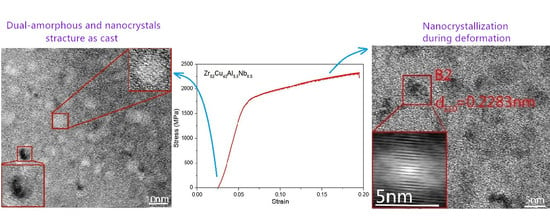

Improvement the Plasticity via Dual-Amorphous and Nanocrystals Synergistically in a Zr-Cu-Al-Nb Bulk Metallic Glass Composite

Abstract

1. Introduction

2. Experimental

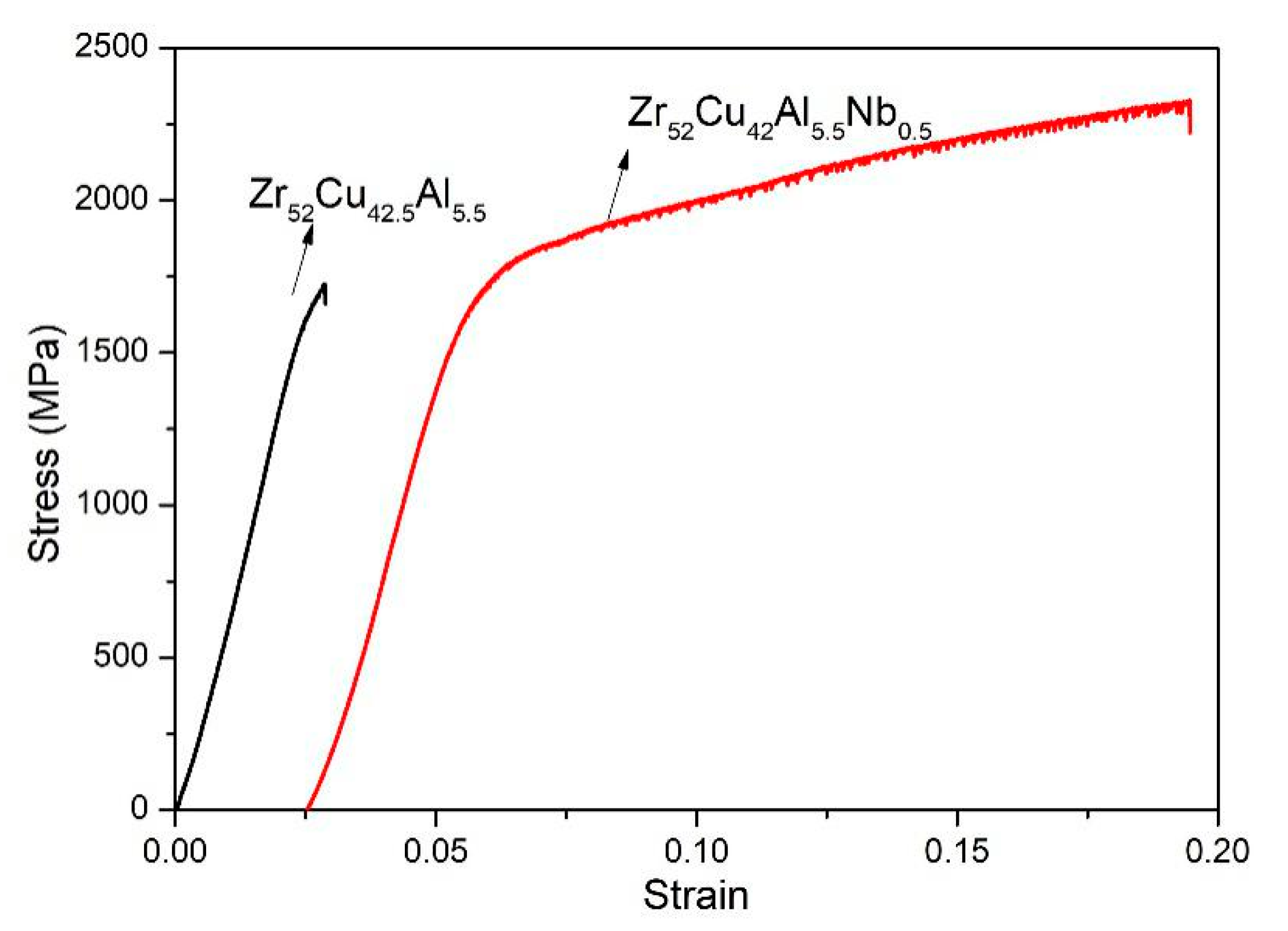

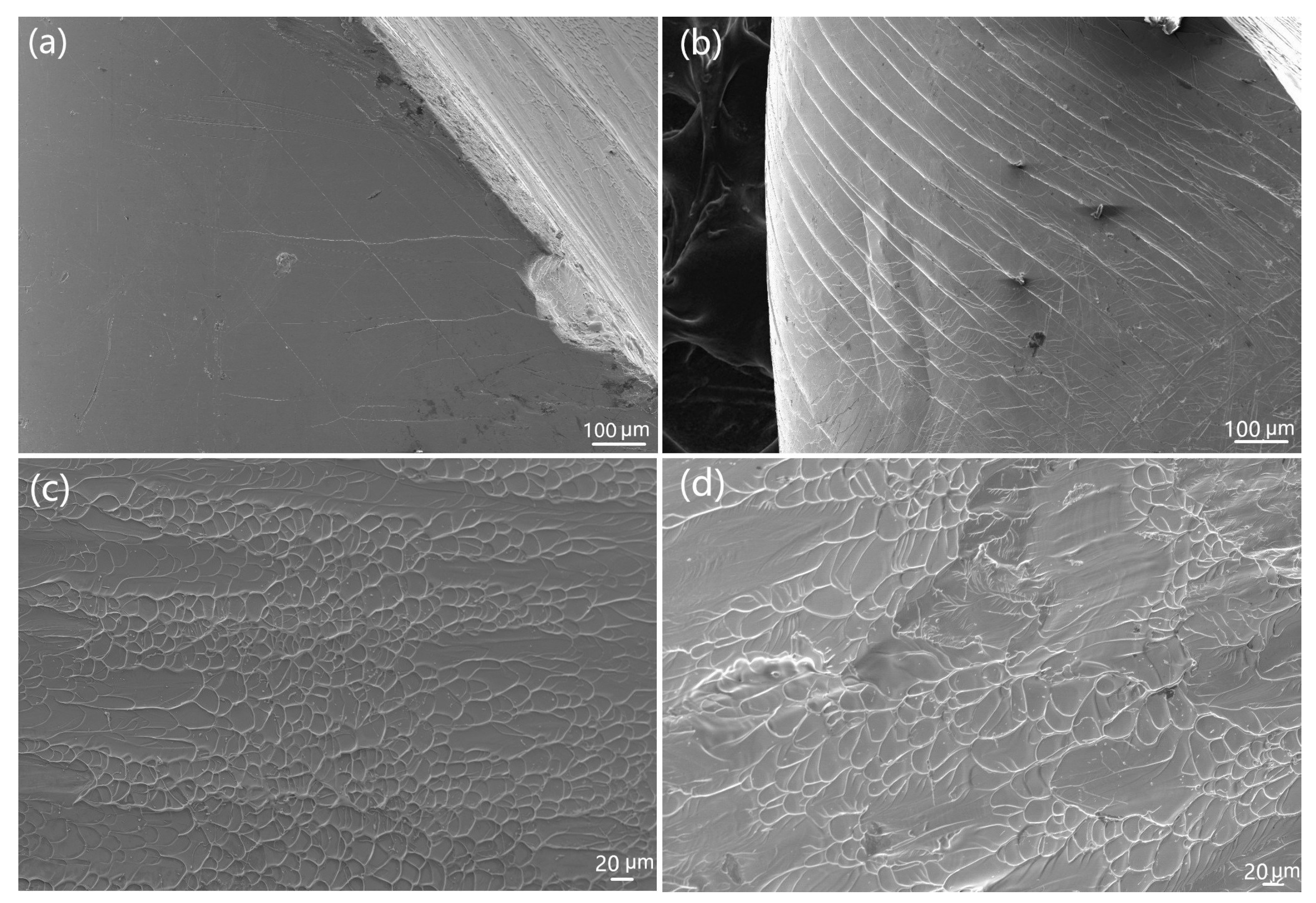

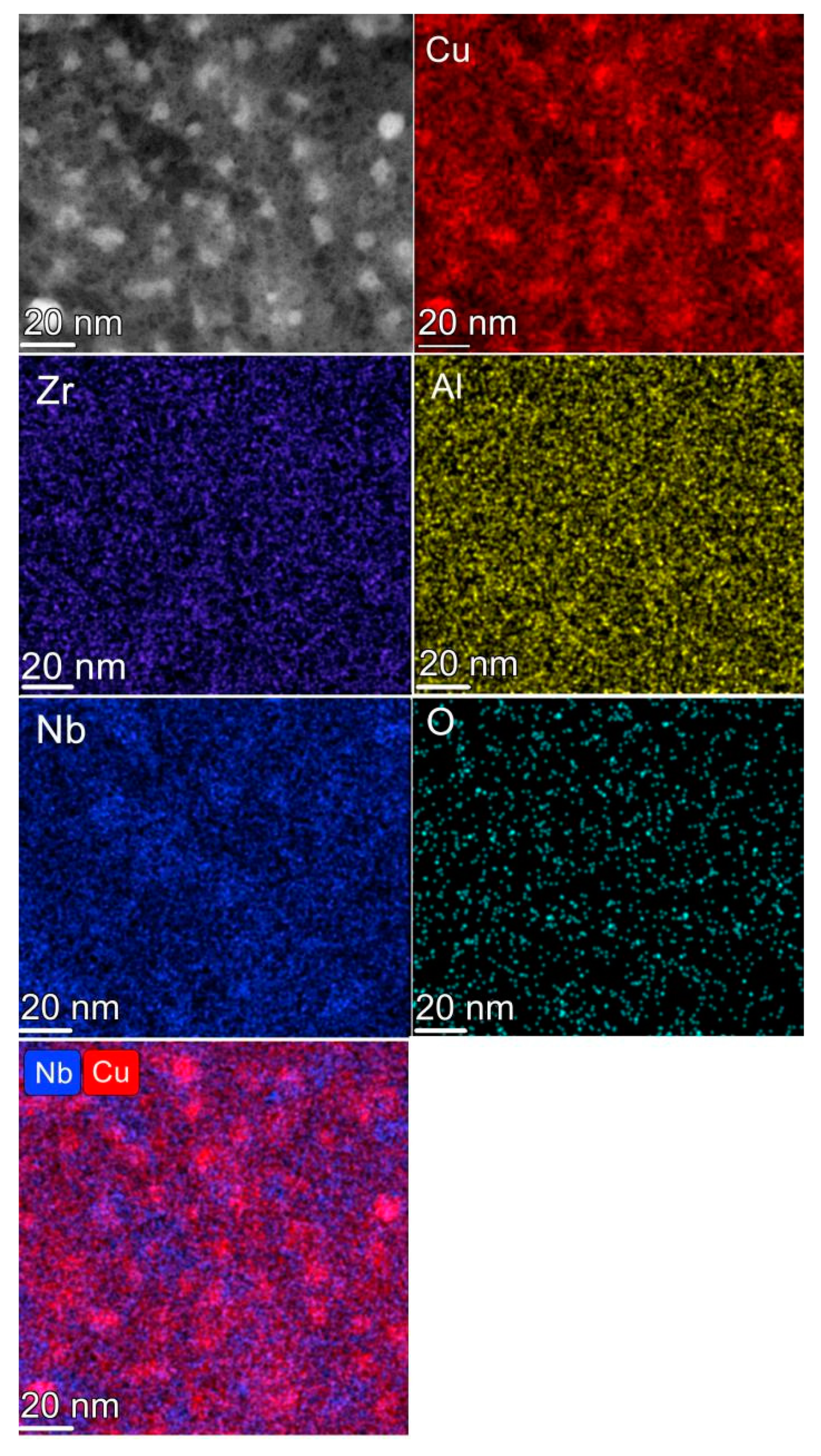

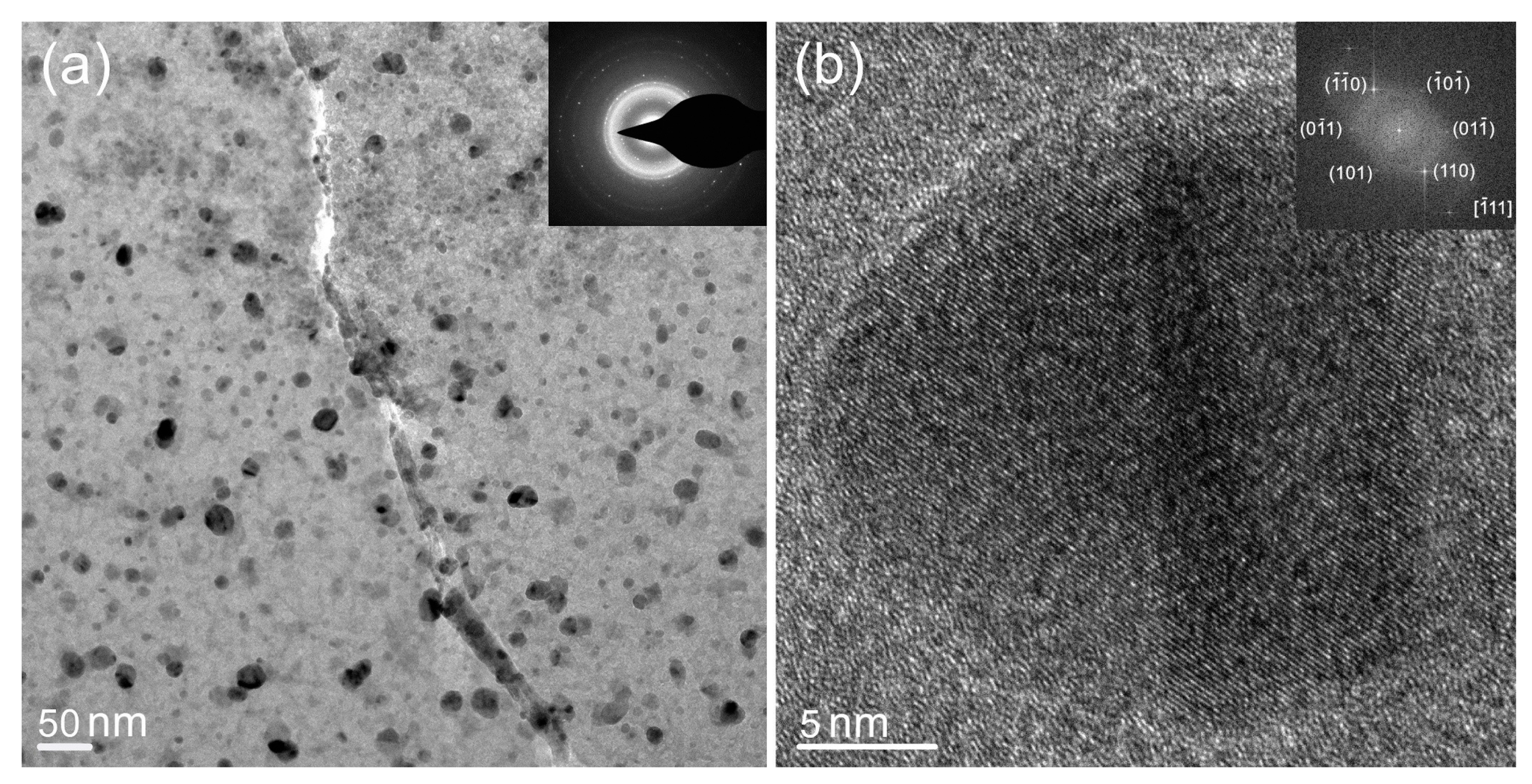

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, W.H.; Dong, C.; Shek, C.H. Bulk metallic glasses. Mater. Sci. Eng. R Rep. 2004, 44, 45–89. [Google Scholar] [CrossRef]

- Inoue, A.; Shen, B.L.; Koshiba, H.; Kato, H.; Yavari, A.R. Cobalt-based bulk glassy alloy with ultrahigh strength and soft magnetic properties. Nat. Mater. 2003, 2, 661–663. [Google Scholar] [CrossRef]

- Ghaemi, M.; Tavakoli, R.; Foroughi, A. Comparing short-range and medium-range ordering in Cu-Zr and Ni-Zr metallic glasses—Correlation between structure and glass form ability. J. Non Cryst. Solids 2018, 499, 227–236. [Google Scholar] [CrossRef]

- Qiao, J.C.; Wang, Q.; Pelletier, J.M.; Kato, H.; Casalini, R.; Crespo, D.; Pineda, E.; Yao, Y.; Yang, Y. Structural heterogeneities and mechanical behavior of amorphous alloys. Prog. Mater. Sci. 2019, 104, 250–329. [Google Scholar] [CrossRef]

- Wang, T.; Hu, L.; Liu, Y.; Hui, X. Intrinsic correlation of the plasticity with liquid behavior of bulk metallic glass forming alloys. Mater. Sci. Eng. A 2019, 744, 316–323. [Google Scholar] [CrossRef]

- Sun, B.A.; Yu, H.B.; Jiao, W.; Bai, H.Y.; Zhao, D.Q.; Wang, W.H. Plasticity of ductile metallic glasses: A self-organized critical state. Phys. Rev. Lett. 2010, 105, 035501. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Li, J.; Gong, P.; Yao, K.; Gao, J.; Li, H. Formation of bulk magnetic ternary Fe80P13C7 glassy alloy. Intermetallics 2012, 26, 62–65. [Google Scholar] [CrossRef]

- Liang, D.D.; Wang, X.D.; Ge, K.; Cao, Q.P.; Jiang, J.Z. Annealing effect on beta-relaxation in a La-based bulk metallic glass. J. Non Cryst. Solids 2014, 383, 97–101. [Google Scholar] [CrossRef]

- Wang, W.H. The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog. Mater. Sci. 2012, 57, 487–656. [Google Scholar] [CrossRef]

- Wu, Y.; Xiao, Y.; Chen, G.; Liu, C.T.; Lu, Z. Bulk metallic glass composites with transformation-mediated work-hardening and ductility. Adv. Mater. 2010, 22, 2770–2773. [Google Scholar] [CrossRef]

- Wang, T.; Lu, W.; Wang, Q.; Liu, Y.; Hui, X. Pronounced plasticity caused by phase separation and β-relaxation synergistically in Zr-Cu-Al-Mo bulk metallic glasses. Sci. Rep. 2017, 7, 1238. [Google Scholar] [CrossRef] [PubMed]

- Park, E.S.; Kim, D.H. Phase separation and enhancement of plasticity in Cu-Zr-Al-Y bulk metallic glasses. Acta Mater. 2006, 54, 2597–2604. [Google Scholar] [CrossRef]

- Choi-Yim, H.; Conner, R.D.; Johnson, W.L. In situ composite formation in the Ni-(Cu)-Ti-Zr-Si system. Scr. Mater. 2005, 53, 1467–1470. [Google Scholar] [CrossRef]

- Pan, J.; Liu, L.; Chan, K.C. Enhanced plasticity by phase separation in CuZrAl bulk metallic glass with micro-addition of Fe. Scr. Mater. 2009, 60, 822–825. [Google Scholar] [CrossRef]

- Liu, Y.H.; Wang, G.; Wang, R.J.; Zhao, D.Q.; Pan, M.X.; Wang, W.H. Super plastic bulk metallic glasses at room temperature. Science 2007, 315, 1385–1388. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, A.; Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Qin, F.X.; Wang, X.M.; Inoue, A. Effect of annealing on microstructure and mechanical property of a Ti-Zr-Cu-Pd bulk metallic glass. Intermetallics 2007, 15, 1337–1342. [Google Scholar] [CrossRef]

- Wang, T.; Si, J.; Wu, Y.; Lv, K.; Liu, Y.; Hui, X. Two-step work-hardening and its gigantic toughening effect in Zr-based bulk metallic glasses. Scr. Mater. 2018, 150, 106–109. [Google Scholar] [CrossRef]

- Chen, H.S. Stored energy in a cold-rolled metallic glass. Appl. Phys. Lett. 1976, 29, 328. [Google Scholar] [CrossRef]

- Hays, C.C.; Kim, P.; Johnson, W.L. Shear band pattern formation in bulk metallic glasses containing in-situ formed ductile phase dendrite dispersions. Phys. Rev. Lett. 2000, 84, 2901–2904. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Yang, X.; Li, Q.; Chang, C. Improvement the Plasticity via Dual-Amorphous and Nanocrystals Synergistically in a Zr-Cu-Al-Nb Bulk Metallic Glass Composite. Metals 2020, 10, 1158. https://doi.org/10.3390/met10091158

Wang T, Yang X, Li Q, Chang C. Improvement the Plasticity via Dual-Amorphous and Nanocrystals Synergistically in a Zr-Cu-Al-Nb Bulk Metallic Glass Composite. Metals. 2020; 10(9):1158. https://doi.org/10.3390/met10091158

Chicago/Turabian StyleWang, Tuo, Xiaohui Yang, Qiang Li, and Chuntao Chang. 2020. "Improvement the Plasticity via Dual-Amorphous and Nanocrystals Synergistically in a Zr-Cu-Al-Nb Bulk Metallic Glass Composite" Metals 10, no. 9: 1158. https://doi.org/10.3390/met10091158

APA StyleWang, T., Yang, X., Li, Q., & Chang, C. (2020). Improvement the Plasticity via Dual-Amorphous and Nanocrystals Synergistically in a Zr-Cu-Al-Nb Bulk Metallic Glass Composite. Metals, 10(9), 1158. https://doi.org/10.3390/met10091158