Effect of Bimodal Grain Structure on the Microstructural and Mechanical Evolution of Al-Mg/CNTs Composite

Abstract

:1. Introduction

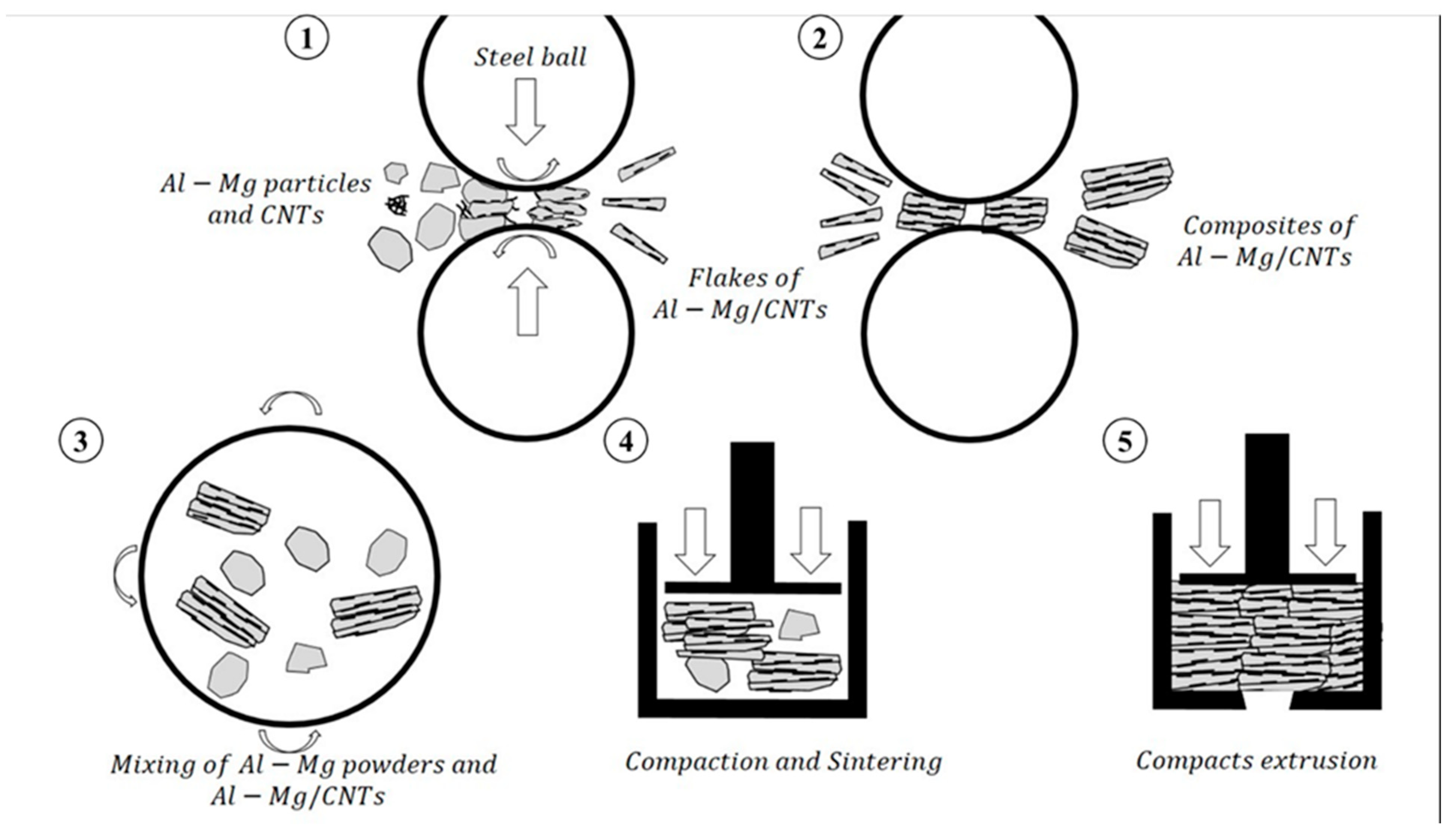

2. Experimental Procedure

2.1. Raw Material and Composite Fabrication

2.2. Material Characterization and Mechanical Tests

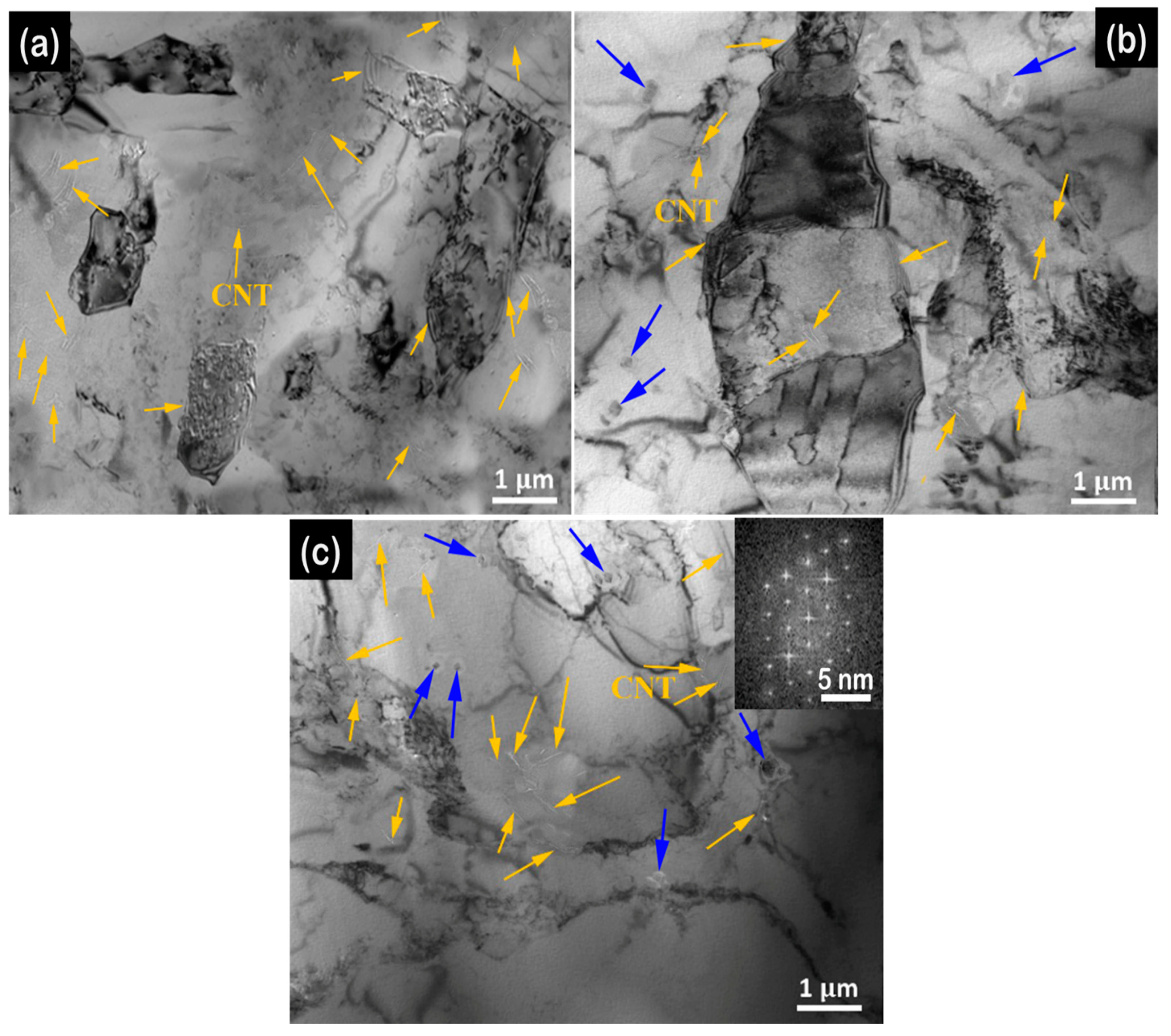

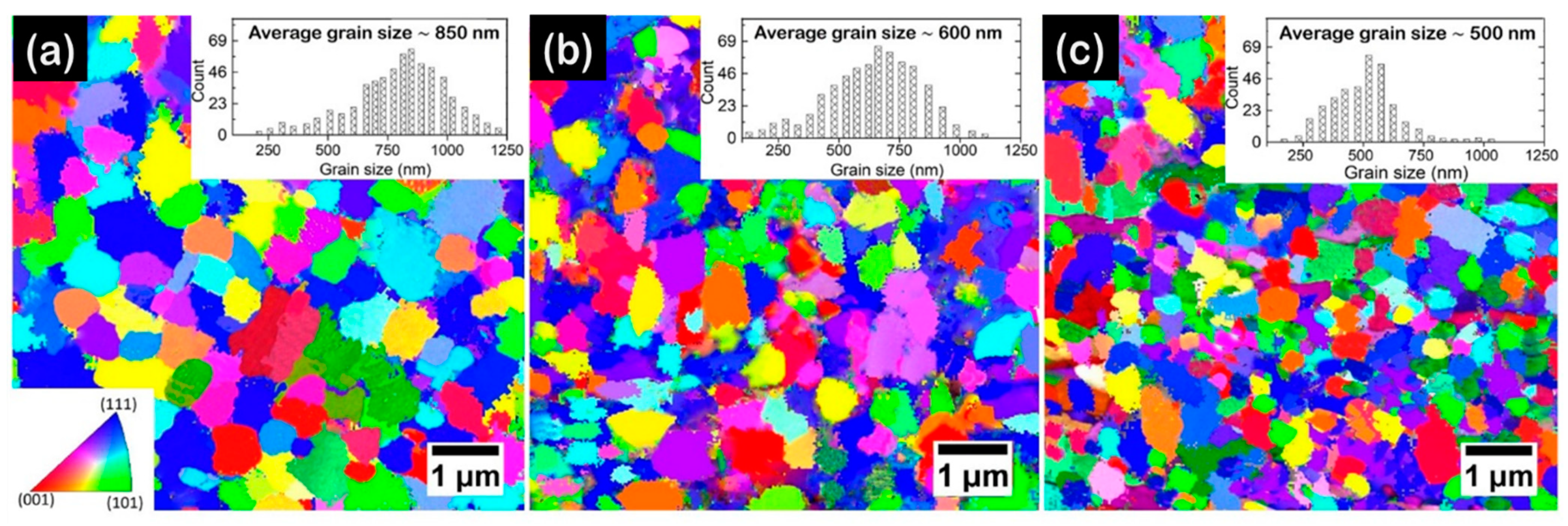

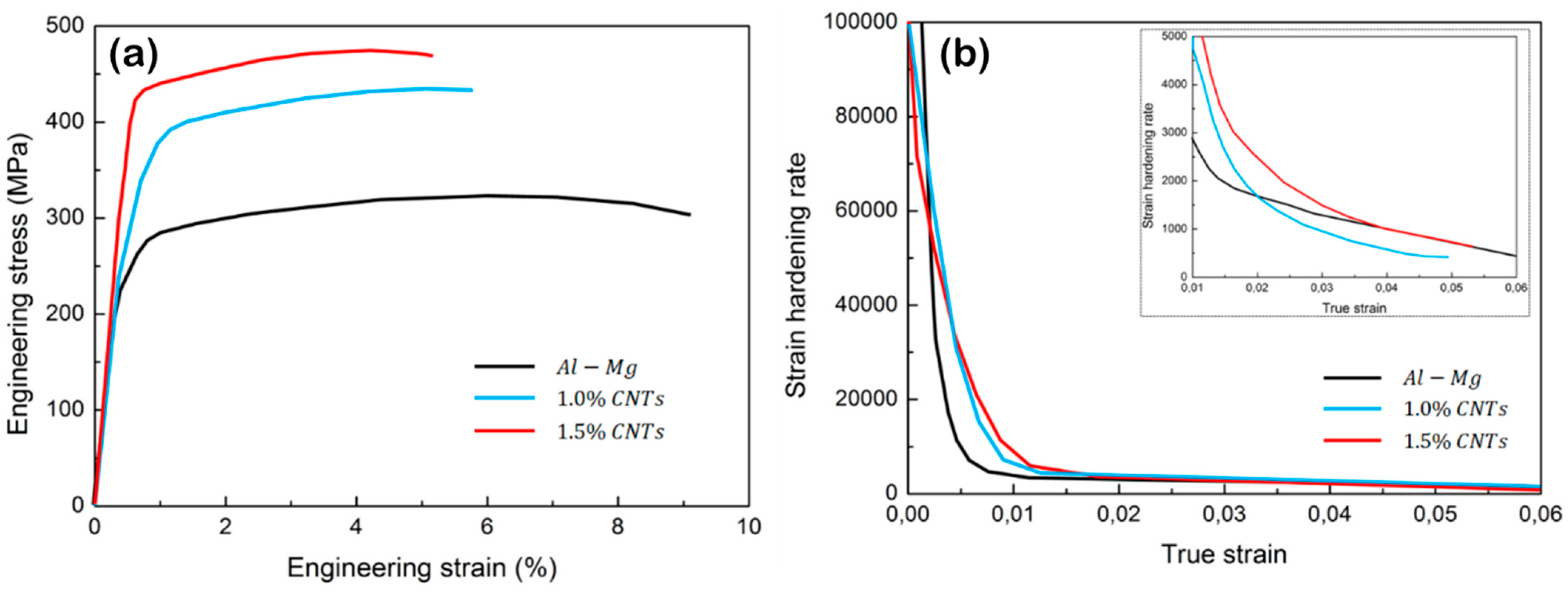

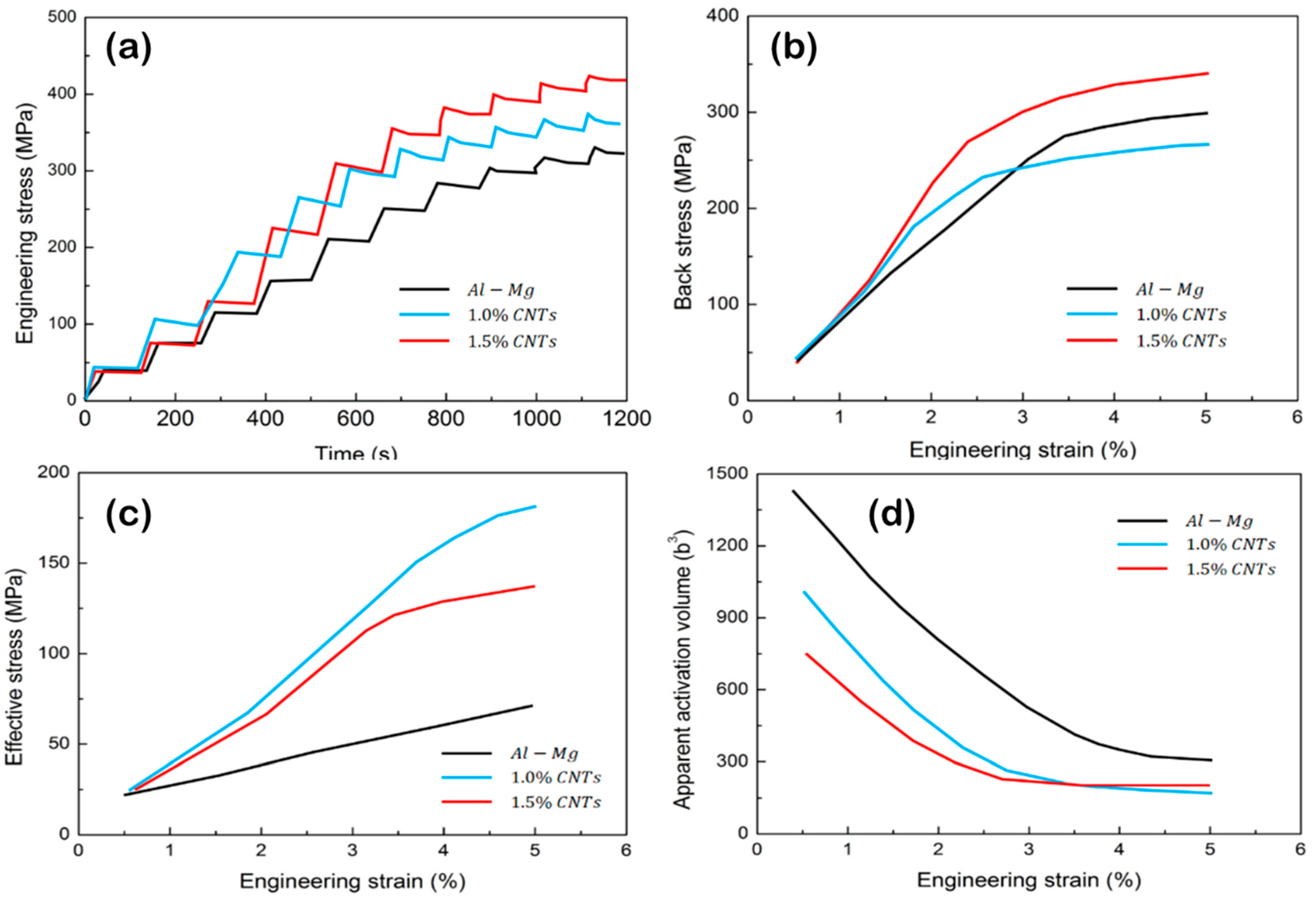

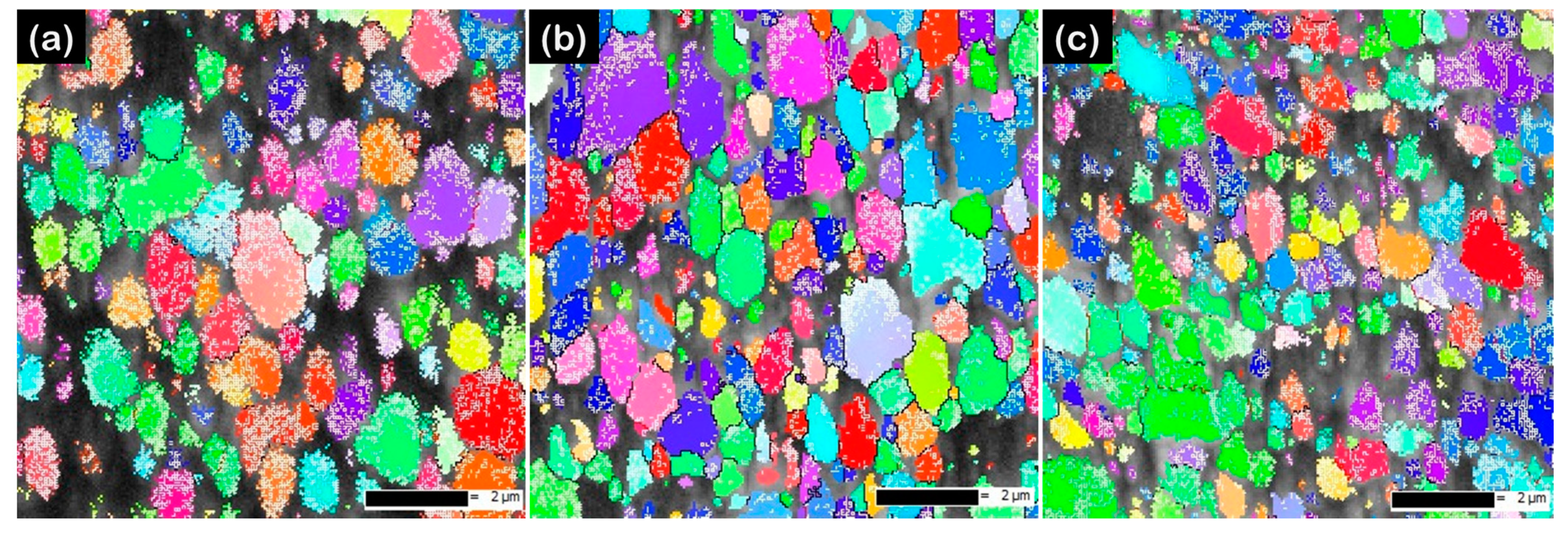

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, M.; Weng, L.; Zhu, H.; Fan, T.; Zhang, D. simultaneously enhancing the strength, ductility and conductivity of copper matrix composites with graphene nanoribbons. Carbon 2017, 118, 250–260. [Google Scholar] [CrossRef]

- Ramakrishnan, N. An analytical study on strengthening of particulate reinforced metal matrix composites. Acta Mater. 1996, 44, 69–77. [Google Scholar] [CrossRef]

- Shao, J.C.; Xiao, B.L.; Wang, Q.Z.; Ma, Z.Y.; Yang, K. An enhanced FEM model for particle size dependent flow strengthening and interface damage in particle reinforced metal matrix composites. Compos. Sci. Technol. 2011, 71, 39–45. [Google Scholar] [CrossRef]

- Bagherpour, E.; Reihanian, M.; Miyamoto, H. Tailoring particle distribution non-uniformity and grain refinement in nanostructured metal matrix composites fabricated by severe plastic deformation (SPD): A correlation with flow stress. J. Mater. Sci. 2017, 52, 3436–3446. [Google Scholar] [CrossRef]

- Cavaliere, P.; Sadeghi, B.; Shabani, A. Carbon nanotube reinforced aluminum matrix composites produced by spark plasma sintering. J. Mater. Sci. 2017, 52, 8618–8629. [Google Scholar] [CrossRef]

- Chen, B.; Shen, J.; Ye, X.; Jia, L.; Li, S.; Umeda, J.; Takahashi, M.; Kondoh, K. Length effect of carbon nanotubes on the strengthening mechanisms in metal matrix composites. Acta Mater. 2017, 140, 317–325. [Google Scholar] [CrossRef]

- Yoo, S.J.; Han, S.H.; Kim, W.J. Strength and strain hardening of aluminum matrix composites with randomly dispersed nanometer-length fragmented carbon nanotubes. Scripta Mater. 2013, 68, 711–714. [Google Scholar] [CrossRef]

- Wu, C.; Ma, W.X.; Chen, Y.P.; Li, Y.; Chen, Y.; Li, J. Progress of the Current Interface Research on Carbon Nanotubes Reinforced Aluminum-matrix Composites. Adv. Mater. Res. 2014, 842, 196–200. [Google Scholar]

- Sadeghi, B.; Qi, J.; Min, X.; Cavaliere, P. Modelling of strain rate dependent dislocation behavior of CNT/Al composites based on grain interior/grain boundary affected zone (GI/GBAZ). Mater. Sci. Eng. A 2021, 820, 141547. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Y. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Jiang, L.; Ma, K.; Yang, H.; Li, M.; Lavernia, E.J.; Shoenung, J.M. The Microstructural Design of Trimodal Aluminum Composites. JOM 2014, 66, 898–908. [Google Scholar] [CrossRef]

- Ye, J.; Han, B.Q.; Schoenung, J.M. Mechanical behaviour of an Al-matrix composite reinforced with nanocrystalline Al-coated B4C particulates. Phil. Mag. Lett. 2006, 86, 721–732. [Google Scholar] [CrossRef]

- Ye, C.; Shi, J.; Cheng, G.J. An eXtended Finite Element Method (XFEM) study on the effect of reinforcing particles on the crack propagation behavior in a metal–matrix composite. Int. J. Fatigue 2012, 44, 151–156. [Google Scholar] [CrossRef]

- Chen, L.; Hou, Z.; Liu, Y.; Luan, C.; Zhu, L.; Li, W. High strength and high ductility copper matrix composite reinforced by graded distribution of carbon nanotubes. Compos. Part A 2020, 138, 106063. [Google Scholar] [CrossRef]

- Lumley, R.; Sercombe, T.; Schaffer, G. Surface oxide and the role of magnesium during the sintering of aluminum. Metall. Mater. Trans. A. 1999, 30, 457–463. [Google Scholar] [CrossRef]

- Sangghaleh, A.; Halali, M. Effect of magnesium addition on the wetting of alumina by aluminium. Appl. Surf. Sci. 2009, 255, 8202–8206. [Google Scholar] [CrossRef]

- Yuan, C.; Zhang, Z.; Tan, Z.; Xu, L.; Zhang, S.; Fan, G.; Zhang, P.; Li, Z. Enhanced ductility by Mg addition in the CNT/Al-Cu composites via flake powder metallurgy. Materials Today Commun. 2021, 26, 101854. [Google Scholar] [CrossRef]

- Balog, M.; Hu, T.; Krizik, P.; Castro Riglos, M.V.; Saller, B.D.; Yang, H.; Schoenung, J.M.; Lavernia, E.J. On the thermal stability of ultrafine-grained Al stabilized by in-situ amorphous Al2O3 network. Mater. Sci. Eng. A. 2015, 648, 61–71. [Google Scholar] [CrossRef]

- Sadeghi, B.; Tan, Z.; Qi, J.; Li, Z.; Min, X.; Yue, Z.; Fan, G. Enhanced mechanical properties of CNT/Al composite through tailoring grain interior/grain boundary affected zones. Compos. Part B 2021, 223, 109133. [Google Scholar] [CrossRef]

- Hart, E.W. A theory for flow of polycrystals. Acta Metall. 1967, 15, 1545–1549. [Google Scholar] [CrossRef]

- Ahn, B.; Lavernia, E.J.; Nutt, S.R. Dynamic observations of deformation in an ultrafine-grained Al–Mg alloy with bimodal grain structure. J. Mater. Sci. 2008, 43, 7403–7408. [Google Scholar] [CrossRef]

- Mohebbi, M.S.; Akbarzadeh, A.; Yoon, Y.-O.; Kim, S.-K. Stress relaxation and flow behavior of ultrafine grained AA 1050. Mech. Mater. 2015, 89, 23–34. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, L.; Guo, Q.; Li, Z.; Fan, G.; Guo, C.; Zhang, D. Enhanced dislocation obstruction in nanolaminated graphene/Cu composite as revealed by stress relaxation experiments. Scr. Mater. 2017, 131, 67–71. [Google Scholar] [CrossRef]

- Fu, X.; Yu, Z.; Tan, Z.; Fan, G.; Li, P.; Wang, M.; Xiong, D.-B.; Li, Z. Enhanced strain hardening by bimodal grain structure in carbon nanotube reinforced Al–Mg composites. Mater. Sci. Eng. A. 2021, 803, 140726. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Z.; Tan, Z.; Zhao, H.; Fan, G.; Xu, Y.; Xiong, D.; Li, Z. Bioinspired hierarchical Al2O3/Al laminated composite fabricated by flake powder metallurgy. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106187. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, R.; Tan, Z.; Ji, G.; Fan, G.; Li, Z.; Xiong, D.-B.; Guo, Q.; Li, Z.; Zhang, D. Interface-induced strain hardening of graphene nanosheet/aluminum composites. Carbon 2019, 146, 17–27. [Google Scholar] [CrossRef]

- Wang, Y.M.; Hamza, A.V.; Ma, E. Temperature-dependent strain rate sensitivity and activation volume of nanocrystalline Ni. Acta Mater. 2006, 54, 2715–2726. [Google Scholar] [CrossRef]

- Dotsenko, V. Stress relaxation in crystals. Phys. Status Solidi B 1979, 93, 11–43. [Google Scholar] [CrossRef]

- Ma, K.; Liu, Z.Y.; Bi, S.; Zhang, X.X.; Xiao, B.L.; Ma, Z.Y. Microstructure evolution and hot deformation behavior of carbon nanotube reinforced 2009Al composite with bimodal grain structure. J. Mater. Sci. Technol. 2021, 70, 73–82. [Google Scholar] [CrossRef]

- Fu, X.; Tan, Z.; Min, X.; Li, Z.; Yue, Z.; Fan, G.; Xiong, D.-B.; Li, Z. Trimodal grain structure enables high-strength CNT/Al-Cu-Mg composites higher ductility by powder assembly & alloying. Mater. Res. Lett. 2021, 9, 50–57. [Google Scholar]

- Singh, L.K.; Bhadauria, A.; Laha, T. Understanding the effect of bimodal microstructure on the strength–ductility synergy of Al–CNT nanocomposites. J. Mater. Sci. 2021, 56, 1730–1748. [Google Scholar] [CrossRef]

- Bi, S.; Liu, Z.Y.; Xiao, B.L.; Xue, P.; Wang, D.; Wang, Q.Z.; Ni, D.R.; Ma, Z.Y. Different fatigue behavior between tension-tension and tension-compression of carbon nanotubes reinforced 7055 Al composite with bimodal structure. Carbon 2021, 184, 364–374. [Google Scholar] [CrossRef]

- Ma, K.; Liu, Z.Y.; Liu, K.; Chen, X.G.; Xiao, B.L.; Ma, Z.Y. Structure optimization for improving the strength and ductility of heterogeneous carbon nanotube/Al–Cu–Mg composites. Carbon 2021, 178, 190–201. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.; Perrone, A. Effect of Al2O3, SiO2 and carbon nanotubes on the microstructural and mechanical behavior of spark plasma sintered aluminum based nanocomposites. Part. Sci. Technol. 2020, 38, 7–14. [Google Scholar] [CrossRef]

- Bach, J.; Stoiber, M.; Schindler, L.; Höppel, H.W.; Göken, M. Deformation mechanisms and strain rate sensitivity of bimodal and ultrafine-grained copper. Acta Mater. 2020, 186, 363–373. [Google Scholar] [CrossRef]

| Sample | After Tensile Test | ||

|---|---|---|---|

| Mirco-Strain (%) | Dislocation Density | Domain Size (nm) | |

| Al-Mg | 1.2 × 10−3 | 4.12 × 1014 | 56 |

| 1.0 wt.% CNTs | 1.3 × 10−3 | 3.19 × 1014 | 61 |

| 1.5 wt.% CNTs | 1.4 × 10−3 | 4.45 × 1014 | 64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadeghi, B.; Cavaliere, P. Effect of Bimodal Grain Structure on the Microstructural and Mechanical Evolution of Al-Mg/CNTs Composite. Metals 2021, 11, 1524. https://doi.org/10.3390/met11101524

Sadeghi B, Cavaliere P. Effect of Bimodal Grain Structure on the Microstructural and Mechanical Evolution of Al-Mg/CNTs Composite. Metals. 2021; 11(10):1524. https://doi.org/10.3390/met11101524

Chicago/Turabian StyleSadeghi, Behzad, and Pasquale Cavaliere. 2021. "Effect of Bimodal Grain Structure on the Microstructural and Mechanical Evolution of Al-Mg/CNTs Composite" Metals 11, no. 10: 1524. https://doi.org/10.3390/met11101524

APA StyleSadeghi, B., & Cavaliere, P. (2021). Effect of Bimodal Grain Structure on the Microstructural and Mechanical Evolution of Al-Mg/CNTs Composite. Metals, 11(10), 1524. https://doi.org/10.3390/met11101524