Effect of Mn Addition on Hot-Working Behavior and Microstructure of Hot-Rolled Medium-Mn Steels

Abstract

1. Introduction

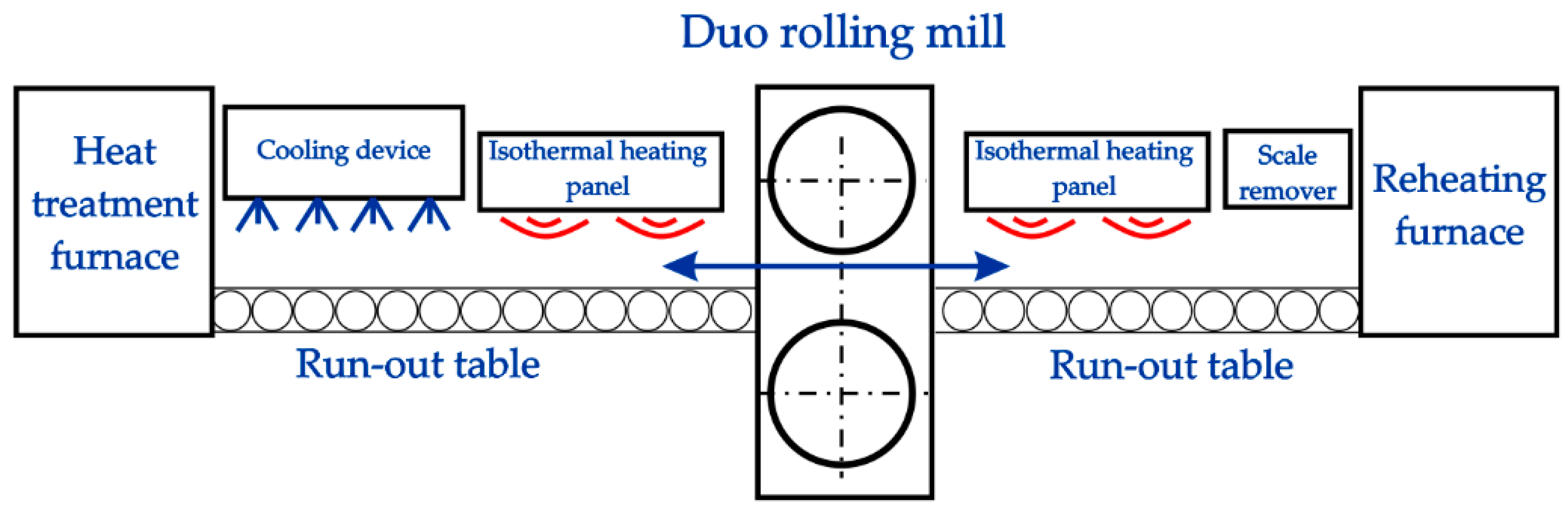

2. Materials and Methods

- Thickness of strip;

- Rolling speed;

- Temperature of strip during cooling;

- Roll load force during rolling;

- Time of pass;

- Time between passes.

3. Results and Discussion

3.1. Casting and Forging

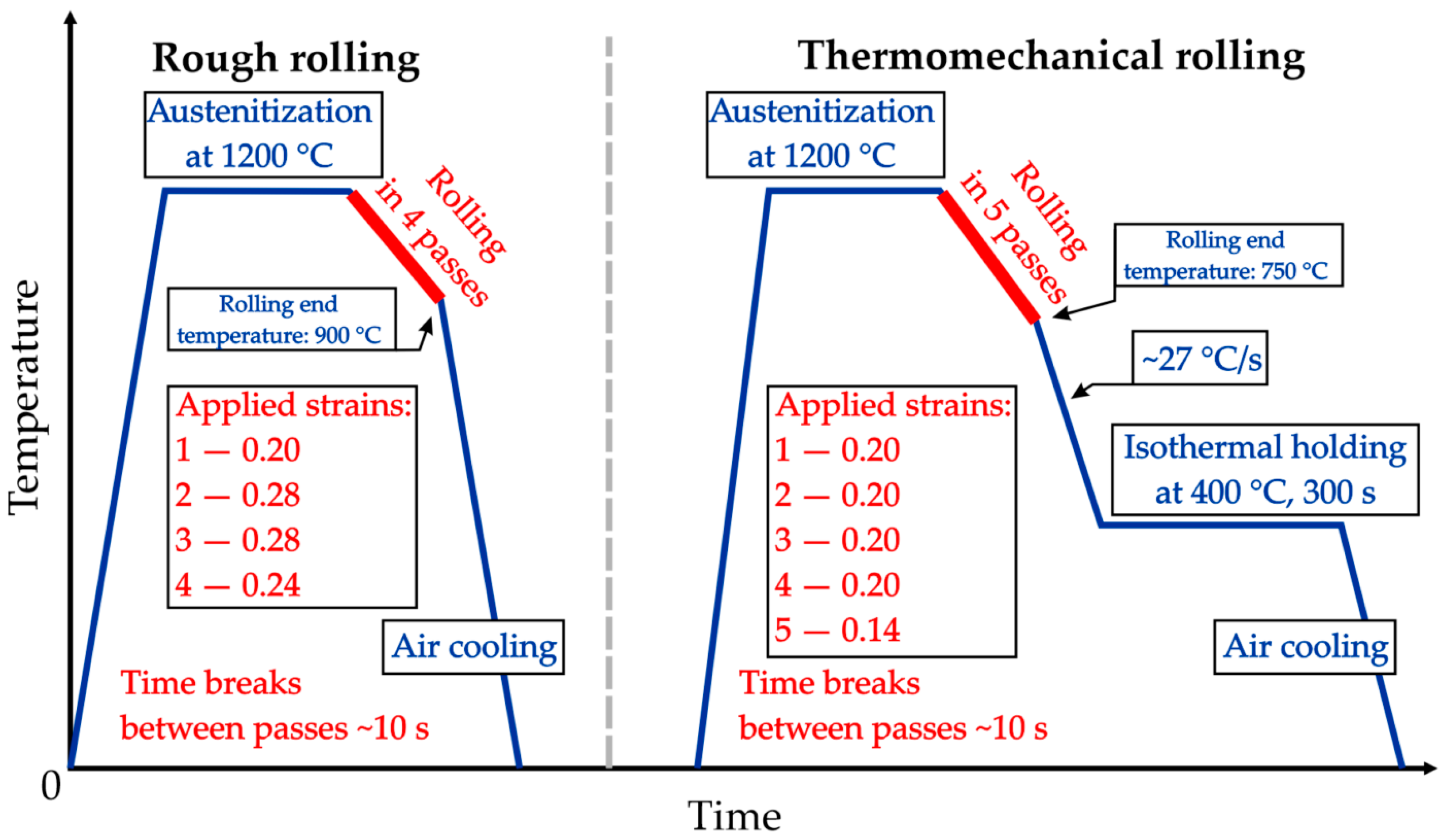

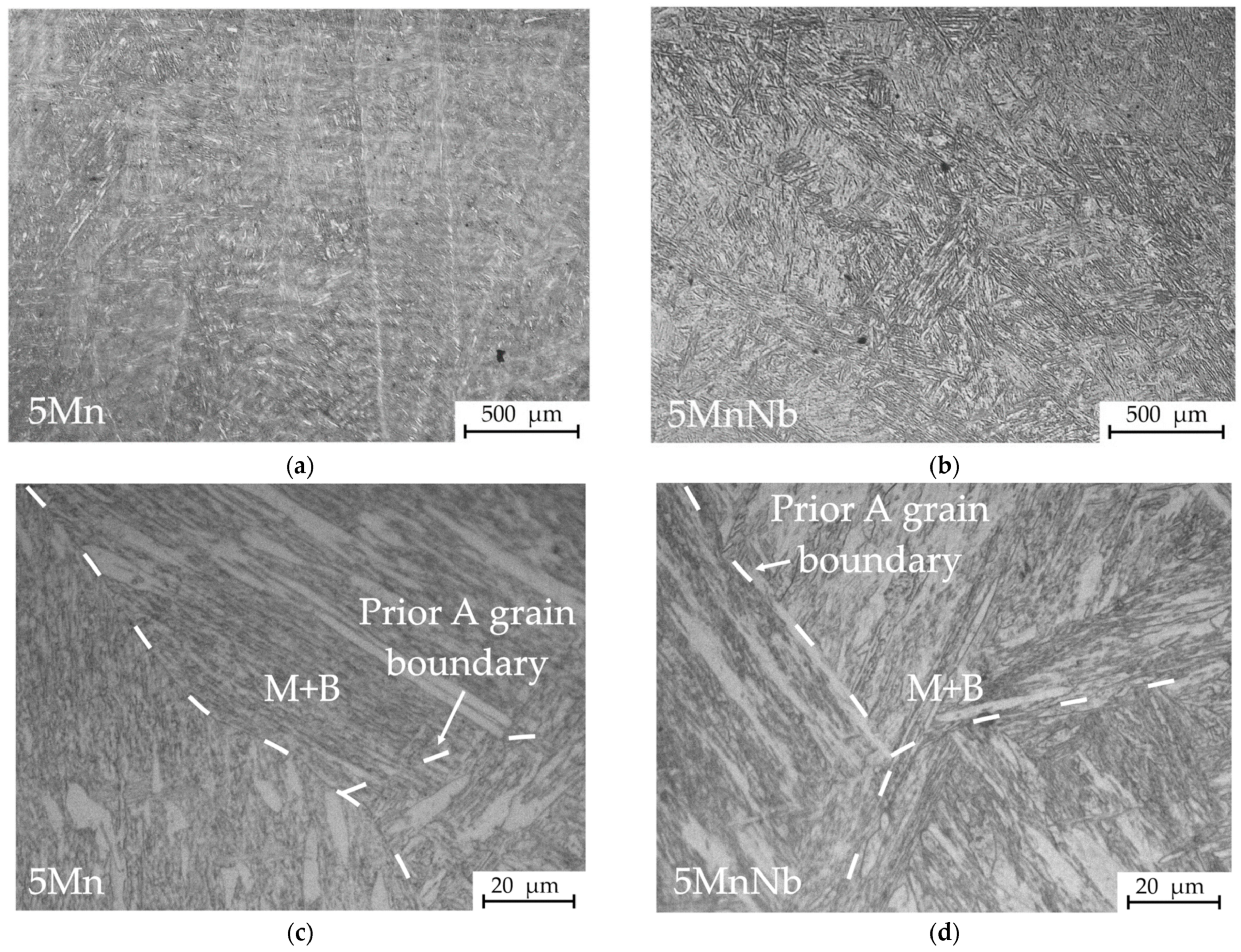

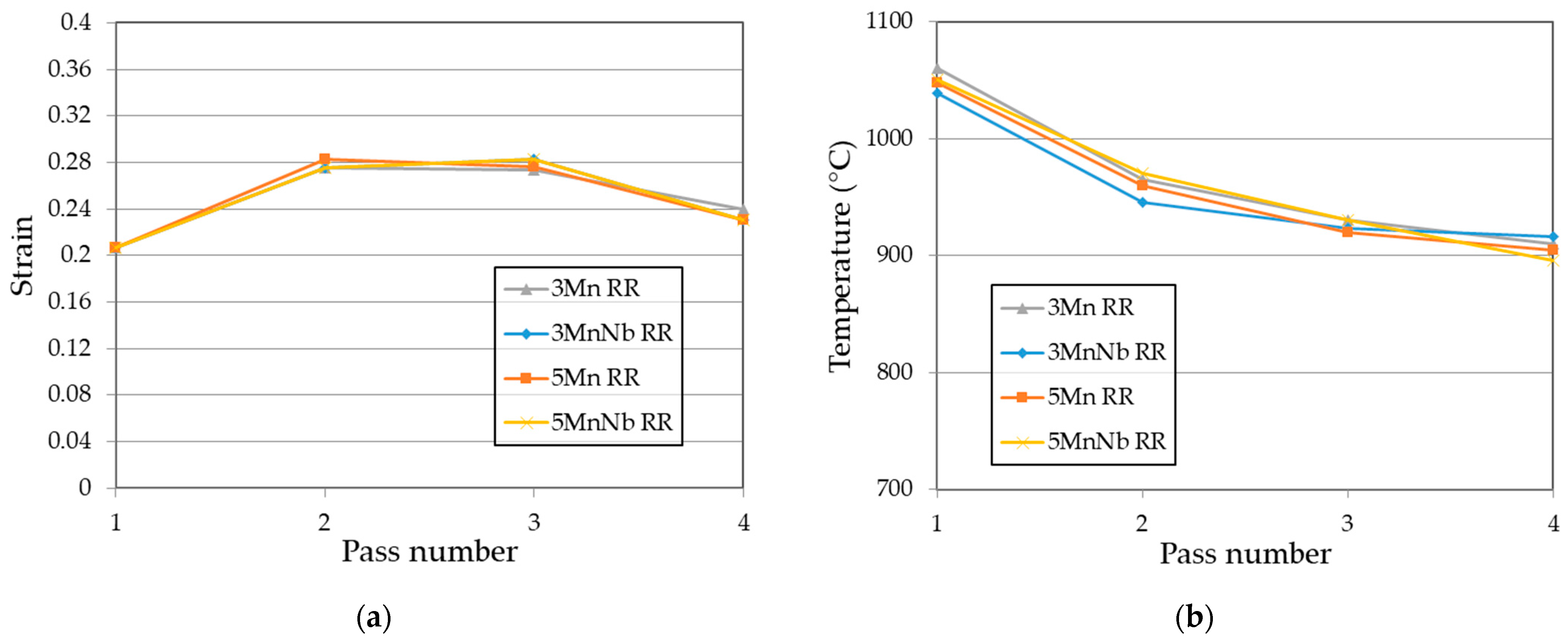

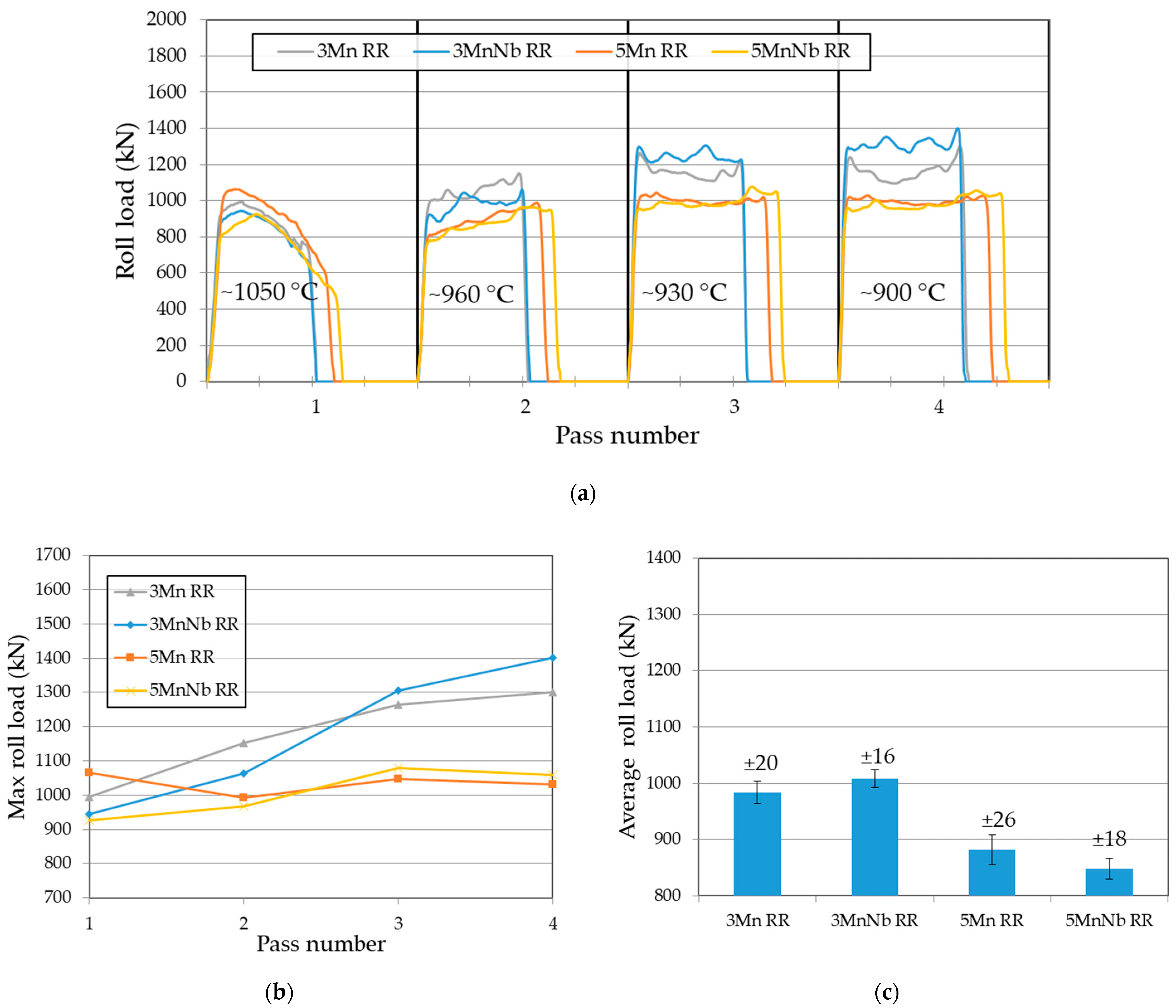

3.2. Rough Rolling

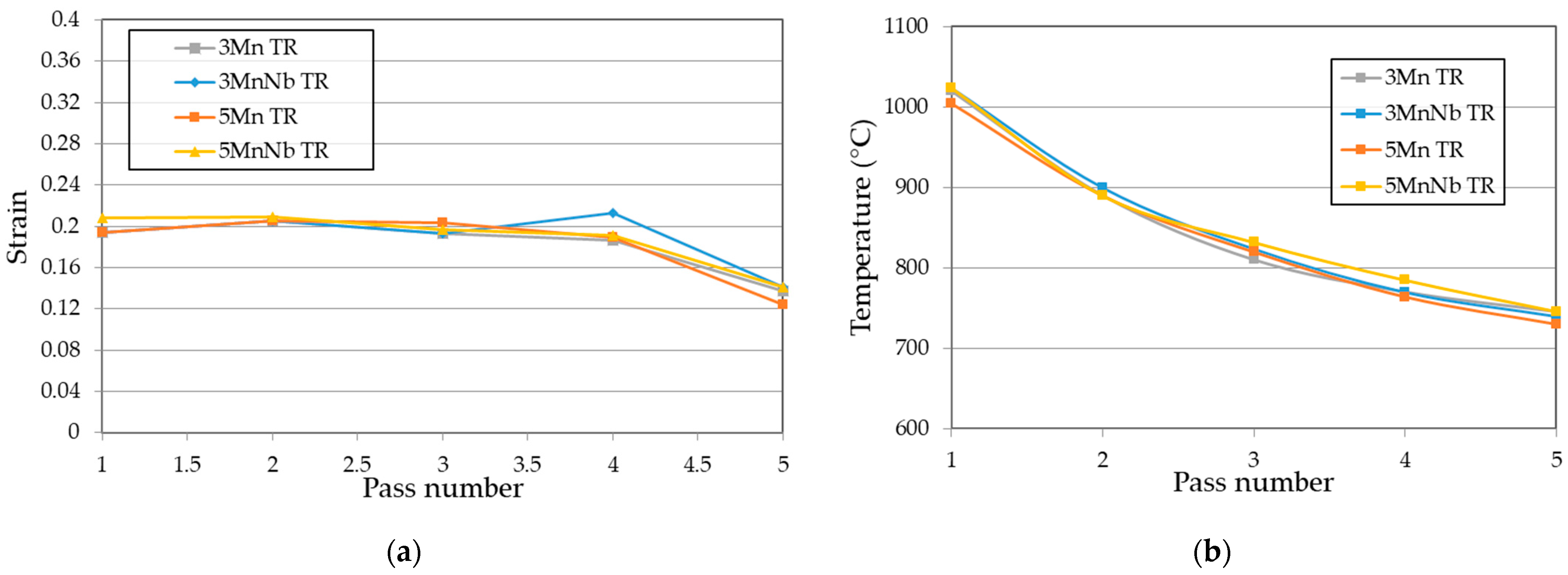

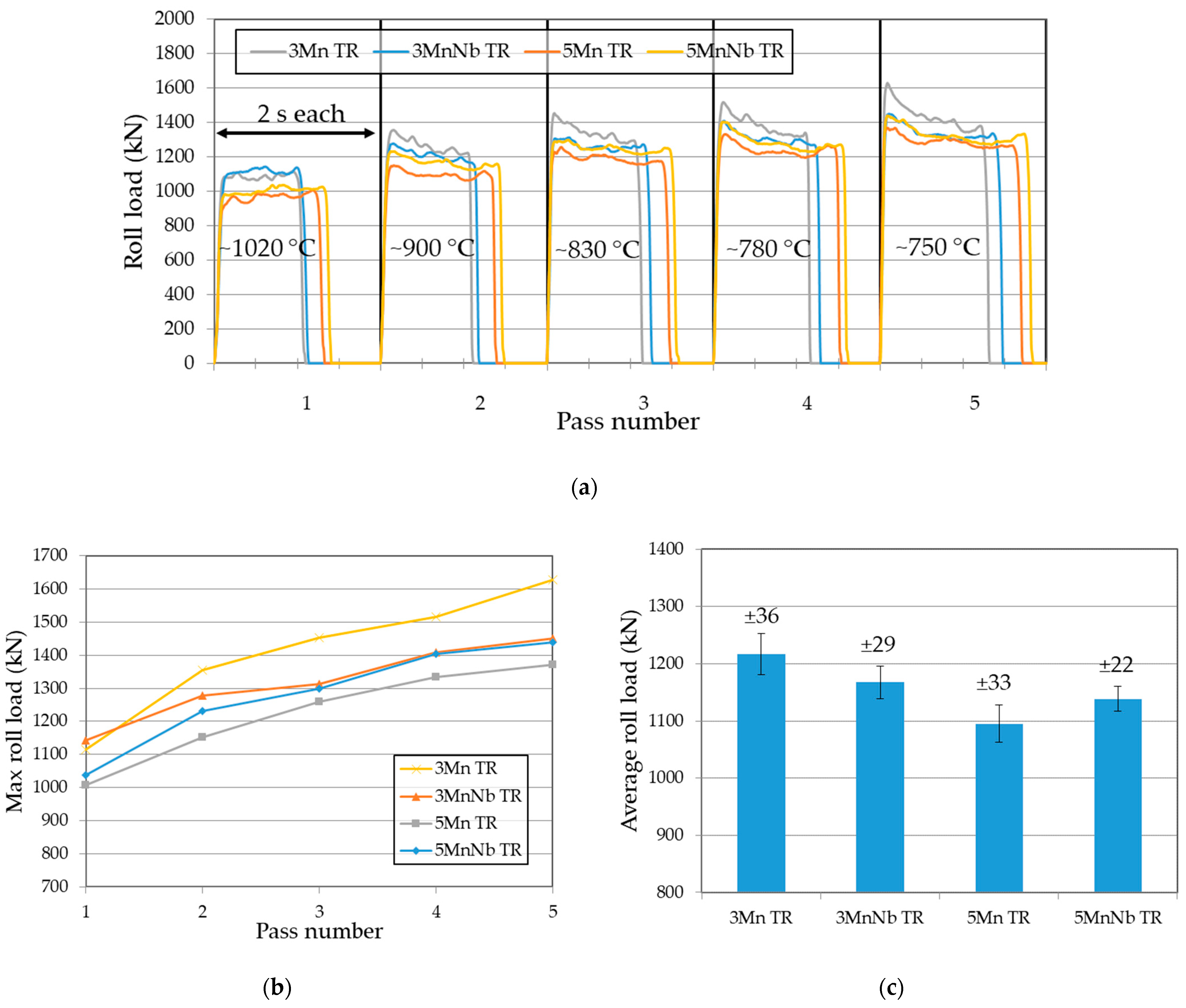

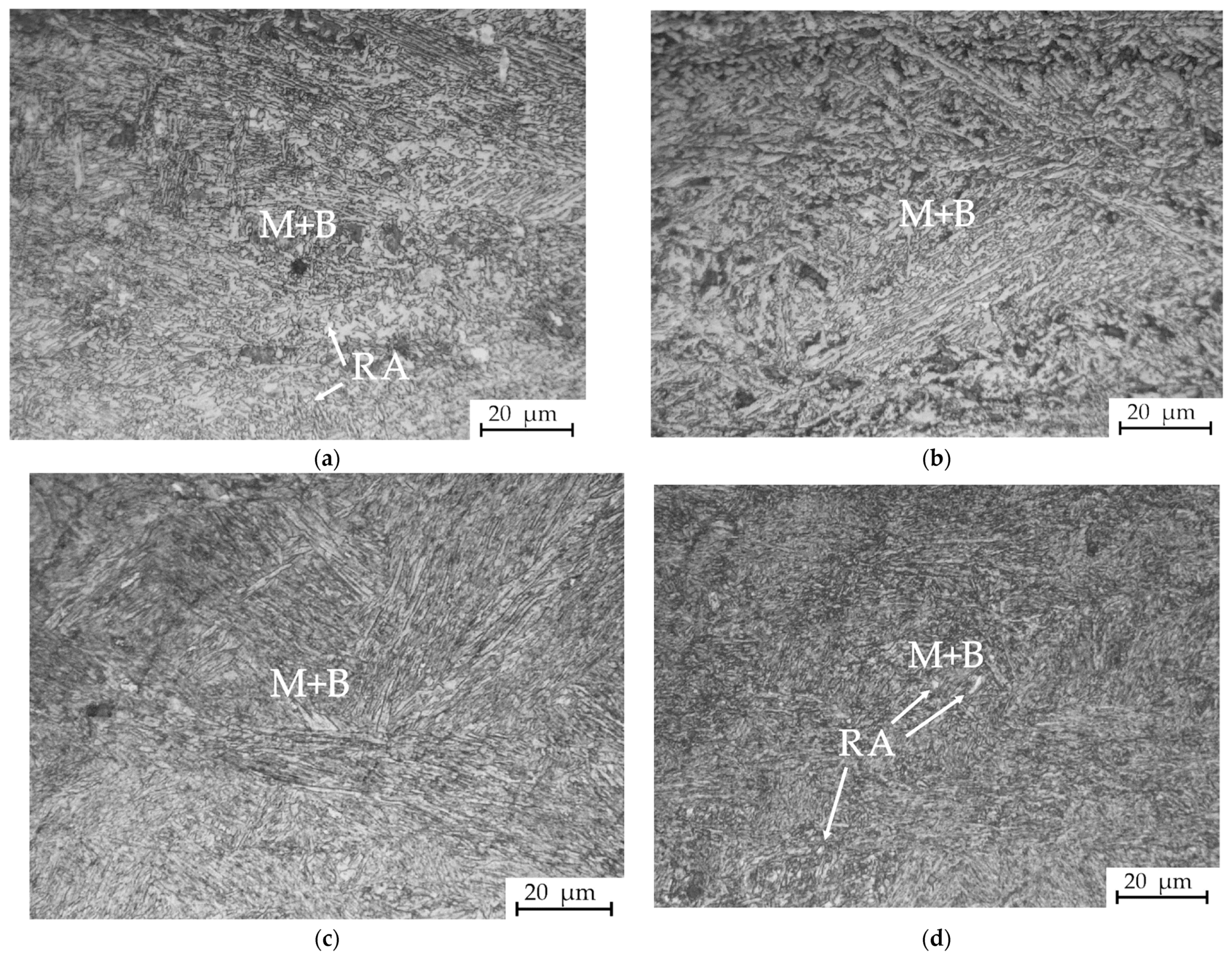

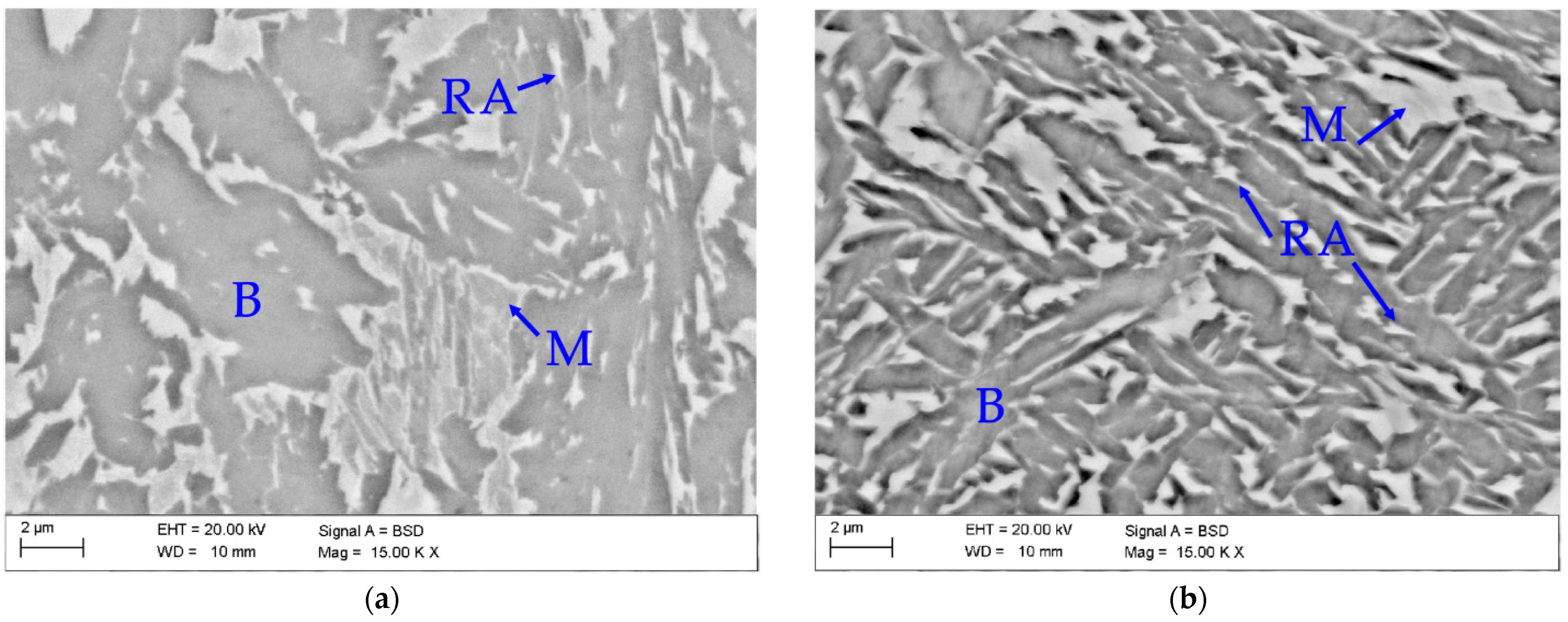

3.3. Thermomechanical Rolling

4. Conclusions

- The applied production process provides obtaining fine-grained multiphase steels with some fractions of retained austenite. For thermomechanically processed steels with a medium-Mn content, the 3Mn concept is more suitable than the 5Mn approach due to the better stabilization of the retained austenite in alloys with the lower Mn content.

- Thermomechanical rolling provides higher microstructure refinement and better homogenization compared to the initial as-forged state.

- The applied semi-industrial rolling line enables the production of good quality sheet samples of medium-Mn steels with a reasonable temperature control and force-energetic parameters acquisition.

- Steels containing 3% Mn generate higher forces both during rough and thermomechanical rolling, which is related to faster recrystallization softening in alloys containing 5% Mn addition.

- The addition of 0.04% Nb has no significant effect on the hot-working behavior of the investigated medium-Mn steels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kučerová, L.; Opatová, K.; Káňa, J.; Jirková, H. High Versatility of Niobium Alloyed AHSS. Arch. Metall. Mater. 2017, 62, 1485–1491. [Google Scholar] [CrossRef]

- Kuziak, R.; Kawalla, R.; Waengler, S. Advanced High Strength Steels for Automotive Industry. Arch. Civ. Mech. Eng. 2008, 8, 103–117. [Google Scholar] [CrossRef]

- Keeler, S.; Kimchi, M.; Mc-oney, P.J. Advanced High-Strength Steels Application Guidelines V6; WorldAutoSteel: Middletown, OH, USA, 2017. [Google Scholar]

- Grajcar, A.; Radwański, K. Microstructural comparison of the thermomechanically treated and cold deformed Nb-microalloyed TRIP steel. Mater. Technol. 2014, 48, 679–683. [Google Scholar]

- Caballero, F.G.; GarcíA-Mateo, C.; Chao, J.; Santofimia, M.J.; Capdevila, C.; de Andrés, C.G. Effects of Morphology and Stability of Retained Austenite on the Ductility of TRIP-Aided Bainitic Steels. ISIJ Int. 2008, 48, 1256–1262. [Google Scholar] [CrossRef]

- Dobrzański, L.; Borek, W. Structure and Properties of High-Manganese TWIP, TRIP and TRIPLEX Steels. Aust. J. Multi-Discip. Eng. 2013, 9, 230–238. [Google Scholar] [CrossRef]

- Jabłońska, M.; Niewielski, G.; Kawalla, R. High Manganese TWIP Steel—Technological Plasticity and Selected Properties. Solid State Phenom. 2013, 212, 87–90. [Google Scholar] [CrossRef]

- Gronostajski, Z.; Niechajowicz, A.; Polak, S. Prospects for the Use of New-Generation Steels of the AHSS Type for Collision Energy Absorbing Components. Arch. Civ. Mech. Eng. 2010, 55, 221–230. [Google Scholar]

- Caballero, F.G.; Chao, J.; Cornide, J.; García-Mateo, C.; Santofimia, M.J.; Capdevila, C. Toughness of Advanced High Strength Bainitic Steels. Mater. Sci. Forum 2010, 638–642, 118–123. [Google Scholar] [CrossRef]

- Arlazarov, A.; Gouné, M.; Bouaziz, O.; Hazotte, A.; Petitgand, G.; Barges, P. Evolution of Microstructure and Mechanical Properties of Medium Mn Steels during Double Annealing. Mater. Sci. Eng. A 2012, 542, 31–39. [Google Scholar] [CrossRef]

- Chen, S.; Cao, Z.; Wang, C.; Huang, C.; Ponge, D.; Cao, W. Effect of Volume Fraction and Mechanical Stability of Austenite on Ductility of Medium Mn Steel. J. Iron Steel Res. Int. 2019, 26, 1209–1218. [Google Scholar] [CrossRef]

- Kozłowska, A.; Janik, A.; Radwański, K.; Grajcar, A. Microstructure Evolution and Mechanical Stability of Retained Austenite in Medium-Mn Steel Deformed at Different Temperatures. Materials 2019, 12, 3042. [Google Scholar] [CrossRef]

- Ding, R.; Tang, D.; Zhao, A.; Dong, R.; Cheng, J.; Meng, X. Effect of Intercritical Temperature on Quenching and Partitioning Steels Originated from Martensitic Pre-Microstructure. J. Mater. Res. 2014, 29, 2525–2533. [Google Scholar] [CrossRef]

- Glover, A.; Gibbs, P.J.; Liu, C.; Brown, D.W.; Clausen, B.; Speer, J.G.; De Moor, E. Deformation Behavior of a Double Soaked Medium Manganese Steel with Varied Martensite Strength. Metals 2019, 9, 761. [Google Scholar] [CrossRef]

- Skowronek, A.; Morawiec, M.; Kozłowska, A.; Pakieła, W. Effect of Hot Deformation on Phase Transformation Kinetics in Isothermally Annealed 3Mn-1.6Al Steel. Materials 2020, 13, 5817. [Google Scholar] [CrossRef] [PubMed]

- Adamczyk, M.; Kuc, D.; Hadasik, E. Modelling of Structure Changes in TRIP Type Steel during Hot Deformation. Arch. Civ. Mech. Eng. 2008, 8, 5–13. [Google Scholar] [CrossRef]

- Kokosza, A.; Pacyna, J. Influence of Austenitising Temperature on Kinetics of Phase Transformations in Medium Carbon TRIP Steel. Mater. Sci. Technol. 2015, 31, 803–807. [Google Scholar] [CrossRef]

- Paul, S.K. A Critical Review on Hole Expansion Ratio. Materialia 2020, 9, 100566. [Google Scholar] [CrossRef]

- Hadasik, E.; Kuziak, R.; Kawalla, R.; Adamczyk, M.; Pietrzyk, M. Rheological Model for Simulation of Hot Rolling of New Generation Steel Strips for Automotive Applications. Steel Res. Int. 2006, 77, 927–933. [Google Scholar] [CrossRef]

- Kučerová, L.; Bystrianský, M. Comparison of Thermo-Mechanical Treatment of C-Mn-Si-Nb and C-Mn-Si-Al-Nb TRIP Steels. Procedia Eng. 2017, 207, 1856–1861. [Google Scholar] [CrossRef]

- Speer, J.G.; Araujo, A.L.; Matlock, D.K.; de Moor, E. Nb-Microalloying in Next-Generation Flat-Rolled Steels: An Overview. Mater. Sci. Forum 2016, 879, 1834–1840. [Google Scholar] [CrossRef]

- Ranjan, R.; Beladi, H.; Singh, S.B.; Hodgson, P.D. Thermo-Mechanical Processing of TRIP-Aided Steels. Metall. Mater. Trans. A 2015, 46, 3232–3247. [Google Scholar] [CrossRef]

- Grajcar, A.; Kuziak, R. Softening Kinetics in Nb-Microalloyed TRIP Steels with Increased Mn Content. Adv. Mater. Res. 2011, 314–316, 119–122. [Google Scholar] [CrossRef]

- Larrañaga-Otegui, A.; Pereda, B.; Jorge-Badiola, D.; Gutiérrez, I. Austenite Static Recrystallization Kinetics in Microalloyed B Steels. Metall. Mater. Trans. A 2016, 47, 3150–3164. [Google Scholar] [CrossRef]

- Felker, C.A.; Speer, J.G.; De Moor, E.; Findley, K.O. Hot Strip Mill Processing Simulations on a Ti-Mo Microalloyed Steel Using Hot Torsion Testing. Metals 2020, 10, 334. [Google Scholar] [CrossRef]

- Nam, A.; Prüfert, U.; Pietrzyk, M.; Kawalla, R.; Prahl, U. Simulation of Thermal Phenomena in Reverse Strip-Rolling Process. Mater. Sci. Forum 2018, 941, 1424–1430. [Google Scholar] [CrossRef]

- Rauch, R.; Bzowski, K.; Kuziak, K.; Uranga, P.; Gutierrez, I.; Isasti, N.; Jacolot, R.; Kitowski, J.; Pietrzyk, M. Computer-Integrated Platform for Automatic, Flexible, and Optimal Multivariable Design of a Hot Strip Rolling Technology Using Advanced Multiphase Steels. Metals 2019, 9, 737. [Google Scholar] [CrossRef]

- Cabañas, N.; Penning, J.; Akdut, N.; De Cooman, B.C. High-Temperature Deformation Properties of Austenitic Fe-Mn Alloys. Metall. Mater. Trans. A 2006, 37, 3305–3315. [Google Scholar] [CrossRef]

- Garbarz, B.; Burian, W.; Woźniak, D. Semi-Industrial Simulation of in-Line Thermomechanical Processing and Heat Treatment of Nano-Duplex Bainite-Austenite Steel. Steel Res. Int. 2012, 1, 1251–1254. [Google Scholar]

- Grajcar, A.; Kuziak, R.; Zalecki, W. Hot Workability of Advanced High Strength Steels with Increased Manganese Content; METAL: Brono, Czech Republic, 2011; pp. 227–233. [Google Scholar]

- Hong, S.G.; Kang, K.B.; Park, C.G. Strain-Induced Precipitation of NbC in Nb and Nb–Ti Microalloyed HSLA Steels. Scr. Mater. 2002, 46, 163–168. [Google Scholar] [CrossRef]

- Opiela, M.; Grajcar, A. Microstructure and Anisotropy of Plastic Properties of Thermomechanically-Processed HSLA-Type Steel Plates. Metals 2018, 8, 304. [Google Scholar] [CrossRef]

- Grajcar, A.; Skrzypczyk, P.; Kuziak, R.; Gołombek, K. Effect of Finishing Hot-Working Temperature on Microstructure of Thermomechanically Processed Mn-Al Multiphase Steels. Steel Res. Int. 2014, 85, 1058–1069. [Google Scholar] [CrossRef]

- Poliak, E.I.; Bhattacharya, D. Aspects of Thermomechanical Processing of 3rd Generation Advanced High Strength Steels. Mater. Sci. Forum 2014, 783–786, 3–8. [Google Scholar] [CrossRef]

- Poddar, D.; Ghosh, C.; Bhattacharya, B.; Singh, V.K. Development of High Ductile Ultra High Strength Structural Steel through Stabilization of Retained Austenite and Stacking Fault. Mater. Sci. Eng. A 2019, 762, 138079. [Google Scholar] [CrossRef]

- Jacques, P.J.; Furnémont, Q.; Lani, F.; Pardoen, T.; Delannay, F. Multiscale Mechanics of TRIP-Assisted Multiphase Steels: I. Characterization and Mechanical Testing. Acta Mater. 2007, 55, 3681–3693. [Google Scholar] [CrossRef]

- Mukherjee, M.; Mohanty, O.N.; Hashimoto, S.; Hojo, T.; Sugimoto, K. Strain-Induced Transformation Behaviour of Retained Austenite and Tensile Properties of TRIP-Aided Steels with Different Matrix Microstructure. ISIJ Int. 2006, 46, 316–324. [Google Scholar] [CrossRef]

- Grajcar, A.; Skrzypczyk, P.; Wozniak, D. Thermomechanically Rolled Medium-Mn Steels Containing Retained Austenite. Arch. Metall. Mater. 2014, 59, 1691–1697. [Google Scholar] [CrossRef]

- Grajcar, A.; Kilarski, A.; Kozlowska, A. Microstructure–Property Relationships in Thermomechanically Processed Medium-Mn Steels with High al Content. Metals 2018, 8, 929. [Google Scholar] [CrossRef]

- Grajcar, A.; Kilarski, A.; Kozłowska, A.; Radwański, K. Microstructure Evolution and Mechanical Stability of Retained Austenite in Thermomechanically Processed Medium-Mn Steel. Materials 2019, 12, 501. [Google Scholar] [CrossRef]

- Sugimoto, K.; Tanino, H.; Kobayashi, J. Impact Toughness of Medium-Mn Transformation-Induced Plasticity-Aided Steels. Steel Res. Int. 2015, 86, 1151–1160. [Google Scholar] [CrossRef]

- Soleimani, M.; Kalhor, A.; Mirzadeh, H. Transformation-Induced Plasticity (TRIP) in Advanced Steels: A Review. Mater. Sci. Eng. A 2020, 795, 140023. [Google Scholar] [CrossRef]

| Steel | Chemical Element, wt.% | Total, wt.% | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Al | Si | Mo | Nb | S | P | ||

| 3Mn | 0.17 | 3.3 | 1.7 | 0.22 | 0.23 | - | 0.014 | 0.010 | 5.4 |

| 3MnNb | 0.17 | 3.1 | 1.6 | 0.22 | 0.22 | 0.04 | 0.005 | 0.008 | 5.2 |

| 5Mn | 0.16 | 4.7 | 1.6 | 0.20 | 0.20 | - | 0.004 | 0.008 | 6.7 |

| 5MnNb | 0.17 | 5.0 | 1.5 | 0.21 | 0.20 | 0.03 | 0.005 | 0.008 | 6.9 |

| Steel | Dimensions, mm | ||

|---|---|---|---|

| Thickness | Length | Width | |

| 3Mn | 23 | 320 | 155 |

| 3MnNb | 360 | ||

| 5Mn | 400 | ||

| 5MnNb | 470 | ||

| Steel | Dimensions, mm | ||

|---|---|---|---|

| Thickness | Length | Width | |

| 3Mn | 8.5 | 485 | 170 |

| 3MnNb | 500 | ||

| 5Mn | 580 | ||

| 5MnNb | 635 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skowronek, A.; Woźniak, D.; Grajcar, A. Effect of Mn Addition on Hot-Working Behavior and Microstructure of Hot-Rolled Medium-Mn Steels. Metals 2021, 11, 354. https://doi.org/10.3390/met11020354

Skowronek A, Woźniak D, Grajcar A. Effect of Mn Addition on Hot-Working Behavior and Microstructure of Hot-Rolled Medium-Mn Steels. Metals. 2021; 11(2):354. https://doi.org/10.3390/met11020354

Chicago/Turabian StyleSkowronek, Adam, Dariusz Woźniak, and Adam Grajcar. 2021. "Effect of Mn Addition on Hot-Working Behavior and Microstructure of Hot-Rolled Medium-Mn Steels" Metals 11, no. 2: 354. https://doi.org/10.3390/met11020354

APA StyleSkowronek, A., Woźniak, D., & Grajcar, A. (2021). Effect of Mn Addition on Hot-Working Behavior and Microstructure of Hot-Rolled Medium-Mn Steels. Metals, 11(2), 354. https://doi.org/10.3390/met11020354