Numerical Verification of Tests on the Influence of the Imposed Thermal Cycles on the Structure and Properties of the S700MC Heat-Affected Zone

Abstract

1. Introduction

2. Description of the Problem

2.1. Material Used for Research

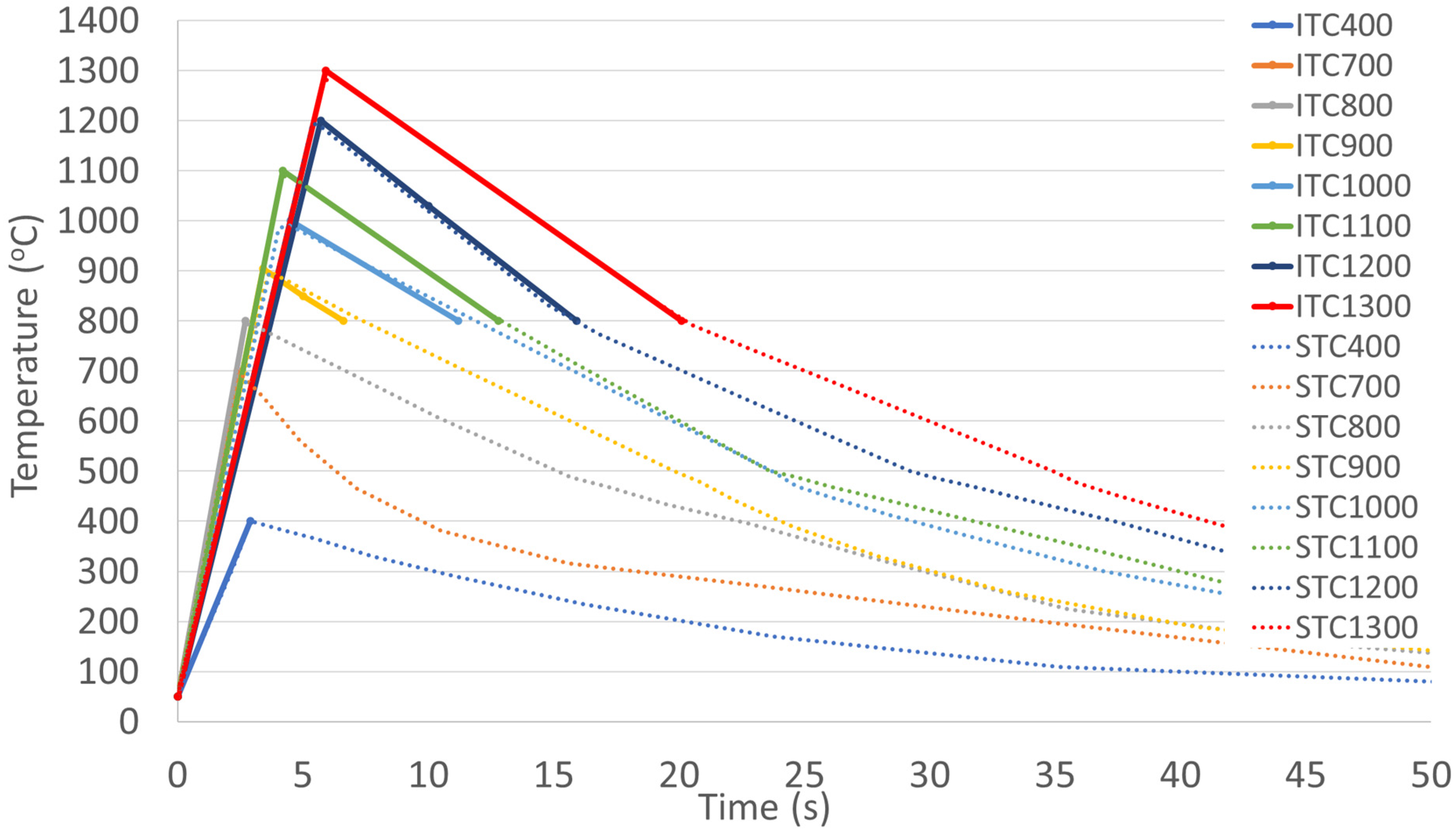

2.2. Assumptions for Testing Structural Changes of S700MC Steel under the Conditions of Simulated Welding Heat Cycles

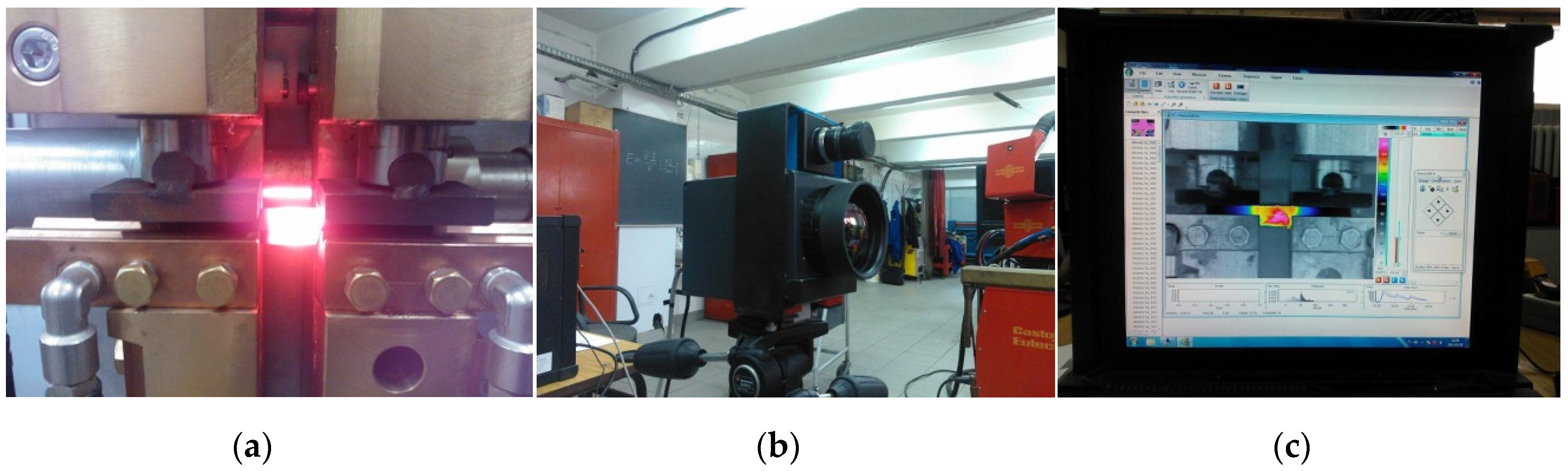

2.3. Testing Equipment

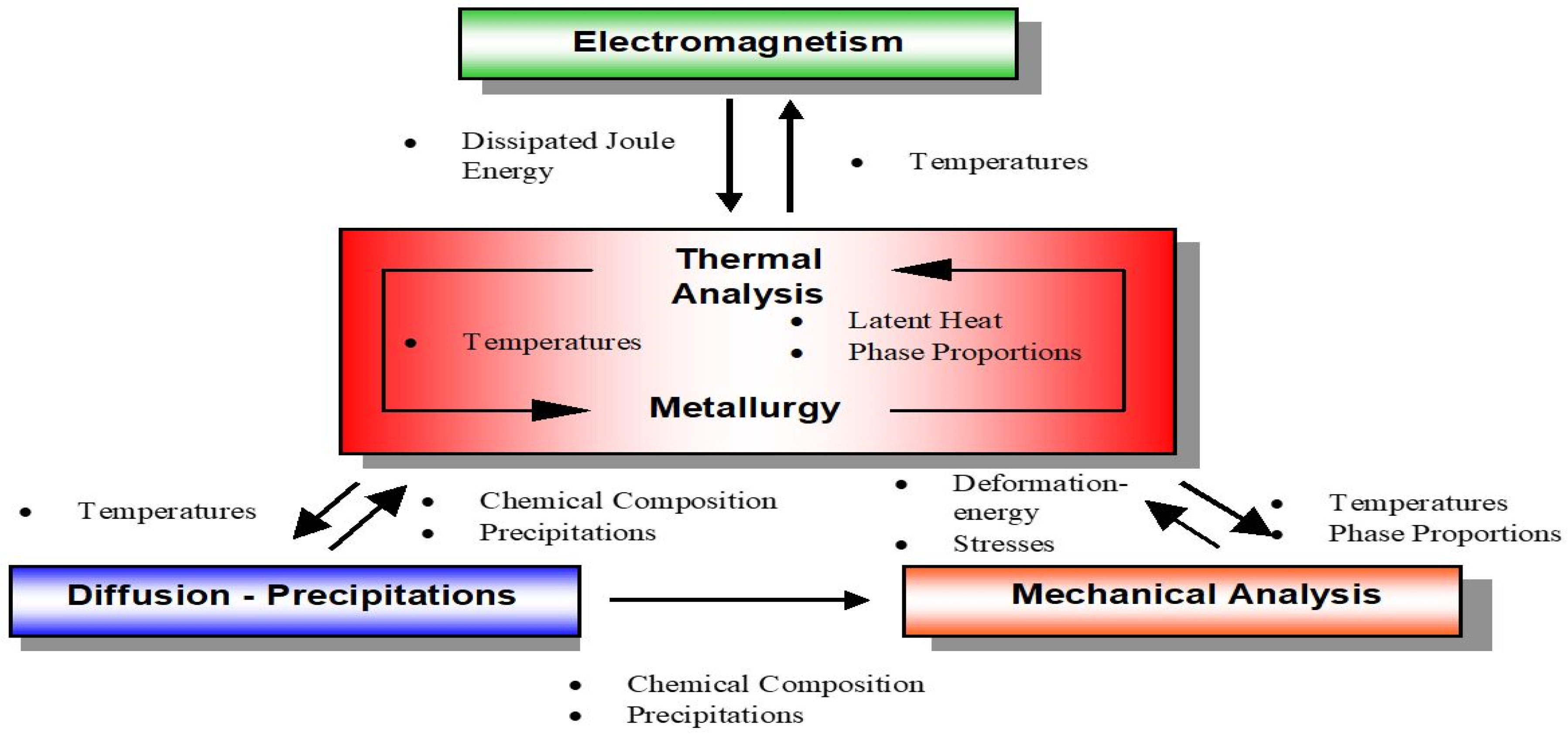

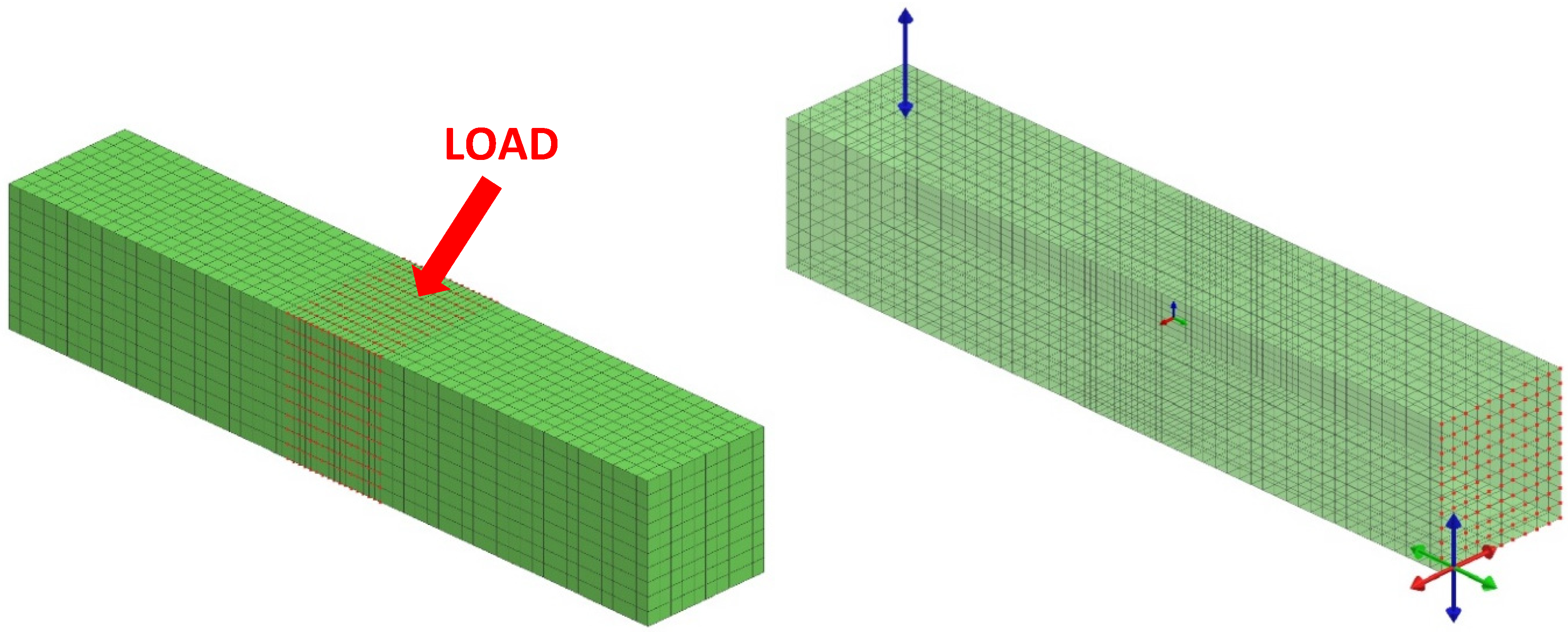

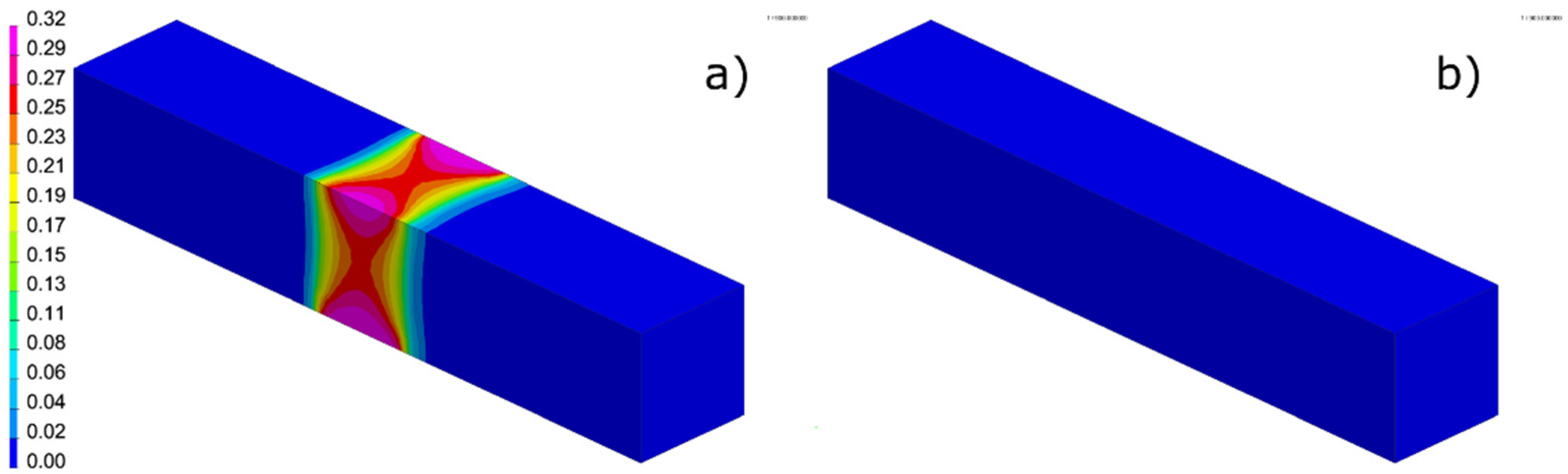

2.4. Computational Model

3. Tests and Simulations Results

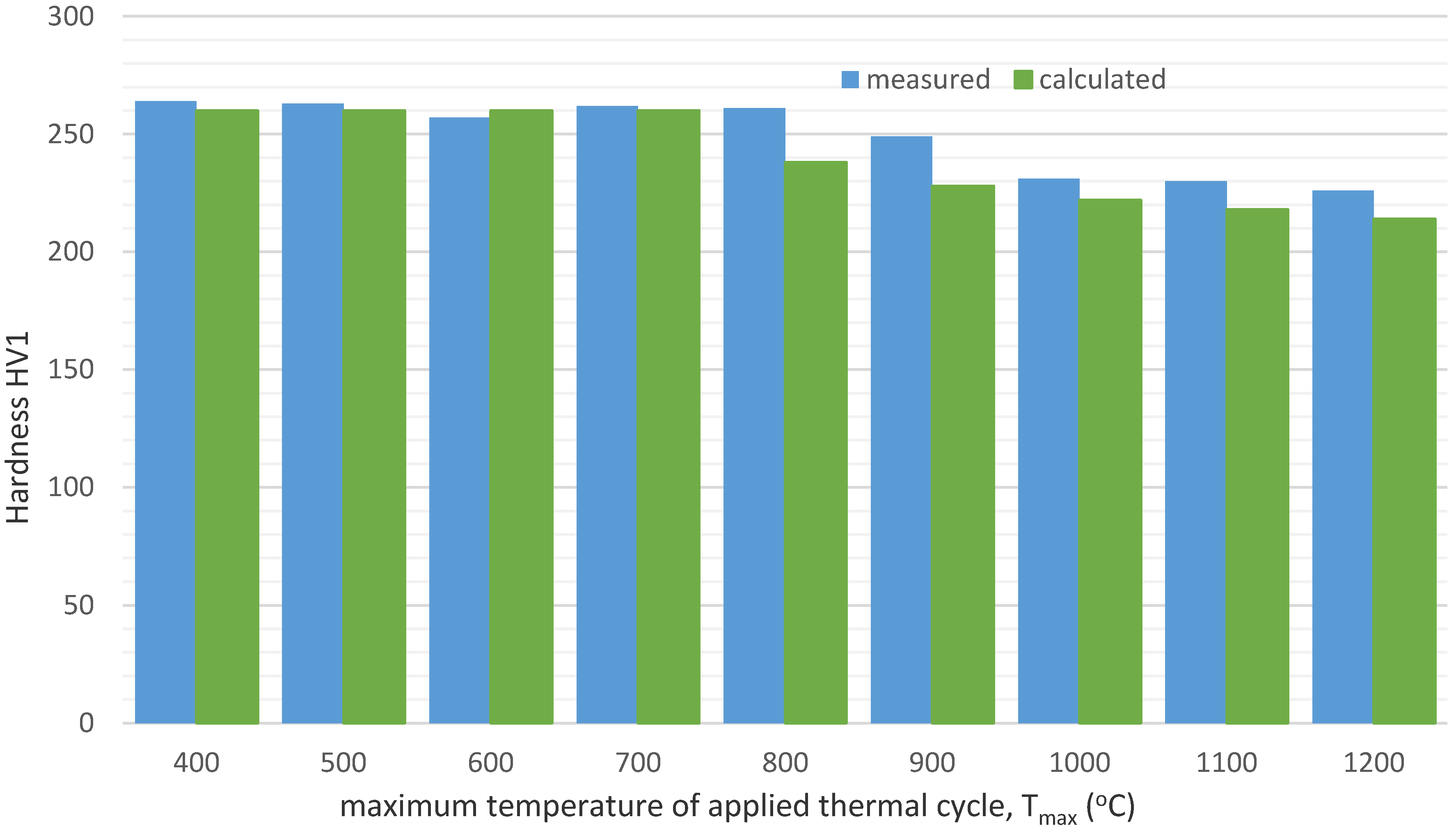

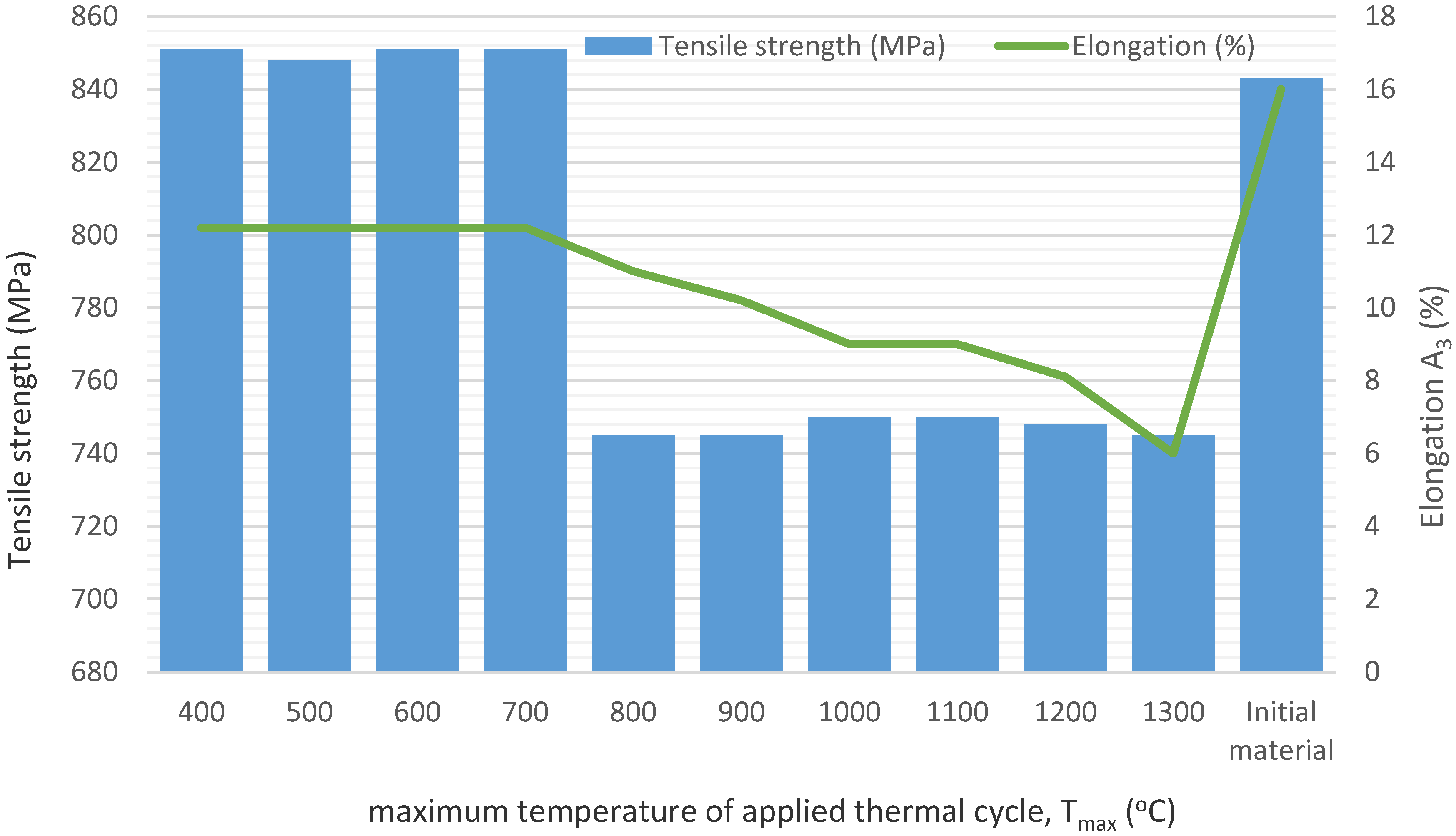

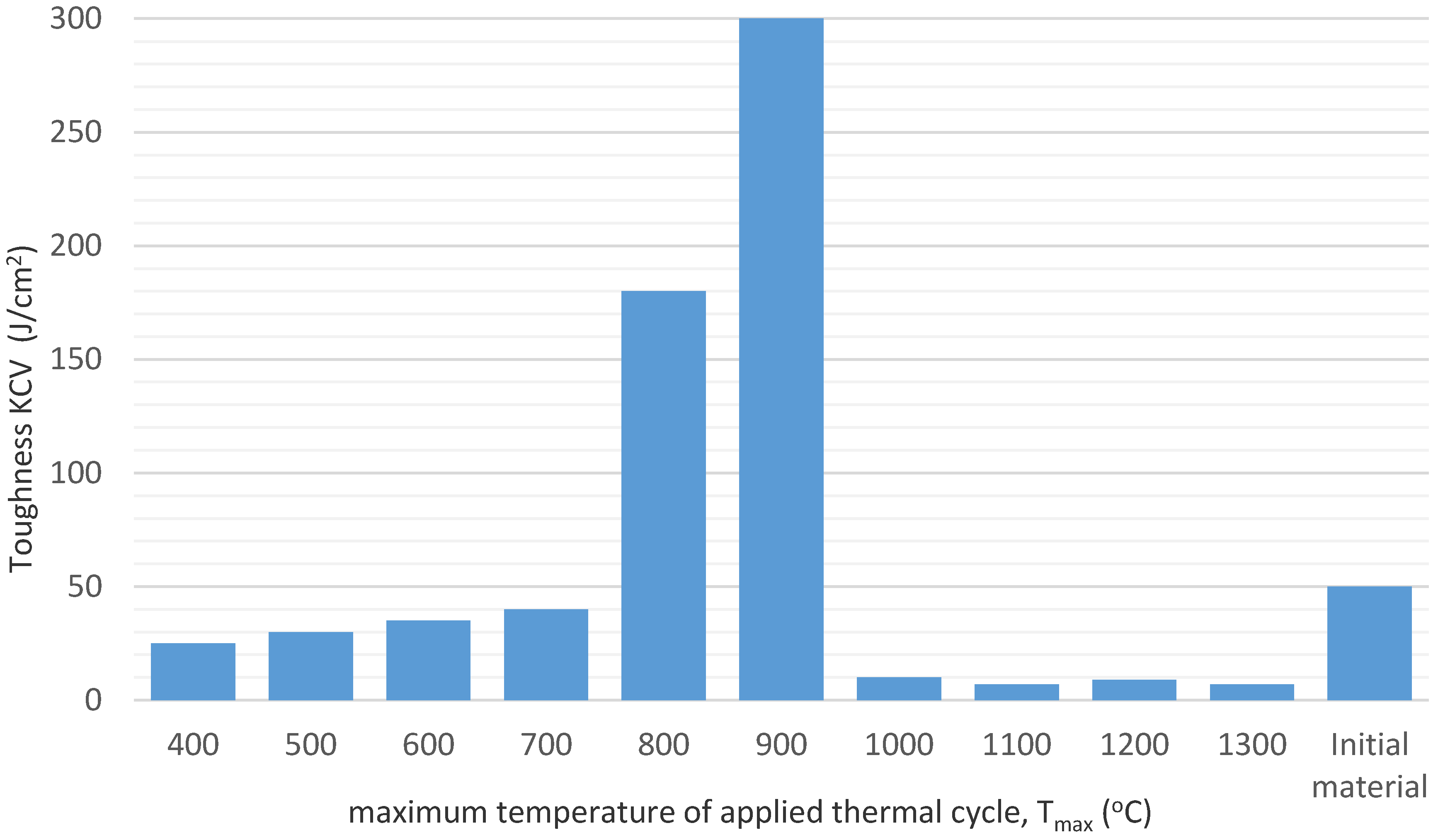

3.1. The Studies of the Influence of the Thermal Cycle Maximum Temperature on the Properties of Simulated HAZ in S700MC Steel

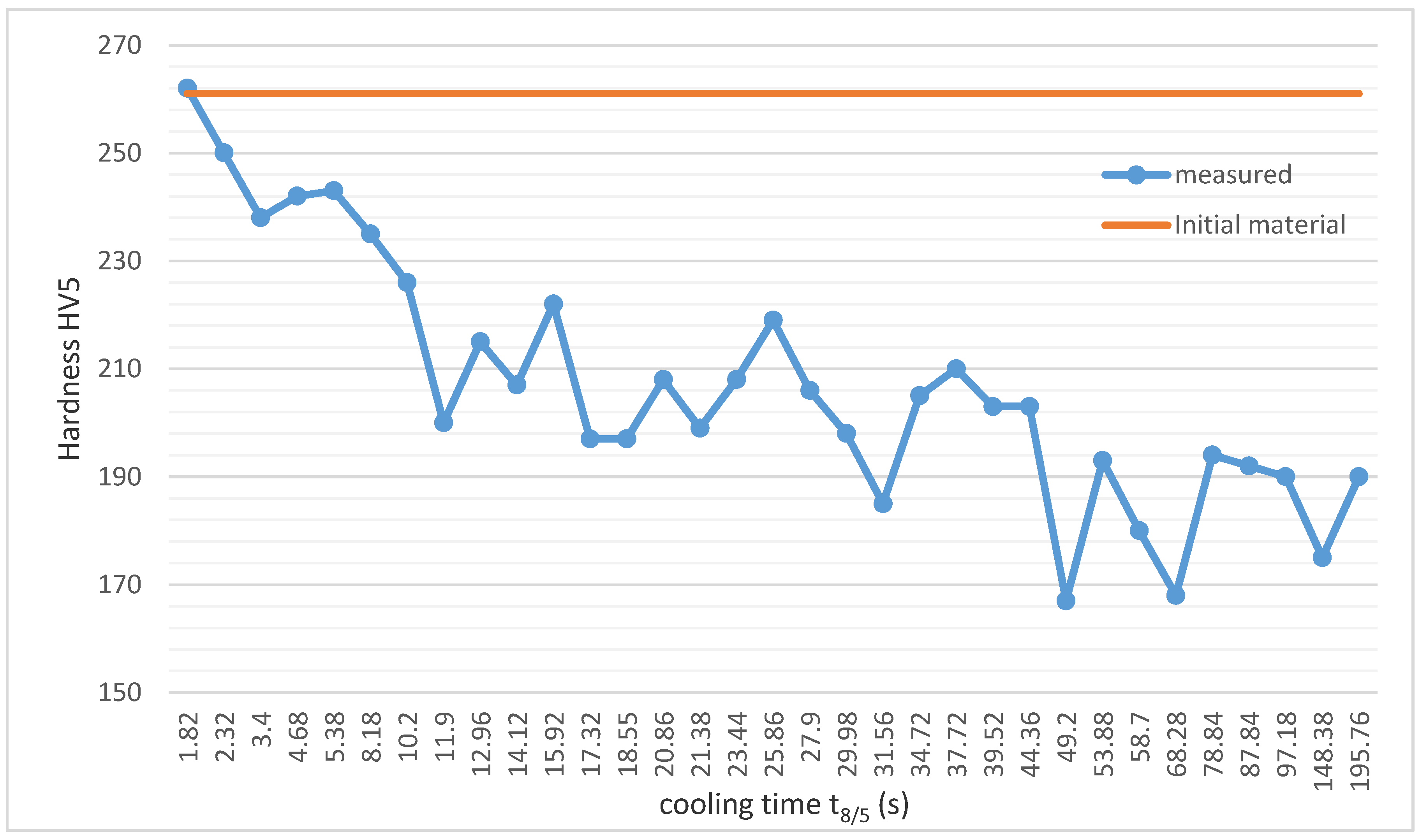

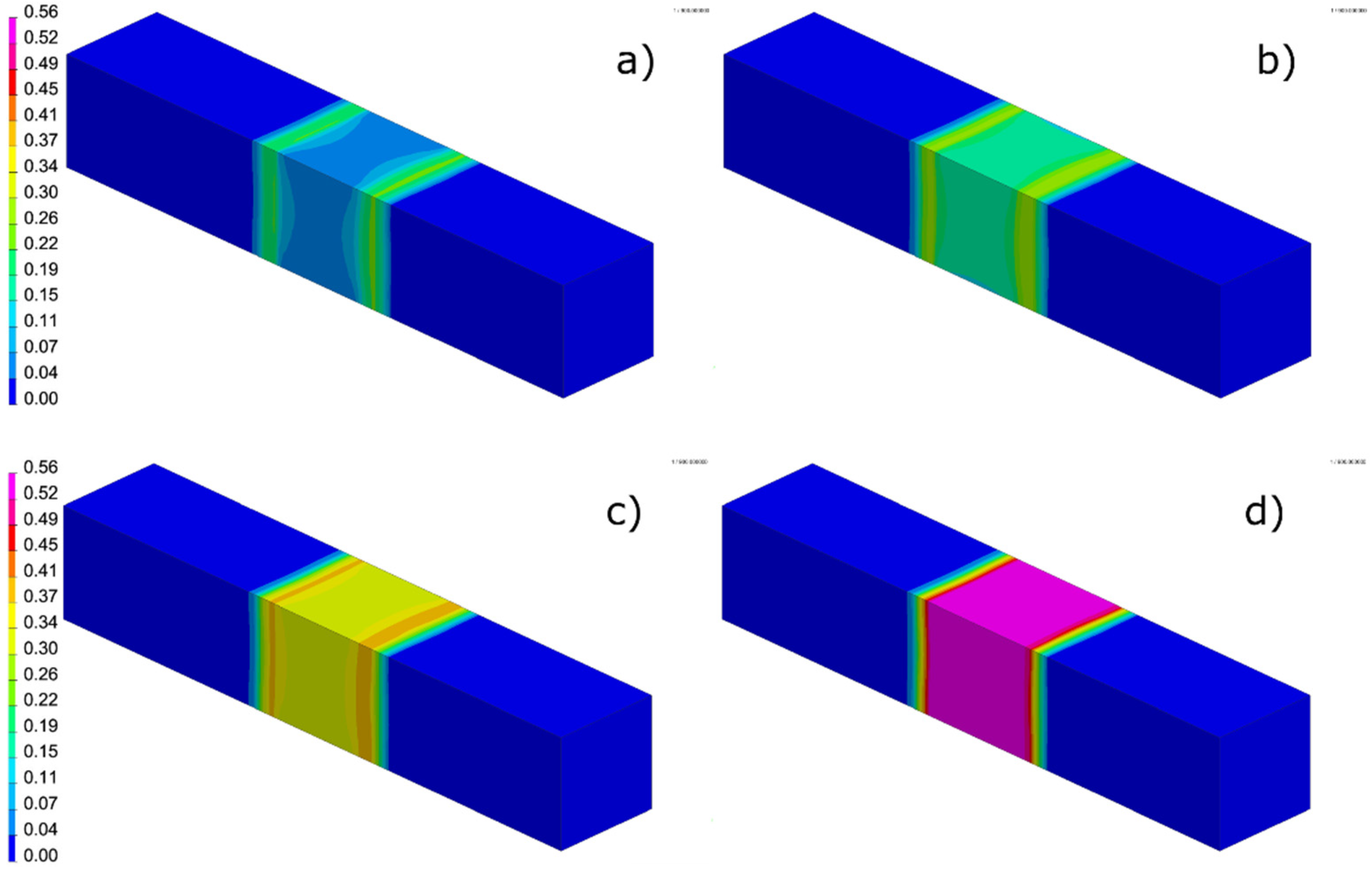

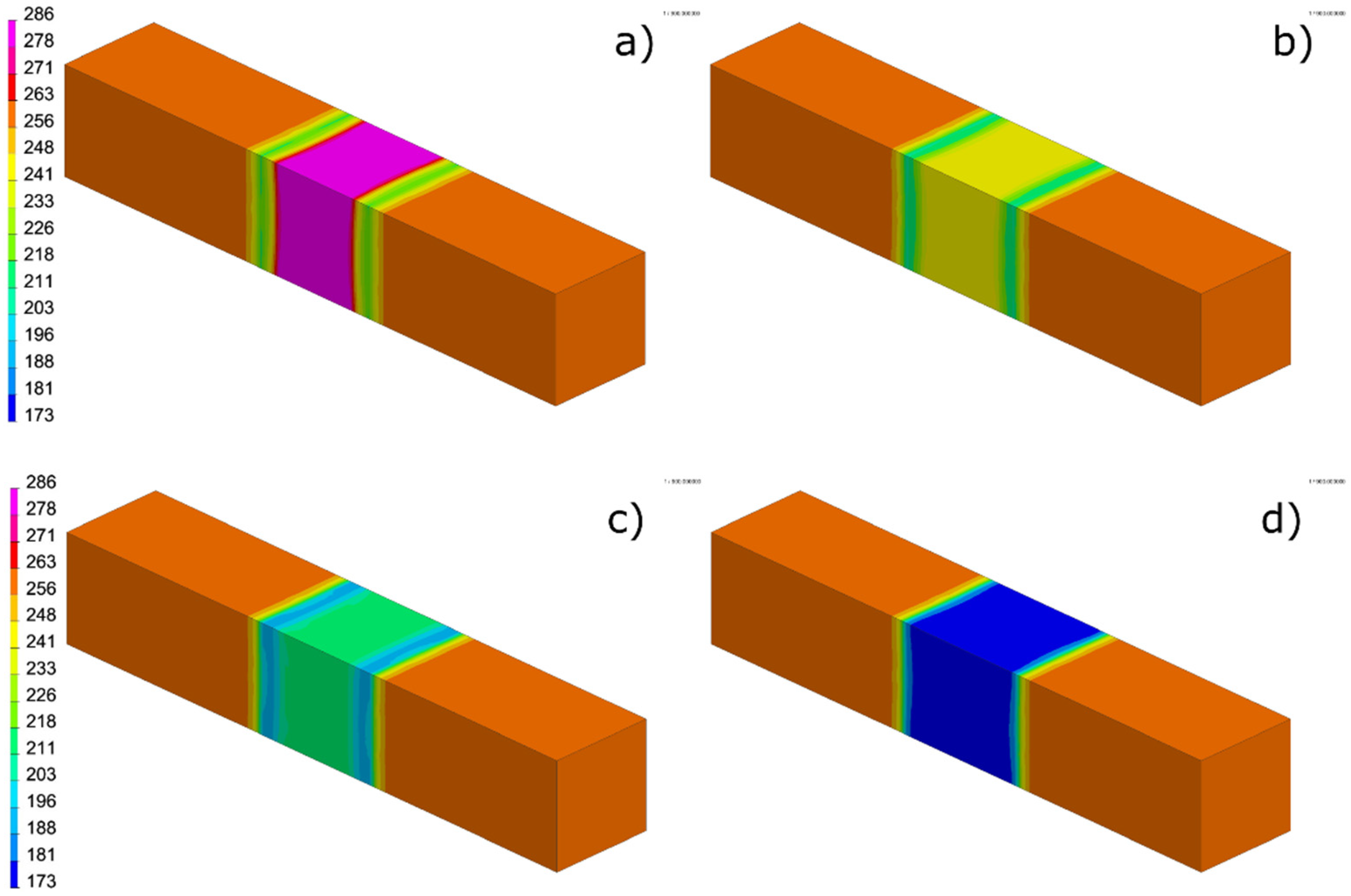

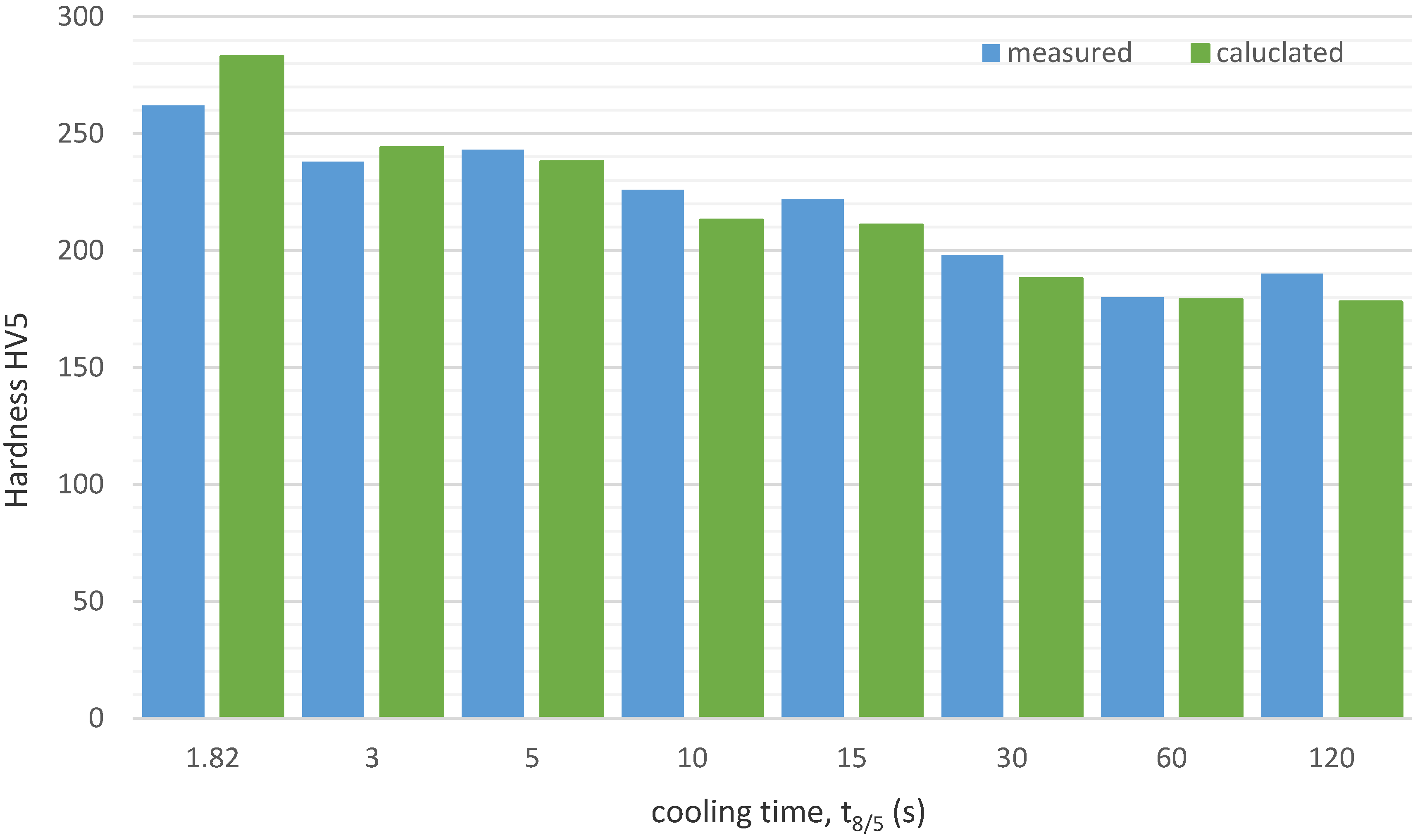

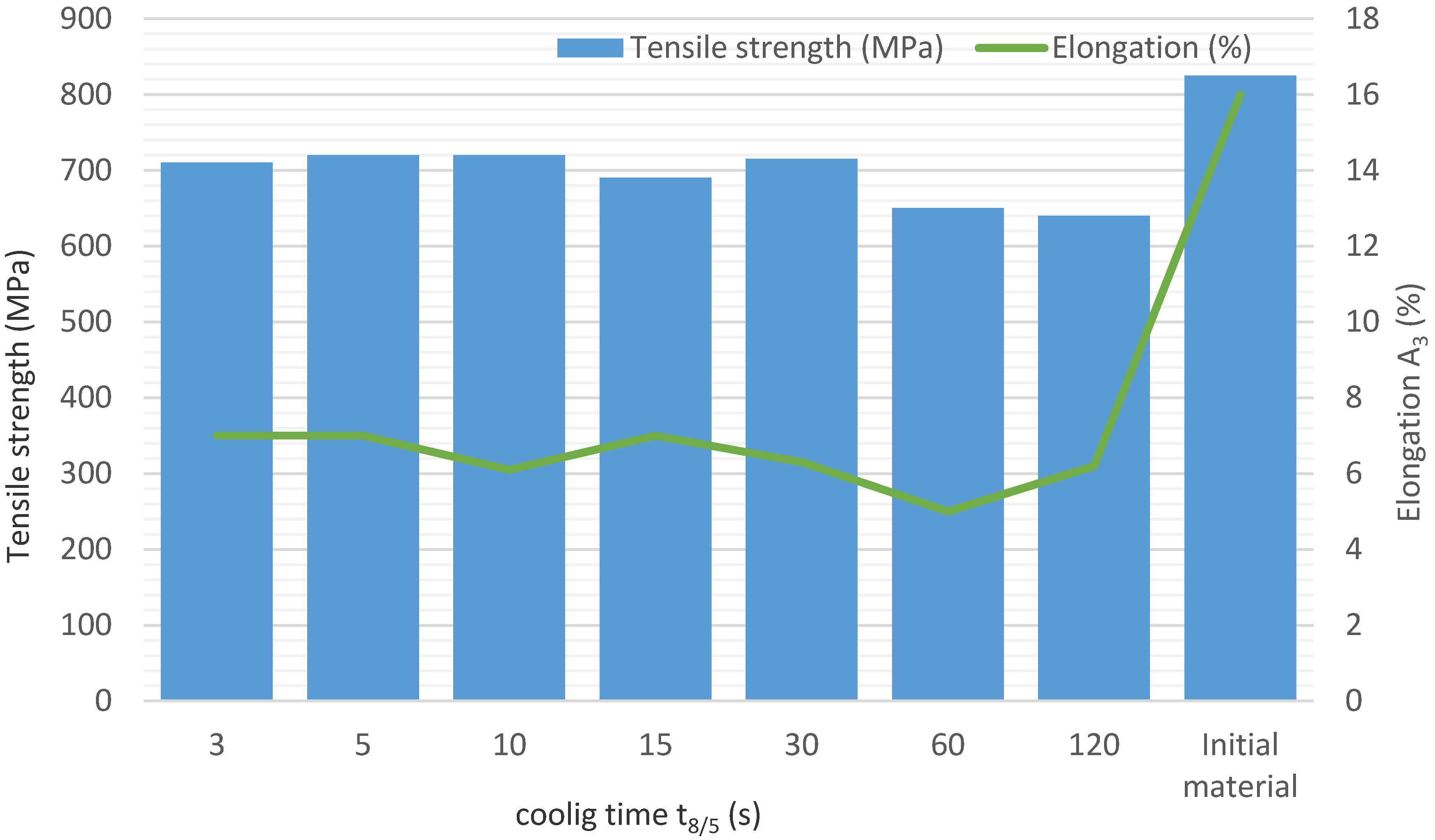

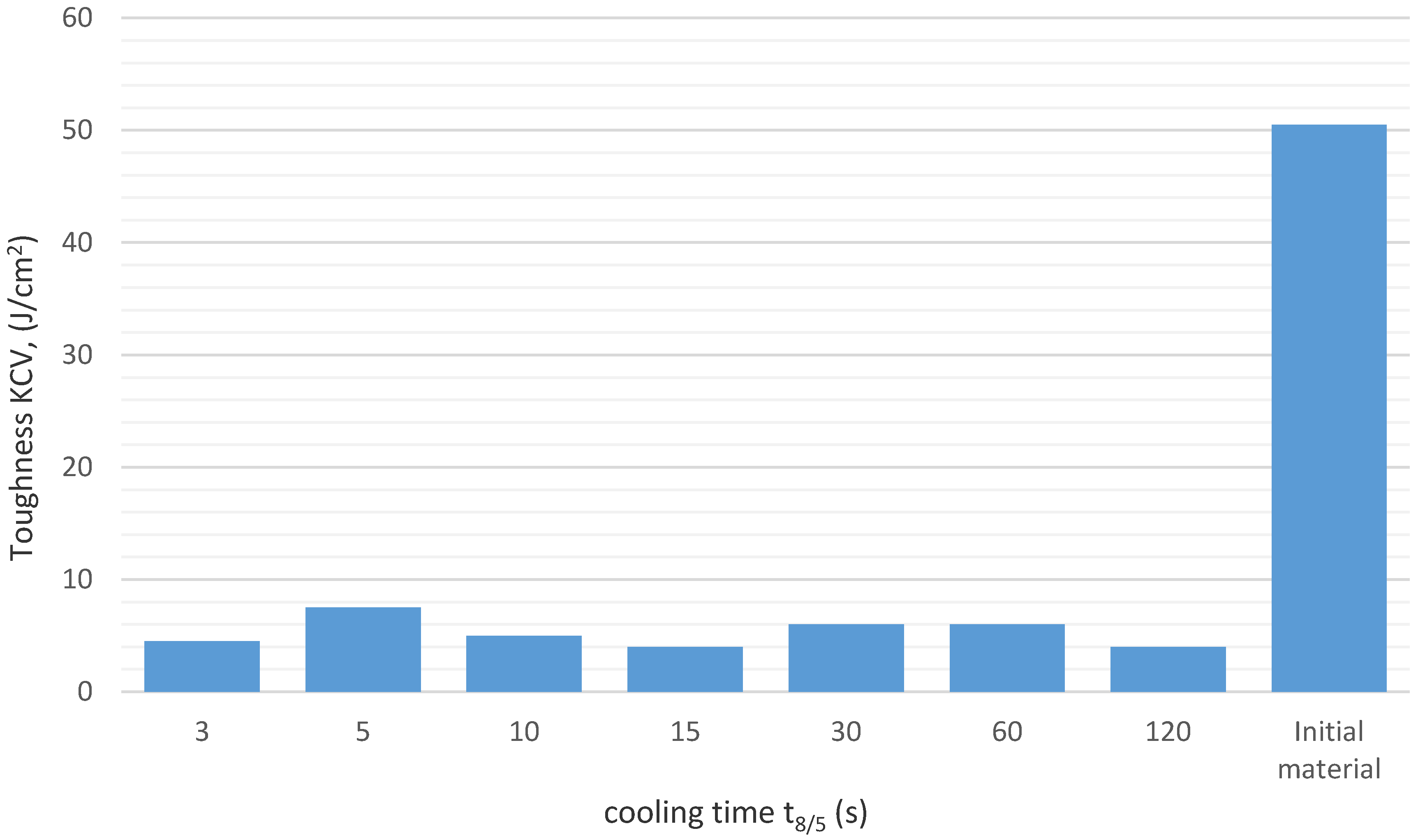

3.2. The Studies on the Influence of Stimulated Thermal Cycles with a Maximum Temperature of 1250 °C and Variable Cooling Time t8/5 on the Structure and Properties of HAZ in S700MC Steel

3.3. Mechanical Properties Tests

4. Results Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Flaxa, V.; Shaw, J. Material applications in ULSAB-AVC. Steel Grips 2003, 1, 255–261. [Google Scholar]

- Mikia, C.; Homma, K.; Tominaga, T. High strength and high performance steels and their use in bridge structures. J. Constr. Steel Res. 2002, 58, 3–20. [Google Scholar] [CrossRef]

- Lee, C.; Shin, H.; Park, K. Evaluation of high strength TMCP steel weld for use in cold regions. J. Constr. Steel Res. 2012, 74, 134–139. [Google Scholar] [CrossRef]

- Shipitsyn, S.; Babaskin, Y.; Kirchu, I.; Smolyakova, L.; Zolotar, N. Microalloyed steel for railroad wheels. Steel Transl. 2008, 38, 782–785. [Google Scholar] [CrossRef]

- Rak, I.; Gliha, V.; Koçak, M. Weldability and toughness assessment of Ti-microalloyed offshore steel. Metall. Mater. Trans. A 1997, 28, 199–206. [Google Scholar] [CrossRef]

- Chang, K.; Lee, C.; Park, K.; Um, T. Experimental and numerical investigations on residual stresses in a multi-pass butt-welded high strength SM570-TMCP steel plate. Int. J. Steel Struct. 2011, 11, 315–324. [Google Scholar] [CrossRef]

- Grajcar, A.; Matter, P.; Stano, S.; Wilk, Z.; Różański, M. Microstructure and hardness profiles of bifocal laser-welded DP-HSLA steel overlap joints. J. Mater. Eng. Perform. 2017, 26, 1920–1928. [Google Scholar] [CrossRef]

- Morawiec, M.; Różański, M.; Grajcar, A.; Stano, S. Effect of dual beam laser welding on microstructure-property relationships of hot-rolled complex phase steel sheets. Arch. Civ. Mech. Eng. 2017, 17, 145–153. [Google Scholar] [CrossRef]

- Mician, M.; Harmaniak, D.; Novy, F.; Winczek, J.; Moravec, J.; Trsko, L. Effect of the t(8/5) Cooling Time on the Properties of S960MC Steel in the HAZ of Welded Joints Evaluated by Thermal Physical Simulation. Metals 2020, 10, 229. [Google Scholar] [CrossRef]

- Grajcar, A.; Różański, M.; Kamińska, M.; Grzegorczyk, B. Effect of gas atmosphere on the non-metallic inclusions in laser-welded TRIP steel with Al and Si additions. Mater. Tehnol. 2016, 50, 945–950. [Google Scholar] [CrossRef]

- Skowronska, B.; Chmielewski, T.; Golanski, D.; Szulc, J. Weldability of S700MC steel welded with the hybrid plasma. Manuf. Rev. 2020, 7, 4. [Google Scholar] [CrossRef]

- Chmielewski, T.; Golański, D. The role of welding in the remanufacturing process. Weld. Int. 2015, 29, 861–864. [Google Scholar] [CrossRef]

- Kurc-Lisiecka, A.; Lisiecki, A. Laser welding of the new grade of advanced high-strength steel Domex 960. Laser 2017, 199, 204. [Google Scholar] [CrossRef]

- Kurc-Lisiecka, A.; Piwnik, J.; Lisiecki, A. Laser welding of new grade of advanced high strength steel STRENX 1100 MC. Arch. Metall. Mater. 2017, 62, 1651–1657. [Google Scholar] [CrossRef]

- Hever, M.; Schröter, F. Modern steel–high performance material for high performance bridges. In Proceedings of the 5th International Symposium on Steel Bridge, Barcelona, Spain, 5–7 March 2003; pp. 80–81. [Google Scholar]

- Rakshe, B.; Patel, J. Modern High Strength Nb-Bearing Structural Steels, Forming Processes. Available online: www.researchgate.net/publication/337670047_Modern_high_strength_Nb-bearing_structural_steels/link/5de427b9299bf10bc33759dc/download (accessed on 20 June 2020).

- Willms, R. High strength steel for steel constructions. In Proceedings of the Nordic Steel Construction Conference—NSCC, Malmo, Sweden, 2–4 September 2009; pp. 597–604. [Google Scholar]

- Nishioka, K.; Ichikawa, K. Progress in termomechanical control of steel plates and their commercialization. Sci. Technol. Adv. Mater. 2012, 13, 1–20. [Google Scholar]

- Dimatteo, A.; Lovicu, G.; Desanctis, M.; Valentini, R.; Solina, A. Correlations between microstructures and properties of transformation induced plasticity steels. Steel Grips 2006, 4, 143–147. [Google Scholar]

- Adamczyk, J. Development of the microalloyed constructional steels. J. Achiev. Mater. Manuf. Eng. 2006, 14, 9–20. [Google Scholar]

- Yan, W.; Shan, Y.; Yang, K. Effect of TiN inclusions on the impact toughness of low-carbon microalloyed steels. Metall. Trans. A 2006, 37A, 2147. [Google Scholar] [CrossRef]

- Chen, B.; Yu, H. Hot ductility behaviour of V-N and V-Nb microalloyed steels. Int. J. Miner. Metall. Mater. 2012, 19, 525. [Google Scholar] [CrossRef]

- Misra, R.D.K. Influence of vanadium on grain boundary segregation of phosphorus in iron and iron-carbon alloys. Bull. Mater. Sci. 1991, 14, 1309–1322. [Google Scholar] [CrossRef]

- Portera, D.; Laukkanenb, A.; Nevasmaab, P.; Rahkab, K.; Wallin, K. Performance of TMCP steel with respect to mechanical properties after cold forming and post-forming heat treatment. Int. J. Press. Vessel. Pip. 2004, 81, 867–877. [Google Scholar] [CrossRef]

- Zhao, M.; Yang, K.; Shan, Y. The effects of thermo-mechanical control process on microstructures and mechanical properties of a commercial pipeline steel. Mater. Sci. Eng. A 2002, 335, 14–20. [Google Scholar] [CrossRef]

- Skowrońska, B.; Szulc, J.; Chmielewski, T.; Sałaciński, T.; Swiercz, R. Properties and microstructure of hybride Plasma+MAG welded joints of thermomechanically treated S700MC steel. In Proceedings of the 27th Anniversary International Conference on Metallurgy and Materials (METAL), Brno, Czech Republic, 15–17 May 2018. [Google Scholar]

- Tomkow, J.; Fydrych, D.; Rogalski, G.; Labanowski, J. Temper Bead welding of S460N steel in wet welding conditions. Adv. Mater. Sci. 2018, 18, 5–14. [Google Scholar] [CrossRef]

- Tomkow, J.; Labanowski, J.; Fydrych, D.; Rogalski, G. Cold cracking of S460N steel welded in water environment. Pol. Marit. Res. 2018, 25, 131–136. [Google Scholar] [CrossRef]

- Hildebrand, J.; Werner, F. Change of structural condition of welded joints between high-strength fine-grained and structural steels. J. Civ. Eng. Manag. 2004, 2, 87–95. [Google Scholar] [CrossRef]

- Górka, J. Influence of welding thermal cycling on the join properties of S 700MC steel treated using thermomechanical method. In Proceedings of the 15th International Conference on Experimental Mechanics, Porto, Portugal, 22–27 July 2012; pp. 197–198. [Google Scholar]

- Górka, J. Microstructure and properties of the high-temperature (HAZ) of thermo-mechanically treated S700MC high-yield-strength steel. Mater. Tehnol. 2016, 50, 617–621. [Google Scholar]

- Górka, J. Analysis of simulated welding thermal cycles S700MC using a thermal imaging camera. In Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2014. [Google Scholar]

- Welding Simulation User Guide, Sysweld Manual ESI Group. Available online: https://www.esigmbh.de/downloads/ESI/Dokumente/Welding/The_Welding_Simulation_Solution_210408 (accessed on 19 July 2020).

- Kik, T. Computational Techniques in Numerical Simulations of Arc and Laser Welding Processes. Materials 2020, 13, 608. [Google Scholar] [CrossRef]

- Kik T, Heat Source Models in Numerical Simulations of Laser Welding. Materials 2020, 13, 2653. [CrossRef]

- Kik, T.; Moravec, J.; Novakova, I. New method of processing heat treatment experiments with numerical simulation support. Modern technologies in industrial engineering V. In Proceedings of the ModTech 2017 International Conference, Sibiu, Romania, 14–17 June 2017. [Google Scholar]

- Kik, T.; Gorka, J. Numerical simulations of S700MC laser and hybrid welding. In Laser Technology 2018: Progress and Applications of Lasers; International Society for Optics and Photonics: Bellingham, DC, USA, 2018. [Google Scholar] [CrossRef]

- Kik, T.; Górka, J. Numerical simulations of laser and hybrid S700MC T-joint welding. Materials 2019, 12, 516. [Google Scholar] [CrossRef]

- Gietka, T.; Ciechacki, K.; Kik, T. Numerical Simulation of Duplex Steel Multipass Welding. Arch. Metall. Mater. 2016, 61, 1975–1983. [Google Scholar] [CrossRef]

| Chemical Composition, % wg. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C Maximum | Si Maximum | Mn Maximum | P Maximum | S Maximum | Al Minimum | Nb Maximum * | V Maximum * | Ti Maximum * | B Maximum | Mo Maximum | Ce ** Maximum |

| 0.12 | 0.60 | 2.10 | 0.008 | 0.015 | 0.015 | 0.09 | 0.20 | 0.22 | 0.005 | 0.50 | 0.61 |

| Mechanical properties | |||||||||||

| Tensile strength, Rm (MPa) | Yield strength Re (MPa) | Elongation A5 (%) | Toughness (J/cm2) (−20 °C) | ||||||||

| 822 | 768 | 19 | 135 | ||||||||

| Chemical Composition, % wg | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | S | P | Al | Nb | Ti | V | N * | Ce |

| 0.056 | 1.68 | 0.16 | 0.005 | 0.01 | 0.027 | 0.044 | 0.12 | 0.006 | 72 | 0.33 |

| Specimen Designation | Temperature, Tmax (°C) | Time tn (s) | Time t8 (s) | Time t5 (s) | Time t8/5 (s) | |

|---|---|---|---|---|---|---|

| Set | Actual | |||||

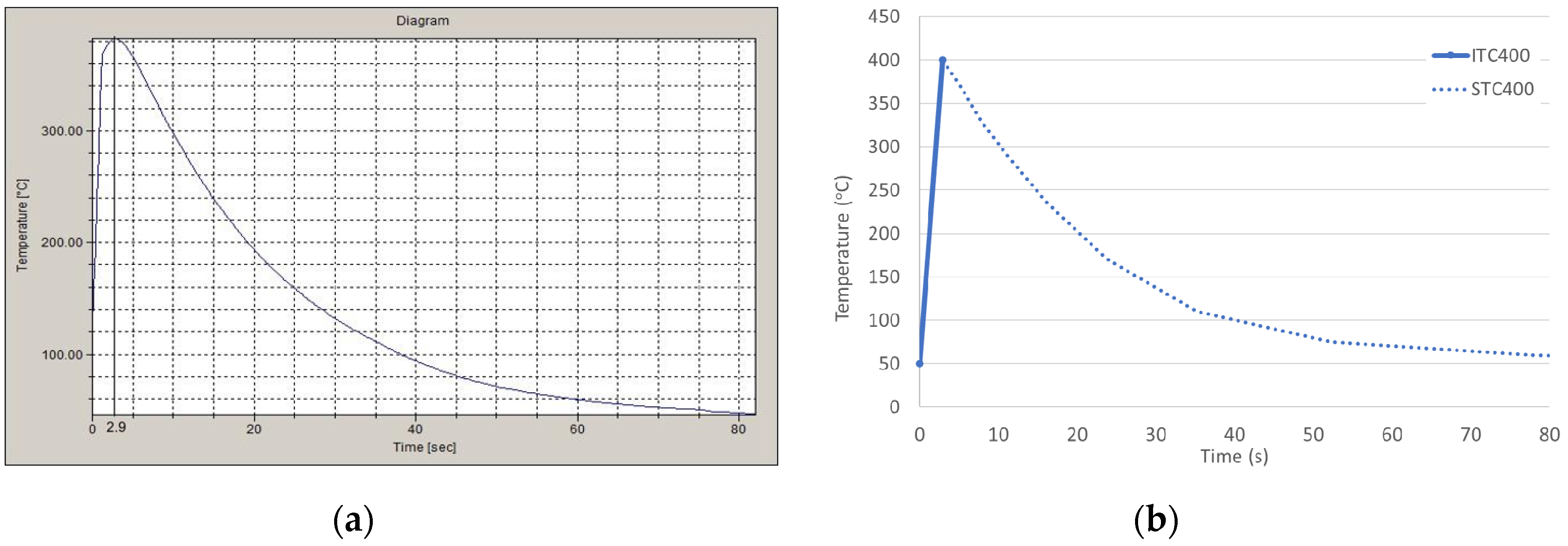

| TC400_1 | 400 | 382 | 2.9 | - | - | - |

| TC400_2 | 453 | 3.2 | - | - | - | |

| TC400_3 | 440 | 3.2 | - | - | - | |

| TC500_1 | 500 | 518 | 2.7 | - | - | - |

| TC500_2 | 552 | 2.7 | - | - | - | |

| TC500_3 | 480 | 2.8 | - | - | - | |

| TC600_1 | 600 | 619 | 2.6 | - | - | - |

| TC600_2 | 595 | 2.1 | - | - | - | |

| TC600_3 | 596 | 2.2 | - | - | - | |

| TC700_1 | 700 | 720 | 2.8 | - | - | - |

| TC700_2 | 720 | 2.4 | - | - | - | |

| TC700_3 | 736 | 2.1 | - | - | - | |

| TC800_1 | 800 | 807 | 2.7 | 3.3 | 16.4 | 13.1 |

| TC800_2 | 793 | 2.7 | 2.7 | 14.7 | 12.0 | |

| TC800_3 | 813 | 2.8 | 3.1 | 20.4 | 17.3 | |

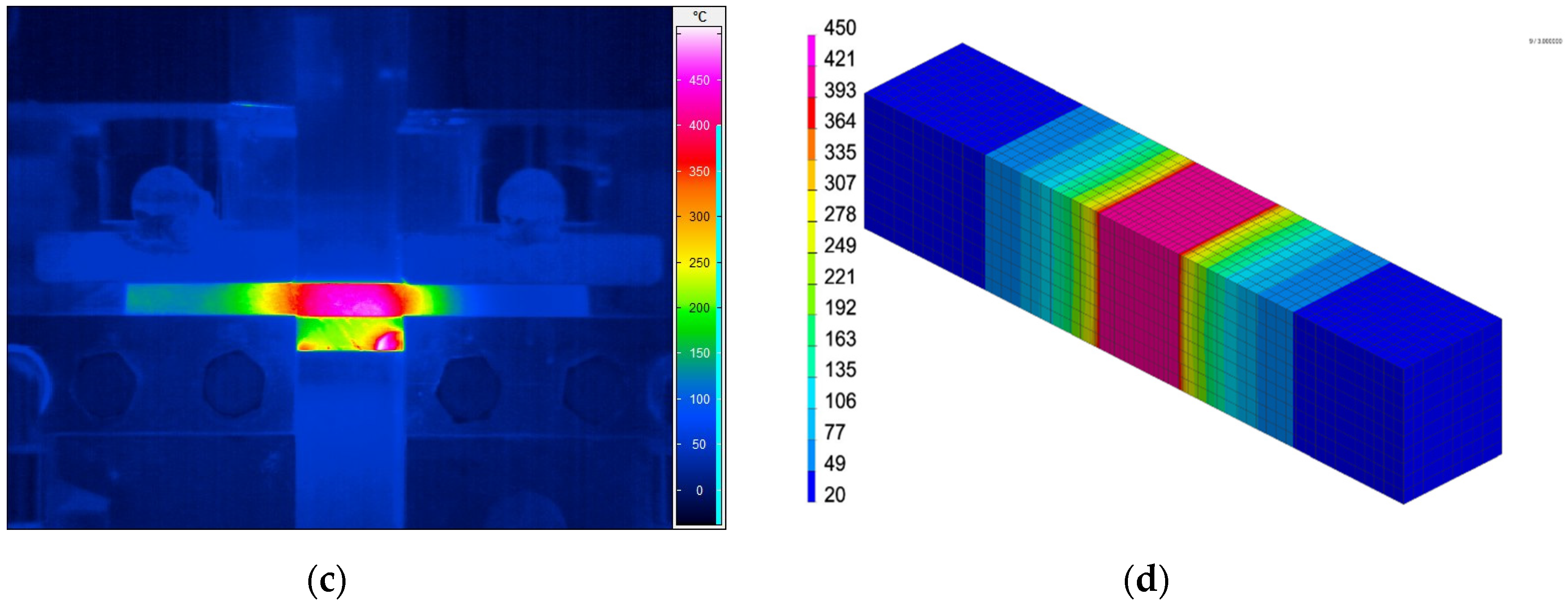

| TC900_1 | 900 | 904 | 3.4 | 6.6 | 19.3 | 12.7 |

| TC900_2 | 929 | 3.6 | 7.4 | 19.8 | 12.4 | |

| TC900_3 | 912 | 3.6 | 7.3 | 19.8 | 12.5 | |

| TC1000_1 | 1000 | 1017 | 4.3 | 12.7 | 23.9 | 11.2 |

| TC1000_2 | 1020 | 4.1 | 11.9 | 23.7 | 11.8 | |

| TC1000_3 | 1037 | 4.3 | 11.6 | 24.8 | 13.2 | |

| TC1100_1 | 1100 | 1136 | 4.4 | 13.6 | 25.6 | 12.0 |

| TC1100_2 | 1086 | 4.2 | 12.8 | 23.6 | 10.8 | |

| TC1100_3 | 1099 | 3.9 | 12.4 | 23.3 | 10.9 | |

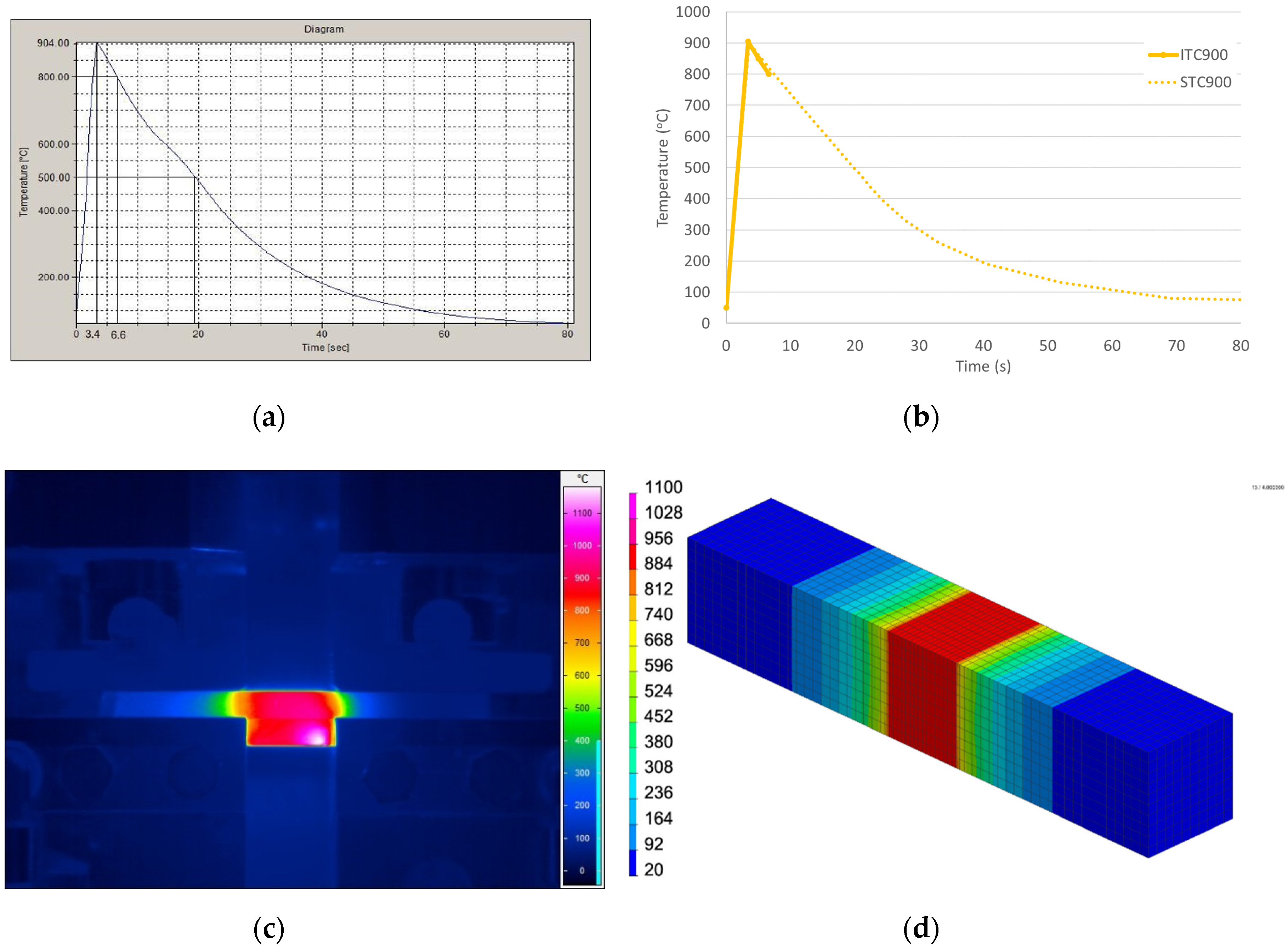

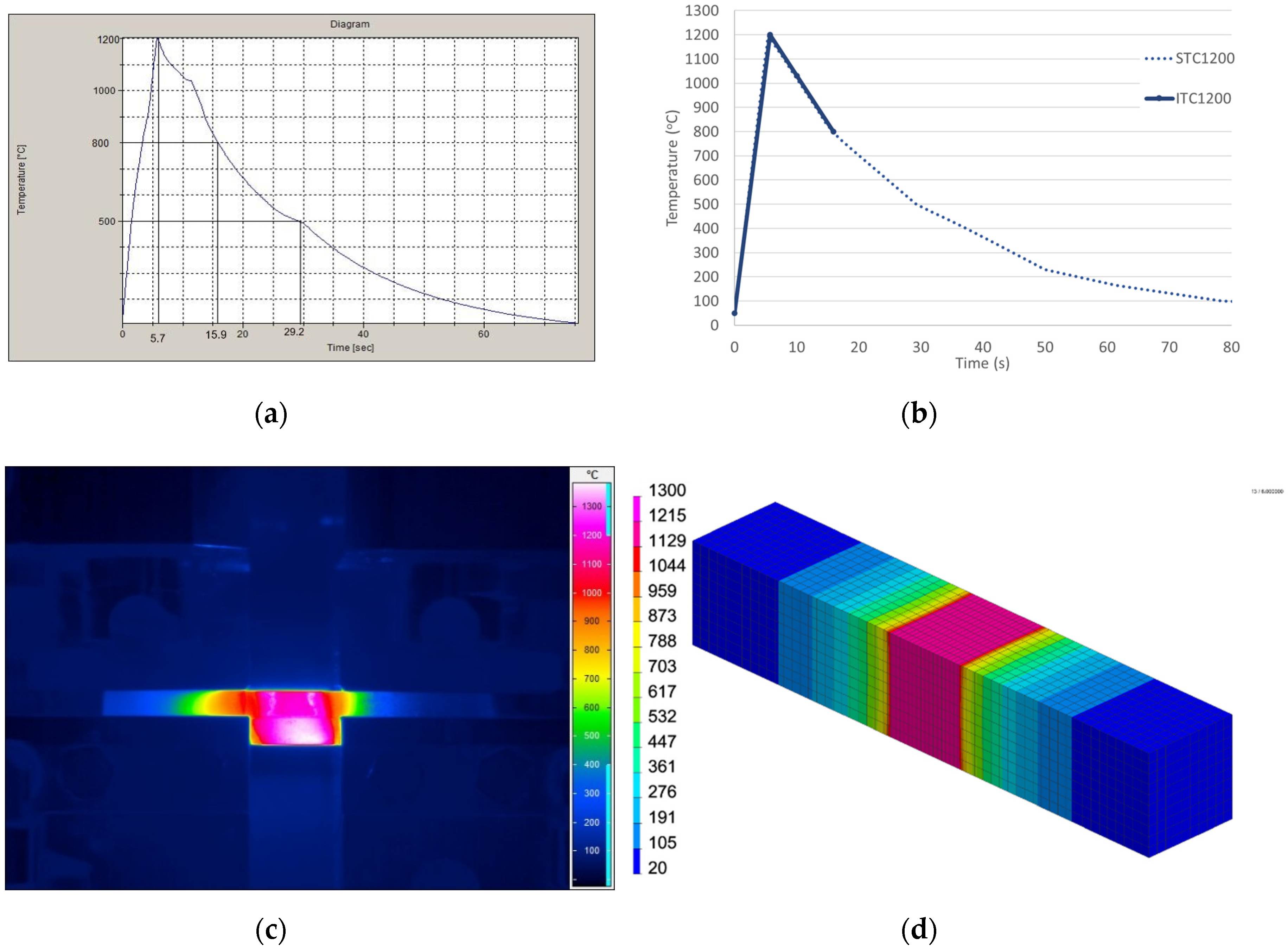

| TC1200_1 | 1200 | 1203 | 5.7 | 15.9 | 29.2 | 13.3 |

| TC1200_2 | 1178 | 5.4 | 15.6 | 29.2 | 13.6 | |

| TC1200_3 | 1191 | 5.3 | 15.6 | 30.0 | 13.6 | |

| TC1300_1 | 1300 | 1282 | 5.2 | 18.8 | 33.0 | 14.2 |

| TC1300_2 | 1285 | 5.9 | 20.1 | 34.9 | 14.8 | |

| TC1300_3 | 1275 | 5.7 | 20.6 | 35.9 | 14.2 | |

| Specimen Designation | Cooling Time between 800 and 500 °C (t8/5) (s) | Maximum Temperature of Thermal Cycle (°C) |

|---|---|---|

| TC0 | 1.82 | 1250 |

| TC1 | 3 | |

| TC2 | 5 | |

| TC3 | 10 | |

| TC4 | 15 | |

| TC5 | 30 | |

| TC6 | 60 | |

| TC7 | 120 |

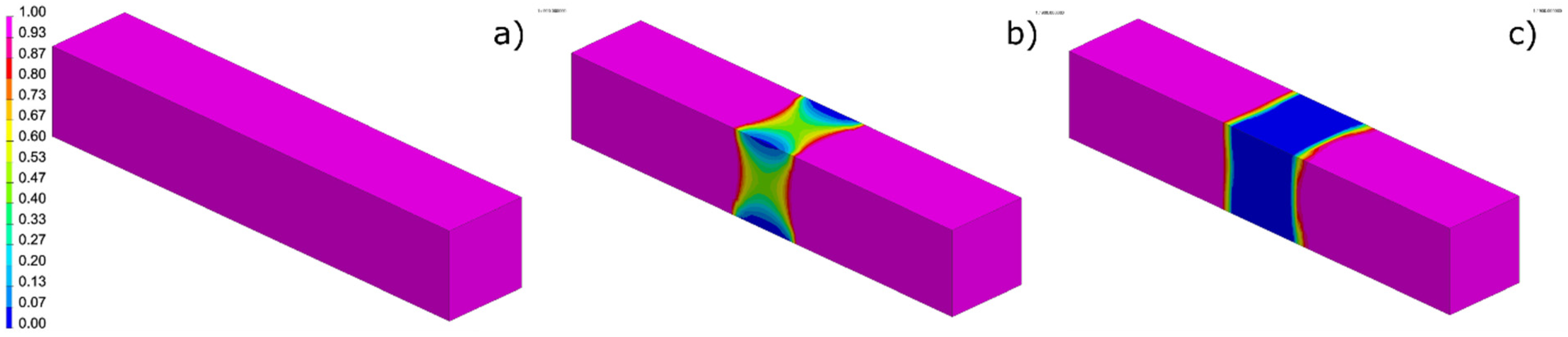

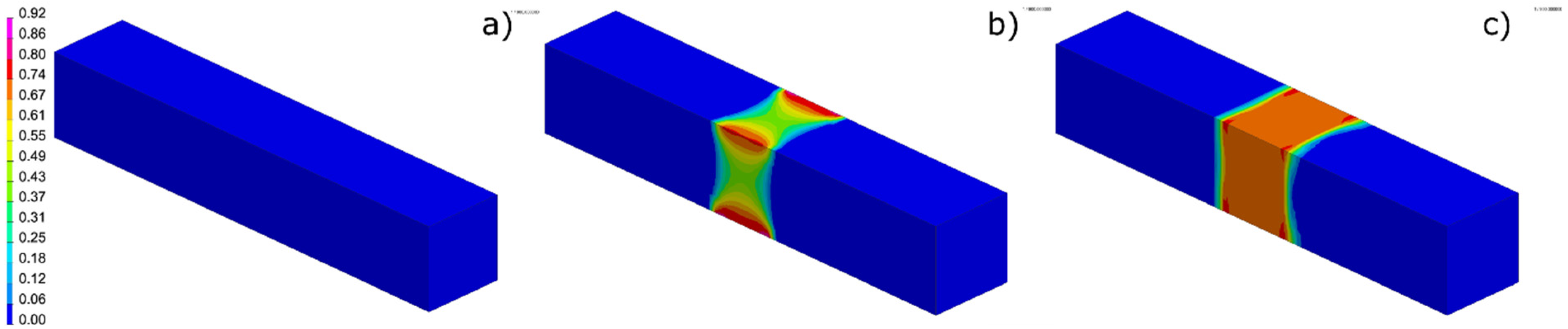

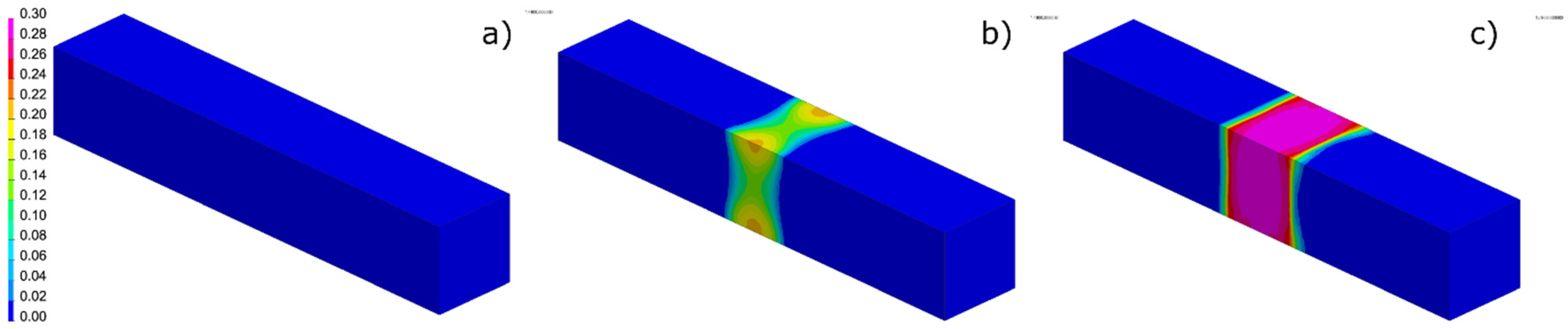

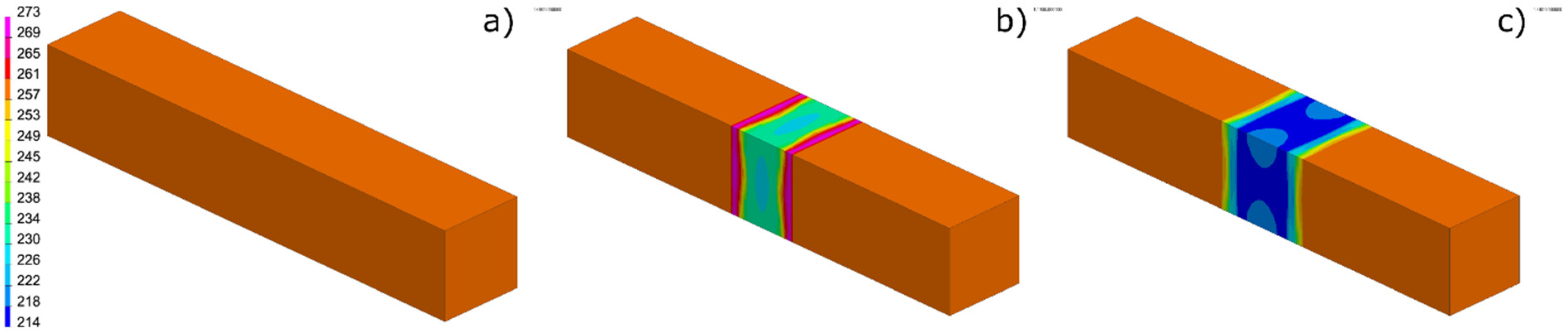

|  |  |

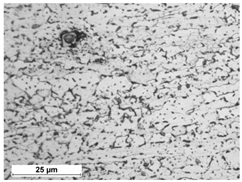

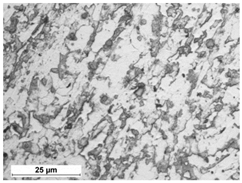

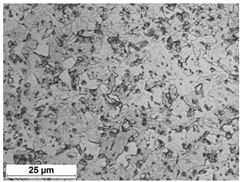

| Tmax = 400 °C | Tmax = 500 °C | Tmax = 600 °C |

|  |  |

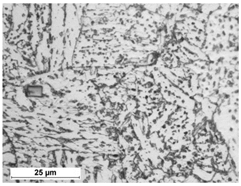

| Tmax = 700 °C | Tmax = 800 °C | Tmax = 900 °C |

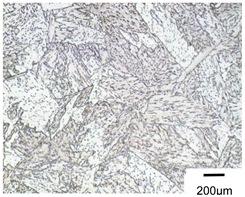

|  |  |

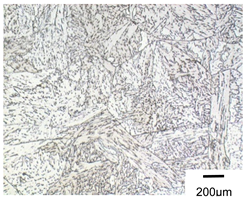

| Tmax = 1000 °C | Tmax = 1100 °C | Tmax = 1200 °C |

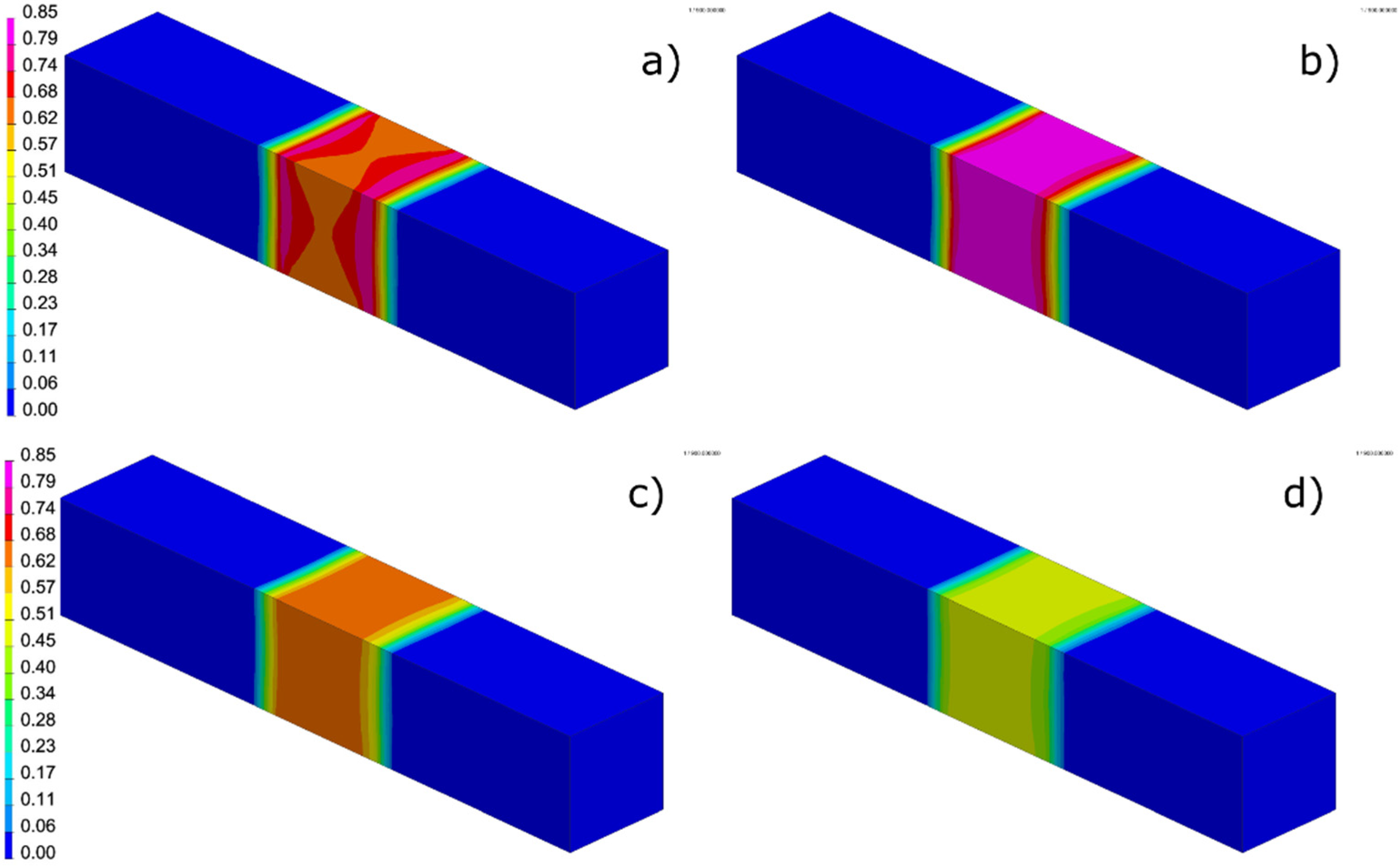

| Phase/Cycle | TC400 | TC700 | TC800 | TC900 | TC1000 | TC1100 | TC1200 |

|---|---|---|---|---|---|---|---|

| Martensite | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Bainite | 0 | 0 | 20.11 | 57.39 | 60.45 | 62.39 | 57.56 |

| Ferrite | 0 | 0 | 10.29 | 38.97 | 40.90 | 41.59 | 47.32 |

| Initial phase (bainite–ferrite) | 100 | 100 | 33.37 | 1.79 | 0 | 0 | 0 |

|  |  |

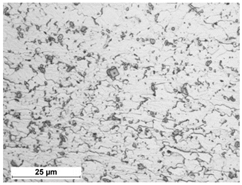

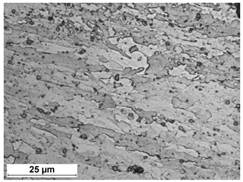

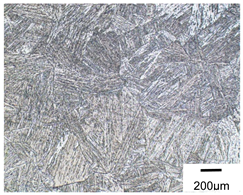

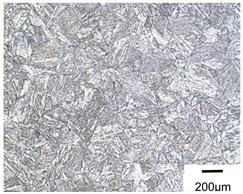

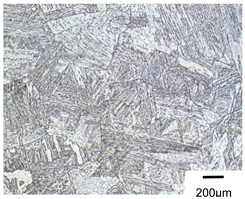

| time t8/5 = 1.82 s matensite | time t8/5 = 3.40 s martensite + bainite | time t8/5 = 5.38 s martensite + bainite |

|  |  |

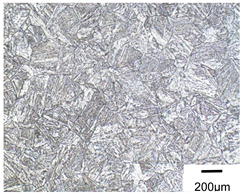

| time t8/5 = 10.20 s bainite + martensite | time t8/5 = 15.92 s bainite + small amounts of ferrite | time t8/5 = 20.86 s bainite + ferrite |

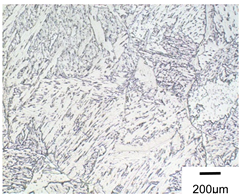

|  |  |

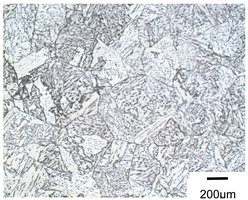

| time t8/5 = 29.98 s bainite + ferrite | time t8/5 = 58.70 s bainite + ferrite | time t8/5 = 97.18 s ferrite + bainite |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kik, T.; Górka, J.; Kotarska, A.; Poloczek, T. Numerical Verification of Tests on the Influence of the Imposed Thermal Cycles on the Structure and Properties of the S700MC Heat-Affected Zone. Metals 2020, 10, 974. https://doi.org/10.3390/met10070974

Kik T, Górka J, Kotarska A, Poloczek T. Numerical Verification of Tests on the Influence of the Imposed Thermal Cycles on the Structure and Properties of the S700MC Heat-Affected Zone. Metals. 2020; 10(7):974. https://doi.org/10.3390/met10070974

Chicago/Turabian StyleKik, Tomasz, Jacek Górka, Aleksandra Kotarska, and Tomasz Poloczek. 2020. "Numerical Verification of Tests on the Influence of the Imposed Thermal Cycles on the Structure and Properties of the S700MC Heat-Affected Zone" Metals 10, no. 7: 974. https://doi.org/10.3390/met10070974

APA StyleKik, T., Górka, J., Kotarska, A., & Poloczek, T. (2020). Numerical Verification of Tests on the Influence of the Imposed Thermal Cycles on the Structure and Properties of the S700MC Heat-Affected Zone. Metals, 10(7), 974. https://doi.org/10.3390/met10070974