Dynamic Simulations of Manufacturing Processes: Hybrid-Evolving Technique

Abstract

:1. Introduction

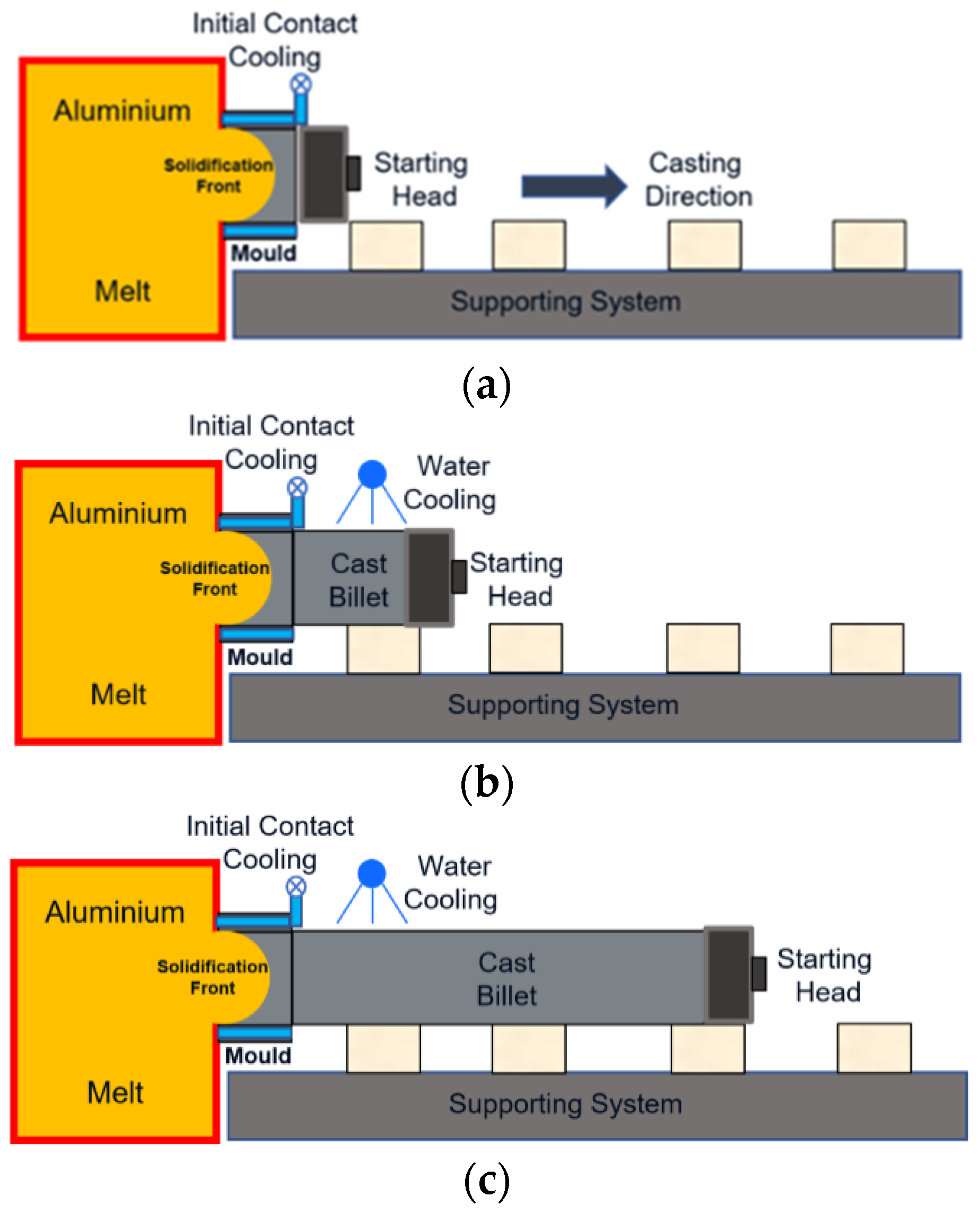

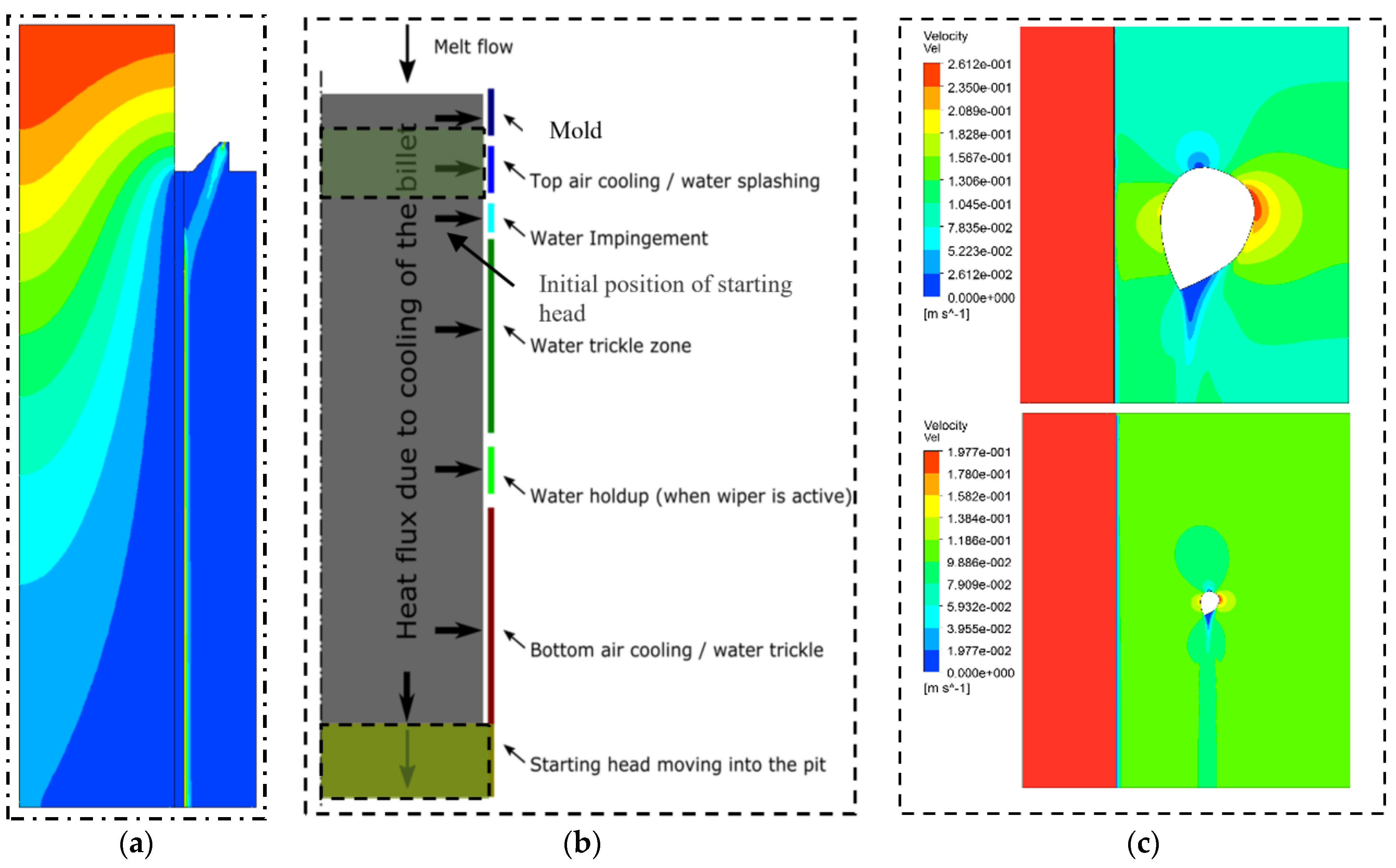

2. Dynamic Processes

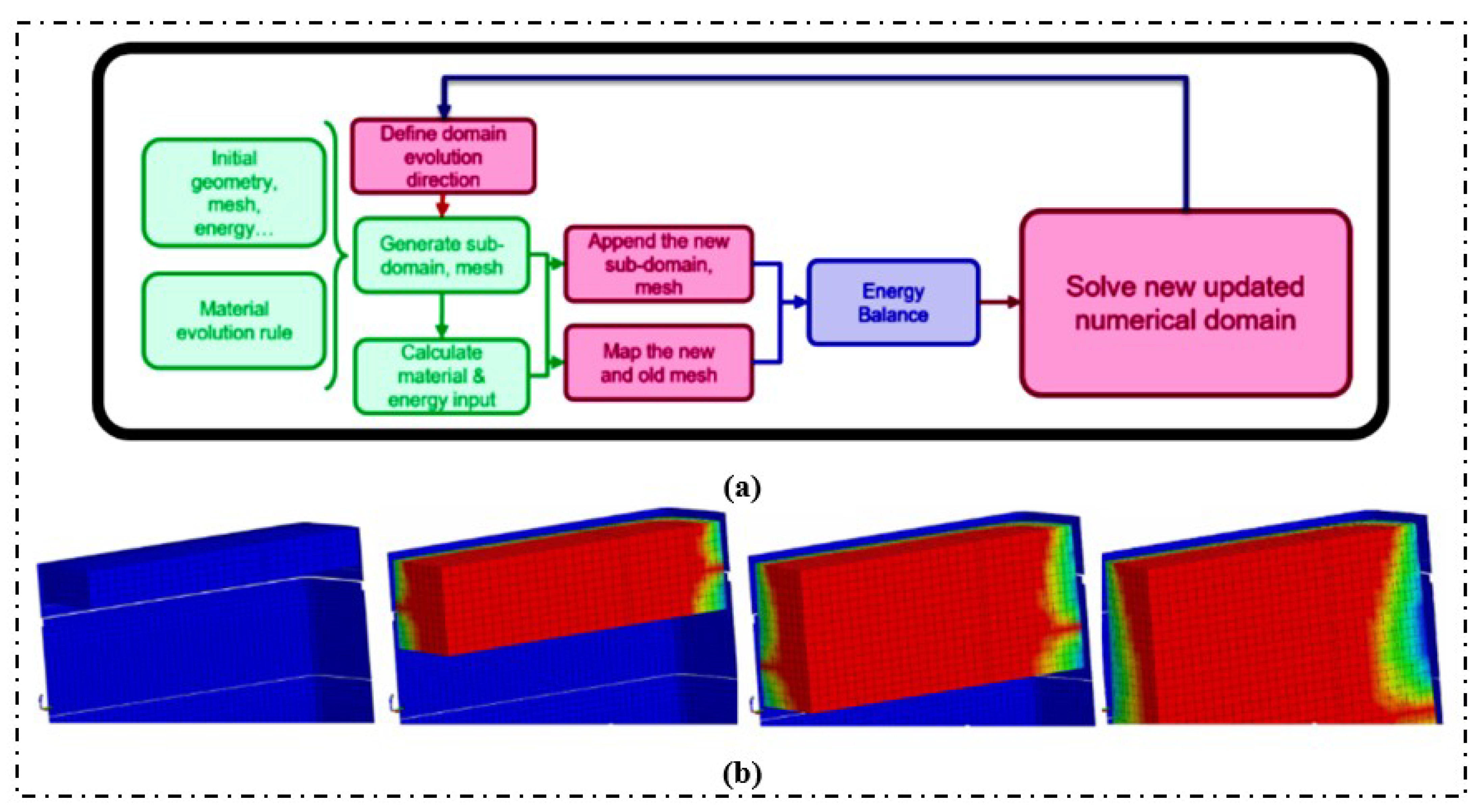

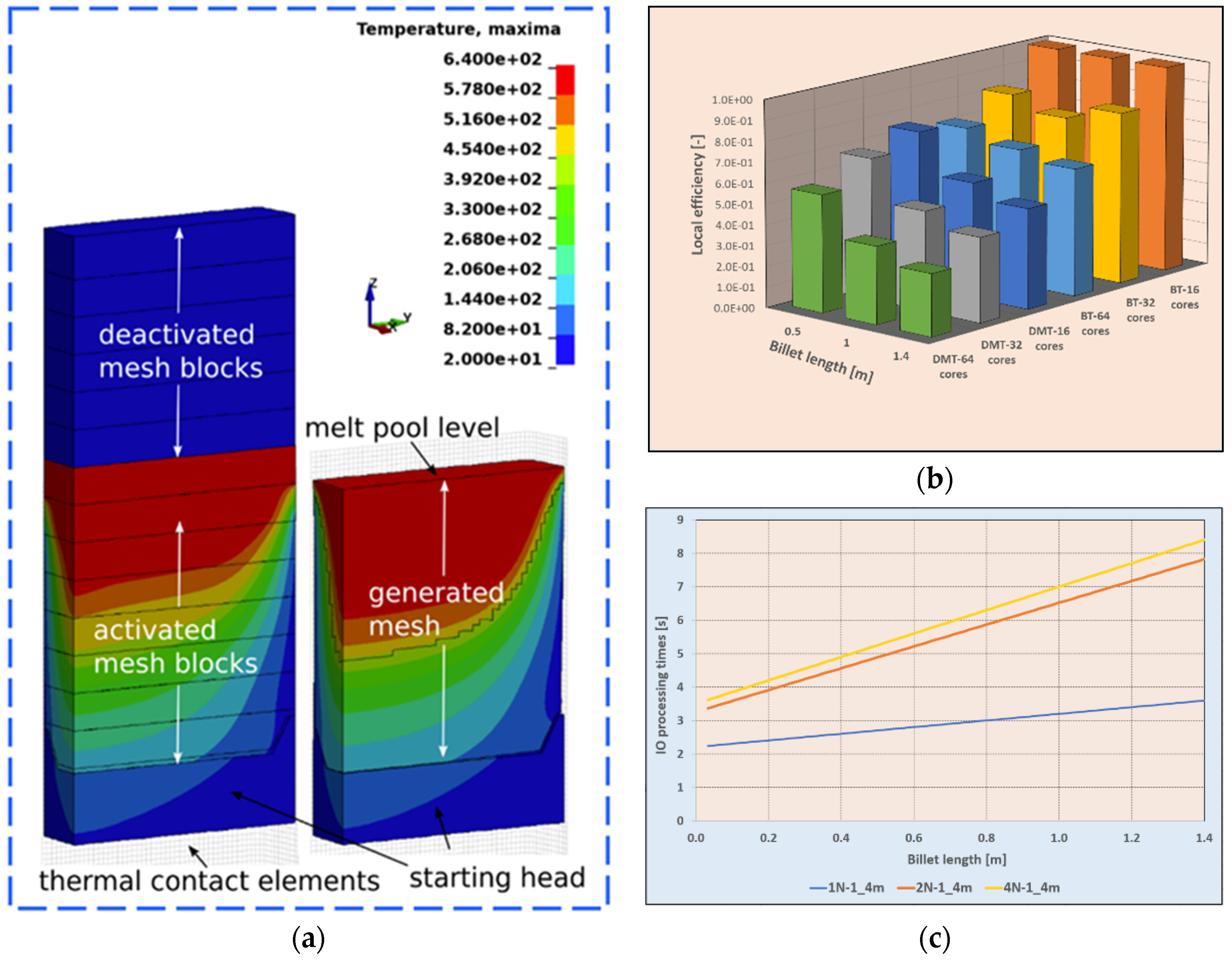

3. Evolving Domain Technique

4. Computational Performance

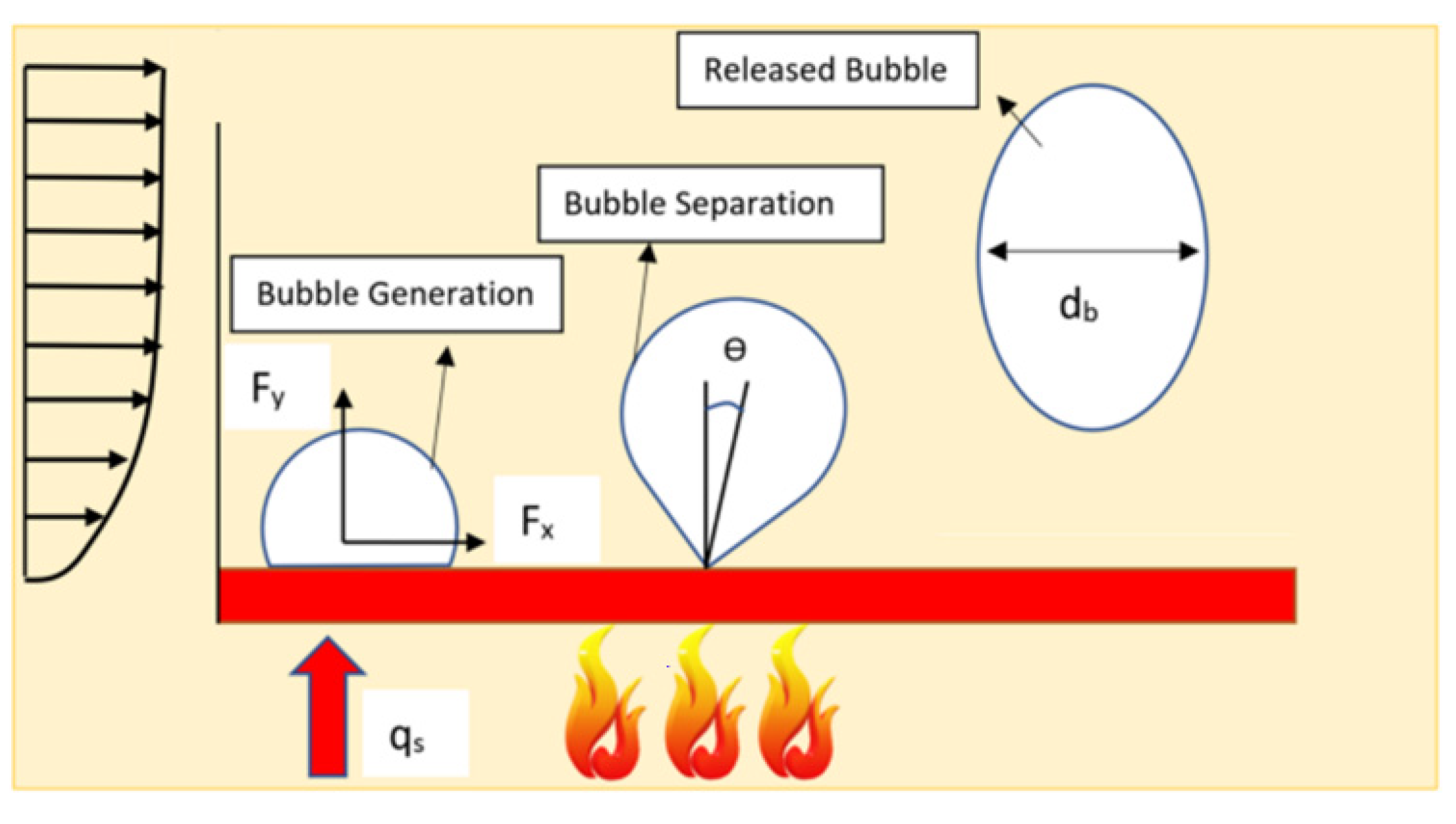

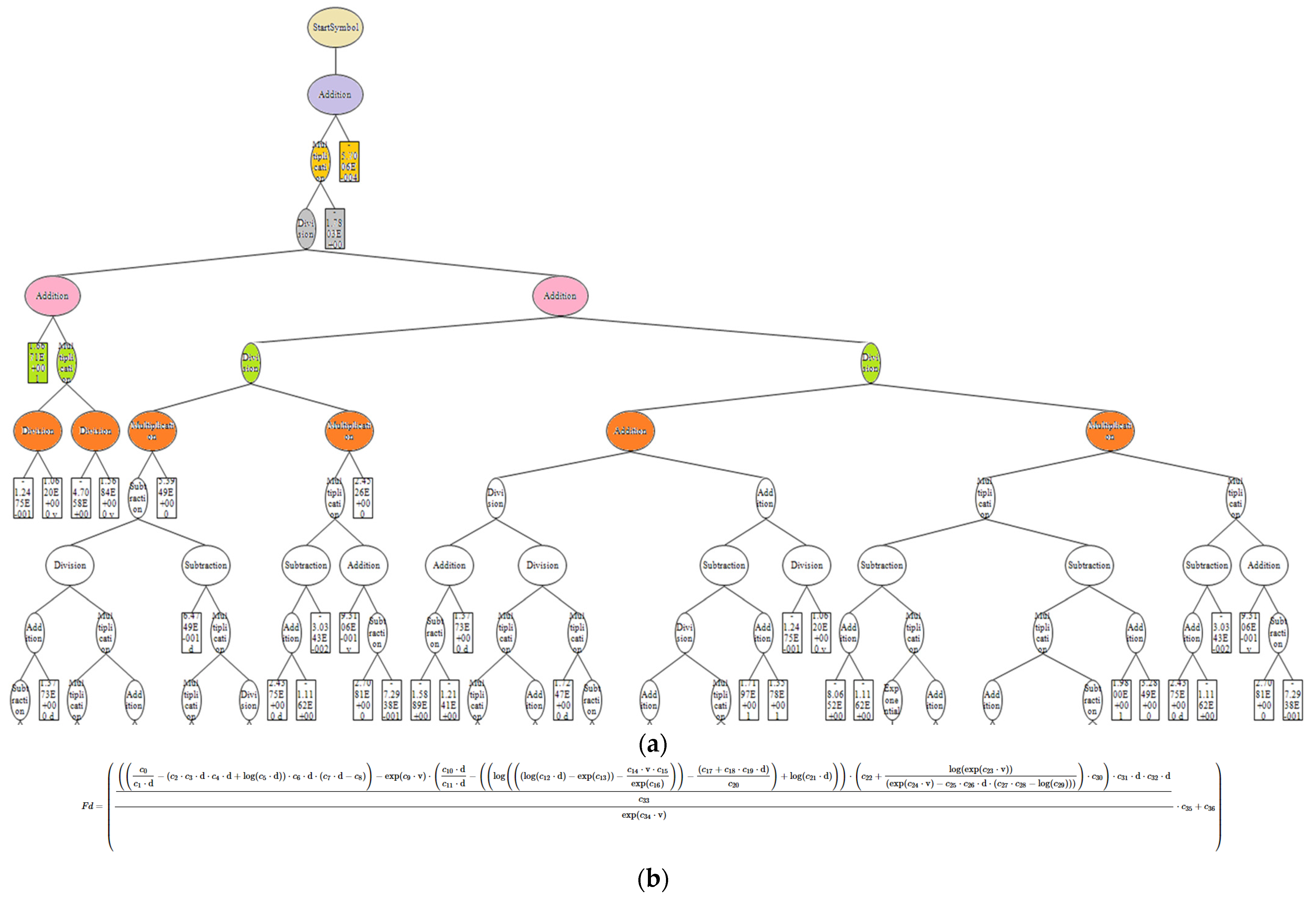

5. Conventional Cooling Models

6. Hybrid Cooling Models

- ➢

- For auxiliary hybrid models, parameters in the physical/empirical models are function-fitted using ML and AI tools

- ➢

- In augmented hybrid models, physical models are augmented with terms derived by function-fitting features of ML and AI tools

- ➢

- Fully hybrid models where data trends from ML and AI are used along with physical laws to derive the hybrid model.

- ➢

- Trained (or dynamic) hybrid models where the existing hybrid model is a subject of ML and AI tools for improvement

- ➢

- Pre-boiling: surface temperature below the water boiling temperature (T < 100°C) where single-phase calculation can be used to estimate the HTC values

- ➢

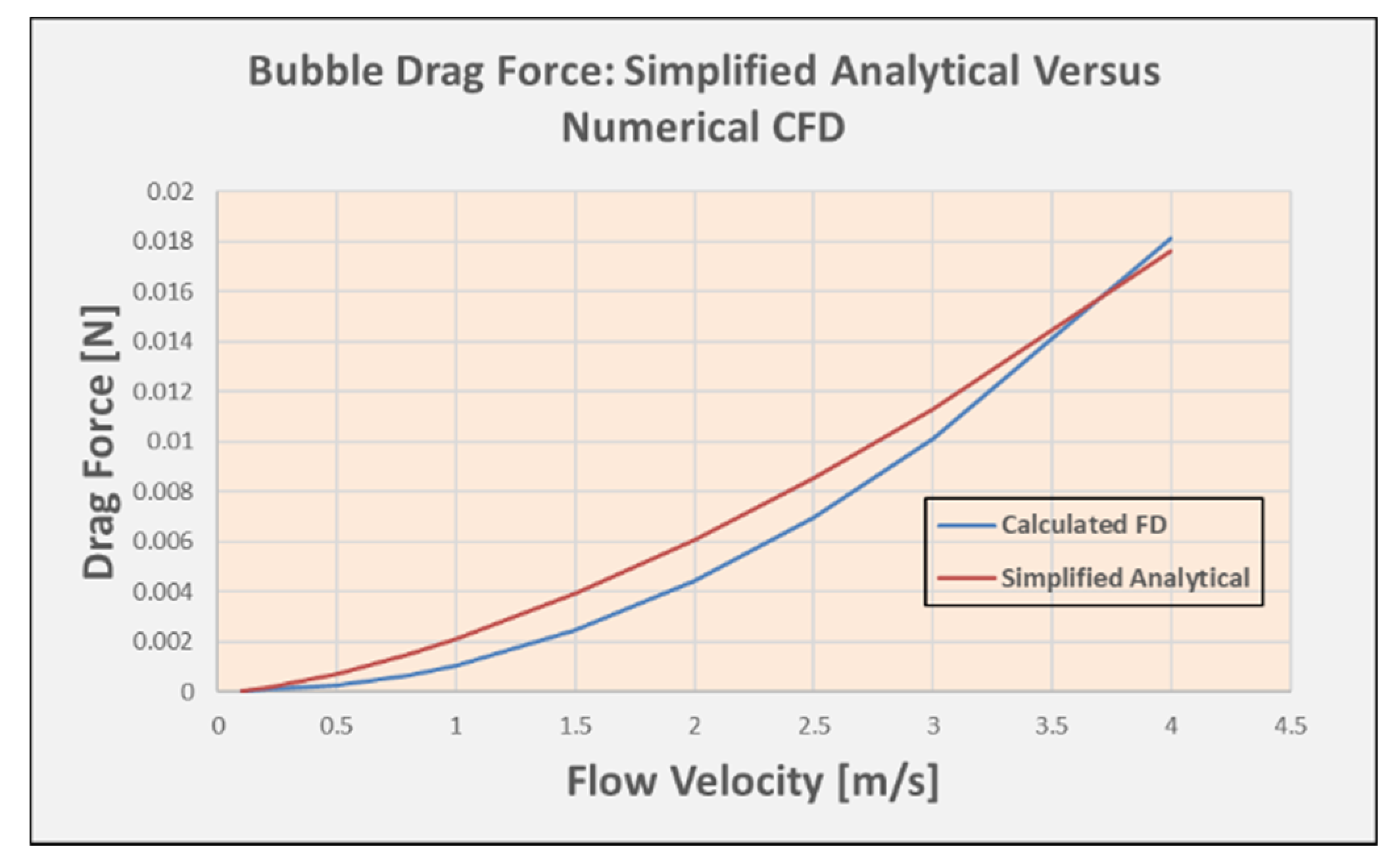

- Nucleate boiling: surface temperature between water boiling temperature and Critical Heat Flux (CHF) temperature where nucleate the boiling regime is dominant. The formation of the discrete bubbles and their movement under drag, lift, and Frank lubrication forces (as discussed earlier) enhances the local fluid motion resulting in an increasing convective HTC. At higher billet surface temperatures near the CHF temperature, the discrete bubbles would coalesce into large size bubbles which further enhances the water flow (the so-called “fully developed nucleate boiling regime”). The rate of change for the surface HTC in the nucleate boiling regime is significant even with small surface temperature changes. For many industrial casting applications, the water-sprayed nucleate boiling regime is preferred since it is generating a high cooling rate.

- ➢

- Transition boiling: surface temperature between CHF and Leidenfrost temperatures where transition boiling regime is taking place. The transition boiling regime and its modeling is one of the challenging issues for HTC calculations during industrial processes. In this type of boiling regime, the surface thermal energy exchange reduces as the billet surface temperature increases.

- ➢

- Film boiling: surface temperature above the Leidenfrost temperature where vapor films are covering the surface of the hot billet. The modeling of cooling for this temperature range can be divided into several cooling regimes based on the different interface of fluid (water) and vapor as continuous, discrete, stable, and unstable.

7. Hybrid-Evolving Technique: Case Study

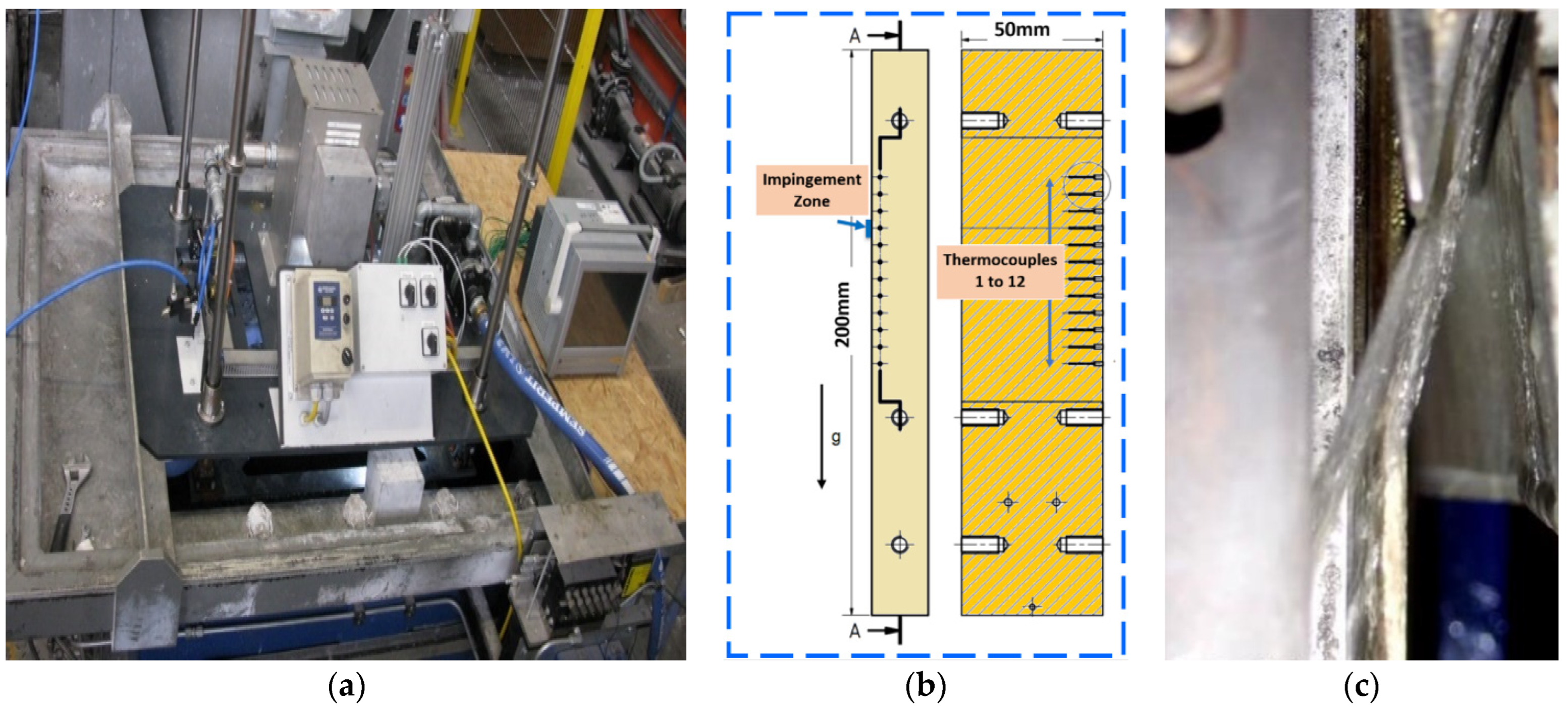

7.1. HTC Estimations

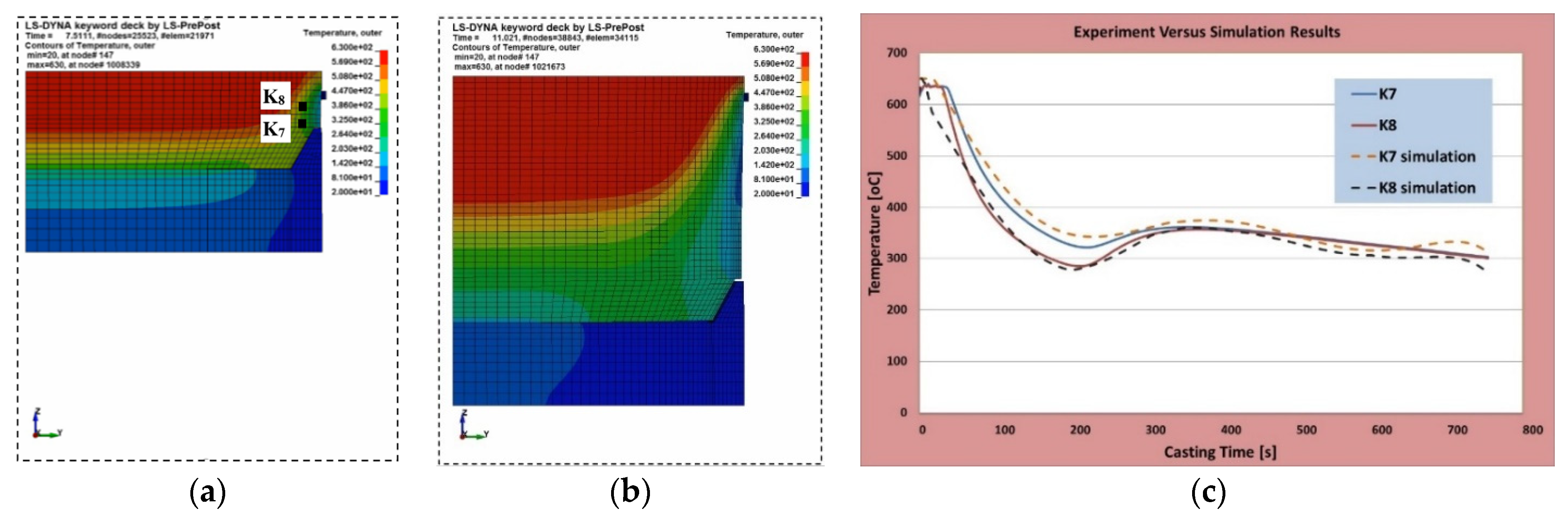

7.2. Hybrid Evolving Simulation

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

- HTC calculator using the hybrid cooling models for the water spray process (using augmenting hybrid method)

- Solidification module [48] for incorporating the change of phase into melt flow during casting processes (not discussed in this paper)

- Controlling module for mixing the cooling and solidification modules using in-house coding

| Zone Number | Parameters | Validity |

|---|---|---|

| I–pre-boiling zone | Q–water flow rate [m3/sec] Lb–billet perimeter [m] Tb –billet surface temp. [°C] α = 1.35 β = 0.3 | 40 < Tb < 100 |

| II–nucleate boiling zone | μ = 0.000267 [Ns/m2] Hfg = 2257e3 [J/kg] cf = 0.016 [J/s] Cp = 4219 [J/kg K] K = 0.68 [W/m K] g = 9.81 [m/s2] rw = 995 [kg/m3] rv = 0.6 [kg/m3] σ = 0.059 [N/m] α = 0.8 β = −0.515 | 100 < Tb < 235 |

| III–transition boiling zone | TCHF = 235 [°C] g = 0.42 | 235 < Tb < 400 |

| IV–film boiling zone | vs= 1 [m/s] α = 0.4 β = 0.5 = 0.5 k = 0.6 l = 0.15 | 400 < Tb < 550 |

References

- Horr, A.M. Multi-resolution simulations of material processes for e-mobility applications. In Proceedings of the 7th Transport Research Arena TRA 2018, Vienna, Austria, 16–19 April 2018. [Google Scholar] [CrossRef]

- Farias A de de Almeida, S.L.R.; Delijaicov, S.; Seriacopi, V.; Bordinassi, E.C. Simple machine learning allied with data-driven methods for monitoring tool wear in machining processes. Int. J. Adv. Manuf. Technol. 2020, 109, 2491–2501. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Fangyuan, S. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Horr, A.M.; Kronsteiner, J. On Numerical Simulation of Casting in New Foundries: Dynamic Process Simulations. Metals 2020, 10, 886. [Google Scholar] [CrossRef]

- Horr, A.M. Notes on New Physical & Hybrid Modelling Trends for Material Process Simulations. J. Phys. Conf. Ser. 2020, 1603, 012008. [Google Scholar]

- Wagner, S.; Affenzeller, M. HeuristicLab: A Generic and Extensible Optimization Environment. In Proceedings of the International Conference in Coimbra, Portugal, 18–19 July 2005; Adaptive and Natural Computing Algorithms; Springer: Berlin/Heidelberg, Germany, 2005; pp. 538–541. [Google Scholar]

- Vijayaram, T.R.; Sulaiman, S.; Hamouda, A.M.S.; Ahmad, M.H.M. Numerical simulation of casting solidification in permanent metallic molds. J. Mat. Pro. Technol. 2006, 178, 29–33. [Google Scholar] [CrossRef]

- Zhihong, G.; Hua, H.; Yuhong, Z.; Shuwei, Q. Numerical Simulation of Squeeze Casting of AZ91D Magnesium Alloy. In Proceedings of the 2010 International Conference on Digital Manufacturing & Automation, Changcha, China, 8–20 December 2010; pp. 30–33. [Google Scholar]

- Brötz, S.; Horr, A.M. Framework for progressive adaption of FE mesh to simulate generative manufacturing processes. J. Manuf. Lett. 2020, 24, 52–55. [Google Scholar] [CrossRef]

- Lindwall, A.L.J.; Lindgren, L.E. Thermal FE-simulation of PBF using adaptive meshing and time stepping. In Proceedings of the Simulation for Additive Manufacturing, Munich, Germany, 11–13 October 2017; pp. 62–63. [Google Scholar]

- Horr, A.M. Computational Evolving Technique for Casting Process of Alloys. J. Math. Probl. Eng. 2019, 2019, 6164092. [Google Scholar] [CrossRef] [Green Version]

- Claus, S.; Bigot, S.; Kerfriden, P. Cutfem Method for Stefan-Signorini Problems with Application in Pulsed Laser Ablation. SIAM J. Sci. 2018, 40, B1444–B1469. [Google Scholar] [CrossRef]

- Bastian, P.; Engwer, C. An unfitted finite element method using discontinuous Galerkin. J. Num. Meth. Eng. 2009, 79, 1557–1576. [Google Scholar] [CrossRef]

- Fausty, J.; Bozzolo, N.; Muñoz, D.; Bernacki, M. A novel level-set finite element formulation for grain growth with heterogeneous grain boundary energies. J. Mat. Des. 2018, 160, 578–590. [Google Scholar] [CrossRef]

- Kleeberg, C. Latest Advancements in Modelling and Simulation for High Pressure Die Castings. In Proceedings of the ALUCAST, Chennai, India, 3–5 December 2010; Aluminium Casters’ Association. pp. 1–18. [Google Scholar]

- Haldenwanger, H.G.; Stich, A. Casting simulation as an innovation in the motor vehicle development process. In Modeling of Casting, Welding and Advanced Solidification; Process IX, SIM 2000; Sahm, R., Hansen, P.N., Conley, J.G., Eds.; United Engineering Foundation: Philadelphia, PA, USA, 2000. [Google Scholar]

- Malik, I.; Anwar Sani, A.; Medi, A. Study on using Casting Simulation Software for Design and Analysis of Riser Shapes in a Solidifying Casting Component. J. Phys. Conf. Ser. 2020, 1500, 012036. [Google Scholar] [CrossRef]

- Francis, L. Materials Processing, A Unified Approach to Processing of Metals, Ceramics and Polymers; Academic Press: Cambridge, MA, USA, 2015; pp. 10–13. [Google Scholar]

- Zhang, L.; Allanore, A.; Wang, C.; Yurko, J.A.; Crapps, J. Materials Processing Fundamentals; John Wiley: Hoboken, NJ, USA, 2013; pp. 63–72. [Google Scholar]

- Horr, A.M. Integrated Material Process Simulation for Lightweight Metal Products. In Computational Methods and Experimental Measurements XVII; WIT Transactions on Modelling and Simulation; WIT Press: Southampton, UK, 2015; Volume 1, pp. 201–212. [Google Scholar]

- Horr, A.M.; Kronsteiner, J.; Mühlstätter, C. Recent Advances in Aluminium Casting Simulation: Evolving Domains & Dynamic Meshing. In Proceedings of the Congress ALUMINUM, Verona, Italy, 20–24 June 2017; pp. 20–24. [Google Scholar]

- Horr, A.M. Thermal Energy Approach for Aluminium Process Simulations: Source-Capacity Technique. J. Mater. Today Proc. 2019, 10, 263–270. [Google Scholar] [CrossRef]

- Horr, A.M. On Analytical Concepts of Novel Multi-Resolution Casting Simulations. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2019, 529, 012055. [Google Scholar] [CrossRef]

- Liu, F.; Nashed, Z.; N’Guerekata, G.; Pokrajac, D.; Qiao, Z.; Shi, X.; Xia, X. Advances in Applied and Computational Mathematics; Nova Science Publishers: New York, NY, USA, 2006; pp. 38–46. [Google Scholar]

- Cai, X.C.; Dryja, M.; Sarkis, M. Overlapping Nonmatching Grid Mortar Element Methods for Elliptic Problems. SIAM J. Num Anal. 1999, 36, 581–606. [Google Scholar] [CrossRef] [Green Version]

- Mingyan, H.; Ziping, H.; Cheng, W.; Pengtao, S.; Shuang, Z. An overlapping domain decomposition method for a polymer exchange membrane fuel cell model. Proc. Comp. Sci. 2011, 4, 1343–1352. [Google Scholar]

- Bellet, M.; Salazar-Betancourt, L.; Jaouen, O.; Costes, F. Modelling of Water Spray Cooling. Impact on Thermomechanics of Solid Shell and Automatic Monitoring to Keep Metallurgical Length Constant. In Proceedings of the 8th European Continuous Casting Conference ECCC, Graz, Austria, 23–26 June 2014; pp. 1202–1210. [Google Scholar]

- Wendelstorf, J.; Spitzer, K.H.; Wendelstorf, R. Spray water cooling heat transfer at high temperatures and liquid mass fluxes. Int. J. Heat Mass Transf. 2008, 51, 4902–4910. [Google Scholar] [CrossRef]

- Krause, F.; Schüttenberg, S.; Fritsching, U. Modelling and simulation of flow boiling heat transfer. Int. J. Num. Meth. Heat Fluid Flow 2010, 20, 312–331. [Google Scholar] [CrossRef]

- Horr, A.M. Optimisation of Aluminium Casting Technology: Thermal Energy Approach. In Proceedings of the Euro Aluminium Congress, Dusseldorf, Germany, 25–26 November 2015; Session 2. pp. 1–13. [Google Scholar]

- Horr, A.M.; Betz, A. Advanced fluid-thermal-mechanical casting simulation of lightweight alloys. In Proceedings of the International Symposium of Liquid Metal Processing & Casting, Leoben, Austria, 20–24 September 2015; pp. 490–497. [Google Scholar]

- Slayzak, S.J.; Viskanta, R.; Incropera, F.P. Effects of interactions between adjoining rows of circular, free-surface jets on local heat transfer from the impingement surface. ASME J. Heat Transf. 1994, 116, 88–95. [Google Scholar] [CrossRef]

- Lienhard, J.H. Liquid Jet Impingement. In Annual Review of Heat Transfer; Tien, C.L., Ed.; Begell House: New York, NY, USA, 1995; Chapter 4; Volume 6, pp. 199–270. [Google Scholar]

- Montáns, F.J.; Chinesta, F.; Bombarelli, R.G.; Nathan Kutz, J. Data-driven modeling and learning in science and engineering. C. R. Mécanique 2019, 347, 845–855. [Google Scholar] [CrossRef]

- Pan, Y.; Hu, M. A data-driven modeling approach for digital material additive manufacturing process planning. In Proceedings of the 2016 International Symposium on Flexible Automation (ISFA), Cleveland, OH, USA, 1–3 August 2016; pp. 223–228. [Google Scholar]

- Wang, D.M.; Alajbegovič, A.; Su, X.M.; Jan, J. Numerical simulation of water quenching process of an engine cylinder head. In Proceedings of the 4th ASME/JSME Joint Fluids Engineering Conference, Honolulu, HI, USA, 6–10 July 2003; Volume 1, pp. 1571–1578. [Google Scholar]

- Greif, D.; Kopun, R.; Kosir, N.; Zhang, D. Numerical Simulation Approach for Immersion Quenching of Aluminum and Steel Components. Int. J. Auto. Eng. 2017, 8, 45–49. [Google Scholar] [CrossRef] [Green Version]

- Frank, T.; Shi, J.M.; Burns, A.D. Validation of Eulerian multiphase flow models for nuclear safety applications. In Proceedings of the 3rd International Symposium on Two-Phase Flow Modelling and Experimentation, Pisa, Italy, 22–25 September 2004. [Google Scholar]

- Tomiyama, A. Struggle with computational bubble dynamics. In Proceedings of the ICMF ’98, 3rd International Conference of Multiphase Flow, Lyon, France, 8–12 June 1998; pp. 1–18. [Google Scholar]

- Ma, C.; Tian, Y.P.; Tian, Y.C.; Lei, D.H. Liquid jet impingement heat transfer with and without boiling. J. Therm. Sci. 1993, 2, 32–49. [Google Scholar] [CrossRef]

- Kominek, J. Methodology of evaluation of heat transfer experiment on aluminum sample. In Proceedings of the 24th International Conference on Metallurgy and Materials, Brno, Czech Republic, 3–5 June 2015; pp. 1203–1208. [Google Scholar]

- Raudensky, M. Heat transfer coefficient estimation by inverse conduction algorithm. Int. J. Num Meth. Heat. 1993, 3, 257–266. [Google Scholar] [CrossRef]

- Pohanka, M.K.; Awoodbury, A. Downhill Simplex Method for Computation of Interfacial Heat Transfer Coefficients in Alloy Casting. Inverse Probl. Eng. 2003, 11, 409–424. [Google Scholar] [CrossRef]

- Ruch, M.A.; Holman, J.P. Boiling Heat Transfer to a Freoon-113 Jet Impinging Upward onto a Flat Heated Surface. Int. J. Heat Mass Transf. 1975, 18, 51–60. [Google Scholar] [CrossRef]

- Monde, M.; Kitajima, K.; Inoue, T.; Mitsutake, Y. Critical heat flux in a forced convective subcooled boiling with an impinging jet. Inst. Chem. Eng. Sym. Ser. Heat Transf. 1994, 7, 515–520. [Google Scholar]

- Monde, M.; Okuma, Y. Critical heat flux in saturated forced convective boiling on a heated disk with an impinging jet–chf in l-regime. Int. J. Heat Mass Transf. 1985, 28, 547–552. [Google Scholar]

- Berenson, P.J. Film-Boiling Heat Transfer from a Horizontal Surface. J. Heat Transf. 1961, 83, 351–356. [Google Scholar] [CrossRef]

- Jäger, S.; Horr, A.M.; Scheiblhofer, S. Thermal evolution effects on solidification process during continuous casting. In Proceedings of the 6th Decennial International Conference on Solidification Processing, Old Windsor, UK, 25–28 July 2017; pp. 675–678. [Google Scholar]

| Melt Temperature [°C] | Billet Width [m] | Billet Thickness [m] | Casting Speed [m s−1] | Cooling Water Temperature [°C] | HTC- Air Cooling [kW m−2 K−1] | HTC- Water Cooling [kW m−2 K−1] |

|---|---|---|---|---|---|---|

| 630 | 1.24 | 0.3 | 0.01 | 20 | 1.5 (average) | 11 (average) |

| Scenario No. | Billet Length [m] | No. of Elements | CPU Time DMT [s] | CPU Time BT [s] | IO Time DMT [s] | IO Time BT [s] | CPU Ratio DMT/BT |

|---|---|---|---|---|---|---|---|

| S1 | 0.5 | 27,189 | 16,345 | 20,581 | 78.62 | 6.90 | 79% |

| S2 | 1 | 41,357 | 45,577 | 77,387 | 179.18 | 7.02 | 59% |

| S3 | 1.4 | 59,573 | 84,545 | 163,063 | 271.84 | 13.77 | 52% |

| CPU Name | No. of Sockets | Cores per Socket | Total Memory [MB] | Communication Between Nodes | Parallelization Scheme | LS-DYNA Release | Accuracy |

|---|---|---|---|---|---|---|---|

| Intel Xeon E5-2687W v4 | 2 | 8 | 65536 | InfiniBand | Platform MPI 08.02.00.00 [10060] | MPP R8.1.0 | Double precision |

| Vel. [m/s] | 0.1 | 0.2 | 0.5 | 0.8 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. [m] | |||||||||||

| 0.001 | × | × | × | × | × | × | × | × | × | × | |

| 0.002 | × | × | × | × | × | × | × | × | × | × | |

| 0.005 | × | × | × | × | × | × | × | × | × | × | |

| 0.02 | × | × | × | × | × | × | × | × | × | × | |

| 0.05 | × | × | × | × | × | × | × | × | × | × | |

| 0.1 | × | × | × | × | × | × | × | × | × | × | |

| Zone Number | HTC Estimations |

|---|---|

| I–pre-boiling zone 40 < Tb < 100 °C | |

| II–nucleate boiling zone 100 < Tb < 235 | |

| III–transition boiling zone 235 < Tb < 400 | |

| IV–film boiling zone 400 < Tb < 550 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Horr, A.M.; Kronsteiner, J. Dynamic Simulations of Manufacturing Processes: Hybrid-Evolving Technique. Metals 2021, 11, 1884. https://doi.org/10.3390/met11121884

Horr AM, Kronsteiner J. Dynamic Simulations of Manufacturing Processes: Hybrid-Evolving Technique. Metals. 2021; 11(12):1884. https://doi.org/10.3390/met11121884

Chicago/Turabian StyleHorr, Amir M., and Johannes Kronsteiner. 2021. "Dynamic Simulations of Manufacturing Processes: Hybrid-Evolving Technique" Metals 11, no. 12: 1884. https://doi.org/10.3390/met11121884

APA StyleHorr, A. M., & Kronsteiner, J. (2021). Dynamic Simulations of Manufacturing Processes: Hybrid-Evolving Technique. Metals, 11(12), 1884. https://doi.org/10.3390/met11121884