Mechanical Properties and Microstructural Aspects of Two High-Manganese Steels with TWIP/TRIP Effects: A Comparative Study

Abstract

1. Introduction

2. Materials and Methods

3. Results

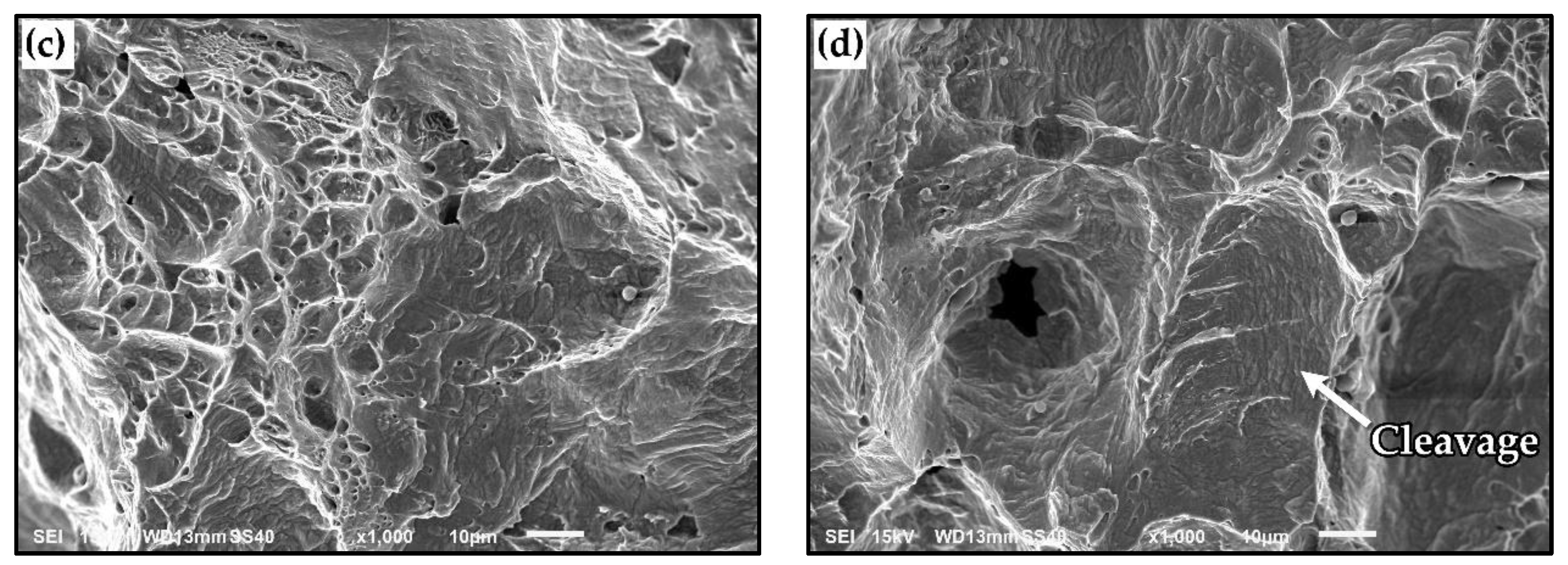

3.1. Chemical Compositions and SFE

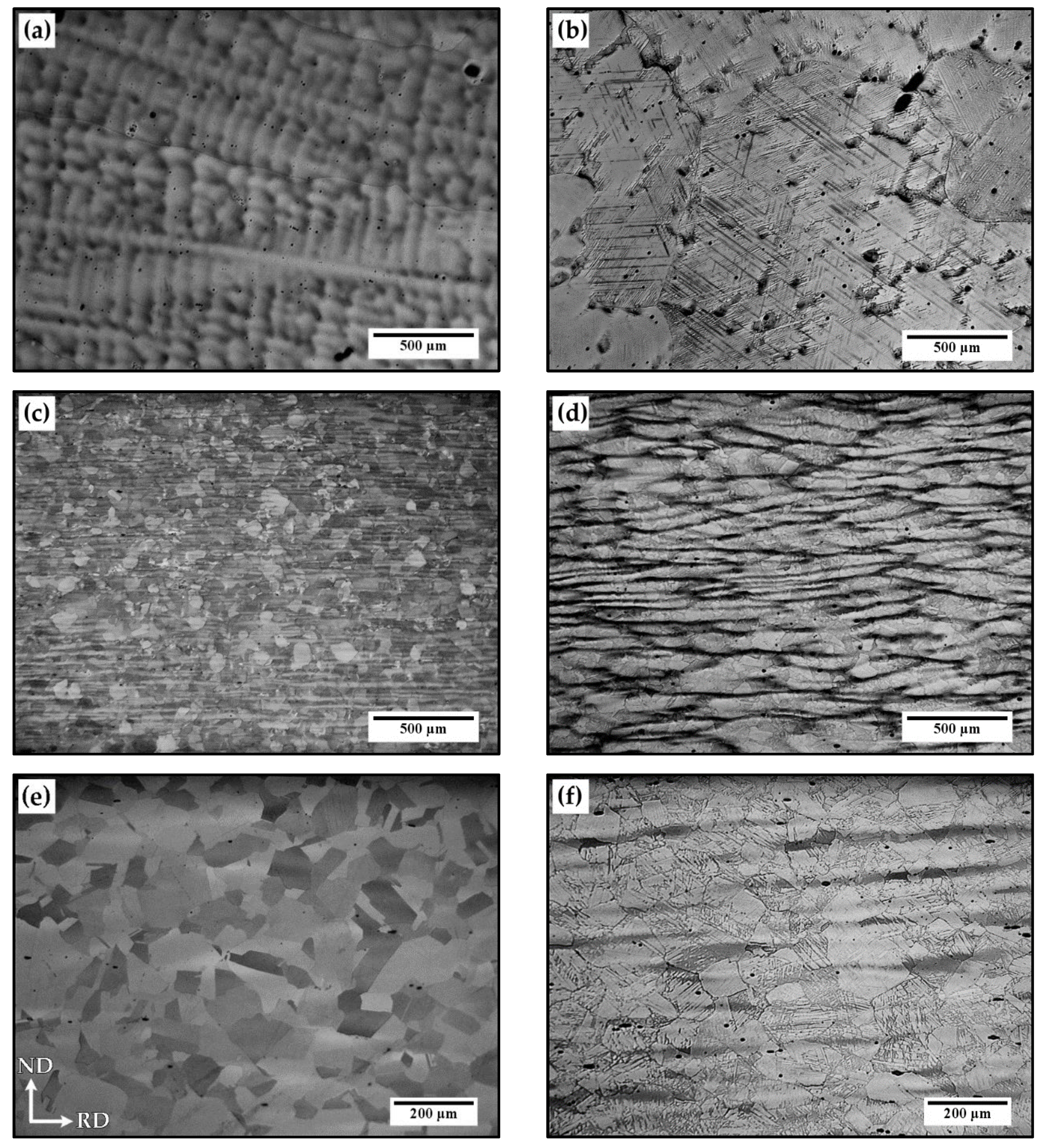

3.2. Initial Microstructural Characterization

3.3. Mechanical Characterization

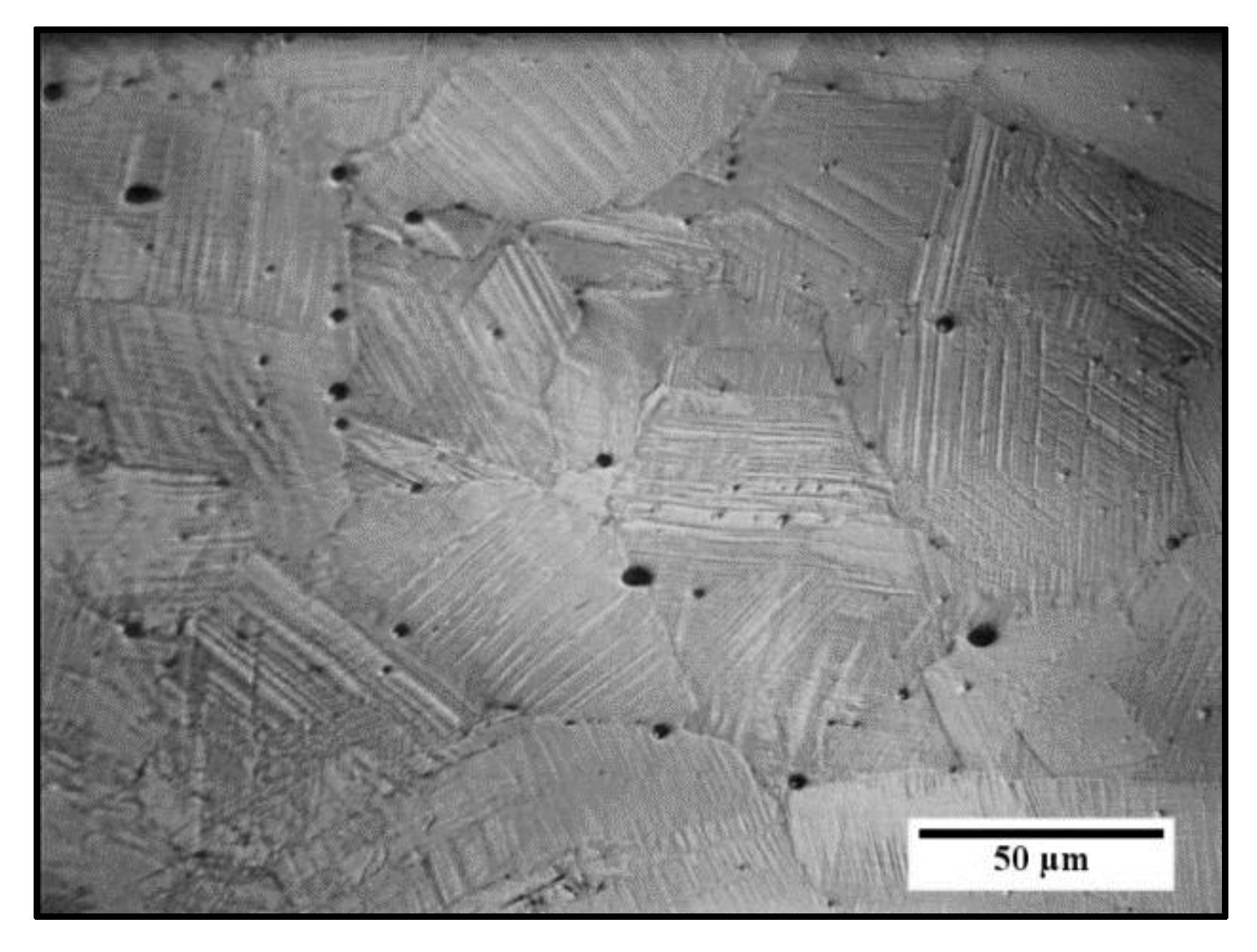

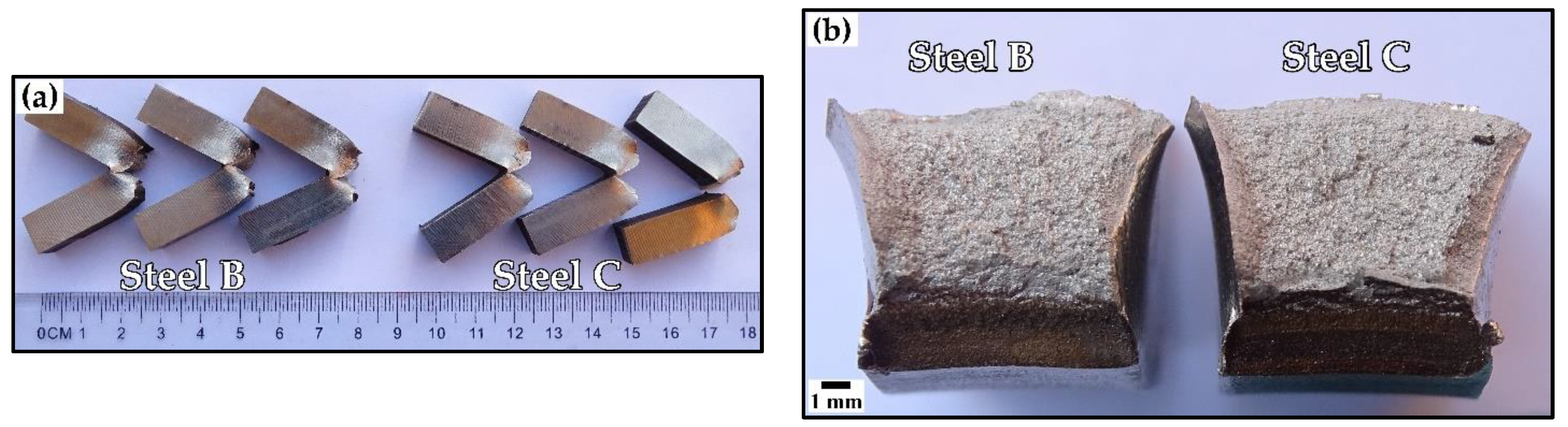

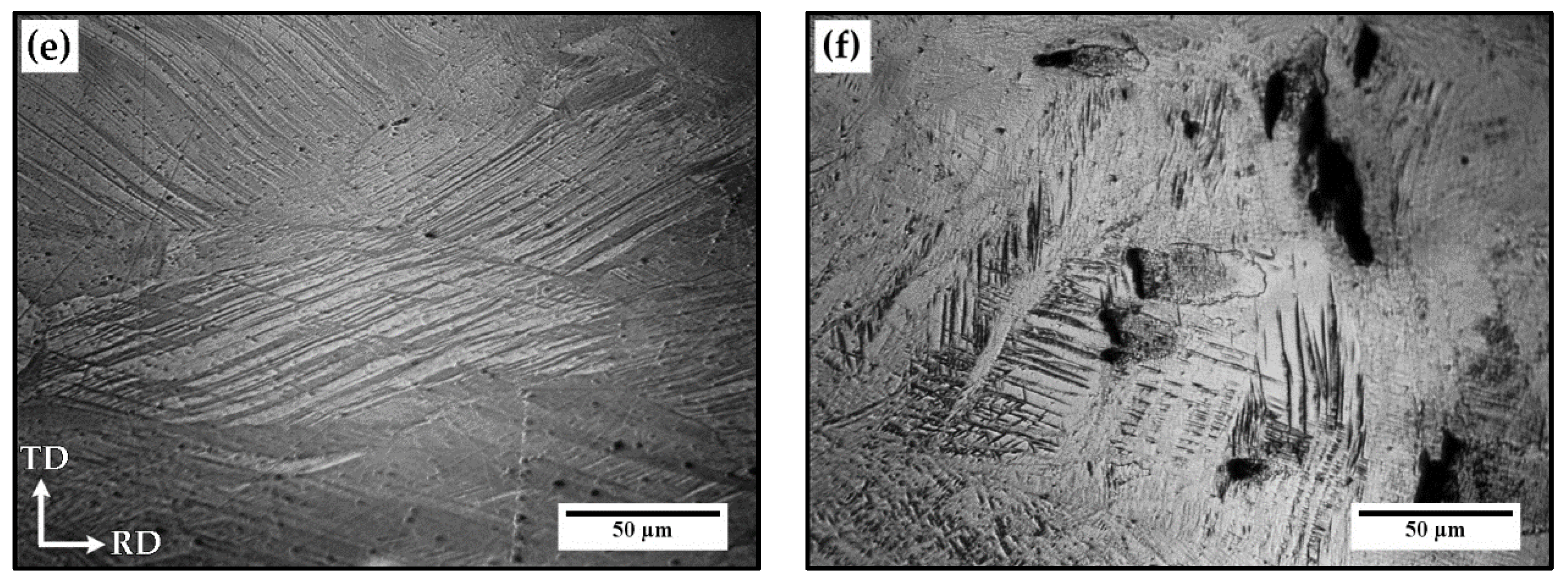

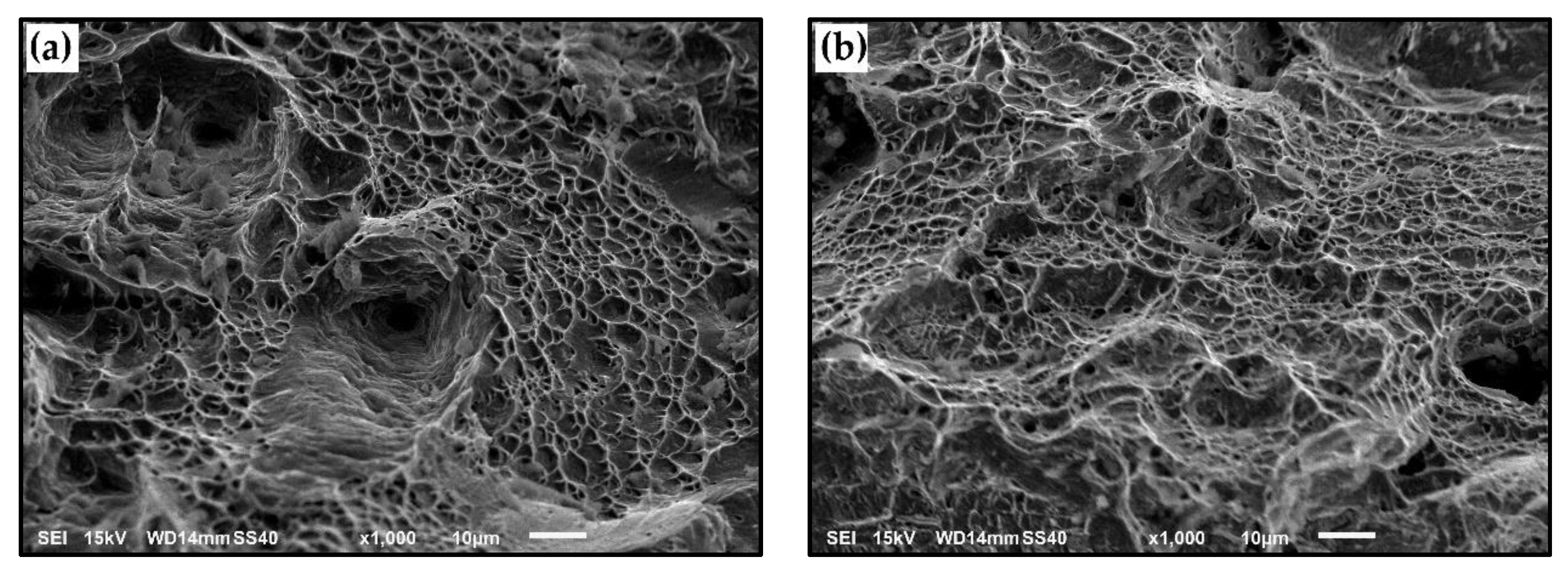

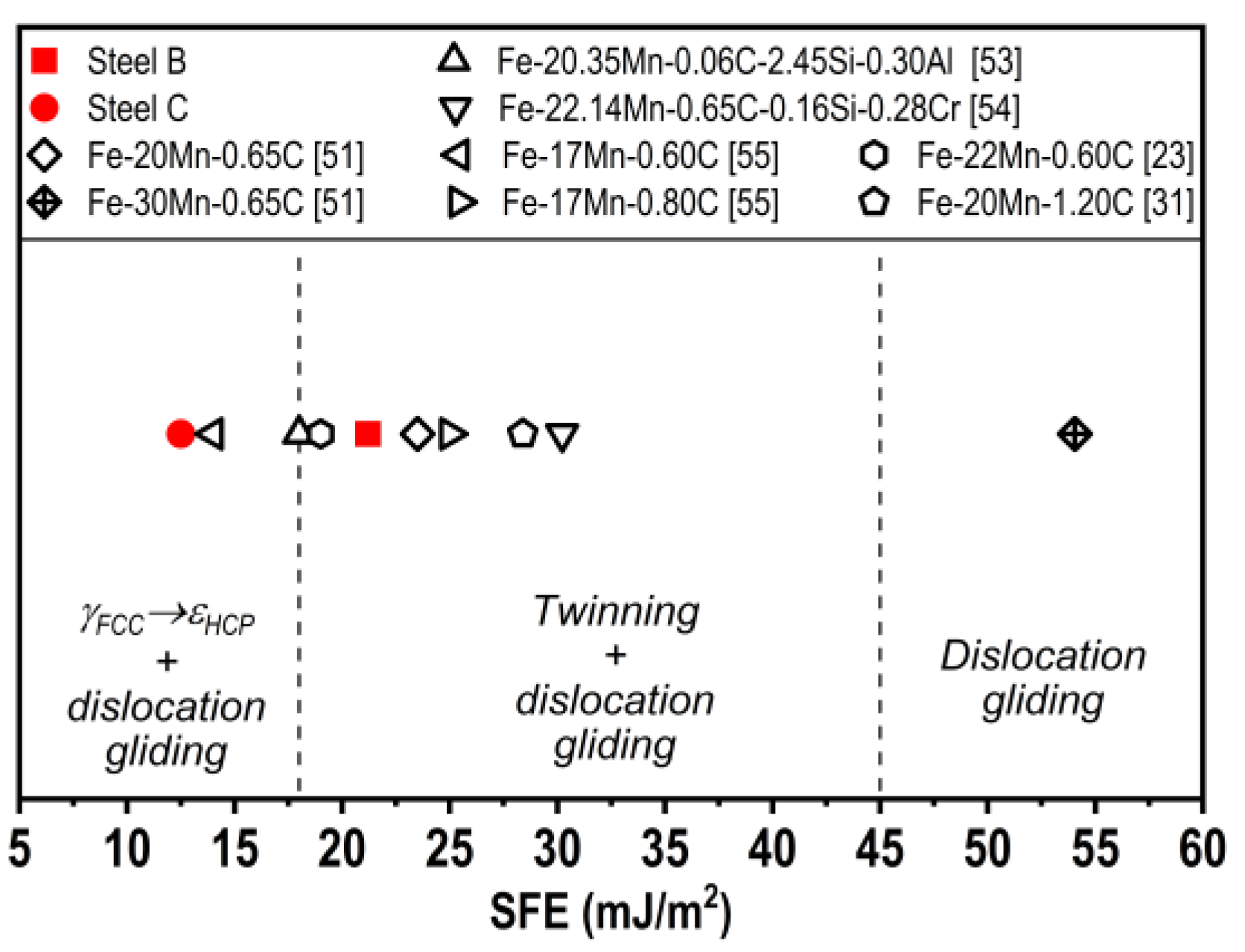

3.4. Fractography

3.5. XRD Analysis

4. Discussion

4.1. SFE, Chemical Compositions and Initial Microstructure

4.2. Mechanical Properties and Their Relationship with Hardening Mechanisms

4.3. Fracture Behavior, Damage Mechanisms and Microstructural Changes under Plastic Deformation

5. Conclusions

- XRD analysis revealed the presence of 100% austenite in Steel B both before and after the tensile tests until fracture. Instead, in Steel C, an increment from 0.45 to 0.69 in ε-martensite volume fraction was determined.

- Steel B clearly presented better performance in tensile and impact tests than Steel C (ultimate tensile strength, 0.2% offset yield stress, elongation to fracture and absorbed energy).

- Normalized strain-hardening rate, (dσt/dεpt)/G, was considerably higher in Steel C at low deformation values due to dislocation glide, continuously decreasing up to fracture. From plastic true strains ≈0.20, Steel B presented higher values (dσt/dεpt)/G than Steel C. These behaviors are the consequence of the operating secondary hardening mechanisms in each alloy (mechanical twinning in Steel B and strain-induced γFCC→εHCP transformation in Steel C).

- Serrated flow related to DSA was observed from plastic true strains of ≈0.025 and ≈0.15 for Steel B and Steel C, respectively.

- The foremost microstructural difference revealed in tensile specimens is the presence of dispersed tiny cracks in the Steel C matrix and close to the fracture surface that could be related to ε-martensite platelets associated with the TRIP effect.

- Typical dimpled fracture surfaces were observed in both alloys under quasi-static loading applied in tensile tests. Under impact load, Steel B fractured in a ductile manner, although a quasi-cleavage mode was observed in Steel C. Isolated cleavage facets connected with the TRIP effect could be the reason for a slight reduction in impact toughness of this alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fonstein, N. Advanced High Strength Sheet Steels; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Rana, R.; Singh, S.B. Automotive Steels: Design, Metallurgy, Processing and Applications; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Chiaberge, M. New Trends and Developments in Automotive System Engineering; IntechOpen: Rijeka, Croatia, 2011. [Google Scholar]

- Rowe, J. Advanced Materials in Automotive Engineering; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Badeshia, H.; Honeycombe, R. Steels. Microstructure and Properties, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Frommeyer, G.; Brüx, U.; Neumann, P. Supra-Ductile and High-Strength Manganese-TRIP/TWIP Steels for High Energy Absorption Purposes. ISIJ Int. 2003, 43, 438–446. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Chin, K.; Kim, J. High Mn TWIP Steels for Automotive Applications. In New Trends and Developments in Automotive System Engineering; InTech: Rijeka, Croatia, 2011. [Google Scholar]

- Remy, L. Kinetics of f.c.c. deformation twinning and its relationship to stress-strain behaviour. Acta Metall. 1978, 26, 443–451. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Findley, K. Introduction to the Mechanical Behavior of Steel; Association for Iron & Steel Technology (AIST): Warrendale, PA, USA, 2018. [Google Scholar]

- Bouaziz, O.; Allain, S.; Scott, C.P. Effect of grain and twin boundaries on the hardening mechanisms of twinning-induced plasticity steels. Scr. Mater. 2008, 58, 484–487. [Google Scholar] [CrossRef]

- Kim, J.K.; Chen, L.; Kim, H.-S.; Kim, S.K.; Estrin, Y.; De Cooman, B.C. On the tensile behavior of high-manganese twinning-induced plasticity steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 3147–3158. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Kikuchi, T.; Kajiwara, S.; Tomota, Y. Microscopic studies on stress-induced martensite transformation and its reversion in an Fe-Mn-Si-Cr-Ni shape memory alloy. Mater. Trans. JIM 1995, 36, 719–728. [Google Scholar] [CrossRef]

- Bergeon, N.; Guenin, G.; Esnouf, C. Characterization of the stress-induced m martensite in a Fe-Mn-Si-Cr-Ni shape memory alloy: Microstructural observation at different scales, mechanism of formation and growth. Mater. Sci. Eng. A 1997, 238, 309–316. [Google Scholar] [CrossRef]

- Sahu, P.; Hamada, A.S.; Ghosh, R.N.; Karjalainen, L.P. X-ray diffraction study on cooling-rate-induced γ fcc → ε hcp martensitic transformation in cast-homogenized Fe-26Mn-0.14C austenitic steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2007, 38, 1991–2000. [Google Scholar] [CrossRef]

- Benzing, J.T.; Poling, W.A.; Pierce, D.T.; Bentley, J.; Findley, K.O.; Raabe, D.; Wittig, J.E. Effects of strain rate on mechanical properties and deformation behavior of an austenitic Fe-25Mn-3Al-3Si TWIP-TRIP steel. Mater. Sci. Eng. A 2018, 711, 78–92. [Google Scholar] [CrossRef]

- Hirth, J. Thermodynamics of Stacking Faults. Metall. Trans. 1970, 1, 2367–2374. [Google Scholar]

- Kelly, A.; Knowles, K. Crystallography and Crystal Defects; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; Volume 2. [Google Scholar]

- Pierce, D.T.; Bentley, J.; Jimenez, J.A.; Wittig, J.E. The Influence of Stacking-Fault Energy on Deformation Mechanisms in an Fe-Mn-Al-Si Austenitic TRIP/TWIP Steel. Acta Mater. 2012, 18, 1894–1895. [Google Scholar] [CrossRef]

- Pierce, D.T.; Jiménez, J.A.; Bentley, J.; Raabe, D.; Wittig, J.E. The influence of stacking fault energy on the microstructural and strain-hardening evolution of Fe-Mn-Al-Si steels during tensile deformation. Acta Mater. 2015, 100, 178–190. [Google Scholar] [CrossRef]

- Bouaziz, O.; Zurob, H.; Chehab, B.; Embury, J.D.; Allain, S.; Huang, M. Effect of chemical composition on work hardening of Fe-Mn-C TWIP steels. Mater. Sci. Technol. 2011, 27, 707–709. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 2010, 58, 5129–5141. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe-Mn-C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, X.H.; Shu, K.Y. Microstructure and Mechanical Properties of Hot-Rolled Fe-Mn-C-Si TWIP Steel. J. Iron Steel Res. Int. 2011, 18, 45–48. [Google Scholar] [CrossRef]

- Kim, J.K.; De Cooman, B.C. Stacking fault energy and deformation mechanisms in Fe-xMn-0.6C-yAl TWIP steel. Mater. Sci. Eng. A 2016, 676, 216–231. [Google Scholar] [CrossRef]

- Lee, S.; Lee, K.; De Cooman, B.C. Observation of the TWIP + TRIP Plasticity-Enhancement Mechanism in Al-Added 6 Wt Pct Medium Mn Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 46, 2356–2363. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Kwon, O.; Chin, K.-G. State-of-the-knowledge on TWIP steel. Mater. Sci. Technol. 2012, 28, 513–527. [Google Scholar] [CrossRef]

- Olson, G.; Cohen, M. A general mechanism of martensitic nucleation: Part I. General concepts and the FCC→ HCP transformation. Metall. Trans. A 1976, 7, 1897–1904. [Google Scholar]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Lee, T.; Koyama, M.; Tsuzaki, K.; Lee, Y.H.; Lee, C.S. Tensile deformation behavior of Fe-Mn-C TWIP steel with ultrafine elongated grain structure. Mater. Lett. 2012, 75, 169–171. [Google Scholar] [CrossRef]

- Zambrano, O.A. Stacking fault energy maps of Fe-Mn-Al-C-Si steels: Effect of temperature, grain size, and variations in compositions. J. Eng. Mater. Technol. 2016, 138, 041010. [Google Scholar] [CrossRef]

- Ishida, K. Direct estimation of stacking fault energy by thermodynamic analysis. Phys. Status Solidi 1976, 36, 717–728. [Google Scholar] [CrossRef]

- Wietbrock, B.; Bambach, M.; Seuren, S.; Hirt, G. Homogenization strategy and material characterization of high-manganese TRIP and TWIP steels. Mater. Sci. Forum 2010, 638, 3134–3139. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Imlau, J.; Prahl, U.; Bleck, W. Derivation and variation in composition-dependent stacking fault energy maps based on subregular solution model in high-manganese steels. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 3076–3090. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.T.; Oikari, A.; Talonen, J.; Hänninen, H. Thermodynamic modeling of the stacking fault energy of austenitic steels. Acta Mater. 2011, 59, 1068–1076. [Google Scholar] [CrossRef]

- Dumay, A.; Chateau, J.P.; Allain, S.; Migot, S.; Bouaziz, O. Influence of addition elements on the stacking-fault energy and mechanical properties of an austenitic Fe-Mn-C steel. Mater. Sci. Eng. A 2008, 483, 184–187. [Google Scholar] [CrossRef]

- Hillert, M.; Jarl, M. A model for alloying in ferromagnetic metals. Calphad 1978, 2, 227–238. [Google Scholar] [CrossRef]

- Li, L.; Hsu, T.Y.; Zuyao, X. Gibbs free energy evaluation of the fcc (γ) and hcp (ε) phases in Fe-Mn-Si alloys. Calphad 1997, 21, 443–448. [Google Scholar] [CrossRef]

- ASTM E18-20. Standard Test Methods for Rockwell Hardness of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM E8/E8M-16ae1. Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM E23-18. Standard Test Methods for Notched Bar Impact Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM E1823-13. Standard Terminology Relating to Fatigue and Fracture Testing; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM E384-17. Standard Test Method for Microindentation Hardness of Materials; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Lutterotti, L. Materials Analysis Using Diffraction (MAUD), Versión 2.93. Available online: http://nanoair.dii.unitn.it:8080/maud/ (accessed on 3 February 2020).

- Popa, N.C. The (hkl) dependence of diffraction-line broadening caused by strain and size for all Laue groups in Rietveld refinement. J. Appl. Crystallogr. 1998, 31, 176–180. [Google Scholar] [CrossRef]

- Warren, B.E. X-Ray Diffraction; Dover Publications, Inc.: New York, NY, USA, 1969. [Google Scholar]

- Dini, G.; Najafizadeh, A.; Monir-Vaghefi, S.M.; Ueji, R. Grain size effect on the martensite formation in a high-manganese TWIP steel by the Rietveld method. J. Mater. Sci. Technol. 2010, 26, 181–186. [Google Scholar] [CrossRef]

- ASTM E112-13. Standard Test Methods for Determining Average Grain Size; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Young, R.A. The Rietveld method. Phys. Scr. 1993, 6, 132–166. [Google Scholar]

- Balogh, L.; Ribárik, G.; Ungár, T. Stacking faults and twin boundaries in fcc crystals determined by x-ray diffraction profile analysis. J. Appl. Phys. 2006, 100, 023512. [Google Scholar] [CrossRef]

- Mazancová, E.; Mazanec, K. Stacking Fault Energy in High Manganese Alloys. Mater. Eng. 2009, 16, 26–31. [Google Scholar]

- Xiong, R.; Peng, H.; Si, H.; Zhang, W.; Wen, Y. Thermodynamic calculation of stacking fault energy of the Fe-Mn-Si-C high manganese steels. Mater. Sci. Eng. A 2014, 598, 376–386. [Google Scholar] [CrossRef]

- Tewary, N.K.; Ghosh, S.K.; Chakrabarti, D.; Chatterjee, S. Deformation behaviour of a low carbon high Mn TWIP/TRIP steel. Mater. Sci. Technol. 2019, 35, 1483–1496. [Google Scholar] [CrossRef]

- De Barbieri, F.; Cerda, F.C.; Pérez-Ipiña, J.; Artigas, A.; Monsalve, A. Temperature dependence of the microstructure and mechanical properties of a twinning-induced plasticity steel. Metals 2018, 8, 262. [Google Scholar] [CrossRef]

- Koyama, M.; Sawaguchi, T.; Lee, T.; Lee, C.S.; Tsuzaki, K. Work hardening associated with ɛ-martensitic transformation, deformation twinning and dynamic strain aging in Fe-17Mn-0.6 C and Fe-17Mn-0.8 C TWIP steels. Mater. Sci. Eng. A 2011, 528, 7310–7316. [Google Scholar] [CrossRef]

- Yang, H.S.; Jang, J.H.; Bhadeshia, H.K.D.H.; Suh, D.W. Critical assessment: Martensite-start temperature for the γ → ε transformation. Calphad Comput. Coupling Phase Diagr. Thermochem. 2012, 36, 16–22. [Google Scholar] [CrossRef]

- Sahu, P.; Hamada, A.S.; Ghosh Chowdhury, S.; Karjalainen, L.P. Structure and microstructure evolution during martensitic transformation in wrought Fe-26Mn-0.14C austenitic steel: An effect of cooling rate. J. Appl. Crystallogr. 2007, 40, 354–361. [Google Scholar] [CrossRef]

- Schumann, H. Martensitische umwandlungen in austenitischen mangan-kohlenstoff-stählen. Neue Hütte 1972, 17, 605–609. [Google Scholar]

- Chen, L.; Kim, H.-S.; Kim, S.-K. Localized Deformation due to Portevin–LeChatelier Effect in 18Mn–0.6C TWIP Austenitic Steel. ISIJ Int. 2007, 47, 1804–1812. [Google Scholar] [CrossRef]

- Yang, E.E. The Effect of Carbon Content on the Mechanical Properties and Microstructural Evolution of Fe-22Mn-C TWIP/TRIP Steels. Master’s Thesis, McMaster University, Hamilton, ON, Canada, 2010. [Google Scholar]

- Chun, Y.S.; Kim, J.S.; Park, K.T.; Lee, Y.K.; Lee, C.S. Role of ε martensite in tensile properties and hydrogen degradation of high-Mn steels. Mater. Sci. Eng. A 2012, 533, 87–95. [Google Scholar] [CrossRef]

- McGuire, M.F. Stainless Steels for Design Engineers; ASM International: Almere, The Netherlands, 2008; ISBN 9780871707178. [Google Scholar]

- Ghasri-Khouzani, M.; McDermid, J.R. Effect of carbon content on the mechanical properties and microstructural evolution of Fe-22Mn-C steels. Mater. Sci. Eng. A 2015, 621, 118–127. [Google Scholar] [CrossRef]

- Dastur, Y.N.; Leslie, W.C. Mechanism of Work Hardening in Hadfield Manganese Steel. Metall. Trans. A 1981, 12, 749–759. [Google Scholar] [CrossRef]

- Mills, W.J. Fracture toughness of type 304 and 316 stainless steels and their welds. Int. Mater. Rev. 1997, 42, 45–82. [Google Scholar] [CrossRef]

- Bracke, L.; Mertens, G.; Penning, J.; De Cooman, B.C.; Liebeherr, M.; Akdut, N. Influence of phase transformations on the mechanical properties of high-strength austenitic Fe-Mn-Cr steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2006, 37, 307–317. [Google Scholar] [CrossRef]

- Li, S.H.; Dan, W.J.; Zhang, W.G.; Lin, Z.Q. A model for strain-induced martensitic transformation of TRIP steel with pre-strain. Comput. Mater. Sci. 2007, 40, 292–299. [Google Scholar] [CrossRef]

| Steels | C | Mn | Si | Cr | P | S | Fe |

|---|---|---|---|---|---|---|---|

| Steel B | 0.54 | 20.69 | 0.19 | 0.13 | 0.021 | 0.001 | Bal. |

| Steel C | 0.28 | 21.18 | 0.20 | 0.14 | 0.022 | 0.001 | Bal. |

| Steels | SFE |

|---|---|

| (mJ/m2) | |

| Steel B | 21.2 |

| Steel C | 12.5 |

| Grain Size | Steel B | Steel C |

|---|---|---|

| G | 2–3 | 4–5 |

| (μm) | 179.6–127.0 | 89.8–63.5 |

| Steels | Hardness | σYS | σUTS | σYS/σUTS | εR (L0 = 50 mm) | (σUTS - σYS)t/εpt-UTS | Absorbed Energy |

|---|---|---|---|---|---|---|---|

| (HRB) | (MPa) | (MPa) | (%) | (MPa) | (J) | ||

| Steel B | 90.3 (1.2) | 356 (20) | 986 (16) | 0.36 (0.01) | 61.1 (2.8) | 2642 (32) | 255 (12) |

| Steel C | 90.8 (2.0) | 156 (4) | 877 (8) | 0.18 (0.00) | 35.4 (1.7) | 3480 (78) | 196 (4) |

| Steels | Microhardness (HV0.2) Condition | ||

|---|---|---|---|

| Thermo-Mechanical Processed Samples | Tensile Specimens | Charpy Specimens | |

| Steel B | 282 (16) | 733 (51) | 573 (61) |

| Steel C | 298 (12) | 690 (52) | 532 (49) |

| Steels | Condition | GoF | Volume Fraction |

|---|---|---|---|

| Steel B | Thermo-mechanical processed | 1.44 | γFCC |

| Tensile | 1.27 | γFCC | |

| Steel C | Thermo-mechanical processed | 1.86 | 0.55 γFCC/0.45 εHCP |

| Tensile | 1.30 | 0.31 γFCC/0.69 εHCP |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bordone, M.; Perez-Ipiña, J.; Bolmaro, R.; Artigas, A.; Monsalve, A. Mechanical Properties and Microstructural Aspects of Two High-Manganese Steels with TWIP/TRIP Effects: A Comparative Study. Metals 2021, 11, 24. https://doi.org/10.3390/met11010024

Bordone M, Perez-Ipiña J, Bolmaro R, Artigas A, Monsalve A. Mechanical Properties and Microstructural Aspects of Two High-Manganese Steels with TWIP/TRIP Effects: A Comparative Study. Metals. 2021; 11(1):24. https://doi.org/10.3390/met11010024

Chicago/Turabian StyleBordone, Matías, Juan Perez-Ipiña, Raúl Bolmaro, Alfredo Artigas, and Alberto Monsalve. 2021. "Mechanical Properties and Microstructural Aspects of Two High-Manganese Steels with TWIP/TRIP Effects: A Comparative Study" Metals 11, no. 1: 24. https://doi.org/10.3390/met11010024

APA StyleBordone, M., Perez-Ipiña, J., Bolmaro, R., Artigas, A., & Monsalve, A. (2021). Mechanical Properties and Microstructural Aspects of Two High-Manganese Steels with TWIP/TRIP Effects: A Comparative Study. Metals, 11(1), 24. https://doi.org/10.3390/met11010024