Numerical Simulation of Moving Heat Flux during Selective Laser Melting of AlSi25 Alloy Powder

Abstract

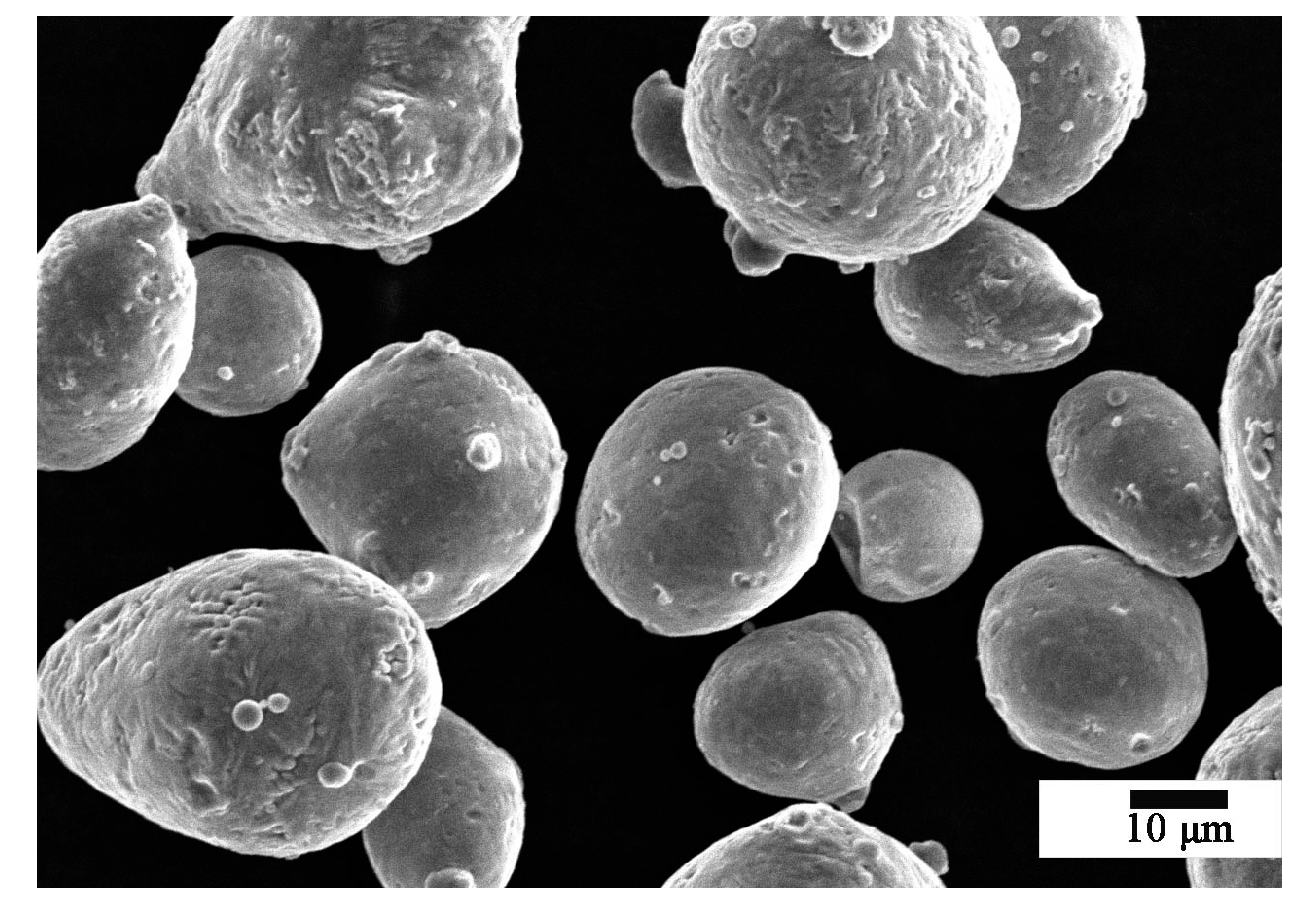

1. Introduction

2. Materials and Methods

2.1. SLM Process Model

2.1.1. Physical Model

2.1.2. Initial and Boundary Constraints

2.1.3. Gaussian Heat Source Model Design

2.1.4. Finite Element Setting

- (1)

- AlSi25 powder layer is regarded as a new continuous homogeneous isotropic medium.

- (2)

- Thermal conductivity and specific heat capacity of the material change with the temperature.

- (3)

- During laser processing, the thermal convection coefficient between the powder surface and the surrounding environment is a fixed constant, which does not vary with temperature.

- (4)

- The laser beam acting on the AlSi25 powder bed is defined as a Gaussian heat source, which is expressed as a heat flux in the simulation process.

- (5)

- The vaporization phenomenon is ignored after the material reaches the boiling point.

2.2. Experiment

3. Results and Discussion

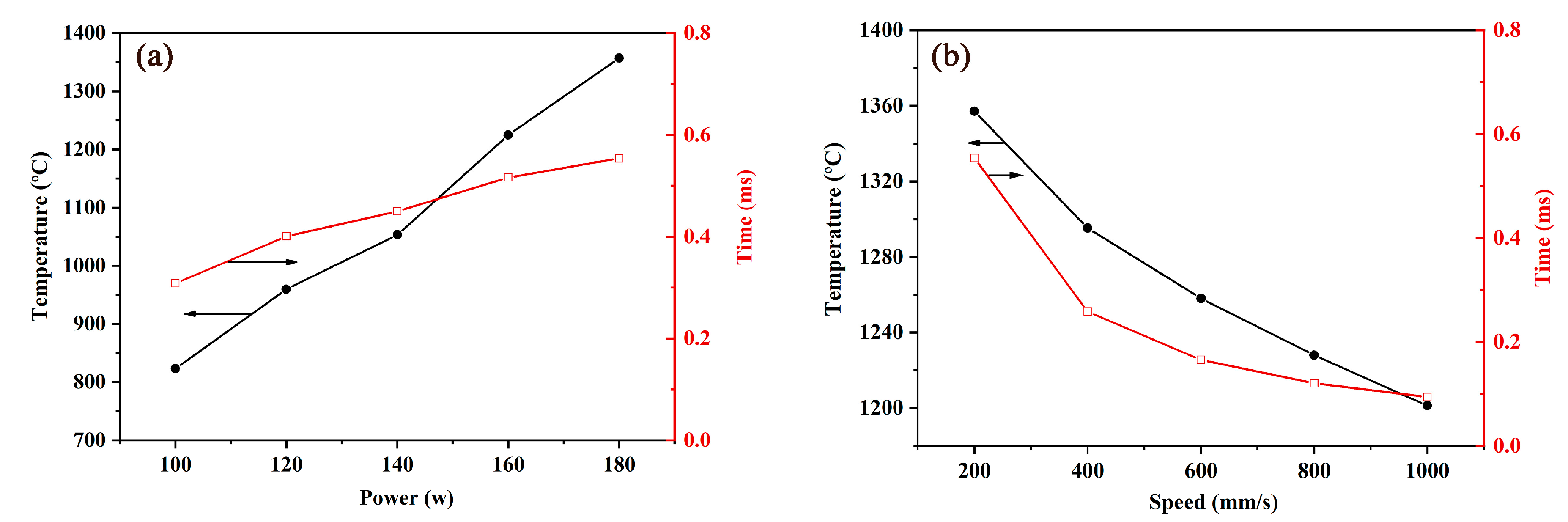

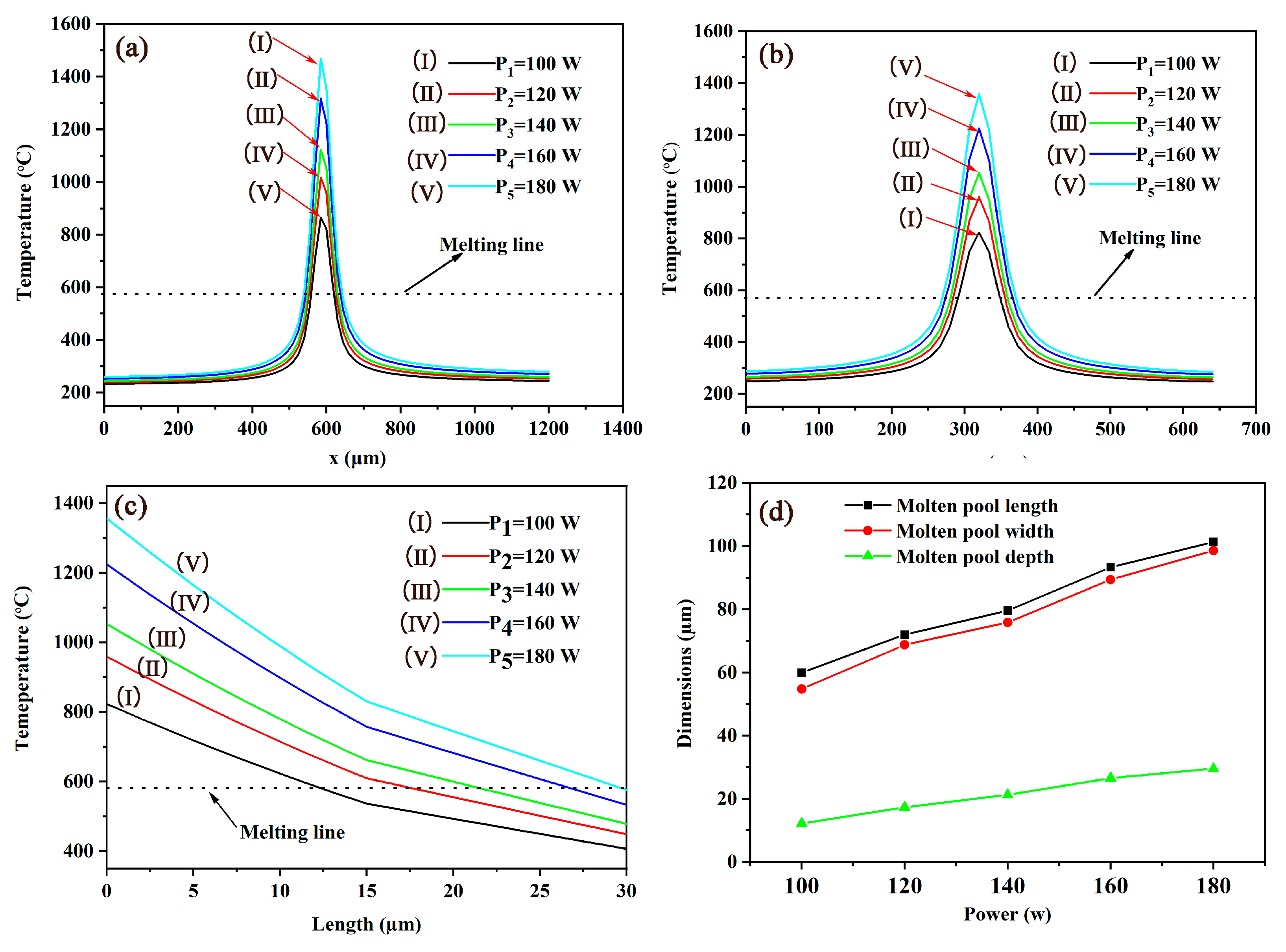

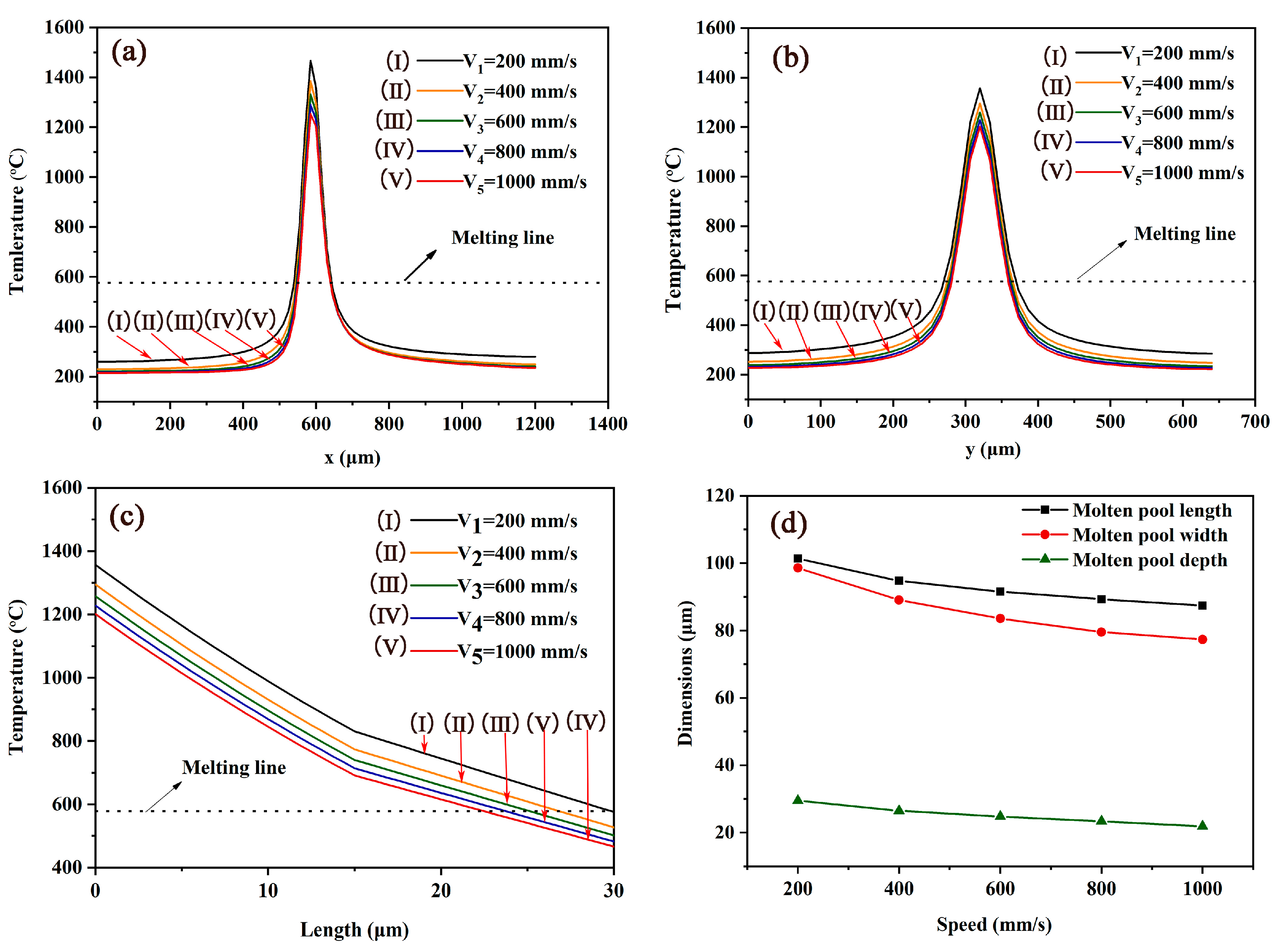

3.1. Characteristics of Temperature Distributions

3.2. Thermal Behaviors

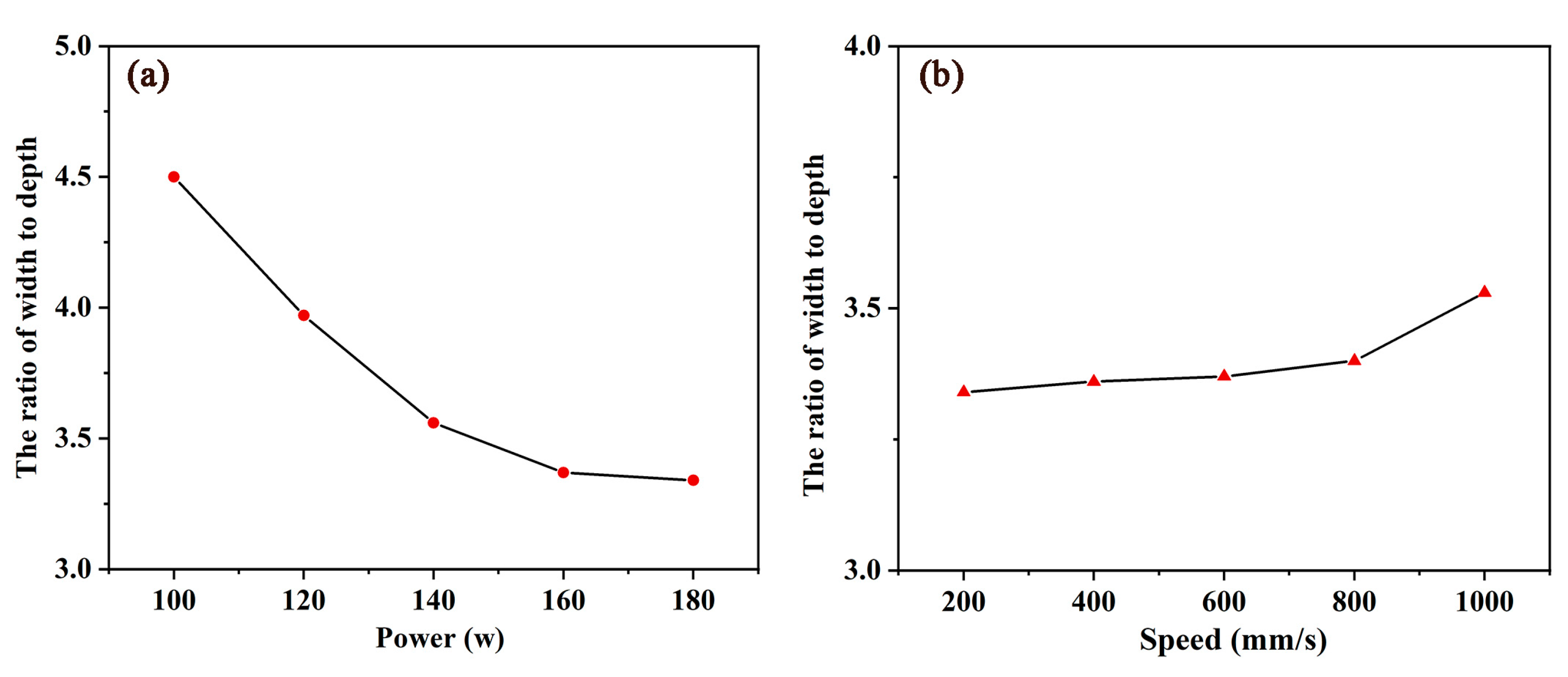

3.3. Molten Pool Configurations

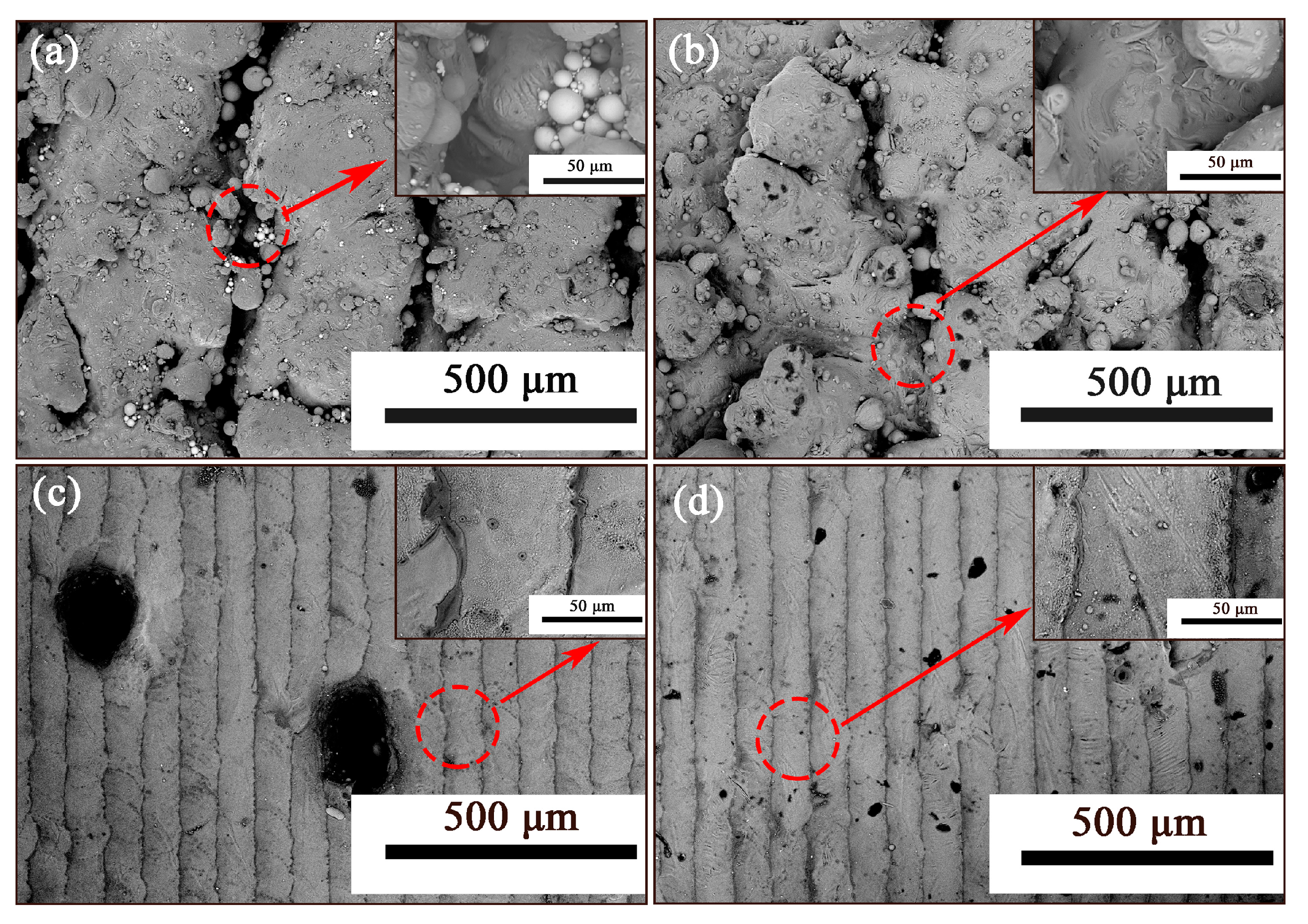

3.4. Experimental Investigation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Pham, M.-S.; Liu, C.; Todd, I.; Lertthanasarn, J. Damage-tolerant architected materials inspired by crystal microstructure. Nature 2019, 565, 305–311. [Google Scholar] [CrossRef]

- Onal, E.; Frith, J.E.; Jurg, M.; Wu, X.; Molotnikov, A. Mechanical Properties and In Vitro Behavior of Additively Manufactured and Functionally Graded Ti6Al4V Porous Scaffolds. Metals 2018, 8, 200–221. [Google Scholar] [CrossRef]

- Vandenbroucke, B.; Kruth, J.-P. Selective laser melting of biocompatible metals for rapid manufacturing of medical parts. Rapid Prototyp. J. 2007, 13, 196–203. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Tejo-Otero, A.; Fenollosa, F. Development of AM Technologies for Metals in the Sector of Medical Implants. Metals 2020, 10, 686–716. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Li, S.; Wei, Q.; Shi, Y.; Zhu, Z.; Zhang, D. Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting. J. Mater. Sci. Technol. 2015, 31, 946–952. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Fatigue performance evaluation of selective laser melted Ti–6Al–4V. Mater. Sci. Eng. A 2014, 598, 327–337. [Google Scholar] [CrossRef]

- Ma, P.; Gokuldoss, P.K.; Scudino, S.; Jia, Y.; Wang, H.; Zou, C.; Wei, Z.; Eckert, J. Influence of Annealing on Mechanical Properties of Al-20Si Processed by Selective Laser Melting. Metals 2014, 4, 28–36. [Google Scholar] [CrossRef]

- Li, Z.; Kuai, Z.; Bai, P.; Nie, Y.; Fu, G.; Liu, W.; Yang, S. Microstructure and Tensile Properties of AlSi10Mg Alloy Manufactured by Multi-Laser Beam Selective Laser Melting (SLM). Metals 2019, 9, 1337. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Saha, P. Crack and wear behavior of SiC particulate reinforced aluminium based metal matrix composite fabricated by direct metal laser sintering process. Mater. Des. 2011, 32, 139–145. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y. Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Mater. Des. 2009, 30, 2903–2910. [Google Scholar] [CrossRef]

- Han, X.; Zhu, H.; Nie, X.; Wang, G.; Zeng, X. Investigation on Selective Laser Melting AlSi10Mg Cellular Lattice Strut: Molten Pool Morphology, Surface Roughness and Dimensional Accuracy. Materials 2018, 11, 392. [Google Scholar] [CrossRef] [PubMed]

- Dadbakhsh, S.; Mertens, R.; Hao, L.; Van Humbeeck, J.; Kruth, J.-P. Selective Laser Melting to Manufacture “In Situ” Metal Matrix Composites: A Review. Adv. Eng. Mater. 2019, 21, 1801244. [Google Scholar] [CrossRef]

- Zhang, B.; Liao, H.; Coddet, C. Effects of processing parameters on properties of selective laser melting Mg–9%Al powder mixture. Mater. Des. 2012, 34, 753–758. [Google Scholar] [CrossRef]

- Manakari, V.; Parande, G.; Gupta, M. Selective Laser Melting of Magnesium and Magnesium Alloy Powders: A Review. Metals 2016, 7, 2–37. [Google Scholar] [CrossRef]

- Shi, Y.; Shen, H.; Yao, Z.; Hu, J. An analytical model based on the similarity in temperature distributions in laser forming. Opt. Lasers Eng. 2007, 45, 83–87. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Smurov, I.; Bertrand, P. Parametric analysis of the selective laser melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Wang, G.; Huang, L.; Liu, Z.; Qin, Z.; He, W.; Liu, F.; Chen, C.; Nie, Y. Process optimization and mechanical properties of oxide dispersion strengthened nickel-based superalloy by selective laser melting. Mater. Des. 2020, 188, 108418. [Google Scholar] [CrossRef]

- Qian, N.; Zhao, Z.; Fu, Y.; Xu, J.; Chen, J. Numerical Analysis on Temperature Field of Grinding Ti-6Al-4V Titanium Alloy by Oscillating Heat Pipe Grinding Wheel. Metals 2020, 10, 670–686. [Google Scholar] [CrossRef]

- Ning, J.; Mirkoohi, E.; Dong, Y.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical modeling of 3D temperature distribution in selective laser melting of Ti-6Al-4V considering part boundary conditions. J. Manuf. Process. 2019, 44, 319–326. [Google Scholar] [CrossRef]

- Sibalic, N.; Vukcevic, M. Numerical Simulation for FSW Process at Welding Aluminium Alloy AA6082-T6. Metals 2019, 9, 747–761. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.; Wang, W.; Attallah, M.M.; Loretto, M. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M.; Tuck, C. Improving the fatigue behaviour of a selectively laser melted aluminium alloy: Influence of heat treatment and surface quality. Mater. Des. 2016, 104, 174–182. [Google Scholar] [CrossRef]

- Delahaye, J.; Tchuindjang, J.T.; Lecomte-Beckers, J.; Rigo, O.; Habraken, A.; Mertens, A. Influence of Si precipitates on fracture mechanisms of AlSi10Mg parts processed by Selective Laser Melting. Acta Mater. 2019, 175, 160–170. [Google Scholar] [CrossRef]

- Zhang, G.-H.; Zhang, J.-X.; Li, B.-C.; Cai, W. Characterization of tensile fracture in heavily alloyed Al-Si piston alloy. Prog. Nat. Sci. 2011, 21, 380–385. [Google Scholar] [CrossRef]

- Hekimoğlu, A.P.; Çalış, M.; Ayata, G. Effect of Strontium and Magnesium Additions on the Microstructure and Mechanical Properties of Al–12Si Alloys. Met. Mater. Int. 2019, 25, 1488–1499. [Google Scholar] [CrossRef]

- Pei, Y.T.; De Hosson, J.T.M. Functionally graded materials produced by laser cladding. Acta Mater. 2000, 48, 2617–2624. [Google Scholar] [CrossRef]

- Kang, N.; Coddet, P.; Liao, H.; Coddet, C. Macrosegregation mechanism of primary silicon phase in selective laser melting hypereutectic Al—High Si alloy. J. Alloys Compd. 2016, 662, 259–262. [Google Scholar] [CrossRef]

- Kang, N.; Coddet, P.; Chen, C.; Wang, Y.; Liao, H.; Coddet, C. Microstructure and wear behavior of in-situ hypereutectic Al–high Si alloys produced by selective laser melting. Mater. Des. 2016, 99, 120–126. [Google Scholar] [CrossRef]

- Yi, H.; Zhang, D. Morphologies of Si phase and La-rich phase in as-cast hypereutectic Al–Si–xLa alloys. Mater. Lett. 2003, 57, 2523–2529. [Google Scholar] [CrossRef]

- Anand, S.; Srivatsan, T.S.; Wu, Y.; Lavernia, E.J. Processing, microstructure and fracture behavior of a spray atomized and deposited aluminum–silicon alloy. J. Mater. Sci. Technol. 1997, 32, 2835–2848. [Google Scholar]

- Liu, G.; Li, G.; Cai, A.; Chen, Z. The influence of Strontium addition on wear properties of Al–20wt% Si alloys under dry reciprocating sliding condition. Mater. Des. 2011, 32, 121–126. [Google Scholar] [CrossRef]

- McDonald, S.A.; Nogita, K.; Dahle, A.K. Eutectic nucleation in Al–Si alloys. Acta Mater. 2004, 52, 4273–4280. [Google Scholar] [CrossRef]

- Mao, F.; Wei, S.; Ou, L.; Zhang, C.; Chen, C.; Wang, X.; Cao, Z. Different Influences of Rare Earth Eu Addition on Primary Si Refinement in Hypereutectic Al–Si Alloys with Varied Purity. Materials 2019, 12, 3505. [Google Scholar] [CrossRef]

- Gremaud, M.; Allen, D.; Rappaz, M.; Perepezko, J. The development of nucleation controlled microstructures during laser treatment of AlSi alloys. Acta Mater. 1996, 44, 2669–2681. [Google Scholar] [CrossRef]

- Roehling, J.D.; Coughlin, D.R.; Gibbs, J.W.; Baldwin, J.K.; Mertens, J.C.; Campbell, G.H.; Clarke, A.J.; McKeown, J.T. Rapid solidification growth mode transitions in Al-Si alloys by dynamic transmission electron microscopy. Acta Mater. 2017, 131, 22–30. [Google Scholar] [CrossRef]

- Olakanmi, E.O. Selective laser sintering/melting (SLS/SLM) of pure Al, Al–Mg, and Al–Si powders: Effect of processing conditions and powder properties. J. Mater. Process. Technol. 2013, 213, 1387–1405. [Google Scholar] [CrossRef]

- Hanemann, T.; Carter, L.N.; Habschied, M.; Adkins, N.J.; Attallah, M.M.; Heilmaier, M. In-situ alloying of AlSi10Mg+Si using Selective Laser Melting to control the coefficient of thermal expansion. J. Alloys Compd. 2019, 795, 8–18. [Google Scholar] [CrossRef]

- Dai, K.; Shaw, L. Thermal and stress modeling of multi-material laser processing. Acta Mater. 2001, 49, 4171–4181. [Google Scholar] [CrossRef]

- Roberts, I.; Wang, C.J.; Esterlein, R.; Stanford, M.; Mynors, D. A three-dimensional finite element analysis of the temperature field during laser melting of metal powders in additive layer manufacturing. Int. J. Mach. Tools Manuf. 2009, 49, 916–923. [Google Scholar] [CrossRef]

- Hu, H.; Ding, X.; Wang, L. Numerical analysis of heat transfer during multi-layer selective laser melting of AlSi10Mg. Optik 2016, 127, 8883–8891. [Google Scholar] [CrossRef]

- Shi, Q.; Gu, D.; Xia, M.; Cao, S.; Rong, T. Effects of laser processing parameters on thermal behavior and melting/solidification mechanism during selective laser melting of TiC/Inconel 718 composites. Opt. Laser Technol. 2016, 84, 9–22. [Google Scholar] [CrossRef]

- Xiao, Z.; Yang, Y.; Wang, D.; Song, C.; Bai, Y. Structural optimization design for antenna bracket manufactured by selective laser melting. Rapid Prototyp. J. 2018, 24, 539–547. [Google Scholar] [CrossRef]

- Salonitis, K.; Al Zarban, S. Redesign Optimization for Manufacturing Using Additive Layer Techniques. Procedia CIRP 2015, 36, 193–198. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Levy, G.; Klocke, F.; Childs, T.H.C. Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann. 2007, 56, 730–759. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, J.; Zheng, M.; Yan, Z.; Lu, X.; Lin, X.; Huang, W. Element Vaporization of Ti-6Al-4V Alloy during Selective Laser Melting. Metals 2020, 10, 435. [Google Scholar] [CrossRef]

- Michaleris, P. Modeling metal deposition in heat transfer analyses of additive manufacturing processes. Finite Elem. Anal. Des. 2014, 86, 51–60. [Google Scholar] [CrossRef]

- Khan, H.; Dirikolu, M.; Koç, E.; Oter, Z.C. Numerical investigation of heat current study across different platforms in SLM processed multi-layer AlSi10Mg. Optik 2018, 170, 82–89. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Seivers, D.E.; Garmestani, H.; Liang, S.Y. Heat Source Modeling in Selective Laser Melting. Materials 2019, 12, 2052–2070. [Google Scholar] [CrossRef] [PubMed]

- Hussein, A.; Hao, L.; Yan, C.; Everson, R. Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Mater. Des. 2013, 52, 638–647. [Google Scholar] [CrossRef]

- Dong, L.; Makradi, A.; Ahzi, S.; Remond, Y. Three-dimensional transient finite element analysis of the selective laser sintering process. J. Mater. Process. Technol. 2009, 209, 700–706. [Google Scholar] [CrossRef]

- Li, Y.; Gu, D. Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder. Mater. Des. 2014, 63, 856–867. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, X.; Zhu, Y.; Zhu, X.; Sun, J.; Yan, B. An approach to predict the residual stress and distortion during the selective laser melting of AlSi10Mg parts. Int. J. Adv. Manuf. Technol. 2018, 97, 3535–3546. [Google Scholar] [CrossRef]

- Dai, K.; Shaw, L. Finite element analysis of the effect of volume shrinkage during laser densification. Acta Mater. 2005, 53, 4743–4754. [Google Scholar] [CrossRef]

- Criales, L.E.; Arısoy, Y.M.; Özel, T. Sensitivity analysis of material and process parameters in finite element modeling of selective laser melting of Inconel 625. Int. J. Adv. Manuf. Technol. 2016, 86, 2653–2666. [Google Scholar] [CrossRef]

| Temperature (°C) | 25 | 100 | 200 | 300 | 400 | 500 |

|---|---|---|---|---|---|---|

| Thermal conductivity, Ks (W/m °C ) | 189 | 175 | 158 | 144 | 132 | 121 |

| Specific heat capacity, c (J/kg °C) | 854 | 901 | 947 | 987 | 1025 | 1069 |

| Density, ρ (kg/m3) | 2684 | − | − | − | − | − |

| Powder | Al | Si |

|---|---|---|

| Mass fraction (%) | 75.44 | 24.56 |

| Parameters | Value |

|---|---|

| Absorption Coefficient, AC | 0.09 |

| Layer thickness, d (μm) | 30 |

| Scanning pitch, S (μm) | 80 |

| Laser facula diameter, D (μm) | 50 |

| Ambient temperature, T (°C) | 25 |

| Laser power, P (W) | 100, 120, 140, 160, 180 |

| Scan speed, v (mm/s) | 200, 400, 600, 800, 1000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; Wei, X.; Yan, B.; Yan, P. Numerical Simulation of Moving Heat Flux during Selective Laser Melting of AlSi25 Alloy Powder. Metals 2020, 10, 877. https://doi.org/10.3390/met10070877

Ma C, Wei X, Yan B, Yan P. Numerical Simulation of Moving Heat Flux during Selective Laser Melting of AlSi25 Alloy Powder. Metals. 2020; 10(7):877. https://doi.org/10.3390/met10070877

Chicago/Turabian StyleMa, Cong, Xianshun Wei, Biao Yan, and Pengfei Yan. 2020. "Numerical Simulation of Moving Heat Flux during Selective Laser Melting of AlSi25 Alloy Powder" Metals 10, no. 7: 877. https://doi.org/10.3390/met10070877

APA StyleMa, C., Wei, X., Yan, B., & Yan, P. (2020). Numerical Simulation of Moving Heat Flux during Selective Laser Melting of AlSi25 Alloy Powder. Metals, 10(7), 877. https://doi.org/10.3390/met10070877