1. Introduction

By replacing steel parts in cars with aluminum components, the total weight of a vehicle can be significantly reduced. Conventional production of car parts by forging results in large volume products; however, the same performance and strength can be obtained by sheet forming resulting in smaller volume of the part. The current method for sheet forming involves unfortunate phenomena such as spring-back, reduced geometrical tolerances, and limited formability. Additionally, many production steps and several operations are required, making this an expensive method. A new method for hot forming and in-die quenching (HFQ) has been developed, eliminating the unwanted effects of cold sheet forming [

1,

2,

3,

4,

5]. The method provides a more efficient and cost-effective solution for production of aluminum components for automotive applications. The method is initially applied on high-strength steel to produce lightweight components for the automotive industry [

6].

The sheet is solution heat treated and brought directly to the press for simultaneous deformation and quenching. A well-established hardening procedure includes natural aging by room temperature storage for several hours, or even days, before artificial aging for a few hours at an elevated temperature. It has been found that for alloys containing more than 1% solute and a Si/Mg ratio larger than 1, the clusters formed during the storage period have a negative effect on the subsequent precipitation during natural aging due to formation of clusters that do not provide any strength [

7,

8,

9]. Additionally, it has been suggested that step quenching, or reduced quenching rate from intermediate temperatures, might provide nucleation sites for strengthening precipitates, which can result in improved final properties of the product [

10].

Step quenching, or interrupted quenching at elevated temperatures, is suggested as the cooling rate slows down in the lower temperature range, 100–25 °C, during in-die quenching. The closed-die time can be reduced by several seconds if the quenching can be interrupted at a temperature below 200 °C. The quench sensitivity is, therefore, investigated in this work.

At temperatures above 250 °C, precipitation of β and β’ occurs, while GP-zones and β’’ phase are formed at lower temperatures, below 250 °C [

11]. The Mg

2Si precipitates formed at high temperatures are coarse and rod-shaped, i.e., the β and β’ phases are typically much larger in size than the β’’ phase [

11,

12]. As the amount of precipitation is increased during cooling, the hardening potential is reduced as precipitated solute will be unavailable for further precipitation reactions. The precipitates formed during slow cooling in the high-temperature region are coarse and do not provide any strength contribution [

13]. Gao, M., et al. [

14] and Shang, B.C., et al. [

15] investigated the quench sensitivity and obtained time-temperature-property (TTP) curves of AA6082. Both found that the alloy has a critical temperature (nose) between 320–400 °C after 10 s. The results indicate that a quenching rate where the nose is reached within 10 s will have small effects on the mechanical properties of the material. Hence, slow cooling from 200 °C might not cause precipitation of unfavorable precipitates.

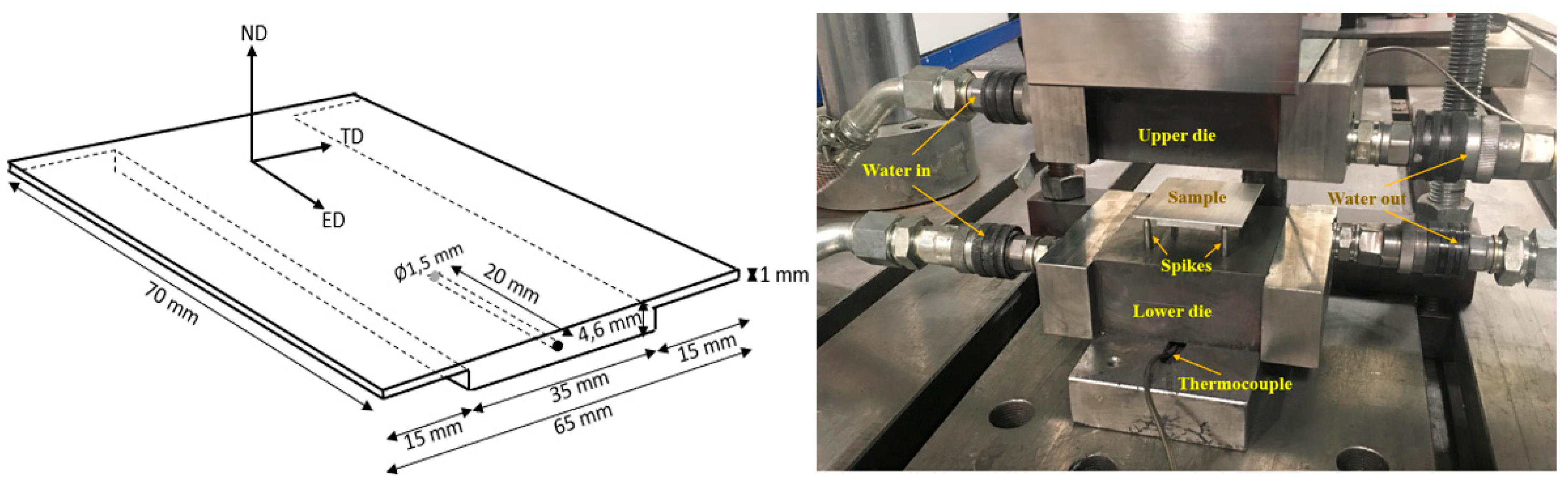

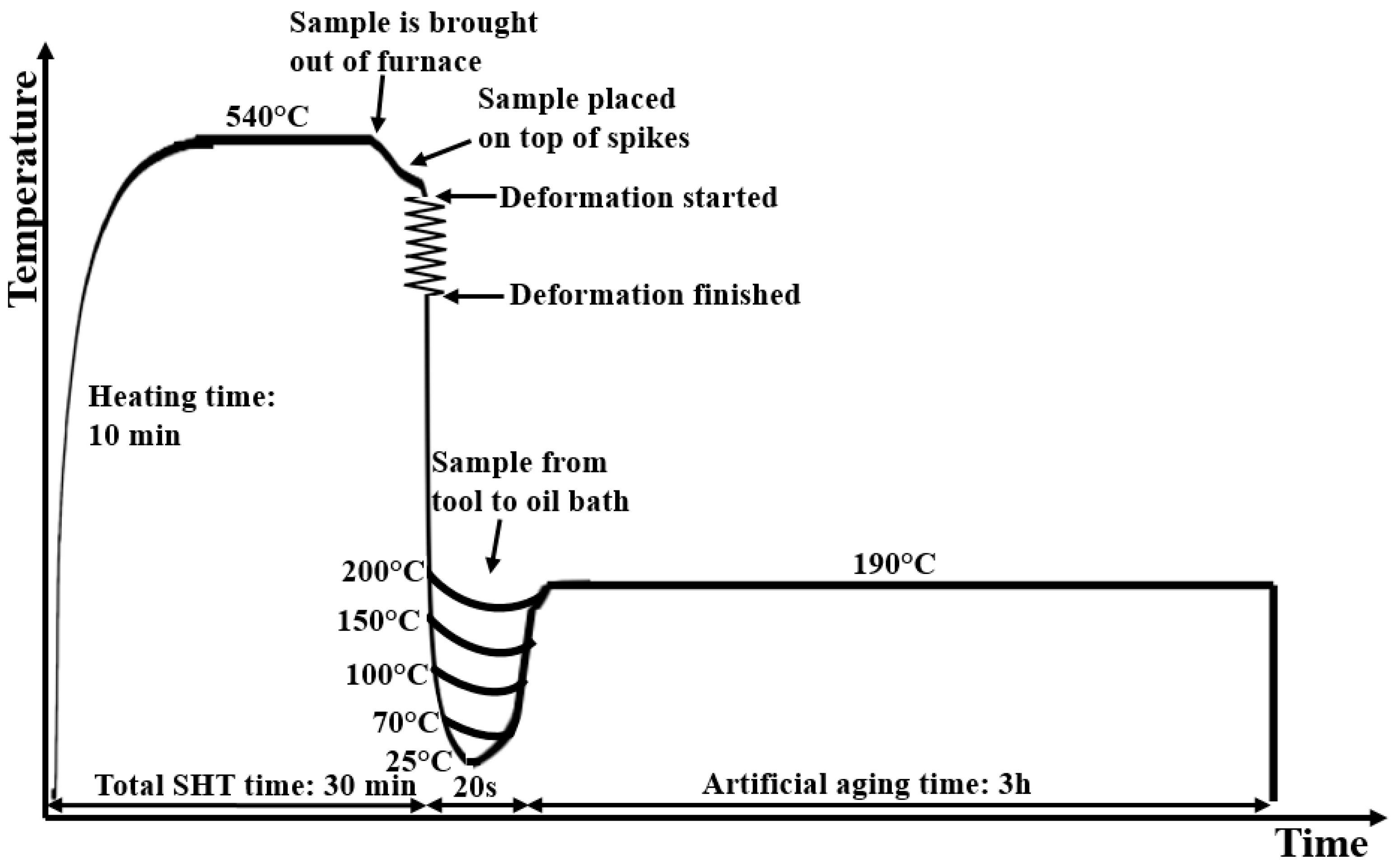

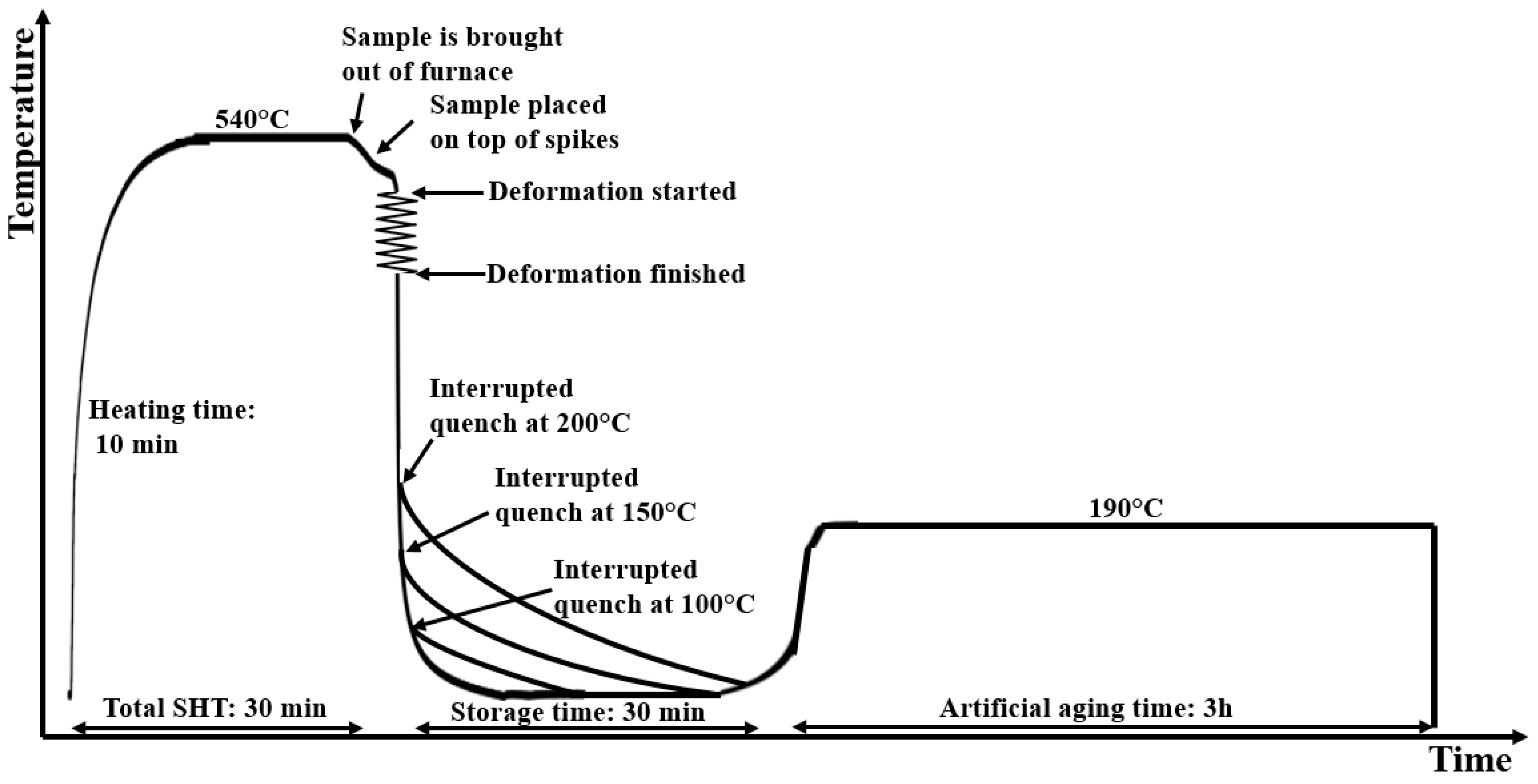

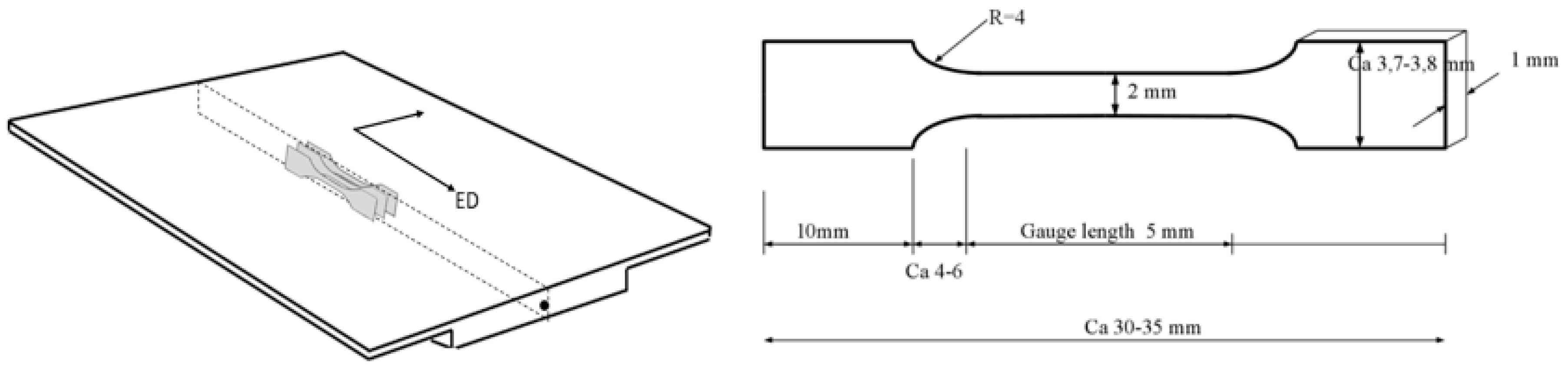

In this work, the new method has been simulated by small-scale laboratory experiments, where the theories and findings presented in the above section were implemented. Samples were solution heat treated in an air circulation furnace before being brought directly to a flat pressing tool for quenching and deformation. The quenching was interrupted at selected temperatures, where some samples were brought directly to an oil bath for natural aging, and some were air cooled to room temperature and naturally aged before artificial aging.

4. Discussion

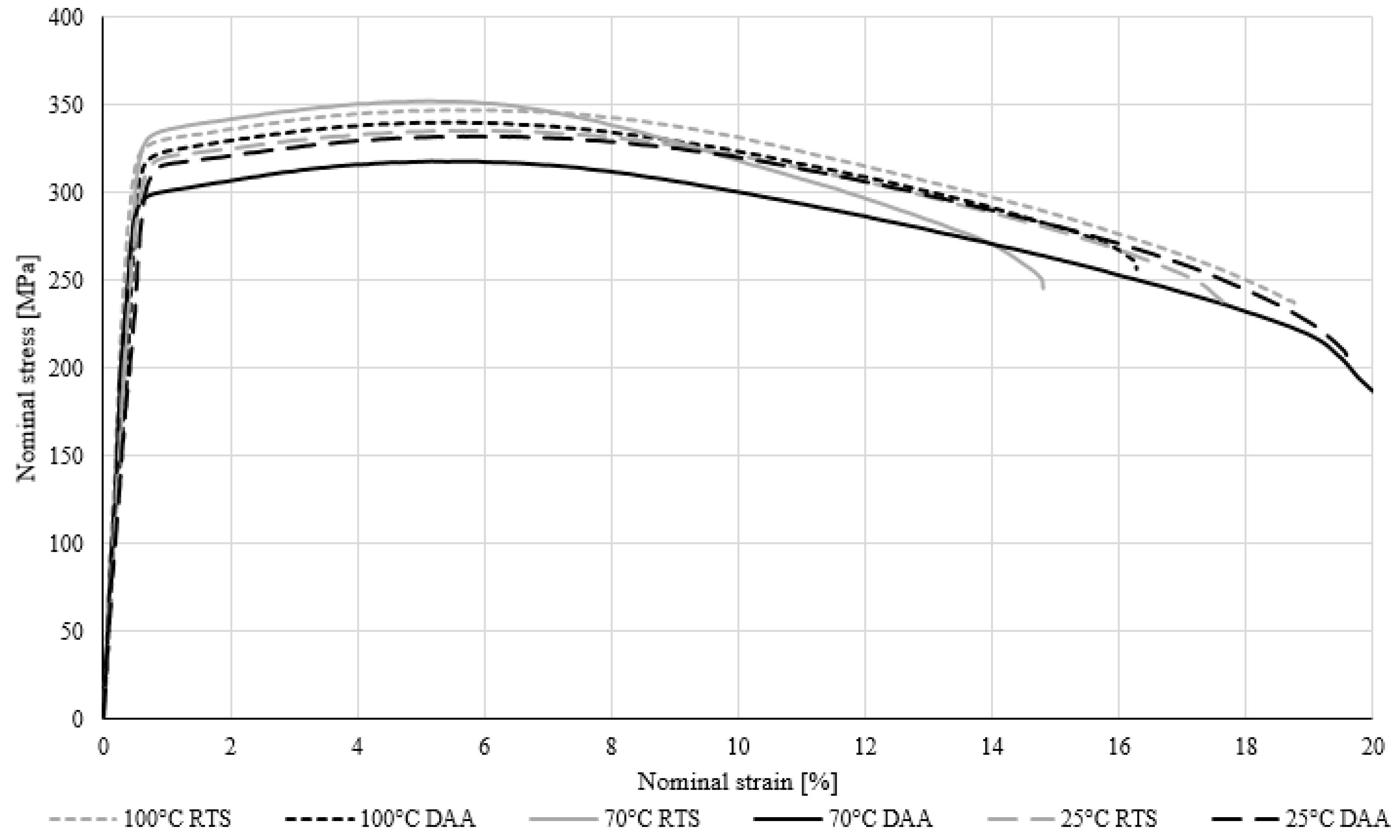

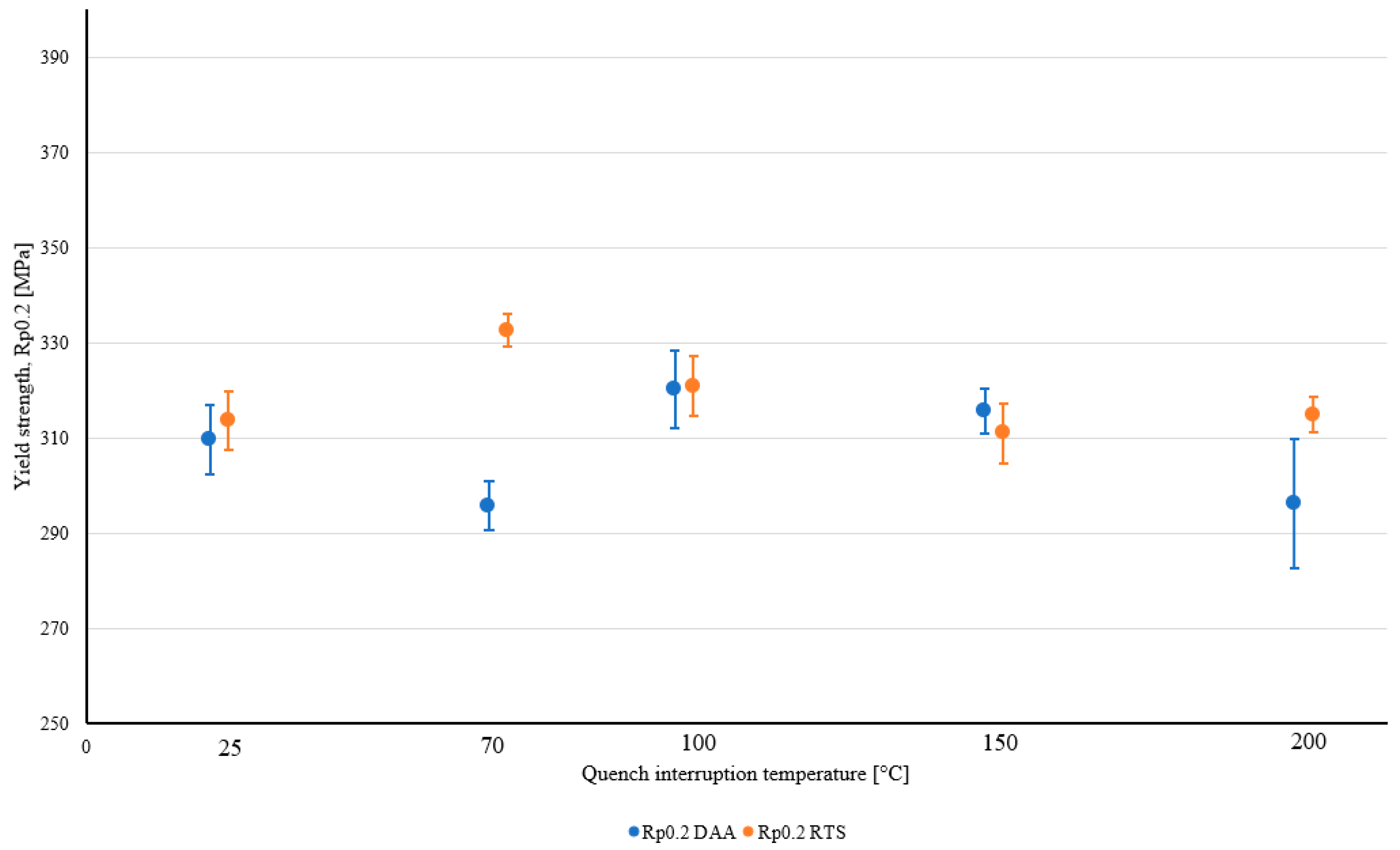

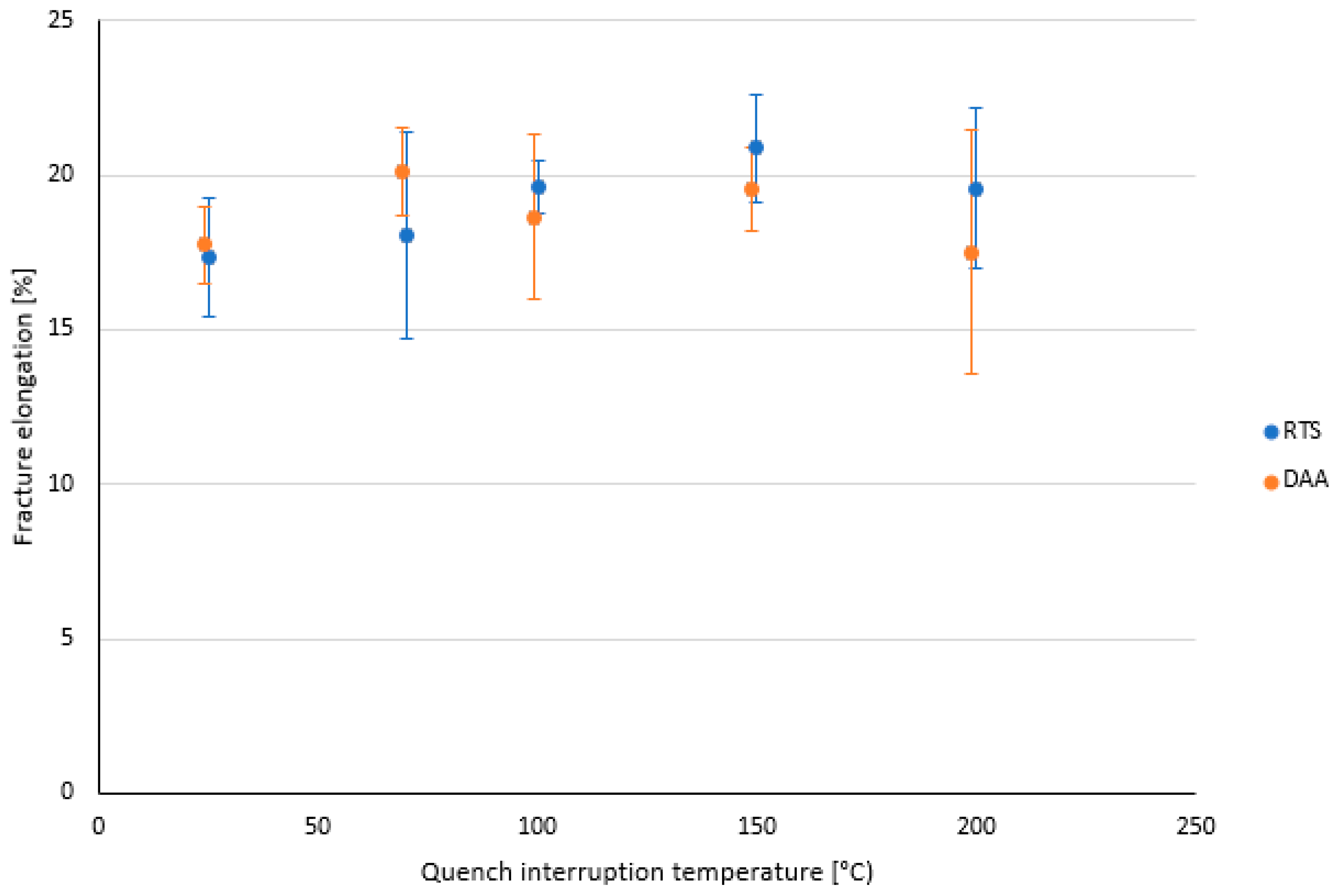

Figure 9 shows the average hardness and yield strength with standard deviations for the samples being quench interrupted at different temperatures before direct artificial aging or room temperature storage. An HFQ process would commonly be carried out by deformation and quenching to room temperature from solution heat treatment before natural aging and artificial aging. The yield strength results propose that introducing direct artificial aging and quench interruption at temperatures lower than 200 °C should not be disadvantageous to the final strength of the material. However, there is one exception to this statement. The samples quench interrupted at 70 °C before direct artificial aging show a significantly lower strength than the others—a difference in average yield strength of approximately 35 MPa compared to those being stored at room temperature. The results are quite unambiguous as the deviations are low, and there is no overlap.

The reason why the difference in strength between direct artificial aging and room temperature storage after quench interruption at 70 °C is so prominent in this case compared to the others is difficult to explain without more comprehensive investigations. One possible theory concerning the high strength of the room temperature storage sample might be formation of clusters occurring during air cooling to room temperature. The slow cooling rate from 70 °C can possibly be compared to the study done by Yamada, K. et al. [

10] where step quenching, i.e., interrupted quenching and holding time at an elevated temperature, promoted the formation of Mg-Si-vacancy clusters that act as nucleation sites for β” precipitates. These experiments also included natural aging before artificial aging. The slow cooling from quench interruption at 70 °C might have been sufficient for formation of these clusters. As for the samples being artificially aged directly after quench interruption at 70 °C, the significantly low strength differs from the other cases of direct artificial aging after quench interruption. This makes it difficult to find a reasonable explanation, as it would be arguable that the same effect should have been seen for the samples being quench interrupted at, for example, 100 °C before direct artificial aging. For the samples being quench interrupted at 70 °C and directly artificially aged, the distinct parameter is the temperature at which the quenching was interrupted in combination with direct artificial aging. The clusters that possibly form during air cooling did not form when the sample was directly heated to artificial aging temperature; i.e., the clustering must have been suppressed as the time was not sufficient for these to form. Thus, the vacancies will not be occupied by these clusters, and neither are they quenched at room temperature. A possible reason for the strength reduction may, therefore, be a significant reduction in number of vacancies for subsequent clustering of nucleation sites. The vacancies might have been lost during the exposure to elevated temperatures, i.e., 70 °C at quench interruption and direct heating to 190 °C. However, Transmission Electron Microscopy (TEM) investigations are necessary to investigate these hypotheses.

No significant change in mechanical properties can be deduced from the results after slow cooling from quench interruption at higher temperatures. This may indicate that little precipitation occurs during slow cooling from temperatures below 200 °C, as was previously addressed in

Section 1. Considering the compressed scale in the result plots and the inherent uncertainties in mechanical testing, the small differences that can be observed should not be severe in an industrial context.

The hardness results and the tensile test results conflict with each other for the quench interruption temperatures of 70 °C and 200 °C and direct artificial aging. This deviation cannot possibly be explained by the material properties or fundamentals, as the tensile tests and hardness measurements have been done on the exact same samples. Instead, one might have to evaluate the mechanical test conditions of the tensile testing and the hardness measurements. Due to the dimensions of the deformation samples and the thickness of the profile, the tensile specimens were so small that minor defects on the sample surface or mounting of the samples might cause consequences for the test results. Any conclusions of the material response in these cases cannot be drawn, as the hardness results do not support the tensile results. Additionally, the spread in fracture elongation is large in these two cases, which also supports the unreliability of the results. New tests for these conditions should be performed to confirm or disprove the deviating results.

In summary, quench interruption temperatures below 200 °C after deformation are, according to the tensile test results, beneficial to the final strength of the product. Direct artificial aging may also be introduced to the process, as it would not be detrimental to the properties, except in the case of quench interruption at 70 °C. The results suggest that an increase in efficiency in the industrial HFQ process is possible by reducing the closed-die time and skipping room temperature storage without inflicting negative effects on the final product properties.

The experiments are intended to be of relevance for the industrial production of aluminum components produced by press form hardening of sheets in 6000-series alloy for car applications. The most obvious differences between the experiments conducted in a laboratory and industrial production are the increased material volume and more extensive tooling resulting in different cooling rates and temperature distributions through the material and the tool, in addition to time consumption and limitations. However, the results should provide a sufficient indication of the material behavior under similar conditions and show the essence of the effects of the different treatments on the material properties as would be seen on an increased scale.

The quench interruption experiments are intended to give an indication of the possibilities and limitations of reduced closed-die time. Even if the time required to quench larger parts is longer in an industrial context, the effect of temperature to which the parts are quenched before air cooling or direct artificial aging should be quite similar to these experiments. A reduction of closed-die time may spare a few seconds in the production for each component and result in reduced cycle time.

The effect of direct artificial aging investigated in this project should also be of relevance to the industry. The storage period in the industry is a bottleneck in the production line of car components. If the room temperature storage period can be avoided without sacrificing strength and hardness, significant time can be spared, that is, several minutes or hours per part produced. This may provide large reductions in production costs and increased production efficiency. Additionally, storage space would not be necessary for natural aging.

Author Contributions

Conceptualization, O.J. and K.E.S.; Investigation, B.M.; Methodology, B.M.; Project administration, K.E.S.; Supervision, O.J. and K.E.S.; Writing—original draft, B.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been carried out as a part of the Norwegian Research Council (NRC) funded BIA-IPN projects iPAl and SUFICCS. The projects include the following partners: Raufoss Technology AS, Hydro Aluminium AS, TDG AS, AP&T, SINTEF Manufacturing, and SINTEF Industry.

Acknowledgments

The experiments were carried out at the Institute of Materials and Engineering at NTNU Trondheim.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jensrud, O.; Snilsberg, K.E.; Kolbu, A. Conceptual Testing of Press Form Hardening of High-Strength Aluminium Alloys; Aluminium Extrusions and Finishing—The International Magazine of the Aluminium Extrusion and Finishing Industry: Florence, Italy, 2016; pp. 16–20. [Google Scholar]

- Snilsberg, K.E.; Myrold, B.; Holmedal, B.; Jensrud, O. Direct artificial aging after integrated hot forming and die quenching of AA6082 extrusions. In Proceedings of the ICAA 16 International Conference of Aluminium Alloys, Montreal, QC, Canada, 17–21 June 2018. [Google Scholar]

- Neugebauer, R.; Schieck, F.; Polster, S.; Mosel, A.; Rautenstrauch, A.; Schönherr, J.; Pierschel, N. Press hardening—An innovative and challenging technology. Arch. Civ. Mech. Eng. 2012, 12, 113–118. [Google Scholar] [CrossRef]

- Tisza, M.; Lukács, Z.; Kovács, P.; Budai, D. Some recent development in sheet metal forming for production of lightweight automotive parts. J. Phys. Conf. Ser. 2017, 896, 012087. [Google Scholar] [CrossRef]

- Garrett, R.P.; Lin, J.; Dean, T.A. An investigation of the effects of solution heat treatment on mechanical properties for AA 6XXX alloys; experiments and modelling. Int. J. Plast. 2005, 21, 1640–1657. [Google Scholar] [CrossRef]

- Garrett, R.P.; Lin, J.; Dean, T.A. Solution Heat Treatment and Cold Die Quenching in Forming AA 6XXX Sheet Components: Feasibility Study. Adv. Mater. Res. 2005, 6–8, 673–680. [Google Scholar] [CrossRef]

- Torsæter, M.; Hasting, H.S.; Lefebvre, W.; Marioara, C.D.; Walmsley, J.C.; Andersen, S.J.; Holmestad, R. The influence of composition and natural aging on clustering during preaging in Al-Mg-Si alloys. J. Appl. Phys. 2010, 108, 073527. [Google Scholar] [CrossRef]

- Zhen, L.; Kang, S.B. DSC analyses of the precipitation behaviour of two Al-Mg-Si alloys naturally aged for different times. Mater. Lett. 1998, 37, 349–353. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andersen, S.J.; Zandbergen, H.W.; Holmestad, R. The influence of alloy composition on precipitates of the Al-Mg-Si system. Metall. Mater. Trans. A 2005, 36, 691–702. [Google Scholar]

- Yamada, K.; Sato, T.; Kamio, A. Effects of quenching conditions on two-step aging behaviour of Al-Mg-Si alloys. Alum. Alloys: Their Phys. Mech. Prop. 2000, 331, 669–674. [Google Scholar]

- Li, N.; Zheng, J.; Zhang, C.; Zheng, K.; Lin, J.; Dean, T.A. Investigation on fast and energy-efficient heat treatments of AA6082 in HFQ processes for automotive applications. In Proceedings of the MATEC Web of Conferences, Singapore, 15–16 September 2015. [Google Scholar]

- Milkereit, B.; Wanderka, N.; Schick, C.; Kessler, O. Continuous Cooling Precipitation Diagrams of Al-Mg-Si alloys. Mater. Sci. Eng. A 2012, 550, 87–96. [Google Scholar] [CrossRef]

- Howard, R.; Bogh, N.; Scott Mackenzie, D. Heat Treating Processes and Equipment, Handbook of Aluminum; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Gao, M.; Wang, M.; Wen, L.; Li, G. TTP Curves and Microstructural Evolution Mechanisms after Quenching in Aluminum Alloy 6082. Appl. Innov. Met. Alloy. Eng. Mater. 2012, 1, 165–169. [Google Scholar] [CrossRef]

- Shang, B.C.; Yin, Z.M.; Wang, G.; Liu, B.; Huang, Z.Q. Investigation of Quench Sensitivity and Transformation Kinetics During Isothermal Treatment in 6082 Aluminum Alloy. Mater. Des. 2011, 32, 3818–3822. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).