Mechanical Behavior Assessment of Ti-6Al-4V ELI Alloy Produced by Laser Powder Bed Fusion

Abstract

:1. Introduction

2. Experimental Details

2.1. Materials and Samples

2.2. Mechanical Testing and Heat Treatment

2.3. Microstructural Characterization

3. Results and Analysis

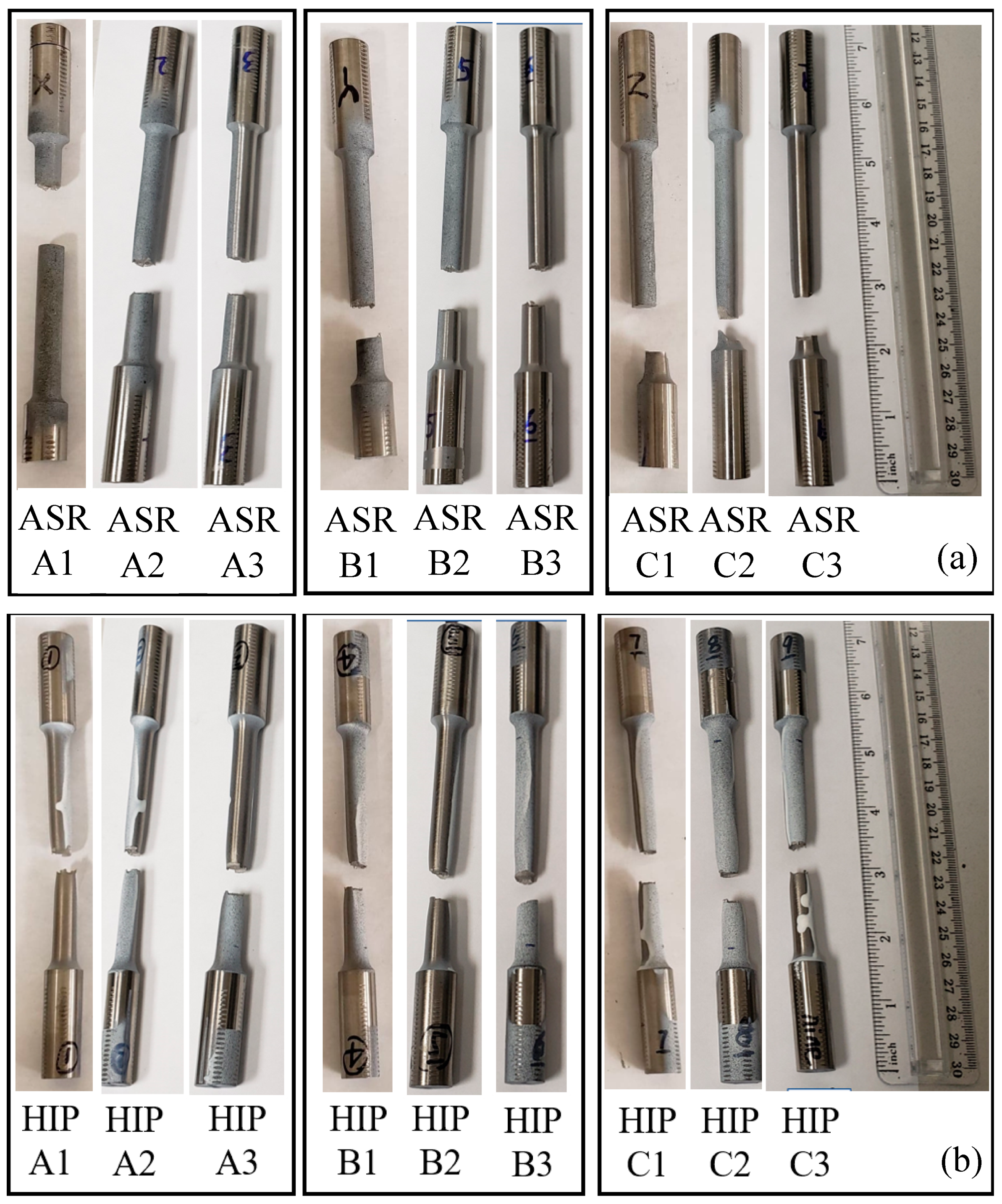

3.1. Visual Examination of Specimens after Tensile Testing

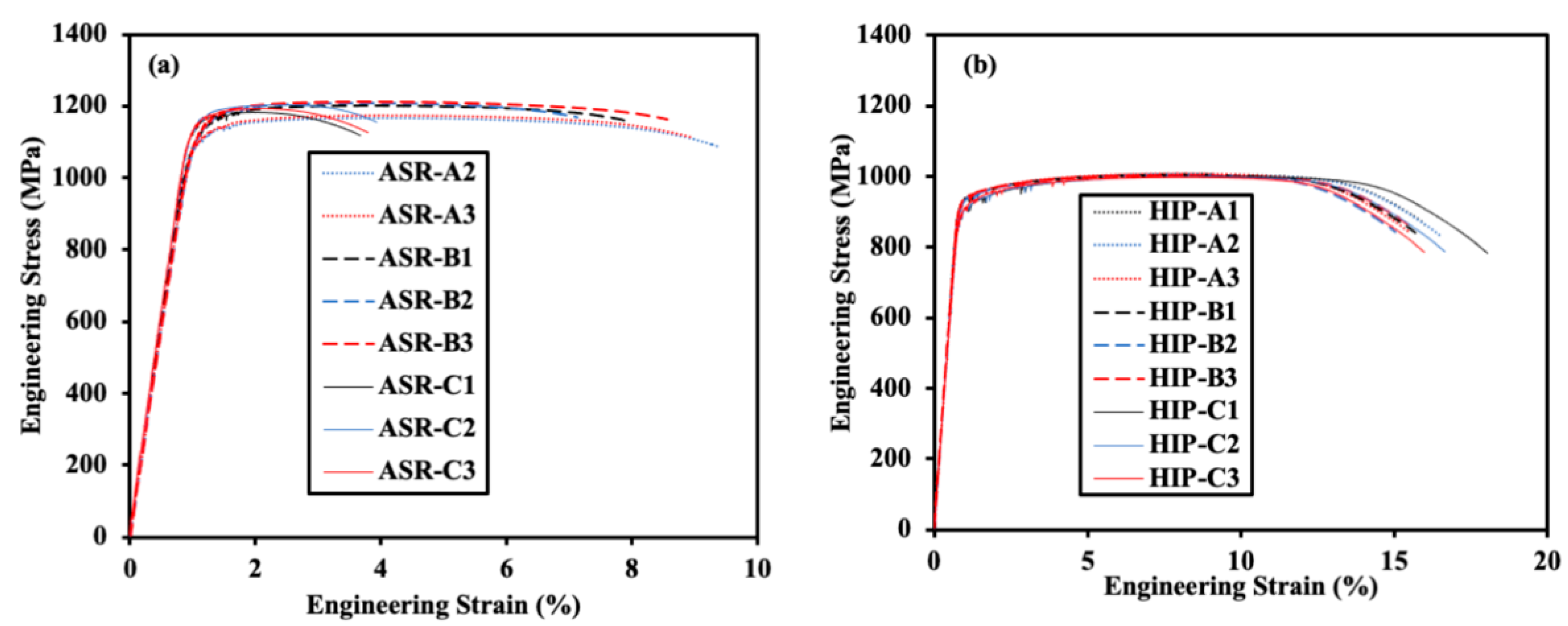

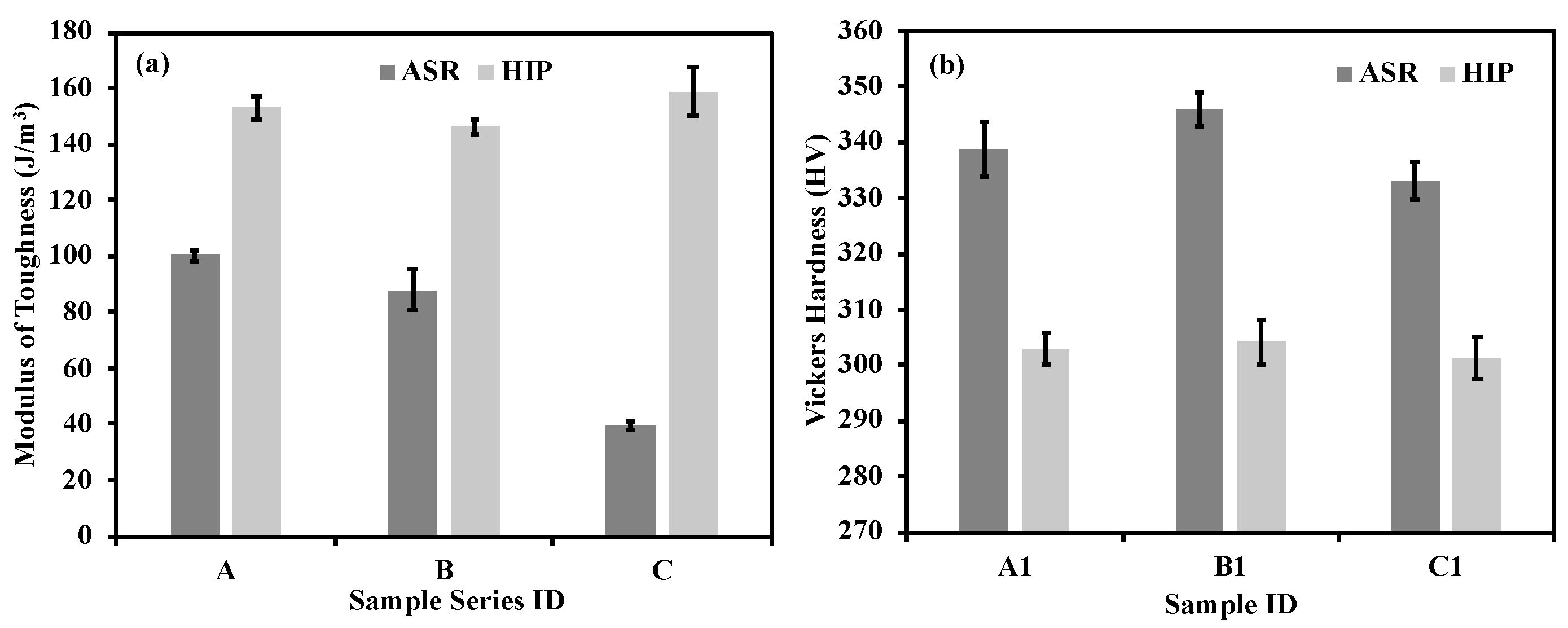

3.2. Mechanical Properties

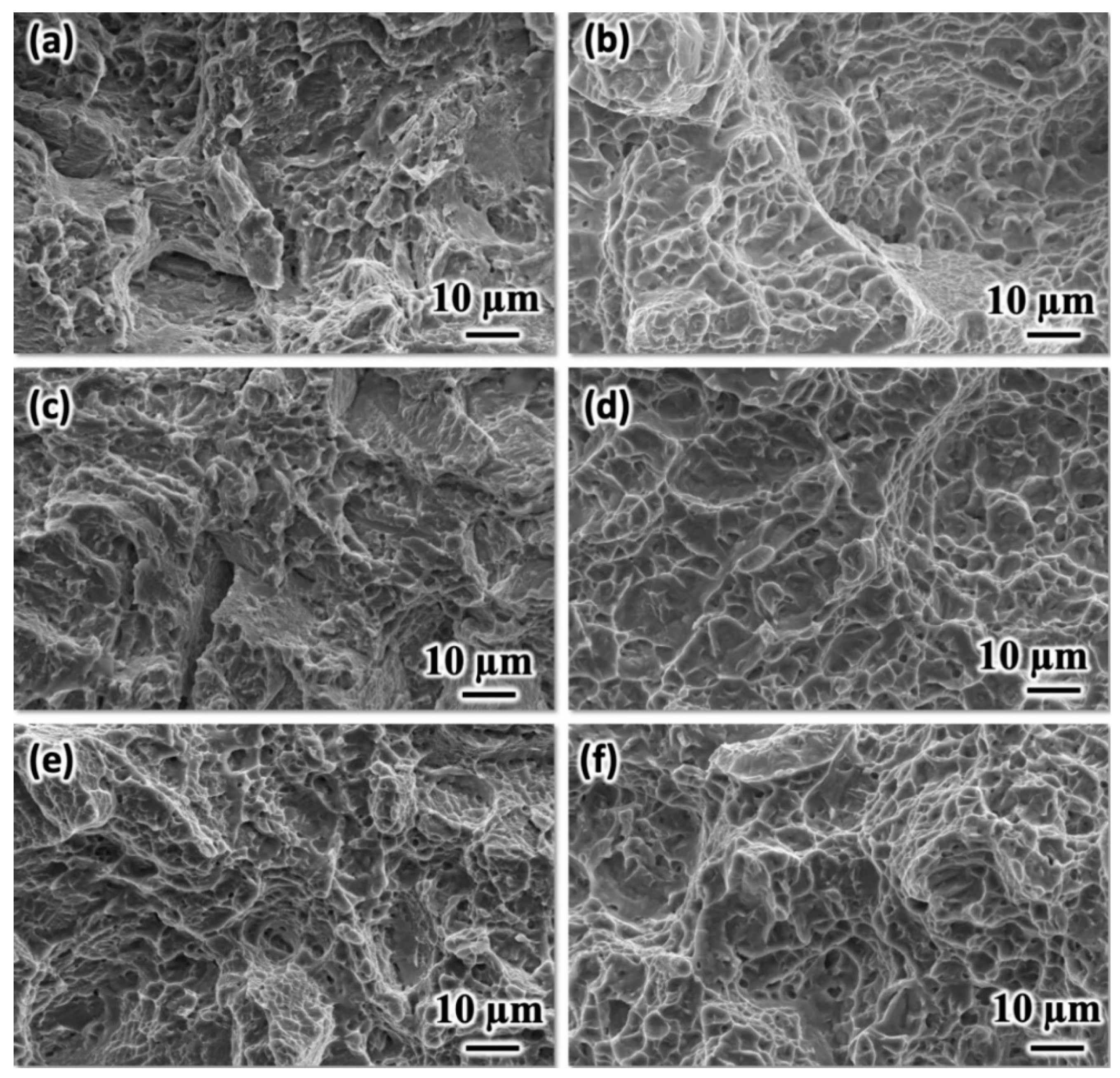

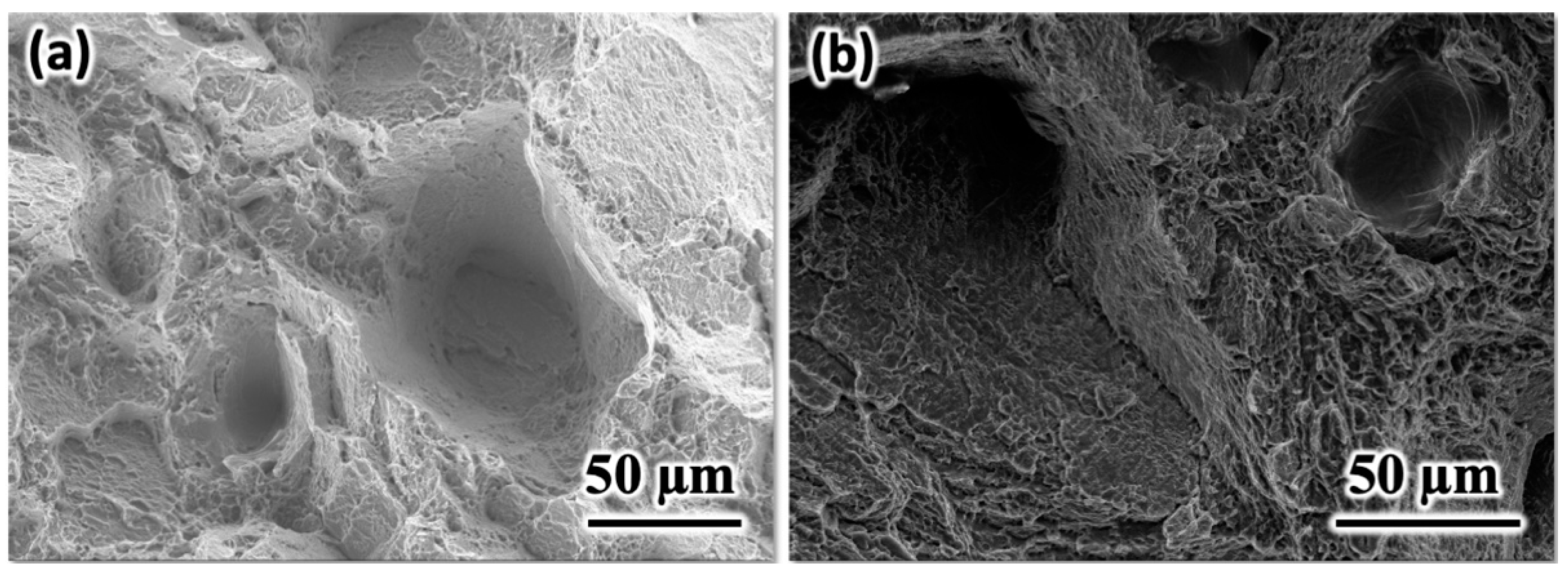

3.3. Fracture Surface Features

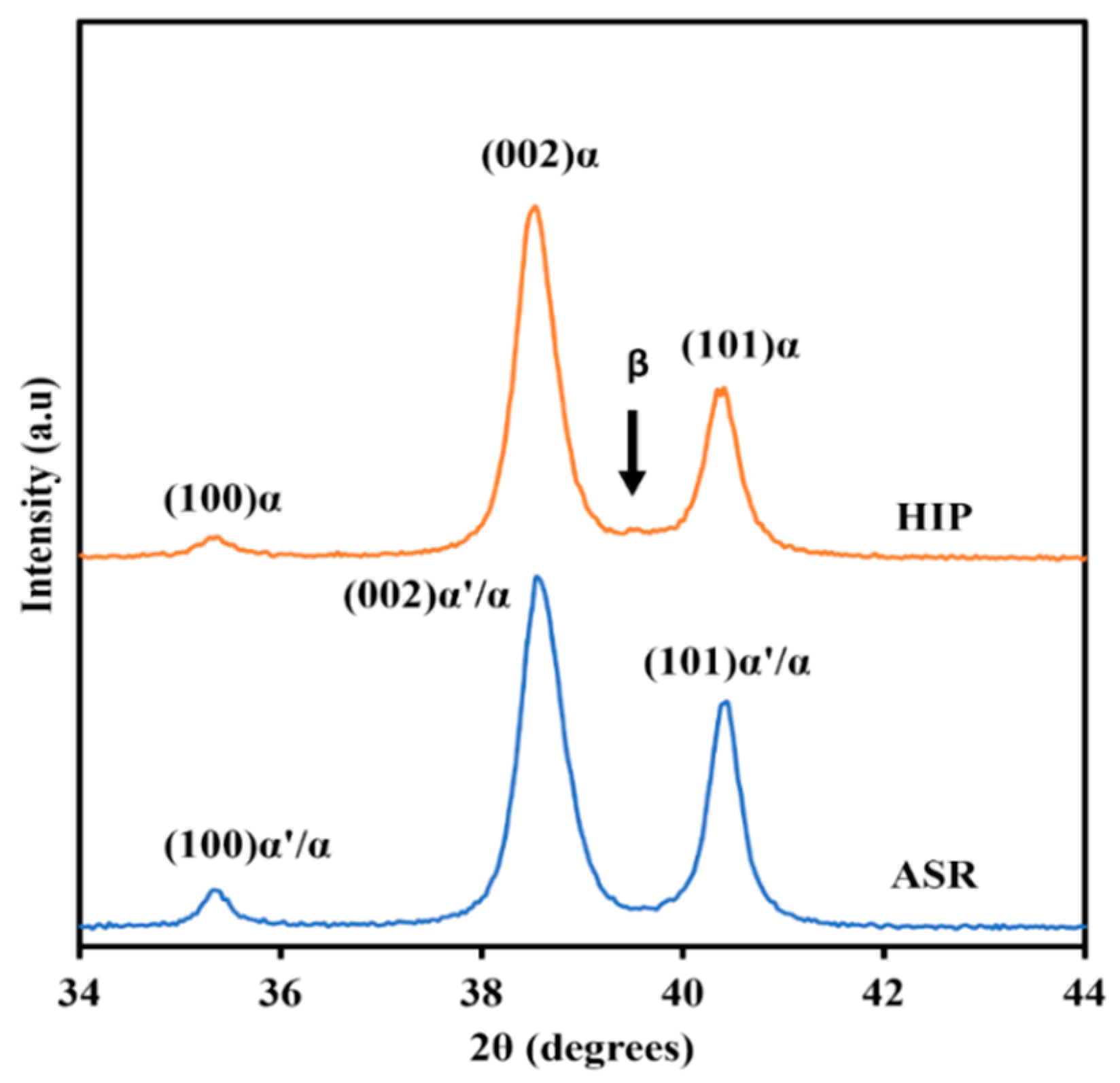

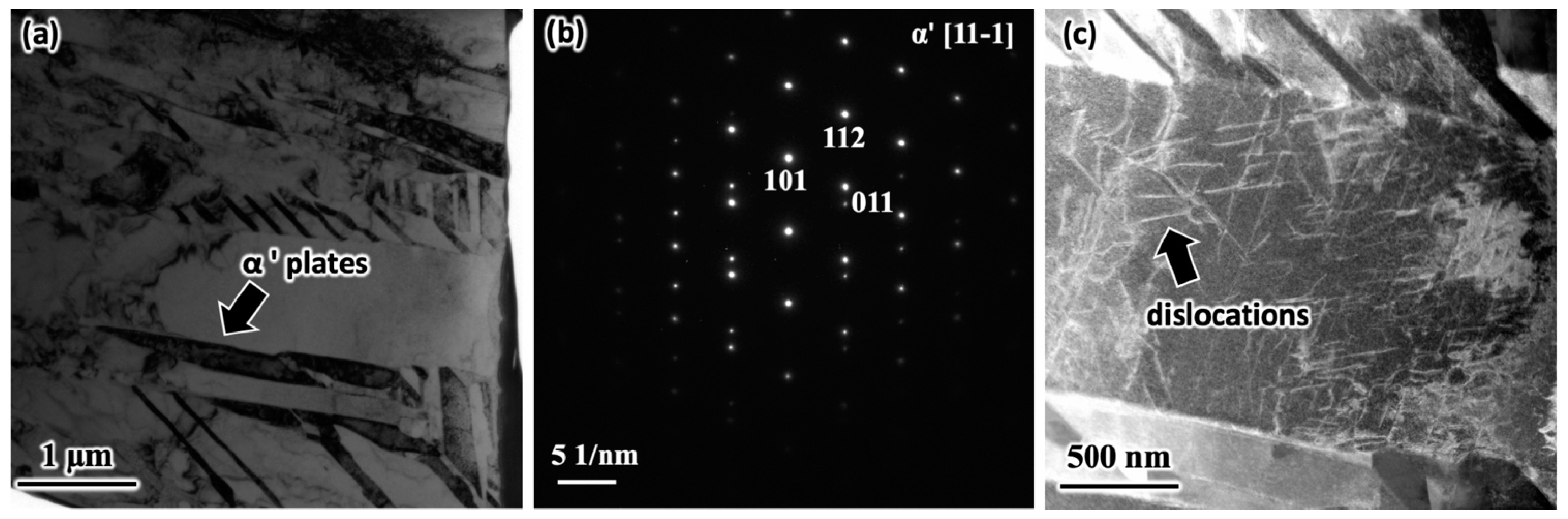

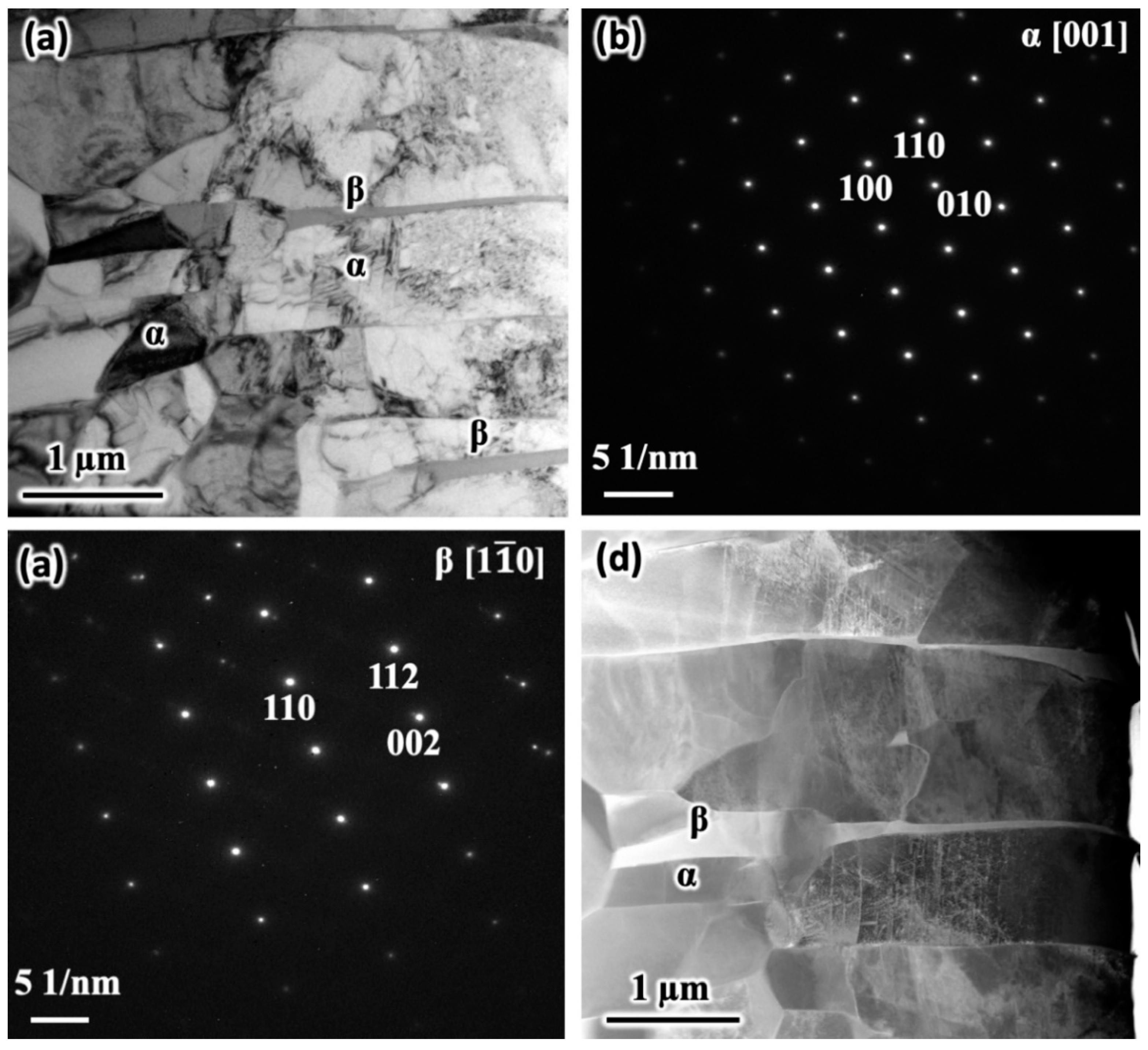

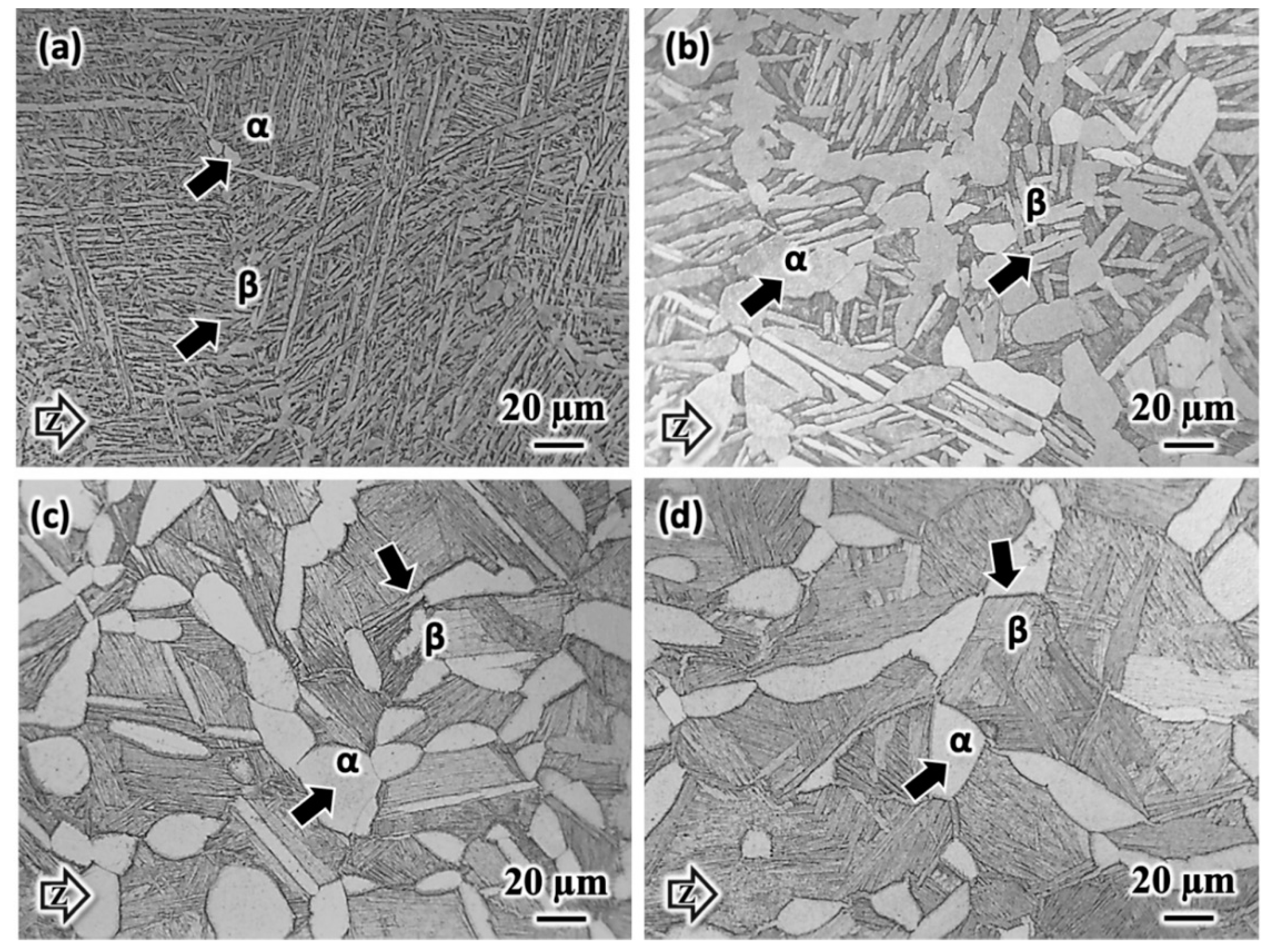

3.4. Phase Constituents and Microstructure

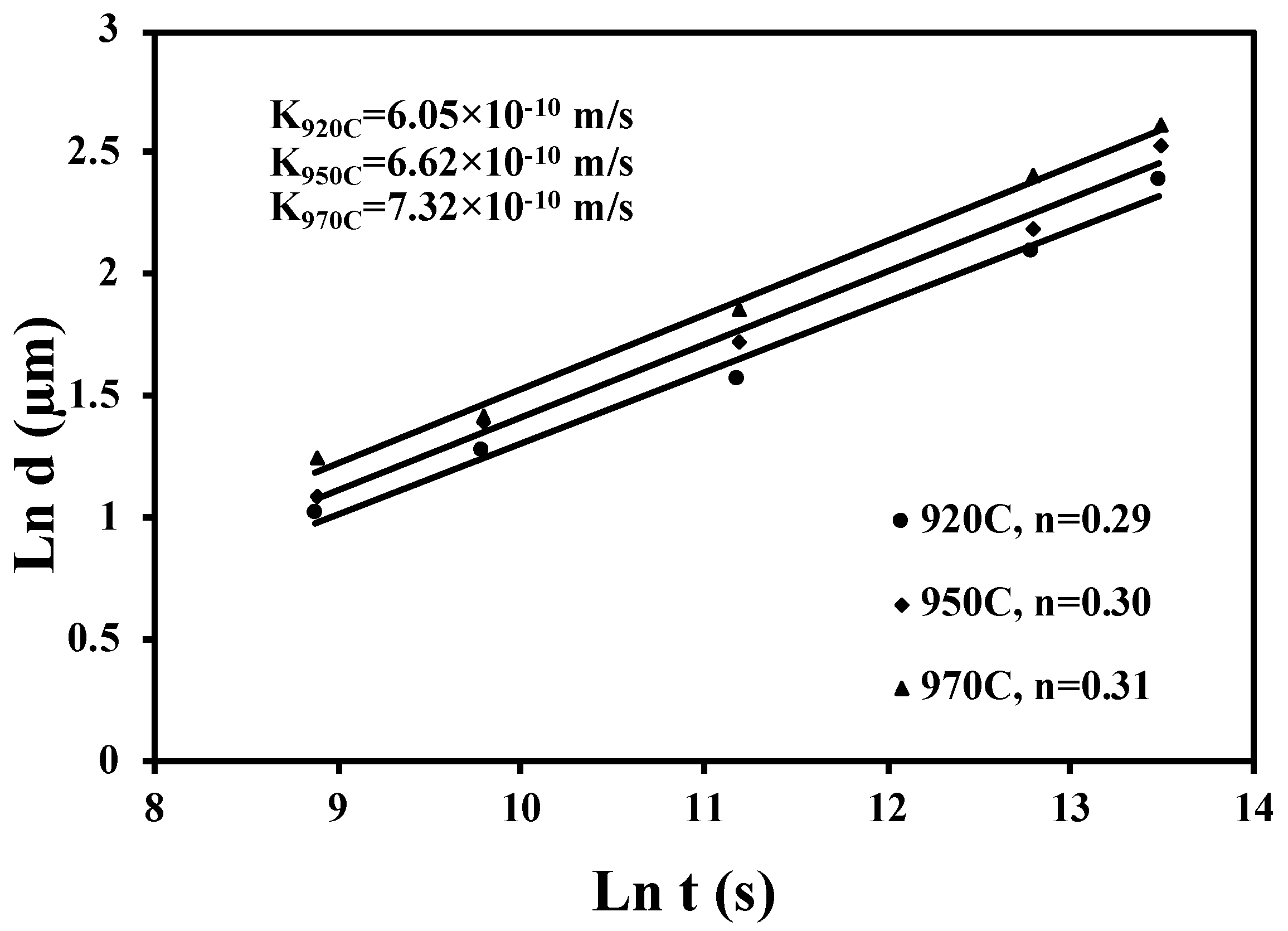

3.5. Coarsening during Heat Treatment

4. Discussion

5. Summary

- Regardless of build direction, the mechanical properties of LPBF Ti-6Al-4V ELI alloy examined by quasi-static tension were consistent and isotropic after hot isostatic pressing (following stress relief treatment at 670 °C for 5 h) at 920 °C for 2 h with a pressure of 100 MPa under an Ar atmosphere.

- The ASR samples in general had a higher strength and lower ductility along with the presence of a fine acicular α′ phase, while the HIP samples had lower strength and higher ductility. The ASR samples built in the build Z-direction had the lowest ductility at 3.8%. This significant anisotropy in ductility for ASR samples built in the Z direction was mainly due to the presence of keyhole porosity associated with the LPBF process.

- The mechanical behavior of the HIP samples was more consistent, isotropic, and can be reported as a yield strength of 928 ± 12 MPa, tensile strength of 1003 ± 3 MPa, 16.1 ± 0.6% elongation at fracture, modulus of toughness of 153 ± 5 J/m3, Young’s modulus of 115 ± 2 GPa, and hardness of 303 ± 1 HV.

- The microstructure of the as-stress-relieved samples was dominated by a fine acicular martensitic α′ phase due to rapid solidification associated with the LPBF. After HIP treatment at 920 °C for 2 h with 100 MPa, the fine acicular martensitic α′ transformed into a fine lamellar mixture of α and β phases. Utilization of HIP would close the lack-of-fusion flaws and keyhole pores, making the alloy considerably more ductile and isotropic, however, with a slight decrease in strength due to the phase transformations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2013, 57, 133–164. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef] [Green Version]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Gorsse, S.; Hutchinson, C.; Goune, M.; Banerjee, R. Additive manufacturing of metals: A brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci. Technol. Adv. Mater. 2017, 18, 584–610. [Google Scholar] [CrossRef] [Green Version]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Sallica-Leva, E.; Jardini, A.L.; Fogagnolo, J.B. Microstructure and mechanical behavior of porous Ti-6Al-4V parts obtained by selective laser melting. J. Mech. Behav. Biomed. Mater. 2013, 26, 98–108. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Selective laser melting of Ti6Al4V alloy for biomedical applications: Temperature monitoring and microstructural evolution. J. Alloys Compd. 2014, 583, 404–409. [Google Scholar] [CrossRef]

- Xu, W.; Sun, S.; Elambasseril, J.; Liu, Q.; Brandt, M.; Qian, M. Ti-6Al-4V Additively Manufactured by Selective Laser Melting with Superior Mechanical Properties. J. Met. Mater. Miner. 2015, 67, 668–673. [Google Scholar] [CrossRef]

- Qian, M.; Xu, W.; Brandt, M.; Tang, H.P. Additive manufacturing and postprocessing of Ti-6Al-4V for superior mechanical properties. MRS Bull. 2016, 41, 775–784. [Google Scholar] [CrossRef] [Green Version]

- Wu, S.Q.; Lu, Y.J.; Gan, Y.L.; Huang, T.T.; Zhao, C.Q.; Lin, J.J.; Guo, S.; Lin, J.X. Microstructural evolution and microhardness of a selective-laser-melted Ti–6Al–4V alloy after post heat treatments. J. Alloys Compd. 2016, 672, 643–652. [Google Scholar] [CrossRef]

- Khorasani, A.; Gibson, I.; Goldberg, M.; Littlefair, G. On the role of different annealing heat treatments on mechanical properties and microstructure of selective laser melted and conventional wrought Ti-6Al-4V. Rapid Prototyp. J. 2017, 23, 295–304. [Google Scholar] [CrossRef]

- Wang, D.; Dou, W.; Yang, Y. Research on Selective Laser Melting of Ti6Al4V: Surface Morphologies, Optimized Processing Zone, and Ductility Improvement Mechanism. Metals 2018, 8, 471. [Google Scholar] [CrossRef] [Green Version]

- Khorasani, A.M.; Gibson, I.; Ghaderi, A.; Mohammed, M.I. Investigation on the effect of heat treatment and process parameters on the tensile behaviour of SLM Ti-6Al-4V parts. Int. J. Adv. Manuf. Technol. 2018, 101, 3183–3197. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Xu, W.; Brandt, M.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, K.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar] [CrossRef]

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, M.; Brandt, M. In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Beese, A.M.; Carroll, B.E. Review of Mechanical Properties of Ti-6Al-4V Made by Laser-Based Additive Manufacturing Using Powder Feedstock. J. Met. Mater. Miner. 2015, 68, 724–734. [Google Scholar] [CrossRef]

- Liu, J.; Jin, Y.; Fang, X.; Chen, C.; Feng, Q.; Liu, X.; Chen, Y.; Suo, T.; Zhao, F.; Huang, T.; et al. Dislocation Strengthening without Ductility Trade-off in Metastable Austenitic Steels. Sci. Rep. 2016, 6, 35345. [Google Scholar] [CrossRef]

- Qiu, C.; Adkins, N.J.E.; Attallah, M.M. Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti–6Al–4V. Mater. Sci. Eng. A 2013, 578, 230–239. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Fatigue performance evaluation of selective laser melted Ti–6Al–4V. Mater. Sci. Eng. A 2014, 598, 327–337. [Google Scholar] [CrossRef]

- Parry, L.; Ashcroft, I.A.; Wildman, R.D. Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Addit. Manuf. 2016, 12, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Mishurova, T.; Cabeza, S.; Artzt, K.; Haubrich, J.; Klaus, M.; Genzel, C.; Requena, G.; Bruno, G. An Assessment of Subsurface Residual Stress Analysis in SLM Ti-6Al-4V. Materials 2017, 10, 348. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gloaguen, D.; Girault, B.; Courant, B.; Dubos, P.-A.; Moya, M.-J.; Edy, F.; Rebelo Kornmeier, J. Study of Residual Stresses in Additively Manufactured Ti-6Al-4V by Neutron Diffraction Measurements. Metall. Mater. Trans. A 2019, 51, 951–961. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Yadroitsava, I.; Plessis, A.D.; MacDonald, E. Fundamentals of Laser Powder Bed Fusion of Metals, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 245–276. [Google Scholar]

- Syed, A.K.; Ahmad, B.; Guo, H.; Machry, T.; Eatock, D.; Meyer, J.; Fitzpatrick, M.E.; Zhang, X. An experimental study of residual stress and direction-dependence of fatigue crack growth behaviour in as-built and stress-relieved selective-laser-melted Ti6Al4V. Mater. Sci. Eng. A 2019, 755, 246–257. [Google Scholar] [CrossRef]

- Hrabe, N.; Gnäupel-Herold, T.; Quinn, T. Fatigue properties of a titanium alloy (Ti–6Al–4V) fabricated via electron beam melting (EBM): Effects of internal defects and residual stress. Int. J. Fatigue 2017, 94, 202–210. [Google Scholar] [CrossRef] [Green Version]

- Wauthle, R.; Vrancken, B.; Beynaerts, B.; Jorissen, K.; Schrooten, J.; Kruth, J.-P.; Van Humbeeck, J. Effects of build orientation and heat treatment on the microstructure and mechanical properties of selective laser melted Ti6Al4V lattice structures. Addit Manuf. 2015, 5, 77–84. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Tao, P.; Li, H.-X.; Huang, B.-Y.; Hu, Q.-D.; Gong, S.-L.; Xu, Q.-Y. Tensile behavior of Ti-6Al-4V alloy fabricated by selective laser melting: Effects of microstructures and as-built surface quality. China Foundry 2018, 15, 243–252. [Google Scholar] [CrossRef] [Green Version]

- Kasperovich, G.; Hausmann, J. Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting. J. Mater. Process. Technol. 2015, 220, 202–214. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef] [Green Version]

- Cao, S.; Hu, Q.; Huang, A.; Chen, Z.; Sun, M.; Zhang, J.; Fu, C.; Jia, Q.; Lim, C.V.S.; Boyer, R.R.; et al. Static coarsening behaviour of lamellar microstructure in selective laser melted Ti–6Al–4V. J. Mater. Sci. Technol. 2019, 35, 1578–1586. [Google Scholar] [CrossRef]

- Yan, X.; Yin, S.; Chen, C.; Huang, C.; Bolot, R.; Lupoi, R.; Kuang, M.; Ma, W.; Coddet, C.; Liao, H.; et al. Effect of heat treatment on the phase transformation and mechanical properties of Ti6Al4V fabricated by selective laser melting. J. Alloys Compd. 2018, 764, 1056–1071. [Google Scholar] [CrossRef]

- Ti-6Al-4V (Ti0.94V0.01Al0.05 rt) Crystal Structure: Datasheet from “PAULING FILE Multinaries Edition—2012” in SpringerMaterials. Available online: https://materials.springer.com/isp/crystallographic/docs/sd_1931746 (accessed on 17 October 2020).

- Stephens, P.W. Rietveld Refinement. In Uniting Electron Crystallography and Powder Diffraction, 1st ed.; Kolb, U., Shankland, K., Meshi, L., Avilov, A., David, W., Eds.; Springer: Dordrecht, The Netherlands, 2011; pp. 15–26. [Google Scholar]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and Mechanical Properties of Ti6Al4V Parts Fabricated by Selective Laser Melting and Electron Beam Melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Yu, J.; Rombouts, M.; Maes, G.; Motmans, F. Material Properties of Ti6Al4V Parts Produced by Laser Metal Deposition. Phys. Procedia 2012, 39, 416–424. [Google Scholar] [CrossRef] [Green Version]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; Höges, S.; Wissenbach, K. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders. Rapid Prototyp J. 2010, 16, 450–459. [Google Scholar] [CrossRef]

- Attallah, M.M.; Zabeen, S.; Cernik, R.J.; Preuss, M. Comparative determination of the α/β phase fraction in α + β-titanium alloys using X-ray diffraction and electron microscopy. Mater. Charact. 2009, 60, 1248–1256. [Google Scholar] [CrossRef]

- Pederson, R. Microstructure and Phase Transformation of Ti-6Al-4V. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2002. [Google Scholar]

- Motyka, M. Martensite formation and decompostion during Traditional and AM processing of Two-Phase Titanium Alloys-An Overview. Metals 2021, 11, 481. [Google Scholar] [CrossRef]

- Sofinowski, K.; Šmíd, M.; Kuběna, I.; Vivès, S.; Casati, N.; Godet, S.; Van Swygenhoven, H. In situ characterization of a high work hardening Ti-6Al-4V prepared by electron beam melting. Acta Mater. 2019, 179, 224–236. [Google Scholar] [CrossRef]

- Fultz, J.H.B. Transmission Electron Microscopy and Diffractometry of Materials, A.6 Indexed Single Crystal Diffraction Patterns, 3rd ed.; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2004; pp. 709–711. [Google Scholar]

- Lifshitz, M.; Slyozov, V.V. The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 1961, 19, 35–50. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Kirby, B.C.; Salishchev, G.A. Coarsening Behavior of an Alpha-Beta Titanium Alloy. Metall. Mater. Trans. A 2004, 35A, 2809–2819. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Zeng, W.; Jia, Z.; Sun, X.; Zhao, Y. Coarsening Kinetics and Morphological Evolution in a Two-Phase Titanium Alloy During Heat Treatment. J. Mater. Eng. Perform. 2016, 25, 734–743. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, W.; Sun, X.; Jia, Z.; Zhou, J. Static coarsening behavior of the lamellar alpha in Ti-17 alloy. J. Alloys Compd. 2015, 631, 248–254. [Google Scholar] [CrossRef]

- Zuback, J.S.; DebRoy, T. The Hardness of Additively Manufactured Alloys. Materials 2018, 11, 2070. [Google Scholar] [CrossRef] [Green Version]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-Fabricated and Heat-Treated Microstructures of the Ti-6Al-4V Alloy Processed by Selective Laser Melting. Metall. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Baghi, A.D.; Nafisi, S.; Hashemi, R.; Edendorff-Heiderpriem, H.; Ghomashchi, R. Effective Post Processing of SLM Fabricated Ti-6Al-4V Alloy: Machining vs Thermal Treatment. J. Manuf. Proc. 2021, 68, 1031–1046. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Janaki Ram, G.D.; Starr, T.; Stucker, B. Influence of defects on mechanical properties of Ti–6Al–4V components produced by selective laser melting and electron beam melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Baghi, A.D.; Nafisi, S.; Hashemi, R.; Edendorff-Heiderpriem, H.; Ghomashchi, R. Experimental Realisation of Build Orientation Effects on The Mechanical Properties of Truly As-Built Ti-6Al-4V SLM Parts. J. Manuf. Proc. 2021, 64, 140–152. [Google Scholar] [CrossRef]

| Sample | Build Direction | ||

|---|---|---|---|

| Horizontal—X | Horizontal—Y | Vertical—Z | |

| As stress relieved (ASR) | ASR-A1 | ASR-B1 | ASR-C1 |

| ASR-A2 | ASR-B2 | ASR-C2 | |

| ASR-A3 | ASR-B3 | ASR-C3 | |

| Hot isostatically pressed (HIP) | HIP-A1 | HIP-B1 | HIP-C1 |

| HIP-A2 | HIP-B2 | HIP-C2 | |

| HIP-A3 | HIP-B3 | HIP-C3 | |

| Sample | YS, σ0.2% (MPa) | UTS (MPa) | % EL at Fracture | Young’s Modulus (GPa) |

|---|---|---|---|---|

| ASR-A2 | 1107.52 | 1164.61 | 9.40 | 115.75 |

| ASR-A3 | 1115.96 | 1175.71 | 9.00 | 115.00 |

| Average and Standard deviation for ASR-A | 1111.74 ± 4.22 | 1169.66 ± 5.05 | 9.20 ± 0.20 | 115.88 ± 0.13 |

| ASR-B1 | 1137.38 | 1200.47 | 7.95 | 116.18 |

| ASR-B2 | 1149.13 | 1209.02 | 7.13 | 113.68 |

| ASR-B3 | 1153.60 | 1211.45 | 8.57 | 113.38 |

| Average and Standard deviation for ASR-B | 1146.70 ± 6.84 | 1206.98 ± 4.71 | 7.88 ± 0.59 | 114.75 ±1.05 |

| ASR-C1 | 1157.11 | 1182.57 | 3.68 | 121.53 |

| ASR-C2 | 1169.93 | 1203.25 | 3.95 | 120.23 |

| ASR-C3 | 1163.30 | 1192.64 | 3.80 | 121.62 |

| Average and Standard deviation for ASR-C | 1163.45 ± 5.23 | 1192.82 ± 8.44 | 3.81 ± 0.11 | 121.13 ± 0.64 |

| Sample | YS, σ0.2% (MPa) | UTS (MPa) | % EL at Fracture | Young’s Modulus (GPa) |

|---|---|---|---|---|

| HIP-A1 | 937.40 | 1006.94 | 16.05 | 115.87 |

| HIP-A2 | 936.69 | 1006.33 | 16.55 | 115.36 |

| HIP-A3 | 936.08 | 1007.57 | 15.49 | 115.34 |

| Average and Standard deviation for HIP-A | 936.72 ± 0.54 | 1006.94 ± 0.51 | 16.03 ± 0.43 | 115.5 ± 0.25 |

| HIP-B1 | 933.55 | 1003.55 | 15.68 | 118.60 |

| HIP-B2 | 933.80 | 1003.82 | 15.02 | 114.15 |

| HIP-B3 | 939.09 | 1002.50 | 15.44 | 117.88 |

| Average and Standard deviation for HIP-B | 935.48 ± 2.55 | 1003.29 ± 0.57 | 15.38 ±0.27 | 116.88 ± 1.95 |

| HIP-C1 | 907.72 | 1000.27 | 18.03 | 112.98 |

| HIP-C2 | 908.70 | 998.85 | 16.64 | 113.32 |

| HIP-C3 | 915.68 | 997.67 | 15.97 | 112.97 |

| Average and Standard deviation for HIP-C | 910.70 ± 3.54 | 998.93 ± 1.06 | 16.88 ± 0.86 | 113.09 ± 0.16 |

| Sample ID | Density by Image Analysis (%) | Archimedes Density (%) |

|---|---|---|

| ASR-A1 | 99.97 ± 0.01 | 99.37 ± 0.03 |

| ASR-B1 | 99.96 ± 0.01 | 99.60 ± 0.05 |

| ASR-C1 | 99.95 ± 0.01 | 99.54 ± 0.05 |

| HIP-A1 | 99.99 ± 0.01 | 99.22 ± 0.06 |

| HIP-B1 | 99.99 ± 0.01 | 99.05 ± 0.09 |

| HIP-C1 | 99.98 ± 0.02 | 99.19 ± 0.07 |

| Parameters | α′ Phase | α Phase | β Phase |

|---|---|---|---|

| ICDD database code | 01-089-5009 | 01-089-5009 | 01-081-9813 |

| ICSD database code | 76,265 | 76,265 | 187,067 |

| Volume percent | 100 | 98.59 | 1.41 |

| Weight per cent | 100 | 89.30 | 10.70 |

| Space group (No.) | P63/mmc (194) | P63/mmc (194) | Imm (229) |

| Lattice parameter: a | 2.9440 Å | 2.9440 Å | 3.2322 Å |

| Lattice parameter: c | 4.6780 Å | 4.6780 Å | 3.2322 Å |

| R (weighted profile) | 7.05% | 8.41% | 8.41% |

| Goodness of fit (GOF) | 1.90 | 2.35 | 2.35 |

| Heat Treatment Time (hours) | 920 °C | 950 °C | 970 °C |

|---|---|---|---|

| Lamellar Width (µm) | |||

| 0 | 2.19 ± 0.55 | 2.19 ± 0.55 | 2.19 ± 0.55 |

| 2 h | 2.74 ± 0.57 | 2.95 ± 0.67 | 3.45 ± 0.46 |

| 5 h | 3.56 ± 1.15 | 3.99 ± 1.21 | 4.1 ± 0.82 |

| 20 h | 4.78 ± 1.32 | 5.6 ± 2.41 | 6.34 ± 2.31 |

| 100 h | 8.02 ± 3.41 | 8.88 ± 4.67 | 10.99 ± 3.71 |

| 200 h | 10.83 ± 3.90 | 12.54 ± 4.79 | 13.54 ± 4.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmud, A.; Huynh, T.; Zhou, L.; Hyer, H.; Mehta, A.; Imholte, D.D.; Woolstenhulme, N.E.; Wachs, D.M.; Sohn, Y. Mechanical Behavior Assessment of Ti-6Al-4V ELI Alloy Produced by Laser Powder Bed Fusion. Metals 2021, 11, 1671. https://doi.org/10.3390/met11111671

Mahmud A, Huynh T, Zhou L, Hyer H, Mehta A, Imholte DD, Woolstenhulme NE, Wachs DM, Sohn Y. Mechanical Behavior Assessment of Ti-6Al-4V ELI Alloy Produced by Laser Powder Bed Fusion. Metals. 2021; 11(11):1671. https://doi.org/10.3390/met11111671

Chicago/Turabian StyleMahmud, Asif, Thinh Huynh, Le Zhou, Holden Hyer, Abhishek Mehta, Daniel D. Imholte, Nicolas E. Woolstenhulme, Daniel M. Wachs, and Yongho Sohn. 2021. "Mechanical Behavior Assessment of Ti-6Al-4V ELI Alloy Produced by Laser Powder Bed Fusion" Metals 11, no. 11: 1671. https://doi.org/10.3390/met11111671

APA StyleMahmud, A., Huynh, T., Zhou, L., Hyer, H., Mehta, A., Imholte, D. D., Woolstenhulme, N. E., Wachs, D. M., & Sohn, Y. (2021). Mechanical Behavior Assessment of Ti-6Al-4V ELI Alloy Produced by Laser Powder Bed Fusion. Metals, 11(11), 1671. https://doi.org/10.3390/met11111671