Microstructure and Mechanical Properties of V-Alloyed Rebars Subjected to Tempcore Process

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

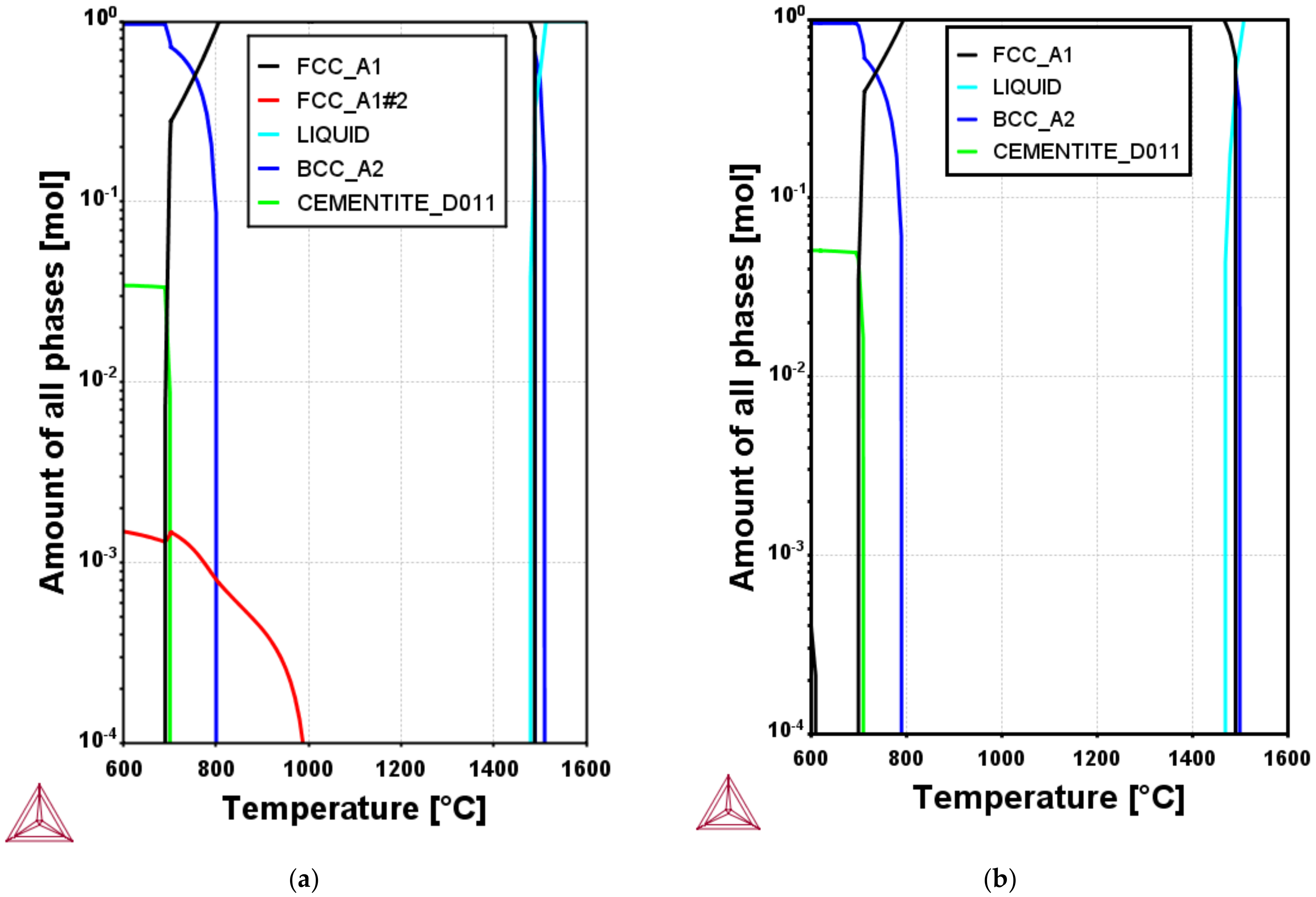

3.1. Thermo Dynamic Calculations

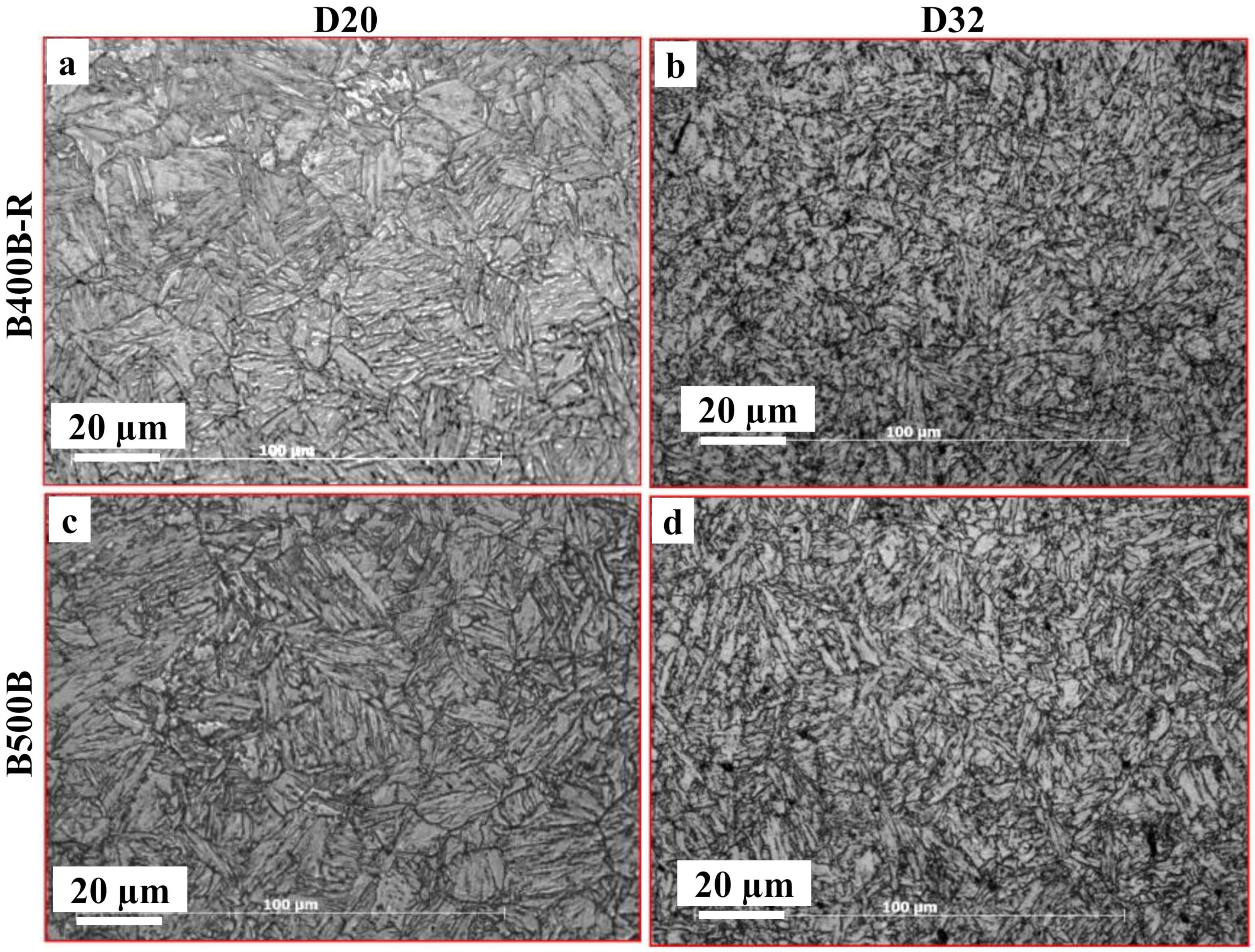

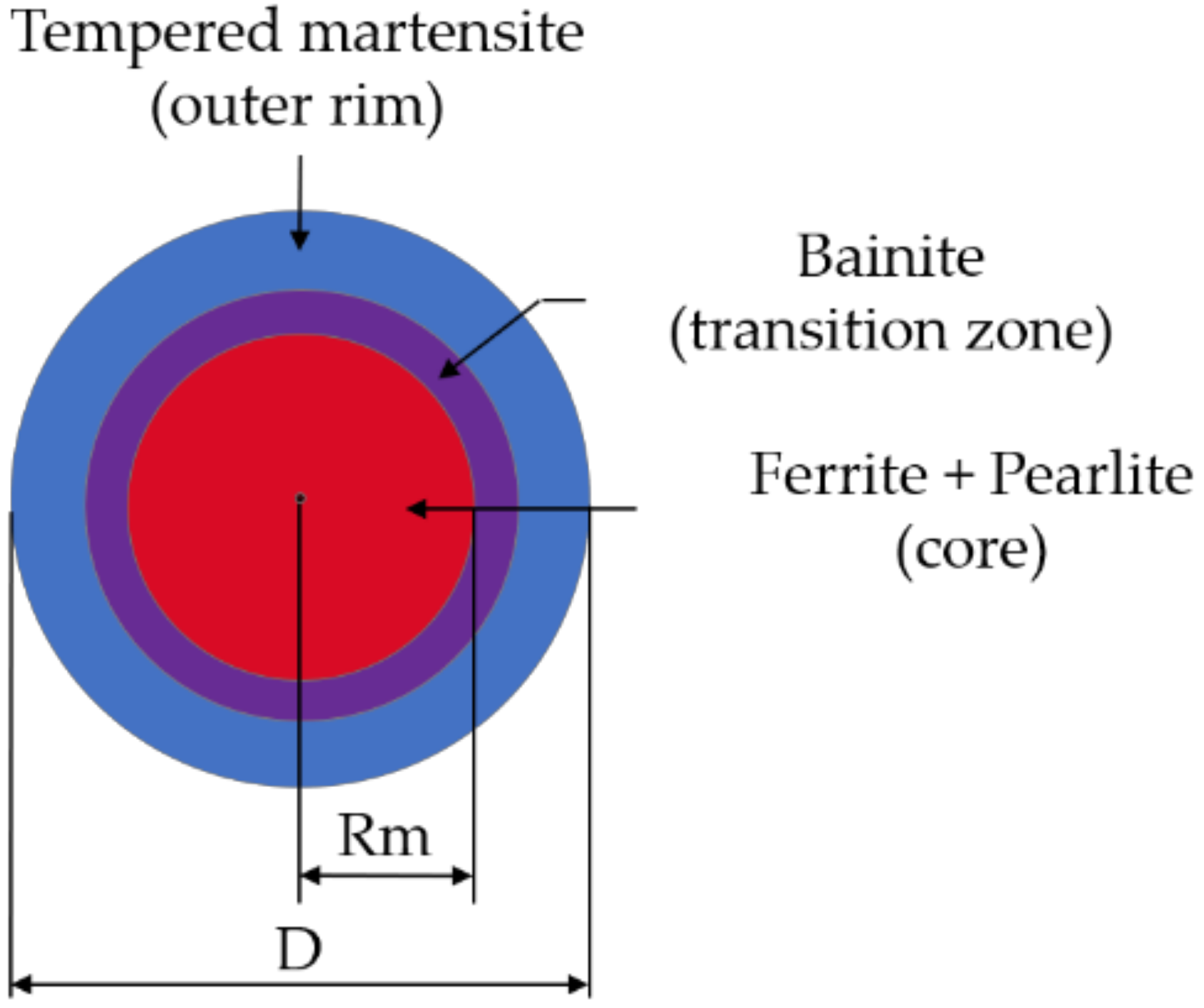

3.2. Microstructure Characteristics

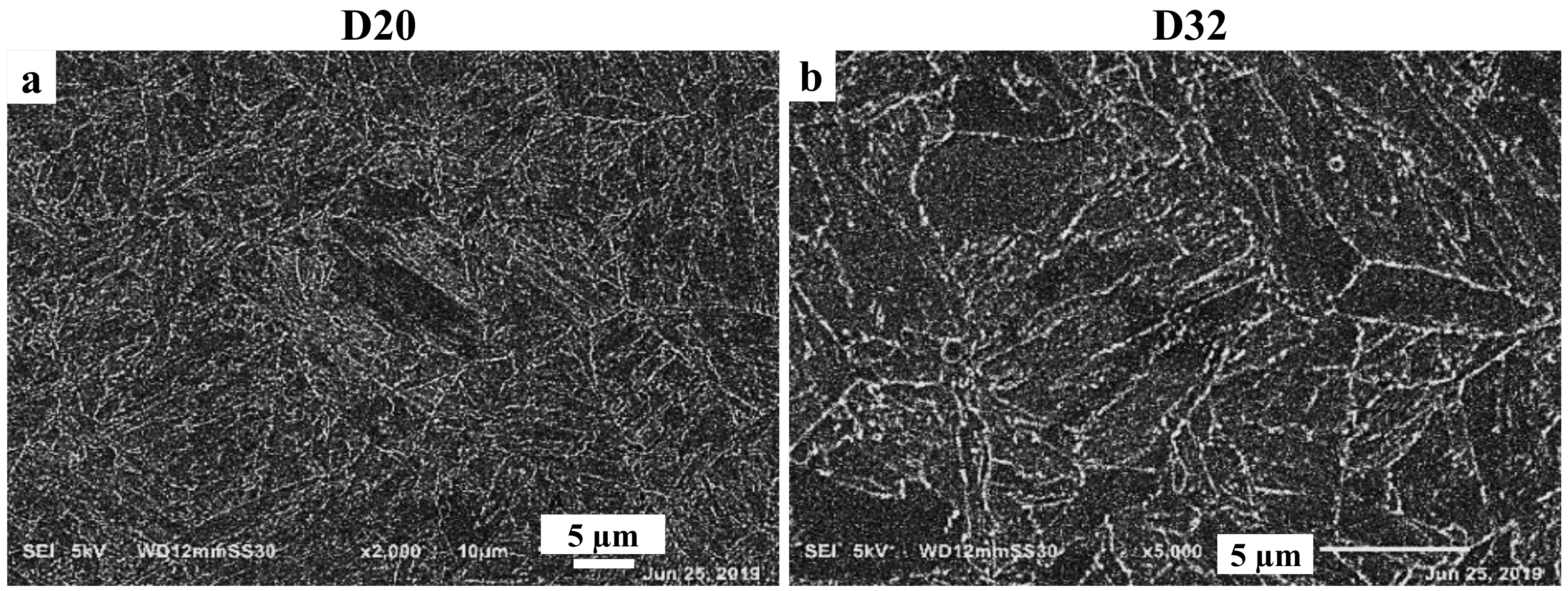

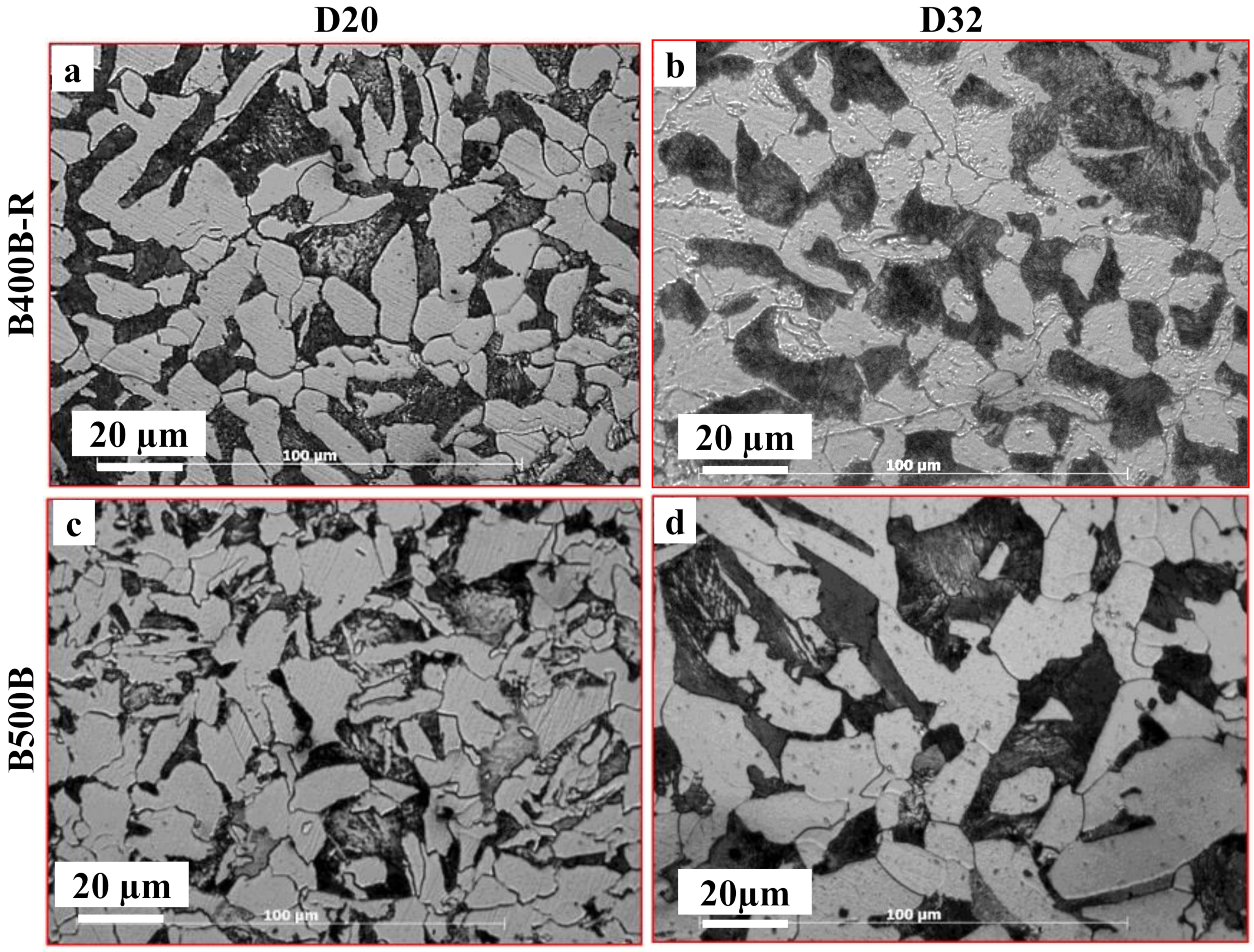

3.2.1. Outer Surface (rim)

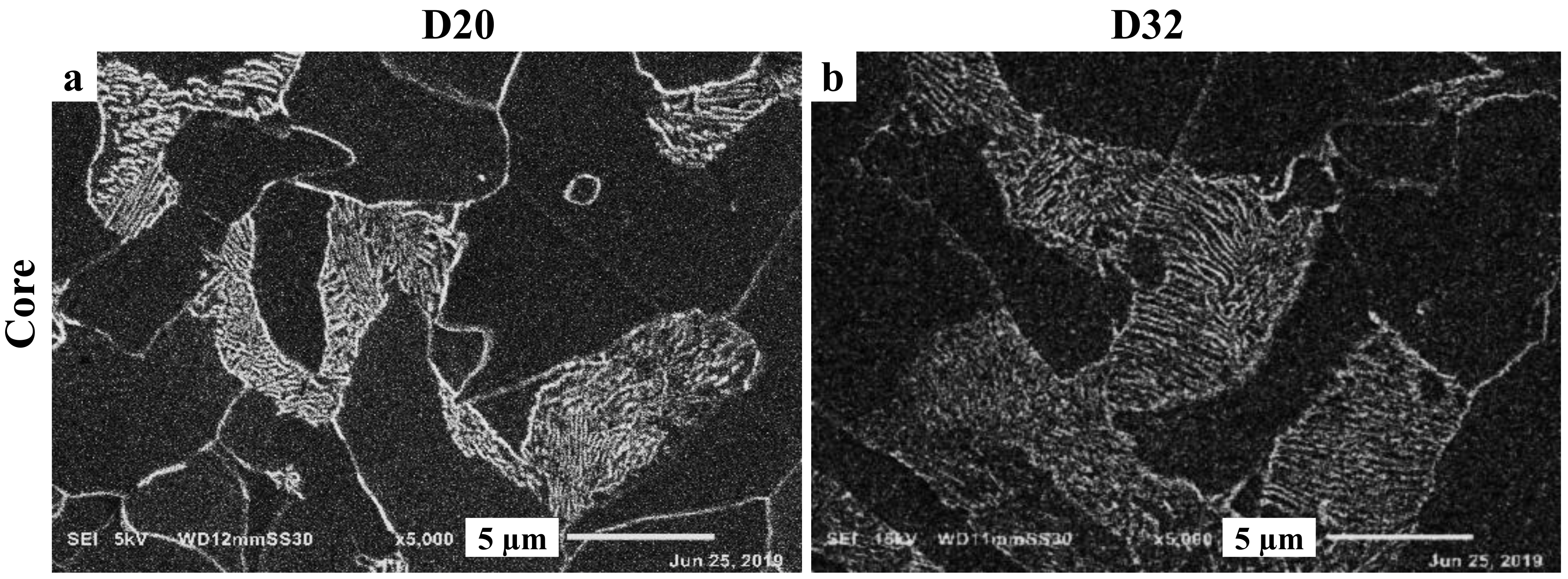

3.2.2. Core Zone

3.3. Mechanical Properties

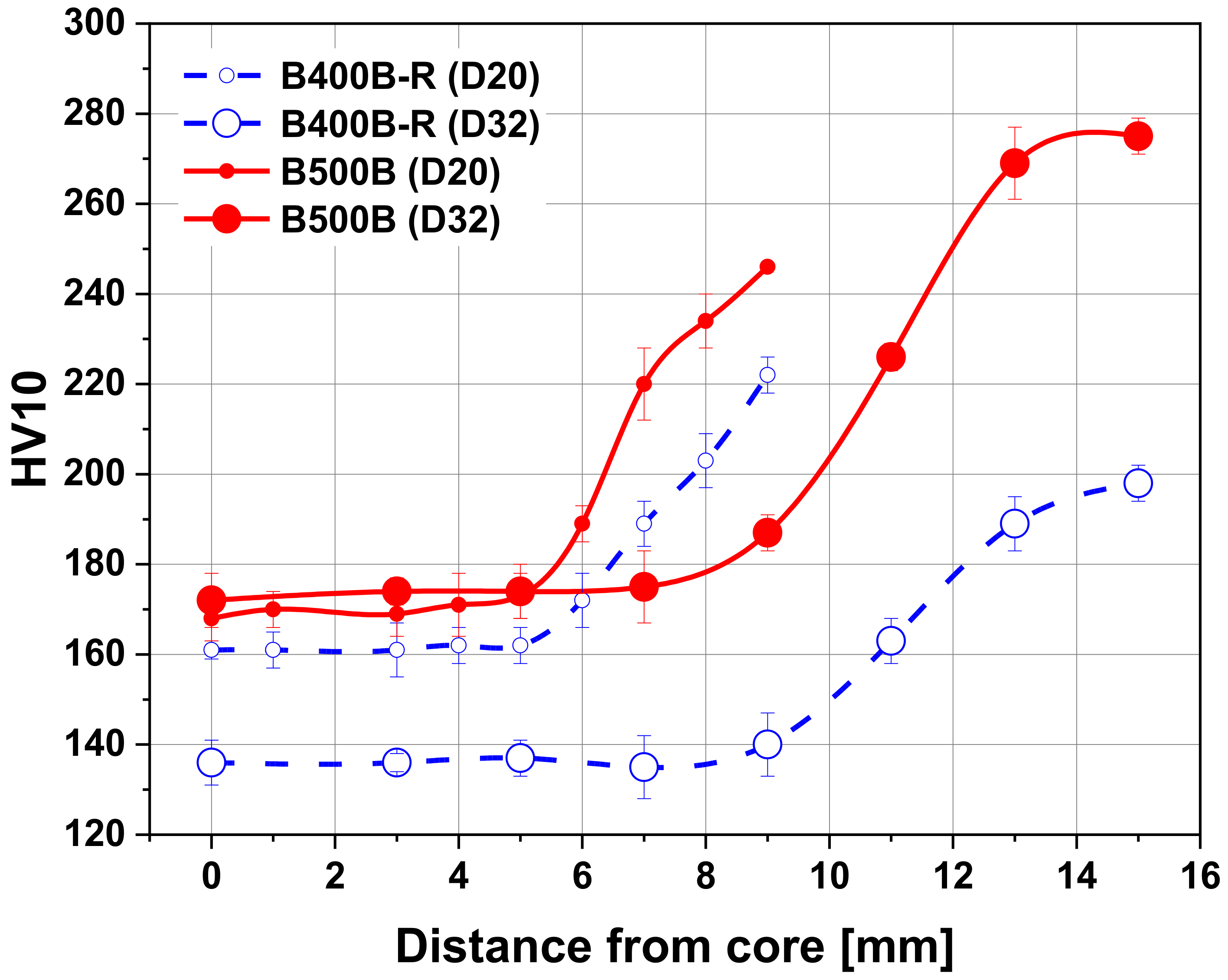

3.3.1. Hardness Profile

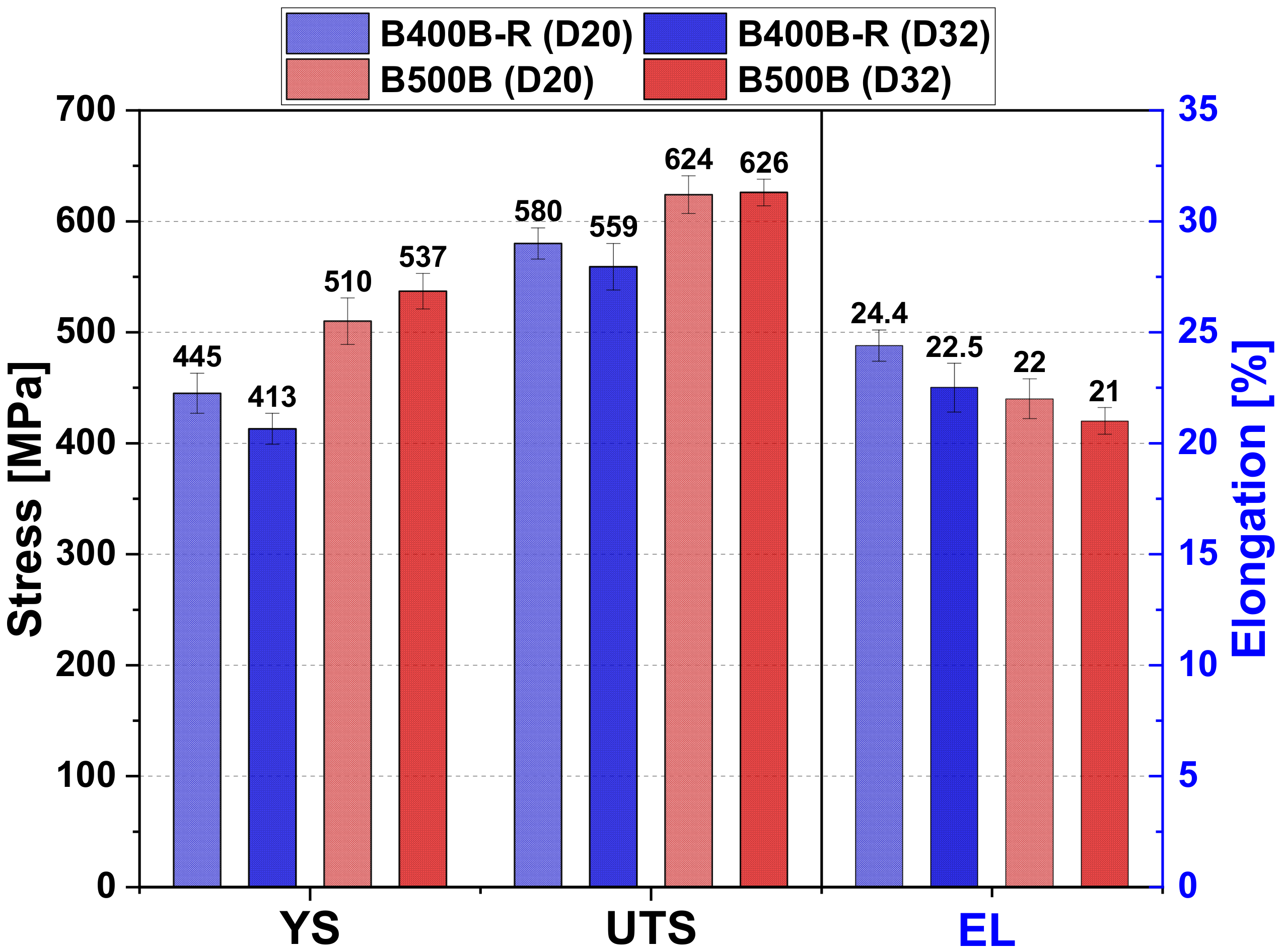

3.3.2. Tensile Strength

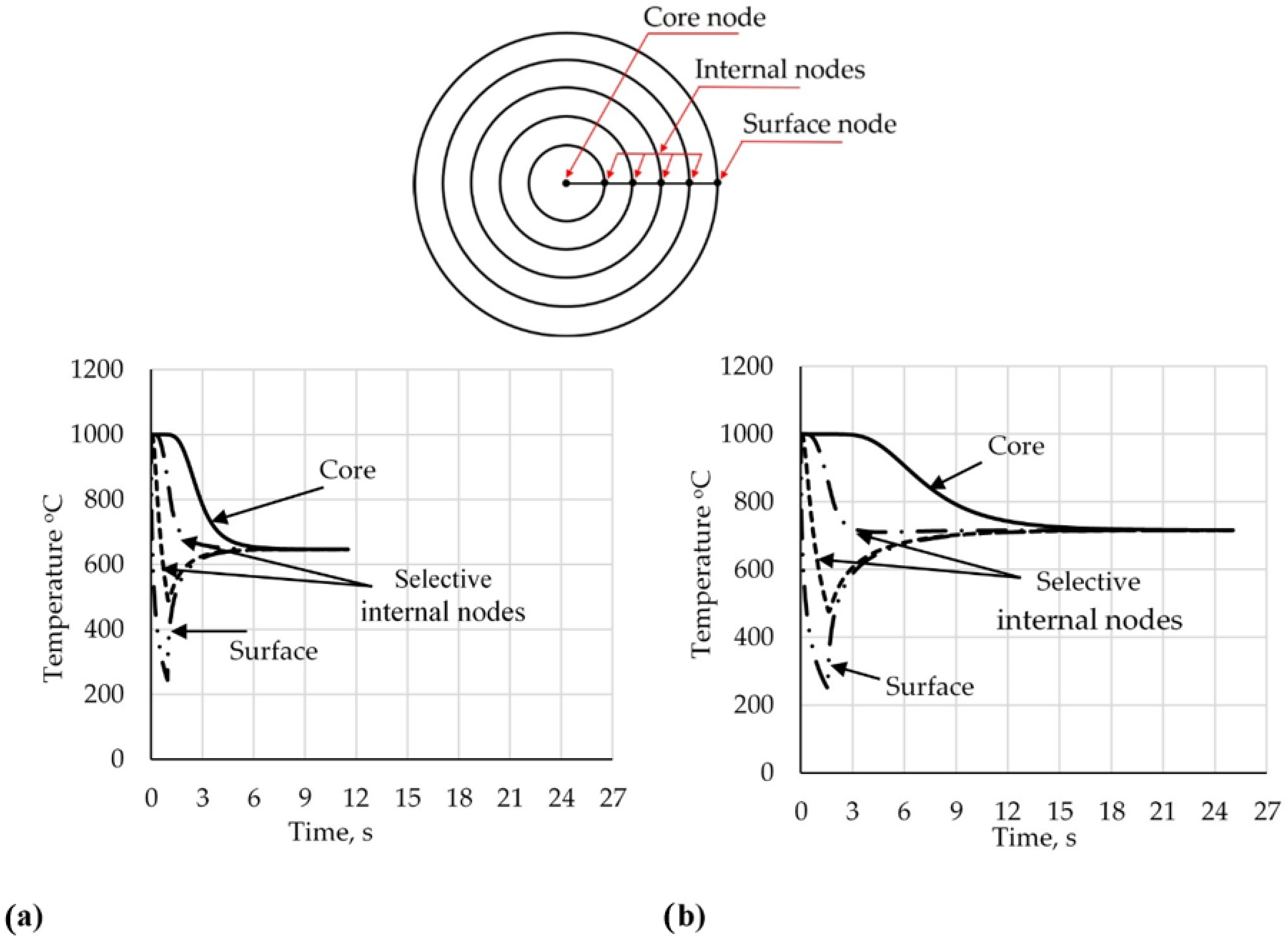

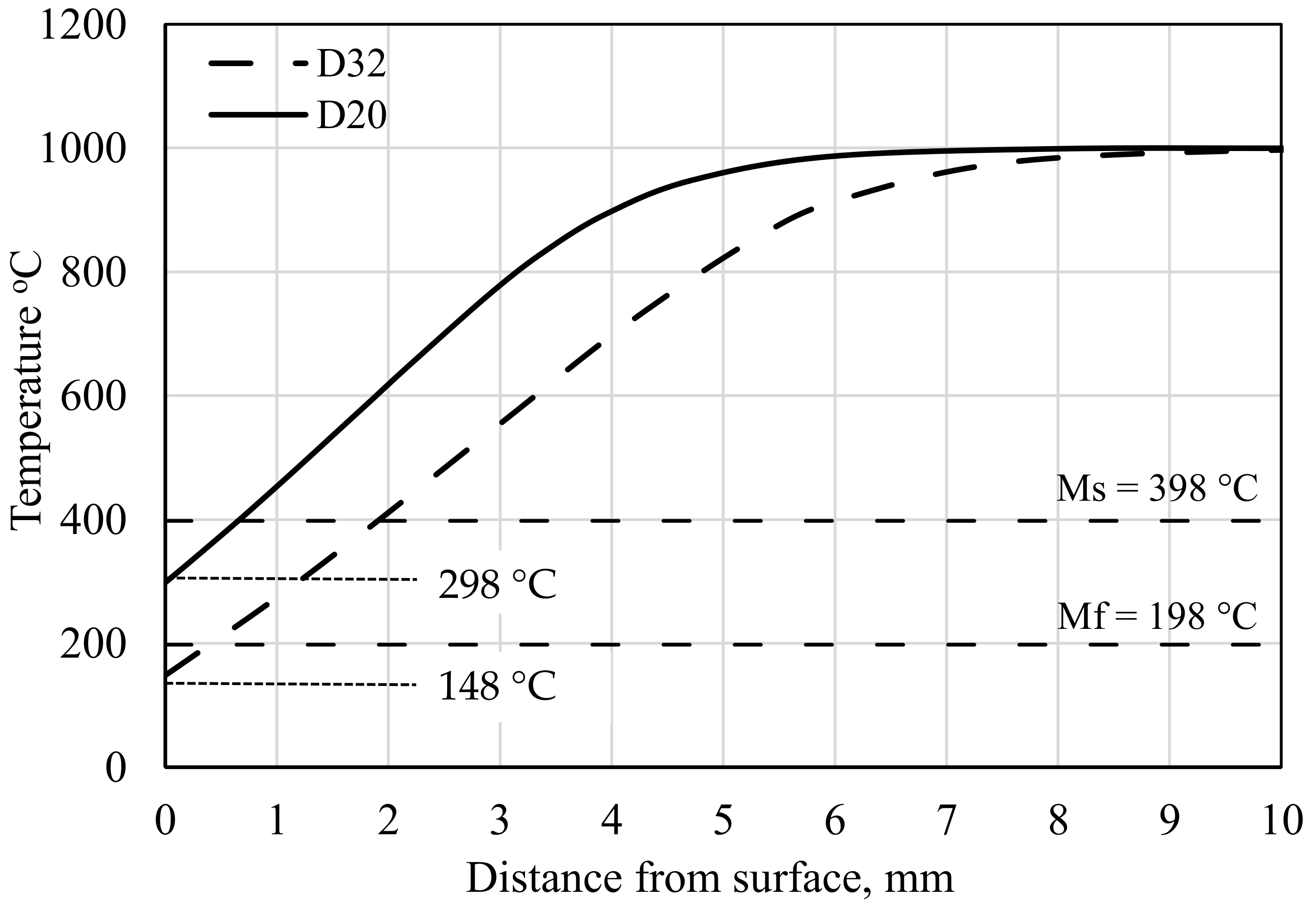

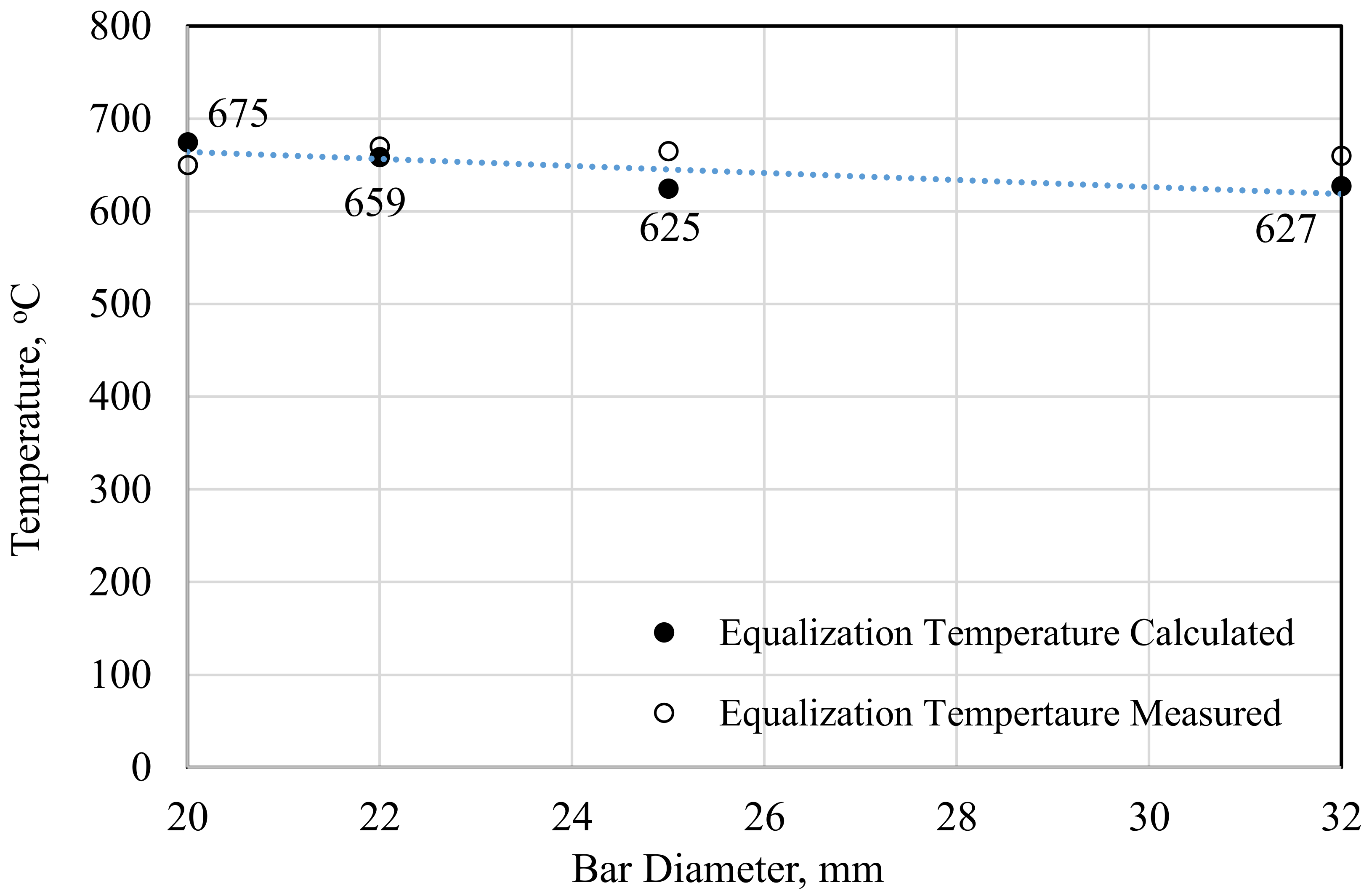

3.4. Evolution of Thermal Cycles

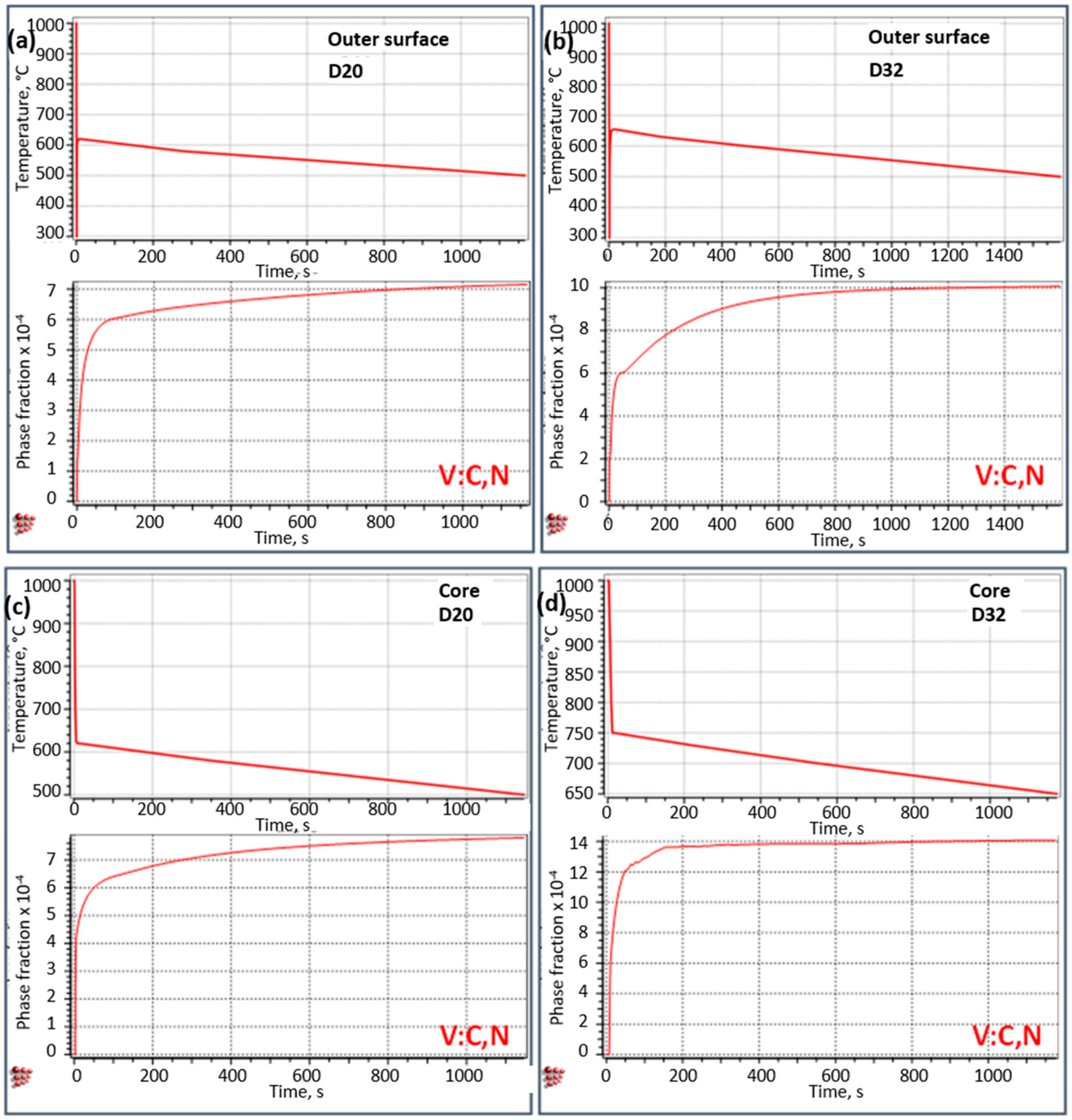

3.5. Precipitation Kinetics

4. Conclusions

- −

- Typical graded microstructures consisting of soft ferrite-pearlite core encapsulated with hard tempered martensite surface were observed for both diameters of each steel grade.

- −

- For both of B400B-R and B500B grades, the adopted speed of hot rolling-line of 7 m/s to manufacture D32 rebars is responsible for increasing the quenching time in the QTB and the corresponding increase in the tempered martensite depth compared with its counterpart during manufacturing D20 rebars processed by 13 m/s as the speed of rolling-line.

- −

- For B400B-R grade, D32 rebars show relatively softer microstructure with lower yield and tensile strength values than D20 rebars exhibit, which can be explained by the higher attainable core temperature for D32 as indicated from the thermal model. Such high core temperature leads to a larger degree of tempering for the martensite surface layer and relatively coarser ferrite-pearlite core, which were reflected by lower hardness values.

- −

- For V-alloyed B500B grade, an opposite behavior than that of B400B-R grade is observed. The higher attainable core temperature in case of processing D32 rebars renders the exploitation of full potential of V(N,C) precipitation possible in both of the core as well as the surface zones, which allows increasing the hardness, yield strength and tensile strength values compared with their counterparts in case of D20 rebars that experience relatively short precipitation time at relatively lower temperature.

- −

- The V-addition to B500B steel grade does not scarify the attainable total elongation in comparison to the B400B-R steel grade, since the observed differences are below 2.5%.

- −

- The current work emphasizes the additional advantages of tuning the microstructure and mechanical properties that can be realized from V-alloyed rebars processed by Tempcore practices, when the suitable equalizing temperature and quenching time can be properly adjusted to control and exploit the full potential of precipitation process. In the future work, the electrochemical behavior and bending characteristics of such rebars will be carefully investigated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Saastamoinen, A.; Kaijalainen, A.; Porter, D.A.; Suikkanen, P.; Yang, J.-R.; Tsai, Y.-T. The effect of finish rolling temperature and tempering on the microstructure, mechanical properties and dislocation density of direct-quenched steel. Mater. Charact. 2018, 139, 1–10. [Google Scholar] [CrossRef]

- Das Bakshi, S.; Javed, N.; Sasidhar, K.; Dhande, T.; Sharma, V.; Mukherjee, M. Effect of microstructure and crystallographic texture on mechanical anisotropy of Ti-Nb microalloyed hot rolled 800 MPa HSLA steel. Mater. Charact. 2018, 136, 346–357. [Google Scholar] [CrossRef]

- Simon, P.; Economopoulos, M.; Nilles, P. Tempcore, an Economical Process for the Production of High Quality Rebars. Metall. Plant Technol. 1984, 7, 1–6. [Google Scholar]

- Park, C.S.; Yi, H.J.; Kim, Y.-T.; Han, S.; Lee, T.; Moon, Y.H. Tempcore Process Simulator to Analyze Microstructural Evolution of Quenched and Tempered Rebar. Appl. Sci. 2019, 9, 2938. [Google Scholar] [CrossRef]

- Nikolaou, J.; Papadimitriou, G. Microstructures and mechanical properties after heating of reinforcing 500 MPa class weldable steels produced by various processes (Tempcore, microalloyed with vanadium and work-hardened). Constr. Build. Mater. 2004, 18, 243–254. [Google Scholar] [CrossRef]

- Węglowski, M.S. Fabrication of Reinforcement Bars in Unalloyed Steel. Biul. Inst. Spaw. 2019, 2019, 17–31. [Google Scholar] [CrossRef]

- Viswanatha, C.S.; Prasad, L.N.; Radhakrishna; Nataraja, H.S. Sub-standard rebars in the indian market: An insight. Indian Concr. J. 2004, 78, 52–55. [Google Scholar]

- Lundberg, S.E. Quenched and self-tempered rebar—Process overview, layouts, operational parameters and cost savings. In Proceedings of the AISTech—Iron and Steel Technology Conference Proceedings, Pittsburgh, PA, USA, 3–6 May 2010. [Google Scholar]

- Selzer, J. Quenched and tempered bar. In Proceedings of the AISTech—Iron and Steel Technology Conference Proceedings, A Publication of the Association for Iron and Steel Technology, Atlanta, GA, USA, 7–10 May 2012; pp. 120–126. [Google Scholar]

- Murta, R.H.F.; Braga, F.D.; Maia, P.P.N.; Diógenes, O.B.F.; De Moura, E.P. Mathematical modelling for predicting mechanical properties in rebar manufacturing. Ironmak. Steelmak. 2020, 1–9. [Google Scholar] [CrossRef]

- Kabir, M.S.; Islam, M.M.; Bepari, M.M.A. Impact Toughness of Concrete Reinforcement Bars Produced by the THERMEX Process and Ordinary Rolling Process. Int. J. Innov. Tech. Explor. Eng. 2014, 4, 53–59. [Google Scholar]

- Orta, A.H.; Kayabasi, I.; Senol, M. Prediction of mechanical properties of cold rolled and continuous annealed steel grades via analytical model integrated neural networks. Ironmak. Steelmak. 2019, 47, 596–605. [Google Scholar] [CrossRef]

- Bauer, J.; Flu¨ss, P.; Amoris, E.; Schwinn, V. Microstructure and properties of thermomechanical controlled processing steels for linepipe applications. Ironmak. Steelmak. 2005, 32, 325–330. [Google Scholar] [CrossRef]

- Kim, N.J. The Physical Metallurgy of HSLA Linepipe Steels—A Review. JOM 1983, 35, 21–27. [Google Scholar] [CrossRef]

- Yao, Z.S.; Xu, G.; Zhou, M.X. Effect of Vanadium on the Microstructure and Property of Rebar Steel. Mater. Sci. Forum 2018, 928, 269–272. [Google Scholar] [CrossRef]

- Domov, D.V.; Frantov, I.I.; Seregin, A.N.; Bortsov, A.N.; Fofanov, A.A.; Tsyba, O.O.; Vlasyuk, N.V.; Surikov, I.N.; Savrasov, I.P.; Vostrov, M.S. Effect of Vanadium on the Mechanical and Service Properties of Weldable Reinforcement Steels in Strength Classes A500C and A600C. Metals 2016, 59, 941–947. [Google Scholar] [CrossRef]

- Salman, A.; Djavanroodi, F. Variability of Chemical Analysis of Reinforcing Bar Produced in Saudi Arabia; IOP Publishing: Bristol, UK, 2018; Volume 348, p. 012015. [Google Scholar]

- Kah, P.; Layus, P.; Martikainen, J. Influence of alloying elements on the low-temperature properties of steel. Proc. Int. Offshore Polar Eng. Conf. 2015, 2015, 360–367. [Google Scholar]

- Allen, M. An Investigation of the Suitability of Using AISI 1117 Carbon Steel in a Quench and Self-Tempering Process to Satisfy ASTM A 706 Standard of Rebar by an Investigation of the Suitability of Using AISI 1117 Carbon Steel in a Quench and Self-Tempering Proces; University of Toronto: Toronto, ON, Canada, 2011. [Google Scholar]

- Sankar, I.B.; Rao, K.M.; Krishna, A.G. Prediction of heat transfer coefficient of steel bars subjected to Tempcore process using nonlinear modeling. Int. J. Adv. Manuf. Technol. 2009, 47, 1159–1166. [Google Scholar] [CrossRef]

- Woodard, P.R.; Chandrasekar, S.; Yang, H.T.Y. Analysis of temperature and microstructure in the quenching of steel cylinders. Met. Mater. Trans. A 1999, 30, 815–822. [Google Scholar] [CrossRef]

- DiMatteo, A.; Vannucci, M.; Colla, V. A Finite Element Method for the Prediction of Thermal, Metallurgical, and Mechanical Behavior of Rebars in the TempCore Process. Steel Res. Int. 2015, 87, 276–287. [Google Scholar] [CrossRef]

- Bandyopadhyay, K.; Lee, J.; Shim, J.-H.; Hwang, B.; Lee, M.-G. Modeling and experiment on microstructure evolutions and mechanical properties in grade 600 MPa reinforcing steel rebar subjected to TempCore process. Mater. Sci. Eng. A 2019, 745, 39–52. [Google Scholar] [CrossRef]

- Holman, P.J.; Lloyd, J. Heat Transfer, 10th ed.; McGraw-Hill, Inc.: New York, NY, USA, 2008. [Google Scholar]

- Il’Ichev, M.V.; Mordynskii, V.B.; Tereshonok, D.V.; Tyuftyaev, A.S.; Chikunov, S.E. Experimental determination of the temperature dependence of steel thermal conductivity. High Temp. 2015, 53, 193–198. [Google Scholar] [CrossRef]

- Brandes, E.A.; Brook, G.B.; Paufler, P. Smithells Metals Reference Book; Elsevier: Amsterdam, The Netherlands, 2003; 2080p, ISBN 0-7506-7509-8. [Google Scholar]

- Navarro, M.S.; Hidalgo, J.; Sietsma, J.; Santofimia, M. Characterization of bainitic/martensitic structures formed in isothermal treatments below the M s temperature. Mater. Charact. 2017, 128, 248–256. [Google Scholar] [CrossRef]

- Krauss, G. Steels: Heat Treatment and Processing Principles; ASM Int.: Materials Park, OH, USA, 1990. [Google Scholar]

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279–1288. [Google Scholar] [CrossRef]

- Nandi, S.K.; Tewary, N.K.; Saha, J.K.; Ghosh, S.K. Microstructure, mechanical properties and corrosion performance of a few TMT rebars. Corros. Eng. Sci. Technol. 2016, 51, 1–13. [Google Scholar] [CrossRef]

- Sk, B.; Khan, A.; Lenka, S.; Syed, B.; Chakraborty, J.; Chakrabarti, D.; Deb, A.; Chandra, S.K.; Kundu, S. Effect of microstructure and texture on the impact transition behaviour of thermo-mechanically treated reinforcement steel bars. Mater. Des. 2016, 90, 1136–1150. [Google Scholar] [CrossRef]

- Morris, J.J.W. On the Ductile-Brittle Transition in Lath Martensitic Steel. ISIJ Int. 2011, 51, 1569–1575. [Google Scholar] [CrossRef]

- Dan, M.S.; Gajjar, P.; Palit, P. Government Engineering College Correlation of Micro-Macro Properties with Mechanical Properties in Rebar. Int. J. Eng. Res. 2015, V4, 86–90. [Google Scholar] [CrossRef]

- Kim, Y.M.; Kim, S.K.; Kim, N.J. Simple method for tailoring the optimum microstructures of high-strength low-alloyed steels by the use of constitutive equation. Mater. Sci. Eng. A 2019, 743, 138–147. [Google Scholar] [CrossRef]

- Akbarpour, M.; Ekrami, A. Effect of ferrite volume fraction on work hardening behavior of high bainite dual phase (DP) steels. Mater. Sci. Eng. A 2008, 477, 306–310. [Google Scholar] [CrossRef]

- Bepari, M.A. Structure of continuously cooled low-carbon vanadium steels. Met. Mater. Trans. A 1990, 21, 2839–2855. [Google Scholar] [CrossRef]

- Allam, T.; Guo, X.; Sevsek, S.; Lipińska-Chwałek, M.; Hamada, A.; Ahmed, E.; Bleck, W. Development of a Cr-Ni-V-N Medium Manganese Steel with Balanced Mechanical and Corrosion Properties. Metals 2019, 9, 705. [Google Scholar] [CrossRef]

- Shyamal, S.; Farahani, M.G.; Allam, T.; Hamada, A.; Haase, C.; Kömi, J.; Chakraborti, P.; Sahu, P. Activation of a hybrid twinning mechanism in a Cr-Ni-Si-V-N medium manganese austenitic steel containing precipitates. Scr. Mater. 2021, 192, 83–88. [Google Scholar] [CrossRef]

- Allam, T.; Guo, X.; Lipińska-Chwałek, M.; Hamada, A.; Ahmed, E.; Bleck, W. Impact of precipitates on the hydrogen embrittlement behavior of a V-alloyed medium-manganese austenitic stainless steel. J. Mater. Res. Technol. 2020, 9, 13524–13538. [Google Scholar] [CrossRef]

| Steel Grade | Chemical Analysis, wt.% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | V | Cu | N | Ceq. | |

| B400B-R | 0.28 | 0.14 | 0.73 | 0.015 | 0.025 | 0.05 | 0.07 | 0.003 | 0.29 | 0.0068 | 0.42 |

| B500B | 0.22 | 0.17 | 1.37 | 0.017 | 0.025 | 0.05 | 0.08 | 0.067 | 0.15 | 0.0057 | 0.45 |

| Bar Diameter (mm) | QTB Normal Rolling Speed (m/s) | Actual Hot Rolling Speed (m/s) | Achieved Rolling Speed with QTB * (m/s) | Water Flow (m³/h) | Equalization Temperature (°C) |

|---|---|---|---|---|---|

| 20 | 8 | 13 | 13 | 600 | 665 |

| 32 | 4 | 7 | 7 | 620 | 670 |

| Steel Grade | 20 mm (13 m/s: Rebar Rolling Speed) | 32 mm (7 m/s: Rebar Rolling Speed) | ||||||

|---|---|---|---|---|---|---|---|---|

| Md, mm | Mv, % | Te, °C | Quenching Time, s | Md, mm | Mv, % | Te, °C | Quenching Time, s | |

| B400B-R | 1.52 | 25.73 | 670 | 1.06 | 1.90 | 22.53 | 670 | 1.57 |

| B500B | 1.76 | 29.44 | 655 | 1.06 | 2.25 | 26.15 | 655 | 1.57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, E.; Ibrahim, S.; Galal, M.; Elnekhaily, S.A.; Allam, T. Microstructure and Mechanical Properties of V-Alloyed Rebars Subjected to Tempcore Process. Metals 2021, 11, 246. https://doi.org/10.3390/met11020246

Ahmed E, Ibrahim S, Galal M, Elnekhaily SA, Allam T. Microstructure and Mechanical Properties of V-Alloyed Rebars Subjected to Tempcore Process. Metals. 2021; 11(2):246. https://doi.org/10.3390/met11020246

Chicago/Turabian StyleAhmed, Essam, Samir Ibrahim, Mohamed Galal, Sarah A. Elnekhaily, and Tarek Allam. 2021. "Microstructure and Mechanical Properties of V-Alloyed Rebars Subjected to Tempcore Process" Metals 11, no. 2: 246. https://doi.org/10.3390/met11020246

APA StyleAhmed, E., Ibrahim, S., Galal, M., Elnekhaily, S. A., & Allam, T. (2021). Microstructure and Mechanical Properties of V-Alloyed Rebars Subjected to Tempcore Process. Metals, 11(2), 246. https://doi.org/10.3390/met11020246