Neuro-Fuzzy System for Compensating Slow Disturbances in Adaptive Mold Level Control

Abstract

1. Introduction

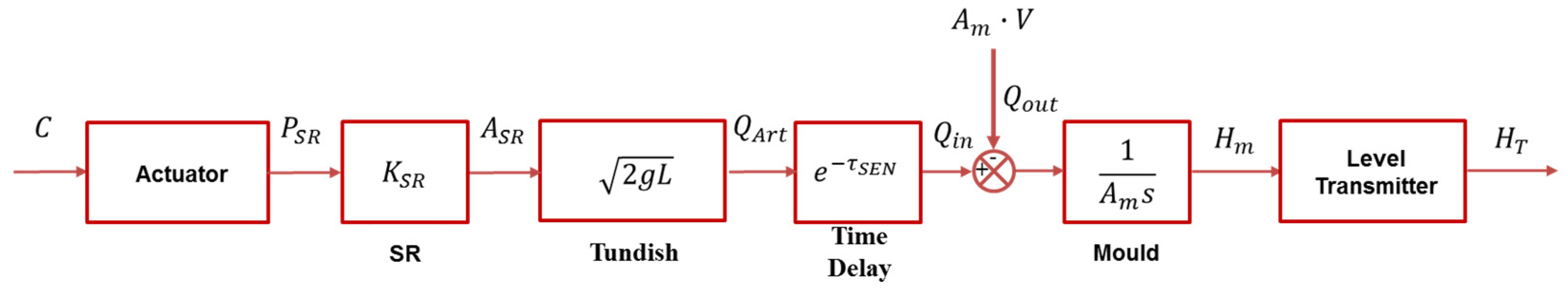

2. Process Description

3. Control Structure

3.1. Conventional Control

3.2. Adaptive Mold Level Control

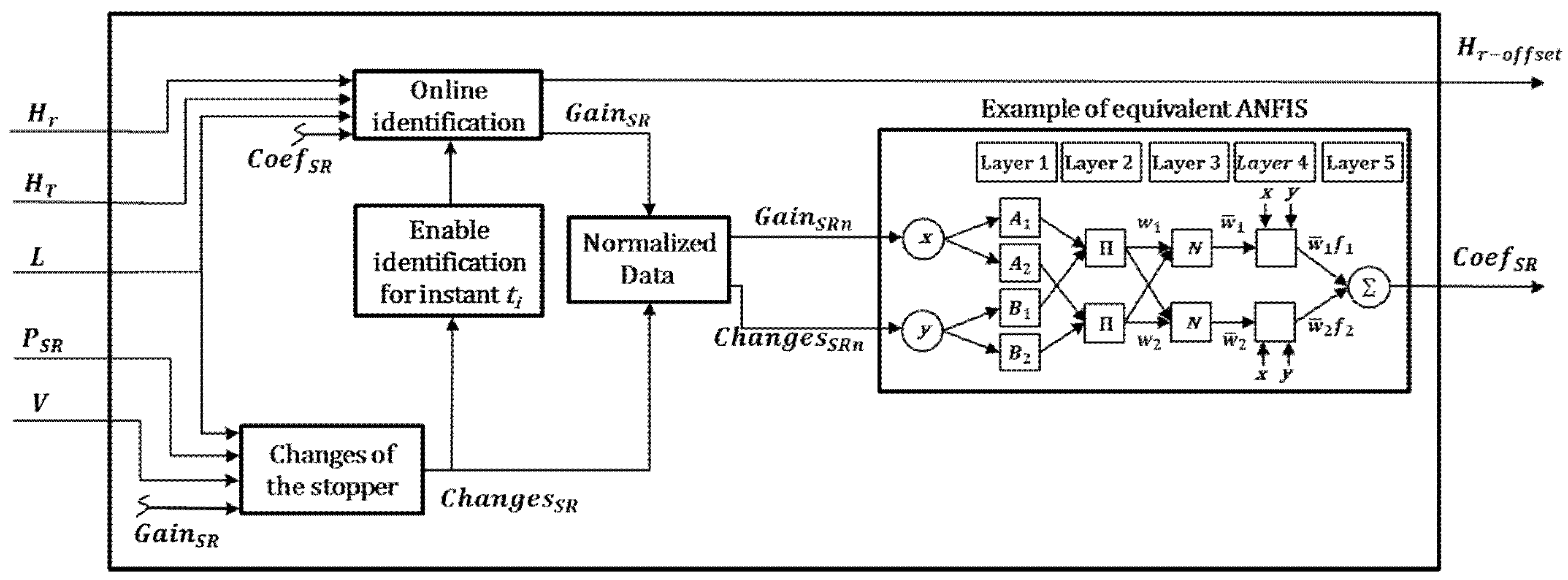

4. Neuro-Fuzzy System for Estimating Valve Gain

- (1)

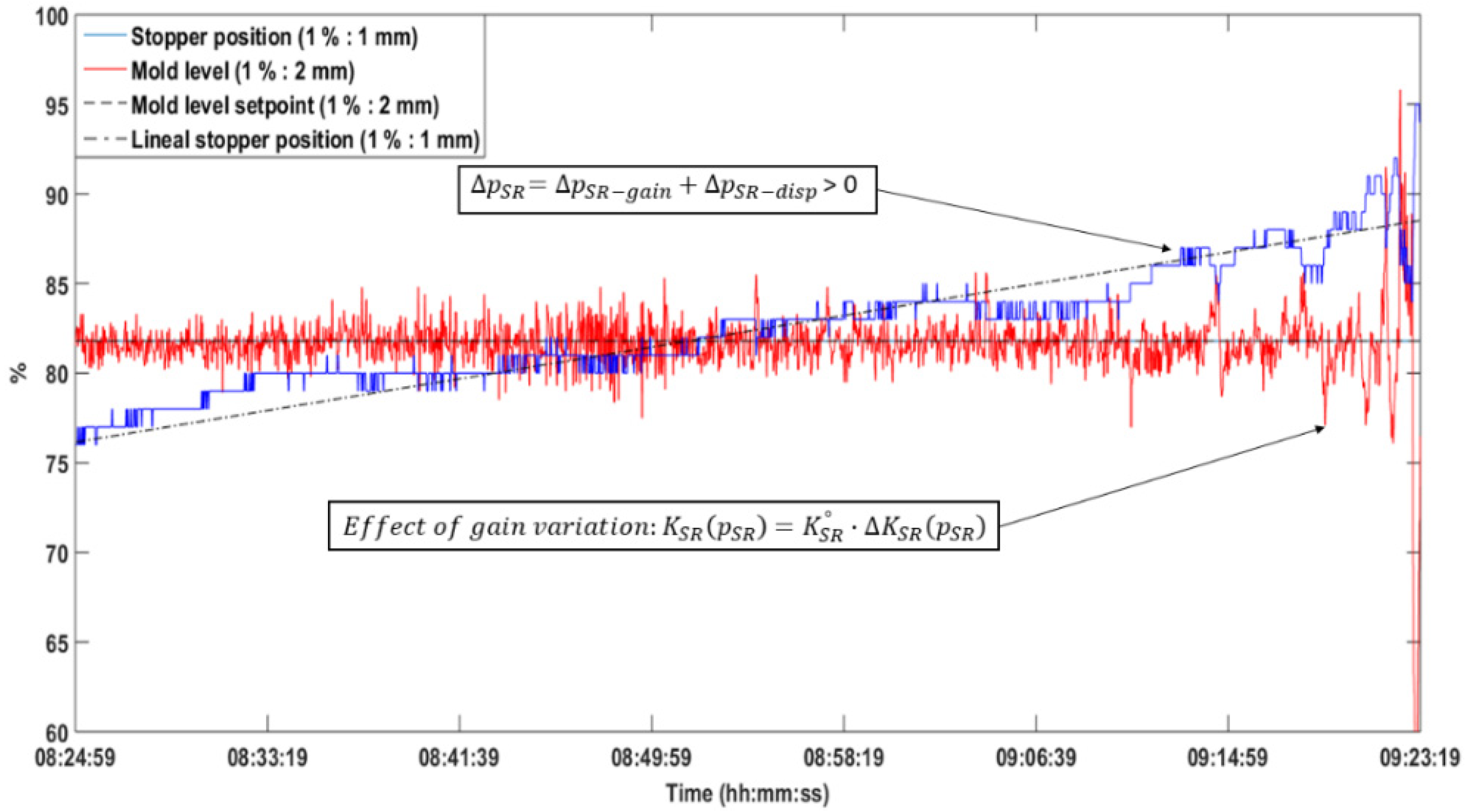

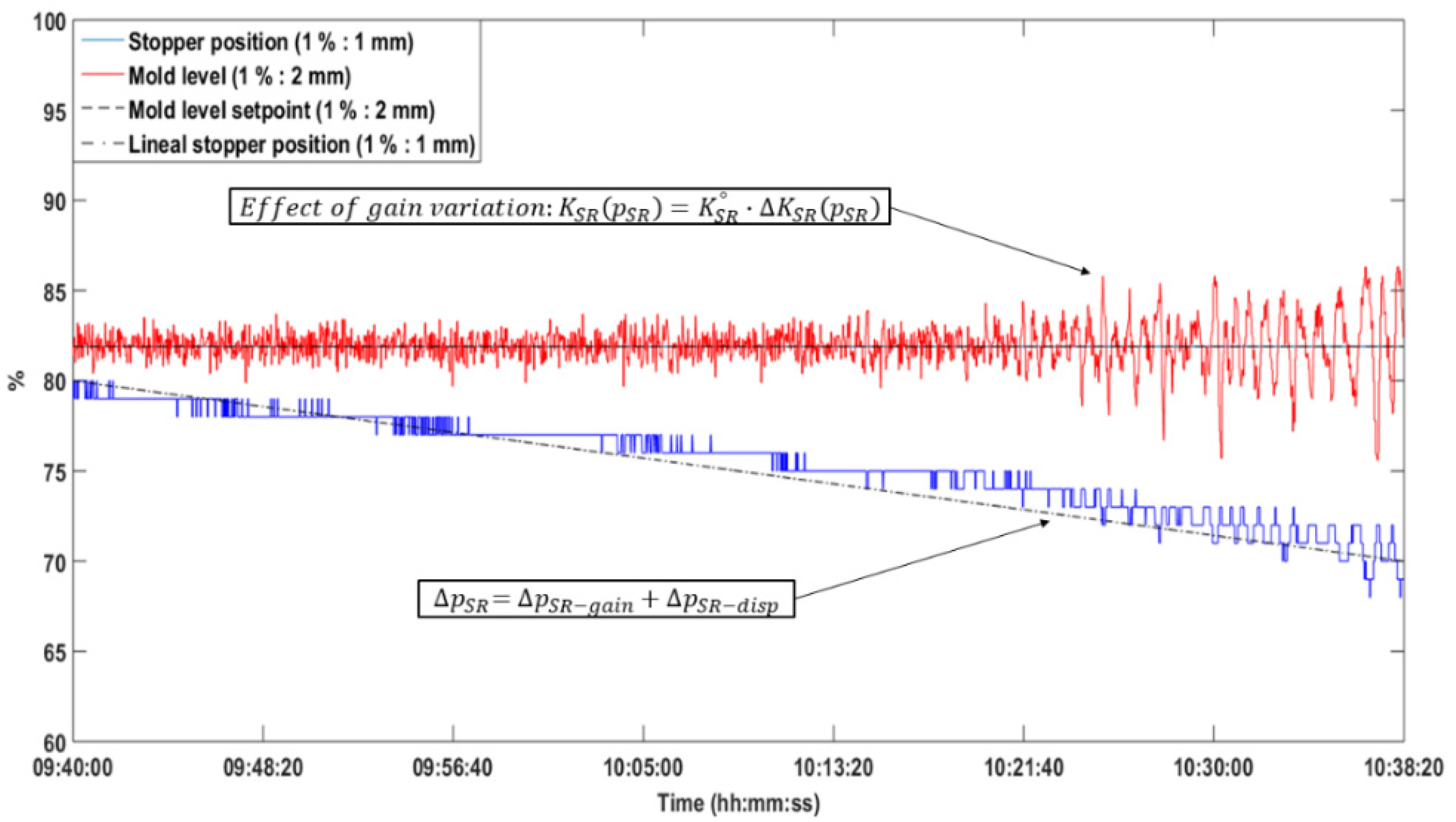

- Problem statement:

- (2)

- System requirements:

- (3)

- Selection of ANN model:

- (4)

- Data available and selection of relevant inputs and output variables:

- (5)

- Selection of training, test and check data sets:

- (6)

- Data pre-processing:

- (7)

- Training process:

- (8)

- Use the model and evaluate its results:

5. Results and Discussion

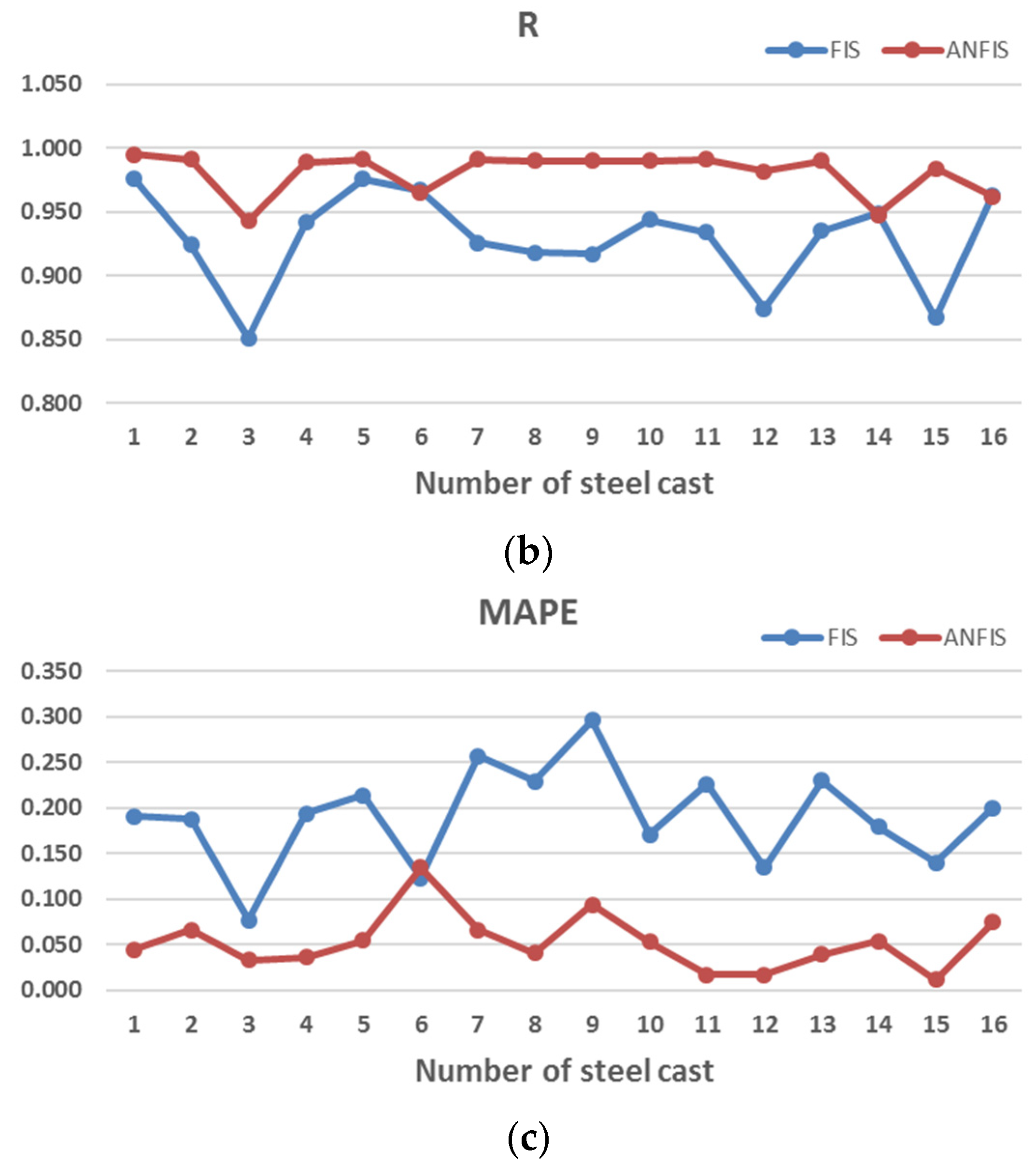

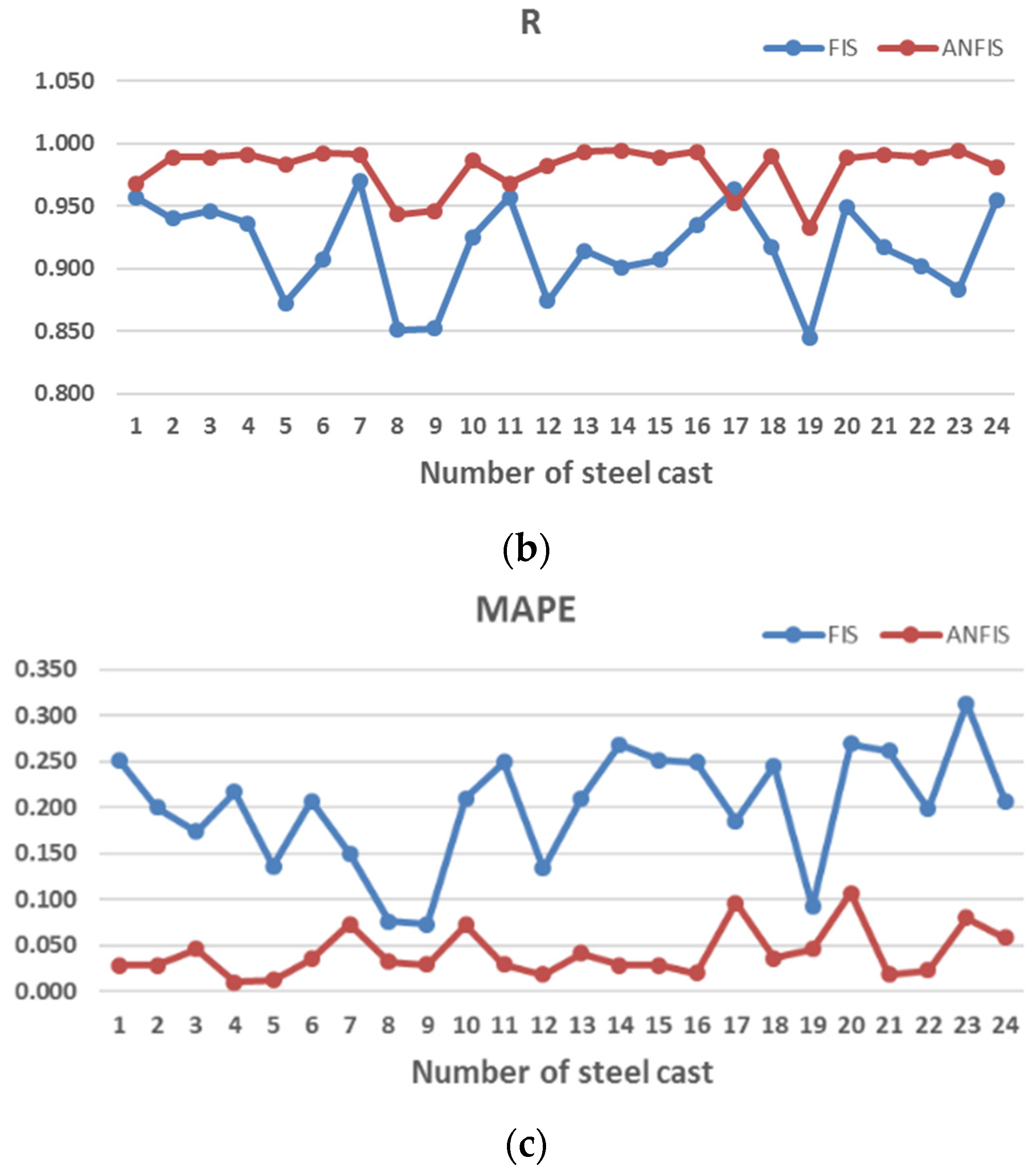

5.1. ANFIS Model Generation

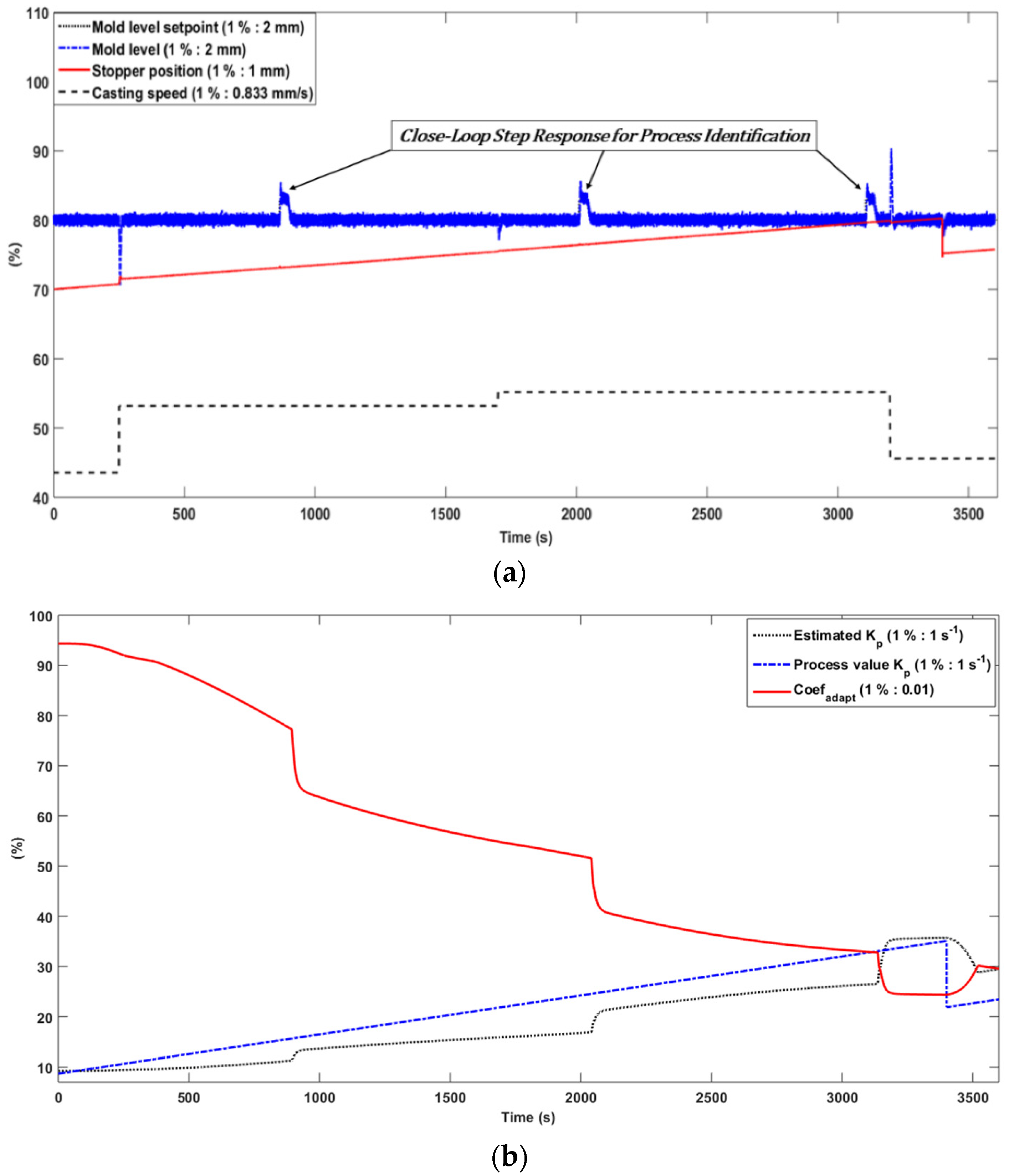

5.2. Use of the ANFIS Model

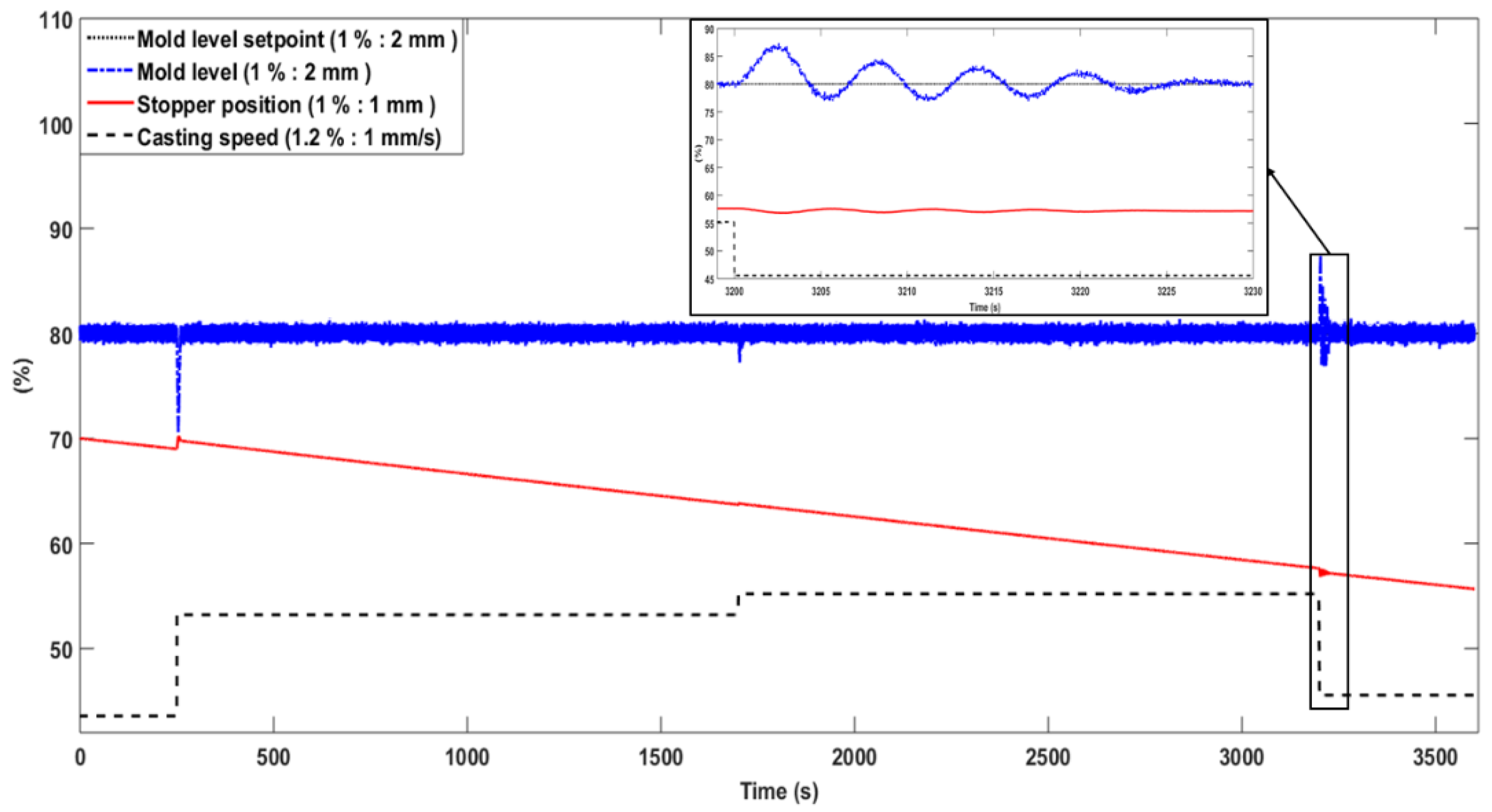

5.3. Neuro-Fuzzy Adaptive Mold Level Control Simulation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vynnycky, M. Continuous Casting. Metals 2019, 9, 643. [Google Scholar] [CrossRef]

- Yero, G.G.; Mendoza, M.R.; Albertos, P. Robust nonlinear adaptive mould level control for steel continuous casting. IFAC-PapersOnLine 2018, 51, 164–170. [Google Scholar] [CrossRef]

- Thomas, B.G. Review on modeling and simulation of continuous casting. Steel Res. Int. 2018, 89, 1700312. [Google Scholar] [CrossRef]

- Jabri, K. Etude et Amélioration des Performances et de la Robustesse des lois de Commande de Procédés Sidérurgiques Application à la Régulation de Niveau en Coulée Continue. Ph.D. Thesis, Université Paris Sud-Paris XI, Orsay, France, 2010. [Google Scholar]

- Yero, G.G. Modelado y Control de Nivel en un Molde de Vaciado Continuo. Ph.D. Thesis, Universidad de Oriente, Santiago de Cuba, Cuba, 2017. [Google Scholar]

- Thomas, B.; Yuan, Q.; Zhao, B.; Vanka, S.P. Transient fluid-flow phenomena in the continuous steel-slab casting mold and defect formation. JOM-e 2006, 58, 16–36. [Google Scholar] [CrossRef]

- Thomas, B.G. Fluid flow in the mold. Chapter 2003, 14, 14.1–14.41. [Google Scholar]

- Camisani-Calzolari, F.; Craig, I.; Pistorius, P. A review on causes of surface defects in continuous casting. IFAC Proc. Vol. 2003, 36, 113–121. [Google Scholar] [CrossRef]

- Thomas, B.G. On-line detection of quality problems in continuous casting of steel. In Modeling, Control and Optimization in Ferrous and Nonferrous Industry, Proceedings of the 2003 Materials Science and Technology Symposium, Chicago, IL, USA, 10–12 November 2003; TMS: Warrendale, PA, USA, 2003; pp. 29–45. [Google Scholar]

- Bergman, L. Measurement Prediction and Control of Steel Flows in the Casting Nozzle and Mould. Master’s Thesis, Lulea University of Technology, Luleå, Sweden, 2006. [Google Scholar]

- Kim, S.; Kim, J.; Kim, J.; Kim, J. Continuous Casting Technologies of Stainless Steel at POSCO Stainless Steelmaking Plant. In AISTech 2007 Proceedings; AIST: Warrendale, PA, USA, 2007; Volume 1, Available online: https://www.tib.eu/en/search/id/tema%3ATEMA20070803165/Continuous-casting-technologies-of-stainless-steel/ (accessed on 18 July 2020).

- Popa, E.M.; Kiss, I. Assessment of surface defects in the continuously cast steel. Acta Tech. Corviniensis-Bull. Eng. 2011, 4, 109. [Google Scholar]

- Zhang, H.; Wang, W. Mold simulator study of the initial solidification of molten steel in continuous casting mold: Part II. Effects of mold oscillation and mold level fluctuation. Metall. Mater. Trans. B 2016, 47, 920–931. [Google Scholar] [CrossRef]

- De Keyser, R. Improved mould-level control in a continuous steel casting line. Control Eng. Pract. 1997, 5, 231–237. [Google Scholar] [CrossRef]

- Schuurmans, J.; Kamperman, A.; Middel, B.; van den Bosch, P. Robust mould level control. In Proceedings of the 2005, American Control Conference, Portland, OR, USA, 8–10 June 2005; pp. 2040–2045. [Google Scholar]

- Smutný, L.; Farana, R.; Víteĉek, A.; Kaĉmář, D. Mould Level Control for the Continuous Steel Casting. IFAC Proc. Vol. 2005, 38, 163–168. [Google Scholar] [CrossRef]

- Åström, K.J.; Wittenmark, B. Adaptive Control, 2nd ed.; Dover Publications Inc.: Mineola, NY, USA, 2013. [Google Scholar]

- Jang, J.-S. ANFIS: Adaptive-network-based fuzzy inference system. IEEE Trans. Syst. Man Cybern. 1993, 23, 665–685. [Google Scholar] [CrossRef]

- Karaboga, D.; Kaya, E. Adaptive network based fuzzy inference system (ANFIS) training approaches: A comprehensive survey. Artif. Intell. Rev. 2019, 52, 2263–2293. [Google Scholar] [CrossRef]

- Ghosh, I.; Chakraborty, N. An Artificial Neural Network Model for the Comprehensive Study of the Solidification Defects During the Continuous Casting of Steel. Comput. Commun. Collab. 2018, 6, 1–14. [Google Scholar]

- He, F.; Zhang, L. Mold breakout prediction in slab continuous casting based on combined method of GA-BP neural network and logic rules. Int. J. Adv. Manuf. Technol. 2018, 95, 4081–4089. [Google Scholar] [CrossRef]

- Abouelazayem, S.; Glavinić, I.; Wondrak, T.; Hlava, J. Adaptive Control of Meniscus Velocity in Continuous Caster based on NARX Neural Network Model. IFAC-PapersOnLine 2019, 52, 222–227. [Google Scholar] [CrossRef]

- Song, G.W.; Tama, B.A.; Park, J.; Hwang, J.Y.; Bang, J.; Park, S.J.; Lee, S. Temperature Control Optimization in a Steel-Making Continuous Casting Process Using a Multimodal Deep Learning Approach. Steel Res. Int. 2019, 90, 1900321. [Google Scholar] [CrossRef]

- Zou, L.; Zhang, J.; Liu, Q.; Zeng, F.; Chen, J.; Guan, M. Prediction of central carbon segregation in continuous casting billet using a regularized extreme learning machine model. Metals 2019, 9, 1312. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Li, X.; Xie, Z.; Liu, R.; Liu, W.; Zhang, Y.; Xu, Y.; Liu, C. Prediction and Analysis of Tensile Properties of Austenitic Stainless Steel Using Artificial Neural Network. Metals 2020, 10, 234. [Google Scholar] [CrossRef]

- Furtmüller, C.; Colaneri, P.; Del Re, L. Adaptive robust stabilization of continuous casting. Automatica 2012, 48, 225–232. [Google Scholar] [CrossRef]

- Cedillo, V.; Morales, R. Biased flows in slab moulds induced by slide gates. Part I: Experimental measurements and flow simulation. Ironmak. Steelmak. 2018, 45, 204–214. [Google Scholar] [CrossRef]

- Shen, P.; Li, H.-X. The consistency control of mold level in casting process. Control Eng. Pract. 2017, 62, 70–78. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, M.; Chen, X.; Chen, L.; Du, S. A Fuzzy PID Controller with Nonlinear Compensation Term for Mold Level of Continuous Casting Process. Inf. Sci. 2020, 539, 487–503. [Google Scholar] [CrossRef]

- Del Brío, B.M.; Molina, A.S. Redes Neuronales y Sistemas Difusos, 3rd ed.; Alfaomega Ra-Ma: Madrid, Spain, 2006. [Google Scholar]

- Liu, T.; Gao, F. Industrial Process Identification and Control Design: Step-Test and Relay-Experiment-Based Methods; Springer Science & Business Media: London, UK, 2011. [Google Scholar]

- MathWorks Fuzzy Logic Toolbox Documentation. Available online: https://www.mathworks.com/help/fuzzy/fuzzy.html (accessed on 18 July 2020).

- Su, W.; Lei, Z.; Yang, L.; Hu, Q. Mold-level prediction for continuous casting using VMD–SVR. Metals 2019, 9, 458. [Google Scholar] [CrossRef]

| Symbol | Definition | Symbol | Definition |

|---|---|---|---|

| Cross section of the mold | Estimated multiplicative uncertainty of the stopper gain | ||

| Stopper flow area | Maximum of the estimated multiplicative uncertainty of the stopper gain | ||

| Output of the external controller | Value of the tundish level | ||

| Output of the adaptive external controller | Nominal value of the tundish level | ||

| Input variable: changes of the stopper | Tundish level | ||

| Maximum of the input variable: changes of the stopper | Minimum of the tundish level | ||

| Normalized input variable: changes of the stopper | Maximum of the tundish level | ||

| Cl | Clogging | M | Medium |

| ClH | High clogging | Mean absolute percentage error | |

| Coefficient for compensating the stopper gain variations | mf | Membership functions | |

| Coefficient for compensating the tundish gain variations | MH | Medium High | |

| Adaptation coefficient | Robustness metric: maximum sensitivity | ||

| E | Erosion | N | Normal |

| EH | High Erosion | Nom | Nominal |

| Acceleration of gravity | Total number of time instant | ||

| Input variable: gain of the stopper | Linear Time Invariant model | ||

| Minimum of the input variable: gain of the stopper | Stopper position | ||

| Maximum of the input variable: gain of the stopper | Vector with two variable parameters within a region Ω | ||

| Normalized input variable: gain of the stopper | Variation of the stopper position | ||

| H | High | Trend of linear displacement of the stopper operating area | |

| Mold level | Displacement of the stopper operating area by the valve gain increase | ||

| Mold level setpoint | Tundish outflow | ||

| Offset of mold level setpoint | Inlet flow | ||

| Mold level measurement | Outflow | ||

| Total number of data | Correlation coefficient | ||

| Tundish gain | Root mean squared error | ||

| Plant gain | Mean average value of | ||

| Mold gain | Time | ||

| Stopper gain | Time instant | ||

| Nominal stopper gain | Time constant | ||

| Mean stopper gain | Time delay | ||

| Minimum of the stopper gain | Nozzle delay | ||

| Maximum of the stopper gain | Relative time | ||

| Estimated stopper gain | Casting speed | ||

| Last identification of the stopper gain | Variation of the casting speed | ||

| Multiplicative uncertainty of the stopper gain | VH | Very High |

| Disturbance | Classification | Slab | Billet | Bloom |

|---|---|---|---|---|

| Bulging | Periodic | x | ||

| Standing waves | Periodic | x | ||

| Biased flows | Periodic | x | ||

| Stopper oscillations | Periodic | x | x | x |

| Unbalanced rolls | Periodic | x | x | x |

| Mold oscillations | Periodic | x | x | x |

| Argon gas injection | Periodic | x | x | x |

| Recirculation in mold | Periodic | x | x | x |

| Level sensor noise | Periodic | x | x | x |

| Valve clogging | Slow | x | x | x |

| Valve erosion | Slow | x | x | x |

| Changes of tundish level | Slow | x | x | x |

| Unclogging | Sudden | x | x | x |

| Sudden changes of casting speed | Sudden | x | x | x |

| Model Training | Epochs | Method | Simulation Time (hh:mm:ss) | Training Error (%) | Test Error (%) | Check Error (%) | Observations |

|---|---|---|---|---|---|---|---|

| 1 | 10 | Hybrid | 0:06:59 | 3.6 | 3.9 | 6.1 | Consequents out of ranges |

| 2 | 10 | Backpropagation | 0:06:51 | 5.2 | 5.4 | 6.8 | Well |

| 3 | 20 | Hybrid | 0:13:52 | 3.5 | 3.7 | 6.3 | Consequents out of ranges |

| 4 | 20 | Backpropagation | 0:13:42 | 4.2 | 4.4 | 5.9 | Well |

| 5 | 30 | Hybrid | 0:20:47 | 3.3 | 3.6 | 6.2 | Consequents out of ranges |

| 6 | 30 | Backpropagation | 0:20:33 | 3.8 | 4 | 5.4 | Well |

| 7 | 40 | Hybrid | 0:27:24 | 2.9 | 3.8 | 7.2 | Consequents out of ranges |

| 8 | 40 | Backpropagation | 0:27:23 | 3.2 | 3.5 | 5 | Well |

| 9 | 50 | Hybrid | 0:34:23 | 2.7 | 3.6 | 9 | Consequents out of ranges |

| 10 | 50 | Backpropagation | 0:34:14 | 2.9 | 3.3 | 4.9 | Well |

| Coef-SR | Changes-SR | |||||

|---|---|---|---|---|---|---|

| EH | E | N | Cl | ClH | ||

| Gain-SR | Nominal | - | 0.5494 | 0.9664 | 0.4821 | - |

| M | 0.265 | 0.4185 | 0.746 | 0.4089 | 0.2877 | |

| MH | 0.2553 | 0.2739 | 0.956 | 0.2832 | 0.2779 | |

| H | 0.2091 | 0.2209 | - | 0.22 | 0.2271 | |

| VH | 0.1655 | - | - | - | 0.1737 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

González-Yero, G.; Ramírez Leyva, R.; Ramírez Mendoza, M.; Albertos, P.; Crespo-Lorente, A.; Reyes Alonso, J.M. Neuro-Fuzzy System for Compensating Slow Disturbances in Adaptive Mold Level Control. Metals 2021, 11, 56. https://doi.org/10.3390/met11010056

González-Yero G, Ramírez Leyva R, Ramírez Mendoza M, Albertos P, Crespo-Lorente A, Reyes Alonso JM. Neuro-Fuzzy System for Compensating Slow Disturbances in Adaptive Mold Level Control. Metals. 2021; 11(1):56. https://doi.org/10.3390/met11010056

Chicago/Turabian StyleGonzález-Yero, Guillermo, Reynier Ramírez Leyva, Mercedes Ramírez Mendoza, Pedro Albertos, Alfons Crespo-Lorente, and Juan Manuel Reyes Alonso. 2021. "Neuro-Fuzzy System for Compensating Slow Disturbances in Adaptive Mold Level Control" Metals 11, no. 1: 56. https://doi.org/10.3390/met11010056

APA StyleGonzález-Yero, G., Ramírez Leyva, R., Ramírez Mendoza, M., Albertos, P., Crespo-Lorente, A., & Reyes Alonso, J. M. (2021). Neuro-Fuzzy System for Compensating Slow Disturbances in Adaptive Mold Level Control. Metals, 11(1), 56. https://doi.org/10.3390/met11010056