Review of Laser Powder Bed Fusion of Gamma-Prime-Strengthened Nickel-Based Superalloys

Abstract

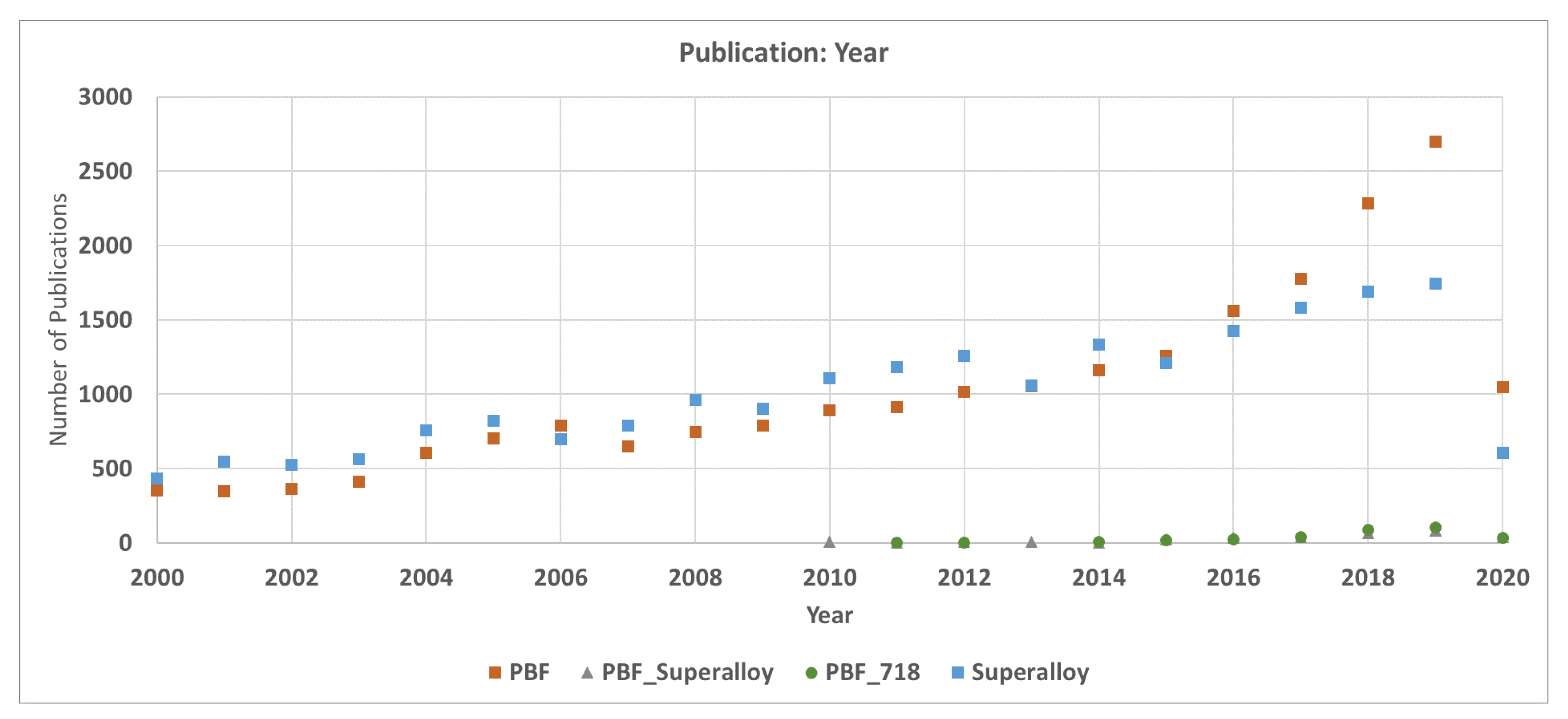

1. Introduction

2. Laser Powder Bed Fusion

2.1. Overview

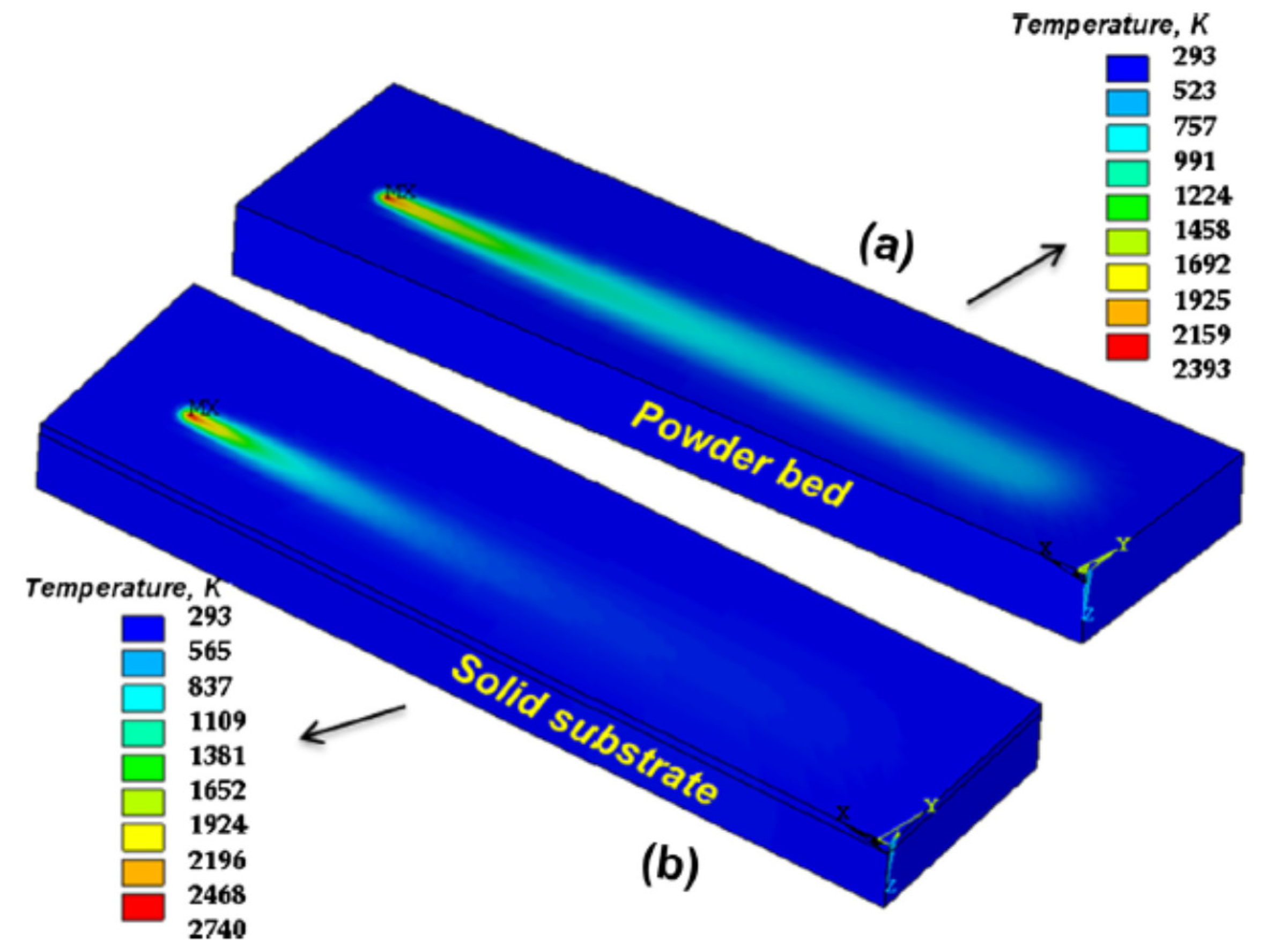

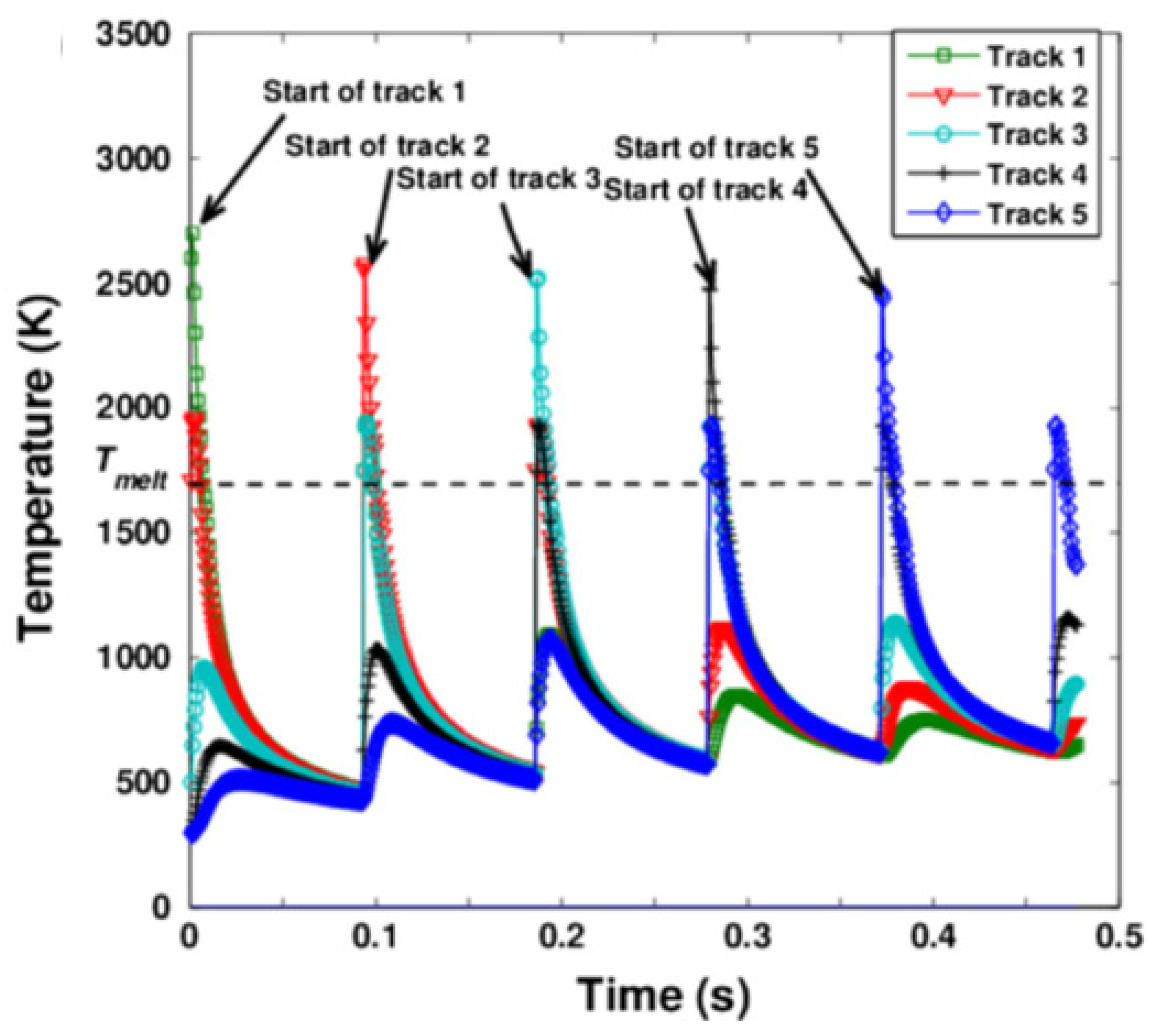

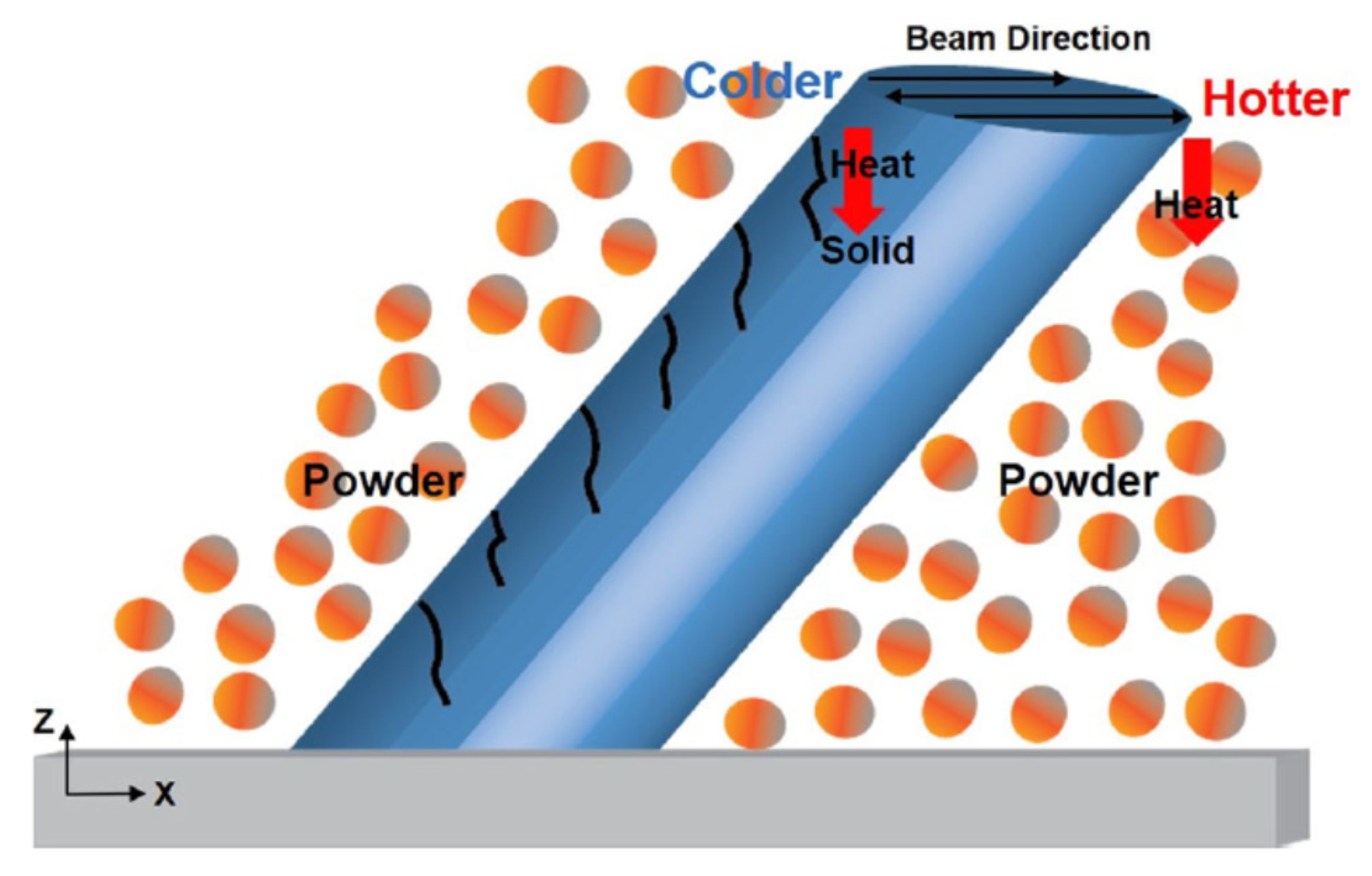

2.2. Heat Source and Material Interaction in the L-PBF Process

3. Defects Occurring from L-PBF of γ′ Nickel-Based Superalloys

3.1. Overview of Cracking and Porosity

3.2. Influence of Process Parameters on Cracking and Porosity

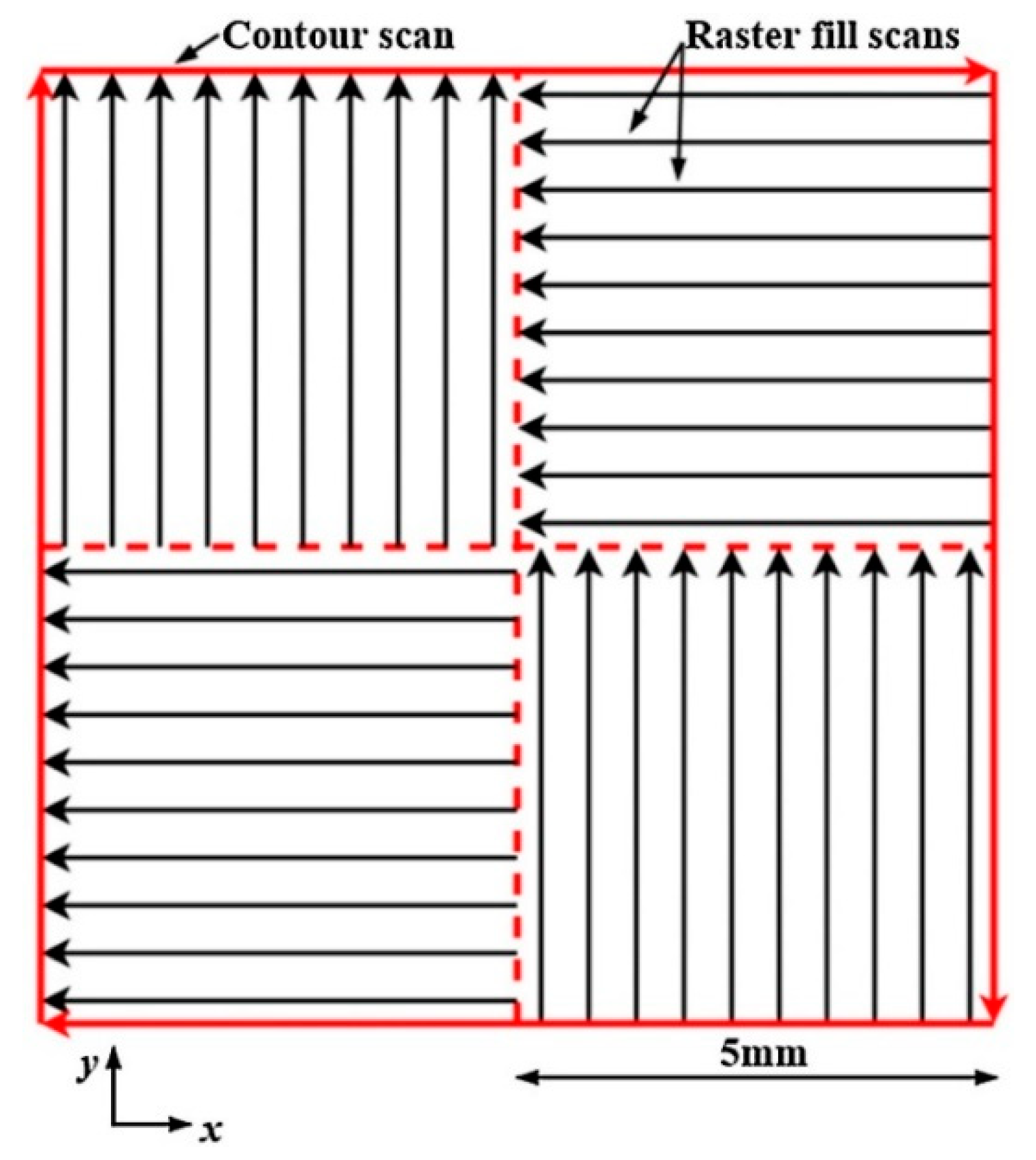

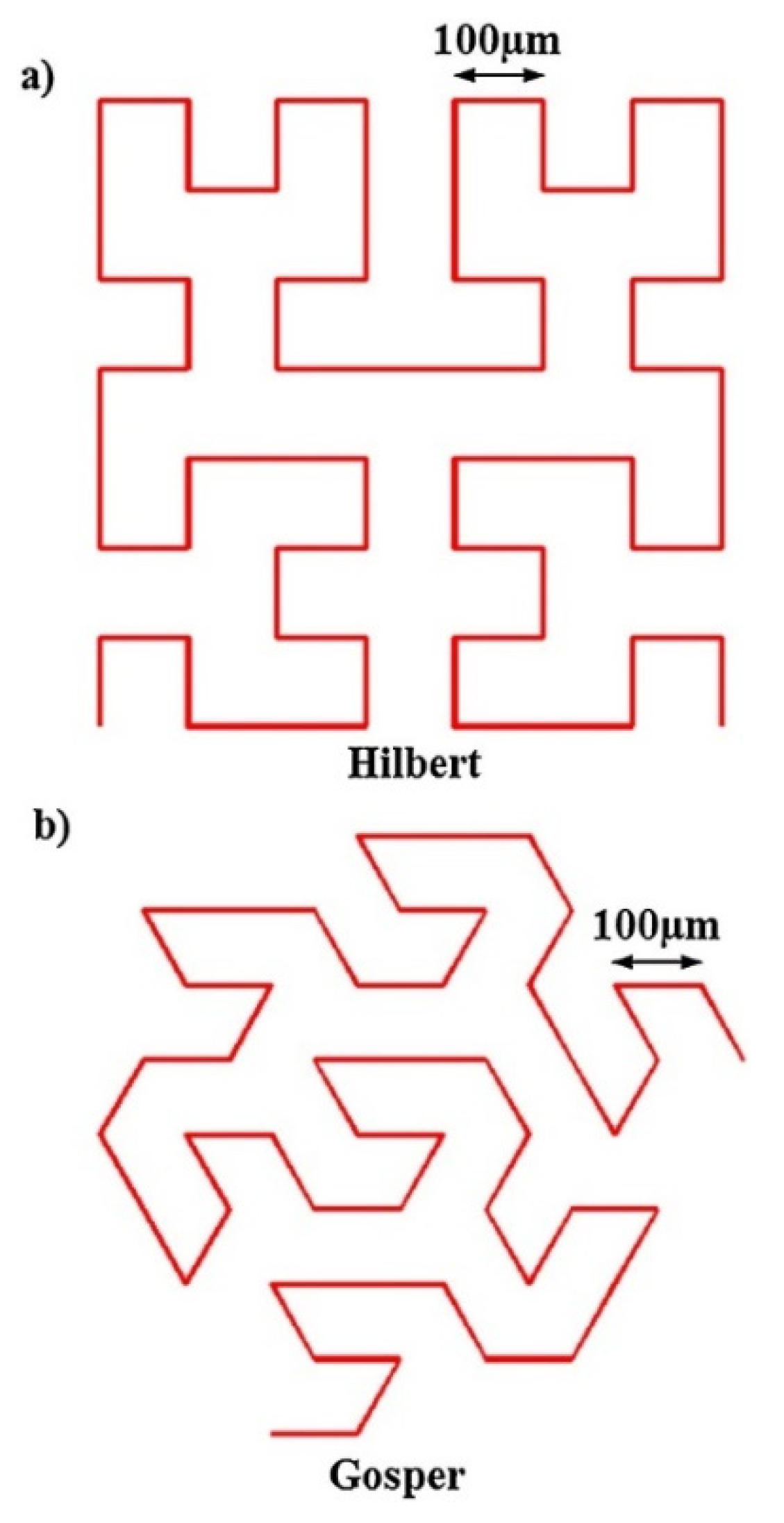

3.3. Influence of Laser Scanning Strategy on Cracking

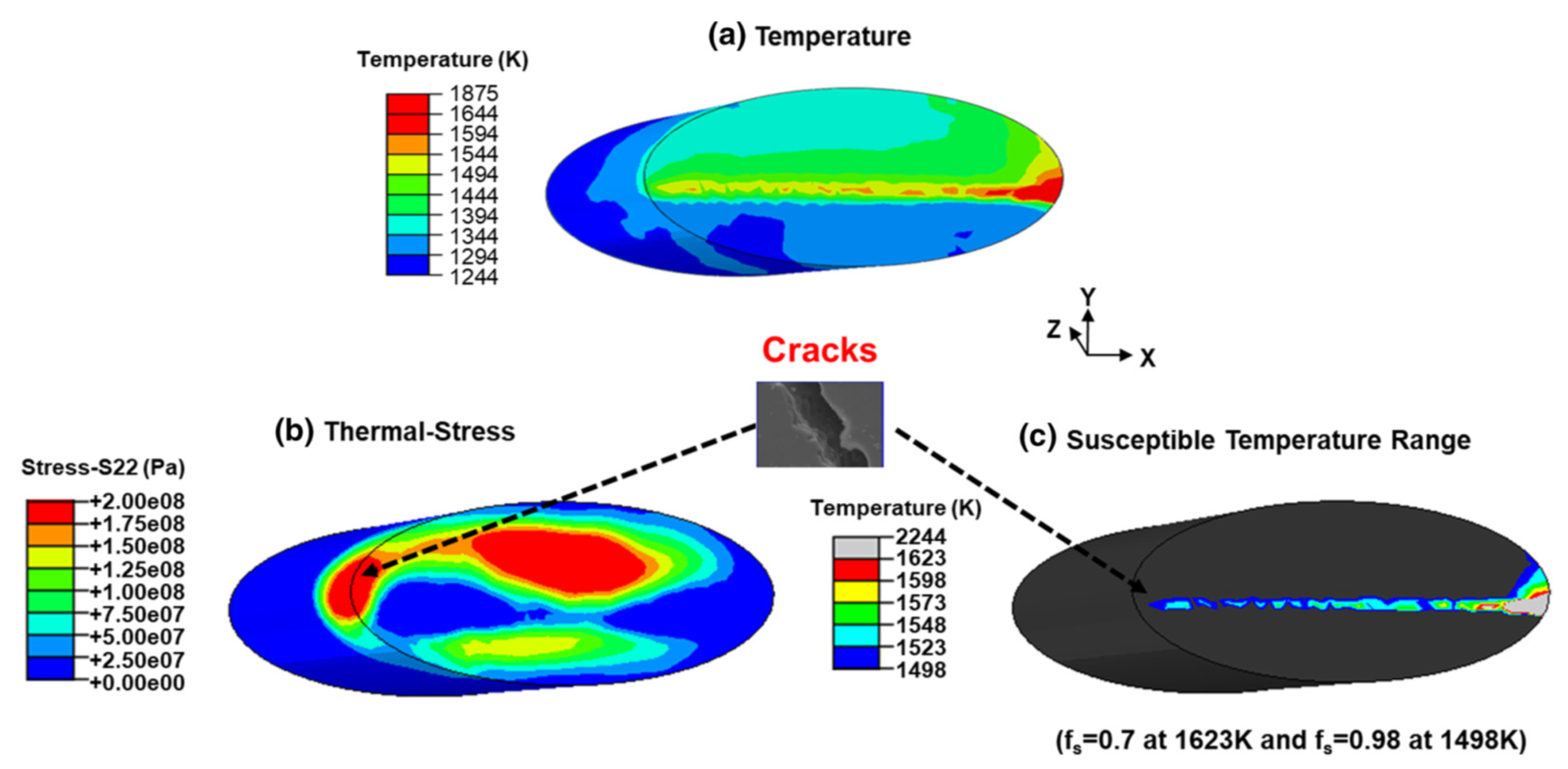

3.4. Influence of Stress on Cracking

3.5. Influence of Powder Composition on Porosity and Cracking

3.6. Influence of Solidification on Cracking

3.7. Solutions to Cracking

4. Microstructure

4.1. Grain Structure

4.2. Phases in L-PBF Microstructure

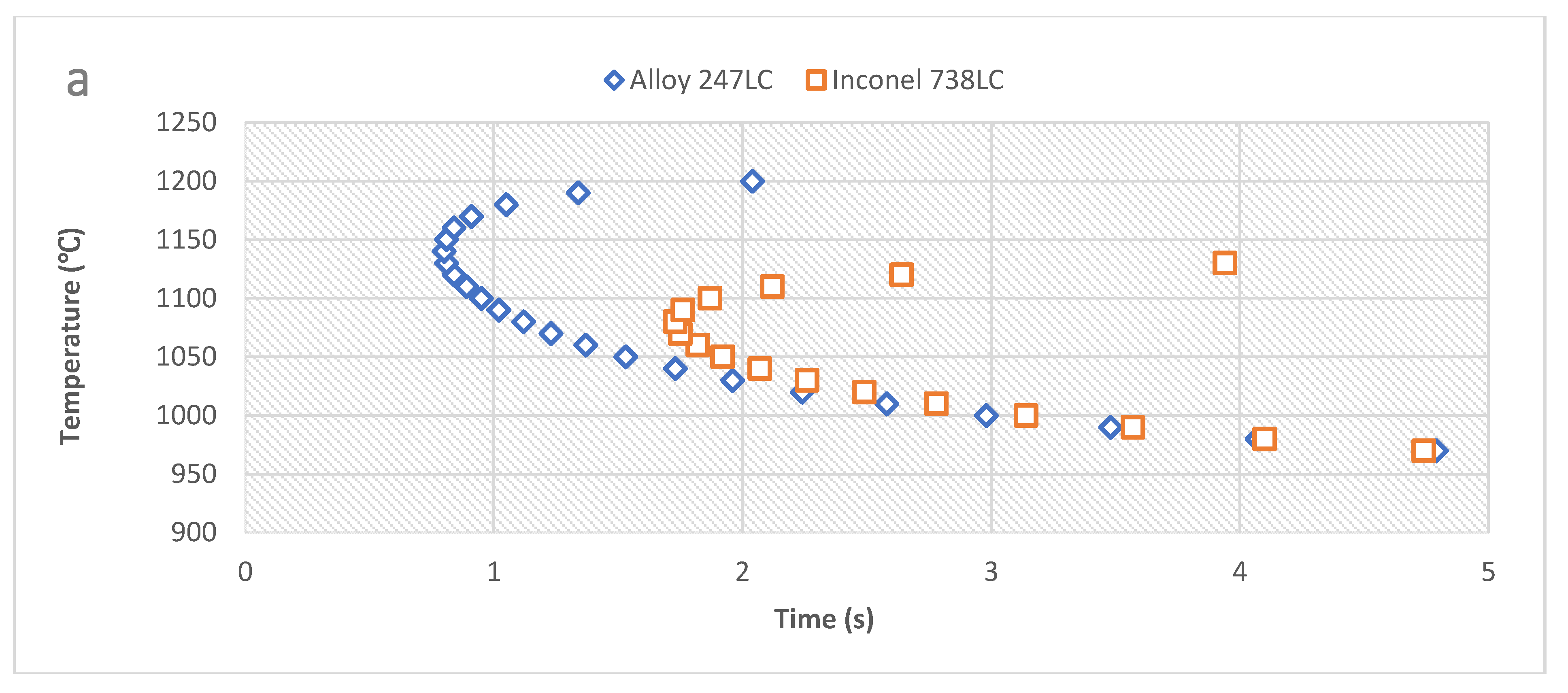

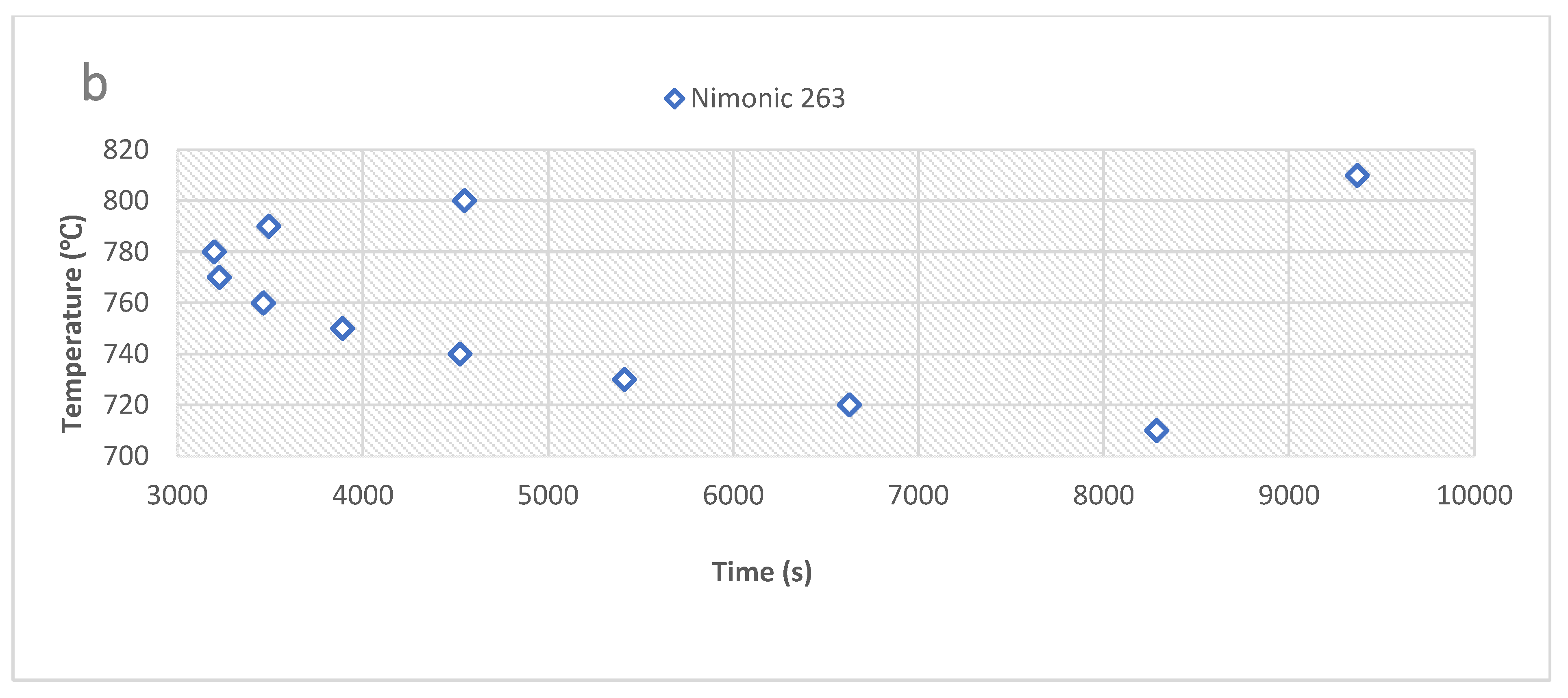

4.3. Influence of the Thermal Cycle on Microstructure Evolution

4.4. Role of Other Microconstituents

5. Mechanical Properties and Performance

6. Summary

- There remains an industrial requirement to optimize L-PBF process parameters for γ′-strengthened superalloys.

- Complex heat transfer mechanisms, including conduction, convection, and radiation, are characteristics of L-PBF processes.

- High thermal gradients, fast cooling rates, and spatial variation of thermal cycles influence the microstructure of the formed materials.

- L-PBF-manufactured γ′ nickel-based superalloys are prone to defects such as cracks, spherical pores, and lack-of-fusion voids.

- Solidification, liquation, SAC, and DDC are known cracking mechanisms in the welding of γ′ nickel-based superalloys; such cracking mechanisms also occur during L-PBF of γ′ nickel-based superalloys.

- L-PBF process parameters, including scanning strategies (patterns) and powder properties, strongly influence defect formation. The presence of Si in the powder increases cracking density.

- For solidification cracking to occur, prerequisites include the presence of liquid films, a wide critical temperature range (CTR), and the presence of residual stress. Segregating elements, such as Zr or B, could cause liquid films to be present in grain boundaries at low temperatures. Scheil-Gulliver thermodynamic plots can identify the CTR.

- The microstructures of L-PBF-manufactured γ′ nickel-based superalloys have constituents that are also found in the corresponding cast alloys. The γ, γ′, and γ/γ′ eutectic and carbides detected in L-PBF materials are important phases and microstructure components.

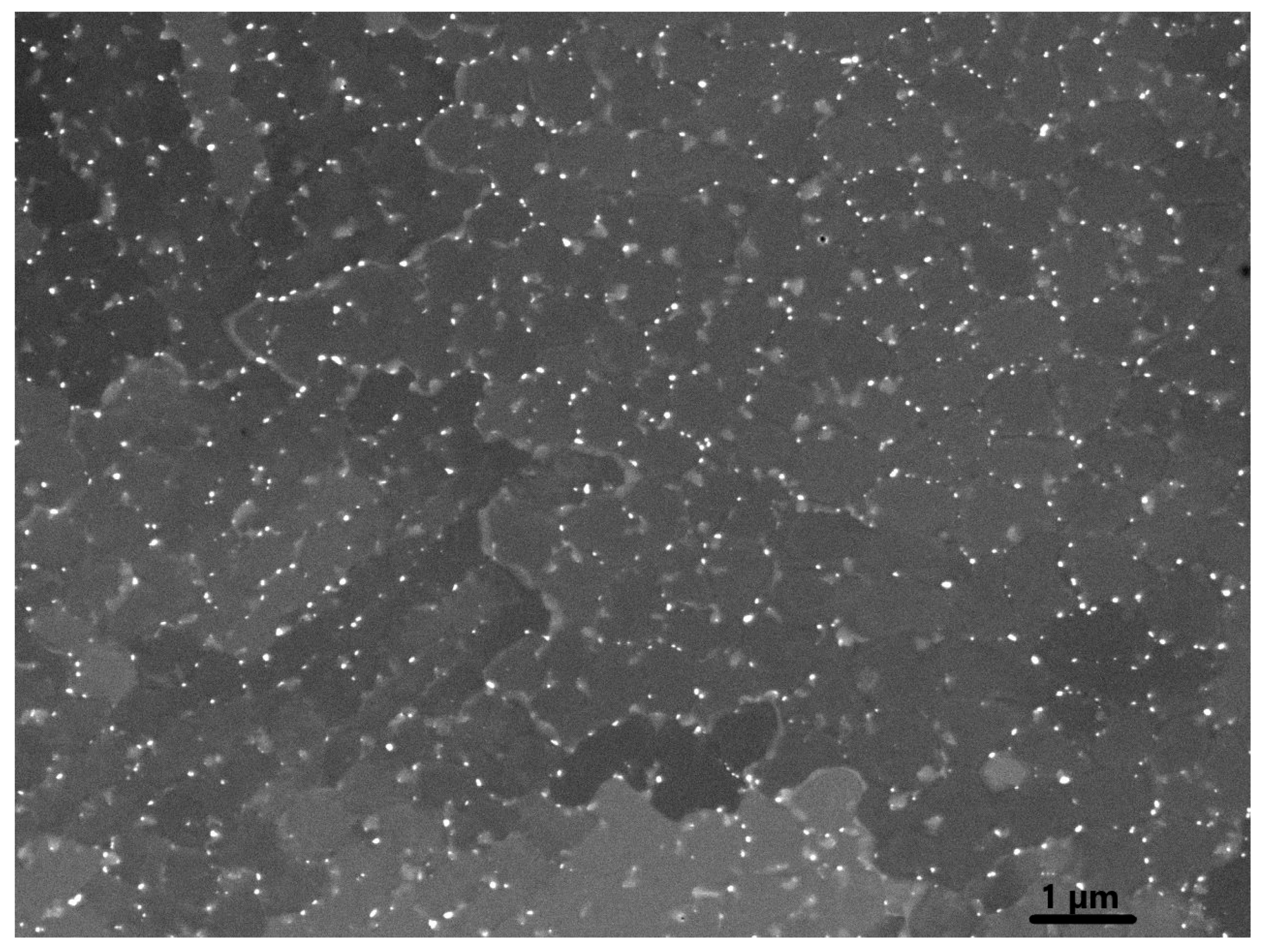

- Cell structures within grains can be characteristic of the microstructure, and enrichment of Ti, Hf, Ta, Mo, and W between cells has been observed.

- The size of γ′ precipitates becomes finer at high cooling rates and may not be observable in as-built L-PBF samples because of their small size. High-resolution electron microscopy analysis, for example TEM, can detect γ′ precipitates at the nanometer scale.

- Vertically built L-PBF samples have creep characteristics that are superior to those of horizontally built samples. However, the creep of cast samples outperforms L-PBF samples because L-PBF samples contain defects or because the grains and precipitates are smaller. Tensile tests also display anisotropy, and yield strength is generally better in horizontal-built specimens than in vertical-built specimens. L-PBF-manufactured samples display better yield strength than equivalent cast materials, and this is linked to the smaller grain sizes in L-PBF-manufactured samples.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sims, C.T.; Stoloff, N.S.; Hagel, W.C. (Eds.) Superalloys II; Wiley: New York, NY, USA, 1987. [Google Scholar]

- Ott, E.A.; Groh, J.; Sizek, H. Metals Affordability Initiative: Application of Allvac Alloy 718Plus for Aircraft Engine Static Structural Components. In Superalloys 718, 625, 706 and Various Derivatives (2005); The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 2005; pp. 35–45. [Google Scholar] [CrossRef]

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2002. [Google Scholar]

- Navrotsky, V.; Graichen, A.; Brodin, H. Industrialization of 3D Printing (Additive Manufacturing) for Gas Turbine Components Repair and Manufacturing; VGB Power Tech 12: Essen, Germany, 2015. [Google Scholar]

- Harris, K.; Erickson, G.L.; Schwer, R.E. MAR M 247 Derivations—CM 247 LC DS Alloy and CMSX Single Crystal Alloys: Properties & Performance. In Superalloys 1984 (Fifth International Symposium); The Minerals, Metals & Materials Society: Pittsburg, PA, USA, 1984; pp. 221–230. [Google Scholar] [CrossRef]

- Andersson, J. Weldability of Precipitation Hardening Superalloys: Influence of Microstructure; Chalmers University of Technology: Göteborg, Germany, 2011. [Google Scholar]

- Basak, A.; Raghu, S.H.; Das, S. Microstructures and Microhardness Properties of CMSX-4® Additively Fabricated Through Scanning Laser Epitaxy (SLE). J. Mater. Eng. Perform. 2017, 26, 5877–5884. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2015. [Google Scholar]

- Yadroitsev, I. Selective Laser Melting: Direct Manufacturing of 3D-Objects by Selective Laser Melting of Metal Powders; Lambert Acad. Publ.: Saarbrücken, Germany, 2009. [Google Scholar]

- Gu, D. Laser Additive Manufacturing of High-Performance Materials; Springer: Berlin, Germany, 2015. [Google Scholar]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. Densification mechanism and microstructural evolution in selective laser sintering of Al–12Si powders. J. Mater. Process. Technol. 2011, 211, 113–121. [Google Scholar] [CrossRef]

- Wang, F.; Wu, X.H.; Clark, D. On direct laser deposited Hastelloy X: Dimension, surface finish, microstructure and mechanical properties. Mater. Sci. Technol. 2011, 27, 344–356. [Google Scholar] [CrossRef]

- Carter, L.N.; Wang, X.; Read, N.; Khan, R.; Aristizabal, M.; Essa, K.; Attallah, M.M. Process optimisation of selective laser melting using energy density model for nickel based superalloys. Mater. Sci. Technol. 2016, 1–5. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components – Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Elmer, J.W.; Allen, S.M.; Eagar, T.W. Microstructural development during solidification of stainless steel alloys. Metall. Trans. A 1989, 20, 2117–2131. [Google Scholar] [CrossRef]

- Li, Y.; Gu, D. Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder. Mater. Des. 2014, 63, 856–867. [Google Scholar] [CrossRef]

- Hussein, A.; Hao, L.; Yan, C.; Everson, R. Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Mater. Des. 1980–2015 2013, 52, 638–647. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- DuPont, J.N.; Lippold, J.C.; Kiser, S.D. Welding Metallurgy and Weldability of Nickel-Base Alloys; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Kou, S. Welding Metallurgy, 2nd ed.; Wiley-Interscience: Hoboken, NJ, USA, 2003. [Google Scholar]

- Pellini, W.S. Strain theory of hot tearing. Foundary 1952, 80, 125. [Google Scholar]

- Pumphrey, W.I. A consideration of the nature of brittleness at temperatures above the solidus in castings and welds in aluminium alloys. J. Inst. Met. 1948, 75, 235. [Google Scholar]

- Borland, J.C. Generalized theory of super-solidus cracking in welds (and castings). Br. Weld J. 1960, 7, 508–512. [Google Scholar]

- Dye, D.; Hunziker, O.; Reed, R.C. Numerical analysis of the weldability of superalloys. Acta Mater. 2001, 49, 683–697. [Google Scholar] [CrossRef]

- Zhong, M.; Sun, H.; Liu, W.; Zhu, X.; He, J. Boundary liquation and interface cracking characterization in laser deposition of Inconel 738 on directionally solidified Ni-based superalloy. Scr. Mater. 2005, 53, 159–164. [Google Scholar] [CrossRef]

- Sidhu, R.K.; Ojo, O.A.; Chaturvedi, M.C. Microstructural Response of Directionally Solidified René 80 Superalloy to Gas-Tungsten Arc Welding. Metall. Mater. Trans. A 2009, 40, 150–162. [Google Scholar] [CrossRef]

- Egbewande, A.T.; Buckson, R.A.; Ojo, O.A. Analysis of laser beam weldability of Inconel 738 superalloy. Mater. Charact. 2010, 61, 569–574. [Google Scholar] [CrossRef]

- Young, G.A.; Capobianco, T.E.; Penik, M.A.; Morris, B.W.; McGee, J.J. The mechanism of ductility dip cracking in nickel-chromium alloys. Weld. J. 2008, 87, 31–43. [Google Scholar]

- Divya, V.D.; Muñoz-Moreno, R.; Messé, O.M.D.M.; Barnard, J.S.; Baker, S.; Illston, T.; Stone, H.J. Microstructure of selective laser melted CM247LC nickel-based superalloy and its evolution through heat treatment. Mater. Charact. 2016, 114, 62–74. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Carter, L. Selective Laser Melting of Nickel Superalloys for High Temperature Applications. Ph.D. Thesis, University of Birmigham, Birmigham, UK, 2013. [Google Scholar]

- Cloots, M.; Uggowitzer, P.J.; Wegener, K. Investigations on the microstructure and crack formation of IN738LC samples processed by selective laser melting using Gaussian and doughnut profiles. Mater. Des. 2016, 89, 770–784. [Google Scholar] [CrossRef]

- Perevoshchikova, N.; Rigaud, J.; Sha, Y.; Heilmaier, M.; Finnin, B.; Labelle, E.; Wu, X. Optimisation of selective laser melting parameters for the Ni-based superalloy IN-738 LC using Doehlert’s design. Rapid Prototyp. J. 2017, 23, 881–892. [Google Scholar] [CrossRef]

- Rickenbacher, L.; Etter, T.; Hövel, S.; Wegener, K. High temperature material properties of IN738LC processed by selective laser melting (SLM) technology. Rapid Prototyp. J. 2013, 19, 282–290. [Google Scholar] [CrossRef]

- Mumtaz, K.A.; Erasenthiran, P.; Hopkinson, N. High density selective laser melting of Waspaloy®. J. Mater. Process. Technol. 2008, 195, 77–87. [Google Scholar] [CrossRef]

- Catchpole-Smith, S.; Aboulkhair, N.; Parry, L.; Tuck, C.; Ashcroft, I.A.; Clare, A. Fractal scan strategies for selective laser melting of ‘unweldable’ nickel superalloys. Addit. Manuf. 2017, 15, 113–122. [Google Scholar] [CrossRef]

- Cloots, M.; Kunze, K.; Uggowitzer, P.J.; Wegener, K. Microstructural characteristics of the nickel-based alloy IN738LC and the cobalt-based alloy Mar-M509 produced by selective laser melting. Mater. Sci. Eng. A 2016, 658, 68–76. [Google Scholar] [CrossRef]

- Lee, Y.S.; Kirka, M.M.; Kim, S.; Sridharan, N.; Okello, A.; Dehoff, R.R.; Babu, S.S. Asymmetric Cracking in Mar-M247 Alloy Builds during Electron Beam Powder Bed Fusion Additive Manufacturing. Metall. Mater. Trans. A 2018, 49, 5065–5079. [Google Scholar] [CrossRef]

- Chauvet, E.; Kontis, P.; Jägle, E.A.; Gault, B.; Raabe, D.; Tassin, C.; Blandin, J.J.; Dendievel, R.; Vayre, B.; Abed, S.; et al. Hot cracking mechanism affecting a non-weldable Ni-based superalloy produced by selective electron Beam Melting. Acta Mater. 2018, 142, 82–94. [Google Scholar] [CrossRef]

- Attallah, M.M.; Jennings, R.; Wang, X.; Carter, L.N. Additive manufacturing of Ni-based superalloys: The outstanding issues. MRS Bull. 2016, 41, 758–764. [Google Scholar] [CrossRef]

- Prabhakar, P.; Sames, W.J.; Dehoff, R.; Babu, S.S. Computational modeling of residual stress formation during the electron beam melting process for Inconel 718. Addit. Manuf. 2015, 7, 83–91. [Google Scholar] [CrossRef]

- Griffith, M.L.; Schlienger, M.E.; Harwell, L.D.; Oliver, M.S.; Baldwin, M.D.; Ensz, M.T.; Essien, M.; Brooks, J.; Robino, C.V.; Smugeresky, E.J.; et al. Understanding thermal behavior in the LENS process. Mater. Des. 1999, 20, 107–113. [Google Scholar] [CrossRef]

- Labudovic, M.; Hu, D.; Kovacevic, R. A three dimensional model for direct laser metal powder deposition and rapid prototyping. J. Mater. Sci. 2003, 38, 35–49. [Google Scholar] [CrossRef]

- Song, X.; Xie, M.; Hofmann, F.; Illston, T.; Connolley, T.; Reinhard, C.; Atwood, R.C.; Connor, L.; Drakopoulos, M.; Frampton, L.; et al. Residual stresses and microstructure in Powder Bed Direct Laser Deposition (PB DLD) samples. Int. J. Mater. Form. 2015, 8, 245–254. [Google Scholar] [CrossRef]

- Shiomi, M.; Osakada, K.; Nakamura, K.; Yamashita, T.; Abe, F. Residual Stress within Metallic Model Made by Selective Laser Melting Process. CIRP Ann. 2004, 53, 195–198. [Google Scholar] [CrossRef]

- Boswell, J.H.; Clark, D.; Li, W.; Attallah, M.M. Cracking during thermal post-processing of laser powder bed fabricated CM247LC Ni-superalloy. Mater. Des. 2019, 174, 107793. [Google Scholar] [CrossRef]

- Wang, X.; Carter, L.N.; Pang, B.; Attallah, M.M.; Loretto, M.H. Microstructure and yield strength of SLM-fabricated CM247LC Ni-Superalloy. Acta Mater. 2017, 128, 87–95. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, L.; Tan, L.; Bai, P.; Li, J.; Wu, L.; Liao, H.; Cheng, Y. Simulation of Stress Field during the Selective Laser Melting Process of the Nickel-Based Superalloy, GH4169. Materials 2018, 11, 1525. [Google Scholar] [CrossRef] [PubMed]

- Engeli, R.; Etter, T.; Hövel, S.; Wegener, K. Processability of different IN738LC powder batches by selective laser melting. J. Mater. Process. Technol. 2016, 229, 484–491. [Google Scholar] [CrossRef]

- Holt, R.T.; Wallace, W. Impurities and trace elements in nickel-base superalloys. Int. Met. Rev. 1976, 21, 1–24. [Google Scholar] [CrossRef]

- Engeli, R.; Etter, T.; Geiger, F.; Stankowski, A.; Wegner, K. Effect of Si on the SLM processability of IN738LC. Available online: Sffsymposium.engr.utexas.edu (accessed on 20 July 2020).

- Hagedorn, Y.; Risse, J.; Meiners, W.; Pirch, N.; Wissenbach, K.; Propawe, R. Processing of nickel based superalloy MAR M-247 by means of high temperature–selective laser melting (HT-SLM). In Proceedings of the the International Conference on Advanced Research in Virtual and Rapid Prototyping (VRAP 2013), Leiria, Portugal, 1–5 October 2013; pp. 291–295. [Google Scholar]

- Basak, A.; Das, S. Microstructure of nickel-base superalloy MAR-M247 additively manufactured through scanning laser epitaxy (SLE). J. Alloys Compd. 2017, 705, 806–816. [Google Scholar] [CrossRef]

- Basak, A.; Das, S. Additive Manufacturing of Nickel-Base Superalloy IN100 Through Scanning Laser Epitaxy. JOM 2018, 70, 53–59. [Google Scholar] [CrossRef]

- Acharya, R.; Bansal, R.; Gambone, J.J.; Kaplan, M.A.; Fuchs, G.E.; Rudawski, N.G.; Das, S. Additive Manufacturing and Characterization of René 80 Superalloy Processed Through Scanning Laser Epitaxy for Turbine Engine Hot-Section Component Repair: Additive Manufacturing and Characterization of. Adv. Eng. Mater. 2015, 17, 942–950. [Google Scholar] [CrossRef]

- Basak, A.; Acharya, R.; Das, S. Additive Manufacturing of Single-Crystal Superalloy CMSX-4 Through Scanning Laser Epitaxy: Computational Modeling, Experimental Process Development, and Process Parameter Optimization. Metall. Mater. Trans. A 2016, 47, 3845–3859. [Google Scholar] [CrossRef]

- Basak, A.; Das, S. Additive Manufacturing of Nickel-Base Superalloy René N5 through Scanning Laser Epitaxy (SLE)—Material Processing, Microstructures, and Microhardness Properties: Additive Manufacturing of Superalloy René N5. Adv. Eng. Mater. 2017, 19, 1600690. [Google Scholar] [CrossRef]

- Basak, A.; Acharya, R.; Das, S. Epitaxial deposition of nickel-based superalloy René 142 through scanning laser epitaxy (SLE). Addit. Manuf. 2018, 22, 665–671. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Ramos, J.A.; Murphy, J.; Lappo, K.; Wood, K.; Bourell, D.L.; Beaman, J.J. Single-layer Deposits of Nickel Base Superalloy by means of Selective Laser Melting. Presented at the Solid Free form Fabrication Symposium, Austin, TX, USA, 17–19 August 2002. [Google Scholar]

- Kanagarajah, P.; Brenne, F.; Niendorf, T.; Maier, H.J. Inconel 939 processed by selective laser melting: Effect of microstructure and temperature on the mechanical properties under static and cyclic loading. Mater. Sci. Eng. A 2013, 588, 188–195. [Google Scholar] [CrossRef]

- Kunze, K.; Etter, T.; Grässlin, J.; Shklover, V. Texture, anisotropy in microstructure and mechanical properties of IN738LC alloy processed by selective laser melting (SLM). Mater. Sci. Eng. A 2015, 620, 213–222. [Google Scholar] [CrossRef]

- Muñoz-Moreno, R.; Divya, V.D.; Driver, S.L.; Messé, O.M.; Illston, T.; Baker, S.; Carpenter, M.A.; Stone, H.J. Effect of heat treatment on the microstructure, texture and elastic anisotropy of the nickel-based superalloy CM247LC processed by selective laser melting. Mater. Sci. Eng. A 2016, 674, 529–539. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, S.; Wei, Z.; Zhang, L.; Wei, P.; Lu, B.; Zhang, S.; Xiang, Y. Anisotropy of nickel-based superalloy K418 fabricated by selective laser melting. Prog. Nat. Sci. Mater. Int. 2018, 28, 496–504. [Google Scholar] [CrossRef]

- Adegoke, O.; Andersson, J.; Ojo, O.A.; Brodin, H.; Pederson, R. Laser Beam Powder Bed Fusion and Post Processing of Alloy 247LC; Material Science and Technology: Portland, OR, USA, 2019; pp. 27–34. [Google Scholar]

- Porter, D.A.; Easterling, K.E.; Sherif, M.Y. Phase Transformations in Metals and Alloys, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Krakhmalev, P.; Fredriksson, G.; Svensson, K.; Yadroitsev, I.; Yadroitsava, I.; Thuvander, M.; Peng, R. Microstructure, Solidification Texture, and Thermal Stability of 316 L Stainless Steel Manufactured by Laser Powder Bed Fusion. Metals 2018, 8, 643. [Google Scholar] [CrossRef]

- Geiger, F.; Kunze, K.; Etter, T. Tailoring the texture of IN738LC processed by selective laser melting (SLM) by specific scanning strategies. Mater. Sci. Eng. A 2016, 661, 240–246. [Google Scholar] [CrossRef]

- Rappaz, M.; Jacot, A.; Boettinger, W.J. Last-stage solidification of alloys: Theoretical model of dendrite-arm and grain coalescence. Metall. Mater. Trans. A 2003, 34, 467–479. [Google Scholar] [CrossRef]

- Wang, N.; Mokadem, S.; Rappaz, M.; Kurz, W. Solidification cracking of superalloy single- and bi-crystals. Acta Mater. 2004, 52, 3173–3182. [Google Scholar] [CrossRef]

- Collins, M.J.; Ramirez, A.J.; Lippold, J.C. An investigation of ductility-dip cracking in nickel-based weld metals—Part II. Weld. J. 2003, 82, 348–354. [Google Scholar]

- Collins, M.J.; Ramirez, A.J.; Lippold, J.C. An investigation of ductility-dip cracking in nickel-based weld metals—Part III. Weld. J. 2004, 83, 39–49. [Google Scholar]

- Liao, J.-H.; Bor, H.-Y.; Wei, C.-N.; Chao, C.-G.; Liu, T.-F. Influence of microstructure and its evolution on the mechanical behavior of modified MAR-M247 fine-grain superalloys at 871 °C. Mater. Sci. Eng. A 2012, 539, 93–100. [Google Scholar] [CrossRef]

- Mostafaei, M.; Abbasi, S.M. Influence of Zr content on the incipient melting behavior and stress-rupture life of CM247 LC nickel base superalloy. J. Alloys Compd. 2015, 648, 1031–1037. [Google Scholar] [CrossRef]

- Ojo, O.A.; Richards, N.L.; Chaturvedi, M.C. Contribution of constitutional liquation of gamma prime precipitate to weld HAZ cracking of cast Inconel 738 superalloy. Scr. Mater. 2004, 50, 641–646. [Google Scholar] [CrossRef]

- Babu, S.S.; Miller, M.K.; Vitek, J.M.; David, S.A. Characterization of the microstructure evolution in a nickel base superalloy during continuous cooling conditions. Acta Mater. 2001, 49, 4149–4160. [Google Scholar] [CrossRef]

- Kusabiraki, K.; Zhang, X.; Ooka, T. The Growth of GAMMA Precipitates in a 53Ni-20Co-15Cr Superalloy. ISIJ Int. 1995, 35, 1115–1120. [Google Scholar] [CrossRef]

- Radis, R.; Schaffer, M.; Albu, M.; Kothleitner, G.; Pölt, P.; Kozeschnik, E. Multimodal size distributions of γ′ precipitates during continuous cooling of UDIMET 720 Li. Acta Mater. 2009, 57, 5739–5747. [Google Scholar] [CrossRef]

- Chen, J.; Xue, L. Process-induced microstructural characteristics of laser consolidated IN-738 superalloy. Mater. Sci. Eng. A 2010, 527, 7318–7328. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D.; Nazé, L.; Sennour, M. Microstructural and mechanical approaches of the selective laser melting process applied to a nickel-base superalloy. Mater. Sci. Eng. A 2012, 534, 446–451. [Google Scholar] [CrossRef]

- Babu, S.S.; Raghavan, N.; Raplee, J.; Foster, S.J.; Frederick, C.; Haines, M.; Dinwiddie, R.; Kirka, M.K.; Plotkowski, A.; Lee, Y.; et al. Additive Manufacturing of Nickel Superalloys: Opportunities for Innovation and Challenges Related to Qualification. Metall. Mater. Trans. A 2018, 49, 3764–3780. [Google Scholar] [CrossRef]

- Qiu, C.; Chen, H.; Liu, Q.; Yue, S.; Wang, H. On the solidification behaviour and cracking origin of a nickel-based superalloy during selective laser melting. Mater. Charact. 2019, 148, 330–344. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Cao, X.; Wanjara, P.; Medraj, M. Oxide films in laser additive manufactured Inconel 718. Acta Mater. 2013, 61, 6562–6576. [Google Scholar] [CrossRef]

- Hilal, H.; Lancaster, R.; Jeffs, S.; Boswell, J.; Stapleton, D.; Baxter, G. The Influence of Process Parameters and Build Orientation on the Creep Behaviour of a Laser Powder Bed Fused Ni-based Superalloy for Aerospace Applications. Materials 2019, 12, 1390. [Google Scholar] [CrossRef]

- Bauer, T.; Dawson, K.; Spierings, A. Microstructure and mechanical characterization of SLM processed Haynes 230. Presented at the International Solid Freeform Symposium, Austin, TX, USA, 4–6 August 2015. [Google Scholar]

| Alloy | C | Cr | Ni | Co | Mo | W | Ta | Ti | Al | B | Zr | Hf | Nb | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 247 | 0.15 | 8.4 | balance | 10 | 0.7 | 10 | 3 | 1 | 5.5 | 0.015 | 0.05 | 1.5 | - | - |

| 247LC | 0.07 | 8.1 | balance | 9.2 | 0.5 | 9.5 | 3.2 | 0.7 | 5.6 | 0.015 | 0.015 | 1.4 | - | - |

| 738LC * | 0.11 | 16 | 61 | 8.5 | 1.7 | 2.6 | 1.7 | 3.4 | 3.4 | 0.010 | 0.05 | - | 0.9 | - |

| 939 ** | 0.15 | 22.5 | 48 | 19 | - | 2 | 1.4 | 3.7 | 1.9 | 0.009 | 0.09 | - | 1 | - |

| Waspaloy | 0.07 | 19.5 | 57.5 | 13.5 | 4.2 | - | - | 3 | 1.2 | 0.005 | 0.09 | - | - | 1 |

| 100 *** | 0.18 | 10 | 60.5 | 15 | 3 | - | - | 5 | 5.5 | 0.01 | 0.06 | - | - | - |

| Rene 80 | 0.17 | 14 | 60 | 9.5 | 4 | 4 | - | 5 | 3 | 0.015 | 0.03 | - | - | - |

| CMSX-4 | 6.5 | balance | 9.7 | 0.4 | 6.4 | 6.5 | 1 | 5.6 | Re 3 | |||||

| Haynes 230 | 0.1 | 22 | 57 | - | 2 | 14 | - | - | 0.3 | - | - | Mn 0.5 | Si 0.4 | - |

| Nimonic 263 | 0.06 | 20 | 51 | 20 | 5.9 | - | - | 2.1 | 0.5 | 0.001 | 0.02 | Mn 0.4 | Si 0.3 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adegoke, O.; Andersson, J.; Brodin, H.; Pederson, R. Review of Laser Powder Bed Fusion of Gamma-Prime-Strengthened Nickel-Based Superalloys. Metals 2020, 10, 996. https://doi.org/10.3390/met10080996

Adegoke O, Andersson J, Brodin H, Pederson R. Review of Laser Powder Bed Fusion of Gamma-Prime-Strengthened Nickel-Based Superalloys. Metals. 2020; 10(8):996. https://doi.org/10.3390/met10080996

Chicago/Turabian StyleAdegoke, Olutayo, Joel Andersson, Håkan Brodin, and Robert Pederson. 2020. "Review of Laser Powder Bed Fusion of Gamma-Prime-Strengthened Nickel-Based Superalloys" Metals 10, no. 8: 996. https://doi.org/10.3390/met10080996

APA StyleAdegoke, O., Andersson, J., Brodin, H., & Pederson, R. (2020). Review of Laser Powder Bed Fusion of Gamma-Prime-Strengthened Nickel-Based Superalloys. Metals, 10(8), 996. https://doi.org/10.3390/met10080996