Integrated Physical-Constitutive Computational Framework for Plastic Deformation Modeling

Abstract

1. Introduction

2. The model

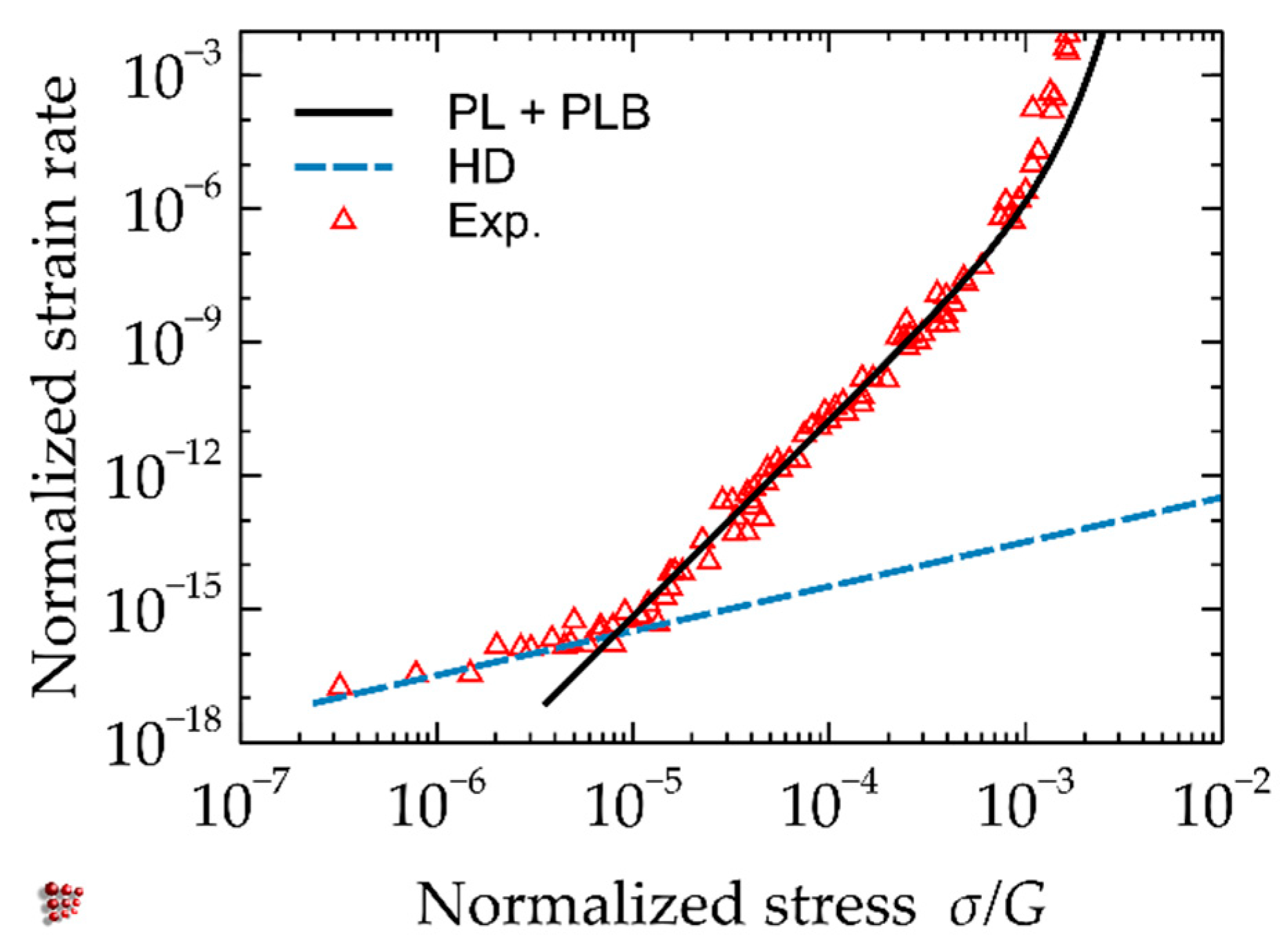

2.1. Constitutive Modeling of Creep

2.2. Physical Modeling of Microstructure Evolution

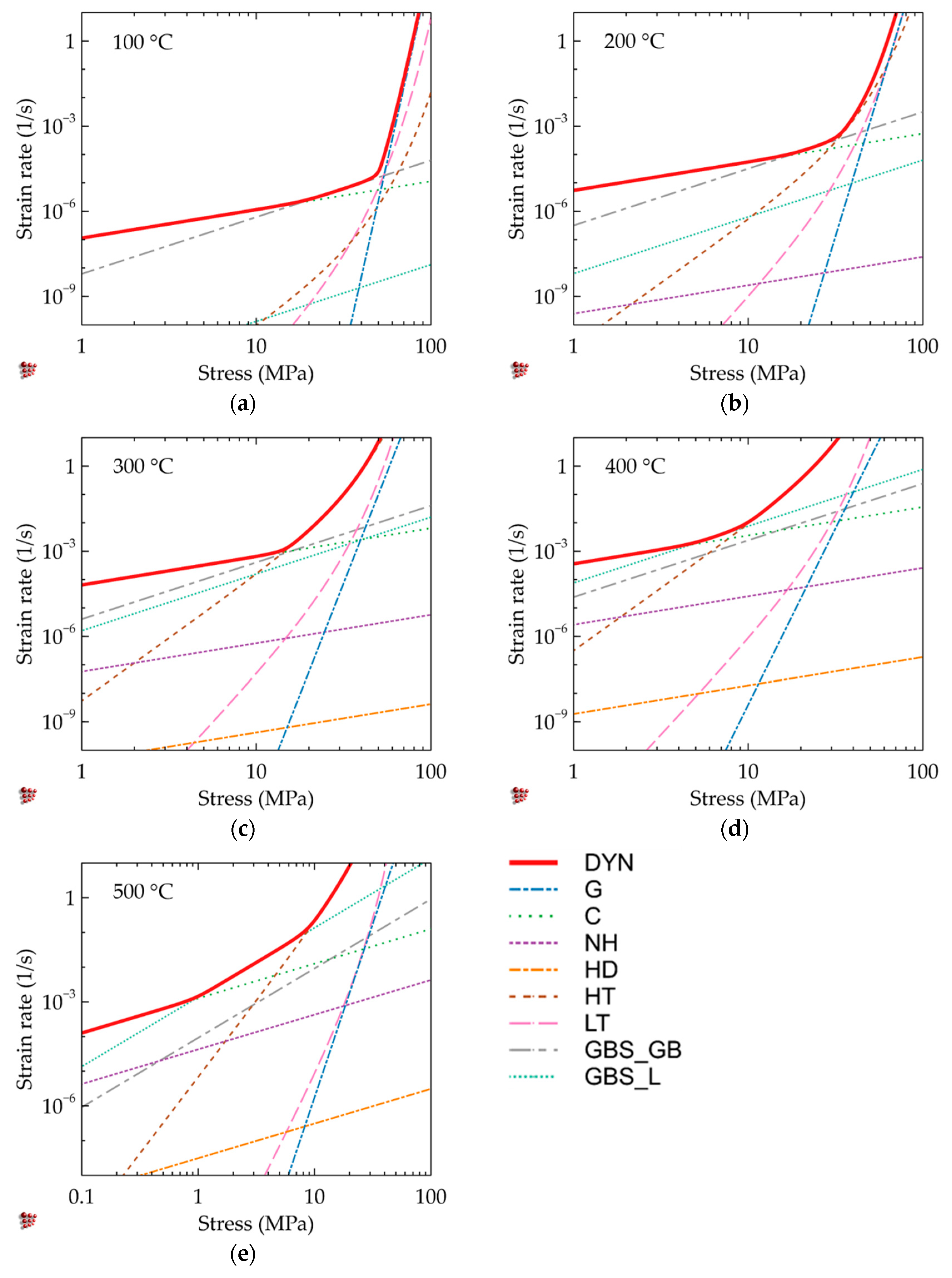

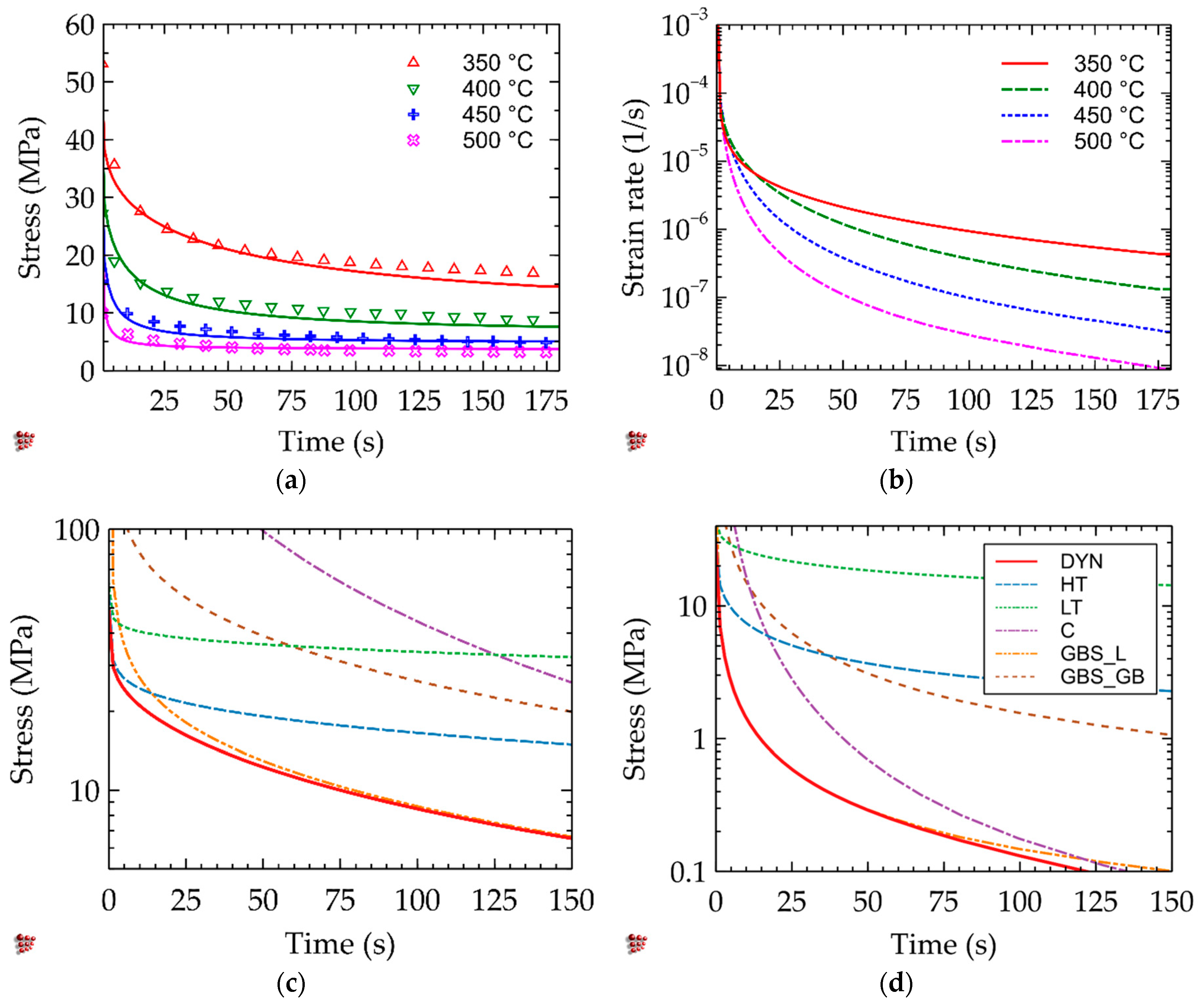

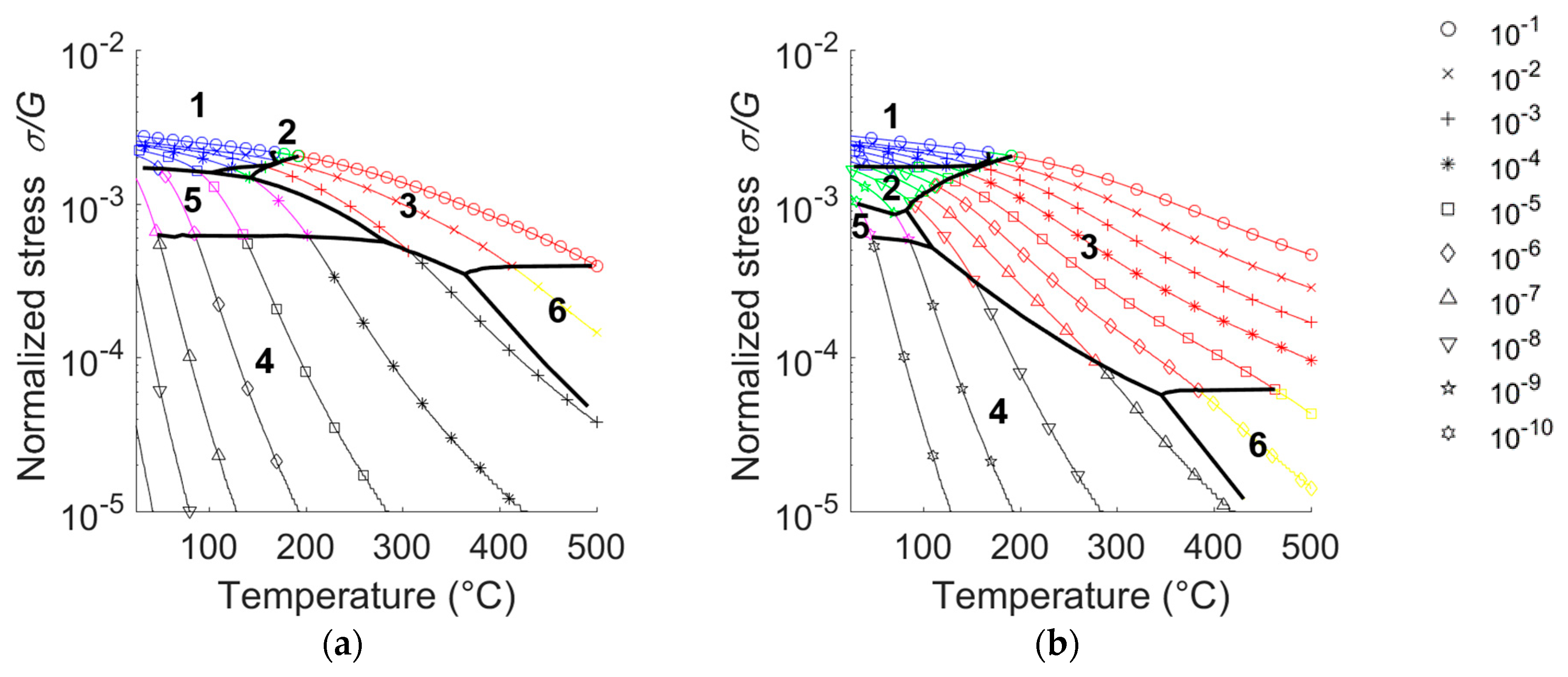

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ardell, A.J. Harper-Dorn creep—The dislocation network theory revisited. Scr. Mater. 2013, 69, 541–544. [Google Scholar] [CrossRef]

- Kumar, P.; Kassner, M.E.; Langdon, T.G. Fifty years of Harper-Dorn creep: A viable creep mechanism or a Californian artifact? J. Mater. Sci. 2007, 42, 409–420. [Google Scholar] [CrossRef]

- Blum, W.; Maier, W. Harper-Dorn Creep—A Myth? Phys. Stat. Sol. 1999, 467, 467–474. [Google Scholar] [CrossRef]

- Mohamed, F.A. Harper-Dorn creep: Controversy, requirements, and origin. Mater. Sci. Eng. A 2007, 463, 177–184. [Google Scholar] [CrossRef]

- Coble, R.L. A Model for Boundary Diffusion Controlled Creep in Polycrystalline Materials. J. Appl. Phys. 1963, 34, 1679–1682. [Google Scholar] [CrossRef]

- Herring, C. Diffusional viscosity of a polycrystalline solid. J. Appl. Phys. 1950, 21, 437–445. [Google Scholar] [CrossRef]

- Harper, J.G.; Shepard, L.A.; Dorn, J.E. Creep of aluminum under extremely small stresses. Acta Metall. 1958, 6, 509–518. [Google Scholar] [CrossRef]

- Yavari, P.; Miller, D.A.; Langdon, T.G. An investigation of harper-dorn creep-I. Mechanical and microstructural characteristics. Acta Metall. 1982, 30, 871–879. [Google Scholar] [CrossRef]

- Kassner, M.E.; Kumar, P.; Blum, W. Harper-Dorn creep. Int. J. Plast. 2007, 23, 980–1000. [Google Scholar] [CrossRef]

- Ruano, O.A.; Wadsworth, J.; Sherby, O.D. Harper-dorn creep in pure metals. Acta Metall. 1988, 36, 1117–1128. [Google Scholar] [CrossRef]

- Barrett, C.R.; Nix, W.D. High Temperature-Low Stress Creep of AI and AI + 0.5% Fe. Mater. Sci. Eng. 1972, 10, 33–42. [Google Scholar] [CrossRef]

- Lüthy, H.; White, R.A.; Sherby, O.D. Grain boundary sliding and deformation mechanism maps. Mater. Sci. Eng. 1979, 39, 211–216. [Google Scholar] [CrossRef]

- Ruano, O.A.; Miller, A.K.; Sherby, O.D. The influence of pipe diffusion on the creep of fine-grained materials. Mater. Sci. Eng. 1981, 51, 9–16. [Google Scholar] [CrossRef]

- Hayden, H.W.; Floreen, S.; Goodell, P.D. Deformation mechanisms of superplasticity. Met. Trans. 1972, 3, 833–842. [Google Scholar] [CrossRef]

- Alden, T.H. The origin of superplasticity in the sn-5%bi alloy. Acta Metall. 1967, 15, 469–480. [Google Scholar] [CrossRef]

- Herriot, G.; Suery, M.; Baudelet, B. Superplastic behaviour of the industrial Cu7wt.%P ALLOY. Scr. Metall. 1972, 6, 657–662. [Google Scholar] [CrossRef]

- Soliman, M.; Shan, Y.V.; Mendez-Martin, F.; Kozeschnik, E.; Palkowski, H. Strain Aging Characterization and Physical Modelling of Over-Aging in Dual Phase Steel. Mater. Sci. Eng. A 2020, 788, 139595. [Google Scholar] [CrossRef]

- Kocks, U.F. Laws for work hardening and low temperature creep.pdf. J. Eng. Mater. Technol. 1976, 98, 76–85. [Google Scholar] [CrossRef]

- Follansbee, P.S.; Kocks, U.F. A constitutive description of the deformation of copper based on the use of the mechanical threshold stress as an internal state variable. Acta Metall. 1988, 36, 81–93. [Google Scholar] [CrossRef]

- Frost, H.J.; Ashby, M.F. Deformation-Mechanism Maps, The Plasticity and Creep of Metals and Ceramics, 1st ed.; Pergamon Press: Oxford, UK, 1982. [Google Scholar]

- Schoeck, G. The Activation Energy of Dislocation Movement. Phys. Stat. Sol. 1965, 8, 499–507. [Google Scholar] [CrossRef]

- Argon, A.S. Mechanical Properties of Single-Phase Crystalline Media: Deformation at Low Temperatures, 4th ed.; Elsevier B.V.: Amsterdam, The Netherlands, 1996. [Google Scholar]

- Schulze, V.; Voehringer, O. Influence of Alloying Elements on the Strain Rate and Temperature Dependence of the Flow Stress of Steels. Metall. Mater. Trans. A 2000, 31, 825–830. [Google Scholar] [CrossRef]

- Kreyca, J.; Kozeschnik, E. State parameter-based constitutive modelling of stress strain curves in Al-Mg solid solutions. Int. J. Plast. 2018, 103, 67–80. [Google Scholar] [CrossRef]

- Walser, B.; Sherby, O.D. The Structure dependence of power law creep. Scr. Metall. 1982, 16, 213–219. [Google Scholar] [CrossRef]

- Brown, A.M.; Ashby, M.F. On the power-law creep equation. Scr. Metall. 1980, 14, 1297–1302. [Google Scholar] [CrossRef]

- Fischer, F.D.; Svoboda, J.; Kozeschnik, E. Interstitial diffusion in systems with multiple sorts of traps. Model. Simul. Mater. Sci. Eng. 2013, 21, 025008. [Google Scholar] [CrossRef]

- Fischer, F.D.; Svoboda, J.; Appel, F.; Kozeschnik, E. Modeling of excess vacancy annihilation at different types of sinks. Acta Mater. 2011, 59, 3463–3472. [Google Scholar] [CrossRef]

- Radis, R.; Kozeschnik, E. Numerical simulation of NbC precipitation in microalloyed steel. Model. Simul. Mater. Sci. Eng. 2012, 20, 055010. [Google Scholar] [CrossRef]

- Dutta, B.; Palmiere, E.J.; Sellars, C.M. Modelling the kinetics of strain induced precipitation in Nb microalloyed steels.pdf. Acta Mater. 2001, 49, 785–794. [Google Scholar] [CrossRef]

- Stechauner, G.; Kozeschnik, E. Assessment of substitutional self-diffusion along short-circuit paths in Al, Fe and Ni. Calphad Comput. Coupling Phase Diagr. Thermochem. 2014, 47, 92–99. [Google Scholar] [CrossRef]

- Jonas, J.J. The back stress in high temperature deformation. Acta Metall. 1969, 17, 397–405. [Google Scholar] [CrossRef]

- Wong, W.A.; Jonas, J.J. Aluminum Extrusion as a Thermally Activated Process. Met. Soc. AIME Trans. 1968, 242, 2271–2280. [Google Scholar]

- Langdon, T.G.; Mohamed, F.A. A new type of deformation mechanism map for high-temperature creep. Mater. Sci. Eng. 1978, 32, 103–112. [Google Scholar] [CrossRef]

- Mohamed, F.A.; Langdon, T.G. Deformation Mechanism Maps Based on Grain Size. Met. Trans. 1974, 5, 2339–2345. [Google Scholar] [CrossRef]

- Maalekian, M.; Radis, R.; Militzer, M.; Moreau, A.; Poole, W.J. In situ measurement and modelling of austenite grain growth in a Ti/Nb microalloyed steel. Acta Mater. 2012, 60, 1015–1026. [Google Scholar] [CrossRef]

- Cha, S.C.; Hong, S.-H.; Kim, M.-Y.; Park, J.; Shim, J.-H.; Jung, W.-S.; Rath, M.; Kozeschnik, E. CALPHAD-based alloy design for advanced automotive steels—Part II: Compositional and microstructural modification for advanced carburizing steels. Calphad Comput. Coupling Phase Diagr. Thermochem. 2016, 54, 172–180. [Google Scholar] [CrossRef]

- Taylor, G.I. The Mechanism of Plastic Deformation of Crystals. Part I. Theoretical. Proc. R. Soc. A Math. Phys. Eng. Sci. 1934, 145, 362–387. [Google Scholar]

- Sauzay, M.; Kubin, L.P. Scaling laws for dislocation microstructures in monotonic and cyclic deformation of fcc metals. Prog. Mater. Sci. 2011, 56, 725–784. [Google Scholar] [CrossRef]

- Buken, H.; Kozeschnik, E. State parameter-based modelling of microstructure evolution in micro-alloyed steel during hot forming. IOP Conf. Ser. Mater. Sci. Eng. 2016, 119, 012023. [Google Scholar] [CrossRef]

- Svoboda, J.; Fischer, F.D.; Fratzl, P.; Kozeschnik, E. Modelling of kinetics in multi-component multi-phase systems with spherical precipitates I: Theory. Mater. Sci. Eng. A 2004, 385, 166–174. [Google Scholar]

- Kozeschnik, E.; Svoboda, J.; Fratzl, P.; Fischer, F.D. Modelling of kinetics in multi-component multi-phase systems with spherical precipitates II: Numerical solution and application. Mater. Sci. Eng. A 2004, 385, 157–165. [Google Scholar]

- Kozeschnik, E.; Svoboda, J.; Fischer, F.D. Modified evolution equations for the precipitation kinetics of complex phases in multi-component systems. Calphad Comput. Coupling Phase Diagr. Thermochem. 2004, 28, 379–382. [Google Scholar] [CrossRef]

- Russell, K.C. Nucleation in solids: The induction and steady state effects. Adv. Colloid Interface Sci. 1980, 13, 205–318. [Google Scholar] [CrossRef]

- Kozeschnik, E. Modeling Solid-State Precipitation; Momentum Press LLC: New York, NY, USA, 2013. [Google Scholar]

- Ahmadi, M.R.; Povoden-Karadeniz, E.; Öksüz, K.I.; Falahati, A.; Kozeschnik, E. A model for precipitation strengthening in multi-particle systems. Comput. Mater. Sci. 2014, 91, 173–186. [Google Scholar] [CrossRef]

- Kreyca, F.J. State Parameter Based Modelling of Stress-Strain Curves in Aluminium Alloys; TU Wien: Vienna, Austria, 2017. [Google Scholar]

- Straub, S.; Blum, W. Does the natural third power law of steady state creep hold for pure aluminium. Scr. Metall. Mater. 1990, 24, 1837–1842. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Sietsma, J.; Rivera-Díaz-Del-Castillo, P.E.J. Dislocation annihilation in plastic deformation: II. Kocks-Mecking Analysis. Acta Mater. 2012, 60, 2615–2624. [Google Scholar] [CrossRef]

- Falkinger, G.; Simon, P. Static recovery of an AlMg4.5Mn aluminium alloy during multi-pass hot-rolling. Procedia Eng. 2017, 207, 31–36. [Google Scholar] [CrossRef]

| Symbol | Name | Unit | Value | Equation | Source |

|---|---|---|---|---|---|

| Shear modulus | MPa | 29,438.4–15,052T | (13), (14), (21), (22) | [49] | |

| b | Burgers Vector | m | 2.86−10 | (9), (10), (13), (14), (21), (22) | [20] |

| α | Strengthening coefficient | - | 0.34 | (16) | [39] |

| M | Taylor factor | - | 3.06 | (16) | [24] |

| Activation energy | J/mol | 0.25b3 | (19) | [20] | |

| constant | - | 1.46 | (19) | [24] | |

| Effective boundary thickness | m | 2−9 | (10) | (MatCalc) | |

| d | Grain size | m | 56 | (9), (10), (13), (14) | This work |

| LT constant | - | 5.7110−13 | (22) | This work | |

| HT constant | - | 4.2310−7 | (22) | This work | |

| HD constant | - | 110−10 | (21) | [20] | |

| -controlled GBS coefficient | - | (13) | [12] | ||

| -controlled GBS coefficient | - | (14) | [12] | ||

| coupling coefficient | - | 10 | (24) | This work | |

| α’ | PLB | - | 1000 | (24) | [20] |

| LT exponent | - | 6.4 | (22) | [20] | |

| HT exponent | - | 4.4 | (22) | [20] | |

| HD exponent | - | 1 | (21) | [20] | |

| Activation energy for bulk diffusion | J/mol | 127,200 | (7), (11) | [31] | |

| Activation energy for dislocation core diffusion | J/mol | 83,200 | (7) | [31] | |

| Activation energy for grain boundary | J/mol | 60,200 | (11) | [31] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Viernstein, B.; Kozeschnik, E. Integrated Physical-Constitutive Computational Framework for Plastic Deformation Modeling. Metals 2020, 10, 869. https://doi.org/10.3390/met10070869

Viernstein B, Kozeschnik E. Integrated Physical-Constitutive Computational Framework for Plastic Deformation Modeling. Metals. 2020; 10(7):869. https://doi.org/10.3390/met10070869

Chicago/Turabian StyleViernstein, Bernhard, and Ernst Kozeschnik. 2020. "Integrated Physical-Constitutive Computational Framework for Plastic Deformation Modeling" Metals 10, no. 7: 869. https://doi.org/10.3390/met10070869

APA StyleViernstein, B., & Kozeschnik, E. (2020). Integrated Physical-Constitutive Computational Framework for Plastic Deformation Modeling. Metals, 10(7), 869. https://doi.org/10.3390/met10070869