Google Scholar]

- ANSYS. Academic Research Mechanical, Release 19.2, Help System. In Coupled Field Analysis Guide, 2020; ANSYS, Inc.: Canonsburg, PA, USA, 2020. [Google Scholar]

- Walters, M.C.; Paulino, G.H.; Dodds, R.H., Jr. Interaction integral procedures for 3-D curved cracks including surface tractions. Eng. Fract. Mech. 2005, 72, 1635–1663. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Cleveland, OH, USA, 2017. [Google Scholar]

- Miranda, A.C.O.; Meggiolaro, M.A.; Castro, J.T.P.; Martha, L.F.; Bittencourt, T.N. Fatigue life and crack path predictions in generic 2D structural components. Eng. Fract. Mech. 2003, 70, 1259–1279. [Google Scholar] [CrossRef]

- Azócar, D.; Elgueta, M.; Rivara, M.C. Automatic LEFM crack propagation method based on local Lepp–Delaunay mesh refinement. Adv. Eng. Softw. 2010, 41, 111–119. [Google Scholar] [CrossRef]

- Guo, Y.; Li, Q. Material configurational forces applied to mixed mode crack propagation. Theor. Appl. Fract. Mech. 2017, 89, 147–157. [Google Scholar] [CrossRef]

- Ma, W.; Liu, G.; Wang, W. A coupled extended meshfree–Smoothed meshfree method for crack growth simulation. Theor. Appl. Fract. Mech. 2020, 107, 102572. [Google Scholar] [CrossRef]

- Fett, T. Stress Intensity Factors, T-Stresses, Weight Functions: Supplement Volume; KIT Scientific Publishing: Karlsruhe, Germeny, 2009; Volume 55. [Google Scholar]

- Giner, E.; Sukumar, N.; Tarancón, J.E.; Fuenmayor, F.J. An Abaqus implementation of the extended finite element method. Eng. Fract. Mech. 2009, 76, 347–368. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, H. How to control the crack to propagate along the specified path feasibly? Comput. Methods Appl. Mech. Eng. 2018, 336, 554–577. [Google Scholar] [CrossRef]

- Rice, J.R. Mechanics of crack tip deformation and extension by fatigue. In Fatigue Crack Propagation; ASTM: West Conshohocken, PA, USA, 1967; pp. 247–309. [Google Scholar]

| Property | Value in Metric Units |

|---|---|

| Modulus of elasticity, E | 205 GPa |

| Poisson’s ratio, υ | 0.333 |

| Yield strength, | 491 MPa |

| Threshold stress intensity factor, Kth | |

| Paris’ law coefficient, C | |

| Paris’ law exponent, m | 2.1 |

| Property | Value in Metric Units |

|---|---|

| Modulus of elasticity, E | 71.7 GPa |

| Poisson’s ratio, υ | 0.33 |

| Yield strength, σy | 469 MPa |

| Ultimate strength, σu | 538 MPa |

| Fracture toughness of KIC | 938.25 MPa mm0.5 |

| Paris’ law coefficient, C | 5.27 × 10−10 |

| Paris’ law exponent, m | 2.947 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fageehi, Y.A. Fatigue Crack Growth Analysis with Extended Finite Element for 3D Linear Elastic Material. Metals 2021, 11, 397. https://doi.org/10.3390/met11030397

Fageehi YA. Fatigue Crack Growth Analysis with Extended Finite Element for 3D Linear Elastic Material. Metals. 2021; 11(3):397. https://doi.org/10.3390/met11030397

Chicago/Turabian StyleFageehi, Yahya Ali. 2021. "Fatigue Crack Growth Analysis with Extended Finite Element for 3D Linear Elastic Material" Metals 11, no. 3: 397. https://doi.org/10.3390/met11030397

APA StyleFageehi, Y. A. (2021). Fatigue Crack Growth Analysis with Extended Finite Element for 3D Linear Elastic Material. Metals, 11(3), 397. https://doi.org/10.3390/met11030397