Influence of Surface Ultrasonic Rolling on Microstructure and Corrosion Property of T4003 Ferritic Stainless Steel Welded Joint

Abstract

1. Introduction

2. Experimental Materials and Methods

3. Results and Discussion

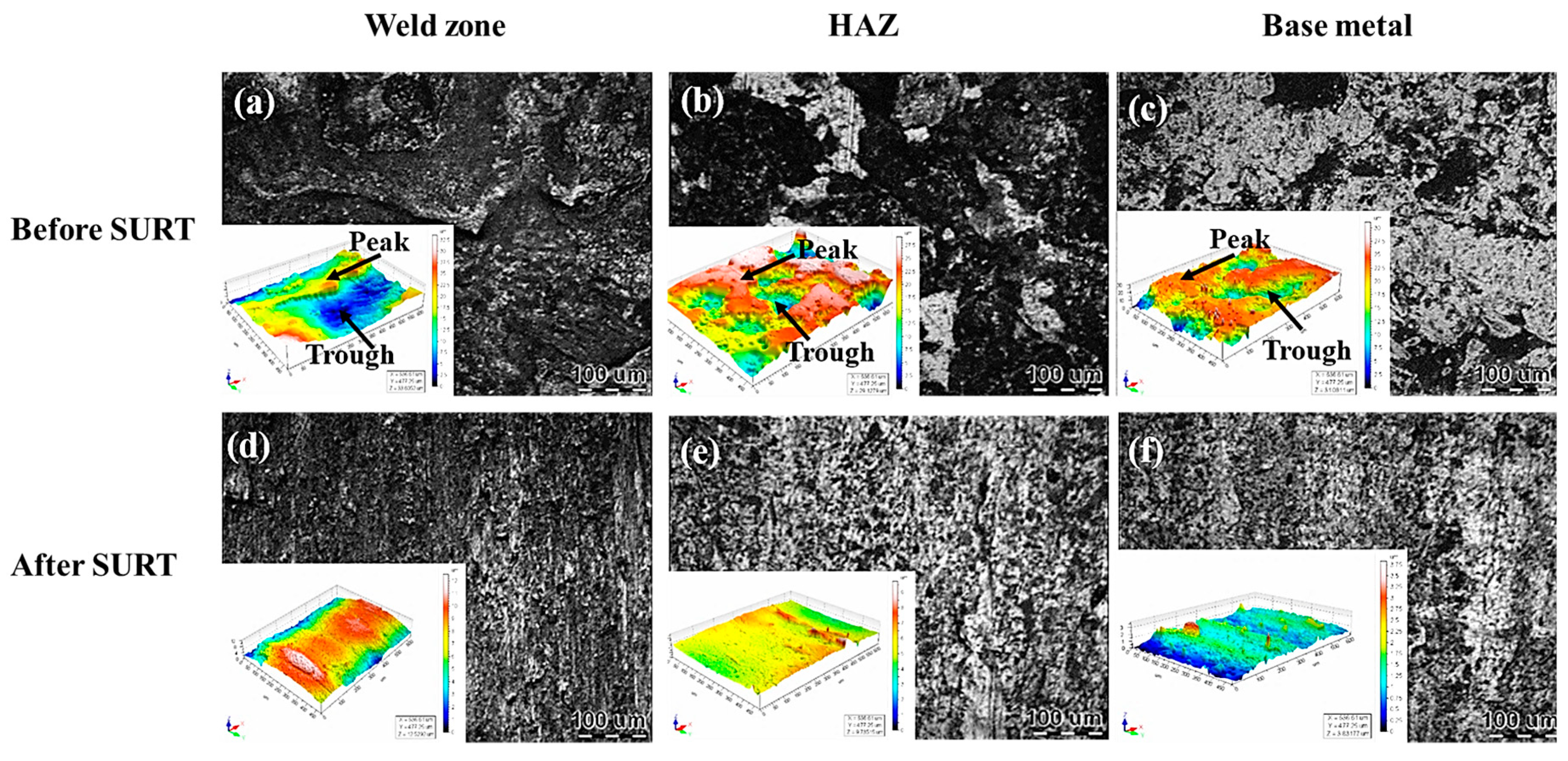

3.1. Surface Morphology

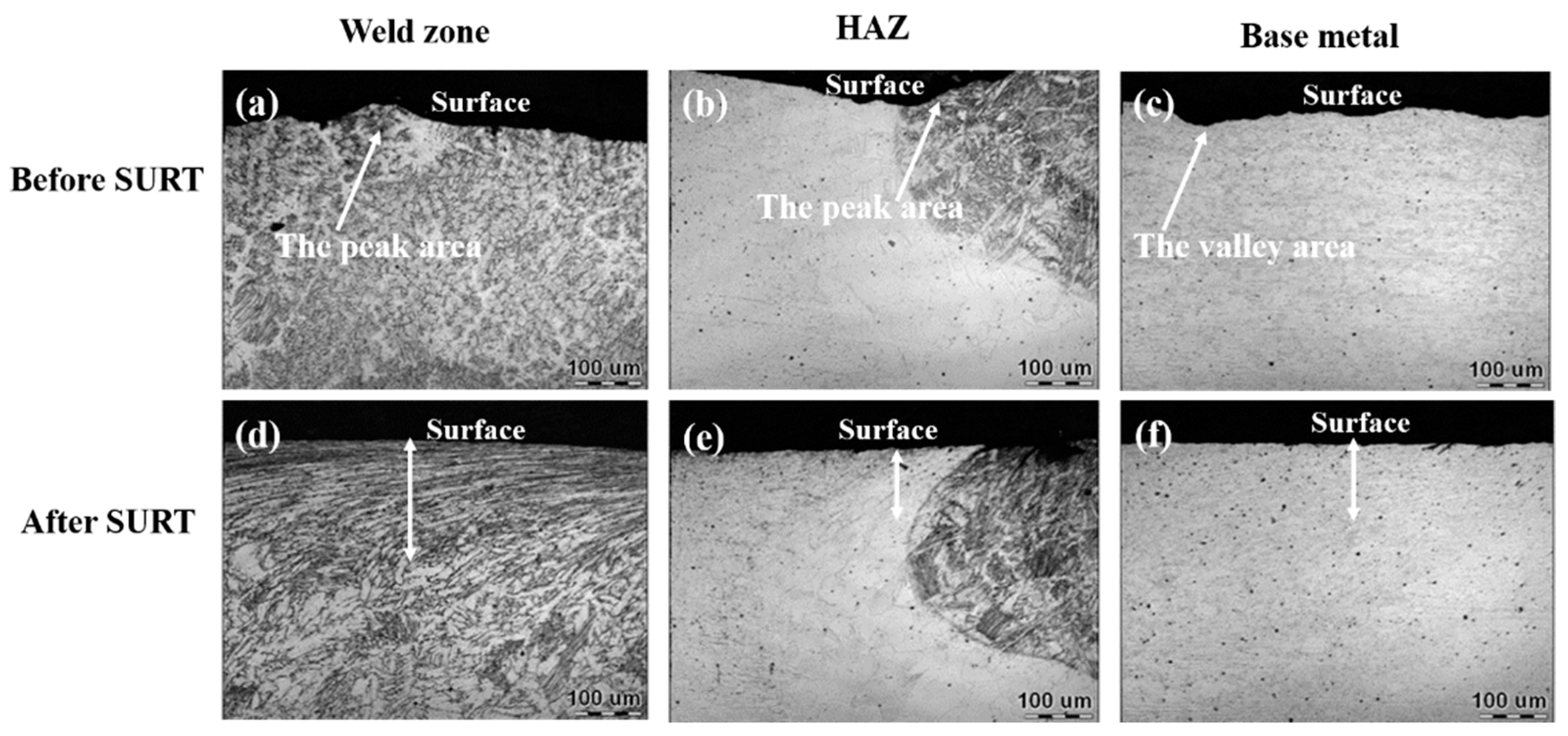

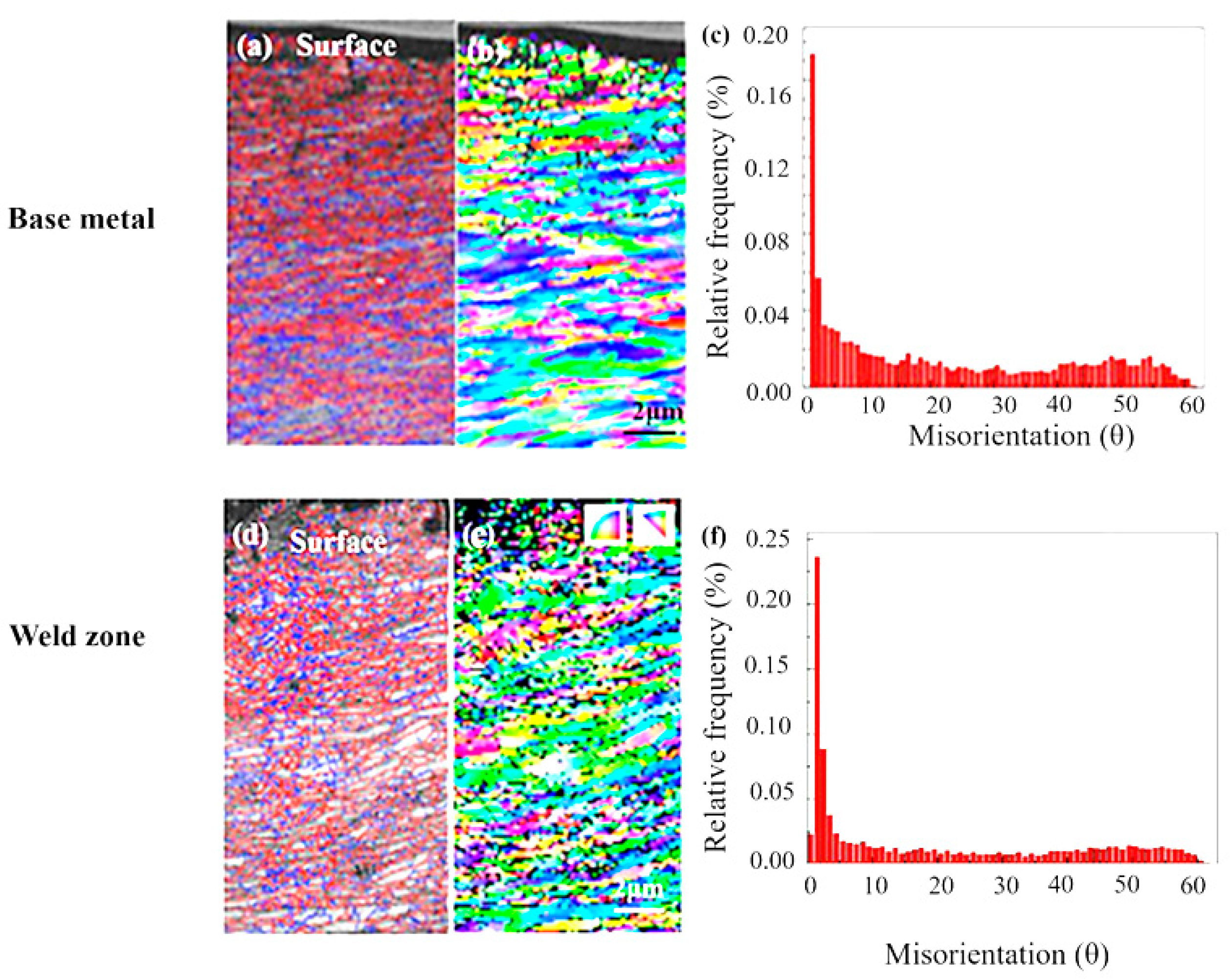

3.2. Surface Microstructure

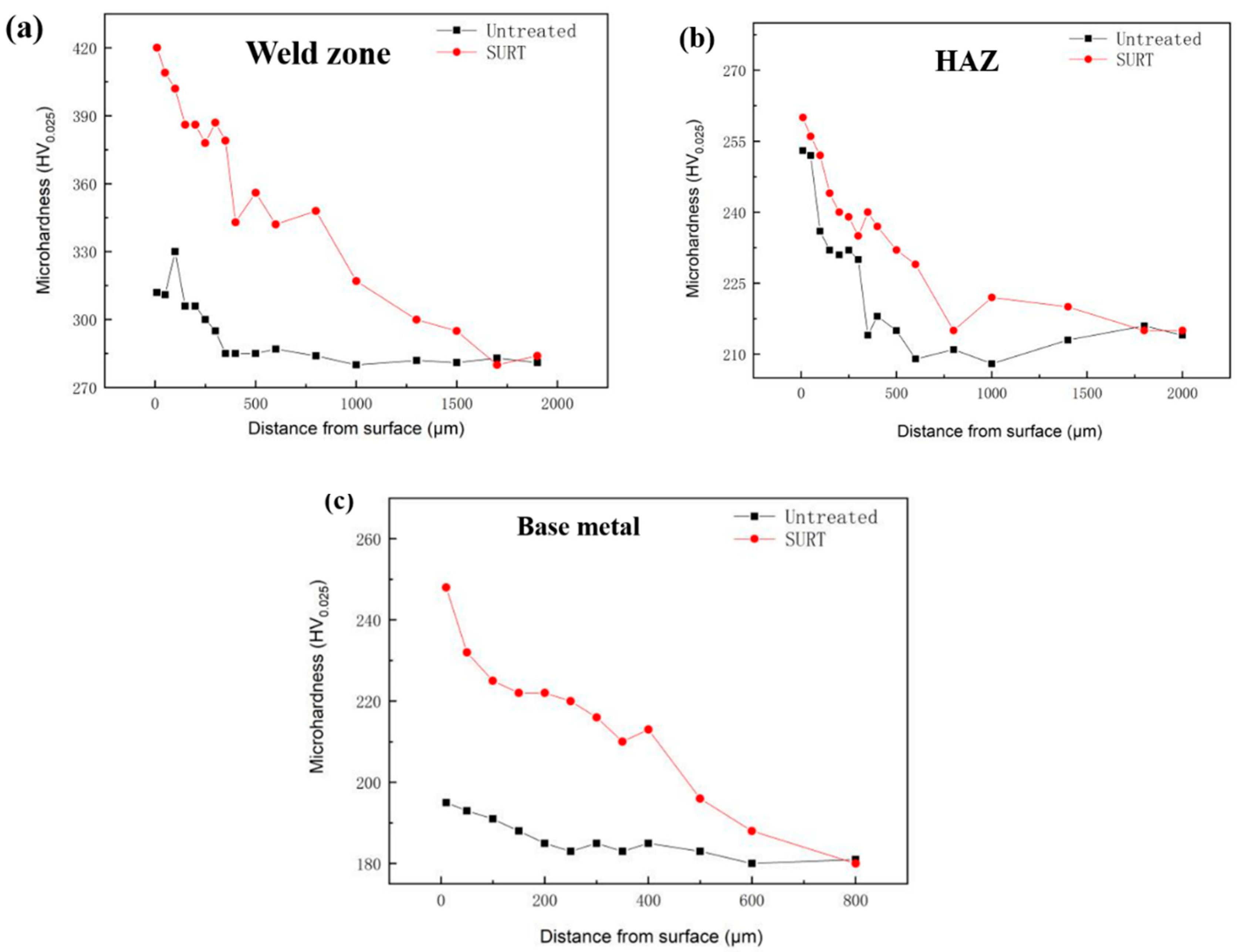

3.3. Surface Hardness

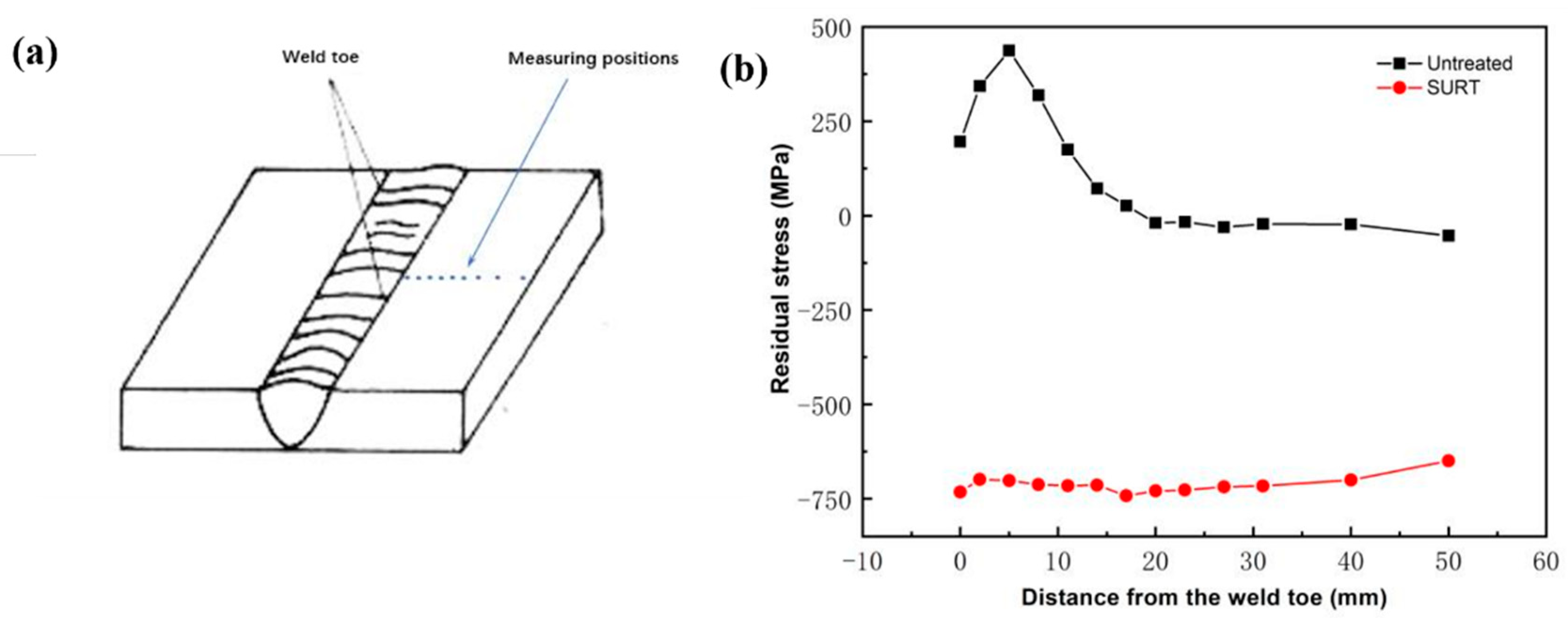

3.4. Surface Residual Stress

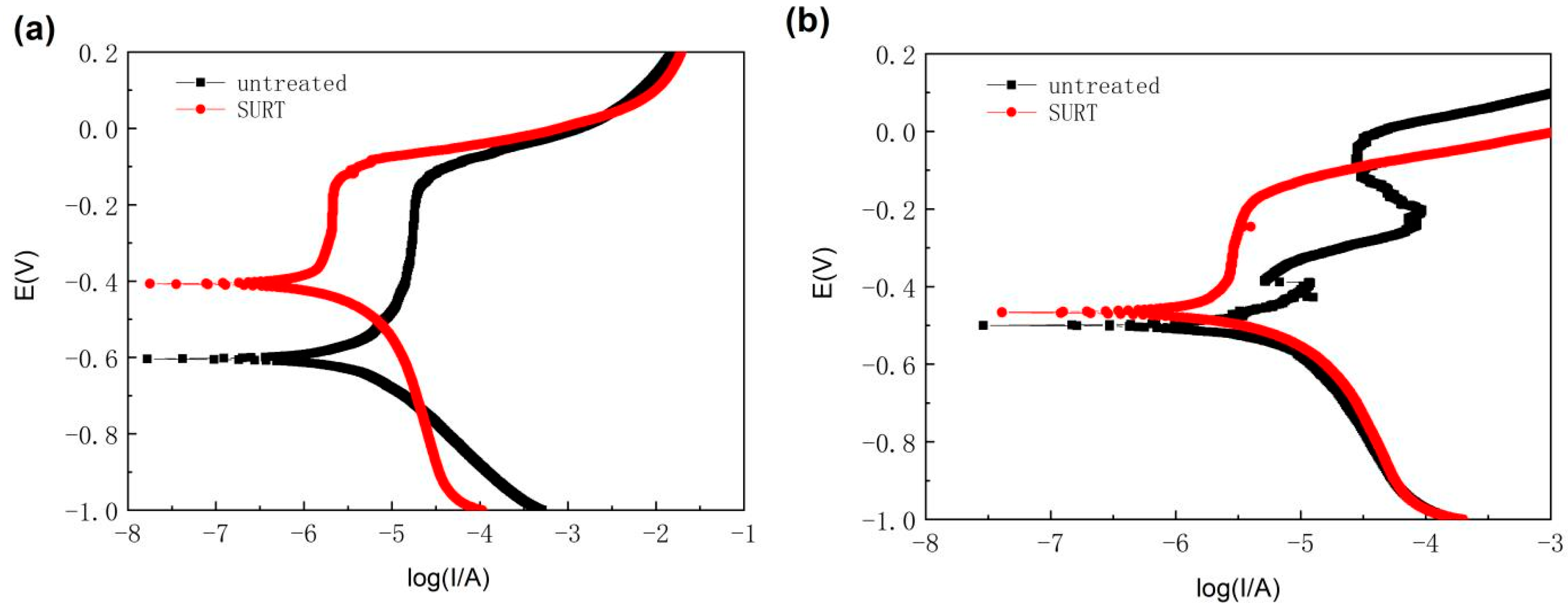

3.5. Corrosion Property

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Widiyarta, I.M.; Franklin, F.J.; Kapoor, A. Modelling thermal effects in ratcheting led wear and rolling contact fatigue. Wear 2008, 256, 1325–1331. [Google Scholar] [CrossRef]

- Stone, D.H.; Steel, R.K. The effect of mechanical properties upon the performance of railroad rails. In Rail Steels—Developments, Processing and Use; ASTM International: Philadelphia, PA, USA, 1976; pp. 21–43. [Google Scholar]

- Zheng, H.B.; Ye, X.N.; Jiang, L.Z.; Wang, B.S.; Liu, Z.Y.; Wang, G.D. Study on microstructure of low carbon 12% chromium stainless steel in high temperature heat-affected zone. Mater. Des. 2010, 31, 4836–4841. [Google Scholar] [CrossRef]

- Taban, E.; Kaluc, E.; Dhooge, A. Hybrid (plasma + gas tungsten arc) weldability of modified 12% Cr ferritic stainless steel. Mater. Des. 2009, 30, 4236–4242. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, S.; Cui, X.; Zhang, C.H.; Liu, Y.; Zhang, J.B. Tribological and cavitation erosion behaviors of nickel-based and iron-based coatings deposited on AISI 304 stainless steel by cold metal transfer. J. Mater. Res. Technol 2020, 9, 6665–6681. [Google Scholar] [CrossRef]

- Bagherifard, S.; Fernandez-Pariente, I.; Ghelichi, R.; Guagliano, M. Effect of severe shot peening on microstructure and fatigue strength of cast iron. Int. J. Fatigue 2014, 65, 64–70. [Google Scholar] [CrossRef]

- Mikova, K.; Bagherifard, S.; Bokuvka, O.; Guagliano, M.; Trško, L. Fatigue behavior of X70 microalloyed steel after severe shot peening. Int. J. Fatigue 2013, 55, 33–42. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Lai, F.Q.; Qu, S.G.; Liu, H.P.; Jia, D.S.; Du, S.F. Effect of ultrasonic surface rolling on microstructure and rolling contact fatigue behavior of 17Cr2Ni2MoVNb steel. Surf. Coat. Technol. 2019, 366, 321–330. [Google Scholar] [CrossRef]

- Yang, J.; Liu, D.X.; Zhang, X.H.; Liu, M.X.; Zhao, W.D.; Liu, C.S. The effect of ultrasonic surface rolling process on the fretting fatigue property of GH4169 superalloy. Int. J. Fatigue 2020, 133, 105373. [Google Scholar] [CrossRef]

- Arola, D.; WillIams, C.L. Estimating the fatigue stress concentration factor of machined Surfaces. Int. J. Fatigue 2002, 24, 923–930. [Google Scholar] [CrossRef]

- Kapoor, A.; Franklin, F.J.; Wong, S.K.; Ishida, M. Surface roughness and plastic flow in rail wheel contact. Wear 2002, 253, 257–264. [Google Scholar] [CrossRef]

- Nandagopal, A.; Chai, R.; Boay, G.; Srikanth, N. Influence of stress ratio and stress concentration on the fatigue behaviour of hygrothermal aged multidirectional CFRP composite laminate. Int. J. Fatigue 2020, 137, 105651. [Google Scholar] [CrossRef]

- Bagehorn, S.; Wehr, J.; Maier, H.J. Application of mechanical surface finishing processes for roughness reduction and fatigue improvement of additively manufactured Ti-6Al-4V parts. Int. J. Fatigue 2017, 102, 135–142. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Wang, Z.B.; Wang, W.X.; Yan, Z.F.; Dong, P.; Du, H.Y.; Ding, M. Microstructure evolution in heat affected zone of T4003 ferritic stainless steel. Mater. Des. 2015, 68, 114–120. [Google Scholar] [CrossRef]

- Izotov, V.I.; Pozdnyakov, V.A.; Luk’yanenko, E.V.; Yu, O.; Sanova, U.; Filippov, G.A. Influence of the pearlite fineness on the mechanical properties, deformation behavior, and fracture characteristics of carbon steel. Phys. Met. Metallogr 2007, 103, 519–529. [Google Scholar] [CrossRef]

- Tao, N.R.; Wang, Z.B.; Tong, W.P.; Sui, M.L.; Lu, J.; Lu, K. An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment. Acta Mater 2002, 50, 4603–4616. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Wegener, T.; Yapici, G.G.; Niendorf, T. Effect of grain size on the very high cycle fatigue behavior and notch sensitivity of titanium. Theor. Appl. Fract. Mech. 2019, 104, 102362. [Google Scholar] [CrossRef]

- Petch, N. The cleavage strength of polycrystals. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Busby, J.T.; Hash, M.C.; Was, G.S. The relationship between hardness and yield stress in irradiated austenitic and ferrite steels. J. Nucl. Mater. 2005, 336, 267–278. [Google Scholar] [CrossRef]

- Liu, C.M.; Wang, J.J.; Lin, R.R.; Cui, W.F.; Bai, Y.G. Role of small amounts of carbon in fine grain strengthening of steels. Mater. Sci. Technol. 2001, 9, 301–304. (In Chinese) [Google Scholar]

- Li, H.Y.; Sun, H.L.; Bowen, P.; Knott, J.F. Effects of compressive residual stress on short fatigue crack growth in a nickel-based superalloy. Int. J. Fatigue 2018, 108, 53–61. [Google Scholar] [CrossRef]

- McCallion, H.; Lotifi, M. Tensile surface stresses and fatigue in plain journal bearings. Tribo. Int. 1992, 25, 247–257. [Google Scholar] [CrossRef]

- Li, W.; Li, D.Y. Influence of surface morphology on corrosion and electronic behavior. Acta Mater. 2006, 54, 445–452. [Google Scholar] [CrossRef]

- Ye, H.; Sun, X.; Liu, Y.; Rao, X.X.; Gu, Q. Effect of ultrasonic surface rolling process on mechanical properties and corrosion resistance of AZ31B Mg alloy. Surf. Coat. Technol. 2019, 372, 288–298. [Google Scholar] [CrossRef]

| Materials | C | Si | Mn | P | S | Cr | Ni | Ti | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| T4003 | ≤0.03 | ≤1.0 | 1.00–2.50 | ≤0.04 | ≤0.015 | 11.00–13.00 | 0.30–1.0 | 0.1–0.35 | ≤0.025 | Bal. |

| ER308LSi | 0.018 | 0.61 | 1.91 | 0.011 | 0.017 | 19.84 | 9.95 | - | - | Bal. |

| Welding Current/A | Arc Voltage/V | Wire Feed Rate m/min | Welding Rate mm/min | Gas Flow l/min | Stick Out/mm | Gap/mm |

|---|---|---|---|---|---|---|

| 220 | 22.8 | 9.2 | 360 | 15 | 12 | 0 |

| Samples | Weld Zone | HAZ | Base Metal |

|---|---|---|---|

| Non-surface ultrasonic rolling sample | 0.593 | 4.671 | 1.081 |

| 1.817 | 2.577 | 2.083 | |

| 1.275 | 2.796 | 3.087 | |

| 0.636 | 2.699 | 3.361 | |

| 0.993 | 1.331 | 1.192 | |

| Average value | 1.060 | 2.810 | 2.160 |

| surface ultrasonic rolling sample | 0.292 | 0.107 | 0.390 |

| 0.312 | 0.143 | 0.282 | |

| 0.318 | 0.126 | 0.159 | |

| 0.297 | 0.228 | 0.154 | |

| 0.381 | 0.176 | 0.148 | |

| Average value | 0.320 | 0.156 | 0.227 |

| Sample | βa (mV/dec) | βc (mV/dec) | Ecorr (V) | icorr (10−7A/cm2) | η (%) |

|---|---|---|---|---|---|

| weld-untreated | 68.719 | −37.030 | −0.61 | −2.410 | |

| weld-SURT | 54.941 | −20.171 | −0.41 | −0.505 | 79.05% |

| base metal-untreated | 28.580 | −21.862 | −0.50 | −2.809 | |

| base metal-SURT | 51.824 | −24.130 | −0.46 | −1.188 | 57.71% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Yu, R.; Gao, X.; Zhang, G. Influence of Surface Ultrasonic Rolling on Microstructure and Corrosion Property of T4003 Ferritic Stainless Steel Welded Joint. Metals 2020, 10, 1081. https://doi.org/10.3390/met10081081

Liu P, Yu R, Gao X, Zhang G. Influence of Surface Ultrasonic Rolling on Microstructure and Corrosion Property of T4003 Ferritic Stainless Steel Welded Joint. Metals. 2020; 10(8):1081. https://doi.org/10.3390/met10081081

Chicago/Turabian StyleLiu, Pengtao, Runze Yu, Xinhuan Gao, and Guanzhen Zhang. 2020. "Influence of Surface Ultrasonic Rolling on Microstructure and Corrosion Property of T4003 Ferritic Stainless Steel Welded Joint" Metals 10, no. 8: 1081. https://doi.org/10.3390/met10081081

APA StyleLiu, P., Yu, R., Gao, X., & Zhang, G. (2020). Influence of Surface Ultrasonic Rolling on Microstructure and Corrosion Property of T4003 Ferritic Stainless Steel Welded Joint. Metals, 10(8), 1081. https://doi.org/10.3390/met10081081