Stress Corrosion Cracking in an Extruded Cu-Free Al-Zn-Mg Alloy

Abstract

1. Introduction

2. Experimental

2.1. Materials

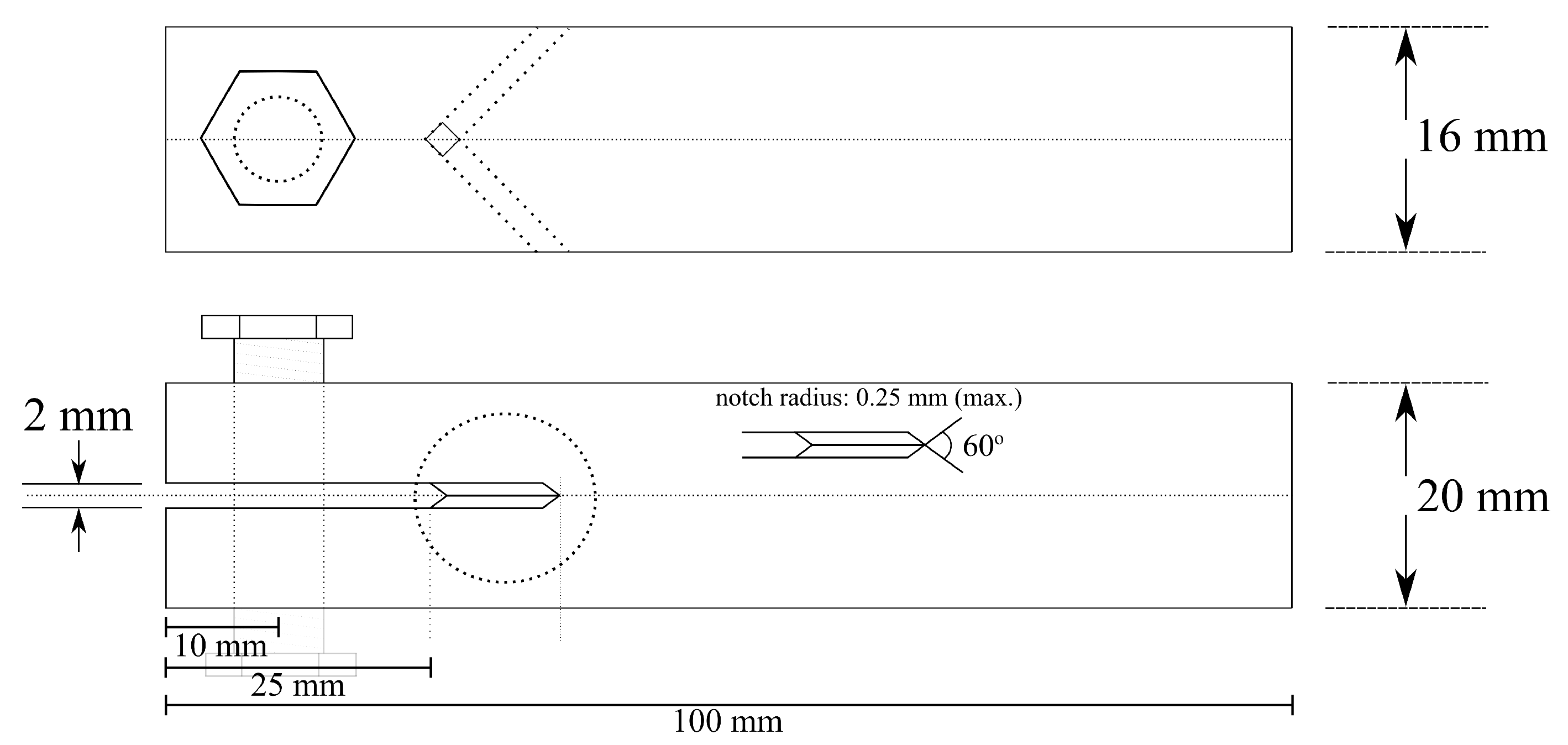

2.2. Double Cantilever Beam

2.3. Slow Strain Rate Testing

2.4. Potentiodynamic Polarisation

2.5. Electrical Conductivity

2.6. Electron Microscopy

3. Results

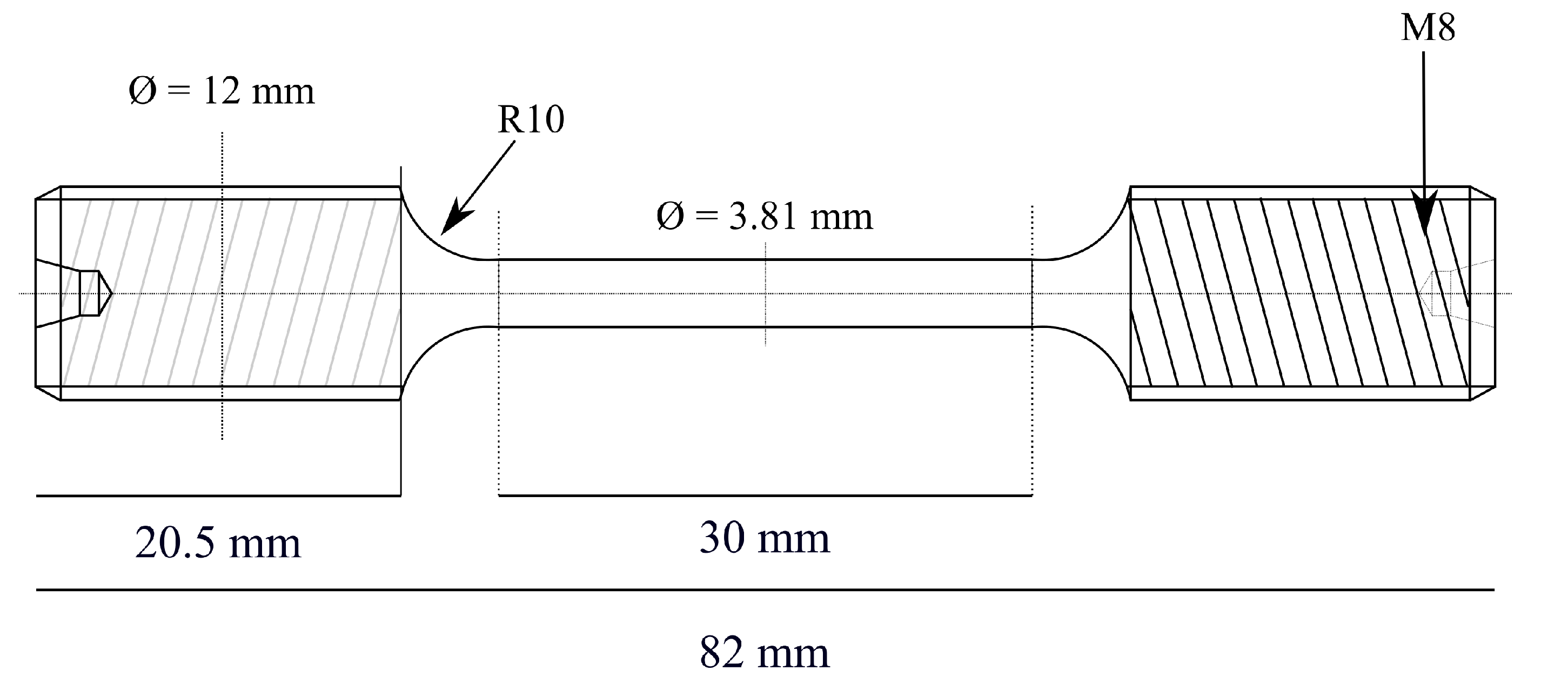

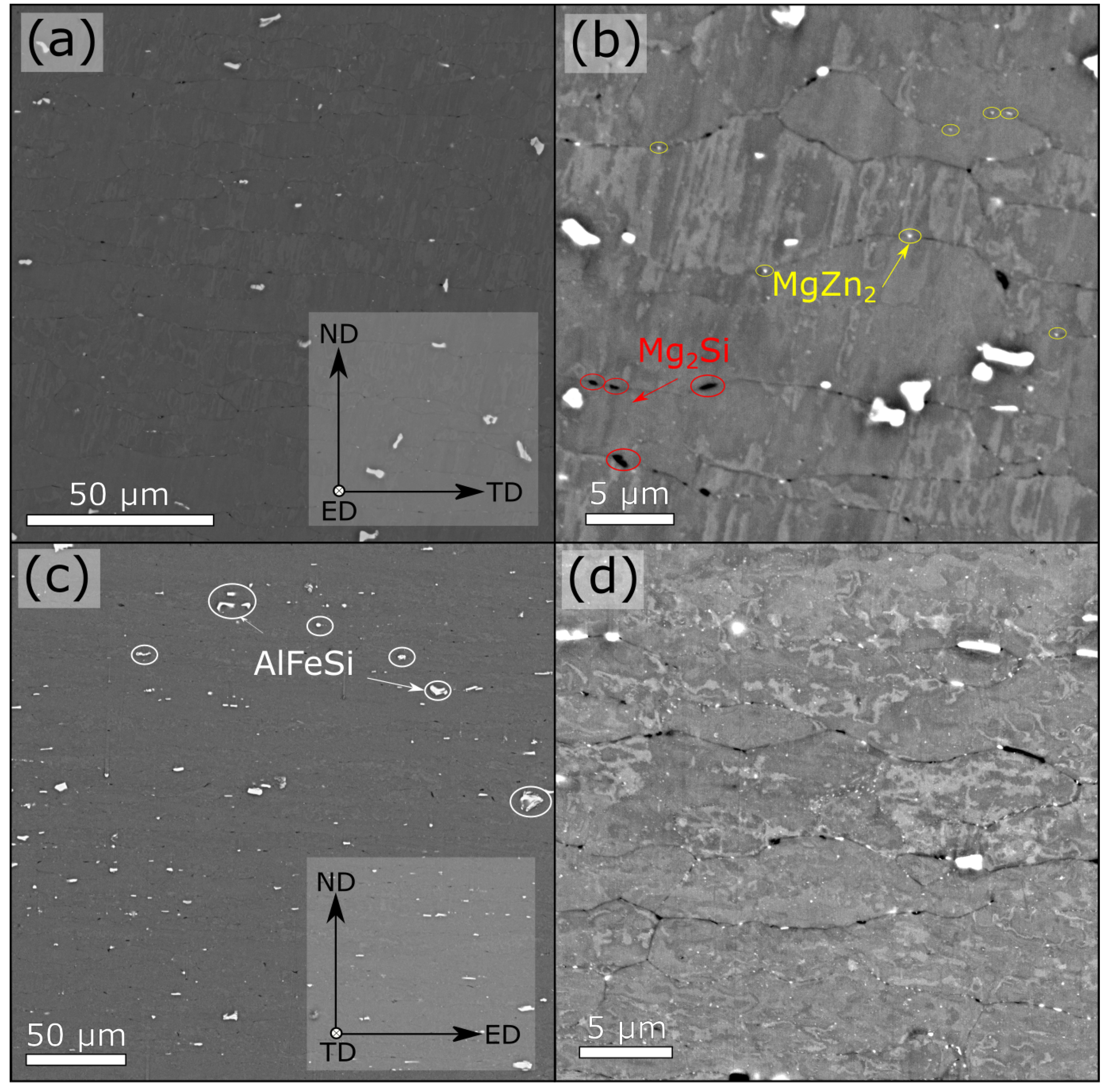

3.1. Microstructure

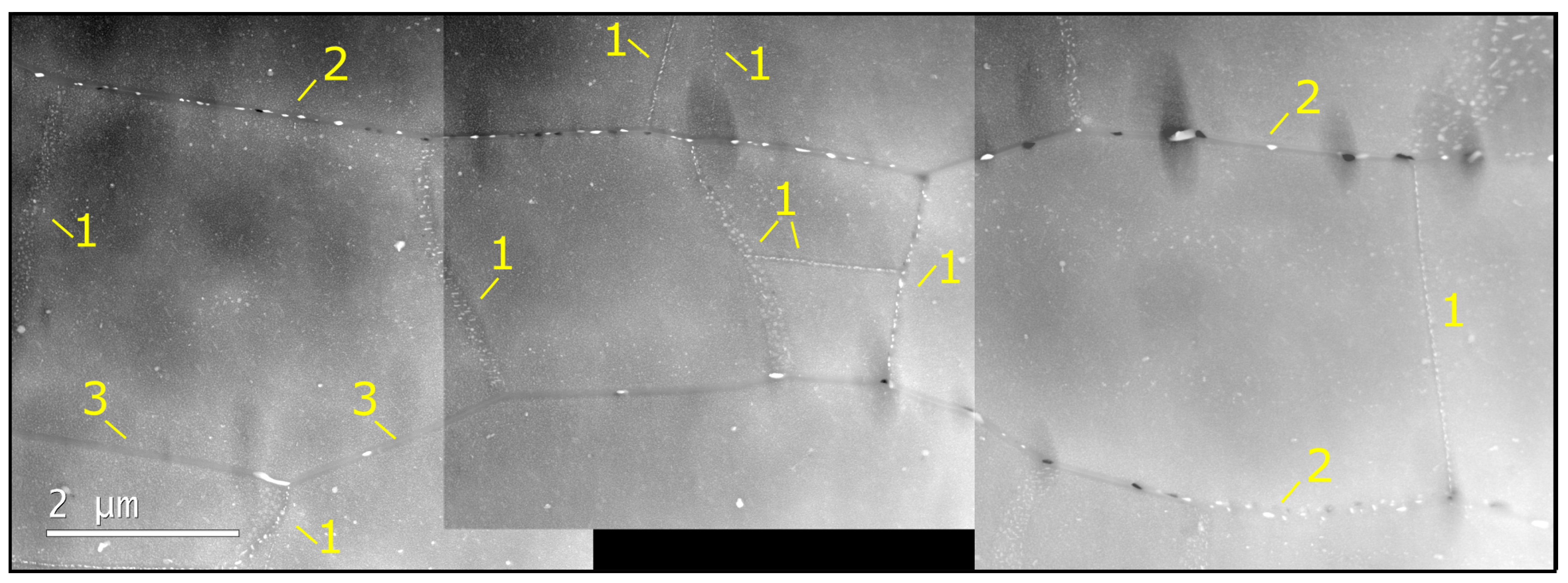

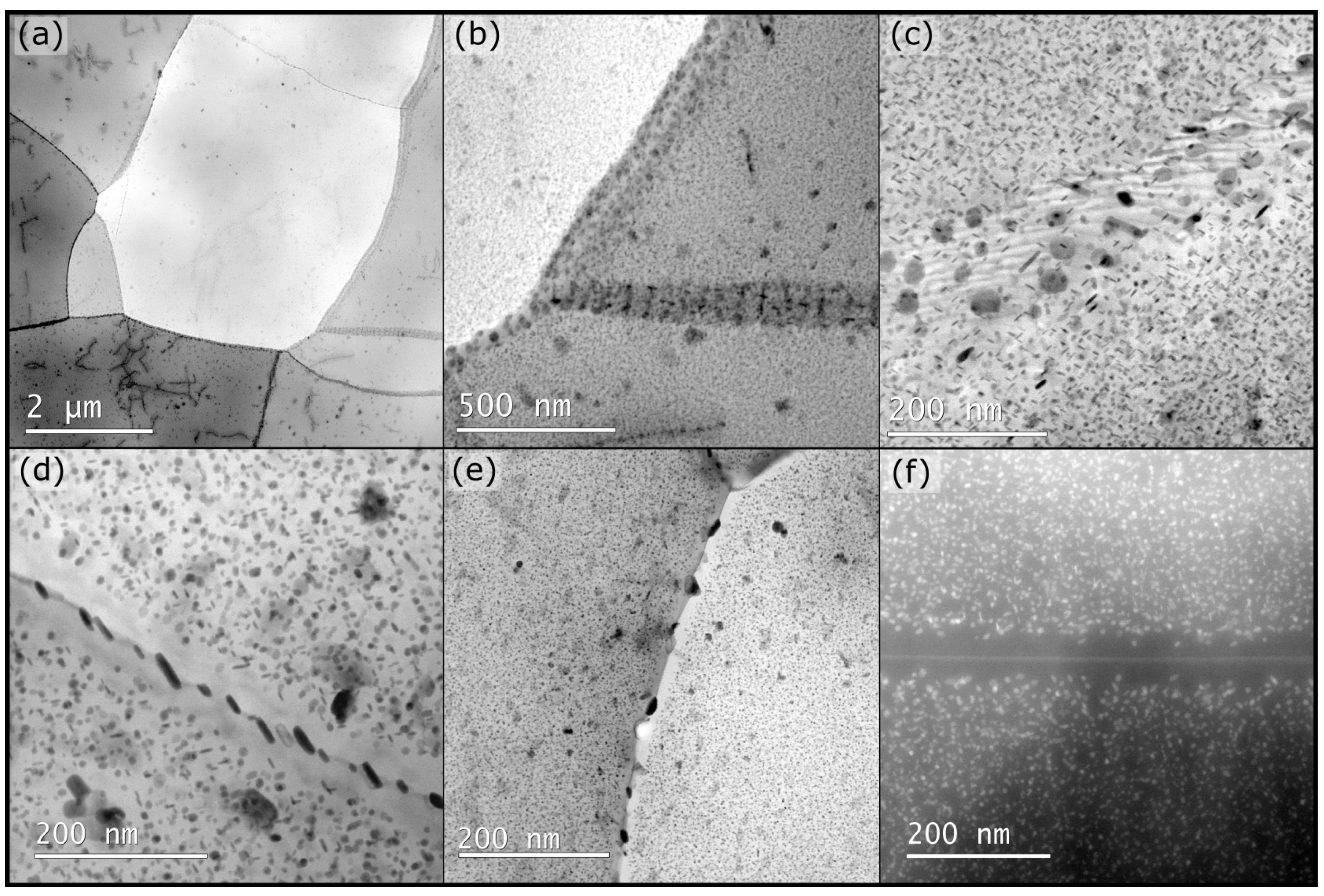

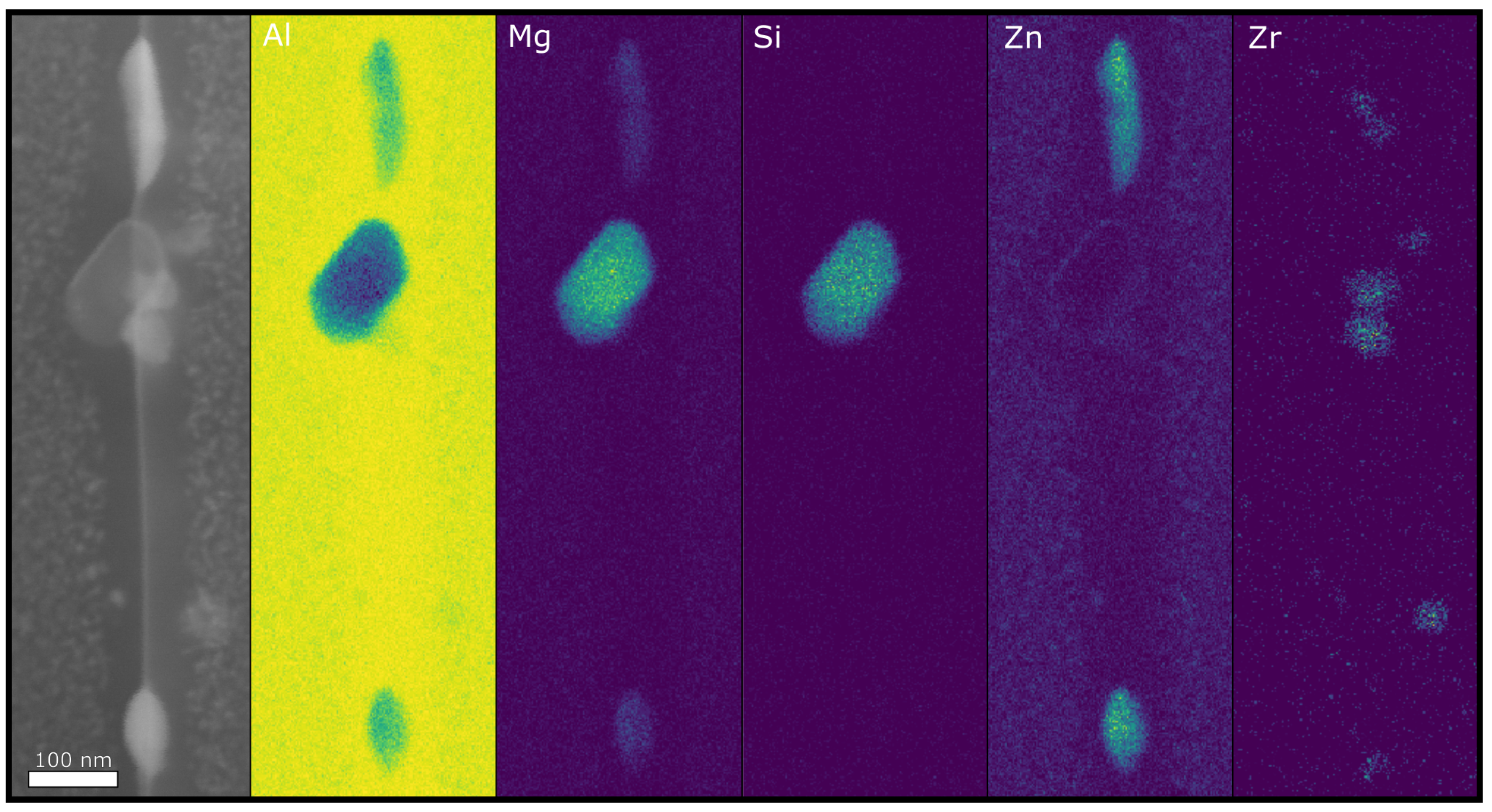

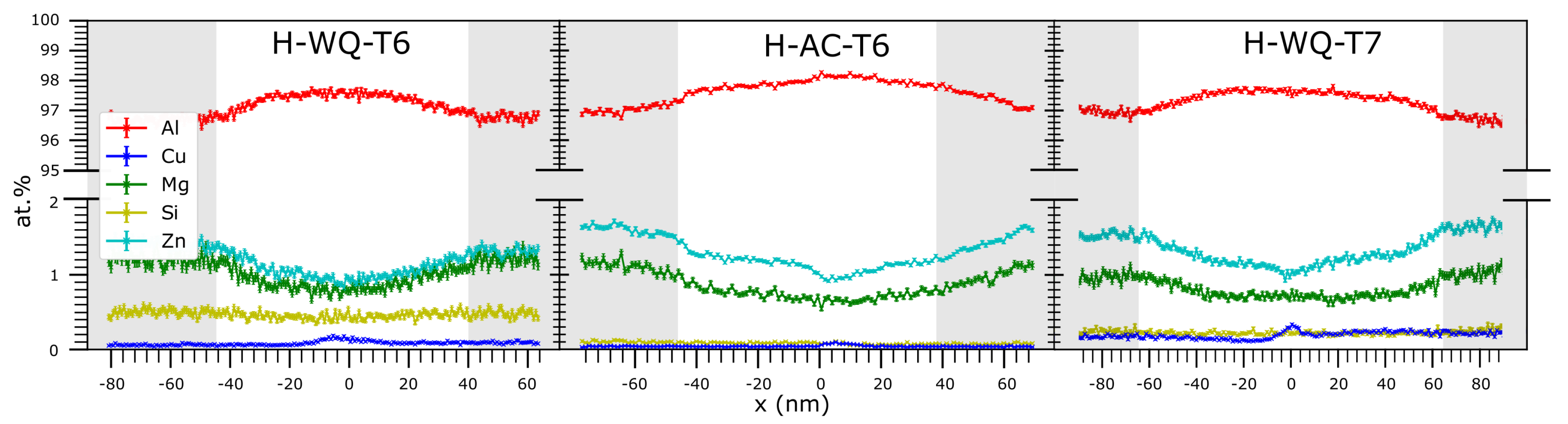

3.2. Grain Boundaries in TEM

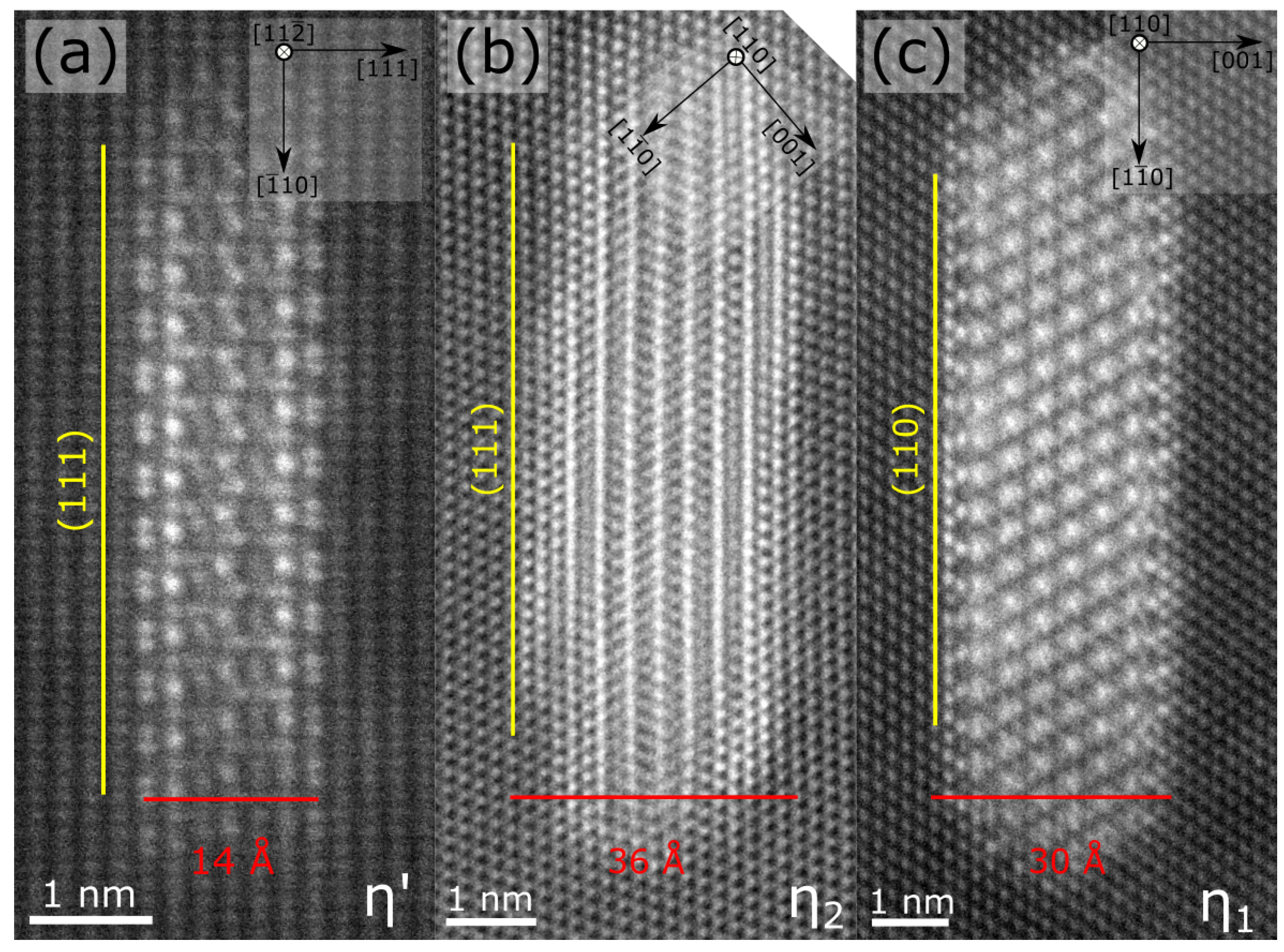

3.3. Matrix Precipitates

3.4. Electrical Conductivity

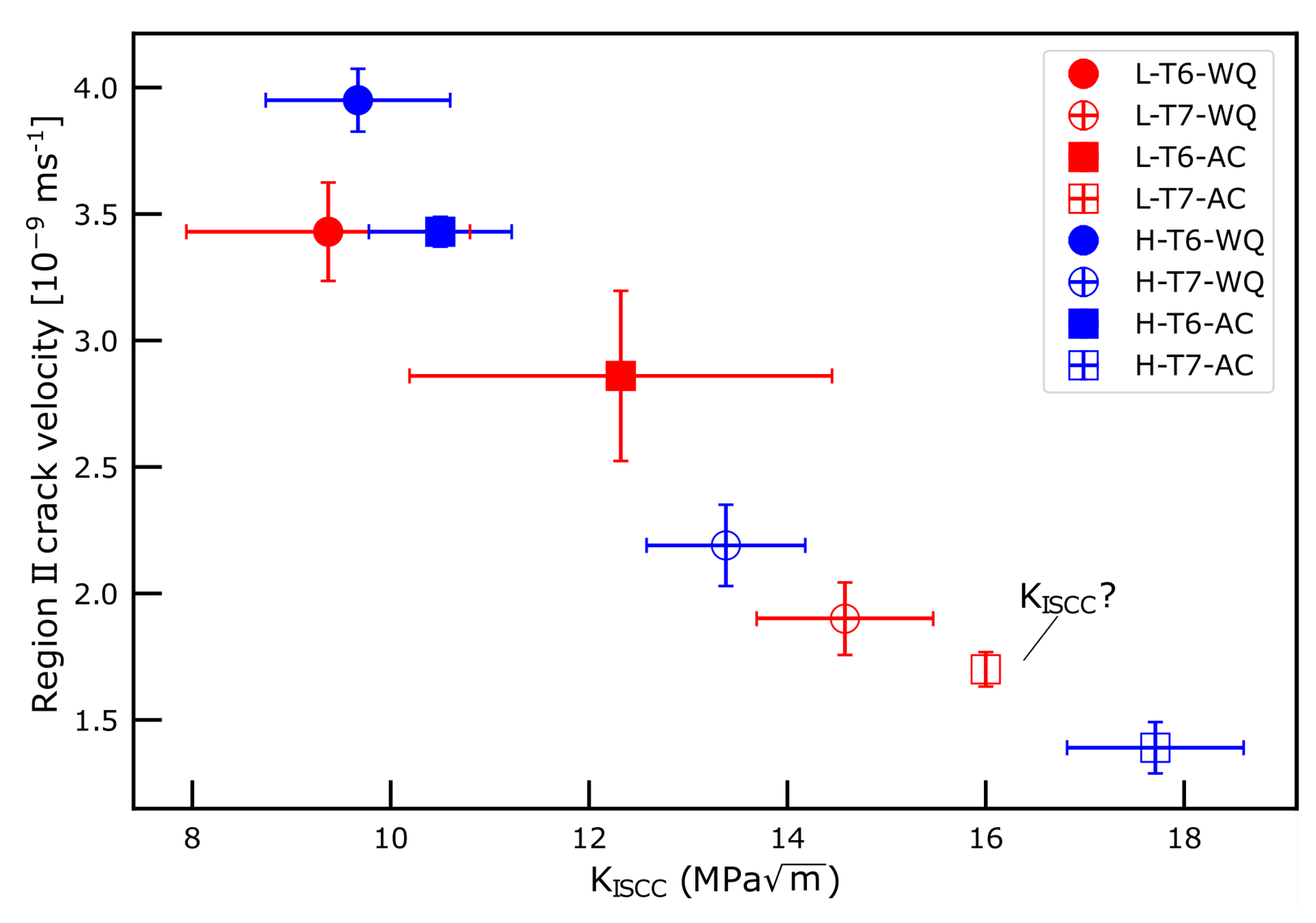

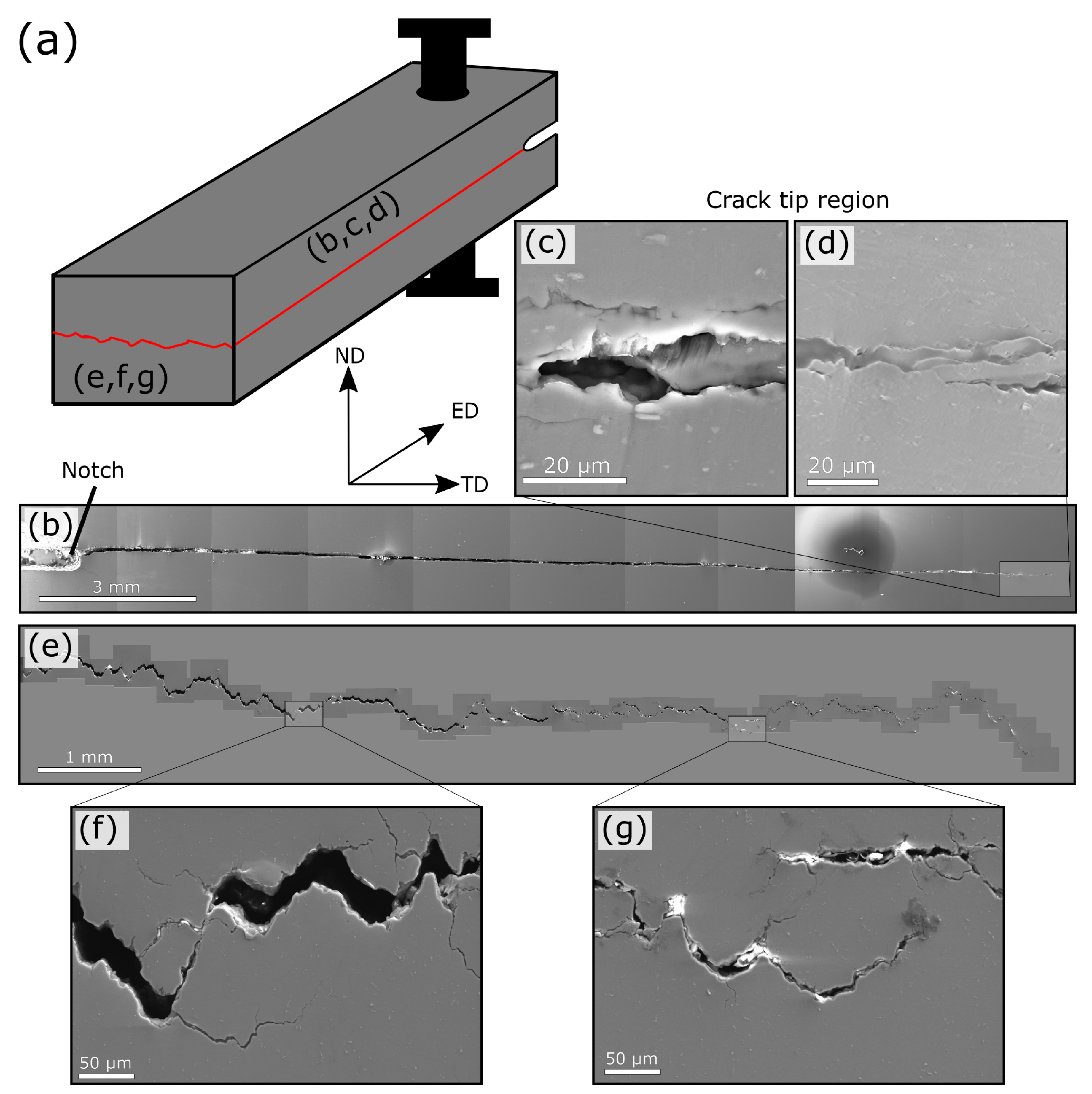

3.5. DCB Testing

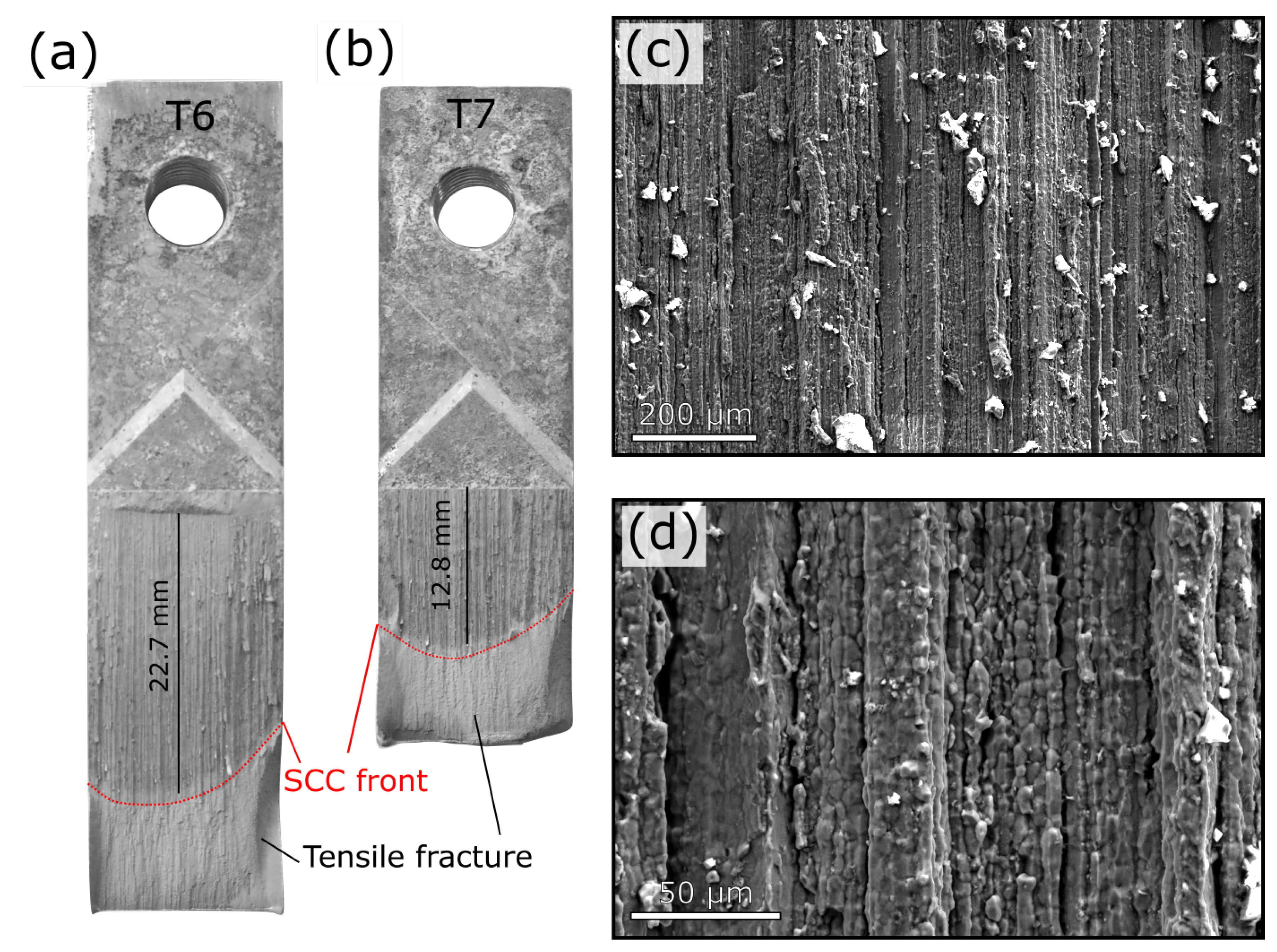

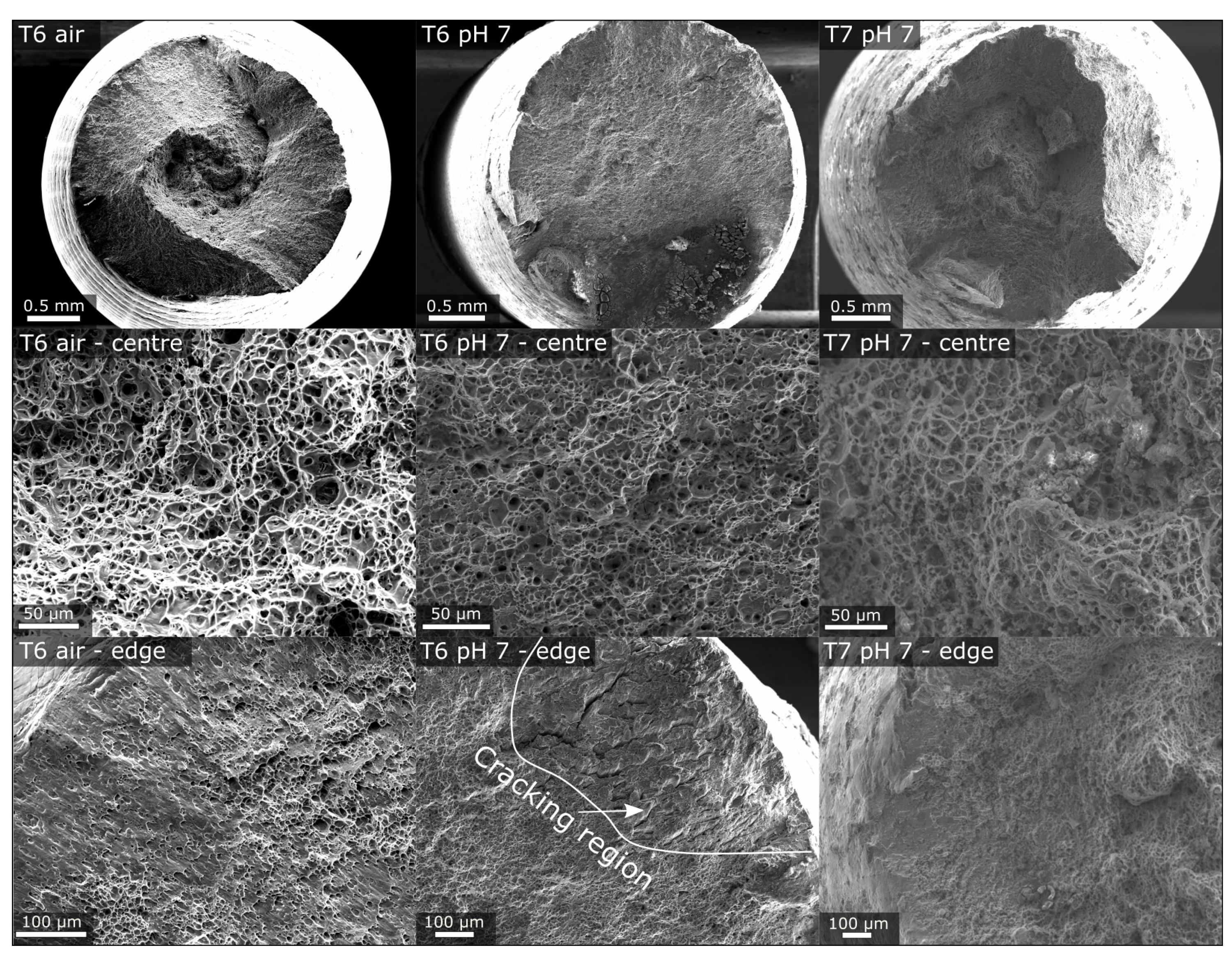

3.6. Slow Strain Rate Tests

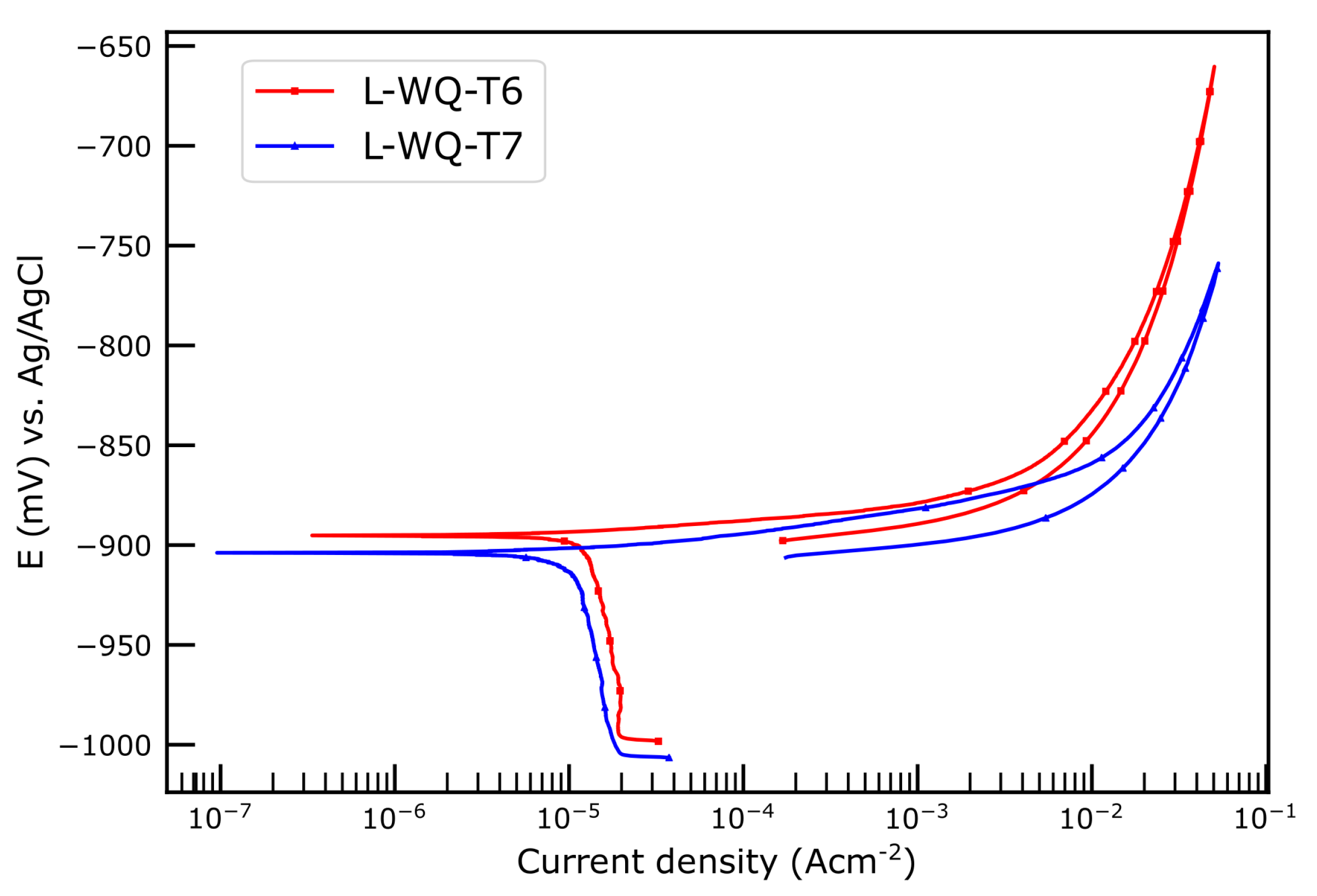

3.7. Polarisation Curves

4. Discussion

5. Conclusions

- Overageing (T7) increases the K value and decreases the region II crack velocity. This is likely related to differences in bulk precipitates, which may change the slip characteristics from shearing in T6 to looping in T7, and ultimately affect the degree of strain localisation at the grain boundaries.

- Low-angle sub-grain boundaries have a near continuous distribution of small grain boundary particles, while other grain boundaries vary greatly in particle density and may have none, few, or many particles present.

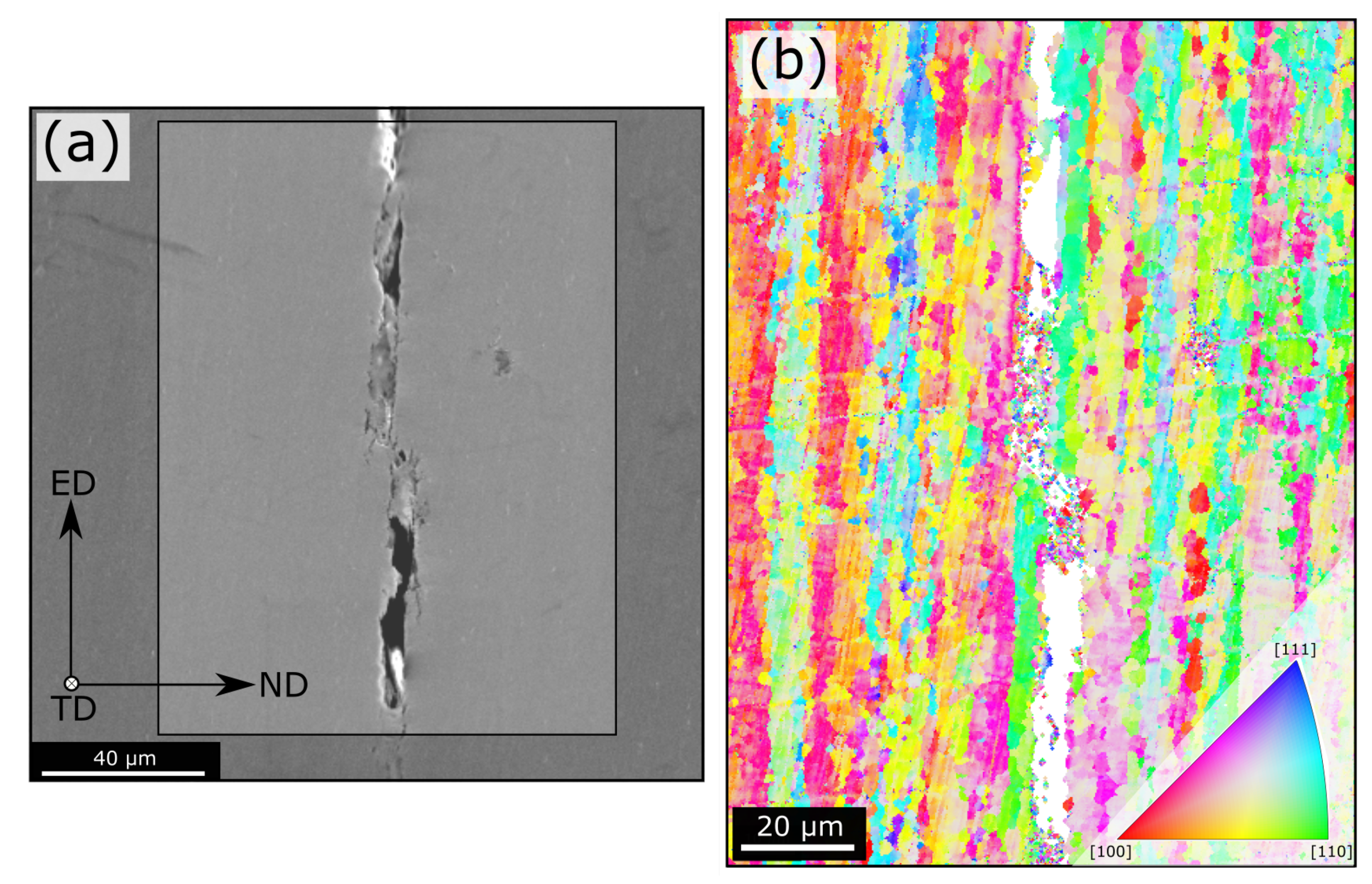

- The cracks follow predominantly the high-angle grain boundaries between the fibrous grains.

- Cracking behaviour observed in SSRT, only occurred in the T6 tempers.

- The small variations in Si content between the alloys herein have no clear influence on the measured SCC properties.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Jensrud, O. High Strength Aluminium Alloys Extrusions—A Review of the Thermo-Mechanical-Process in High Performance Profile Manufacturing. Progress in Extrusion Technology and Simulation of Light Metal Alloys. Key Eng. Mater. 2012, 491, 11–18. [Google Scholar] [CrossRef]

- Speidel, M.O. Stress corrosion cracking of aluminum alloys. Metall. Trans. A 1975, 6, 631–651. [Google Scholar] [CrossRef]

- Rao, A.C.U.; Vasu, V.; Govindaraju, M.; Srinadh, K.V.S. Stress corrosion cracking behaviour of 7xxx aluminum alloys: A literature review. Trans. Nonferrous Met. Soc. China 2016, 26, 1447–1471. [Google Scholar] [CrossRef]

- Holroyd, N.J.H.; Scamans, G.M. Stress corrosion cracking in Al-Zn-Mg-Cu aluminum alloys in saline environments. Metall. Mater. Trans. A 2013, 44, 1230–1253. [Google Scholar] [CrossRef]

- Holroyd, N.J.H.; Scamans, G.M. Crack propagation during sustained-load cracking of Al-Zn-Mg-Cu aluminum alloys exposed to moist air or distilled water. Metall. Mater. Trans. A 2011, 42, 3979–3998. [Google Scholar] [CrossRef]

- Braun, R. Environmentally assisted cracking of aluminium alloys. Materialwissenschaft und Werkstofftechnik 2007, 38, 674–689. [Google Scholar] [CrossRef]

- Burleigh, T.D. The Postulated Mechanisms for Stress Corrosion Cracking of Aluminum Alloys: A Review of the Literature 1980–1989. Corrosion 1991, 47, 89–98. [Google Scholar] [CrossRef]

- Lynch, S. Hydrogen embrittlement phenomena and mechanisms. Corros. Rev. 2012, 30, 105–123. [Google Scholar] [CrossRef]

- Najjar, D.; Magnin, T.; Warner, T. Influence of critical surface defects and localized competition between anodic dissolution and hydrogen effects during stress corrosion cracking of a 7050 aluminium alloy. Mater. Sci. Eng. A 1997, 238, 293–302. [Google Scholar] [CrossRef]

- Bland, L.G.; Locke, J.S. Chemical and electrochemical conditions within stress corrosion and corrosion fatigue cracks. npj Mater. Degrad. 2017, 1, 12. [Google Scholar] [CrossRef]

- Cornish, A.J.; Day, M.K.B. The effect of variable quenching conditions on the relationship between the stress-corrosion resistance, tensile properties, and microstructure of high-purity Al-Zn-Mg alloy. J. Inst. Met. 1971, 99, 377–384. [Google Scholar]

- Poulose, P.K.; Morral, J.E.; McEvily, A.J. Stress corrosion crack velocity and grain boundary precipitates in an Al-Zn-Mg alloy. Metall. Trans. 1974, 5, 1393–1400. [Google Scholar] [CrossRef]

- Christodoulou, L.; Flower, H.M. Hydrogen embrittlement and trapping in Al6%Zn-3%Mg. Acta Metall. 1980, 28, 481–487. [Google Scholar] [CrossRef]

- Sarkar, B.; Marek, M.; Starke, E.A. The effect of copper content and heat treatment on the stress corrosion characteristics of Ai-6Zn-2Mg-X Cu alloys. Metall. Trans. A 1981, 12, 1939–1943. [Google Scholar] [CrossRef]

- Puiggali, M.; Zielinski, A.; Olive, J.M.; Renauld, E.; Desjardins, D.; Cid, M. Effect of microstructure on stress corrosion cracking of an Al-Zn-Mg-Cu alloy. Corros. Sci. 1998, 40, 805–819. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, B.; Lin, H.; Zhou, Y.; Sun, L.; Wang, J.; Han, E.H.; Ke, W. Correlations between stress corrosion cracking susceptibility and grain boundary microstructures for an Al–Zn–Mg alloy. Corros. Sci. 2013, 77, 103–112. [Google Scholar] [CrossRef]

- Viswanadham, R.K.; Sun, T.S.; Green, J.A. Grain boundary segregation in Al-Zn-Mg alloys-Implications to stress corrosion cracking. Metall. Mater. Trans. A 1980, 11, 85–89. [Google Scholar] [CrossRef]

- Scamans, G.M.; Holroyd, N.J.H.; Tuck, C.D.S. The role of magnesium segregation in the intergranular stress corrosion cracking of aluminium alloys. Corros. Sci. 1987, 27, 329–347. [Google Scholar] [CrossRef]

- Song, R.G.; Tseng, M.K.; Zhang, B.J.; Liu, J.; Jin, Z.H.; Shin, K.S. Grain boundary segregation and hydrogen-induced fracture in 7050 aluminium alloy. Acta Mater. 1996, 44, 3241–3248. [Google Scholar] [CrossRef]

- Song, R.G.; Dietzel, W.; Zhang, B.J.; Liu, W.J.; Tseng, M.K.; Atrens, A. Stress corrosion cracking and hydrogen embrittlement of an Al–Zn–Mg–Cu alloy. Acta Mater. 2004, 52, 4727–4743. [Google Scholar] [CrossRef]

- Vasudevan, A.K.; Sadananda, K. Role of slip mode on stress corrosion cracking behavior. Metall. Mater. Trans. A 2011, 42, 405–414. [Google Scholar] [CrossRef]

- Wu, L.M.; Wang, W.H.; Hsu, Y.F.; Trong, S. Effects of Microstructure on the Mechanical Properties and Stress Corrosion Cracking of an Al-Zn-Mg-Sc-Zr Alloy by Various Temper Treatments. Mater. Trans. 2007, 48, 600–609. [Google Scholar] [CrossRef][Green Version]

- Baumgartner, M.; Kaesche, H. Intercrystalline Corrosion and Stress Corrosion Cracking of AlZnMg Alloys. Corrosion 1988, 44, 231–239. [Google Scholar] [CrossRef]

- Hardwick, D.A.; Thompson, A.W.; Bernstein, I.M. The effect of copper content and microstructure on the hydrogen embrittlement of Al-6Zn-2Mg alloys. Metall. Trans. A 1983, 14, 2517–2526. [Google Scholar] [CrossRef]

- Albrecht, J.; Thompson, A.W.; Bernstein, I.M. The role of microstructure in hydrogen-assisted fracture of 7075 aluminum. Metall. Trans. A 1979, 10, 1759–1766. [Google Scholar] [CrossRef]

- Day, M.K.B.; Cornish, A.J.; Dent, T. The relationship between structure and stress-corrosion life in Al-Zn-Mg alloy. Met. Sci. J. 1969, 3, 175–182. [Google Scholar] [CrossRef]

- Knight, S.P.; Birbilis, N.; Muddle, B.C.; Trueman, A.R.; Lynch, S.P. Correlations between intergranular stress corrosion cracking, grain-boundary microchemistry, and grain-boundary electrochemistry for Al-Zn-Mg-Cu alloys. Corros. Sci. 2010, 52, 4073–4080. [Google Scholar] [CrossRef]

- Goswami, R.; Lynch, S.; Holroyd, N.J.H.; Knight, S.P.; Holtz, R.L. Evolution of grain boundary precipitates in Al 7075 upon aging and correlation with stress corrosion cracking behavior. Metall. Mater. Trans. A 2013, 44, 1268–1278. [Google Scholar] [CrossRef]

- Gupta, R.K.; Deschamps, A.; Cavanaugh, M.K.; Lynch, S.P.; Birbilis, N. Relating the Early Evolution of Microstructure with the Electrochemical Response and Mechanical Performance of a Cu-Rich and Cu-Lean 7xxx Aluminum Alloy. J. Electrochem. Soc. 2012, 159, C492–C502. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, X.; Zou, L.; Yu, Y.; Li, Q. Effect of precipitate state on the stress corrosion behavior of 7050 aluminum alloy. Mater. Charact. 2016, 114, 1–8. [Google Scholar] [CrossRef]

- Birbilis, N.; Buchheit, R.G. Electrochemical Characteristics of Intermetallic Phases in Aluminum Alloys An Experimental Survey and Discussion. J. Electrochem. Soc. 2005, 152, B140–B151. [Google Scholar] [CrossRef]

- Lervik, A.; Marioara, C.D.; Kadanik, M.; Walmsley, J.C.; Milkereit, B.; Holmestad, R. Precipitation in an extruded AA7003 aluminium alloy: Observations of 6xxx-type hardening phases. Mater. Des. 2019, 186, 108204. [Google Scholar] [CrossRef]

- Hyatt, M.V. Use of Precracked Specimens in Stress Corrosion Testing of High Strength Aluminum Alloys. Corrosion 1970, 26, 487–503. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX—Free and Open Source Software Toolbox. In Solid State Phenomena; Texture and Anisotropy of Polycrystals III; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2010; Volume 160, pp. 63–68. [Google Scholar] [CrossRef]

- de la Peña, F.; Prestat, E.; Fauske, V.T.; Burdet, P.; Jokubauskas, P.; Nord, M.; Ostasevicius, T.; MacArthur, K.E.; Sarahan, M.; Johnstone, D.N.; et al. hyperspy/hyperspy: HyperSpy v1. 5.2. zndo 2019. [Google Scholar] [CrossRef]

- Dumont, M.; Lefebvre, W.; Doisneau-Cottignies, B.; Deschamps, A. Characterisation of the composition and volume fraction of η′ and η precipitates in an Al–Zn–Mg alloy by a combination of atom probe, small-angle X-ray scattering and transmission electron microscopy. Acta Mater. 2005, 53, 2881–2892. [Google Scholar] [CrossRef]

- Zhao, H.; Gault, B.; Ponge, D.; Raabe, D.; De Geuser, F. Parameter free quantitative analysis of atom probe data by correlation functions: Application to the precipitation in Al-Zn-Mg-Cu. Scr. Mater. 2018, 154, 106–110. [Google Scholar] [CrossRef]

- Wu, H.; Fan, G. An overview of tailoring strain delocalization for strength-ductility synergy. Prog. Mater. Sci. 2020, 113, 100675. [Google Scholar] [CrossRef]

- Guyot, P.; Cottignies, L. Precipitation kinetics, mechanical strength and electrical conductivity of AlZnMgCu alloys. Acta Mater. 1996, 44, 4161–4167. [Google Scholar] [CrossRef]

- Oger, L.; Lafouresse, M.C.; Odemer, G.; Peguet, L.; Blanc, C. Hydrogen diffusion and trapping in a low copper 7xxx aluminium alloy investigated by Scanning Kelvin Probe Force Microscopy. Mater. Sci. Eng. A 2017, 706, 126–135. [Google Scholar] [CrossRef]

- Tsuru, T.; Yamaguchi, M.; Ebihara, K.; Itakura, M.; Shiihara, Y.; Matsuda, K.; Toda, H. First-principles study of hydrogen segregation at the MgZn2 precipitate in Al-Mg-Zn alloys. Comput. Mater. Sci. 2018, 148, 301–306. [Google Scholar] [CrossRef]

- Tsuru, T.; Shimizu, K.; Yamaguchi, M.; Itakura, M.; Ebihara, K.; Bendo, A.; Matsuda, K.; Toda, H. Hydrogen-accelerated spontaneous microcracking in high-strength aluminium alloys. Sci. Rep. 2020, 10, 1–8. [Google Scholar] [CrossRef]

- Oger, L.; Malard, B.; Odemer, G.; Peguet, L.; Blanc, C. Influence of dislocations on hydrogen diffusion and trapping in an Al-Zn-Mg aluminium alloy. Mater. Des. 2019, 180, 107901. [Google Scholar] [CrossRef]

- Unwin, P.N.; Nicholson, R.B. The nucleation and initial stages of growth of grain boundary precipitates in Al-Zn-Mg and Al-Mg alloys. Acta Metall. 1969, 17, 1379–1393. [Google Scholar] [CrossRef]

- Gronsky, R.; Furrer, P. Grain Boundary Precipitation in Aluminum Alloys: Effect of Boundary Structure. Metall. Trans. A 1981, 12, 121–127. [Google Scholar] [CrossRef]

- Chung, T.F.; Yang, Y.L.; Shiojiri, M.; Hsiao, C.N.; Li, W.C.; Tsao, C.S.; Shi, Z.; Lin, J.; Yang, J.R. An atomic scale structural investigation of nanometre-sized η precipitates in the 7050 aluminium alloy. Acta Mater. 2019, 174, 351–368. [Google Scholar] [CrossRef]

- Bendo, A.; Matsuda, K.; Lervik, A.; Tsuru, T.; Nishimura, K.; Nunomura, N.; Holmestad, R.; Marioara, C.D.; Shimizu, K.; Toda, H.; et al. An unreported precipitate orientation relationship in Al-Zn-Mg based alloys. Mater. Charact. 2019, 158, 109958. [Google Scholar] [CrossRef]

- Butler, E.P.; Swann, P.R. In situ observations of the nucleation and initial growth of grain boundary precipitates in an Al-Zn-Mg alloy. Acta Metall. 1976, 24, 343–352. [Google Scholar] [CrossRef]

- Zhao, H.; Huber, L.; Lu, W.; Peter, N.J.; An, D.; De Geuser, F.; Dehm, G.; Ponge, D.; Neugebauer, J.; Gault, B.; et al. Interplay of Chemistry and Faceting at Grain Boundaries in a Model Al Alloy. Phys. Rev. Lett. 2020, 124, 106102. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.S.; Loza, J.J.; Merkle, A.P.; Chawla, N. Three dimensional microstructural characterization of nanoscale precipitates in AA7075-T651 by focused ion beam (FIB) tomography. Mater. Charact. 2016, 118, 102–111. [Google Scholar] [CrossRef]

- Tang, J.; Zhang, Y.; Ye, L.; Qu, M.; Wu, J.; Zhang, Z.; Liu, S.; Deng, Y. Effect of Grain Boundary and Crystallographic Orientation on the Stress Corrosion Behavior of an Al-Zn-Mg Alloy. J. Mater. Eng. Perform. 2019, 28, 2954–2966. [Google Scholar] [CrossRef]

- She, H.; Chu, W.; Shu, D.; Wang, J.; Sun, B.d. Effects of silicon content on microstructure and stress corrosion cracking resistance of 7050 aluminum alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 2307–2313. [Google Scholar] [CrossRef]

- Singh, S.S.; Stannard, T.J.; Xiao, X.; Chawla, N. In Situ X-ray Microtomography of Stress Corrosion Cracking and Corrosion Fatigue in Aluminum Alloys. Jom 2017, 69, 1404–1414. [Google Scholar] [CrossRef]

- Magaji, N.; Mayrhofer, R.; Kröger, B.; Schnatterer, C.; Zander, D. Comparison of test methods used to analyze stress corrosion cracking of differently tempered 7xxx alloys. Mater. Corros. 2019, 70, 1192–1204. [Google Scholar] [CrossRef]

- Robinson, J.S.; Pirling, T.; Truman, C.E.; Panzner, T. Residual stress relief in the aluminium alloy 7075. Mater. Sci. Technol. 2017, 33, 1765–1775. [Google Scholar] [CrossRef]

| Alloy | Fe | Mg | Si | Zn | Cu | Zr | Ti | Al | Zn/Mg |

|---|---|---|---|---|---|---|---|---|---|

| 7003-H | 0.20 | 0.68 | 0.11 | 5.56 | 0.01 | 0.17 | 0.02 | Bal. | 8.20 |

| 7003-L | 0.20 | 0.71 | 0.05 | 5.65 | <0.01 | 0.15 | 0.01 | Bal. | 8.20 |

| Single GBP Composition (at.%) | Multiple | GBP Size (nm) | PFZ (nm) | ||||

|---|---|---|---|---|---|---|---|

| Al | Zn | Mg | Avg. Zn/Mg | Type 1 (Sub-GB) | Type 2 | ||

| H-WQ-T6 | 47.0 ± 4.4 | 36.7 ± 3.1 | 16.5 ± 2.1 | 2.21 | 23.0 ± 8.9 | 65.1 ± 30.2 | 80 ± 6 |

| H-WQ-T7 | 49.5 ± 10.4 | 36.5 ± 7.6 | 13.9 ± 3.7 | 2.56 | 107 ± 15 | ||

| H-AC-T6 | 60.4 ± 5.2 | 28.2 ± 3.9 | 11.2 ± 2.4 | 1.64 | 103 ± 13 | ||

| H-AC-T7 | 53.9 ± 7.9 | 32.9 ± 5.9 | 13.0 ± 3.3 | 2.57 | 34.9 ± 8.2 | 88.9 ± 27.0 | 116 ± 10 |

| H-WQ-T6 | H-WQ-T7 | H-AC-T6 | H-AC-T7 | |

|---|---|---|---|---|

| MS/m | 26.15 ± 0.16 | 27.15 ± 0.13 | 26.13 ± 0.11 | 27.23 ± 0.09 |

| YS (MPa) | UTS (MPa) | Total Elongation (%) | RA (%) | RRA (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | Air | pH 7 | pH 3 | Air | pH 7 | pH 3 | Air | pH 7 | pH 3 | Air | pH 7 | pH 3 | pH 7 | pH 3 |

| L-WQ-T6 | 362 | 365 | 366 | 376 | 379 | 380 | 14.4 | 17.8 | 13.7 | 49.3 | 32.4 | 36.6 | 0.66 | 0.74 |

| H-WQ-T6 | 357 | 359 | 371 | 374 | 379 | 386 | 15.5 | 15.6 | 14.4 | 56.4 | 44.5 | 40.9 | 0.79 | 0.72 |

| L-WQ-T7 | 311 | 323 | 316 | 322 | 335 | 328 | 15.7 | 14.4 | 14.9 | 63.7 | 61.1 | 49.2 | 0.96 | 0.77 |

| H-WQ-T7 | 322 | 315 | 319 | 333 | 327 | 332 | 15.9 | 15.2 | 15.4 | 65.0 | 56.8 | 46.2 | 0.87 | 0.71 |

| L-AC-T6 | 354 | 361 | 367 | 372 | 380 | 384 | 14.4 | 15.6 | 14.5 | 56.9 | 44.5 | 40.9 | 0.71 | 0.78 |

| H-AC-T6 | 358 | 355 | 354 | 375 | 373 | 373 | 16.1 | 14.7 | 14.9 | 58.8 | 40.6 | 34.9 | 0.69 | 0.59 |

| L-AC-T7 | 315 | 315 | 315 | 326 | 329 | 329 | 14.7 | 16.4 | 16.3 | 57.6 | 58.1 | 59.7 | 1.01 | 1.03 |

| H-AC-T7 | 313 | 311 | 314 | 324 | 322 | 328 | 14.7 | 16.1 | 14.5 | 60.6 | 50.7 | 57.9 | 0.84 | 0.95 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lervik, A.; C. Walmsley, J.; Lodgaard, L.; D. Marioara, C.; Johnsen, R.; Lunder, O.; Holmestad, R. Stress Corrosion Cracking in an Extruded Cu-Free Al-Zn-Mg Alloy. Metals 2020, 10, 1194. https://doi.org/10.3390/met10091194

Lervik A, C. Walmsley J, Lodgaard L, D. Marioara C, Johnsen R, Lunder O, Holmestad R. Stress Corrosion Cracking in an Extruded Cu-Free Al-Zn-Mg Alloy. Metals. 2020; 10(9):1194. https://doi.org/10.3390/met10091194

Chicago/Turabian StyleLervik, Adrian, John C. Walmsley, Lars Lodgaard, Calin D. Marioara, Roy Johnsen, Otto Lunder, and Randi Holmestad. 2020. "Stress Corrosion Cracking in an Extruded Cu-Free Al-Zn-Mg Alloy" Metals 10, no. 9: 1194. https://doi.org/10.3390/met10091194

APA StyleLervik, A., C. Walmsley, J., Lodgaard, L., D. Marioara, C., Johnsen, R., Lunder, O., & Holmestad, R. (2020). Stress Corrosion Cracking in an Extruded Cu-Free Al-Zn-Mg Alloy. Metals, 10(9), 1194. https://doi.org/10.3390/met10091194