Effect of Laser Cladding Stellite 6-Cr3C2-WS2 Self-Lubricating Composite Coating on Wear Resistance and Microstructure of H13

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

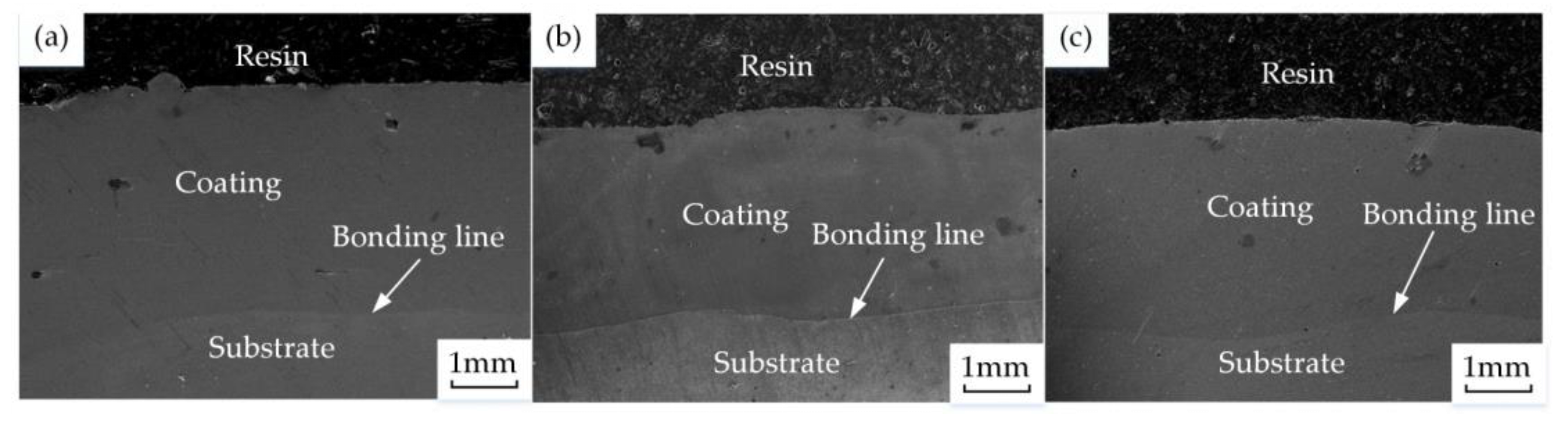

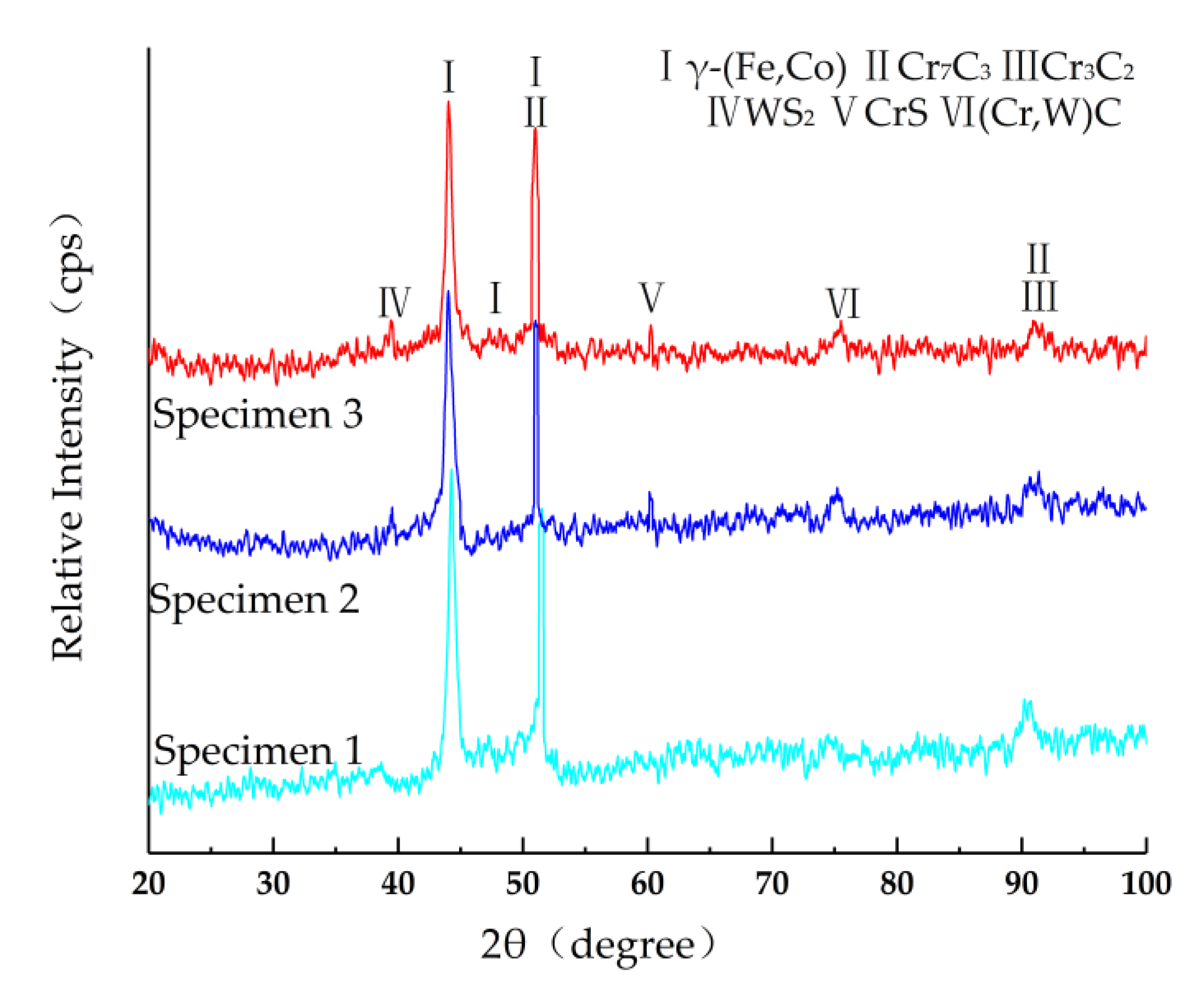

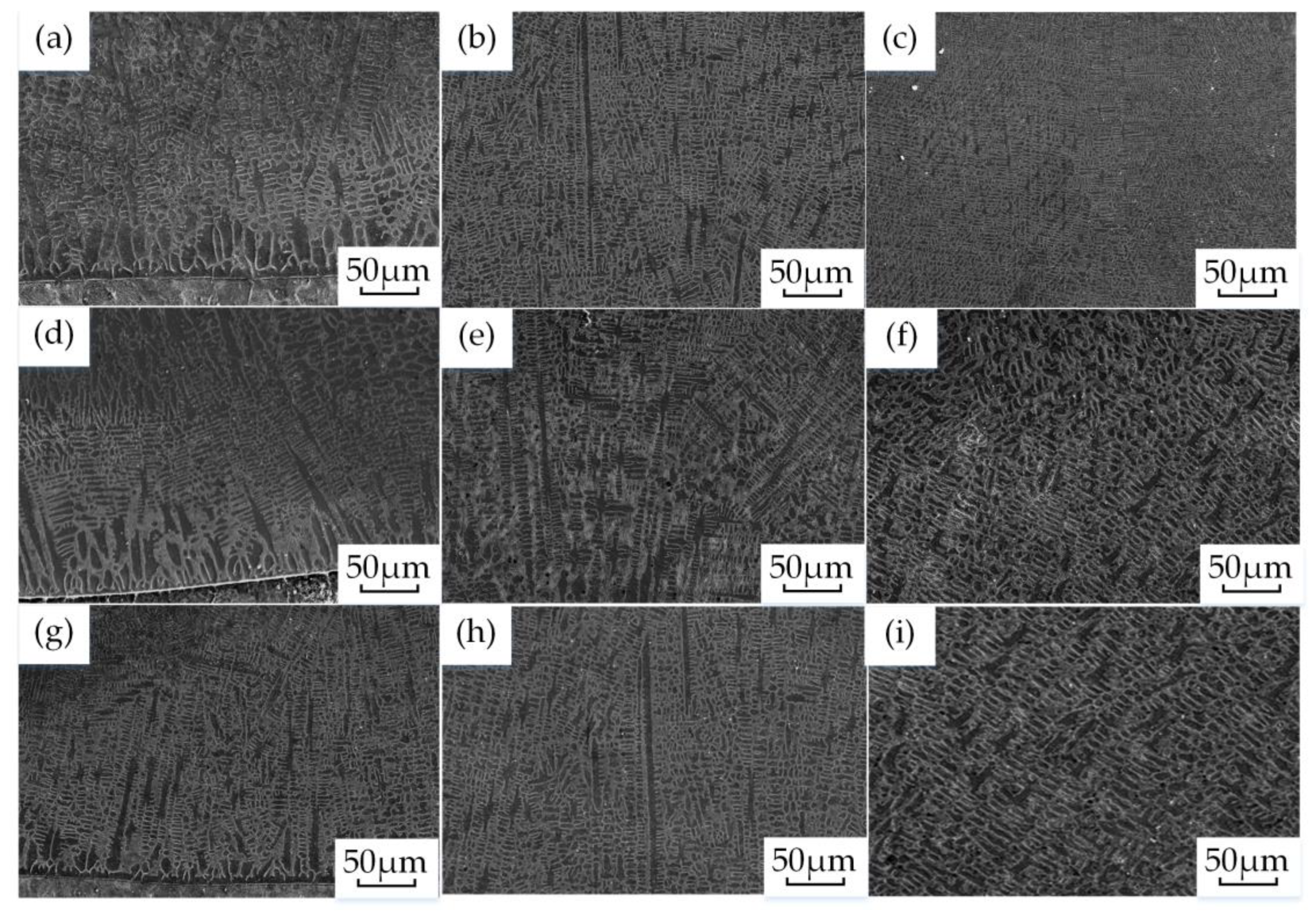

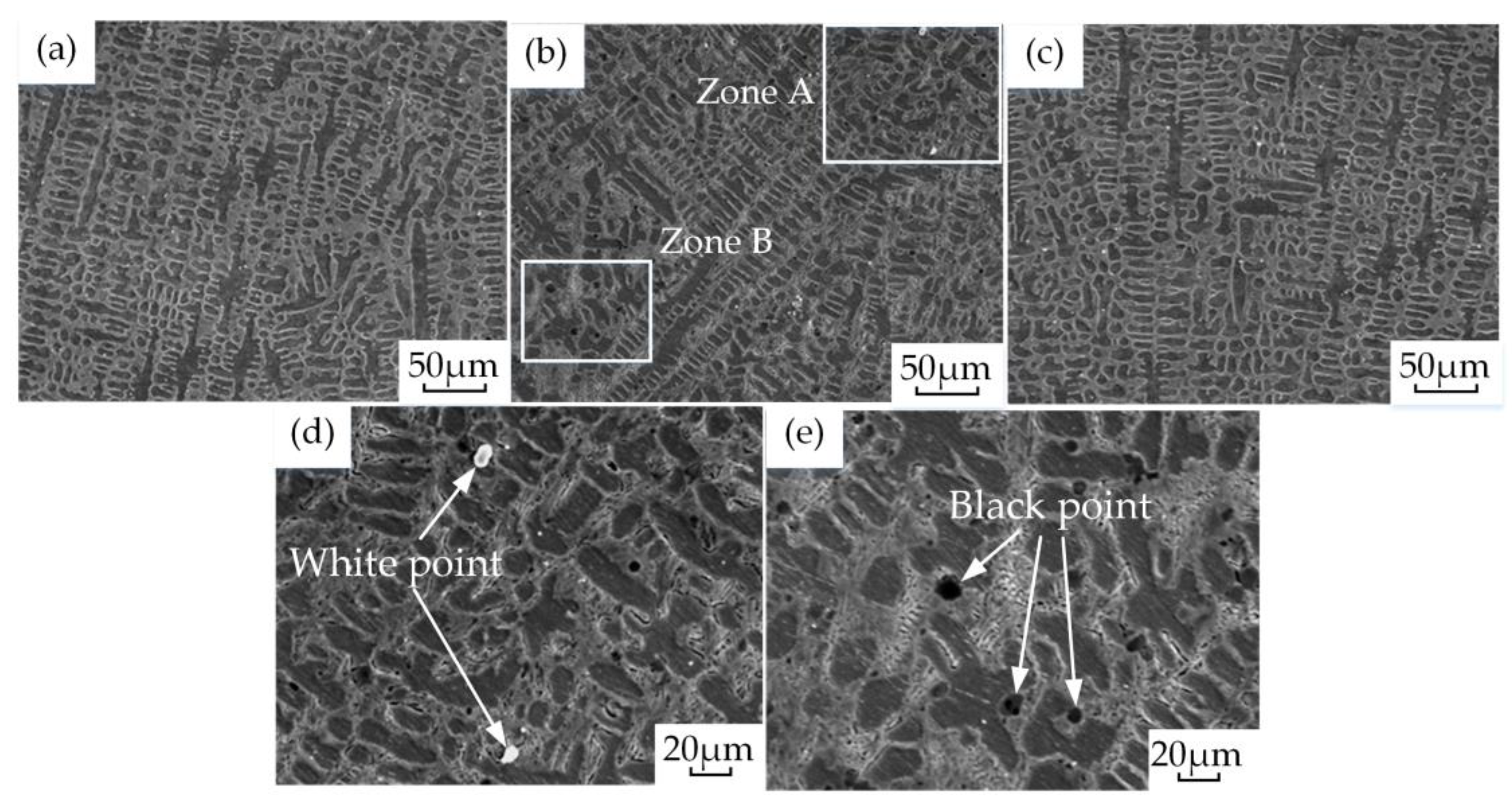

3.1. Constituent Phase and Microstructure

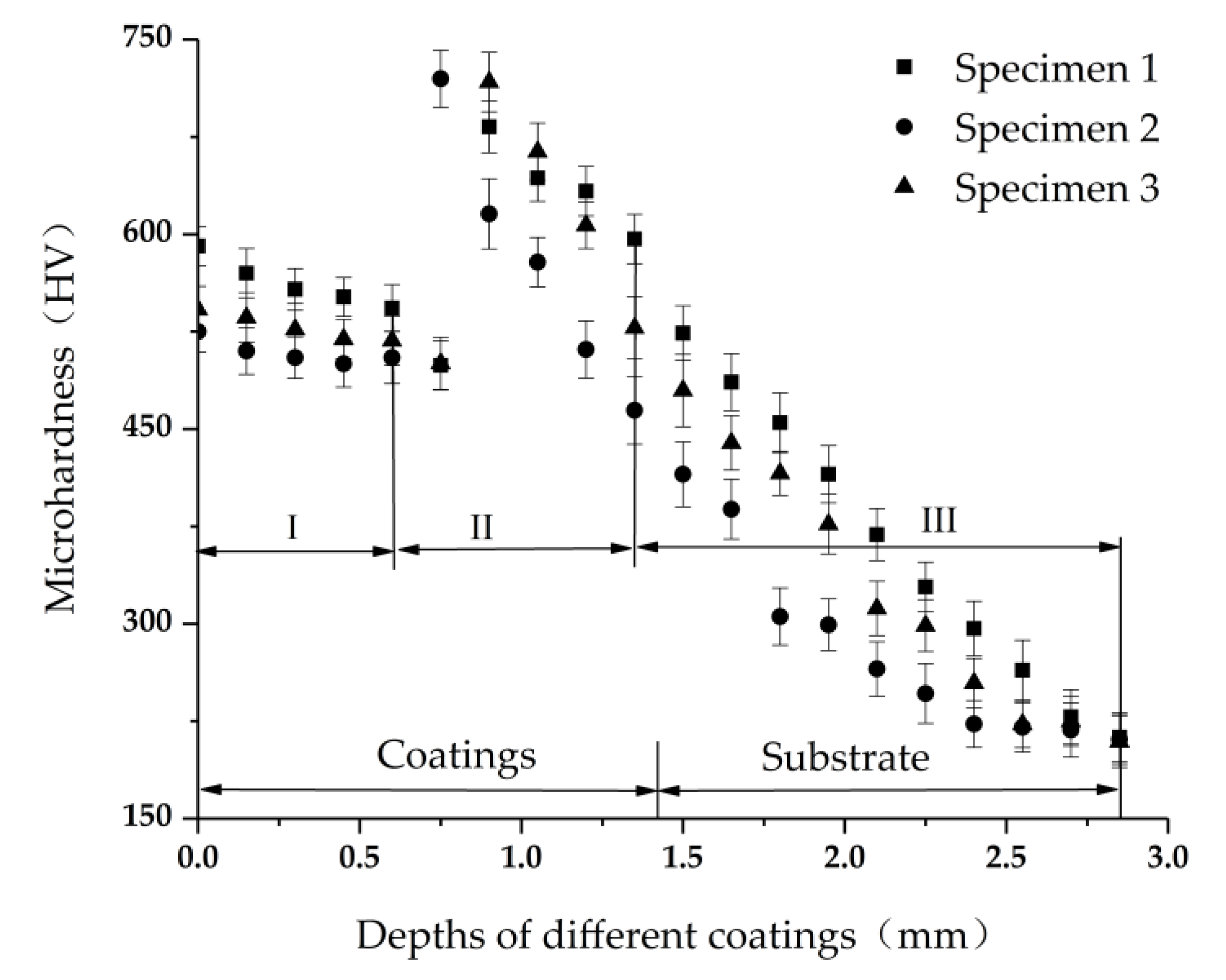

3.2. Microhardness

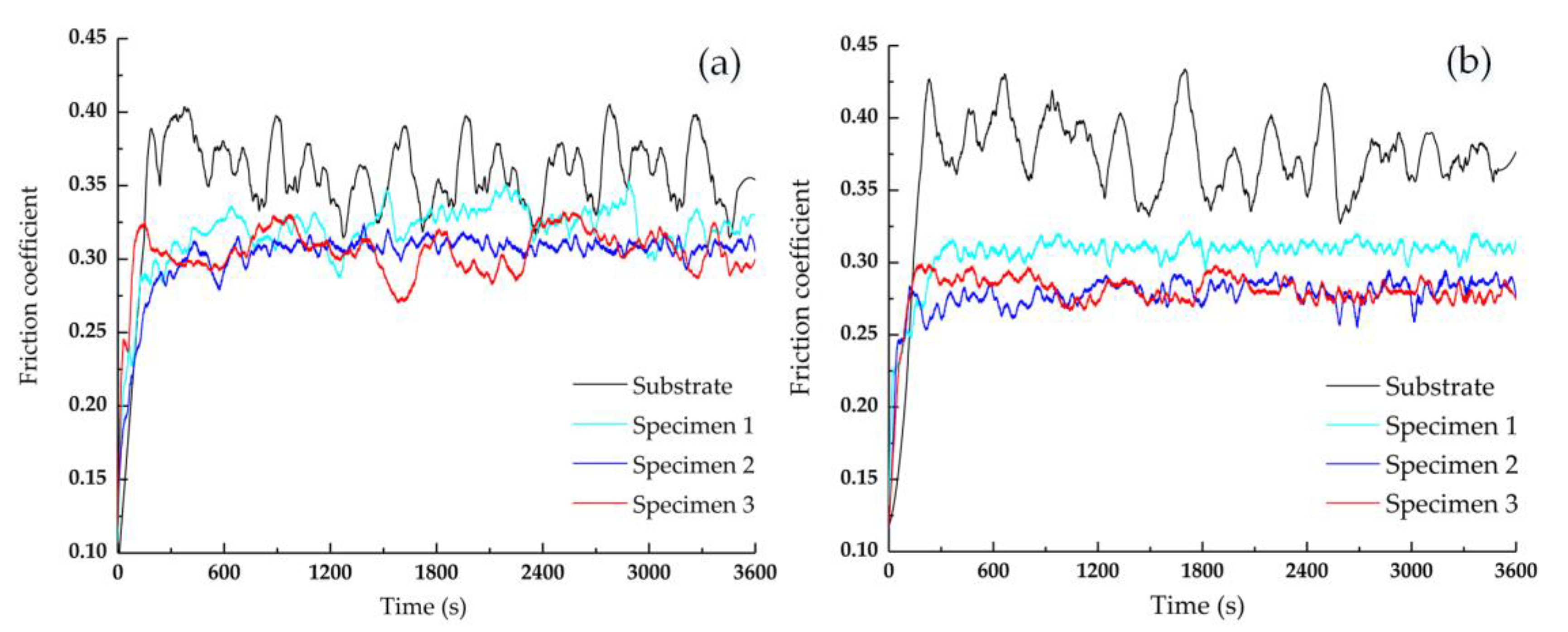

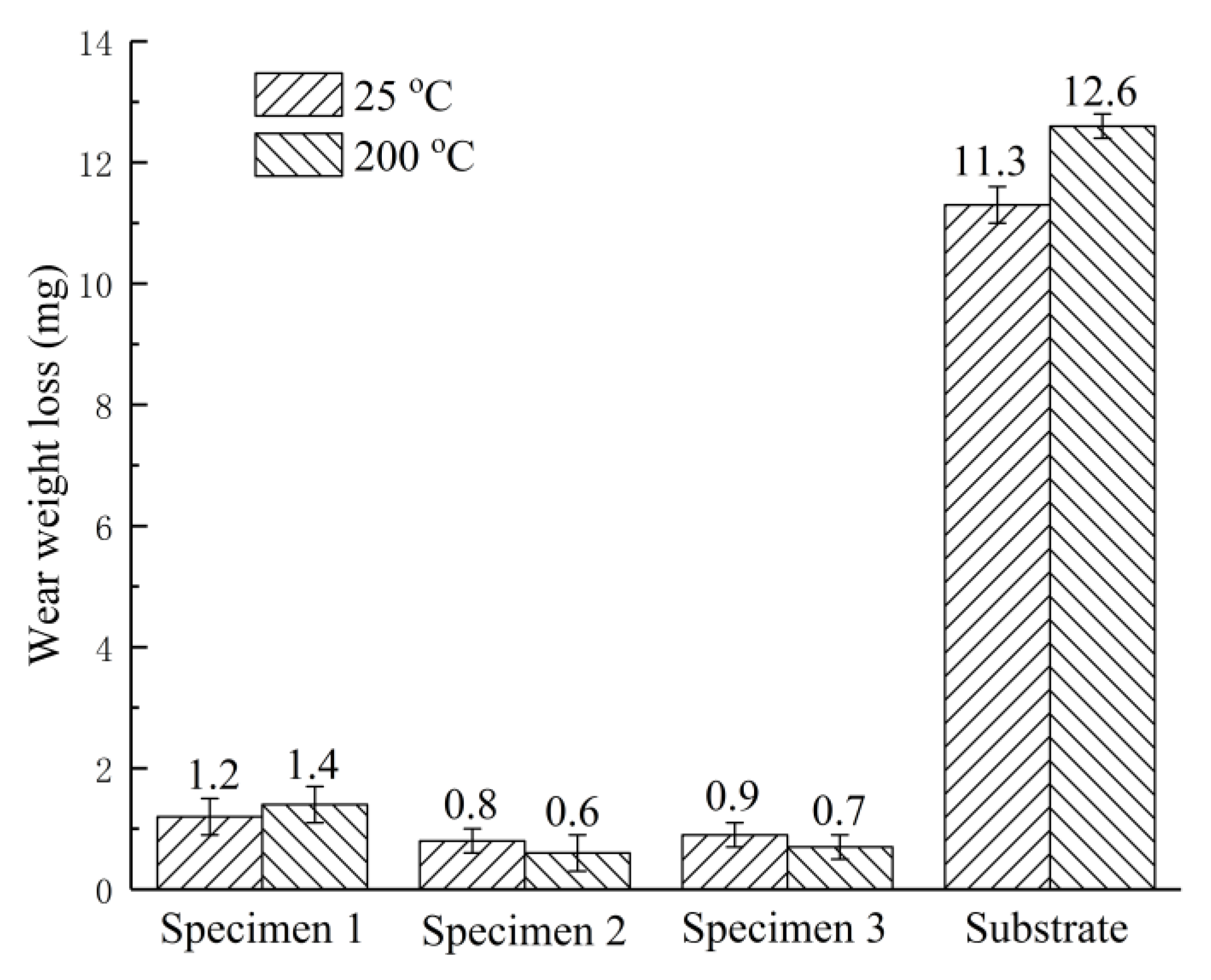

3.3. Friction Coefficient and Weight Loss

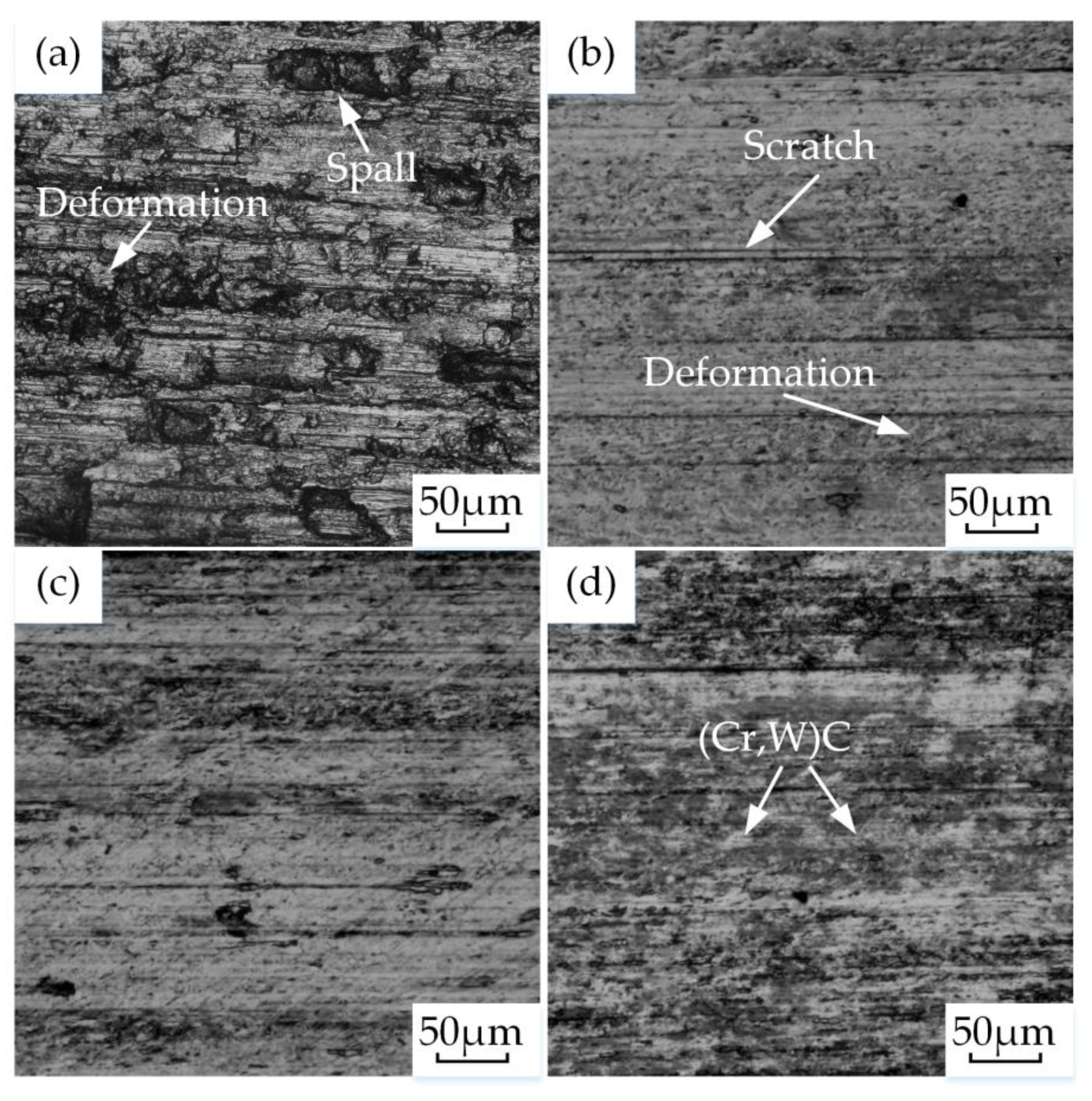

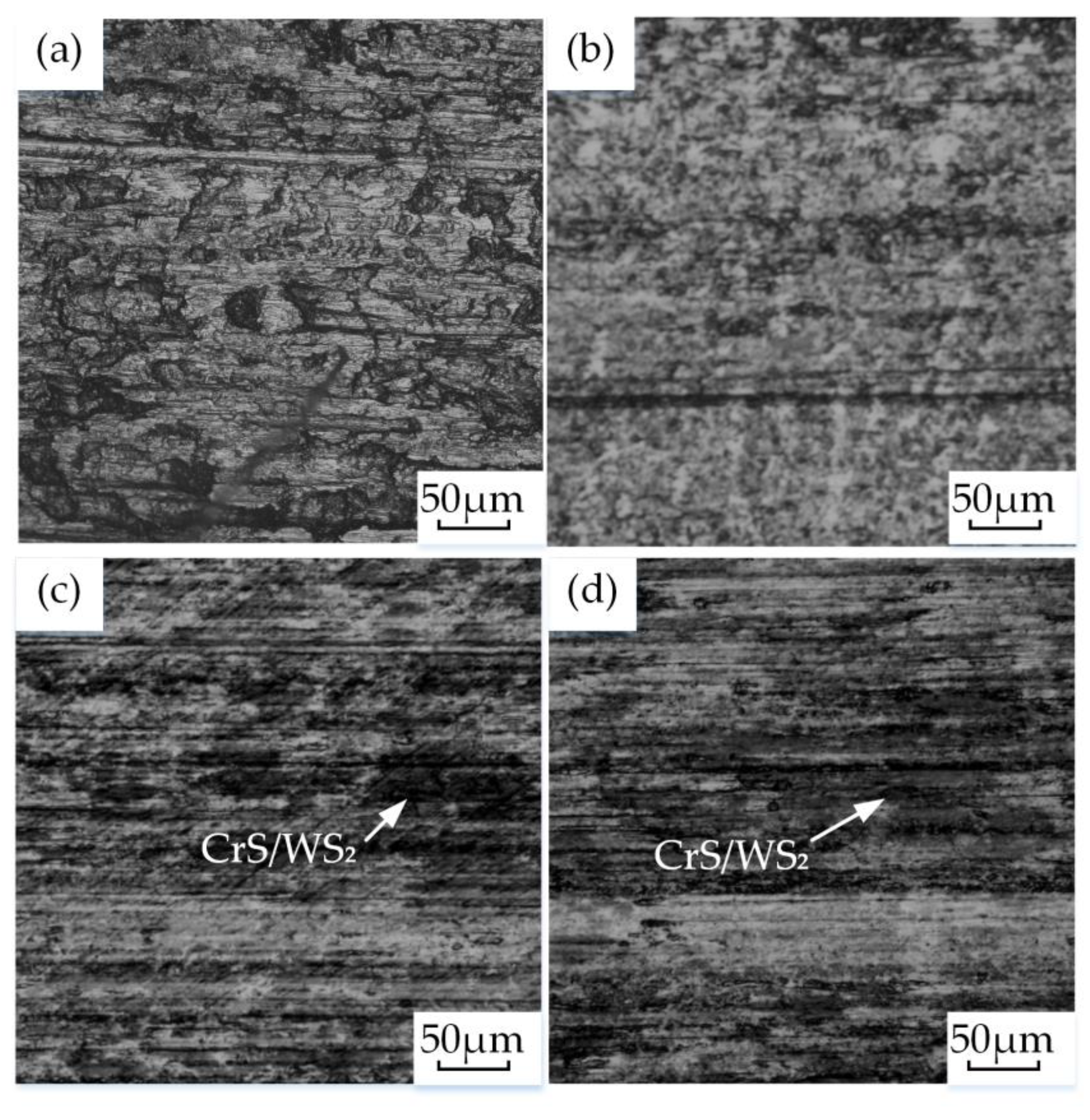

3.4. Wear Mechanism

4. Conclusions

- The Stellite 6-Cr3C2-WS2 laser cladding coating mainly consists of hard phases γ-(Fe, Co), Cr7C3 and Cr3C2, self-lubricating phase CrS and residual WS2. The obtained coating without cracks and pores demonstrates good metallurgical combination with the substrate.

- The hardness of laser cladding coatings is 2–3 times higher than that of the substrate due to the generation of γ-Co saturated solution and (Cr, W)C carbide hard phase.

- The laser cladding coating on the substrate reduces the friction coefficient to 70% of the substrate at 200 °C. In particular, the generation of the self-lubricating phase CrS at 200 °C acts as the lubricating film on the contact surface, thus produces less wear weight loss than that observed at 25 °C.

- The change of wear mechanism in cladding coatings remarkably reduces the degree of abrasive wear and adhesive wear due to the presence of hard phase and self-lubricating phase in the coatings.

- The 85% Stellite 6-10% Cr3C2-5% WS2 laser cladding coating provided good anti-wear properties and self-lubricating ability at 200 °C. The friction coefficient of specimen 2 was 0.26–0.28, and the wear weight loss was 0.6 mg.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zang, C.L.; Zhou, T.; Zhou, H.; Yuan, Y.H.; Zhang, P.; Meng, C.; Zhang, Z.H. Effects of substrate microstructure on biomimetic unit properties and wear resistance of H13 steel processed by laser remelting. Opt. Laser Technol. 2018, 106, 299–310. [Google Scholar] [CrossRef]

- Koneshlou, M.; Asl, K.M.; Khomamizadeh, F. Effect of cryogenic treatment on microstructure, mechanical and wear behaviors of AISI H13 hot work tool steel. Cryogenics 2011, 51, 55–61. [Google Scholar] [CrossRef]

- Chen, L.; Chen, W.; Xu, F.; Zhu, Y.X.; Zhu, Y.T. A pre-design method for drilled cooling pipes in hot stamping tool based on pipe parameter window. Int. J. Adv. Manuf. Technol. 2019, 103, 891–900. [Google Scholar] [CrossRef]

- Girisha, V.A.; Joshi, M.M.; Kirthan, L.J.; Bharatish, A. Thermal fatigue analysis of H13 steel die adopted in pressure-die-casting process. Sādhanā 2019, 44, 148. [Google Scholar] [CrossRef]

- Wang, M.; Wu, Y.; Wei, Q.S.; Shi, Y.S. Thermal Fatigue Properties of H13 Hot-Work Tool Steels Processed by Selective Laser Melting. Metals 2020, 10, 116. [Google Scholar] [CrossRef]

- Ning, A.G.; Mao, W.W.; Chen, X.C.; Guo, H.J.; Guo, J. Precipitation behavior of carbides in H13 hot work die steel and its strengthening during tempering. Metals 2017, 7, 70. [Google Scholar] [CrossRef]

- Wang, G.Y.; Zhang, J.Z.; Shu, R.Y.; Yang, S. High temperature wear resistance and thermal fatigue behavior of Stellite6/WC coatings produced by laser cladding with Co-coated WC powder. Int. J. Refract. Met. Hard Mater. 2019, 81, 63–70. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, J.; Zhang, P.L.; Yu, Z.S.; Li, C.G.; Xu, P.Q.; Lu, Y.L. Laser cladding of Co-based alloy/TiC/CaF2 self-lubricating composite coatings on copper for continuous casting mold. Surf. Coat. Technol. 2013, 232, 362–369. [Google Scholar] [CrossRef]

- Telasang, G.; Majumdar, J.D.; Padmanabham, G.; Manna, M.T. Effect of laser para-meters on microstructure and hardness of laser clad and tempered AISI H13 tool steel. Surf. Coat. Technol. 2014, 258, 1108–1118. [Google Scholar] [CrossRef]

- Liu, M.; Qin, Z.H.; Yang, X.Q.; Lin, Z.; Guo, T. Fabricating controllable hierarchical pores on smooth carbon sheet for synthesis of supercapacitor materials. Vacuum 2019, 168, 108806. [Google Scholar] [CrossRef]

- Kong, L.; Guo, Y.; Wang, X.; Zhang, X. Double-walled hierarchical porous silica nanotubes loaded Au nanoparticles in the interlayer as a high-performance catalyst. Nanotechnology 2019, 31, 015701. [Google Scholar] [CrossRef] [PubMed]

- Dervaux, J.; Cormier, P.A.; Konstantinidis, S.; Ciuccio, R.D.; Coulembier, O.; Dubois, P.; Snyders, R. Deposition of porous titanium oxide thin films as anode material for dye sensitized solar cells. Vacuum 2015, 114, 213–220. [Google Scholar] [CrossRef]

- Peyre, P. Additive layer manufacturing using metal deposition. Metals 2020, 10, 459. [Google Scholar] [CrossRef]

- Knoop, D.; Lutz, A.; Mais, B.; Hehl, A.V. A tailored AlSiMg alloy for laser powder bed fusion. Metals 2020, 10, 514. [Google Scholar] [CrossRef]

- Li, C.G.; Zeng, M.; Liu, C.M.; Wang, F.F.; Guo, Y.J.; Wang, J.Q.; Yang, Y.; Li, W.G.; Wang, Y. Microstructure and tribological behavior of laser cladding TiAlSi composite coatings reinforced by alumina–titania ceramics on Ti6Al4V alloys. Mater. Chem. Phys. 2020, 240, 122271. [Google Scholar] [CrossRef]

- Mostajeran, A.; Shoja-Razavi, R.; Hadi, M.; Erfanmanesh, M.; Barekat, M.; Firouzabadi, M.S. Evaluation of the mechanical properties of WC-FeAl composite coating fabricated by laser cladding method. Int. J. Refract. Met. Hard Mater. 2020, 88, 105199. [Google Scholar] [CrossRef]

- Li, M.; Han, B.; Song, L.; He, Q. Enhanced surface layers by laser cladding and ion sulfurization processing towards improved wear-resistance and self-lubrication performances. Appl. Surf. Sci. 2020, 503, 144226. [Google Scholar] [CrossRef]

- Ke, J.; Liu, X.B.; Liang, J.; Liang, L.; Yang, S.L. Microstructure and fretting wear of laser cladding self-lubricating anti-wear composite coatings on TA2 alloy after aging treatment. Opt. Laser Technol. 2019, 119, 105599. [Google Scholar] [CrossRef]

- Zhang, P.L.; Zhao, G.P.; Wang, W.W.; Wang, B.; Shi, P.Y.; Qi, G.; Yi, G.W. Study on the Mechanical and Tribological Properties and the Mechanisms of Cr-Free Ni-Based Self-Lubricating Composites at a Wide Temperature Range. Metals 2020, 20, 268. [Google Scholar] [CrossRef]

- Mi, P.B.; Ye, F.X. Wear performance of the WC/Cu self-lubricating textured coating. Vacuum 2018, 157, 17–20. [Google Scholar] [CrossRef]

- Torres, H.; Vuchkov, T.; Slawik, S.; Gachot, C. Self-lubricating laser claddings for reducing friction and wear from room temperature to 600 °C. Wear 2018, 408, 22–33. [Google Scholar] [CrossRef]

- Torres, H.; Slawik, S.; Gachot, C.; Prakash, B.; Rodríguez Ripoll, M. Microstructural design of self-lubricating laser claddings for use in high temperature sliding applications. Surf. Coat. Technol. 2018, 337, 24–34. [Google Scholar] [CrossRef]

- Li, A.N.; Wei, C.J.; Liu, J.J.; Zhou, W.L.; Wang, H.J.; Shi, S.D. Microstructure and tribological properties of laser cladding iron base Cr3C2/MoS2 cladding. China Surf. Eng. 2015, 28, 77–85. [Google Scholar]

- Chen, Z.F.; Yan, H.; Zhang, P.L.; Yu, Z.H.; Lu, Q.H.; Guo, J.L. Microstructural evolution and wear behaviors of laser-clad Stellite 6/NbC/h-BN self-lubricating coatings. Surf. Coat. Technol. 2019, 372, 218–228. [Google Scholar] [CrossRef]

- Li, X.; Zhang, C.H.; Zhang, S.; Wu, C.L.; Liu, Y.; Zhang, J.B.; Shahzad, M.B. Manufacturing of Ti3SiC2 lubricated Co-based alloy coatings using laser cladding technology. Opt. Laser Technol. 2019, 114, 209–215. [Google Scholar] [CrossRef]

- Torres, H.; Caykara, T.; Rojacz, H.; Prakash, B.; Rodríguez Ripoll, M. The tribology of Ag/MoS2-based self-lubricating laser claddings for high temperature forming of aluminium alloys. Wear 2020, 203110. [Google Scholar] [CrossRef]

- Piasecki, A.; Kotkowiak, M.; Makuch, N.; Kulka, M. Wear behavior of self-lubricating boride layers produced on Inconel 600-alloy by laser alloying. Wear 2019, 426, 919–933. [Google Scholar] [CrossRef]

- Nghia, T.V.; Sen, Y.; Anh, P.T. Microstructure and properties of Cu/TiB2 wear resistance composite coating on H13 steel prepared by in-situ laser cladding. Opt. Laser Technol. 2018, 108, 480–486. [Google Scholar]

- Cui, X.H.; Jin, Y.X.; Chen, W.; Zhang, Q.Y.; Wang, S.Q. Improvement of tribological performance of AISI H13 steel by means of a self-lubricated oxide-containing tribo-layer. J. Mater. Eng. Perform. 2018, 27, 1945–1956. [Google Scholar] [CrossRef]

- Yang, M.S.; Liu, X.B.; Fan, J.W.; He, X.M.; Shi, S.H.; Fu, G.Y.; Wang, M.D.; Chen, S.F. Microstructure and wear behaviors of laser clad NiCr/Cr3C2-WS2 high temperature self-lubricating wear-resistant composite coating. Appl. Surf. Sci. 2012, 258, 3757–3762. [Google Scholar] [CrossRef]

- Cui, S.; Li, W.S.; He, L.; Feng, L.; An, G.S.; Hu, W.; Hu, C.X. Tribological behavior of a Ni-WS2 composite coating across wide temperature ranges. Rare Met. 2019, 38, 1078–1085. [Google Scholar] [CrossRef]

- Lu, J.Z.; Cao, J.; Lu, H.F.; Zhang, L.Y.; Luo, K.Y. Wear properties and microstructural analyses of Fe-based coatings with various WC contents on H13 die steel by laser cladding. Surf. Coat. Technol. 2019, 369, 228–237. [Google Scholar] [CrossRef]

| Material | Element (wt%) | |||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | V | Co | Fe | |

| H13 | 0.40 | 1.00 | 0.30 | 5.15 | 1.35 | 1.10 | - | Bal. |

| Stellite 6 | 1.15 | 1.10 | 0.05 | 29.00 | 1.00 | - | Bal. | 3.00 |

| No. | Specimen 1 | Specimen 2 | Specimen 3 |

|---|---|---|---|

| Substrate | H13 | H13 | H13 |

| Coating | 90% Stellite 6-10% Cr3C2 composite coatings | 85% Stellite 6-10% Cr3C2-5% WS2 composite coatings | 80% Stellite 6-10% Cr3C2-10% WS2 composite coatings |

| Point | Composition (wt%) | |||||

|---|---|---|---|---|---|---|

| Co | C | Cr | S | W | Mn | |

| White point | 7.21 | 27.37 | 57.71 | - | - | 5.17 |

| Black point | 1.10 | 1.92 | 56.71 | 38.28 | 1.63 | 0.36 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Liu, B.; Chen, L.; Xu, J.; Zhu, Y. Effect of Laser Cladding Stellite 6-Cr3C2-WS2 Self-Lubricating Composite Coating on Wear Resistance and Microstructure of H13. Metals 2020, 10, 785. https://doi.org/10.3390/met10060785

Chen W, Liu B, Chen L, Xu J, Zhu Y. Effect of Laser Cladding Stellite 6-Cr3C2-WS2 Self-Lubricating Composite Coating on Wear Resistance and Microstructure of H13. Metals. 2020; 10(6):785. https://doi.org/10.3390/met10060785

Chicago/Turabian StyleChen, Wei, Bo Liu, Long Chen, Jiangping Xu, and Yingxia Zhu. 2020. "Effect of Laser Cladding Stellite 6-Cr3C2-WS2 Self-Lubricating Composite Coating on Wear Resistance and Microstructure of H13" Metals 10, no. 6: 785. https://doi.org/10.3390/met10060785

APA StyleChen, W., Liu, B., Chen, L., Xu, J., & Zhu, Y. (2020). Effect of Laser Cladding Stellite 6-Cr3C2-WS2 Self-Lubricating Composite Coating on Wear Resistance and Microstructure of H13. Metals, 10(6), 785. https://doi.org/10.3390/met10060785