Estimation of Fatigue Crack Growth Rate in Heat-Resistant Steel by Processing of Digital Images of Fracture Surfaces

Abstract

1. Introduction

2. Materials and Methods

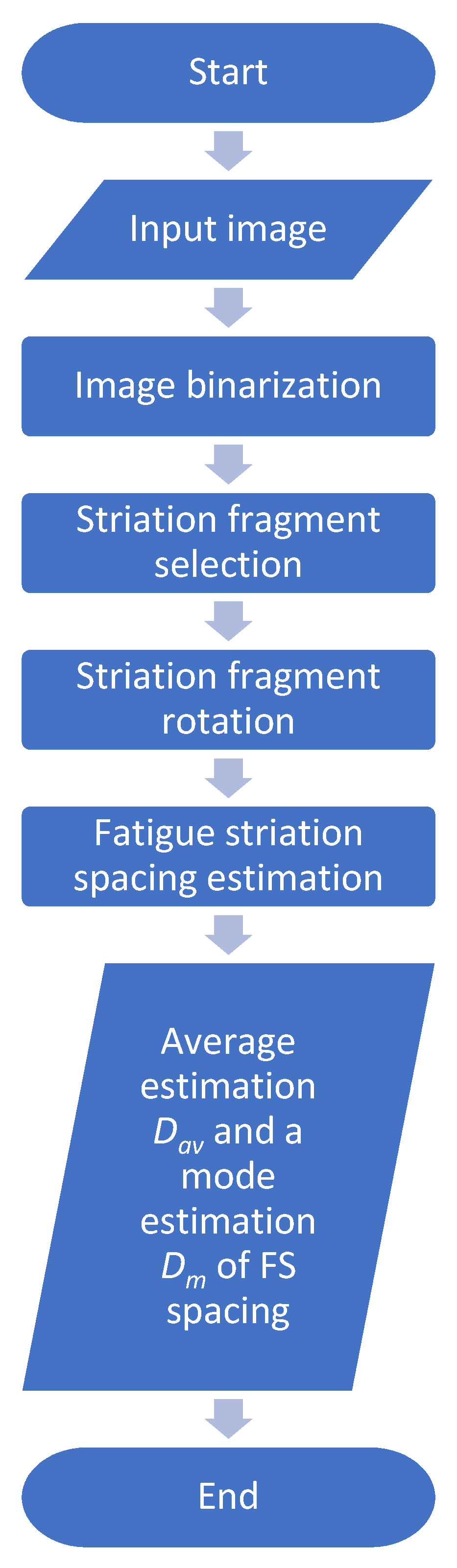

3. Method of Quantitative Analysis of Digital Fractographic Images

- -

- Image binarization by selection of local minima along all columns of the input image with further morphological processing;

- -

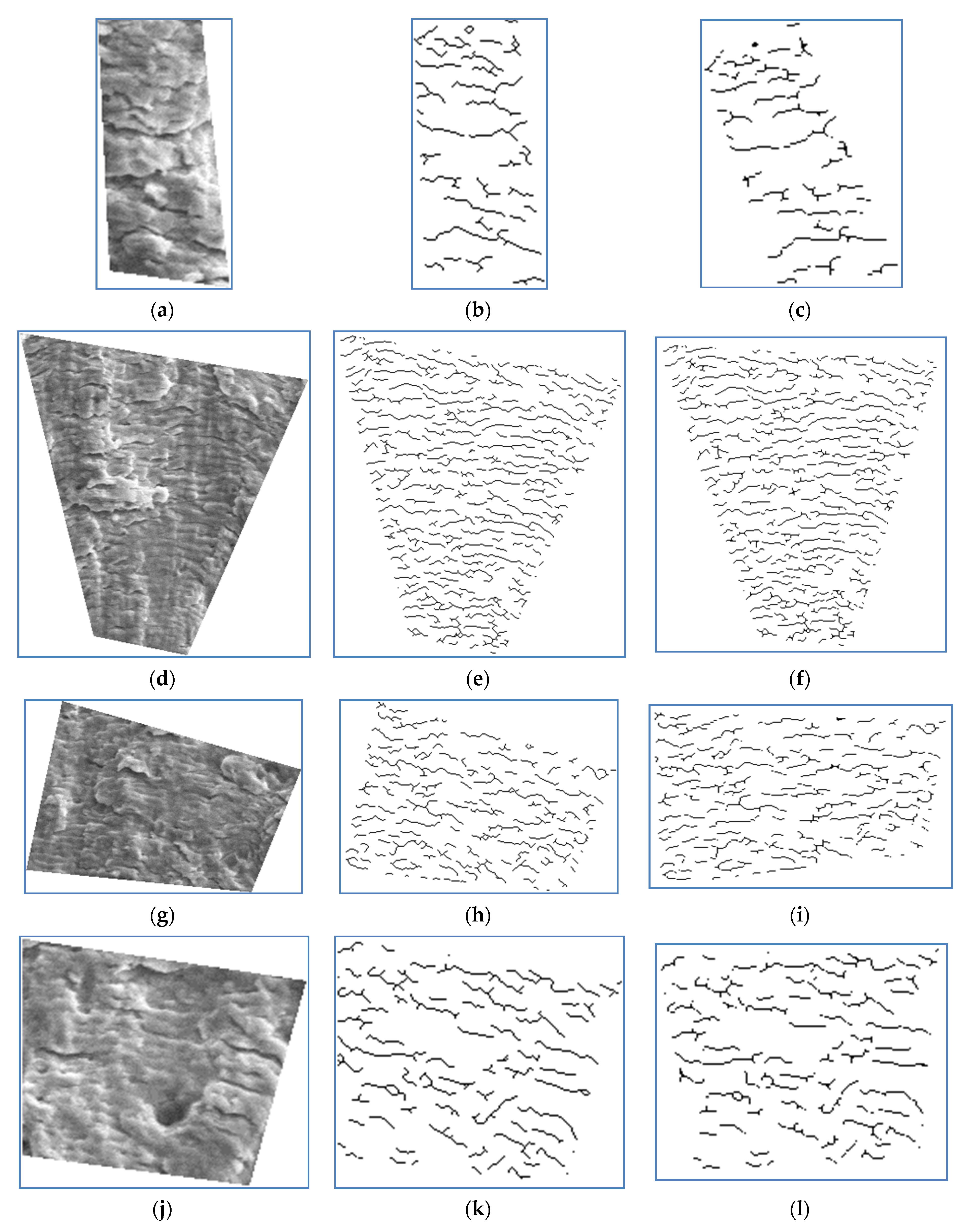

- Selection of binary image fragments with clear lines corresponding to the striations;

- -

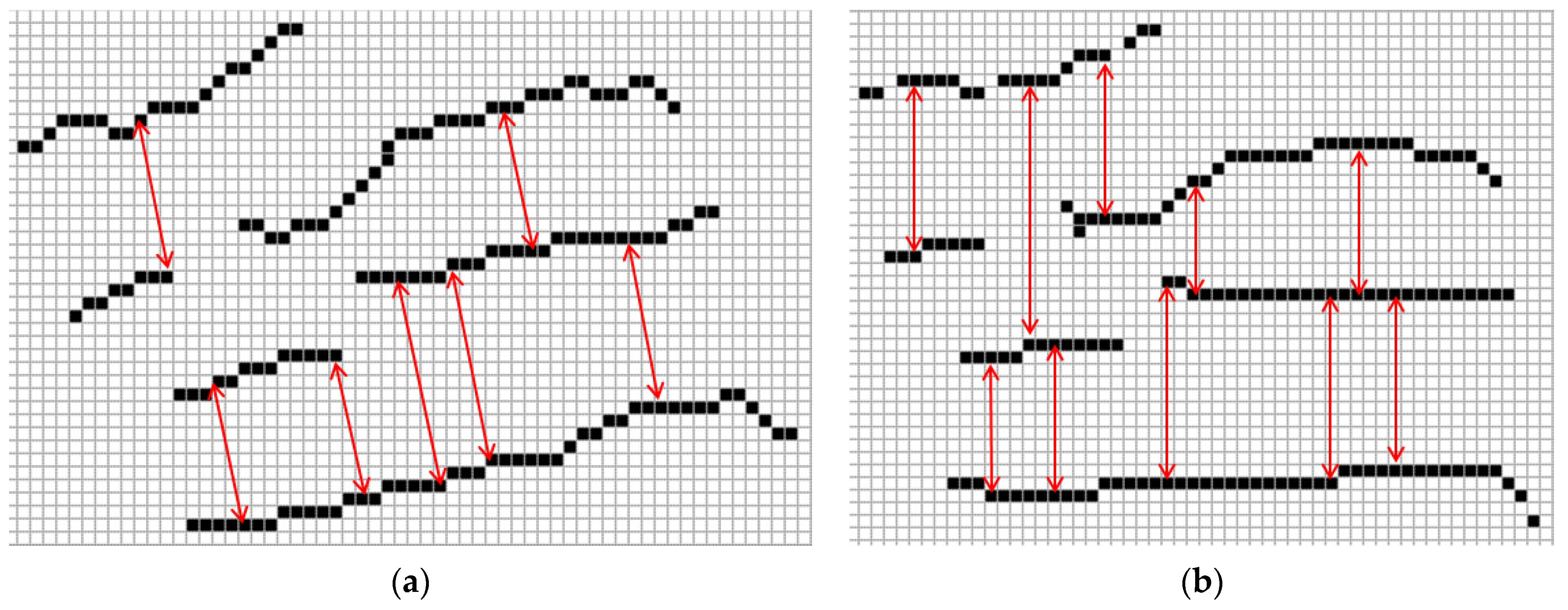

- Rotation of each of the fragments to achieve the horizontal orientation of the lines corresponding to the striations;

- -

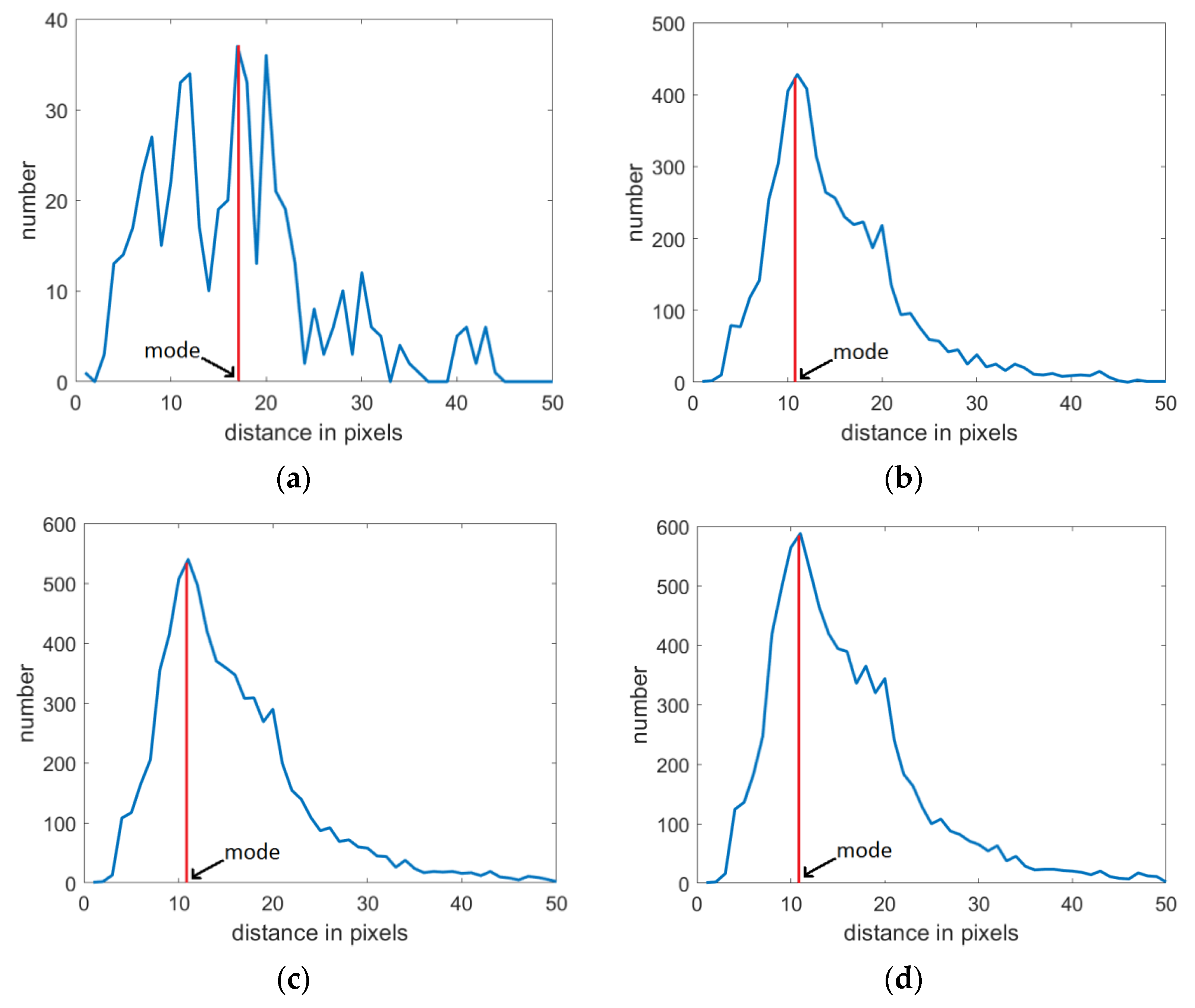

- Estimation of a FS spacing by one of two methods: average estimate or by calculation of a mode of vertical distances between lines corresponding to striations along all columns of binary image fragments.

4. Approbation of the Developed Method for Quantitative Assessment of the Fatigue Crack Growth Rates

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sakin, R. Investigation of bending fatigue-life of aluminum sheets based on rolling direction. Alexandria Eng. J. 2018, 57, 35–47. [Google Scholar] [CrossRef]

- Konovalenko, I.V.; Maruschak, P.O. New Optical-Digital Methods of Technical Diagnostics of Materials and Structures; Ternopil Ivan Puluj National Technical University: Ternopil, Ukraine, 2018; 201p. [Google Scholar]

- Maruschak, P.O.; Sorochak, A.P.; Menou, A.; Maruschak, O.V. Regularities in macro- and micromechanisms of fatigue crack growth in a bimetal of continuous caster rolls. Case Stud. Eng. Fail. Anal. 2013, 1, 165–170. [Google Scholar] [CrossRef]

- Vorobel, R.; Ivasenko, I.; Berehulyak, O.; Mandzii, T. Segmentation of rust defects on painted steel surfaces by intelligent image analysis. Autom. Construct. 2021, 123, 103515. [Google Scholar] [CrossRef]

- Ivasenko, I.; Chervatyuk, V. Detection of rust defects of protective coatings based on HSV color model. In Proceedings of the IEEE Ukraine Conference on Electrical and Computer Engineering, Lviv, Ukraine, 2–6 July 2019; pp. 1143–1146. [Google Scholar]

- Vorobel, R.; Ivasenko, I.; Berehulyak, O. Automatized computer system for evaluation of rust using modified single-scale retinex. In Proceedings of the 2017 IEEE 1st Ukraine Conference on Electrical and Computer Engineering UKRCON 2017, Kyiv, Ukraine, 29 May–2 June 2017; pp. 1002–1006. [Google Scholar] [CrossRef]

- Javorskyj, R.; Yuzefovych, I.; Matsko, I.; Kravets, I.B. The stochastic recurrence structure of geophysical phenomena. In Cyclostationarity: Theory and Methods II; Chaari, F., Leskow, J., Napolitano, A., Zimroz, R., Wylomanska, A., Dudek, A., Eds.; Springer International Publishing Switzerland, Applied Condition Monitoring: New York, NY, USA, 2015; Volume 3, pp. 55–88. [Google Scholar] [CrossRef]

- Vorobel, R.A.; Zhuravel, I.M.; Svirs’ka, L.M.; Student, O.Z. Automatic selection and quantitative analysis of carbides on grain boundaries of 12Kh1MF steel after operation at a steam pipeline of a thermal power plant. Mater. Sci. 2011, 47, 393–400. [Google Scholar] [CrossRef]

- Berehulyak, O.; Vorobel, R. The algebraic model with an asymmetric characteristic of logarithmic transformation. In Proceedings of the 15th International Scientific and Technical Conference on Computer Sciences and Information Technologies, Zbarazh, Ukraine, 23–26 September 2020; pp. 119–122. [Google Scholar] [CrossRef]

- Mandziy, T. Inhomogeneity inforced piecewise smooth Chan-Vese model for image segmetation. In Proceedings of the 2nd IEEE Ukraine Conference on Electrical and Computer Engineering, Lviv, Ukraine, 2–6 July 2019; pp. 1158–1161. [Google Scholar]

- Lauschmann, H. Computer aided fractography: The automatical evaluation of striation parameters. Eng. Mechan. 1998, 5, 377–380. [Google Scholar]

- Tsopanidis, S.; Moreno, R.H.; Osovski, S. Toward quantitative fractography using convolutional neural networks. Eng. Fract. Mechan. 2020, 23, 15. [Google Scholar] [CrossRef]

- Tsopanidis, S.; Osovski, S. Unsupervised Machine Learning in Fractography: Evaluation and Interpretation. Available online: https://engrxiv.org/wjtg2 (accessed on 2 November 2021).

- Sun, Y.; Li, Z.; Yan, J. Recognition method of metal fracture images based on Wavelet kurtosis and relevance vector machine. MATEC Web. Conf. 2016, 39, 02004. [Google Scholar] [CrossRef]

- Ranganathan, N.; Sedghi, N.; Joly, D.; Do, T.; Leroy, R.; Chalon, F.; Feraud, P. A method for quantitative fatigue fracture surface analysis. In Proceedings of the 4th International Conference on Crack Path, Gaeta, Italy, 19–21 September 2012; Available online: https://hal.archives-ouvertes.fr/hal-01689617 (accessed on 2 November 2021).

- Ruellan, B.; Robin, E.; Le Cam, J.-B.; Jeanneau, I.; Canévet, F.; Mauvoisin, G.; Loison, D. Contribution to fatigue striation phenomenon analysis by using image processing. In Advancement of Optical Methods & Digital Image Correlation in Experimental Mechanics, Proceedings of the 2018 SEM Annual Conference & Exposition on Experimental and Applied Mechanics, Greenville, SC, USA, 4–7 June 2018; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- de Olivera Hein, L.R.; de Oliveira, J.A.; de Campos, K.A. Correlative light-electron fractography for fatigue striations characterization in metallic alloys. Microsc. Res. Technique. 2013, 76, 909–913. [Google Scholar] [CrossRef]

- Ritchie, R.O. Mechanisms of fatigue-crack propagation in ductile and brittle solids. Int. J. Fract. 1999, 100, 55–83. [Google Scholar] [CrossRef]

- Romaniv, O.M.; Yarema, S.Y.; Nykyforchyn, H.M.; Makhutov, N.A.; Stadnyk, M.M. Fatigue and cyclic crack resistance of structural materials. In Reference Guide: Fracture Mechanics and Strength of Materials in 4 Volumes; Panasyuk, V.V., Ed.; Naukova dumka: Kyiv, Ukraine, 1990; Volume 4, p. 680. (In Russian) [Google Scholar]

- Yarema, S.Y.; Panasiuk, V.V. General features of fatigue fracture diagrams of metals. Strength Probl. 1996, 1, 30–35. [Google Scholar]

- Kocanda, S. Fatigue Failure of Metals; Sijthoff & Noordhoff International Publishers: Alphen aan den Rijn, The Netherlands, 1978; p. 367. [Google Scholar]

- Tóth, L.; Yarema, S.Y. Formation of the science of fatigue of metals. Part 1. Mater. Sci. 2006, 42, 673–680. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 1998; p. 704. [Google Scholar]

- Pantazopoulos, G.A. A short review on fracture mechanisms of mechanical components operated under industrial process conditions: Fractographic analysis and selected prevention strategies. Metals 2019, 9, 148. [Google Scholar] [CrossRef]

- Song, Y.; Chai, M.; Han, Z. Experimental investigation of fatigue crack growth behavior of the 2.25Cr1Mo0.25V steel welded joint used in hydrogenation reactors. Materials 2021, 14, 1159. [Google Scholar] [CrossRef]

- Von Bestenbostel, W.; Friedrich, K. The appearance of fatigue striations in the SEM. In Proceedings of the 17th International Conference on Composite Materials, Edinburgh, UK, 27–31 July 2009. [Google Scholar]

- Ivanova, V.S.; Shanyavsky, A.A. Quantitative Fractography: Fatigue Failure; Metallurgia: Chelyabinsk, Ukraine, 1988; p. 396. (In Russian) [Google Scholar]

- Shanyavsky, A.A. Safe Fatigue Failure of Aircraft Structural Elements. Synergetics in Engineering Applications; Ufa Printing Plant: Ufa, Russia, 2003; p. 803. (In Russian) [Google Scholar]

- Botvina, L.R. Fracture: Kinetics, Mechanisms, General Laws. In Monograph; Nauka: Moscow, Russia, 2008; p. 334. (In Russian) [Google Scholar]

- Forsyth, P.J.E.; Ryder, D.A. Fatigue fracture. Aircr. Eng. 1960, 32, 96–99. [Google Scholar] [CrossRef]

- Nedbal, I.; Siegl, J.; Kunz, J.; Lauschmann, H. Fractographic reconstitution of fatigue crack history–Part I. Fatig. Fract. Eng. Mater. Struct. 2008, 31, 164–176. [Google Scholar] [CrossRef]

- Nedbal, I.; Kunz, J.; Lauschmann, H. Fractographic reconstitution of fatigue crack history–Part II. Fatig. Fract. Eng. Mater. Struct. 2008, 31, 177–183. [Google Scholar] [CrossRef]

- Nedbal, I.; Siegl, J.; Kunz, J. Relation between striation spacing and fatigue crack growth rate in Al-alloy sheets. In Edvances in Fracture Research, ICF 7; Salama, K., Ed.; Pergamon Press: Houston, TX, USA, 1989; Volume 5, pp. 3484–3491. [Google Scholar]

- Kunz, J.; Nedbal, I.; Siegl, J. Application of fractography in full-scale tests of aircraft structure parts. In Fracture Behaviour and Design of Materials and Structures, ECF 8; Firrao, D., Ed.; Cradley Heath: EMAS: Torino, Italy, 1990; Volume III, pp. 1662–1669. [Google Scholar]

- Kunz, J.; Siegl, J.; Nedbal, I. Quantitative fractography–well spring of intimate knowledge in fatigue crack growth history. Communications 2006, 4, 10–14. [Google Scholar]

- Jun, H.; Yilun, L.; Chi, L.; Qing, W.; Liyong, M. A Fatigue Crack Growth Rate of an Al-Cu-Mg Alloy. IOP Conf. Ser. Earth Environ. Sci. 2019, 237, 032122. [Google Scholar] [CrossRef]

- Williams, J.J.; Yazzie, K.E.; Connor Phillips, N.; Chawla, N.; Xiao, X.; Carlo, F.; Iyyer, N.; Kittur, M. On the correlation between fatigue striation spacing and crack growth rate: A three-dimensional (3-D) X-ray synchrotron tomography study. Metallurg. Mater. Trans. A. 2011, 42, 3845–3848. [Google Scholar] [CrossRef]

- Mills, W.J.; James, L.A. Effect of heat-treatment on elevated temperature fatigue-crack growth behavior of two heats of alloy 718. In ASME Winter Annual Meeting; Westinghouse Hanford Company Richland: Washington, DC, USA, 1978; p. 35. [Google Scholar]

- Bulloch, J.H.; Callagy, A.G. A detailed study of the relationship between fatigue crack growth rate and striation spacing in a range of low alloy ferritic steels. Eng. Fail. Anal. 2010, 17, 168–178. [Google Scholar] [CrossRef]

- Bogdanowicz, Z.; Kocańda, D.; Torzewski, J. Applying fractographic analysis for the evaluation of the effects of variable-amplitude loads on fatigue crack growth rates for the 2024-T3 aluminium alloy. Arch. Mechan. Eng. 2009, 4, 383–404. [Google Scholar] [CrossRef]

- Furukawa, K. Method for estimating service load from striation width and height. Mater. Sci. Eng. A. 2000, 285, 80–84. [Google Scholar] [CrossRef]

- Ruckert, C.O.F.T.; Messias Filho, A.A.; Bose Filho, W.W.; Spinelli, D.; Tarpani, J.R. Load ratio estimation through striation height and spacing analysis of an aerospace al alloy 7475-T7351. J. Mater. Eng. Perf. 2011, 20, 382–389. [Google Scholar] [CrossRef]

- Wareing, J.; Vaughan, H.G. The relationship between striation spacing, macroscopic crack growth rate, and the low-cycle fatigue life of a Type 316 stainless steel at 625 oC. Met. Sci. 1977, 11, 439–446. [Google Scholar] [CrossRef]

- Romaniv, O.N.; Shur, E.A.; Tkach, A.N.; Simin’kovich, V.N.; Kiseleva, T.N. The kinetics and mechanism of fatigue crack growth in iron. Soviet Mater. Sci. 1981, 17, 158–166. [Google Scholar] [CrossRef]

- Krasovskii, A.Y.; Ostash, O.P.; Stepanenko, V.A.; Yarema, S.Y. The effect of low temperatures on the rate and microfractographic features of the development of a fatigue crack in low-carbon steel. Strength Mater. 1977, 9, 458–463. [Google Scholar] [CrossRef]

- Grinberg, N.M. Spacing of fatigue striations and crack growth rate. Soviet Mater. Sci. 1985, 21, 153–160. [Google Scholar] [CrossRef]

- Grinberg, N.M.; Kudryavtseva, E.E.; Serdyuk, V.A. Fatigue crack growth in IMV6 magnesium alloy at temperatures of 293 and 140°K. Soviet Mater. Sci. 1985, 21, 445–449. [Google Scholar] [CrossRef]

- Krasowsky, A. Edvanced SEM methods in fatigue and fracture research. Kov. Mater. 1998, 36, 193–199. [Google Scholar]

- Hayley, S. Micro-fatigue crack growth testing and 3d characterization of small cracks in Ti-6Al-4V made by additive manufacturing using synchrotron X-ray tomography. In A Thesis for the Degree of Master of Science in Materials Science and Engineering; Worcester Polytechnic Institute: Wuster, MA, USA, 2014. [Google Scholar]

- Yasniy, P.; Maruschak, P.; Lapusta, Y. Experimental study of crack growth in a bimetal under fatigue and fatigue-creep conditions. Int. J. Fract. 2006, 139, 545–552. [Google Scholar] [CrossRef]

- DeVries, P.H.; Ruth, K.T.; Dennies, D.P. Counting on fatigue: Striations and their measure. J. Fail. Anal. Preven. 2010, 10, 120–137. [Google Scholar] [CrossRef]

- Ruellan, B.; Robin, E.; Le Cam, J.-B.; Jeanneau, I.; Canévet, F.; Mauvoisin, G.; Loison, D. Contribution to fatigue striation phenomenon analysis by using image processing. In Advancement of Optical Methods & Digital Image Correlation in Experimental Mechanics, Conference Proceedings of the Society for Experimental Mechanics Series, Reno, NV, USA, 3–6 June 2019; Lamberti, L., Lin, M.T., Furlong, C., Sciammarella, C., Reu, P., Sutton, M., Eds.; Springer: Cham, Switzerland, 2019; Volume 3. [Google Scholar] [CrossRef]

- de Matos, P.F.P.; Moreira, P.M.G.P.; Pina, J.C.P.; Dias, A.M.; de Castro, P.M.S.T. Residual stress effect on fatigue striation spacing in a cold-worked rivet hole. Theor. Appl. Fract. Mechan. 2004, 42, 139–148. [Google Scholar] [CrossRef]

- Hershko, E.; Mandelker, N.; Gheorghiu, G.; Sheinkopf, H.; Cohen, I.; Levy, O. Assessment of fatigue striation counting accuracy using high resolution scanning electron microscope. Eng. Fail. Anal. 2008, 15, 20–27. [Google Scholar] [CrossRef]

- Lenets, Y.N.; Bellows, R.S. Crack propagation life prediction for Ti-6Al-4V based on striation spacing measurements. Int. J. Fatig. 2000, 22, 521–529. [Google Scholar] [CrossRef]

- Connors, W.C. Fatigue striation spacing analysis. Mater. Character. 1994, 33, 245–253. [Google Scholar] [CrossRef]

- Lauschmann, H.; Nedbal, I. Applications of Image Analysis in Fractography of Fatigue Failures. Procedia Struct. Integr. 2019, 23, 107–112. [Google Scholar] [CrossRef]

- Lauschmann, H. Textural fractography: Estimation of the mean striation spacing and direction. In International Conference on Stereology and Image Analysis in Materials Science; Polish Society for Stereology: Cracow, Poland, 2000; pp. 241–246. [Google Scholar]

- Yamagiwa, K.; Izumi, S.; Sakai, S. Detecting method of striation region of fatigue fracture surface using wavelet transform. J. Soc. Mater. Sci. Japan. 2004, 53, 306–312. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Student, O.; Tkachuk, Y.; Sydor, P. Technical Expertise of Damaged Structural Elements of Power Plant Steam Turbine. In Proceedings of the 14th International Conference “Mechanika–2009”, Kaunas, Lithuania, 2–3 April 2009; pp. 396–400. [Google Scholar]

- Serra, J.; Soille, P. Mathematical Morphology and Its Applications to Image Processing; Springer: Amsterdam, The Netherlands, 1994; p. 385. [Google Scholar]

- Duda, R.O.; Hart, P.E. Use of the Hough transformation to detect lines and curves in pictures. Comm. ACM. 1972, 15, 11–15. [Google Scholar] [CrossRef]

- Tkachuk, Y.M.; Student, O.Z. Features of fracture and fatigue durability of the maintained steel of disks of the steam turbine of thermal power station. Metallof. Noveishie Tekhnol. 2011, 33, 449–460. [Google Scholar]

- Student, O.Z.; Krechkovska, H.V.; Svirska, L.M.; Kindratsky, B.I.; Shyrokov, V.V. Ranking of mechanical characteristics of steels of steam pipelines of TPPs according to their sensitivity to operational degradation. Phys. Chem. Mechan. Mater. 2021, 57, 110–117. (In Ukrainian) [Google Scholar]

- Nykyforchyn, H.M.; Student, O.Z.; Krechkovs’ka, H.V.; Markov, A.D. Evaluation of the influence of shutdowns of a technological process on changes in the in-service state of the metal of main steam pipelines of thermal power plants. Mater. Sci. 2010, 46, 177–189. [Google Scholar] [CrossRef]

- McEvily, A.J.; Matsunaga, H. On fatigue striations. Trans. B. Mechan. Eng. 2010, 17, 75–82. [Google Scholar]

- Student, O.Z.; Cichosz, P.; Szimkowski, J. Correlation between the fracture roughness and fatigue graded threshold high steel. Mater. Sci. 1999, 35, 796–801. [Google Scholar] [CrossRef]

- Student, O.Z.; Dudziński, W.; Nykyforchyn, H.M.; Kamińska, A. Effect of high-temperature degradation of heat-resistant steel on the mechanical and fractographic characteristics of fatigue crack growth. Mater. Sci. 1999, 35, 499–508. [Google Scholar] [CrossRef]

- Dmytrakh, I.M.; Syrotyuk, A.M.; Leshchak, R.L. Specific effects of hydrogen concentration on resistance to fracture of ferrite-pearlitic pipeline steels. Proc. Struct. Int. 2019, 16, 113–120. [Google Scholar] [CrossRef]

- Smiyan, O.D.; Student, O.Z. Fractographic signs of gigacyclic fatigue and hydrogenation during operation of heat-resistant steels. Mater. Sci. 2020, 56, 1–11. (In Ukrainian) [Google Scholar]

- Nykyforchyn, H.M.; Student, O.Z. Influence of hydrogen of the formation of fatigue thresholds in structural steels. Mater. Sci. 2001, 37, 252–263. [Google Scholar] [CrossRef]

- Birenis, D.; Ogawa, Y.; Matsunaga, H.; Takakuwae, O.; Yamabe, J.; Prytz, O.; Thøgersen, A. Interpretation of hydrogen-assisted fatigue crack propagation in BCC iron based on dislocation structure evolution around the crack wake. Acta Mater. 2018, 156, 245–253. [Google Scholar] [CrossRef]

- Matsunaga, H.; Noda, H. Visualization of hydrogen diffusion in a hydrogen-enhanced fatigue crack growth in type 304 stainless steel. Metall. Mater. Trans. A 2011, 42, 2696–2705. [Google Scholar] [CrossRef]

- Maruschak, P.O.; Panin, S.V.; Stachowicz, F.; Danyliuk, I.M.; Vlasov, I.V.; Bishchak, R.T. Structural levels of fatigue failure and damage estimation in 17Mn1Si steel on the basis of a multilevel approach of physical mesomechanics. Acta Mechan. 2016, 227, 151–157. [Google Scholar] [CrossRef]

| Steel State | C | Ni | Cr | Mo | Si | Mn | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Initial state | 0.33 | 2.90 | 0.90 | 0.30 | 0.37 | 0.62 | 0.035 | 0.030 | Rest |

| After operation | 0.32 | 2.80 | 0.91 | 0.29 | 0.41 | 0.59 | 0.053 | 0.039 | Rest |

| Steel State | σUTS, MPa | σYS, MPa | RA, % | El, % |

|---|---|---|---|---|

| Initial state | 856.3 | 690.5 | 61.3 | 18.4 |

| After operation | 1002.5 | 936.7 | 51.2 | 13.5 |

| The Number of the Fragment Analyzed in Figure 1 | ||||

|---|---|---|---|---|

| Pixel | μm | Pixel | μm | |

| 1 | 17 | 2.23 | 16 | 2.11 |

| 2 | 11 | 1.45 | 14 | 1.84 |

| 3 | 11 | 1.45 | 16 | 2.11 |

| 4 | 11 | 1.45 | 16 | 2.11 |

| All images | 11 | 1.45 | 16 | 2.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maruschak, P.; Vorobel, R.; Student, O.; Ivasenko, I.; Krechkovska, H.; Berehulyak, O.; Mandziy, T.; Svirska, L.; Prentkovskis, O. Estimation of Fatigue Crack Growth Rate in Heat-Resistant Steel by Processing of Digital Images of Fracture Surfaces. Metals 2021, 11, 1776. https://doi.org/10.3390/met11111776

Maruschak P, Vorobel R, Student O, Ivasenko I, Krechkovska H, Berehulyak O, Mandziy T, Svirska L, Prentkovskis O. Estimation of Fatigue Crack Growth Rate in Heat-Resistant Steel by Processing of Digital Images of Fracture Surfaces. Metals. 2021; 11(11):1776. https://doi.org/10.3390/met11111776

Chicago/Turabian StyleMaruschak, Pavlo, Roman Vorobel, Oleksandra Student, Iryna Ivasenko, Halyna Krechkovska, Olena Berehulyak, Teodor Mandziy, Lesia Svirska, and Olegas Prentkovskis. 2021. "Estimation of Fatigue Crack Growth Rate in Heat-Resistant Steel by Processing of Digital Images of Fracture Surfaces" Metals 11, no. 11: 1776. https://doi.org/10.3390/met11111776

APA StyleMaruschak, P., Vorobel, R., Student, O., Ivasenko, I., Krechkovska, H., Berehulyak, O., Mandziy, T., Svirska, L., & Prentkovskis, O. (2021). Estimation of Fatigue Crack Growth Rate in Heat-Resistant Steel by Processing of Digital Images of Fracture Surfaces. Metals, 11(11), 1776. https://doi.org/10.3390/met11111776