Plasma Spheroidisation of Irregular Ti6Al4V Powder for Powder Bed Fusion

Abstract

:1. Introduction

2. Materials and Methods

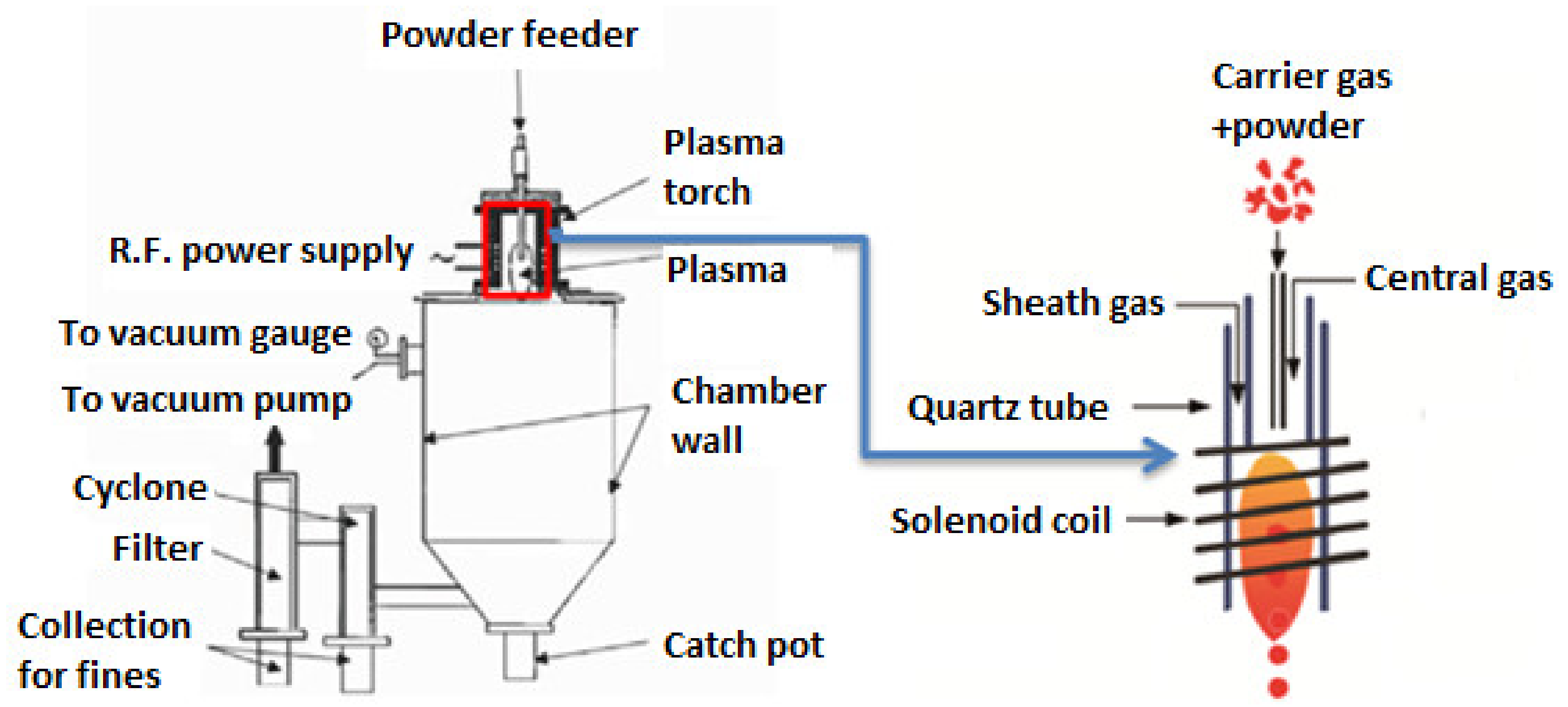

2.1. PS Process

2.2. Characterisation of the Spheroidised Powder

3. Results and Discussion

3.1. Particle Morphology

3.2. Particle Porosity

3.3. PSD

3.4. Powder Composition

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mineral Commodity Summaries 2020; US. Geological Survey: Reston, VA, USA, 2020; pp. 176–177. [CrossRef] [Green Version]

- International Titanium Association. South Africa Moves Forward, Stakes Its Claim as Hub for Titanium Powder Metal Innovation. Titan. Today 2018, 22, 22–23. [Google Scholar]

- Oosthuizen, S.J.; Swanepoel, J.J. Development status of the CSIR-Ti Process. IOP Conf. Ser. Mater. Sci. Eng. 2018, 430, 012008. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Lalonde, A.D.; Ma, J. Processing parameters in laser powder bed fusion metal additive manufacturing. Mater. Des. 2020, 193, 1–12. [Google Scholar] [CrossRef]

- Sun, P.; Fang, Z.Z.; Zhang, Y.; Xia, Y. Review of the Methods for Production of Spherical Ti and Ti Alloy Powder. J. Mater. Sci. 2017, 69, 1853–1860. [Google Scholar] [CrossRef] [Green Version]

- Oliveira, J.P.; Panton, B.; Zeng, Z.; Andrei, C.M.; Zhou, Y.; Miranda, R.M.; Fernandes, F.M.B. Laser joining of NiTi to Ti6Al4V using a Niobium interlayer Acta Materialia Laser joining of NiTi to Ti6Al4V using a Niobium interlayer. Acta Mater. 2016, 105, 9–15. [Google Scholar] [CrossRef]

- Callegari, B.; Oliveirac, J.P.; Aristizabal, K.; Coelho, R.S.; Brito, P.P.; Wug, L.; Schell, N.; Soldera, F.A.; Mücklich, F.; Pinto, H.C. Materials Characterization In-situ synchrotron radiation study of the aging response of Ti-6Al-4V alloy with di ff erent starting microstructures. Mater. Charact. 2020, 165, 1–10. [Google Scholar] [CrossRef]

- Lisiecki, A.; Piwnik, J. Tribological characteristic of titanium alloy surface layers produced by diode laser gas nitriding. Arch. Metall. Mater. 2016, 61, 543–552. [Google Scholar] [CrossRef]

- Gospodinov, D.; Ferdinandov, N.; Dimitrov, S. Classification, properties and application of titanium and its alloys. Proc. Univ. Ruse 2016, 55, 27–32. [Google Scholar]

- Veiga, C.; Davim, J.P.; Loureiro, A. Properties and applications of titanium alloys: A brief review. Rev. Adv. Mater. Sci. 2012, 32, 14–34. [Google Scholar]

- Elias, C.N.; Lima, J.H.C.; Valiev, R.; Meyers, M.A. Biomedical applications of titanium and its alloys. JOM 2008, 60, 46–49. [Google Scholar] [CrossRef]

- Guo, J.; Fan, X.; Dolbec, R.; Xue, S.; Jurewicz, J.; Boulos, M. Development of nanopowder synthesis using induction plasma. Plasma Sci. Technol. 2010, 12, 188–199. [Google Scholar]

- Vert, R.; Pontone, R.; Dolbec, R.; Dionne, L.; Boulos, M.I. Induction plasma technology applied to powder manufacturing: Example of Titanium-based materials. Key Eng. Mater. 2016, 704, 282–286. [Google Scholar] [CrossRef]

- Zi, X.; Chen, C.; Wang, X.; Wang, P.; Zhang, X.; Zhou, K. Spheroidisation of tungsten powder by radio frequency plasma for selective laser melting. Mater. Sci. Technol. 2018, 34, 735–742. [Google Scholar] [CrossRef]

- Bissett, H.; van der Wall, I.J. Metal and alloy spheroidisation for the Advanced Metals Initiative of South Africa, using high-temperature radio-frequency plasmas. J. S. Afr. Inst. Min. Metall. 2017, 117, 975–980. [Google Scholar] [CrossRef] [Green Version]

- Sheng, Y.W.; Guo, Z.M.; Hao, J.J.; Yang, D.H. Effect of spheroidization of Ti-6Al-4V powder on characteristics and rheological behaviors of gelcasting slurry. Procedia Eng. 2012, 36, 299–306. [Google Scholar] [CrossRef] [Green Version]

- Wei, W.; Wang, L.; Chen, T.; Duan, X.; Li, W. Study on the flow properties of Ti-6Al-4V powders prepared by radio-frequency plasma spheroidization. Advance 2017, 28, 2431–2437. [Google Scholar] [CrossRef]

- Xie, B.; Fan, Y.; Zhao, S. Characterization of Ti6Al4V powders produced by different methods for selective laser melting Characterization of Ti6Al4V powders produced by different methods for selective laser melting. Mater. Res. Express 2021, 8, 1–12. [Google Scholar] [CrossRef]

- Li, J.; Hao, Z.; Shu, Y.; He, J. Fabrication of spherical Ti-6Al-4V powder for additive manufacturing by radio frequency plasma spheroidization and deoxidation using calcium. J. Mater. Res. Technol. 2020, 9, 14792–14798. [Google Scholar] [CrossRef]

- Chong, Z.; Chaoyang, M.; Zicheng, W.; Yongge, C.; Ran, M.; Xuanyi, Y. Spheroidization of TC4 (Ti6Al4V) Alloy Powders by Radio Frequency Plasma Processing. Rare Met. Mater. Eng. 2019, 48, 2. [Google Scholar]

- Yang, S.; Gwak, J.; Lim, T.; Kim, Y.; Yun, J. Preparation of Spherical Titanium Powders from Polygonal Titanium Hydride Powders by Radio Frequency Plasma Treatment. Mater. Trans. 2013, 54, 2313–2316. [Google Scholar] [CrossRef] [Green Version]

- Daswa, P.; Gxowa, Z.; Monareng, M.; Mutombo, K. Effect of milling speed on the formation of Ti-6Al-4V via mechanical alloying. IOP Conf. Ser. Mater. Sci. Eng. 2018, 430, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Bissett, H.; van der Walt, I.J.; Havenga, J.L.; Nel, J.T. Titanium and zirconium metal powder spheroidization by thermal plasma processes. J. S. Afr. Inst. Min. Mettallurgy 2015, 115, 937–942. [Google Scholar] [CrossRef]

- ASTM F3049-14 Standard Guide for Characterizing Properties of Metal Powders Used for Additive Manufacturing Processes; ASTM International: West Conshohocken, PA, USA, 2014; pp. 1–3.

- Li, Q.; Zhang, L.; Wei, D.; Ren, S.; Qu, X. Porous Nb-Ti based alloy produced from plasma spheroidized powder. Results Phys. 2017, 7, 1289–1298. [Google Scholar] [CrossRef]

- Thejane, K.; Chikosha, S.; du Preez, W.B. Characterisation and monitoring of TI6AL4V (ELI) powder used in different selective laser melting systems. S. Afr. J. Ind. Eng. 2017, 28, 161–171. [Google Scholar] [CrossRef] [Green Version]

| Plasma Plate Power (kW) | 11–13 |

| Feed Rate (kg/h) | 1 |

| Carrier Gas Flowrate (slpm) | 2 |

| Plasma Gas Flowrate (slpm) | 10 |

| Sheath Gas Flowrate (slpm) | 40 |

| Particle Size Range (µm) | <45 |

| Group I | <20 µm | Not Recommended | 3.2% |

| Group II | 20–63 µm | Powder Bed Fusion | 73.4% |

| Group III | 63–150 µm | Direct Energy Deposition | 18.3% |

| Group IV | >150 µm | Not Recommended | 5.1% |

| D10 | 26.4 µm | / | / |

| D50 | 47.9 µm | / | / |

| D90 | 78.6 µm | / | / |

| Mean (µm) | 58.8 µm | / | / |

| Median (µm) | 47.9 µm | / | / |

| Element | Coarse Surface | Smooth Surface | ASTM F3001 Ti6Al4V (ELI) |

|---|---|---|---|

| Ti (wt %) | 93.82 | 92.08 | 89 |

| Al (wt %) | 3.65 | 4.25 | 6.5–5.5 |

| V (wt %) | 2.53 | 3.68 | 3.5–4.5 |

| Elements | Ti | Al | V | Fe |

|---|---|---|---|---|

| Spheroidised Ti6Al4V (wt %) | 92.3 | 3.91 | 2.73 | 0.08 |

| ASTM F3001 Ti6Al4V (ELI; wt %) | 89 | 5.5–6.5 | 3.5–4.5 | 0.25 |

| Elements | Concentration |

|---|---|

| Oxygen | 1.08% |

| Nitrogen | 0.0905% |

| Sample | Oxygen (%) | Nitrogen (%) | Hydrogen (%) |

|---|---|---|---|

| Spheroidised Ti6Al4V powder | 0.704 | 0.0486 | 0.068 |

| ASTM F3001 Ti6Al4V (ELI) | 0.13 | 0.05 | 0.012 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nkhasi, N.; du Preez, W.; Bissett, H. Plasma Spheroidisation of Irregular Ti6Al4V Powder for Powder Bed Fusion. Metals 2021, 11, 1763. https://doi.org/10.3390/met11111763

Nkhasi N, du Preez W, Bissett H. Plasma Spheroidisation of Irregular Ti6Al4V Powder for Powder Bed Fusion. Metals. 2021; 11(11):1763. https://doi.org/10.3390/met11111763

Chicago/Turabian StyleNkhasi, Nthateng, Willie du Preez, and Hertzog Bissett. 2021. "Plasma Spheroidisation of Irregular Ti6Al4V Powder for Powder Bed Fusion" Metals 11, no. 11: 1763. https://doi.org/10.3390/met11111763

APA StyleNkhasi, N., du Preez, W., & Bissett, H. (2021). Plasma Spheroidisation of Irregular Ti6Al4V Powder for Powder Bed Fusion. Metals, 11(11), 1763. https://doi.org/10.3390/met11111763