The High-Temperature Deformation Behavior of As-Cast Ti90 Titanium Alloy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Hot Compression

2.3. Microstructure Characterization

3. Results and Discussion

3.1. Flow Strain–Stress Curves

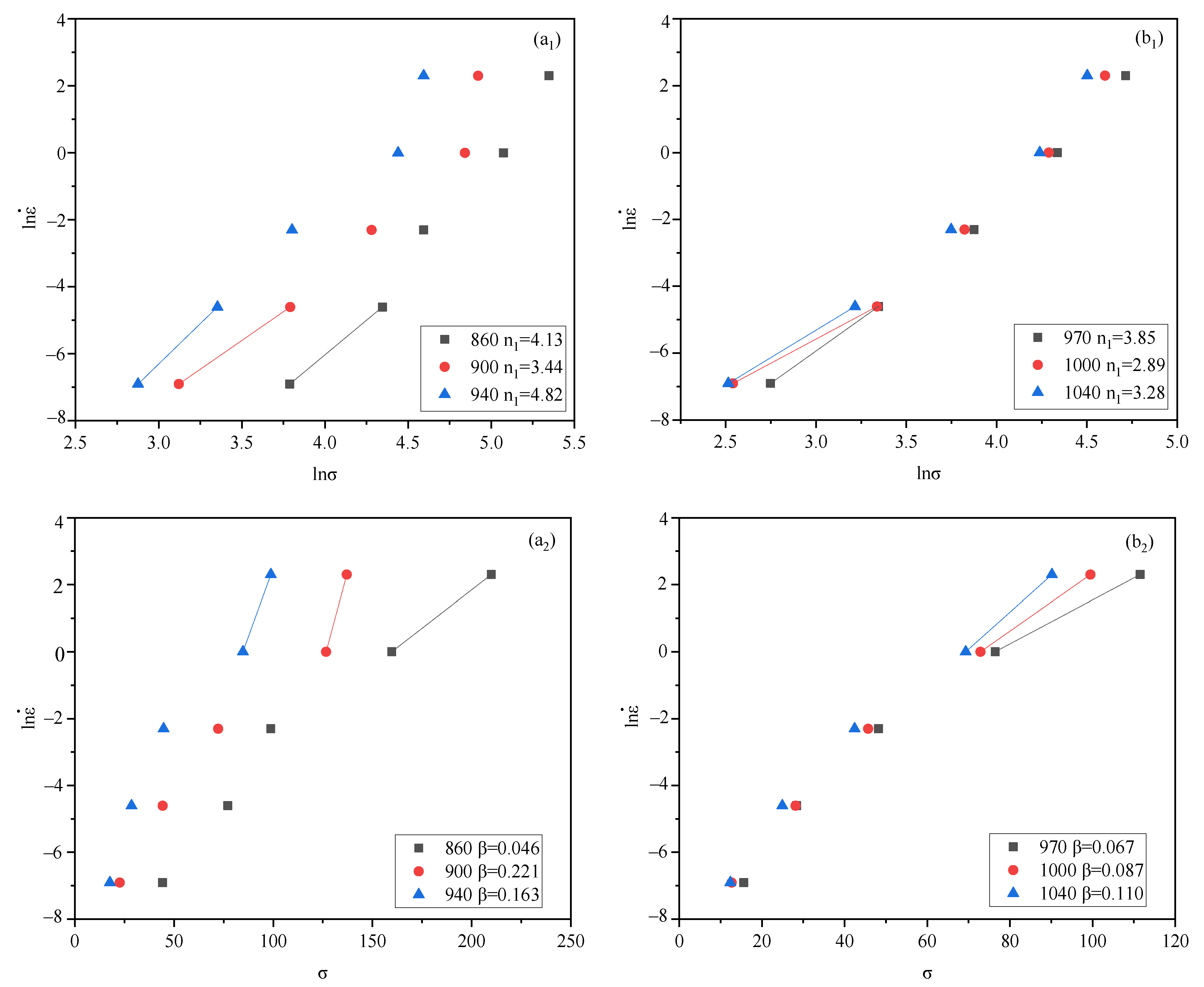

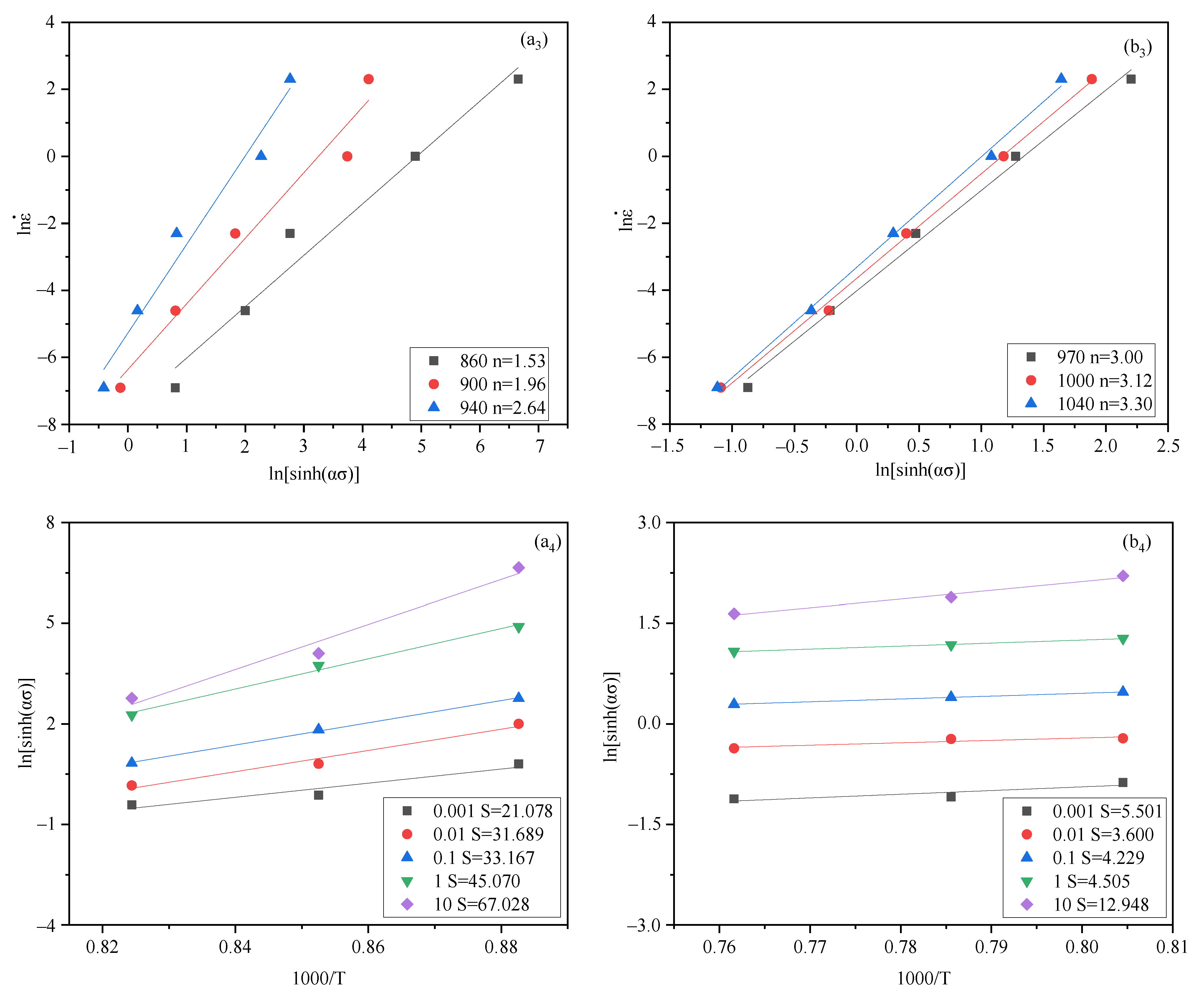

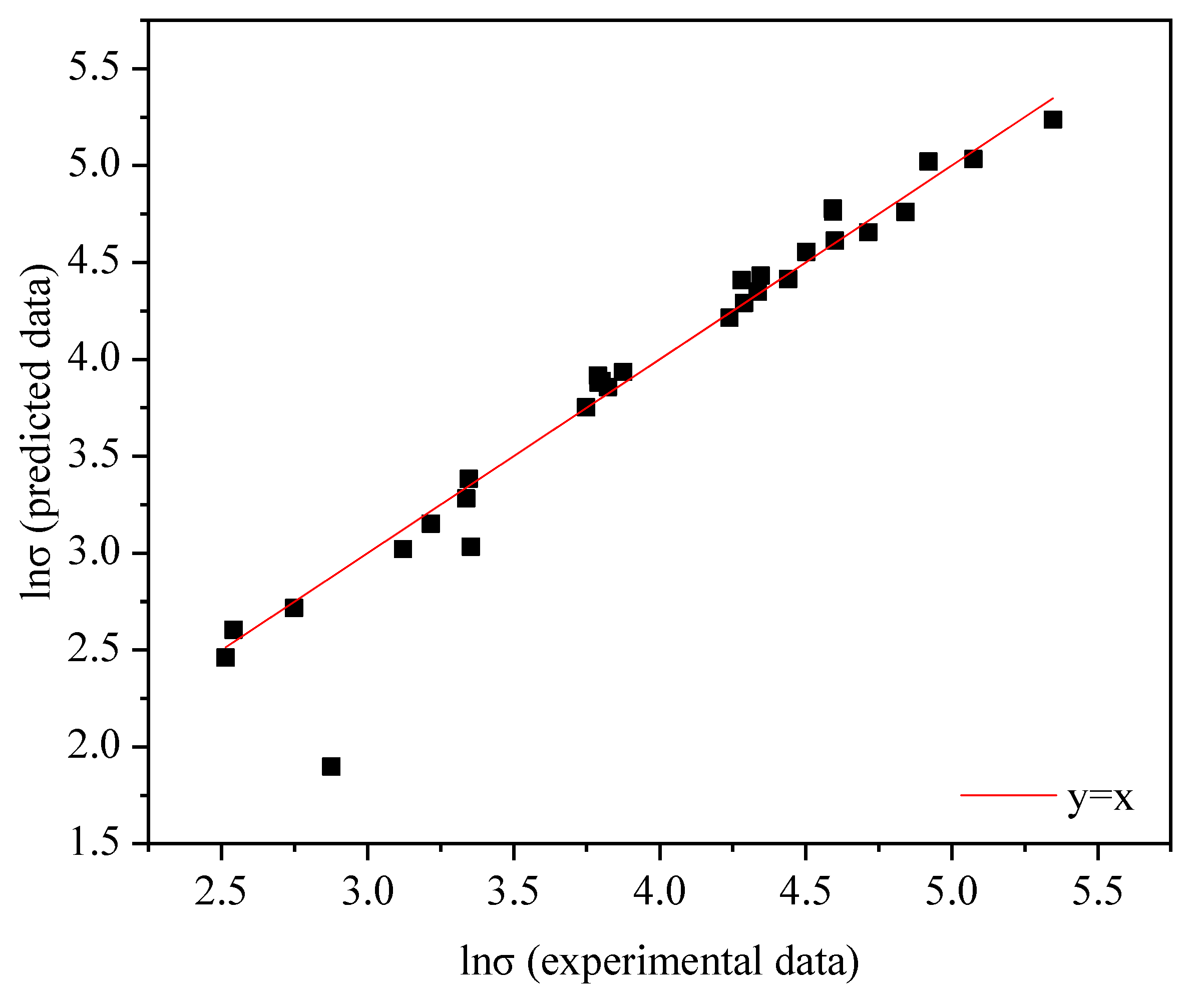

3.2. The Constitutive Equation

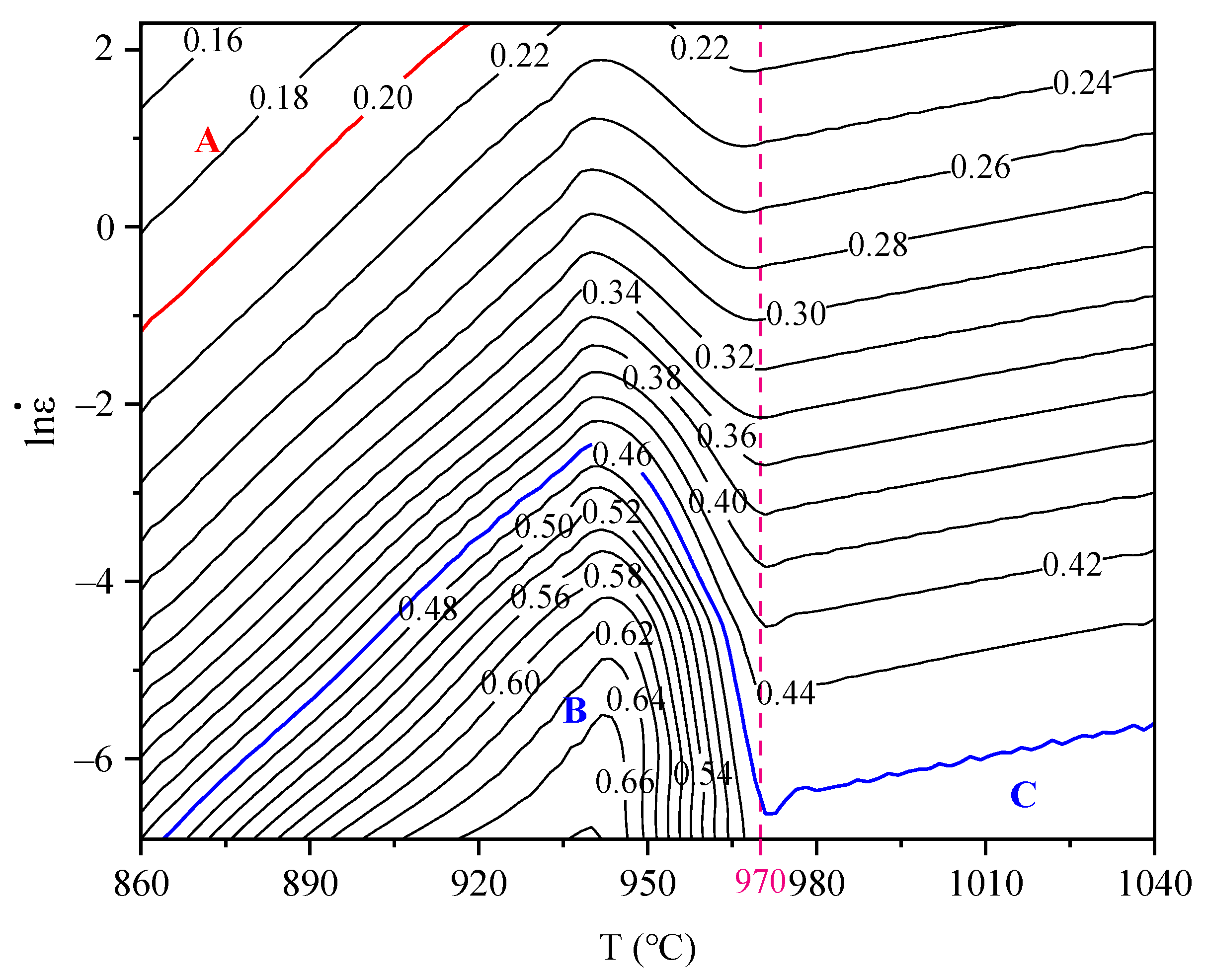

3.3. Processing Map

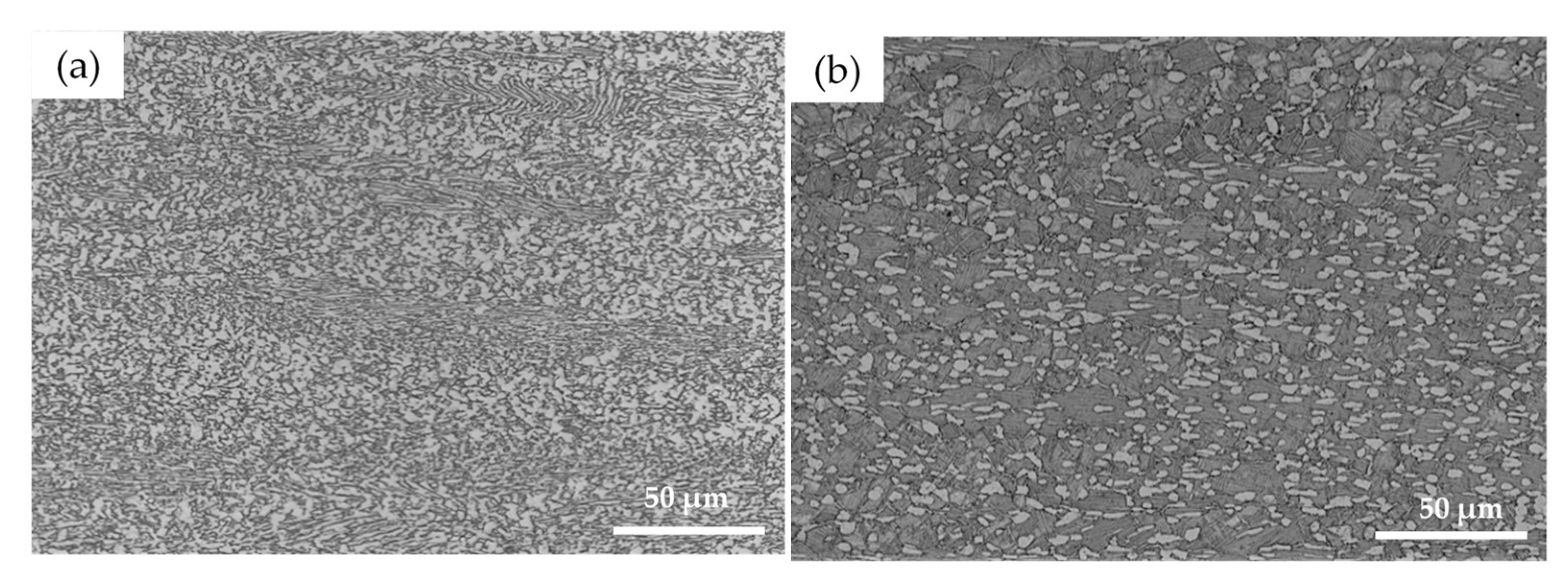

3.4. Microstructure Evolution

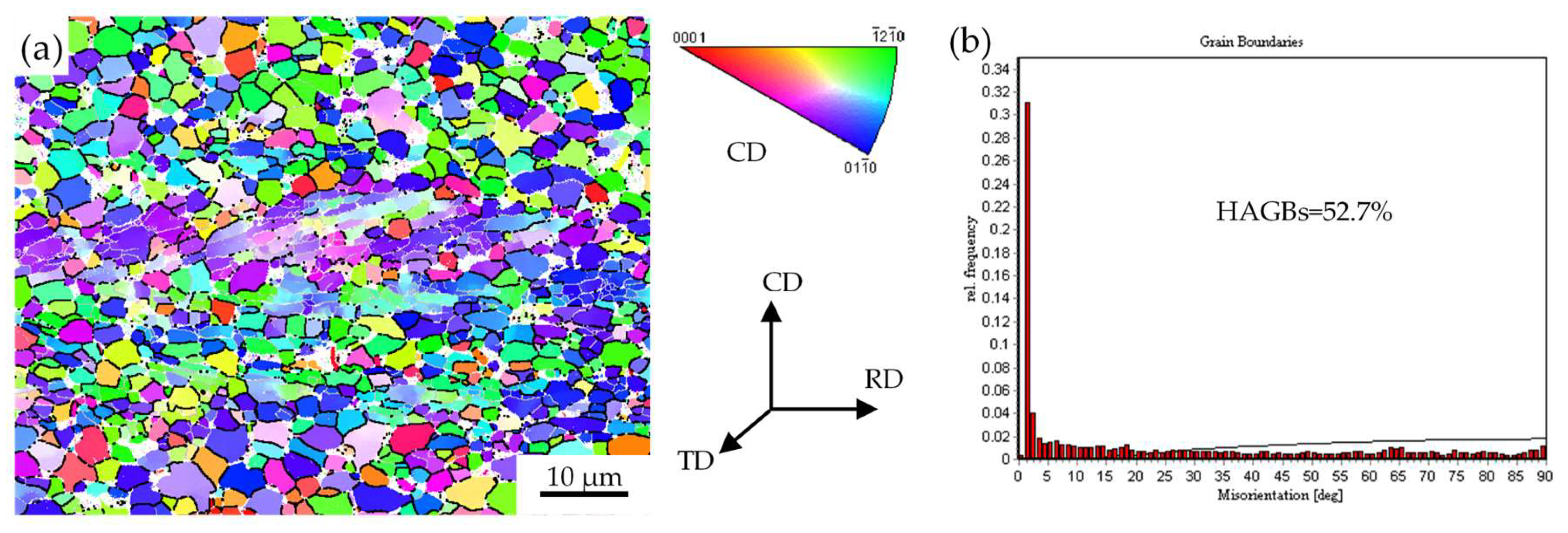

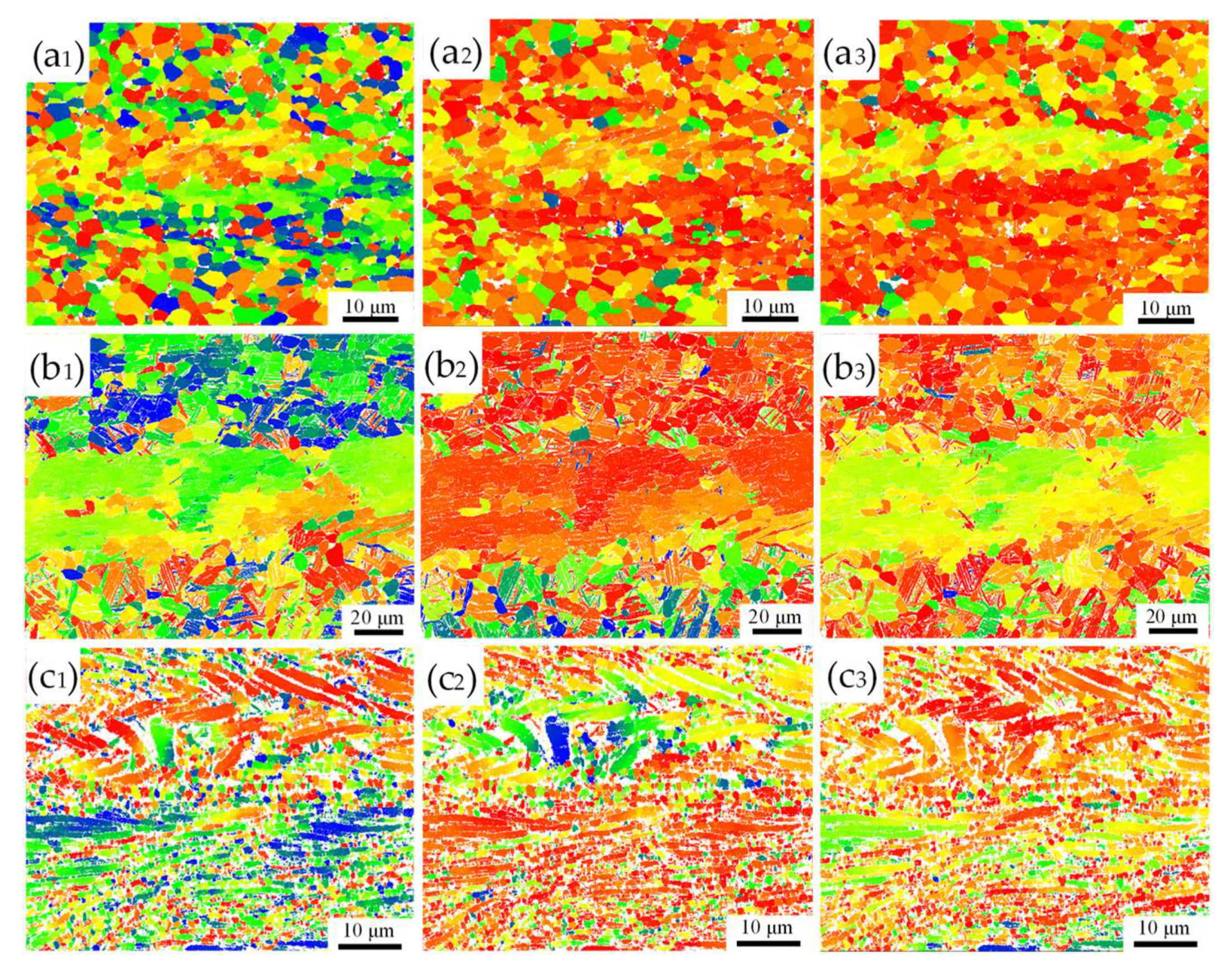

3.4.1. β Single-Phase Region

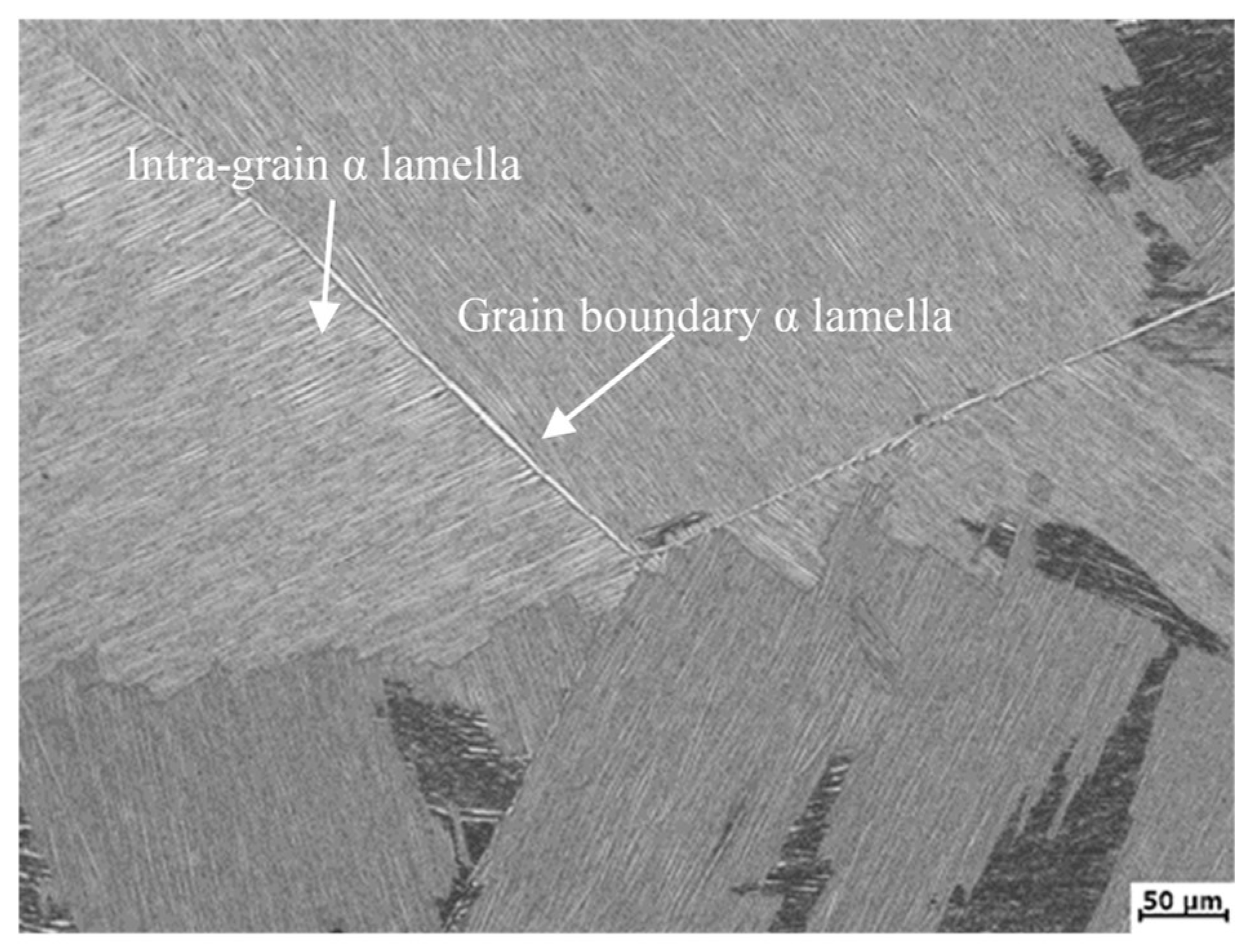

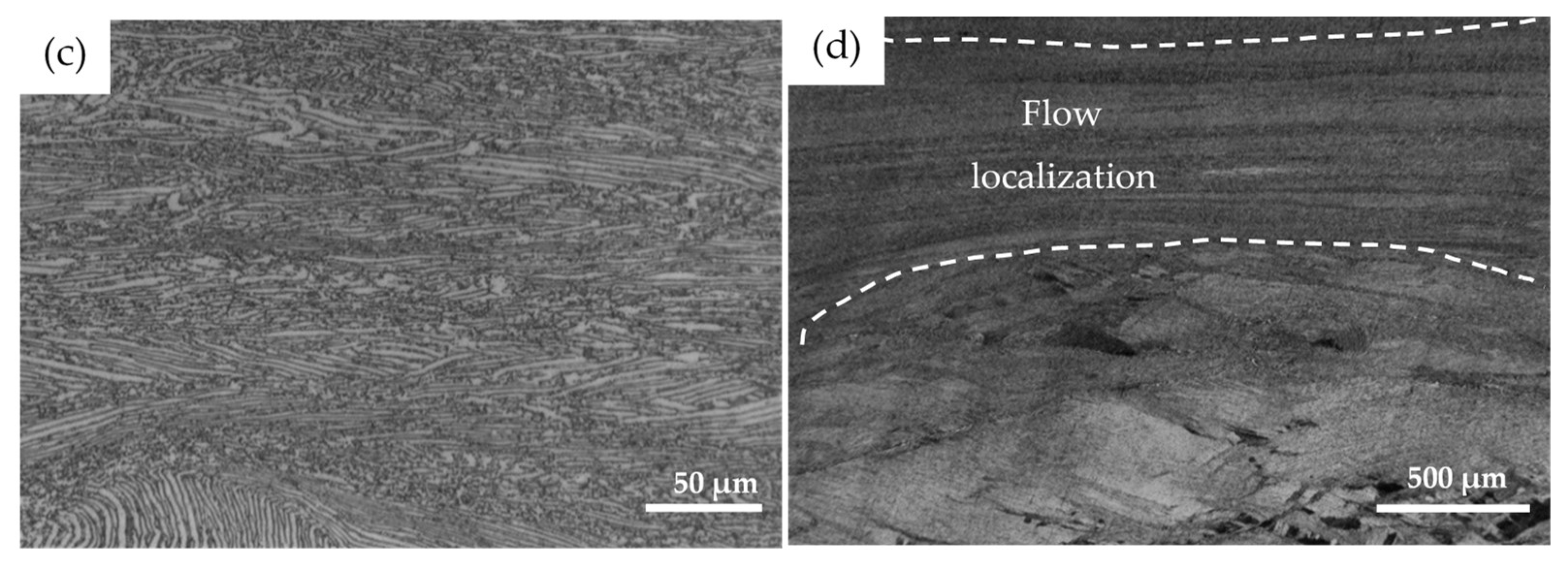

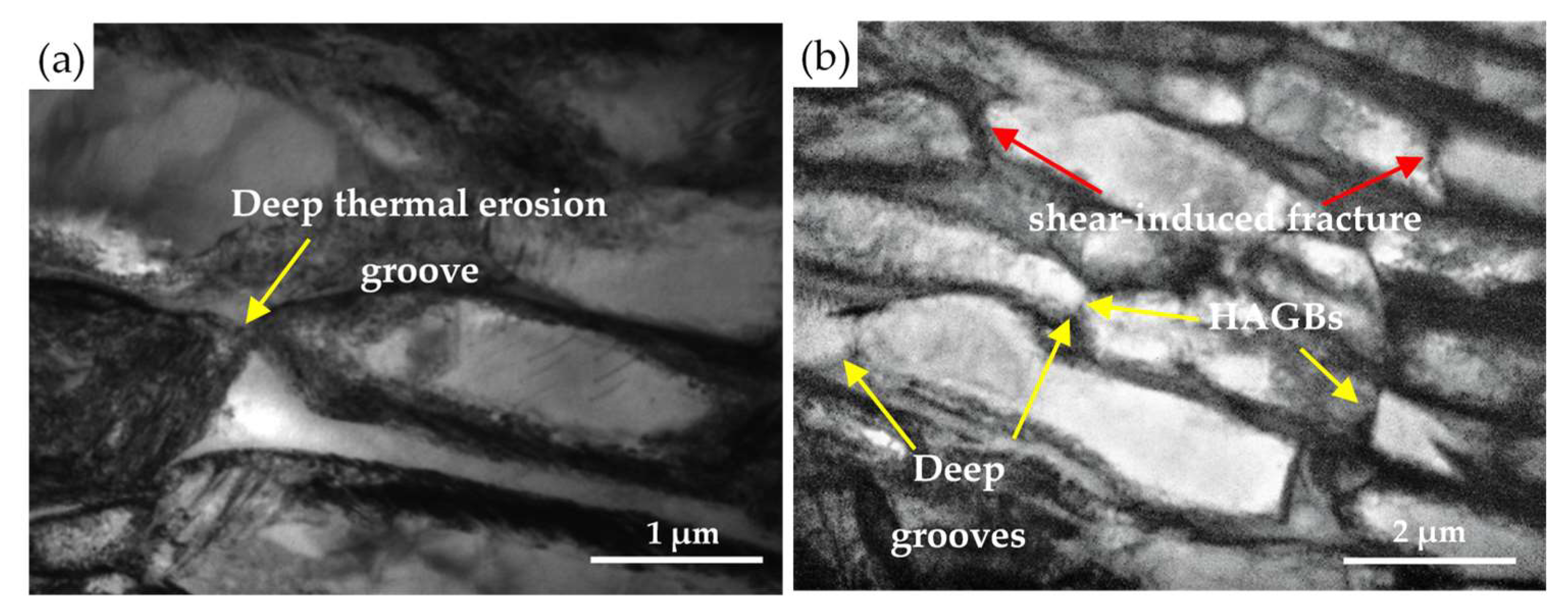

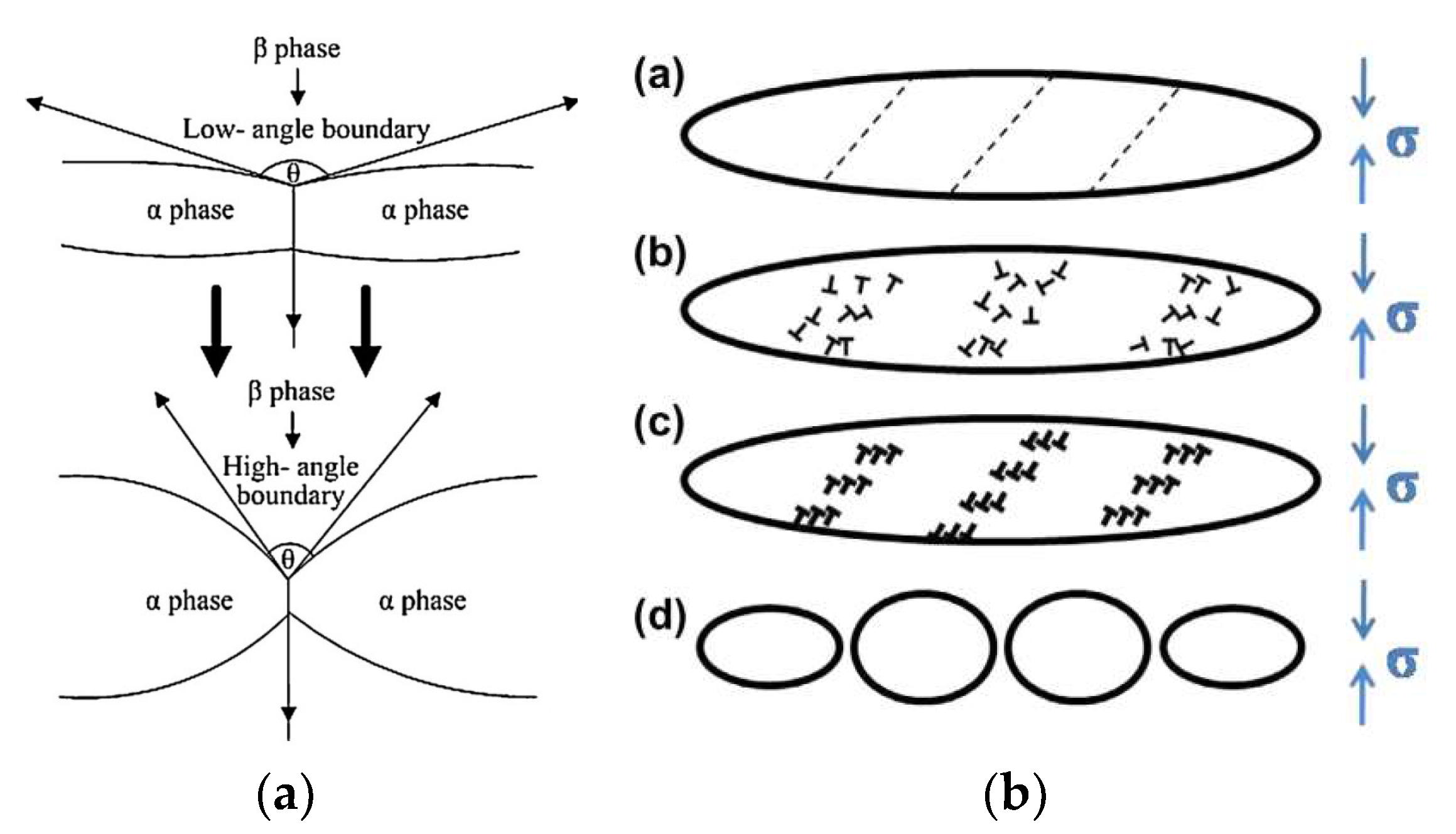

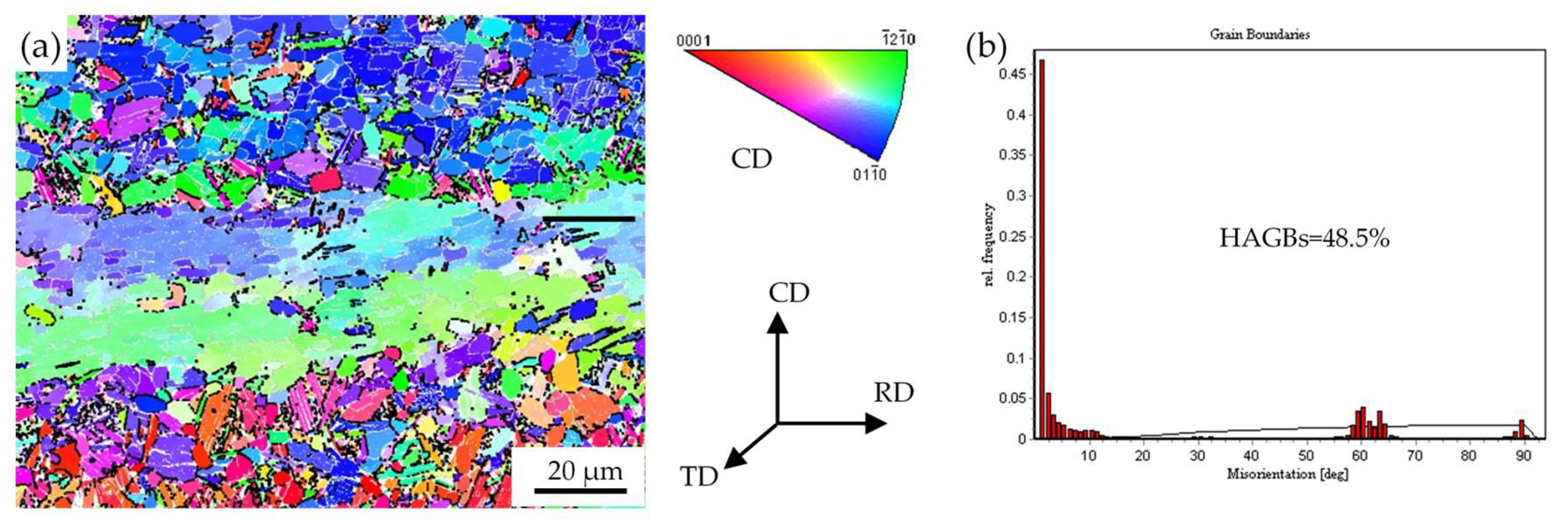

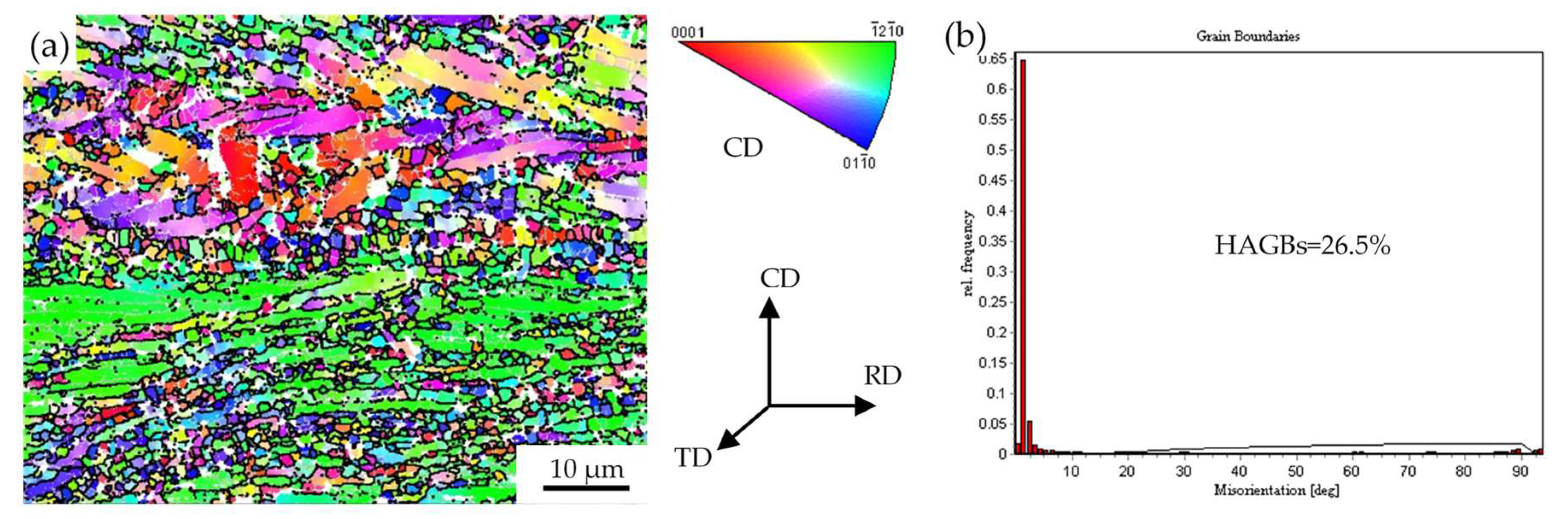

3.4.2. α + β Two-Phase Region

3.4.3. The Crystallographic Orientation Change of Lamellar α

4. Conclusions

- In the α + β two-phase region, the flow stress reaches the peak and then decreases gradually until reaching the stable state under large strain, while in the β single-phase region, the flow stress directly reaches a stable state after reaching the peak value. The increase of strain rate and the decrease of temperature both lead to the increase of flow stress, and the effect of the former is more significant.

- The Arrhenius constitutive equations and processing map of Ti90 alloy were established. The values of deformation activation energy Q were calculated to be 673 kJ·mol−1 in the α + β two-phase region and 161 kJ·mol−1 in the β single-phase region. The DRV of β phase is the dominate deformation behavior for Ti90 alloy in the β single-phase region, while the kinking and dynamic globularization of α lamellae are the dominate deformation behaviors for Ti90 alloy in the α + β region.

- Based on the processing map, the low η region within the temperature range of 860–918 °C with a strain rate range of 0.318–10 s−1 should be avoided to prevent the occurrence of deformation instability during the selection of hot processing parameters of Ti90 alloy.

- The dynamic globularization of α lamellae is thought to be mainly caused by the wedge of the β phase into α lath and the shearing of the α lath result from the applied shear strain; the prismatic slip and the pyramidal slip are easier activated than that of the basic slip. The Schmid factor depends on the morphology of the α phase and the geometric orientation of lamellar α.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, D.; Zeng, W.; Xu, J.; Wang, S.; Chen, W. Evolution of equiaxed and lamellar α during hot compression in a near alpha titanium alloy with bimodal microstructure. Mater. Charact. 2019, 151, 103–111. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, W.; Zhao, Q.; Zhou, D.; He, S.; Jia, R.; Zhou, X. Analysis of deformation behavior and microstructure of a near-alpha titanium alloy in single phase region. Mater. Sci. Eng. A 2021, 803, 140723. [Google Scholar] [CrossRef]

- Zhou, D.; Zeng, W.; Xu, J.; Chen, W.; Wang, S. Characterization of Hot Workability for a Near Alpha Titanium Alloy by Integrating Processing Maps and Constitutive Relationship. Adv. Eng. Mater. 2019, 21, 1801232. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, Y.; Jia, W.; Hou, Z.; Li, S.; Mao, C. Effect of Heat Treatment on Microstructures and Properties of Ti90 Alloy. Rare Met. Mater. Eng. 2021, 50, 552–561. [Google Scholar]

- Jia, W.; Zeng, W.; Zhou, Y.; Liu, J.; Wang, Q. High-temperature deformation behavior of Ti60 titanium alloy. Mater. Sci. Eng. A 2011, 528, 4068–4074. [Google Scholar] [CrossRef]

- Rezaee, M.; Zarei-Hanzaki, A.; Ghambari, M.; Nezhadfar, P.D.; Ghasemi, E. Flow Characterization of a Duplex near α Ti6242 Alloy through Interrelation of Microstructural Evolution, 3D Activation Energy Map, and Processing Map. Adv. Eng. Mater. 2016, 18, 1075–1085. [Google Scholar] [CrossRef]

- Wu, C.; Yang, H.; Li, H. Simulated and experimental investigation on discontinuous dynamic recrystallization of a near-α TA15 titanium alloy during isothermal hot compression in β single-phase field. Trans. Nonferrous Met. Soc. China 2014, 24, 1819–1829. [Google Scholar] [CrossRef]

- Balasundar, I.; Raghu, T.; Kashyap, B.P. Hot working and geometric dynamic recrystallisation behaviour of a near-α titanium alloy with acicular microstructure. Mater. Sci. Eng. A 2014, 600, 135–144. [Google Scholar] [CrossRef]

- Gao, P.; Cai, Y.; Zhan, M.; Fan, X.; Lei, Z. Crystallographic orientation evolution during the development of tri-modal microstructure in the hot working of TA15 titanium alloy. J. Alloys Compd. 2018, 741, 734–745. [Google Scholar] [CrossRef]

- Zhang, Z.; Fan, J.; Tang, B.; Kou, H.; Wang, J.; Chen, Z.; Li, J. Microstructure/texture evolution maps to optimize hot deformation process of near-α titanium alloy. Prog. Nat. Sci. 2020, 30, 86–93. [Google Scholar] [CrossRef]

- Zhao, J.; Lv, L.; Wang, K.; Liu, G. Effects of strain state and slip mode on the texture evolution of a near-α TA15 titanium alloy during hot deformation based on crystal plasticity method. J. Mater. Sci. Technol. 2020, 38, 125–134. [Google Scholar] [CrossRef]

- Peng, W.; Zeng, W.; Wang, Q.; Yu, H. Characterization of high-temperature deformation behavior of as-cast Ti60 titanium alloy using processing map. Mater. Sci. Eng. A 2013, 571, 116–122. [Google Scholar] [CrossRef]

- Lei, J.; Zhu, W.; Chen, L.; Sun, Q.; Xiao, L.; Sun, J. Deformation behaviour and microstructural evolution during the hot compression of Ti-5Al4Zr8Mo7V alloy. Mater. Today Commun. 2020, 23, 100873. [Google Scholar] [CrossRef]

- Su, Y.; Kong, F.; You, F.; Wang, X.; Chen, Y. The high-temperature deformation behavior of a novel near-α titanium alloy and hot-forging based on the processing map. Vacuum 2020, 173, 109135. [Google Scholar] [CrossRef]

- Fan, J.K.; Kou, H.C.; Lai, M.J.; Tang, B.; Chang, H.; Li, J.S. Characterization of hot deformation behavior of a new near beta titanium alloy: Ti-7333. Mater. Eng. 2013, 49, 945–952. [Google Scholar] [CrossRef]

- Peng, W.; Zeng, W.; Wang, Q.; Yu, H. Comparative study on constitutive relationship of as-cast Ti60 titanium alloy during hot deformation based on Arrhenius-type and artificial neural network models. Mater Des. 2013, 51, 95–104. [Google Scholar] [CrossRef]

- Zhao, Q.; Yang, F.; Torrens, R.; Bolzoni, L. Comparison of hot deformation behaviour and microstructural evolution for Ti-5Al-5V-5Mo-3Cr alloys prepared by powder metallurgy and ingot metallurgy approaches. Mater Des. 2019, 169, 107682. [Google Scholar] [CrossRef]

- Sellars, C.M.; Mctegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Sellars, C.M.; Tegart, W. Hot Workability. Int. Mater. Rev. 1972, 17, 1–24. [Google Scholar] [CrossRef]

- Wu, C.; Huang, L.; Li, C.M. Experimental investigation on dynamic phase transformation and texture evolution of Ti55531 high strength titanium alloy during hot compression in the α + β region. Mater. Sci. Eng. A 2020, 773, 138851. [Google Scholar] [CrossRef]

- Viguier, B. Dislocation densities and strain hardening rate in some intermetallic compounds, Materials science & engineering. A, Structural materials: Properties. Microstruct. Process. 2003, 349, 132–135. [Google Scholar]

- Dyment, F.; Libanati, C.M. Self-diffusion of Ti, Zr, and Hf in their hcp phases, and diffusion of Nb95 in hcp Zr. J Mater Sci. 1963, 3, 349–359. [Google Scholar] [CrossRef]

- Reca, N.; Libanati, Y. Autodifusion de titanio beta y hafnio beta. Acta Metall. 1968, 16, 1297–1305. [Google Scholar] [CrossRef]

- Dudova, N.; Belyakov, A.; Sakai, T.; Kaibyshev, R. Dynamic recrystallization mechanisms operating in a Ni-20%Cr alloy under hot-to-warm working. Acta Mater. 2010, 58, 3624–3632. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Seshacharyulu, T. Modelling of hot deformation for microstructural control. Int. Mater. Rev. 1998, 43, 243–258. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Gegel, H.L.; Doraivelu, S.M.; Malas, J.C.; Morgan, J.T.; Lark, K.A.; Barker, D.R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Metall. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Peng, X.; Guo, H.; Shi, Z.; Qin, C.; Zhao, Z.; Yao, Z. Study on the hot deformation behavior of TC4-DT alloy with equiaxed α + β starting structure based on processing map. Mater. Sci. Eng. A 2014, 605, 80–88. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Morgan, J.T.; Malas, J.C.; Frazier, W.G. Hot deformation mechanisms in ELI Grade Ti-6a1-4V. Scr. Mater. 1999, 41, 283–288. [Google Scholar] [CrossRef]

- Sargent, P.M.; Ashby, M.F. Deformation maps for titanium and zirconium. Scr. Metall. 1982, 16, 1415–1422. [Google Scholar] [CrossRef]

- Liu, Y.; Baker, T.N. Deformation characteristics of IMI685 titanium alloy under β isothermal forging solutions. Mater. Sci. Eng. A 1995, 197, 125–131. [Google Scholar] [CrossRef]

- Han, Y.; Zeng, W.; Qi, Y.; Zhao, Y. The influence of thermomechanical processing on microstructural evolution of Ti600 titanium alloy. Mater. Sci. Eng. A 2011, 528, 8410–8416. [Google Scholar] [CrossRef]

- Stefansson, N.; Semiatin, S.L. Mechanisms of globularization of Ti-6Al-4V during static heat treatment, Metallurgical and materials transactions. Metall. Mater. Sci. 2003, 34, 691–698. [Google Scholar]

- Hua, K.; Xue, X.; Kou, H.; Fan, J.; Tang, B.; Li, J. Characterization of hot deformation microstructure of a near beta titanium alloy Ti-5553. J. Alloys Compd. 2014, 615, 531–537. [Google Scholar] [CrossRef]

- Yan, G.; Gm, A.; Xz, C.; Jx, D. Microstructure evolution and hot deformation behavior of Ti-6.5Al–2Zr–1Mo–1V alloy with starting lamellar structure. J. Alloys Compd. 2019, 809, 151852. [Google Scholar]

- Roy, S.; Madhavan, R.; Suwas, S. Crystallographic texture and microstructure evolution during hot compression of Ti 6Al 4V 0.1B alloy in the (α + β)-regime. Philos. Mag. 2014, 94, 358–380. [Google Scholar] [CrossRef]

- Bieler, T.R.; Semiatin, S.L. The origins of heterogeneous deformation during primary hot working of Ti–6Al–4V. Int. J. Plast. 2002, 18, 1165–1189. [Google Scholar] [CrossRef]

- Bridier, F.; Villechaise, P.; Mendez, J. Analysis of the different slip systems activated by tension in a α/β titanium alloy in relation with local crystallographic orientation. Acta Mater. 2005, 53, 555–567. [Google Scholar] [CrossRef]

| Temperature/℃ | Strain Rate/s−1 | Mean Schmid Factor | ||

|---|---|---|---|---|

| (0001) <11–20> | (1–100) <11–20> | (1–101) <11–20> | ||

| 860 | 0.001 | 0.282 | 0.392 | 0.401 |

| 900 | 0.001 | 0.293 | 0.394 | 0.329 |

| 900 | 1 | 0.282 | 0.364 | 0.374 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Zhao, Y.; Jia, W.; Li, S.; Mao, C. The High-Temperature Deformation Behavior of As-Cast Ti90 Titanium Alloy. Metals 2021, 11, 1630. https://doi.org/10.3390/met11101630

Wang K, Zhao Y, Jia W, Li S, Mao C. The High-Temperature Deformation Behavior of As-Cast Ti90 Titanium Alloy. Metals. 2021; 11(10):1630. https://doi.org/10.3390/met11101630

Chicago/Turabian StyleWang, Ke, Yongqing Zhao, Weiju Jia, Silan Li, and Chengliang Mao. 2021. "The High-Temperature Deformation Behavior of As-Cast Ti90 Titanium Alloy" Metals 11, no. 10: 1630. https://doi.org/10.3390/met11101630

APA StyleWang, K., Zhao, Y., Jia, W., Li, S., & Mao, C. (2021). The High-Temperature Deformation Behavior of As-Cast Ti90 Titanium Alloy. Metals, 11(10), 1630. https://doi.org/10.3390/met11101630