A Study on the Fiber YAG Laser Welding of 304L Stainless Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

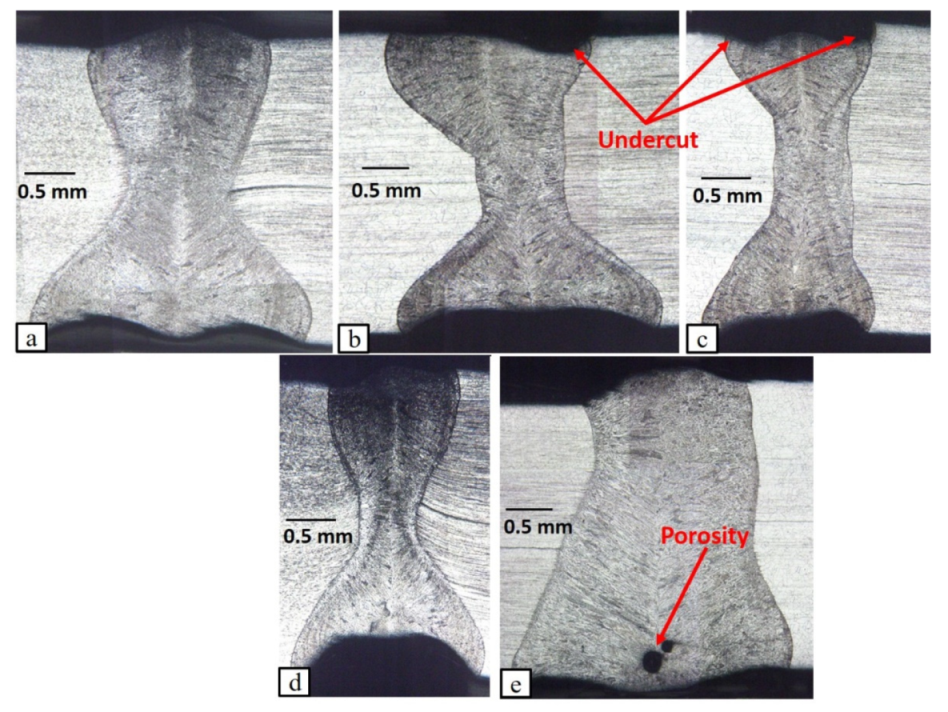

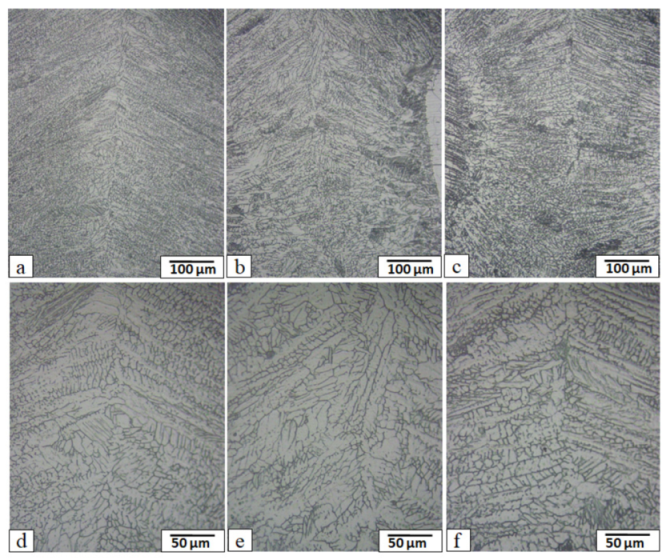

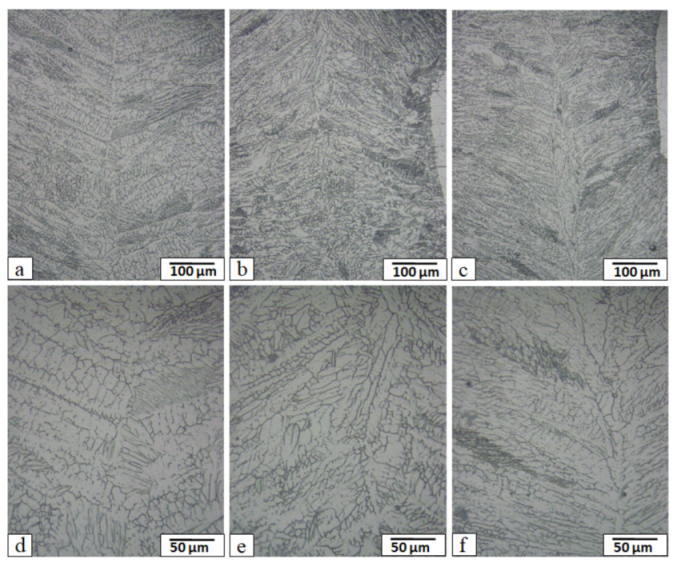

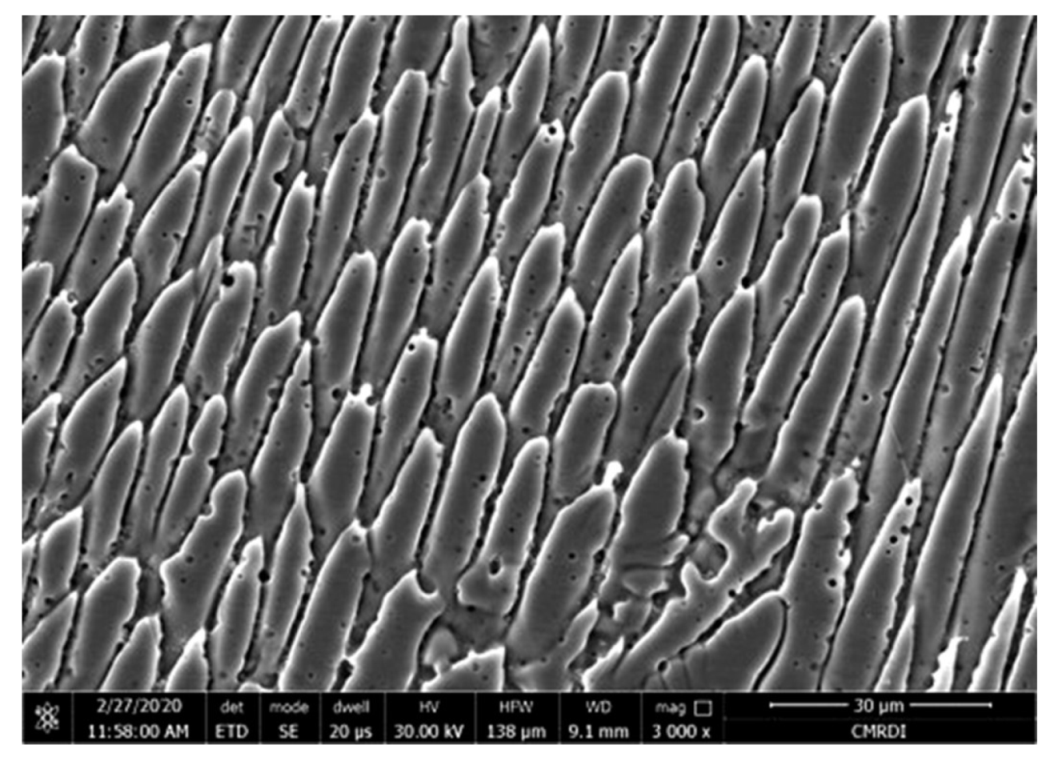

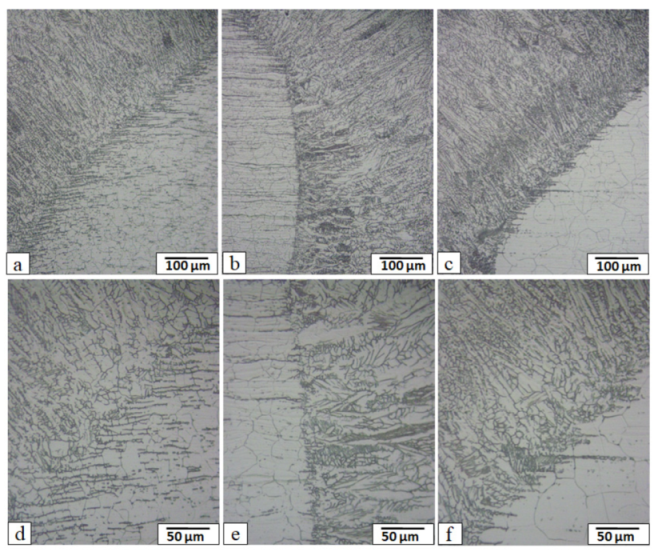

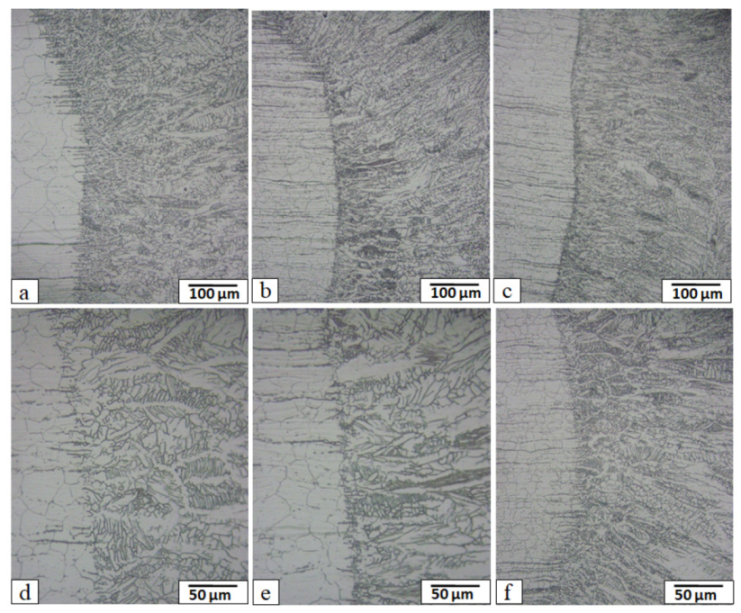

3.1. Macro/Microstructure of the Welded Joints

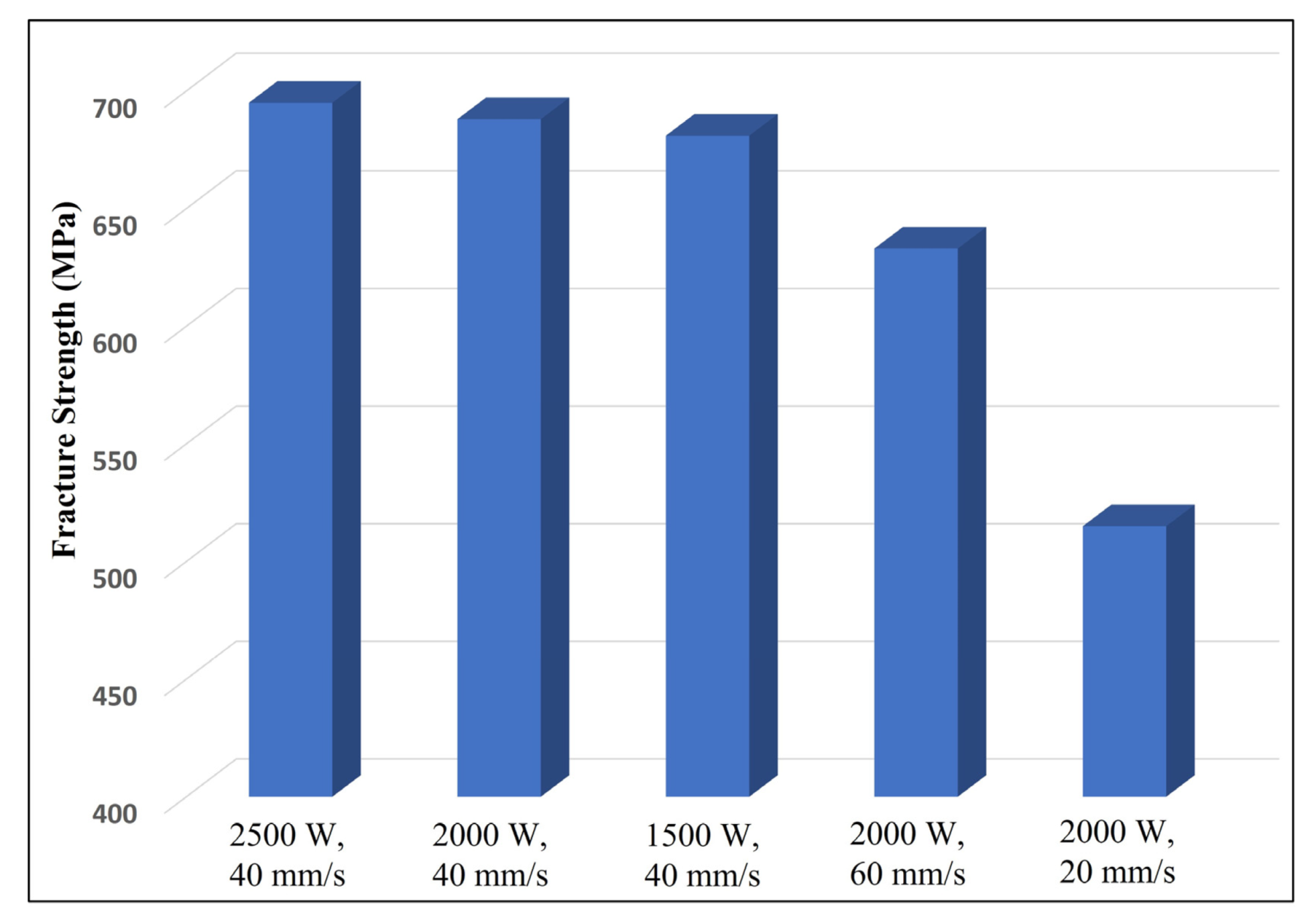

3.2. Mechanical Properties of the Welded Joints

4. Conclusions

- All the weld joints show a typical “hourglass” shape. Only a laser combination of 2500 W/40 mm/s gives a full penetration weld joint without observable defects. At a laser power lower than 2500 W, partial penetration joints were obtained. The heat input has a direct impact on the weld zone size;

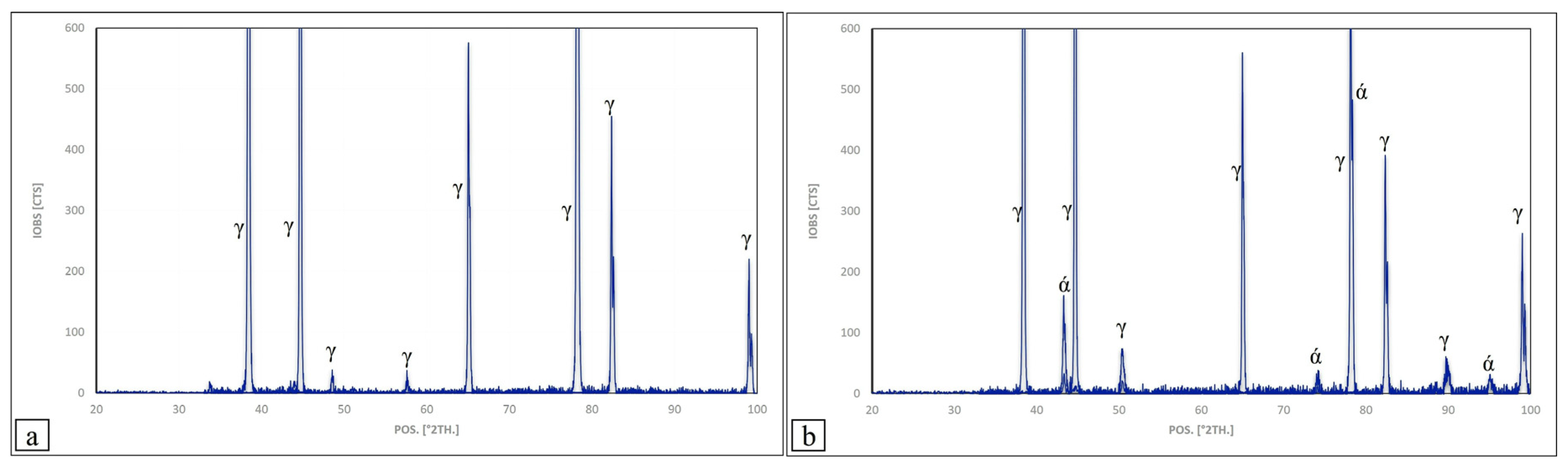

- Columnar dendrite austenite grains with small arm spacing resulted in most of the welded fusion zones. The size of the dendrites became finer at lower heat input (lower power and faster speed). At higher heat input, reasonable amounts of lathy equiaxed grains with some delta ferrite occurred;

- There was almost no HAZ in any of the weld joints. It consisted of an austenitic microstructure with some small amount of delta ferrite appearing at the grain boundaries, which prevented the crack formation during the welding;

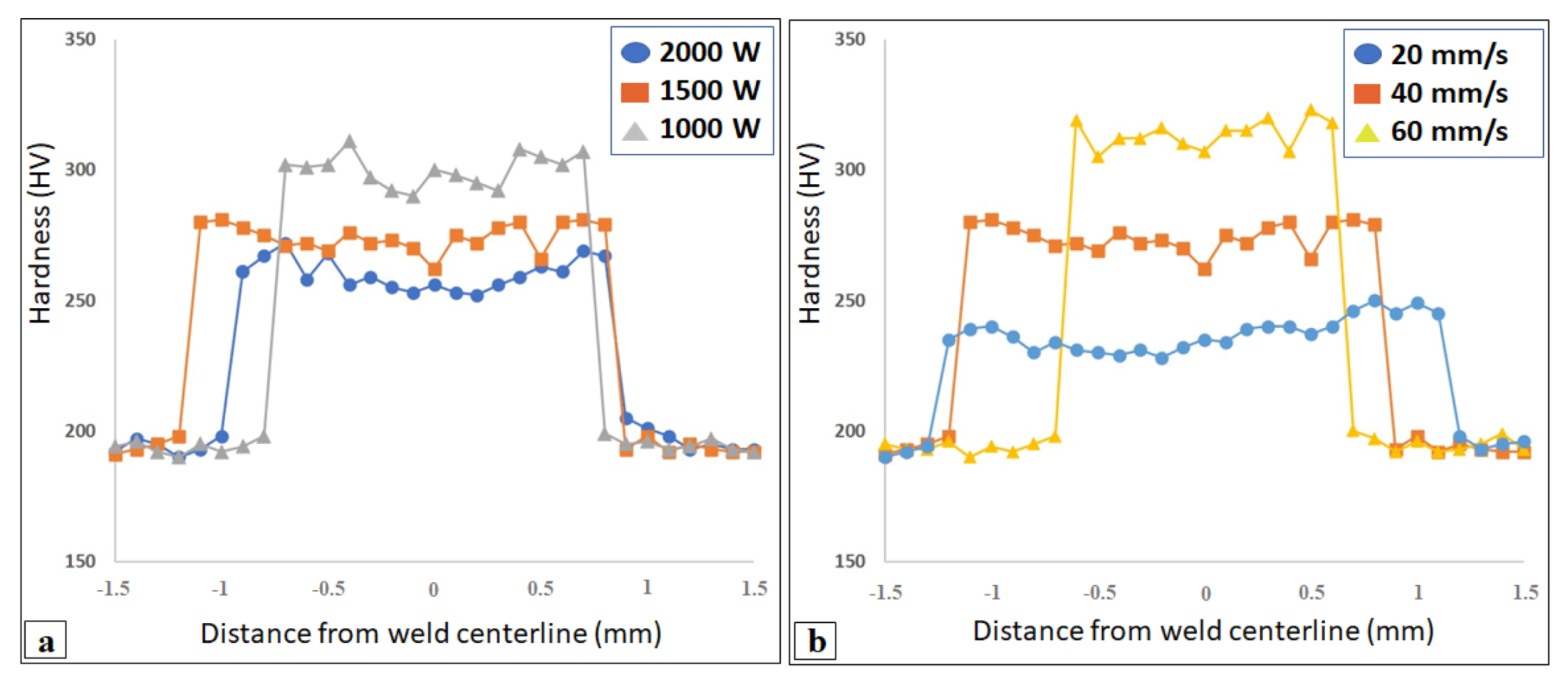

- Fusion zone hardness values for all the joints were significantly greater than that of the base alloy. The highest hardness was obtained in the case of the lower heat input sample (2000 W and 60 mm/s) and the lowest hardness was recorded corresponding to the highest heat input (2000 W and 20 mm/s);

- The fracture strength of the welded joints ranged from 97 to 72% of the base metal. It depends mainly on the welding heat input. Values close to the base alloy were attained at lower heat input without defects.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bahrami, A.; Taheri, P.A. Study on the Failure of AISI 304 Stainless Steel Tubes in a Gas Heater Unit. Metals 2019, 9, 969. [Google Scholar] [CrossRef]

- Kolli, S.; Javaheri, V.; Kömi, J.; Porter, D. On the Role of Grain Size and Carbon Content on the Sensitization and Desensitization Behavior of 301 Austenitic Stainless Steel. Metals 2019, 9, 1193. [Google Scholar] [CrossRef]

- Bell, S.; Steinberg, T.; Will, G. Corrosion mechanisms in molten salt thermal energy storage for concentrating solar power. Renew. Sustain. Energy Rev. 2019, 114, 109328. [Google Scholar] [CrossRef]

- Hurley, M.F.; Olson, C.R.; Ward, L.J.; Jaques, B.J.; Johnson, K.A.; Gunnerson, J.K.; Butt, D.P. Transgranular stress corrosion cracking of 304L stainless steel pipe clamps in direct use geothermal water heating applications. Eng. Fail. Anal. 2013, 33, 336–346. [Google Scholar] [CrossRef][Green Version]

- Antoun, B.R.; Chambers, R.S.; Emery, J.M.; Tandon, R. Small Strain Plasticity Behavior of 304L Stainless Steel in Glass-to-Metal Seal Applications. Chall. Mech. Time-Depend. Mater. 2015, 2, 49–54. [Google Scholar] [CrossRef]

- Sun, C.; Zheng, S.; Wei, C.C.; Wu, Y.; Shao, L.; Yang, Y.; Hartwig, K.T.; Maloy, S.A.; Zinkle, S.J.; Allen, T.R.; et al. Superior radiation-resistant nanoengineered austenitic 304L stainless steel for applications in extreme radiation environments. Sci. Rep. 2015, 5, 7801. [Google Scholar] [CrossRef]

- Desu, R.K.; Krishnamurthy, H.N.; Balu, A.; Gupta, A.K.; Singh, S.K. Mechanical properties of Austenitic Stainless Steel 304L and 316L at elevated temperatures. J. Mater. Res. Technol. 2016, 5, 13–20. [Google Scholar] [CrossRef]

- Jo, B.; Okamoto, K.; Kasahara, N. Creep Buckling of 304 Stainless-Steel Tubes Subjected to External Pressure for Nuclear Power Plant Applications. Metals 2019, 9, 536. [Google Scholar] [CrossRef]

- Chen, Z.; Fang, Y.; Li, P.; Yu, Z.; Wu, X.; Li, D. Microstructure, Residual Stress and Mechanical Properties of a High Strength Steel Weld using Low Transformation Temperature Welding Wires. Mater. Des. 2015, 65, 1214–1221. [Google Scholar] [CrossRef]

- Chuaiphan, W.; Srijaroenpramong, L. Effect of welding speed on microstructures, mechanical properties and corrosion behavior of GTA-welded AISI 201 stainless steel sheets. J. Mater. Process. Technol. 2014, 214, 402–408. [Google Scholar] [CrossRef]

- Suresh, G.G.; Parida, P.K.; Bandi, S.; Ningshen, S. Effect of carbon content on the low temperature sensitization of 304L SS and its corrosion resistance in simulated ground water. Mater. Chem. Phys. 2019, 226, 184–194. [Google Scholar] [CrossRef]

- Yan, J.; Gao, M.; Zeng, X. Study on microstructure and mechanical properties of 304 stainless steel joints by TIG, laser and laser-TIG hybrid welding. Opt. Lasers Eng. 2010, 48, 512–517. [Google Scholar] [CrossRef]

- Costanza, G.; Sili, A.; Tata, M.E. Weldability of austenitic stainless steel by metal arc welding with different shielding gas. Procedia Struct. Integr. 2016, 2, 3508–3514. [Google Scholar] [CrossRef]

- Sathiya, P.; Mishra, M.K.; Shanmugarajan, B. Effect of shielding gases on microstructure and mechanical properties of super austenitic stainless steel by hybrid welding. Mater. Des. 2012, 33, 203–212. [Google Scholar] [CrossRef]

- Sakthivel, T.; Vasudevan, M.; Laha, K.; Parameswaran, P.; Chandravathi, K.S.; Mathew, M.D.; Bhaduri, A.K. Creep rupture strength of activated-TIG welded 316L(N) stainless steel. J. Nucl. Mater. 2011, 413, 36–40. [Google Scholar] [CrossRef]

- Niagaj, J. Influence of Activated Fluxes on the Bead Shape of A-TIG Welds on Carbon and Low-Alloy Steels in Comparison with Stainless Steel AISI 304L. Metals 2021, 11, 530. [Google Scholar] [CrossRef]

- Wegrzyn, T. Delta ferrite in stainless steel weld metals. Weld. Int. 1992, 6, 690–694. [Google Scholar] [CrossRef]

- Shankar, V.; Gill, T.P.S.; Mannan, S.L.; Sundaresan, S. Solidification cracking in austenitic stainless steel welds. Sadhana 2003, 28, 359–382. [Google Scholar] [CrossRef]

- Sharma, R.; Molian, P. Weldability of advanced high strength steels using an Yb:YAG disk laser. J. Mater. Process. Technol. 2011, 211, 1888–1897. [Google Scholar] [CrossRef]

- Parkes, D.; Westerbaan, D.; Nayak, S.S.; Zhou, Y.; Goodwin, F.; Bhole, S.; Chen, D.L. Tensile properties of fiber laser welded joints of high strength low alloy and dual-phase steels at warm and low temperatures. Mater. Des. 2014, 56, 193–199. [Google Scholar] [CrossRef]

- Li, G.; Zhang, C.; Gao, M.; Zeng, X. Role of arc mode in laser-metal active gas arc hybrid welding of mild steel. Mater. Des. 2014, 61, 239–250. [Google Scholar] [CrossRef]

- Soltani, H.M.; Tayebi, M. Comparative study of AISI 304L to AISI 316L stainless steels joints by TIG and Nd:YAG laser welding. J. Alloys Compd. 2018, 767, 112–121. [Google Scholar] [CrossRef]

- Gardner, L.; Bu, Y.; Theofanous, M. Laser-welded stainless steel I-sections: Residual stress measurements and column buckling tests. Eng. Struct. 2016, 127, 536–548. [Google Scholar] [CrossRef]

- Kumar, N.; Mukherjee, M.; Bandyopadhyay, A. Comparative study of pulsed Nd:YAG laser welding of AISI 304 and AISI 316 stainless steels. Opt. Laser Technol. 2017, 88, 24–39. [Google Scholar] [CrossRef]

- Tadamalle, A.P.; Reddy, Y.P.; Ramjee, E.; Reddy, V. Evaluation of Nd: YAG Laser Welding Efficiencies for 304L Stainless Steel. Procedia Mater. Sci. 2014, 6, 1731–1739. [Google Scholar] [CrossRef][Green Version]

- Gnanasekaran, S.; Kumar, S.S.; Venugopal, N.; Upadhyaya, M.; Manjunath, T.C.; Chelladurai, S.S.J.; Padmanaban, G. Effect of laser power on microstructure and tensile properties of pulsed Nd:YAG laser beam welded AISI 301 austenitic stainless steel joints. Mater. Today Proc. 2021, 37, 934–939. [Google Scholar] [CrossRef]

- Saravanan, S.; Sivagurumanikandan, N.; Raghukandan, K. Effect of process parameters in microstructural and mechanical properties of Nd: YAG laser welded super duplex stainless steel. Mater. Today Proc. 2020, 39, 1248–1253. [Google Scholar] [CrossRef]

- Abdo, H.S.; Seikh, A.H.; Mohammed, J.A.; Uzzaman, T. Ameliorative Corrosion Resistance and Microstructure Characterization of 2205 Duplex Stainless Steel by Regulating the Parameters of Pulsed Nd:YAG Laser Beam Welding. Metals 2021, 11, 1206. [Google Scholar] [CrossRef]

- Li, Z.; Yu, G.; He, X.; Li, S.; Tian, C.; Dong, B. Analysis of surface tension driven flow and solidification behavior in laser linear welding of stainless steel. Opt. Laser Technol. 2020, 123, 105914. [Google Scholar] [CrossRef]

- Iamboliev, T.; Katayama, S.; Matsunawa, A. Interpretation of Phase Formation in Austenitic Stainless Steel Welds. Weld. Res. 2003, 82, 337S–347S. [Google Scholar]

- Meng, Y.; Li, G.; Gao, M.; Zeng, X. Effects of groove parameters on space constraint of narrow gap laser-arc hybrid welding. J. Manuf. Process. 2018, 33, 144–149. [Google Scholar] [CrossRef]

- Shin, W.; Son, B.; Song, W.; Sohn, H.; Jang, H.; Kim, Y.; Park, C. Heat treatment effect on the microstructure, mechanical properties, and wear behaviors of stainless steel 316L prepared via selective laser melting. Mater. Sci. Eng. A 2021, 806, 140805. [Google Scholar] [CrossRef]

| C | Cr | Ni | Mo | Si | Mn | P | S | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.023 | 18.5 | 9.7 | 0.007 | 0.55 | 0.12 | 0.02 | 0.008 | Bal. |

| Hardness (HV) | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 192 | 710 | 532 | 39 |

| Specimen No. | Power (W) | Speed (mm/s) | Net Heat Supplied (J/mm) |

|---|---|---|---|

| #1 | 2500 | 40 | 62.5 |

| #2 | 2000 | 40 | 50 |

| #3 | 1500 | 40 | 37.5 |

| #4 | 2000 | 60 | 33.3 |

| #5 | 2000 | 20 | 100 |

| Specimen No. | Top (mm) | Center (mm) | Bottom (mm) |

|---|---|---|---|

| #1 | 1.73 | 1.03 | 2.7 |

| #2 | 1.9 | 0.92 | 2.65 |

| #3 | 1.35 | 0.75 | 1.73 |

| #4 | 1.31 | 0.63 | 1.52 |

| #5 | 1.76 | 2.03 | 2.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmoud, E.R.I.; Almohamadi, H.; Aljabri, A.; Elkotb, M.A. A Study on the Fiber YAG Laser Welding of 304L Stainless Steel. Metals 2021, 11, 2022. https://doi.org/10.3390/met11122022

Mahmoud ERI, Almohamadi H, Aljabri A, Elkotb MA. A Study on the Fiber YAG Laser Welding of 304L Stainless Steel. Metals. 2021; 11(12):2022. https://doi.org/10.3390/met11122022

Chicago/Turabian StyleMahmoud, Essam R. I., Hamad Almohamadi, Abdulrahman Aljabri, and Mohamed Abdelghany Elkotb. 2021. "A Study on the Fiber YAG Laser Welding of 304L Stainless Steel" Metals 11, no. 12: 2022. https://doi.org/10.3390/met11122022

APA StyleMahmoud, E. R. I., Almohamadi, H., Aljabri, A., & Elkotb, M. A. (2021). A Study on the Fiber YAG Laser Welding of 304L Stainless Steel. Metals, 11(12), 2022. https://doi.org/10.3390/met11122022