Study of the Effect of a Plug with Torsion Channels on the Mixing Time in a Continuous Casting Ladle Water Model

Abstract

1. Introduction

2. Materials and Methods

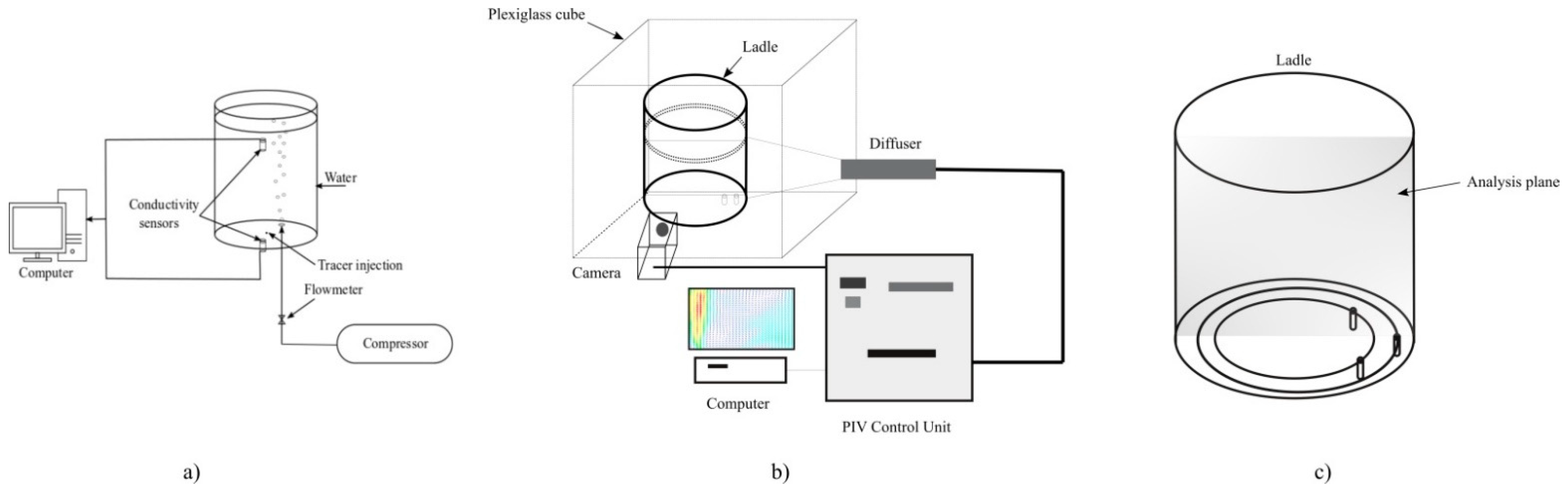

2.1. Experimental Configuration

2.2. Mixing Time

2.3. Obtaining the Velocity Fields with the PIV Technique

3. Results and Discussion

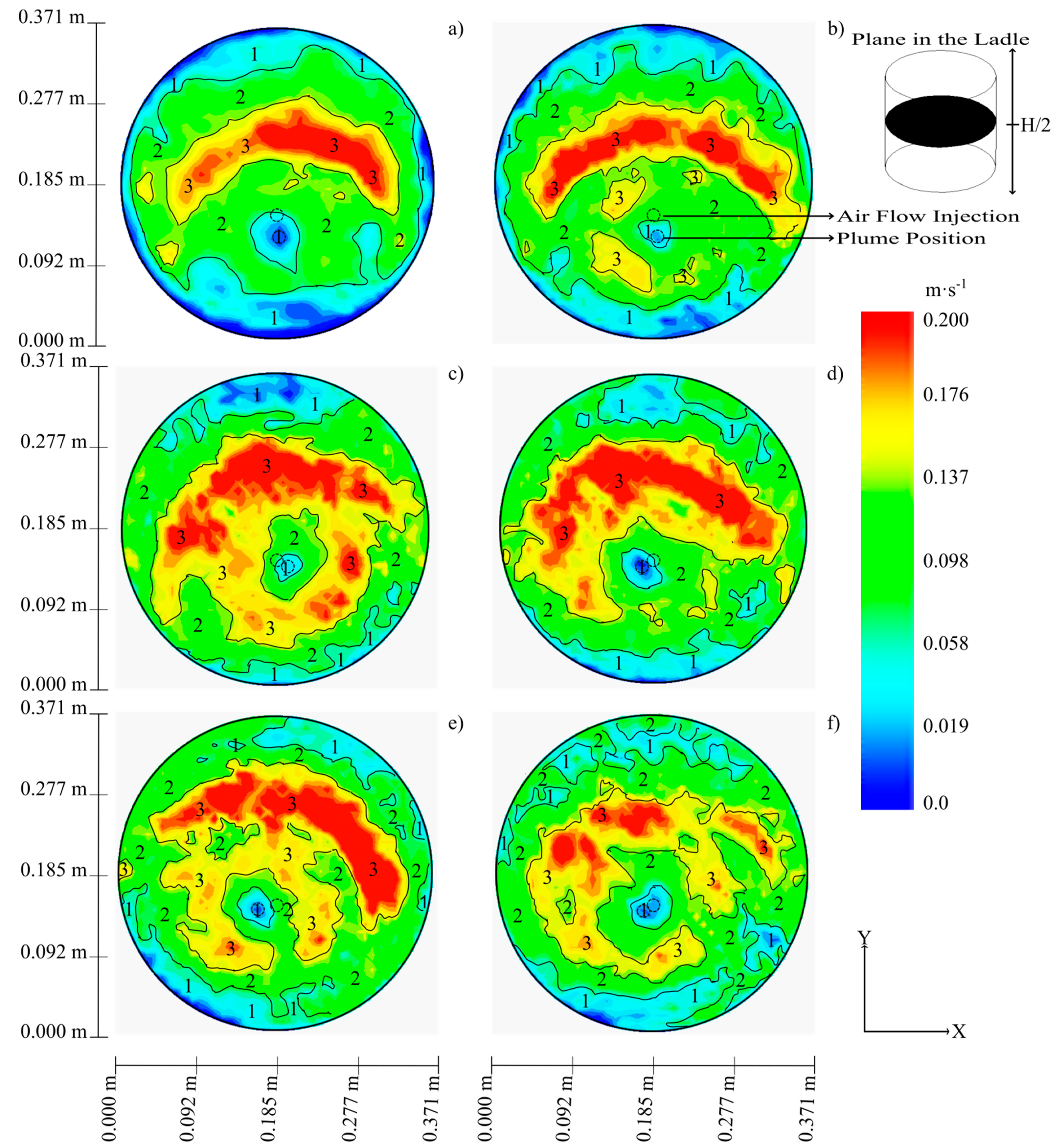

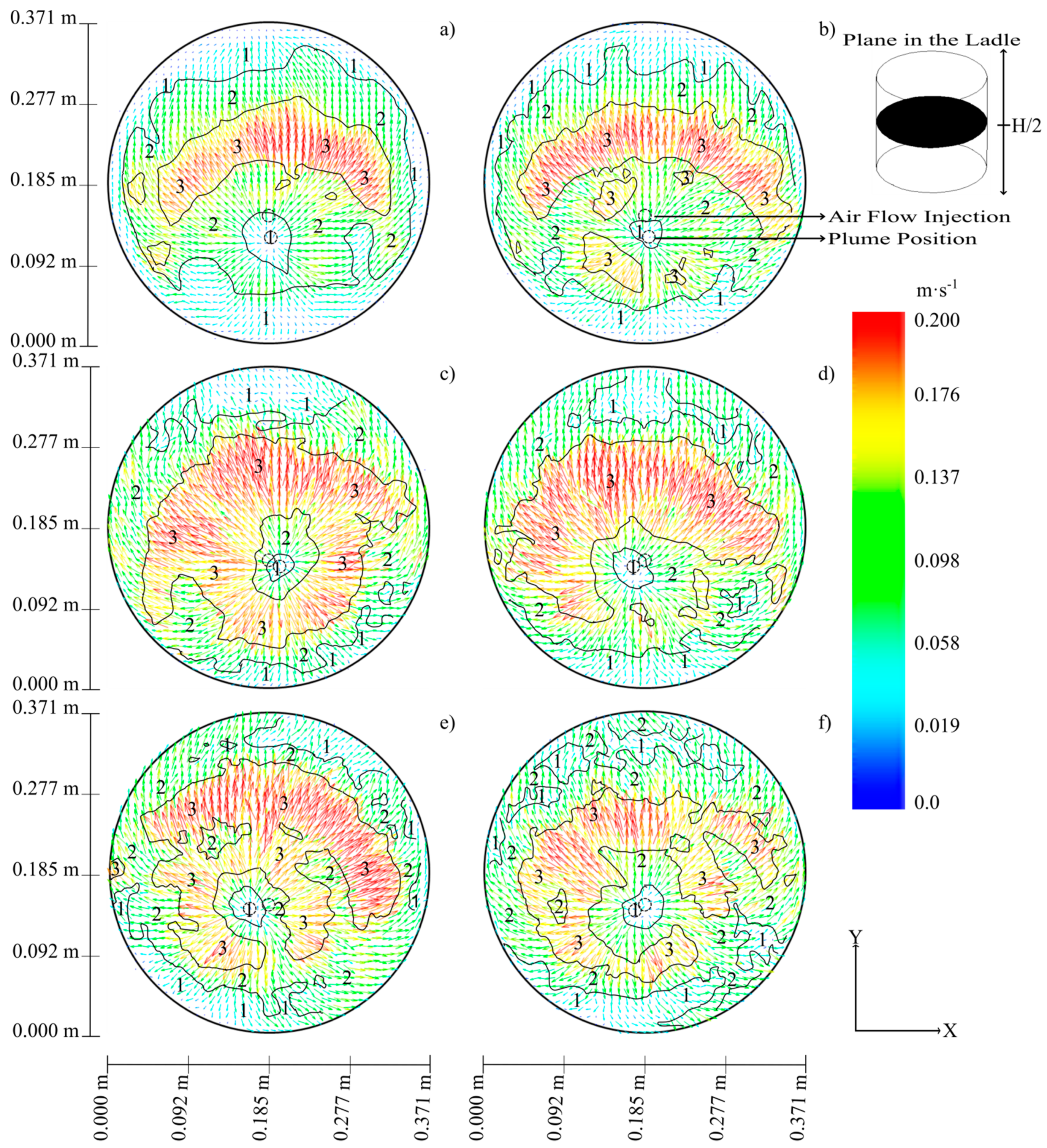

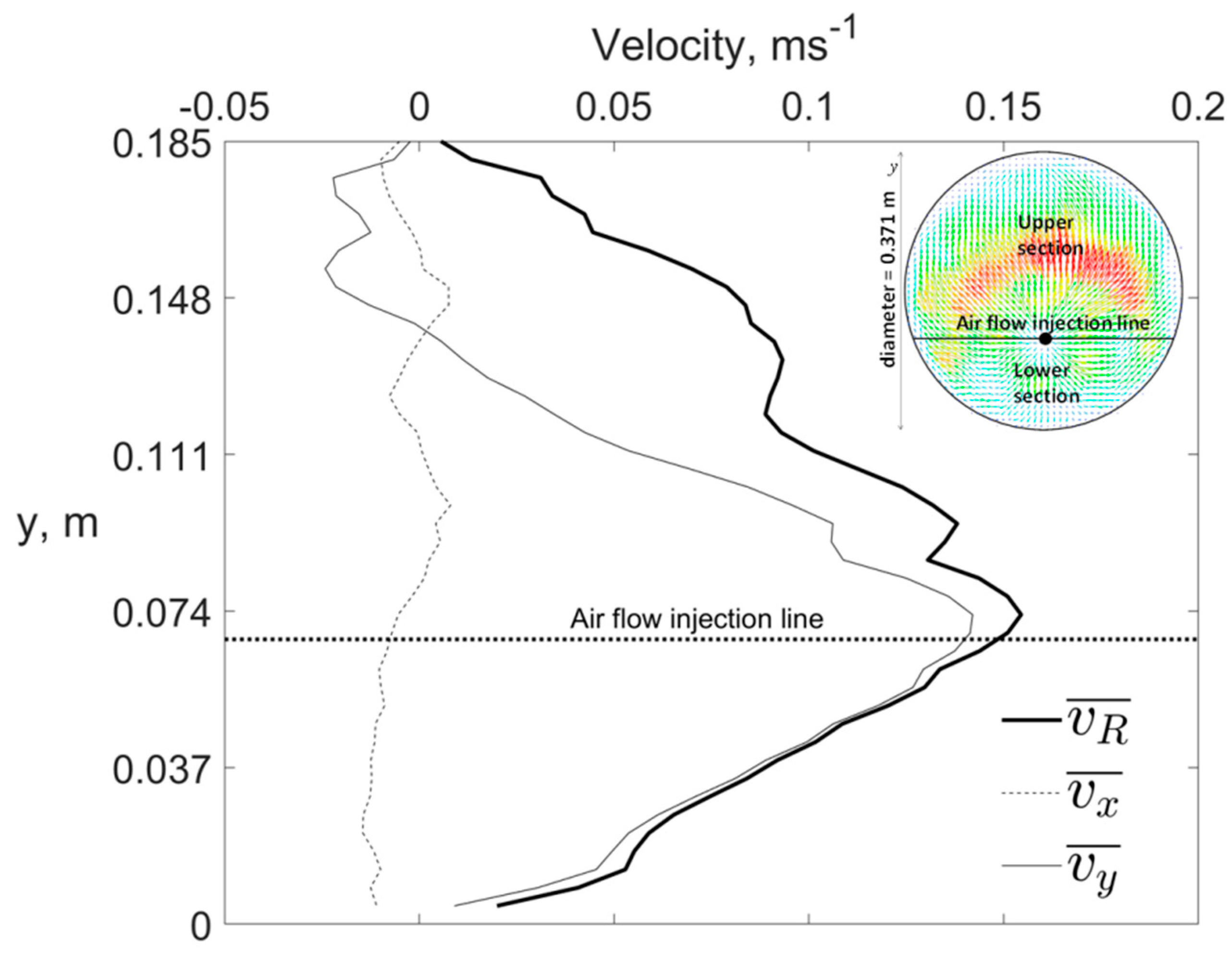

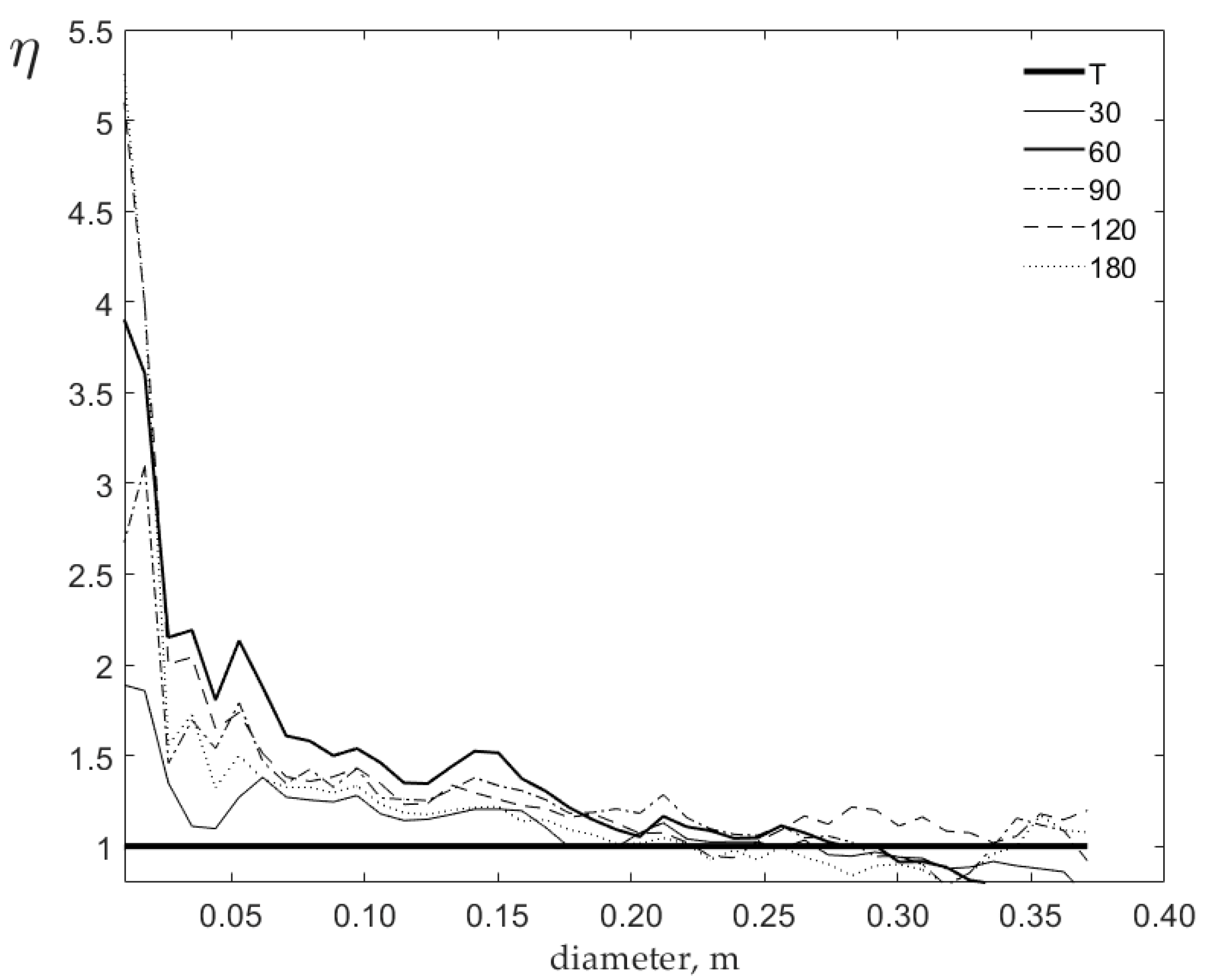

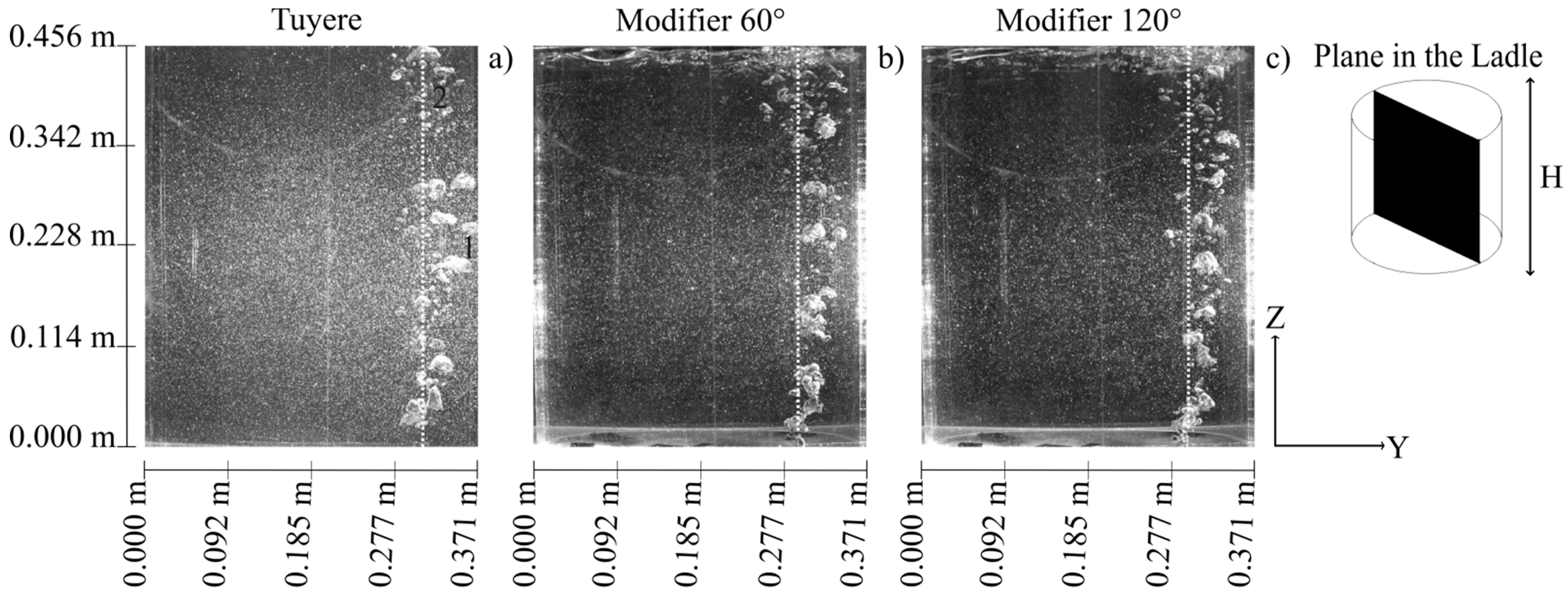

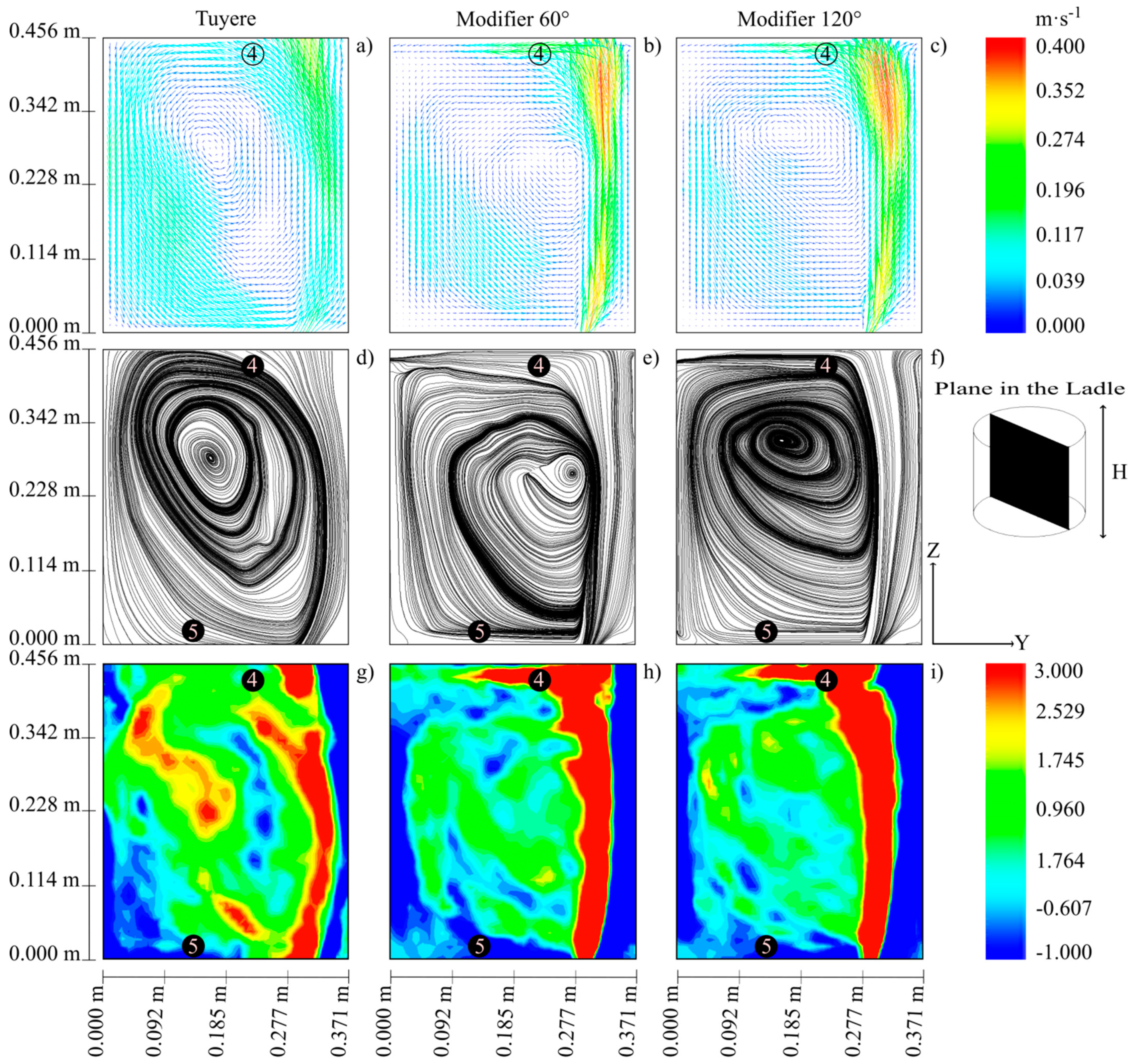

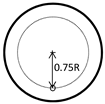

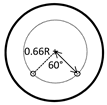

3.1. Selection of the Torsion Angle in the Flow Modifiers

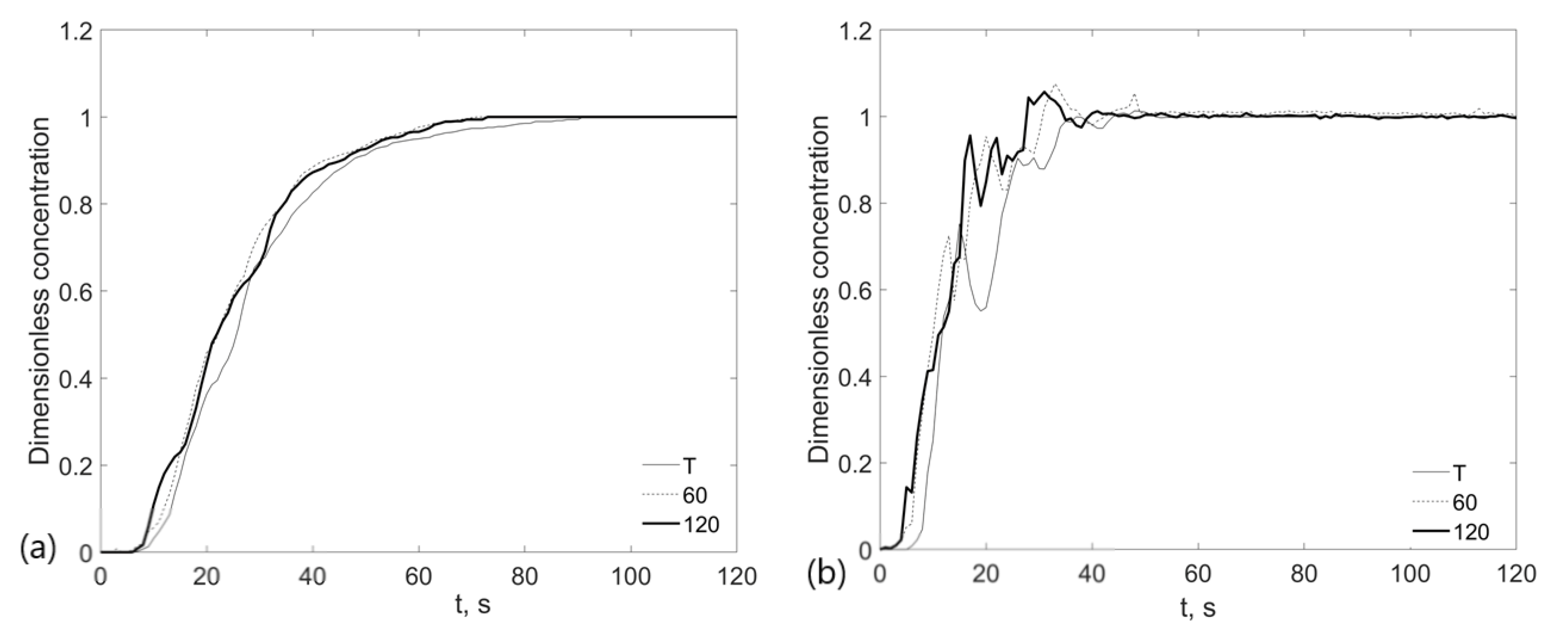

3.2. Mixing Times

4. Conclusions

- -

- The mixing times for the two injection cases with the use of the tuyere are very similar, with 91 s for the case with one localized injection at 0.75 R and 92 s for the case with two localized injections at 0.66 R.

- -

- The use of modifiers with torsion channels with angles of 60° and 120° improves the mixing times for the two injection cases. For the case of one single injection (0.75 R), the mixing time decreases by 22% when the modifier is used with a torsion angle of the channels of 60° and 20% with a torsion angle of 120°. For the case of two injections (0.66 R), the mixing time decreases by 11% when the modifier is used with a torsion angle of the channels of 60° and 8% with a torsion angle of 120°.

- -

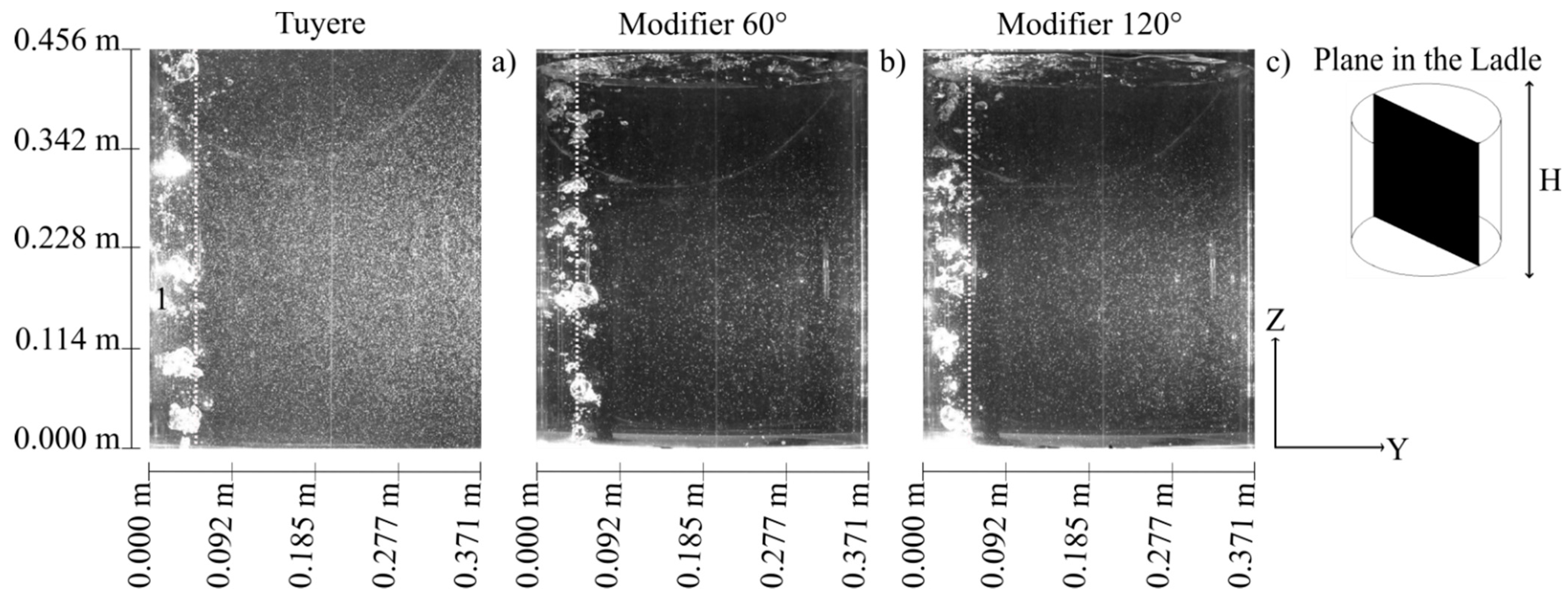

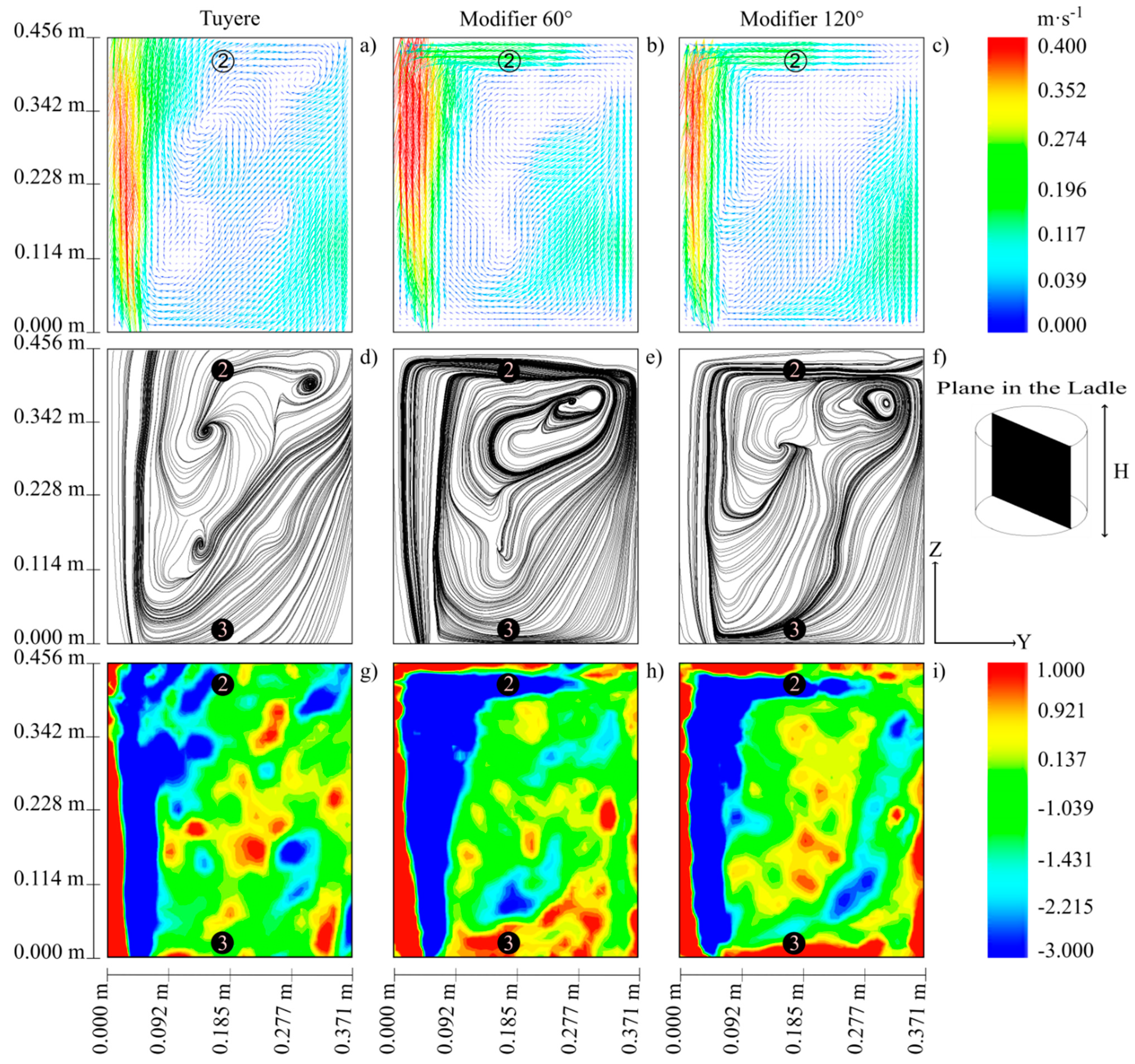

- The channels with the torsion angles give a certain tangential velocity to the air. This allows the plume to maintain a more vertical trajectory and generate fluid dynamics that promote a spiral rotational movement that spans the entire plane of the ladle with closed streamlines paths. This flow pattern is seen more clearly when the modifier is used with the torsion angle at 60°.

- -

- Of the two torsion angles, the 60° angle is the one with which the best mixing times are obtained both for one injection at 0.75 R and for two injections at 0.66 R.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Irons, G.; Senguttuvan, A.; Krishnapisharody, K. Recent advances in the fluid dynamics of ladle metallurgy. ISIJ Int. 2015, 55, 1–6. [Google Scholar] [CrossRef][Green Version]

- Birat, J.P. Impact of steelmaking and casting technologies on processing and properties of steel. Ironmak. Steelmak. 2001, 28, 152–158. [Google Scholar] [CrossRef]

- Gonzalez, R.; Solorio, G.; Ramos, A.; Torres, E.; Hernandez, C.; Zenit, R. Effect of the fluid-dynamic structure on the mixing time of a ladle furnace. Steel Res. Int. 2017, 55, 1700281. [Google Scholar] [CrossRef]

- Villela, J.J.; Ramos, J.A.; Hernandez, C.A.; Urióstegui, A.; Solorio, G. Optimization of the mixing time using asymmetrical arrays in both gas flow and injection positions in a dual-plug ladle. ISIJ Int. 2020, 60, 1172–1178. [Google Scholar] [CrossRef]

- Nunes, R.P.; Pereira, J.A.M.; Vilela, A.C.F.; Der Laan, F.T.V. Visualisation and analysis of the fluid flow structure inside an elliptical steelmaking ladle through image processing techniques. J. Eng. Sci. Technol. 2007, 2, 139–150. [Google Scholar]

- Terrazas, M.; Conejo, A. Effect of nozzle diameter on mixing time during bottom-gas injection in metallurgical ladles. Metall. Mater. Trans. B 2015, 46, 711–718. [Google Scholar] [CrossRef]

- Krishna, G.G.; Mehrotra, S.P.; Ghosh, A. Experimental investigation of mixing phenomena in a gas stirred liquid bath. Metall. Trans. B 1987, 19, 839–850. [Google Scholar]

- Amaro, A.M.; Ramirez, M.A.; Conejo, A.N. Effect of slag properties on mixing phenomena in gas-stirred ladles by physical modeling. ISIJ Int. 2014, 54, 1–8. [Google Scholar] [CrossRef]

- Kuo, T.; Kuo, J. Determination of mixing time in a measurement in a ladle-refining process using optical image processing. ISIJ Int. 2011, 51, 1597–1600. [Google Scholar] [CrossRef]

- Mazumdar, D.; Dhandapani, P.; Sarvanakumar, R. Modeling and optimisation of gas stirred ladle systems. ISIJ Int. 2017, 57, 286–295. [Google Scholar] [CrossRef]

- Helle, L.W. The calculation of the time required to mix liquid metal in a ladle by gas rising. J. South. Afr. Inst. Min. Metall. 1981, 81, 329–337. [Google Scholar]

- Gajjar, P.; Haas, T.; Owusu, K.B.; Eickhoff, M.; Kowitwarangkul, P.; Pfeifer, H. Physical study of the impact of injector design on mixing, convection and turbulence in ladle metallurgy. Eng. Sci. Technol. Int. J. 2019, 22, 538–547. [Google Scholar] [CrossRef]

- Ramírez-Argaez, M.A.; Tapia, J.; Espinoza, J.; Alcantar, E. Modelación matemática del mezclado en hornos-cucharas agitadas con gas. Revista de Metalurgia 2006, 42, 56–75. [Google Scholar] [CrossRef]

- Cloete, S.; Eksteen, J.J.; Bradshaw, S.M. A numerical modelling investigation into design variables influencing mixing efficiency in full scale gas stirred ladles. Miner. Eng. 2013, 46, 16–24. [Google Scholar] [CrossRef]

- Torres, S.; Barron, M.A. Numerical simulations of an argon stirred ladle with top and bottom injection. Open J. Appl. Sci. 2016, 6, 860–867. [Google Scholar] [CrossRef]

- Yu, S.; Zou, Z.S.; Shao, L.; Louhenkilpi, S. A theoretical scaling equation for designing physical modeling of gas-liquid flow in metallurgical ladles. Steel Res. 2016, 87, 1600156. [Google Scholar] [CrossRef]

- Krishnapisharody, K.; Irons, G. A critical review of the modified Froude number in ladle metallurgy. Metall. Mater. Trans. B 2013, 44, 1486–1498. [Google Scholar] [CrossRef]

- Gómez, A.S.; Conejo, A.N.; Zenit, R. Effect of separation angle and nozzle radial position on mixing time in ladles with two nozzles. J. Appl. Fluid Mech. 2018, 11, 11–20. [Google Scholar] [CrossRef]

- Ramasetti, E.K.; Visuri, V.V.; Sulasalmi, P.; Palovaara, T.; Gupta, A.K.; Fabritius, T. Physical and CFD modeling of the effect of top layer properties on the formation of open- eye in gas-stirred ladles with single and dual-plugs. Steel Res. Int. 2019, 90, 1–13. [Google Scholar] [CrossRef]

- Zheng, S.; Zhu, M. New process with argon injected into ladle around the tapping hole for controlling slag carry-over during continuous casting ladle. Metals 2018, 8, 624. [Google Scholar] [CrossRef]

- Liu, Y.; Bai, H.; Liu, H.; Ersson, M.; Jonsson, P.G.; Gan, Y. Physical and numerical modelling on the mixing condition in a 50 t ladle. Metals 2019, 9, 1136. [Google Scholar] [CrossRef]

- Calderon, F.A.; Morales, R.; Chattopadhyay, K.; Garcia, S. Fluid flow turbulence in the proximities of the metal-slag interface in ladle stirring operations. Metals 2019, 9, 192. [Google Scholar] [CrossRef]

- Xiao, J.; Yan, H.; Liu, L.; Möller, F.; Hu, Z.; Unger, S. Effect of bath depth and nozzle geometry on spout height in submerged gas injection at bottom. Metall. Mater. Trans. B 2019, 50, 3002–3011. [Google Scholar] [CrossRef]

- Conejo, A.N.; Kitamura, S.; Maruoka, N.; Kim, S. Effects of top layer, nozzle arrangement, and gas flow rate on mixing time in agitated ladles by bottom gas injection. Miner. Mater. Soc. ASM Int. 2013, 44, 914–923. [Google Scholar] [CrossRef]

- Ni, S.; Wang, H.; Zhang, J.; Lin, L.; Chu, S. A novel criterion of mixing time in gas-stirred ladle systems. Acta Met. Sin. 2014, 27, 1008–1011. [Google Scholar] [CrossRef]

- Chen, C.; Rui, Q.; Cheng, G. Effect of salt tracer amount on the mixing time measurement in a hydrodynamic model of gas-stirred ladle system. Steel Res. Int. 2013, 84, 900–907. [Google Scholar] [CrossRef]

- Zambrano, H.; Bencomo, A.; Trujillo, L.; Sigalotti, L. Numerical simulation of a gas-stirred ladle. In Selected Topics of Computational and Experimental Fluid Mechanics; Springer: Cham, Switzerland, 2015; pp. 271–280. [Google Scholar] [CrossRef]

- Shanqiang, N.; Shaojun, C.; Jun, Z.; Zhongsi, L. Water model study on mixing time in shaking ladle. In Proceedings of the Thirteenth International Ferroalloys Congress Efficient Technologies in Ferroalloy Industry, Almaty, Kazakhstan, 9–13 June 2013. [Google Scholar]

- Mazumdar, D.; Guthrie, R.I.L. Numerical computation of flow and mixing time in ladle metallurgy steelmaking operations C.A.S. Method. Appl. Math. Model. 1986, 10, 25–32. [Google Scholar] [CrossRef]

- Becker, J.U.; Oeters, F. Model experiments of mixing in steel ladles with continuous addition of the substance to be mixed. Steel Res. 1998, 69, 8–16. [Google Scholar] [CrossRef]

- Lou, W.; Zhu, M. Numerical simulations of inclusion behavior and mixing phenomena in gas-stirred ladles with different arrangement of tuyeres. ISIJ Int. 2014, 54, 9–18. [Google Scholar] [CrossRef]

- Cheng, R.; Zhang, L.; Yin, Y.; Zhang, J. Effect of side blowing on fluid and mixing phenomenon in gas stirred ladle. Metals 2021, 11, 369. [Google Scholar] [CrossRef]

- Aoki, J.; Thomas, B.G. Experimental and theoretical investigation of mixing in a bottom gas-stirred ladle. AISTech Proc. 2004, 1, 1045–1056. [Google Scholar]

- Turkoglu, H.; Farouk, B. Mixing time and liquid circulation in steelmaking ladles with vertical gas injection. ISIJ Int. 1991, 31, 1371–1380. [Google Scholar] [CrossRef][Green Version]

- Shen, M.G.; Zhang, D.H.; Wu, C.; Zu, Q.; Qi, Q.H. Study on stirring behavior of liquid steel in bottom-blowing ladle with immersed cylinder. Metalurgija 2016, 55, 601–604. [Google Scholar]

- Fangguan, T.; Zhu, H.; Shengli, J.; Lipin, P.; Yawei, L.; Baokuan, L. Physical modeling evaluation on refining effects of ladle with different purging plug designs. Steel Res. Int. 2020, 91, 1900606. [Google Scholar] [CrossRef]

- Ramírez-Argaez, M.A.; Contreras, F.; González, C. Modelación matemática del mezclado en ollas cucharas de aluminio equipadas con la técnica de desgasificación rotor-inyector. Revista de Metalurgia 2006, 42, 185–202. [Google Scholar] [CrossRef][Green Version]

- Takahashi, K.; Sugo, Y.; Takahata, Y.; Sekine, H.; Nakamura, M. Laminar mixing in stirred tank agitated by an impeller inclined. Int. J. Chem. Eng. 2012, 2012, 858329. [Google Scholar] [CrossRef]

- Solorio, G.; Morales, R.; Palafox, J.; Garcia, L.; Ramos, A. Analysis of fluid flow turbulence in tundishes fed by a swirling ladle shroud. ISIJ Int. 2004, 44, 1024–1032. [Google Scholar] [CrossRef]

- Chen, G.; He, S. Mixing behavior in the RH degasser with bottom gas injection. Vacuum 2016, 130, 48–55. [Google Scholar] [CrossRef]

- Warzecha, M.; Jowsa, J.; Merder, T. Gas mixing and chemical homogenization of steel in 100 T ladle furnace. Metalurgija 2007, 46, 227–232. [Google Scholar]

| Scheme | Case | Injectors | Injection Type |

|---|---|---|---|

| 1 | 1 | Tuyere |

| 2 | Flow modifier at 60° | ||

| 3 | Flow modifier at 120° | ||

| 4 | 2 | Tuyere |

| 5 | Flow modifier at 60° | ||

| 6 | Flow modifier at 120° |

| Angle of the Modifier | Area under the Curve |

|---|---|

| 30° | 2.13 |

| 60° | 13.88 |

| 90° | 11.13 |

| 120° | 14.63 |

| 180° | 9.63 |

| Injection Type | Time in Seconds |

|---|---|

| 1 Tuyere at 0.75R | 91 |

| 1 Modifier 60° at 0.75R | 71 |

| 1 Modifier 120° at 0.75R | 73 |

| 2 Tuyeres at 0.66R | 92 |

| 2 Modifiers 60° at 0.66R | 82 |

| 2 Modifiers 120° at 0.66R | 85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguilar, G.; Solorio-Diaz, G.; Aguilar-Corona, A.; Ramos-Banderas, J.A.; Hernández, C.A.; Saldaña, F. Study of the Effect of a Plug with Torsion Channels on the Mixing Time in a Continuous Casting Ladle Water Model. Metals 2021, 11, 1942. https://doi.org/10.3390/met11121942

Aguilar G, Solorio-Diaz G, Aguilar-Corona A, Ramos-Banderas JA, Hernández CA, Saldaña F. Study of the Effect of a Plug with Torsion Channels on the Mixing Time in a Continuous Casting Ladle Water Model. Metals. 2021; 11(12):1942. https://doi.org/10.3390/met11121942

Chicago/Turabian StyleAguilar, Gerardo, Gildardo Solorio-Diaz, Alicia Aguilar-Corona, José Angel Ramos-Banderas, Constantin A. Hernández, and Fernando Saldaña. 2021. "Study of the Effect of a Plug with Torsion Channels on the Mixing Time in a Continuous Casting Ladle Water Model" Metals 11, no. 12: 1942. https://doi.org/10.3390/met11121942

APA StyleAguilar, G., Solorio-Diaz, G., Aguilar-Corona, A., Ramos-Banderas, J. A., Hernández, C. A., & Saldaña, F. (2021). Study of the Effect of a Plug with Torsion Channels on the Mixing Time in a Continuous Casting Ladle Water Model. Metals, 11(12), 1942. https://doi.org/10.3390/met11121942