Investigation of the Effects of an Intense Pulsed Ion Beam on the Surface Melting of IN718 Superalloy Prepared with Selective Laser Melting

Abstract

1. Introduction

2. Materials and Methods

- (1)

- The powder supply step which distributes the powder for laser melting;

- (2)

- The recoater recoats powder on the powder bed;

- (3)

- The laser device emits a laser and the scanner rotates to control the laser to melt the zone as shown by the slice pattern;

- (4)

- Repeat the above steps, parts will be built up gradually.

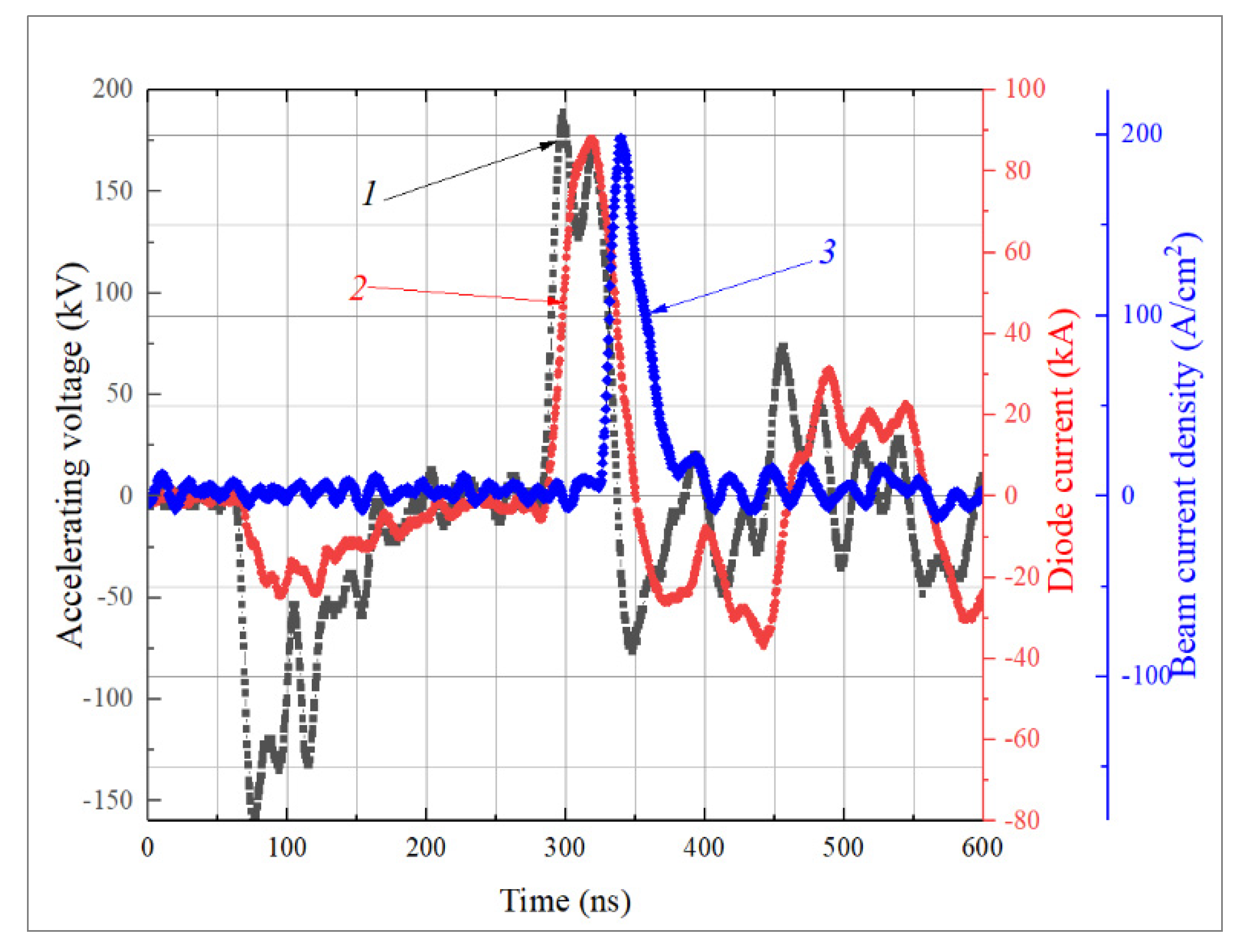

3. Results and Discussion

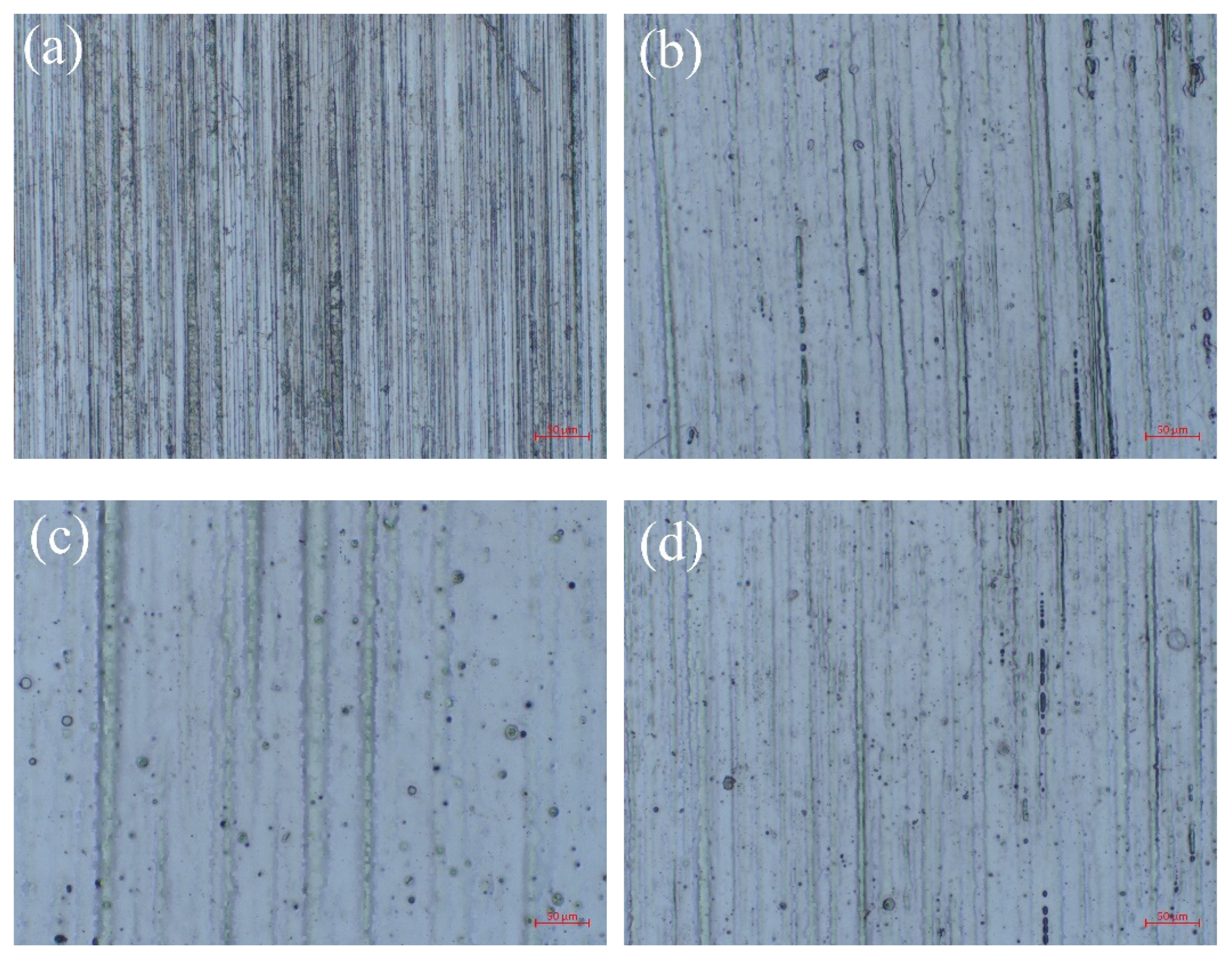

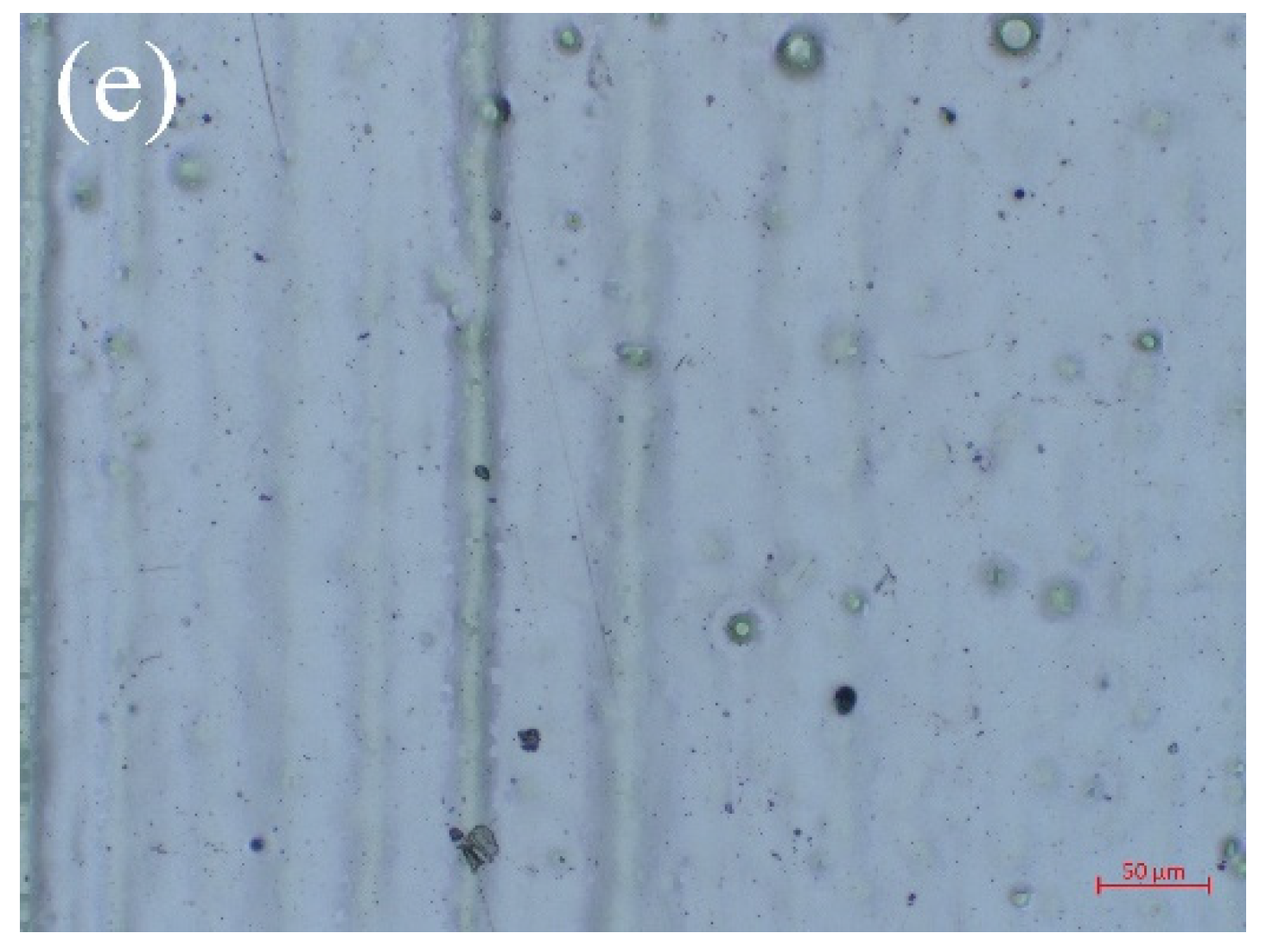

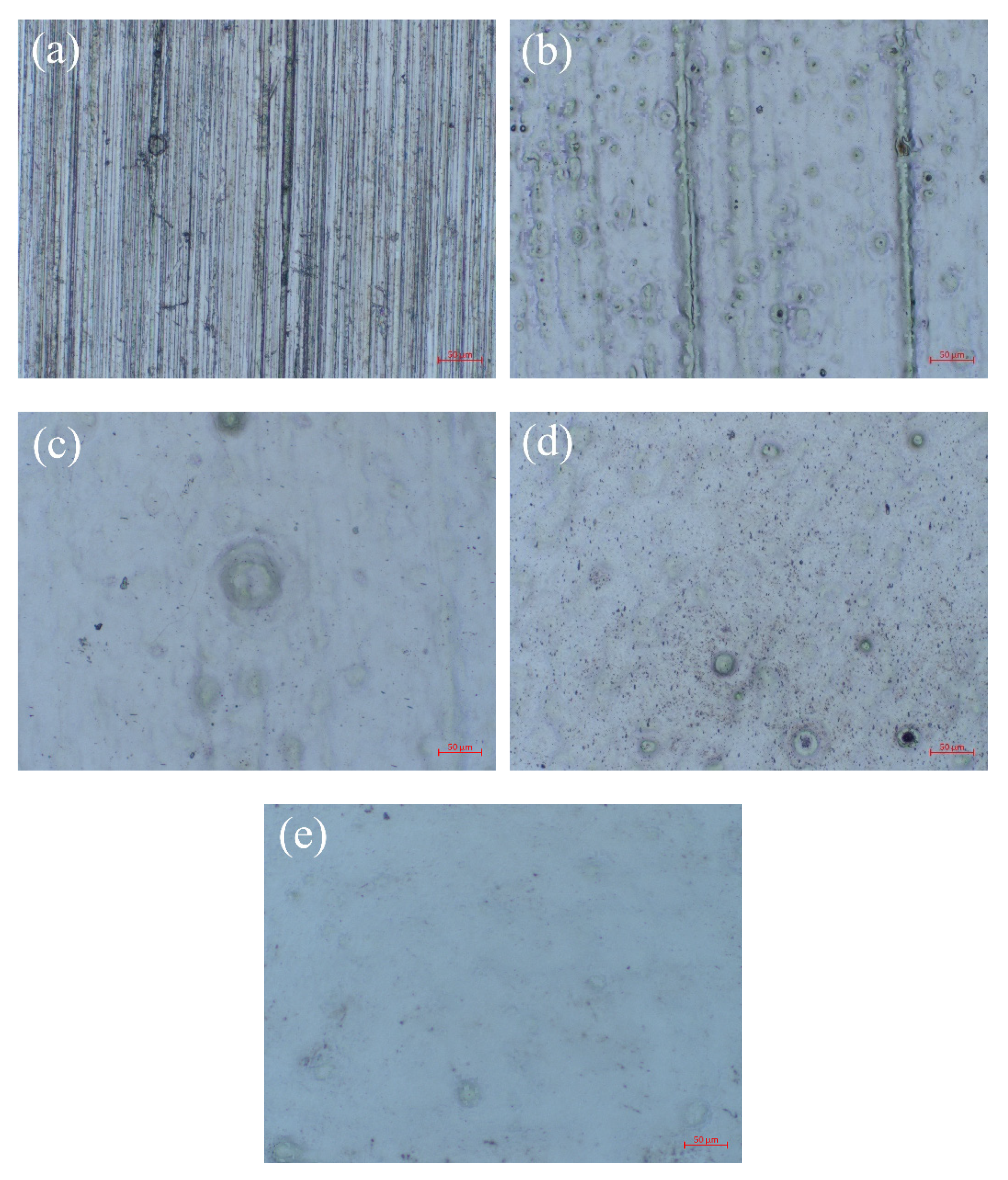

3.1. Effect of IPIB Irradiation on Surface Morphology

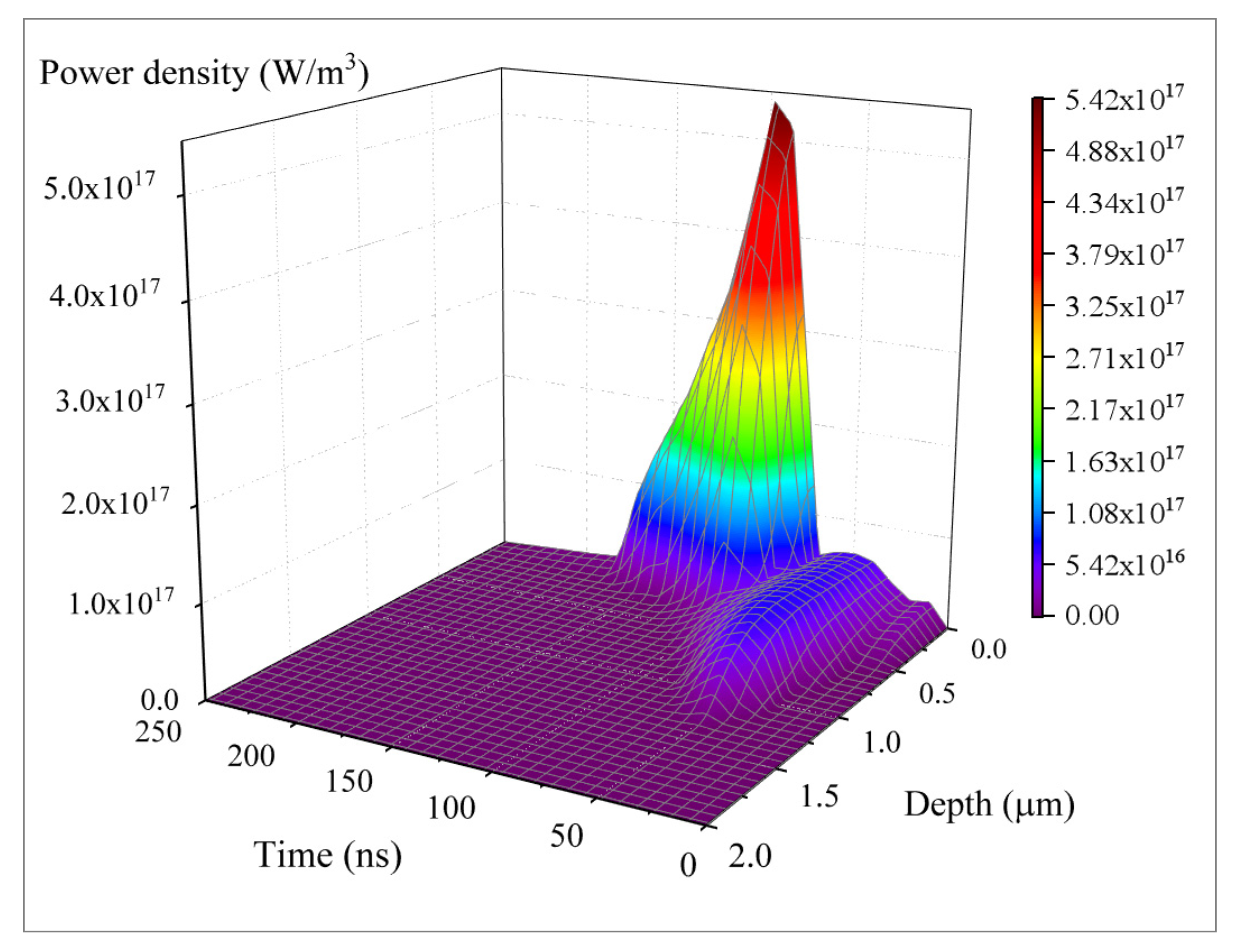

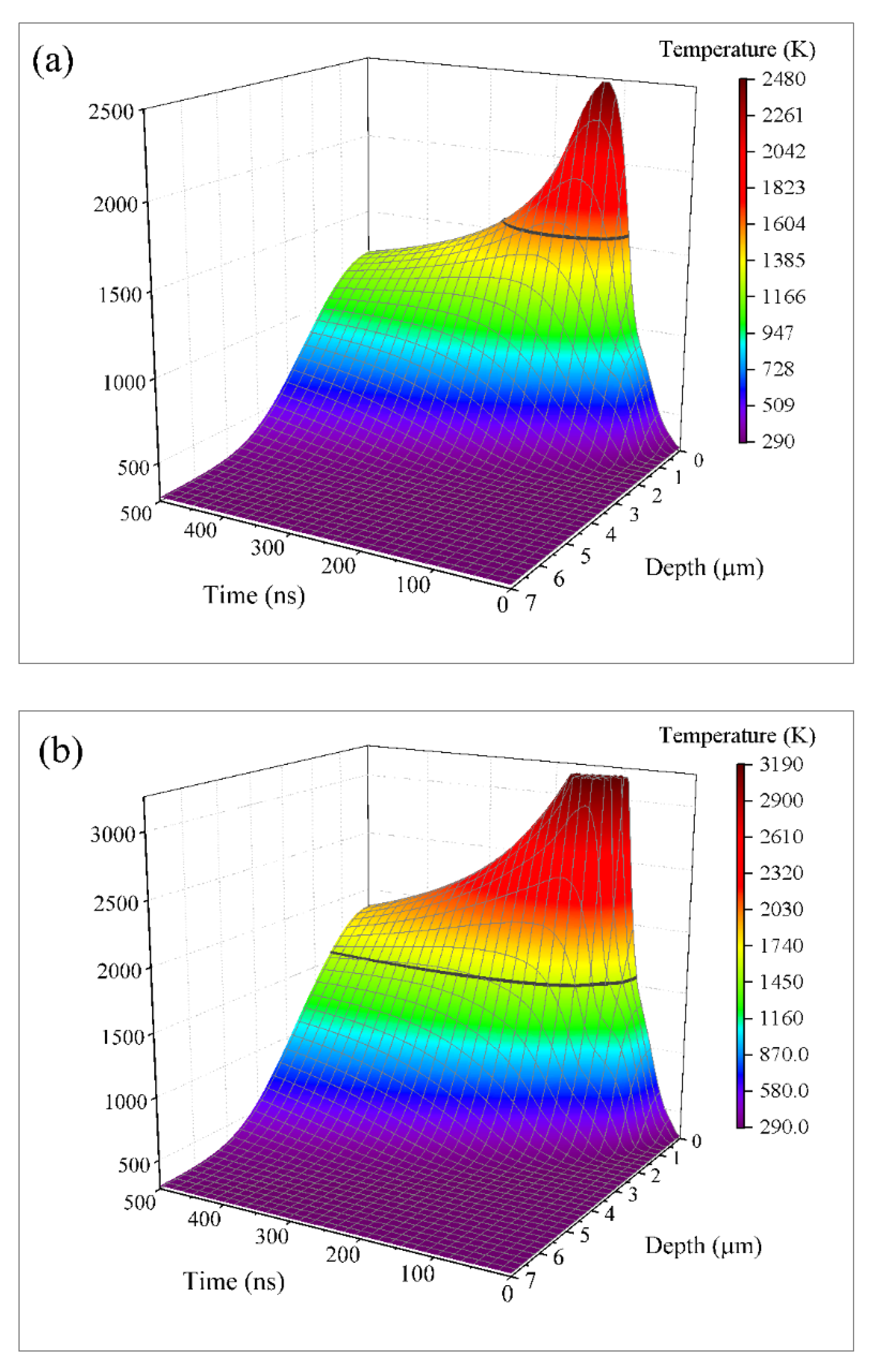

3.2. Thermal Field Simulation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ji, F.; Bao, Y.; Zhou, Y.; Du, F.; Zhu, H.; Zhao, S.; Li, G.; Zhu, X.; Ding, S. Investigation on performance and implementation of Tesla turbine in engine waste heat recovery. Energy Convers. Manag. 2019, 179, 326–338. [Google Scholar] [CrossRef]

- Chen, W.; Yin, G.; Feng, Z.; Liao, X. Effect of powder feedstock on microstructure and mechanical properties of the 316L stainless steel fabricated by selective laser melting. Metals (Basel) 2018, 8, 729. [Google Scholar] [CrossRef]

- Liang, C.; Hu, Y.; Liu, N.; Zou, X.; Wang, H.; Zhang, X.; Fu, Y.; Hu, J. Laser polishing of Ti6Al4V fabricated by selective laser melting. Metals (Basel) 2020, 10, 191. [Google Scholar] [CrossRef]

- Mudge, R.P.; Wald, N.R. Laser engineered net shaping advances additive manufacturing and repair. Weld. J. (Miami Fla) 2007, 86, 44–48. [Google Scholar]

- Das, M.; Balla, V.K.; Basu, D.; Bose, S.; Bandyopadhyay, A. Laser processing of SiC-particle-reinforced coating on titanium. Scr. Mater. 2010, 63, 438–441. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, P.; Yu, Z.; Li, C.; Li, R. Development and characterization of laser surface cladding (Ti,W)C reinforced Ni30Cu alloy composite coating on copper. Opt. Laser Technol. 2012, 44, 1351–1358. [Google Scholar] [CrossRef]

- Zhao, J.R.; Hung, F.Y.; Lui, T.S. Erosion resistance and particle erosion-induced tensile embrittlement of 3d-selective laser melting inconel 718 superalloy. Metals (Basel) 2020, 10, 21. [Google Scholar] [CrossRef]

- Condruz, M.R.; Matache, G.; Paraschiv, A.; Badea, T.; Badilita, V. High temperature oxidation behavior of selective laser melting manufactured in 625. Metals (Basel) 2020, 10, 668. [Google Scholar] [CrossRef]

- Çam, G.; Koçak, M. Progress in joining of advanced materials. Int. Mater. Rev. 1998, 43, 1–44. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Yatsui, K.; Jiang, W.; Suematsu, H.; Imada, G.; Suzuki, T.; Hirai, M.; Zhu, X. Industrial applications of pulsed particle beams and pulsed power technologies. In Proceedings of the 15th International Conference on High-Power Particle Beams-Proceedings, St. Petersburg, Russia, 18–23 July 2004; pp. 613–617. [Google Scholar]

- Stinnett, R.W.; Buchheit, R.G.; Neau, E.L.; Crawford, M.T.; Lamppa, K.P.; Renk, T.J.; Greenly, J.B.; Boyd, I.; Thompson, M.O.; Rej, D.J. Ion beam surface treatment: A new technique for thermally modifying surfaces using intense, pulsed ion beams. In Proceedings of the Digest of Technical Papers-IEEE International Pulsed Power Conference, Albuquerque, NM, USA, 3–6 July 1995; Volume 1, pp. 46–55. [Google Scholar]

- Remnev, G.E.; Isakov, I.F.; Opekounov, M.S.; Matvienko, V.M.; Ryzhkov, V.A.; Struts, V.K.; Grushin, I.I.; Zakoutayev, A.N.; Potyomkin, A.V.; Tarbokov, V.A.; et al. High intensity pulsed ion beam sources and their industrial applications. Surf. Coatings Technol. 1999, 114, 206–212. [Google Scholar] [CrossRef]

- Zaharia, S.M.; Chicoș, L.A.; Lancea, C.; Pop, M.A. Effects of homogenization heat treatment on mechanical properties of inconel 718 sandwich structures manufactured by selective laser melting. Metals (Basel) 2020, 10, 645. [Google Scholar] [CrossRef]

- Humphries, S. Self magnetic insulation of pulsed ion diodes. Plasma Phys. 1977, 19, 399–406. [Google Scholar] [CrossRef]

- Sudan, R.N.; Lovelace, R.V. Generation of intense ion beams in pulsed diodes. Phys. Rev. Lett. 1973, 31, 1174–1177. [Google Scholar] [CrossRef]

- Lopatin, V.S.; Remnev, G.E.; Furman, E.G.; Makeev, V.A.; Stepanov, A.V. An ion diode with external magnetic insulation. Instrum. Exp. Tech. 2004, 47, 70–75. [Google Scholar] [CrossRef]

- Pushkarev, A.I.; Isakova, Y.I. A gigawatt power pulsed ion beam generator for industrial applications. Surf. Coat. Technol. 2013, 228, S382–S384. [Google Scholar] [CrossRef]

- Le, X.Y.; Zhao, W.J.; Yan, S.; Han, B.X.; Xiang, W. The thermodynamical process in metal surface due to the irradiation of intense pulsed ion beam. Surf. Coat. Technol. 2002, 158–159, 14–20. [Google Scholar] [CrossRef]

- Le, X.; Yan, S.; Liu, Z.; Zhao, W. Detection of shocks generated by intense pulsed ion beam irradiation. Surf. Coat. Technol. 2007, 201, 4991–4994. [Google Scholar] [CrossRef]

- Zhu, X.P.; Lei, M.K.; Ma, T.C. Surface morphology of titanium irradiated by high-intensity pulsed ion beam. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2003, 211, 69–79. [Google Scholar] [CrossRef]

- Yu, X.; Zhong, H.; Zhang, Z.; Shen, J.; Zhang, J.; Cui, X.; Liang, G.; Zhang, X.; Zhang, G.; Yan, S.; et al. Hydrodynamic effects on the surface morphology evolution of aluminum alloy under intense pulsed ion beam irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2017, 409, 158–162. [Google Scholar] [CrossRef]

- Zhang, F.; Zhu, X.; Lei, M. Tribological behavior of WC-Ni cemented carbide irradiated by high-intensity pulsed ion beam. Surf. Coat. Technol. 2014, 258, 78–85. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloys Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Yu, X.; Liu, Z.; Shen, J.; Isakova, Y.I.; Zhong, H.W.; Zhang, J.; Yan, S.; Zhang, G.L.; Zhang, X.F.; Le, X.Y. Dynamic energy spectrum and energy deposition in solid target by intense pulsed ion beams. Nucl. Sci. Technol. 2017, 28. [Google Scholar] [CrossRef]

- Zimmerman, W.B.J. Introduction To Comsol Multiphysics. Manual 2006. [Google Scholar] [CrossRef]

- Zhou, Y.; Shao, L.; Zhang, C.; Ji, F.; Liu, J.; Li, G.; Ding, S.; Zhang, Q.; Du, F. Numerical and experimental investigation on dynamic performance of bump foil journal bearing based on journal orbit. Chin. J. Aeronaut. 2020. [Google Scholar] [CrossRef]

- Zhu, X.P.; Zhang, Z.C.; Pushkarev, A.I.; Lei, M.K. Ion beam enhancement in magnetically insulated ion diodes for high-intensity pulsed ion beam generation in non-relativistic mode. Phys. Plasmas 2016. [Google Scholar] [CrossRef]

- Valyaev, A.N.; Kylyshkanov, M.K.; Pogrebnjak, A.D.; Valyaev, A.A.; Plotnikov, S.V. Modification of mechanical and tribological properties of R6M5 steel and Be by intense pulsed-ion and pulsed-electron beams. Vacuum 2000, 58, 53–59. [Google Scholar] [CrossRef]

- Isakova, Y.I.; Pushkarev, A.I. Visualization and analysis of pulsed ion beam energy density profile with infrared imaging. Infrared Phys. Technol. 2018, 89, 140–146. [Google Scholar] [CrossRef]

- Yu, X.; Shen, J.; Qu, M.; Liu, W.; Zhong, H.; Zhang, J.; Yan, S.; Zhang, G.; Le, X. Infrared imaging diagnostics for intense pulsed electron beam. Rev. Sci. Instrum. 2015, 86. [Google Scholar] [CrossRef]

- Xiaoyun, L.E.; Sha, Y.; Weijiang, Z.; Baoxi, H.; Yugang, W.; Jianming, X. Computer simulation of thermal–mechanical effects of high intensity pulsed ion beams on a metal surface. Surf. Coat. Technol. 2000, 128, 381–386. [Google Scholar] [CrossRef]

- Zhou, Y.; Xing, T.; Song, Y.; Li, Y.; Zhu, X.; Li, G.; Ding, S. Digital-twin-driven geometric optimization of centrifugal impeller with free-form blades for five-axis flank milling. J. Manuf. Syst. 2020. [Google Scholar] [CrossRef]

- Yu, X.; Shen, J.; Zhong, H.; Zhang, J.; Yan, S.; Zhang, G.; Zhang, X.; Le, X. Thermo-hydrodynamic process simulation of craters formation and evolution on metal surfaces caused by intense pulsed ion beams. Vacuum 2015, 120, 116–120. [Google Scholar] [CrossRef]

- Wood, B.P.; Perry, A.J.; Bitteker, L.J.; Waganaar, W.J. Cratering behavior in single- and poly-crystalline copper irradiated by an intense pulsed ion beam. Surf. Coat. Technol. 1998, 108–109, 171–176. [Google Scholar] [CrossRef]

| Element | Value (wt.%) |

|---|---|

| Ni | 52.58 |

| Cr | 18.96 |

| Nb | 4.99 |

| Mo | 3.06 |

| Ti | 0.86 |

| Al | 0.48 |

| Si | 0.043 |

| C | 0.042 |

| Co | 0.034 |

| Cu | 0.023 |

| Mn | <0.01 |

| Mg | <0.01 |

| P | 0.0034 |

| S | 0.0022 |

| B | <0.001 |

| Item | Layer Thickness (mm) | Laser Power (W) | Scanning Speed (mm/s) | Scanning Distance (mm) | Preheat Temperature (°C) |

|---|---|---|---|---|---|

| Value | 0.04 | 280 | 960 | 0.09 | 80 |

| Sample | Energy Density (A/cm2) | Pulses | Ra (μm) |

|---|---|---|---|

| 1 | 0 | 0 | 0.225 |

| 2 | 100 | 1 | 0.368 |

| 3 | 100 | 5 | 0.471 |

| 4 | 100 | 10 | 0.335 |

| 5 | 100 | 20 | 0.154 |

| 6 | 200 | 1 | 0.273 |

| 7 | 200 | 5 | 0.409 |

| 8 | 200 | 10 | 0.276 |

| 9 | 200 | 20 | 0.097 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, M.; Ding, S.; Yu, X.; Zhang, S.; Zhong, H.; Remnev, G.E.; Le, X.; Zhou, Y. Investigation of the Effects of an Intense Pulsed Ion Beam on the Surface Melting of IN718 Superalloy Prepared with Selective Laser Melting. Metals 2020, 10, 1178. https://doi.org/10.3390/met10091178

Min M, Ding S, Yu X, Zhang S, Zhong H, Remnev GE, Le X, Zhou Y. Investigation of the Effects of an Intense Pulsed Ion Beam on the Surface Melting of IN718 Superalloy Prepared with Selective Laser Melting. Metals. 2020; 10(9):1178. https://doi.org/10.3390/met10091178

Chicago/Turabian StyleMin, Min, Shuiting Ding, Xiao Yu, Shijian Zhang, Haowen Zhong, Gennady Efimovich Remnev, Xiaoyun Le, and Yu Zhou. 2020. "Investigation of the Effects of an Intense Pulsed Ion Beam on the Surface Melting of IN718 Superalloy Prepared with Selective Laser Melting" Metals 10, no. 9: 1178. https://doi.org/10.3390/met10091178

APA StyleMin, M., Ding, S., Yu, X., Zhang, S., Zhong, H., Remnev, G. E., Le, X., & Zhou, Y. (2020). Investigation of the Effects of an Intense Pulsed Ion Beam on the Surface Melting of IN718 Superalloy Prepared with Selective Laser Melting. Metals, 10(9), 1178. https://doi.org/10.3390/met10091178