Improving Texture and Microstructure Homogeneity in High-Purity Ta Sheets by Warm Cross Rolling and Annealing

Abstract

:1. Introduction

2. Experimental Method

2.1. Materials and Rolling Procedure

2.2. Characterization Methods

3. Results

3.1. Initial Texture and Grain Size Distribution

3.2. Deformation Texture

3.3. Deformation Microstructure

3.4. Recrystallization Microstructure

4. Discussion

4.1. GNDs Distribution

4.2. Analysis of Schmid Factor and Strain Distribution

4.3. Homogeneity of the Recrystallization Microstructure

5. Conclusions

- 1)

- A strong texture gradient existed across different thickness layers in the initial Ta plates prepared by forging and annealing. After 135o warm cross rolling, relatively uniform and ideal deformation texture distribution along sheet thickness could be obtained.

- 2)

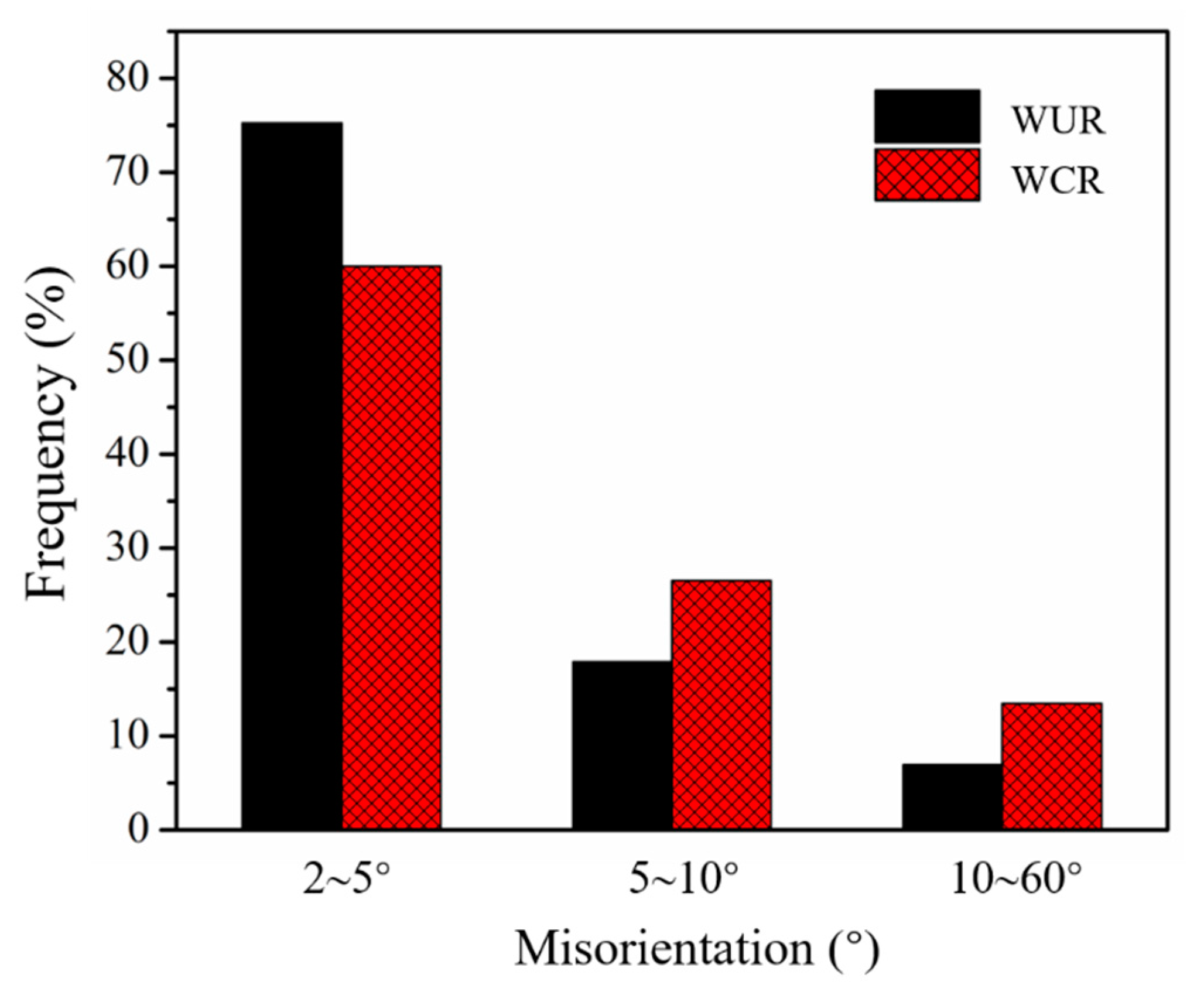

- The change in strain path combined with warm rolling could accelerate the rate of dislocation movement, increase the probability of dislocations rearrangement and annihilation, and thus significantly reduce the fraction of low-angle grain boundaries in WCR processing. Corresponding distribution of geometrically necessary dislocations (GNDs) further confirmed this result.

- 3)

- Analysis of the Schmid factor and comparison with strain contouring maps suggested that the localization of strains could be efficiently reduced by the operation of a relatively uniform number of slip systems within deformed {111} and {100} grains in WCR.

- 4)

- Grains with more uniform in size and more randomly oriented were formed during recrystallization after WCR due to reasonably uniform fragmentation in the microstructure and distribution of stored energy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cardonne, S.M.; Kumar, P.; Michaluk, C.A.; Schwartz, H.D. Tantalum and its Alloys. Int. J. Refract. Met. Hard. Mater. 1993, 13, 187–194. [Google Scholar] [CrossRef]

- Michaluk, C.A. Correlating discrete orientation and grain size to the sputter deposition properties of tantalum. J. Electron. Mater. 2002, 31, 2–9. [Google Scholar] [CrossRef]

- Wickersham, C.E. Crystallographic target effects in magnetron sputtering. J. Vac. Sci. Technol. A 1987, 5, 1755–1758. [Google Scholar] [CrossRef]

- Dunlop, J.A.; Yuan, J.; Kardokus, J.K.; Emigh, R.A. Sputtering Target with Ultra-Fine, Oriented Grains and Method of Making Same. U.S. Patent 5780755A, 14 July 1998. [Google Scholar]

- Choi, G.S.; Lim, J.W.; Munirathnam, N.R.; Kim, I.H.; Kim, J.S. Preparation of 5N grade tantalum by electron beam melting. J. Alloys Compd. 2009, 469, 298–303. [Google Scholar] [CrossRef]

- Sandim, H.; Martins, J.P.; Pinto, A.L.; Padilha, A.F. Recrystallization of oligocrystalline tantalum deformed by cold rolling. Mater. Sci. Eng. A 2005, 392, 209–221. [Google Scholar] [CrossRef]

- Briant, C.L.; Macdonald, E.; Balliett, R.W.; Luong, T. Recrystallization textures in tantalum sheet and wire. Int. J. Refract. Met. Hard Mater. 2000, 18, 1–8. [Google Scholar] [CrossRef]

- Sandim, H.R.Z.; Martins, J.P.; Padilha, A.F. Orientation effects during grain subdivision and subsequent annealing in coarse-grained tantalum. Scripta Mater. 2001, 45, 733–738. [Google Scholar] [CrossRef]

- Deng, C.; Liu, S.F.; Fan, H.Y.; Hao, X.B.; Ji, J.L.; Zhang, Z.Q.; Liu, Q. Elimination of Elongated Bands by Clock Rolling in High-Purity Tantalum. Metall. Mater. Trans. A 2015, 46, 5477–5481. [Google Scholar] [CrossRef]

- Zhu, J.L.; Liu, S.F.; Yuan, X.L.; Liu, Q. Comparing the Through-Thickness Gradient of the Deformed and Recrystallized Microstructure in Tantalum with Unidirectional and Clock Rolling. Materials 2019, 12, 169. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, J.L.; Liu, S.F.; Long, D.D.; Orlov, D.; Liu, Q. Pass number dependence of through-thickness microstructure homogeneity in tantalum sheets under the change of strain path. Mater. Charact. 2020, 160, 110076. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, S.; Yang, S.; Long, D.; Liu, Y.; Yuan, X.; Orlov, D. Strain dependence of deformation and recrystallization microstructure homogeneity in clock-rolled tantalum sheets. Mater. Charact. 2020, 161, 110165. [Google Scholar] [CrossRef]

- Jiao, H.T.; Xu, Y.B.; Zhao, L.Z.; Misra, R.D.; Tang, Y.C.; Zhao, M.J.; Liu, D.J.; Hu, Y.; Shen, M.X. Microstructural evolution and magnetic properties in strip cast non-oriented silicon steel produced by warm rolling. Mater. Charact. 2019, 156, 109876. [Google Scholar] [CrossRef]

- Li, Z.G.; Liang, C.; Tang, J.W.; Sun, W.C.; Zhao, G.Q.; Zhang, G.S. Improving mechanical anisotropy and corrosion resistance of extruded AA7075 alloy by warm cross rolling and annealing. J. Alloys Compd. 2021, 863, 158725. [Google Scholar] [CrossRef]

- Hao, Y.L.; Zhang, Z.B.; Li, S.J.; Yang, R. Microstructure and mechanical behavior of a Ti–24Nb–4Zr–8Sn alloy processed by warm swaging and warm rolling. Acta Mater. 2012, 60, 2169–2177. [Google Scholar] [CrossRef]

- Ebrahimi, F.; Ahmed, Z.; Li, H.Q. Effect of stacking fault energy on plastic deformation of nanocrystalline face-centered cubic metals. Appl. Phys. Lett. 2004, 85, 3749–3751. [Google Scholar] [CrossRef]

- Pegel, B. Stacking Faults on {110} Planes in the B.C.C. Lattice. Phys. Status Solidi B 1968, 28, 603–609. [Google Scholar] [CrossRef]

- Deng, C.; Liu, S.F.; Hao, X.B.; Ji, J.L.; Zhang, Z.Q.; Liu, Q. Orientation dependence of stored energy release and microstructure evolution in cold rolled tantalum. Int. J. Refract. Met. Hard Mater. 2014, 46, 24–29. [Google Scholar] [CrossRef]

- Pawlik, K. Determination of the orientation distribution function from pole figures in arbitrarily defined cells. Phys. Stat. Sol. (b) 1986, 134, 477–483. [Google Scholar] [CrossRef]

- Zhu, J.L.; Liu, S.F.; Long, D.D.; Zhou, S.Y.; Zhu, Y.L.; Orlov, D. The evolution of texture and microstructure uniformity in tantalum sheets during asymmetric cross rolling. Mater. Charact. 2020, 168, 110586. [Google Scholar] [CrossRef]

- Choi, C.H.; Kwon, J.W.; Oh, E.H. Analysis of deformation texture inhomogeneity and stability condition of shear components in f.c.c. metals. Acta Mater. 1997, 45, 5119–5128. [Google Scholar] [CrossRef]

- Engler, O.; Tomé, C.; Huh, M.Y. A study of through-thickness texture gradients in rolled sheets. Metall. Mater. Trans. A 2000, 31, 2299–2315. [Google Scholar] [CrossRef]

- Madhavan, R.; Nagaraju, S.; Suwas, S. Texture Evolution in Nanocrystalline Nickel: Critical Role of Strain Path. Metall. Mater. Trans. A 2015, 46, 915–925. [Google Scholar] [CrossRef]

- Mishra, S.; Kulkarni, K.; Gurao, N.P. Effect of crystallographic texture on precipitation induced anisotropy in an aluminium magnesium silicon alloy. Mater. Des. 2015, 87, 507–519. [Google Scholar] [CrossRef]

- Fan, H.Y.; Liu, S.F.; Li, L.J.; Deng, C.; Liu, Q. Largely alleviating the orientation dependence by sequentially changing strain paths. Mater. Des. 2016, 97, 464–472. [Google Scholar] [CrossRef]

- Deng, C.; Liu, S.F.; Ji, J.L.; Hao, X.B.; Zhang, Z.Q.; Liu, Q. Texture evolution of high purity tantalum under different rolling paths. J. Mater. Process Technol. 2014, 214, 462–469. [Google Scholar] [CrossRef]

- Orlov, D.; Todaka, Y.; Umemoto, M.; Tsuji, N. Formation of bimodal grain structures in high purity Al by reversal high pressure torsion. Scripta Mater. 2011, 64, 498–501. [Google Scholar] [CrossRef]

- Orlov, D.; Todaka, Y.; Umemoto, M.; Tsuji, N. Role of strain reversal in grain refinement by severe plastic deformation. Mater. Sci. Eng. A 2009, 499, 427–433. [Google Scholar] [CrossRef]

- Orlov, D.; Bhattacharjee, P.P.; Todaka, Y.; Umemoto, M.; Tsuji, N. Texture evolution in pure aluminum subjected to monotonous and reversal straining in high-pressure torsion. Scripta Mater. 2009, 60, 893–896. [Google Scholar] [CrossRef]

- Po, G.; Cui, Y.; Rivera, D.; Cereceda, D.; Swinburne, T.D.; Marian, J.; Ghoniem, N. A phenomenological dislocation mobility law for bcc metals. Acta Mater. 2016, 119, 123–135. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.H.; Liu, S.F.; Zhu, J.L.; Deng, C.; Fan, H.Y.; Cao, L.F.; Liu, Q. Strain path dependence of microstructure and annealing behavior in high purity tantalum. Mater. Sci. Eng. A 2017, 707, 518–530. [Google Scholar] [CrossRef]

- Zhu, J.L.; Liu, S.F.; Liu, Y.H.; Lin, N.; Yang, S.; Deng, C.; Liu, Q. Deformation and annealing behavior in the ‘interaction zone’ of cold-rolled tantalum sheets. Vacuum 2019, 164, 105–113. [Google Scholar] [CrossRef]

- Nye, J.F. Some geometrical relations in dislocated crystals. Acta Metall. 1953, 1, 153–162. [Google Scholar] [CrossRef]

- Zhu, J.L.; Liu, S.F.; Long, D.D.; Liu, Y.H.; Lin, N.; Yuan, X.L.; Orlov, D. Asymmetric cross rolling: A new technique for alleviating orientation-dependent microstructure inhomogeneity in tantalum sheets. J. Mater. Res. Technol. 2020, 9, 4566–4577. [Google Scholar] [CrossRef]

- Kröner, E. Continuum Theory of Dislocations and Self-Stresses; Springer: Berlin, Germany, 1958. [Google Scholar]

- Wilkinson, A.J.; Randman, D. Determination of elastic strain fields and geometrically necessary dislocation distributions near nanoindents using electron back scatter diffraction. Philos. Mag. 2010, 90, 1159–1177. [Google Scholar] [CrossRef] [Green Version]

- Kubin, L.P.; Mortensen, A. Geometrically necessary dislocations and strain-gradient plasticity: A few critical issues. Scripta Mater. 2003, 48, 119–125. [Google Scholar] [CrossRef] [Green Version]

- Luo, J.R.; Godfrey, A.; Liu, W.; Liu, Q. Twinning behavior of a strongly basal textured AZ31 Mg alloy during warm rolling. Acta Mater. 2012, 60, 1986–1998. [Google Scholar] [CrossRef]

- Gurao, N.P.; Sethuraman, S.; Suwas, S. Effect of strain path change on the evolution of texture and microstructure during rolling of copper and nickel. Mater. Sci. Eng. A 2011, 528, 7739–7750. [Google Scholar] [CrossRef]

| Rolling Pass | Entrance Thickness/mm | Exit Thickness/mm | Rolling Gap Geometry (l/h) | Total Rolling Reduction/% |

|---|---|---|---|---|

| 1 | 12 | 10.5 | 2.43 | 12.5 |

| 2 | 10.5 | 9.2 | 2.58 | 23.3 |

| 3 | 9.2 | 8.2 | 2.57 | 31.6 |

| 4 | 8.2 | 7.4 | 2.56 | 38.3 |

| 5 | 7.4 | 6.7 | 2.65 | 44.1 |

| 6 | 6.7 | 6 | 2.94 | 50 |

| 7 | 6.0 | 5.4 | 3.03 | 55 |

| 8 | 5.4 | 4.8 | 3.39 | 60 |

| 9 | 4.8 | 4.3 | 3.47 | 64.2 |

| 10 | 4.3 | 4.0 | 2.95 | 66.6 |

| 11 | 4.0 | 3.8 | 2.56 | 68.3 |

| 12 | 3.8 | 3.6 | 2.70 | 70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, D.; Liu, S.; Zhu, J.; Liu, Y.; Zhou, S.; Yuan, X.; Orlov, D. Improving Texture and Microstructure Homogeneity in High-Purity Ta Sheets by Warm Cross Rolling and Annealing. Metals 2021, 11, 1665. https://doi.org/10.3390/met11111665

Long D, Liu S, Zhu J, Liu Y, Zhou S, Yuan X, Orlov D. Improving Texture and Microstructure Homogeneity in High-Purity Ta Sheets by Warm Cross Rolling and Annealing. Metals. 2021; 11(11):1665. https://doi.org/10.3390/met11111665

Chicago/Turabian StyleLong, Doudou, Shifeng Liu, Jialin Zhu, Yahui Liu, Shiyuan Zhou, Xiaoli Yuan, and Dmytro Orlov. 2021. "Improving Texture and Microstructure Homogeneity in High-Purity Ta Sheets by Warm Cross Rolling and Annealing" Metals 11, no. 11: 1665. https://doi.org/10.3390/met11111665

APA StyleLong, D., Liu, S., Zhu, J., Liu, Y., Zhou, S., Yuan, X., & Orlov, D. (2021). Improving Texture and Microstructure Homogeneity in High-Purity Ta Sheets by Warm Cross Rolling and Annealing. Metals, 11(11), 1665. https://doi.org/10.3390/met11111665