Ambivalent Role of Annealing in Tensile Properties of Step-Rolled Ti-6Al-4V with Ultrafine-Grained Structure

Abstract

1. Introduction

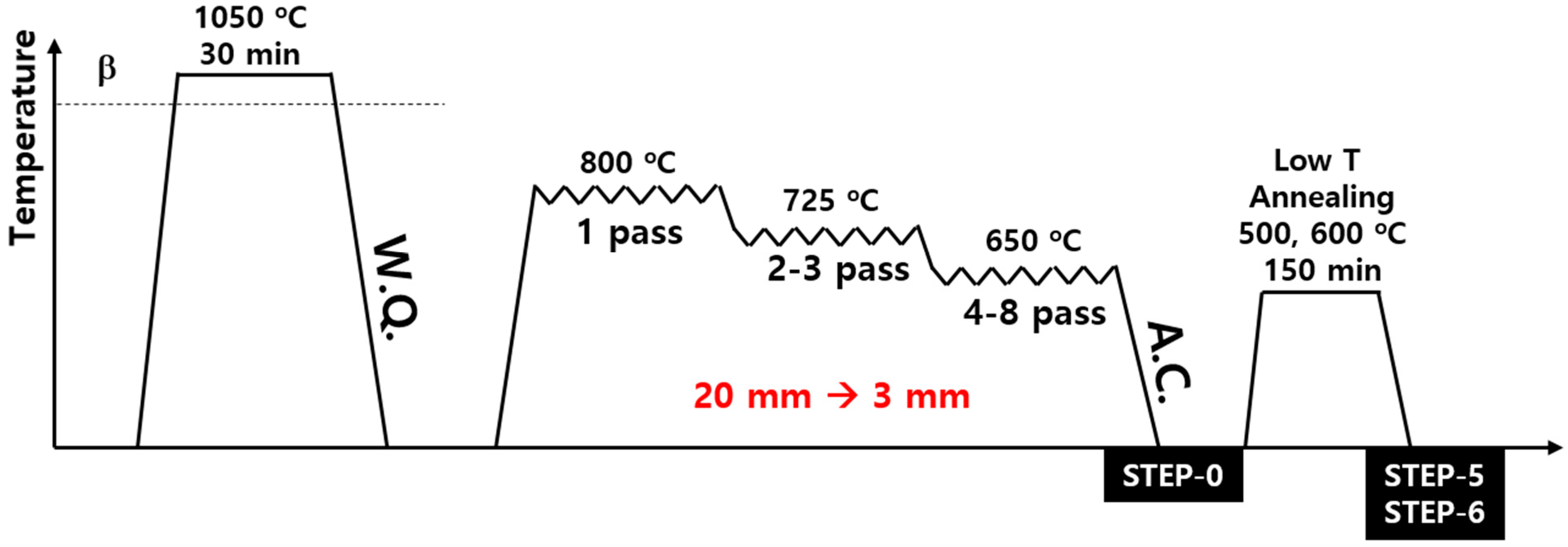

2. Materials and Methods

3. Results and Discussion

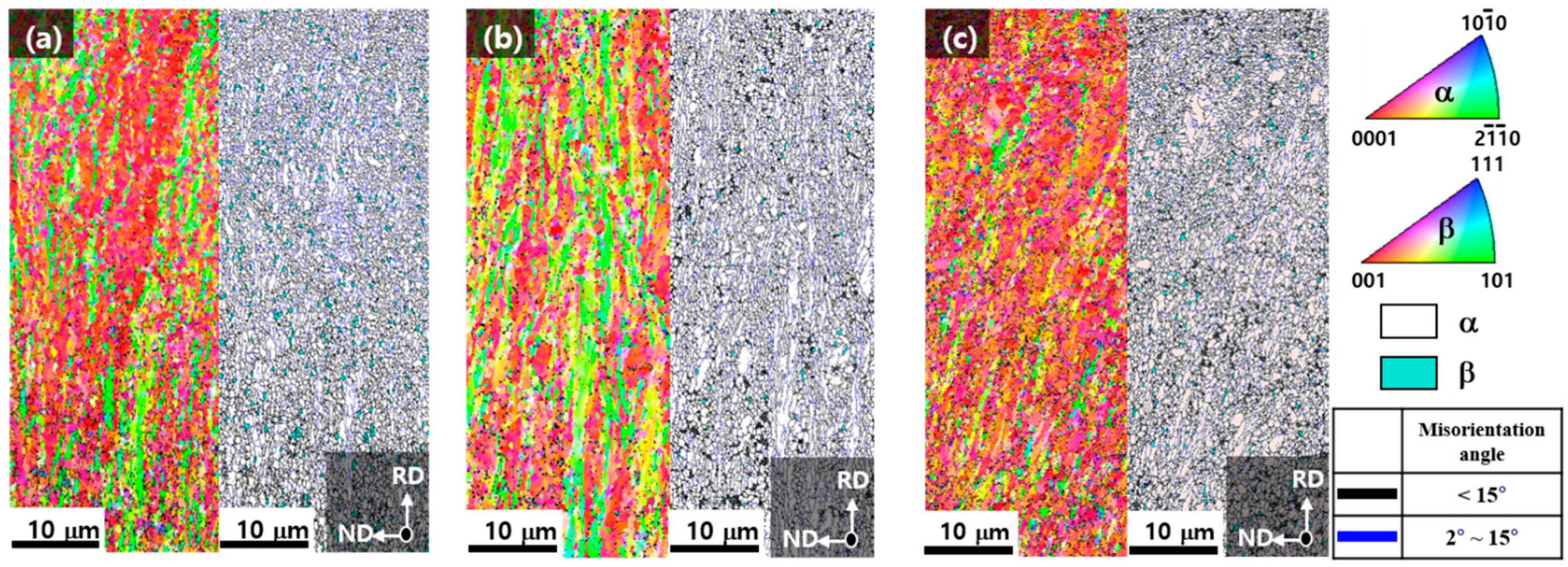

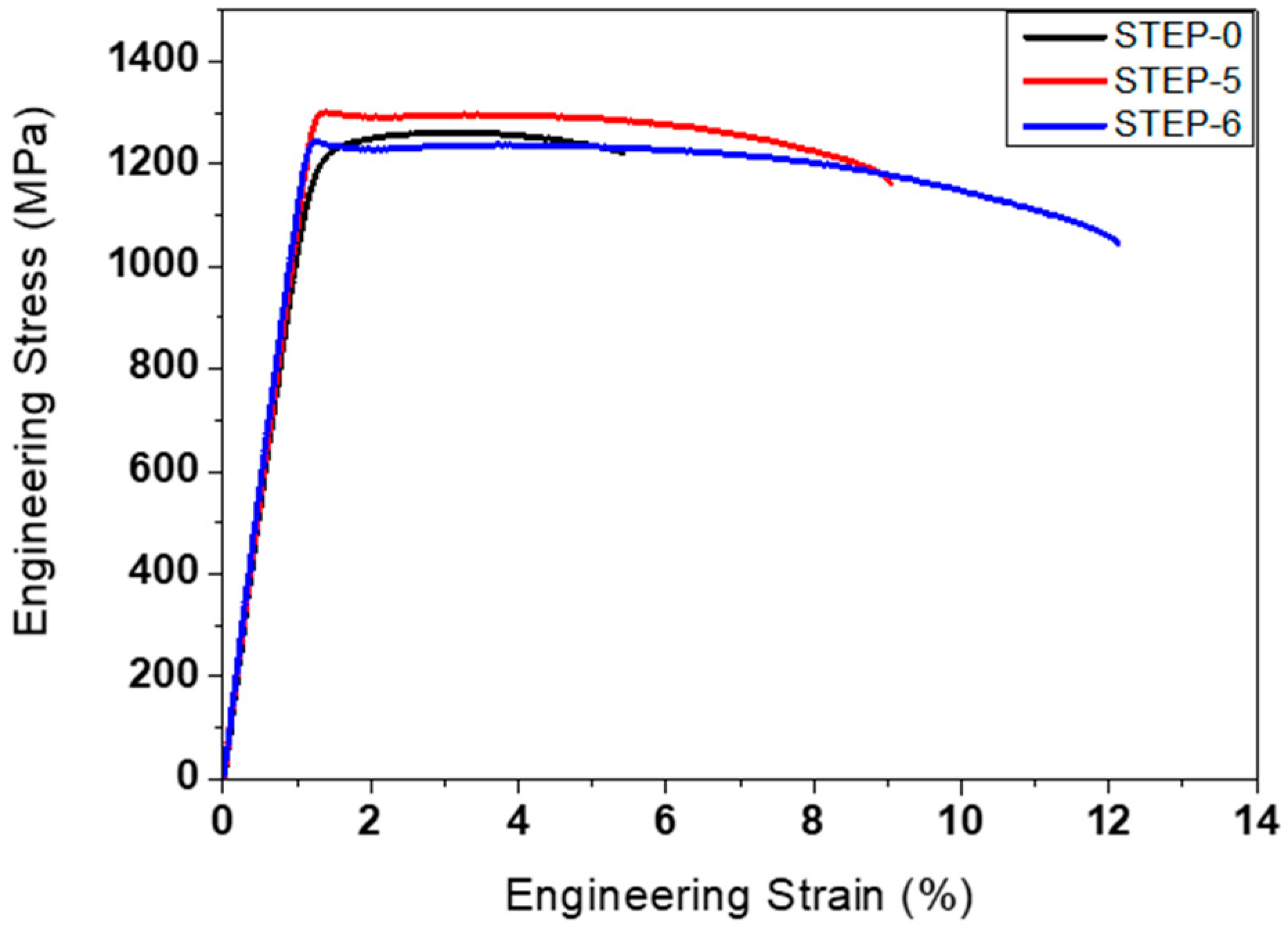

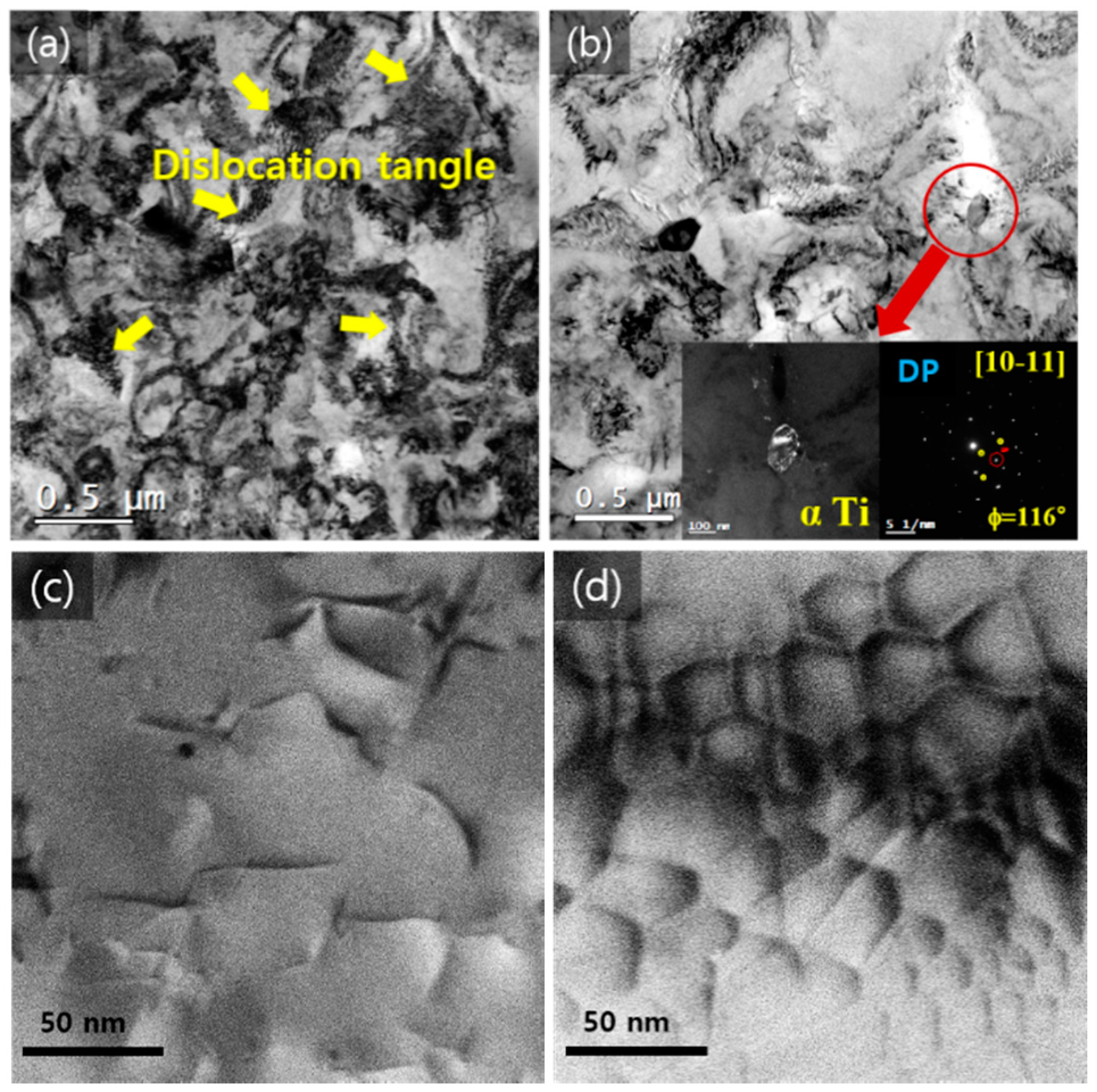

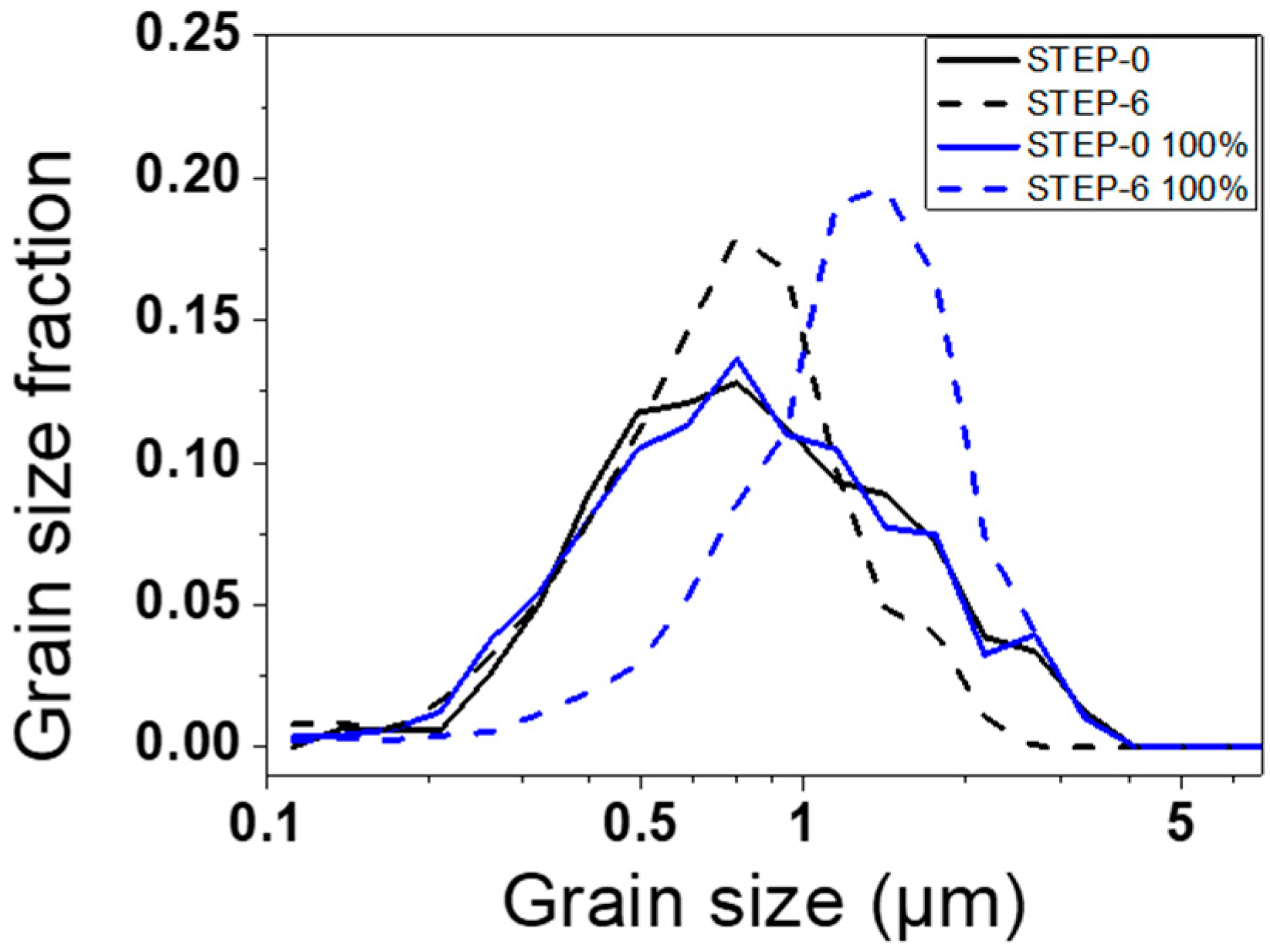

3.1. Deformation Behavior at Room Temperature

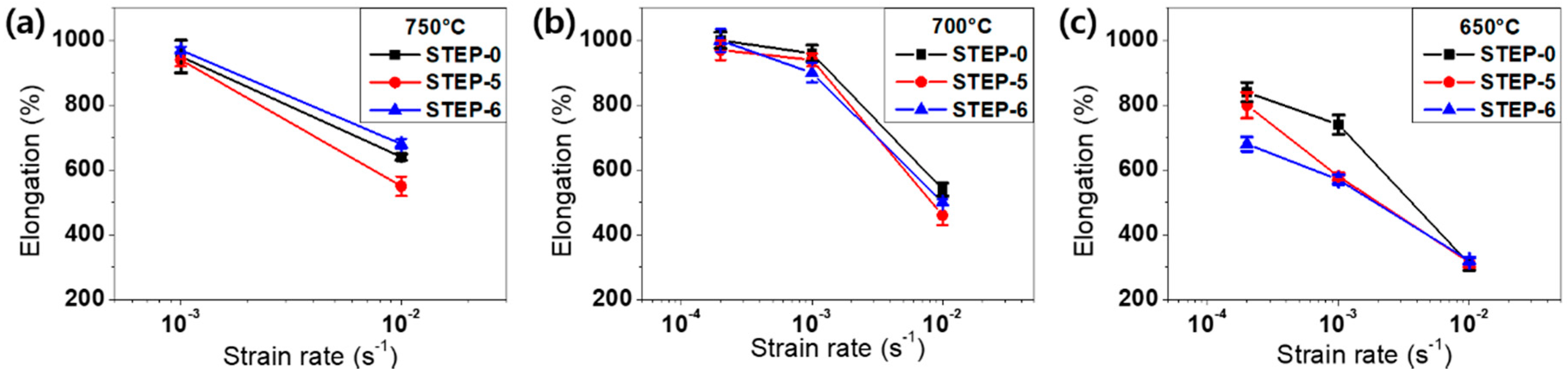

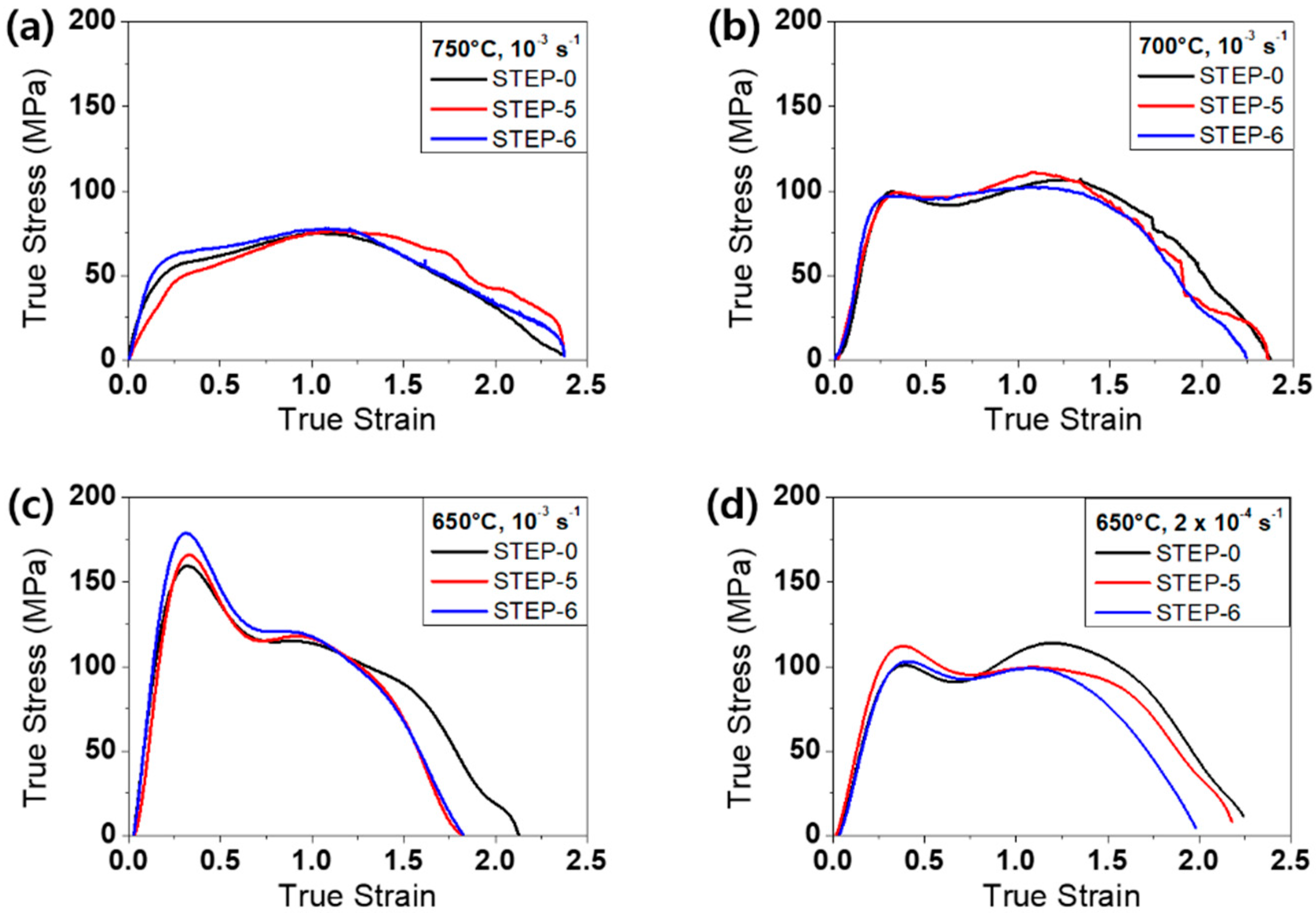

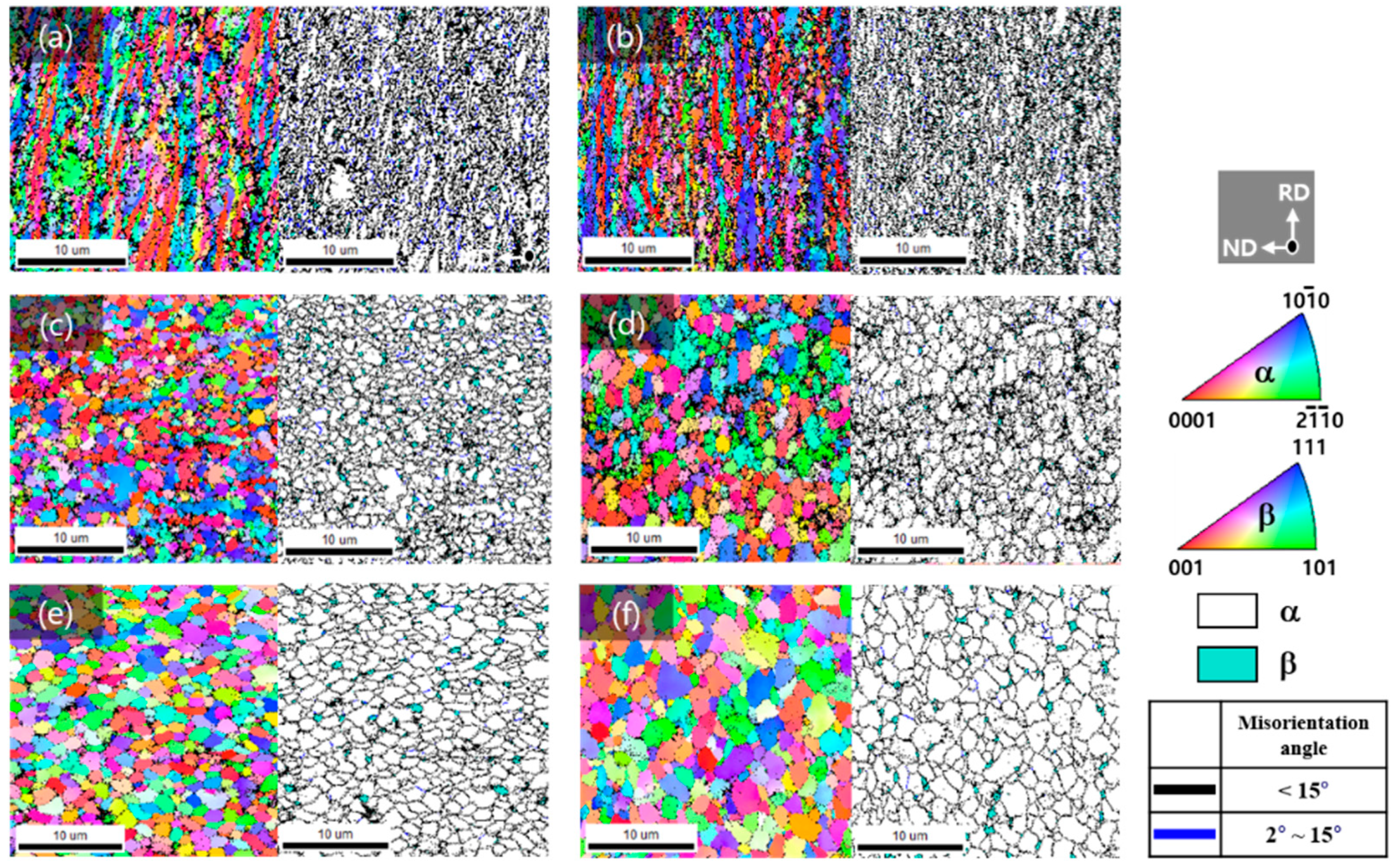

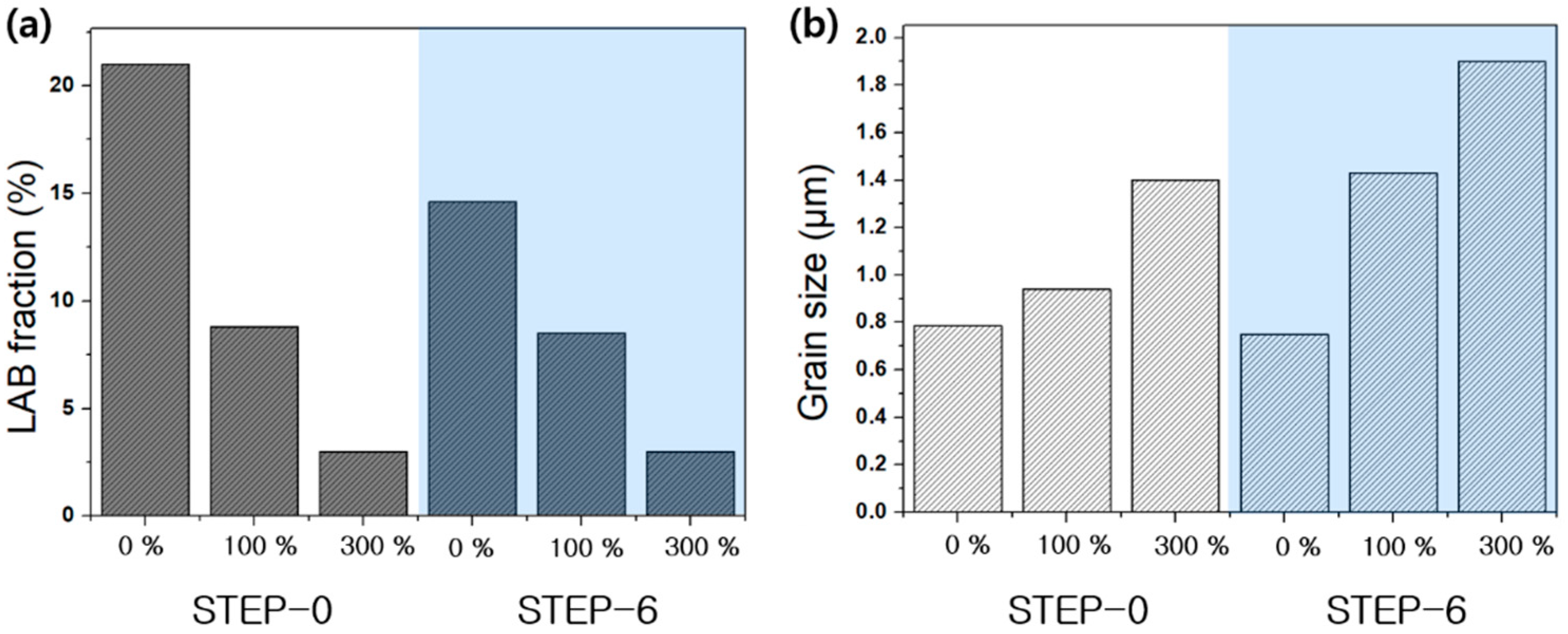

3.2. Deformation Behavior at Elevated Temperatures

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Welsch, G. Materials Properties Handbook: Titanium Alloys; ASM International: Russell Township, OH, USA, 1993; ISBN 9780871704818. [Google Scholar]

- Weisert, E. Proc. AIME Conference on Superplastic Forming of Structural Alloys; Paton, N.E., Hamilton, C.H., Eds.; TMS-AIME Publications: Warrendale, PA, USA, 1982. [Google Scholar]

- Mishra, R.S.; Stolyarov, V.V.; Echer, C.; Valiev, R.Z.; Mukherjee, A.K. Mechanical behavior and superplasticity of a severe plastic deformation processed nanocrystalline Ti–6Al–4V alloy. Mater. Sci. Eng. A 2001, 298, 44–50. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Kudryavtsev, E.A.; Salishchev, G.A.; Straumal, B.B.; Semiatin, S.L. Microstructure evolution and mechanical behavior of ultrafine Ti6Al4V during low-temperature superplastic deformation. Acta Mater. 2016, 121, 152–163. [Google Scholar] [CrossRef]

- Edington, J.W.; Melton, K.N.; Cutler, C.P. Superplasticity. Prog. Mater. Sci. 1976, 21, 61–170. [Google Scholar] [CrossRef]

- Ko, Y.G.; Lee, C.S.; Shin, D.H.; Semiatin, S.L. Low-temperature superplasticity of ultra-fine-grained Ti-6Al-4V processed by equal-channel angular pressing. Metall. Mater. Trans. A 2006, 37, 381–391. [Google Scholar] [CrossRef]

- Shahmir, H.; Naghdi, F.; Pereira, P.H.R.; Huang, Y.; Langdon, T.G. Factors influencing superplasticity in the Ti-6Al-4V alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2018, 718, 198–206. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Kudryavtsev, E.; Kostjuchenko, S.; Malysheva, S.; Salishchev, G. Strength and ductility-related properties of ultrafine grained two-phase titanium alloy produced by warm multiaxial forging. Mater. Sci. Eng. A 2012, 536, 190–196. [Google Scholar] [CrossRef]

- Lee, T.; Shih, D.S.; Lee, Y.; Lee, C.S. Manufacturing Ultrafine-Grained Ti-6Al-4V Bulk Rod Using Multi-Pass Caliber-Rolling. Metals 2015, 5, 777–789. [Google Scholar] [CrossRef]

- Lee, T.; Park, K.-T.T.; Lee, D.J.; Jeong, J.; Oh, S.H.; Kim, H.S.; Park, C.H.; Lee, C.S. Microstructural evolution and strain-hardening behavior of multi-pass caliber-rolled Ti-13Nb-13Zr. Mater. Sci. Eng. A 2015, 648, 359–366. [Google Scholar] [CrossRef]

- Lee, T.; Lee, S.; Kim, I.-S.; Moon, Y.H.; Kim, H.S.; Park, C.H. Breaking the limit of Young’s modulus in low-cost Ti–Nb–Zr alloy for biomedical implant applications. J. Alloy. Compd. 2020, 828, 154401. [Google Scholar] [CrossRef]

- Park, C.H.; Kim, J.H.; Yeom, J.-T.T.; Oh, C.-S.S.; Semiatin, S.L.; Lee, C.S. Formation of a submicrocrystalline structure in a two-phase titanium alloy without severe plastic deformation. Scr. Mater. 2013, 68, 996–999. [Google Scholar] [CrossRef]

- Kim, D.; Won, J.W.; Park, C.H.; Hong, J.K.; Lee, T.; Lee, C.S. Enhancing Superplasticity of Ultrafine-Grained Ti–6Al–4V without Imposing Severe Plastic Deformation. Adv. Eng. Mater. 2019, 21, 1800115. [Google Scholar] [CrossRef]

- Jeong, D.; Kwon, Y.; Goto, M.; Kim, S. High cycle fatigue and fatigue crack propagation behaviors of β-annealed Ti-6Al-4V alloy. Int. J. Mech. Mater. Eng. 2017, 12, 1. [Google Scholar] [CrossRef]

- Morita, T.; Hatsuoka, K.; Iizuka, T.; Kawasaki, K. Strengthening of Ti–6Al–4V Alloy by Short-Time Duplex Heat Treatment. Mater. Trans. 2005, 46, 1681–1686. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Alexandrov, I.V.; Enikeev, N.A.; Murashkin, M.Y.; Semenova, I.P. Towards enhancement of properties of UFG metals and alloys by grain boundary engineering using SPD processing. Rev. Adv. Mater. Sci. 2010, 25, 1–10. [Google Scholar]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Muga, C.O.; Zhang, Z.W. Strengthening Mechanisms of Magnesium-Lithium Based Alloys and Composites. Adv. Mater. Sci. Eng. 2016, 2016, 1078187. [Google Scholar] [CrossRef]

- Langdon, T.G. Seventy-five years of superplasticity: Historic developments and new opportunities. J. Mater. Sci. 2009, 44, 5998. [Google Scholar] [CrossRef]

- Matsumoto, H.; Velay, V.; Chiba, A. Flow behavior and microstructure in Ti–6Al–4V alloy with an ultrafine-grained α-single phase microstructure during low-temperature-high-strain-rate superplasticity. Mater. Des. 2015, 66, 611–617. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Fagin, P.N.; Betten, J.F.; Zane, A.P.; Ghosh, A.K.; Sargent, G.A. Plastic Flow and Microstructure Evolution during Low-Temperature Superplasticity of Ultrafine Ti-6Al-4V Sheet Material. Metall. Mater. Trans. A 2010, 41, 499–512. [Google Scholar] [CrossRef]

- Alabort, E.; Kontis, P.; Barba, D.; Dragnevski, K.; Reed, R.C. On the mechanisms of superplasticity in Ti–6Al–4V. Acta Mater. 2016, 105, 449–463. [Google Scholar] [CrossRef]

- Lee, T.; Yamasaki, M.; Kawamura, Y.; Lee, Y.; Lee, C.S. High strain-rate superplasticity of AZ91 alloy achieved by rapidly solidified flaky powder metallurgy. Mater. Lett. 2019, 234, 245–248. [Google Scholar] [CrossRef]

- Sergueeva, A.V.; Stolyarov, V.V.; Valiev, R.Z.; Mukherjee, A.K. Superplastic behaviour of ultrafine-grained Ti–6A1–4V alloys. Mater. Sci. Eng. A 2002, 323, 318–325. [Google Scholar] [CrossRef]

- Salishchev, G.A.; Galeyev, R.M.; Valiakhmetov, O.R.; Safiullin, R.V.; Lutfullin, R.Y.; Senkov, O.N.; Froes, F.H.; Kaibyshev, O.A. Development of Ti–6Al–4V sheet with low temperature superplastic properties. J. Mater. Process. Technol. 2001, 116, 265–268. [Google Scholar] [CrossRef]

- Paton, N.E.; Hamilton, C.H. Microstructural influences on superplasticity in Ti-6AI-4V. Metall. Trans. A 1979, 10, 241–250. [Google Scholar] [CrossRef]

- Park, C.H.; Ko, Y.G.; Park, J.-W.W.; Lee, C.S. Enhanced superplasticity utilizing dynamic globularization of Ti-6Al-4V alloy. Mater. Sci. Eng. A 2008, 496, 150–158. [Google Scholar] [CrossRef]

- Ovid’ko, I.A.; Sheinerman, A.G. Grain-boundary dislocations and enhanced diffusion in nanocrystalline bulk materials and films. Philos. Mag. 2003, 83, 1551–1563. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Wert, J.A.; Paton, N.E. Enhanced superplasticity and strength in modified Ti-6AI-4V alloys. Metall. Mater. Trans. A 1983, 14, 2535–2544. [Google Scholar] [CrossRef]

- Kim, J.S.; Chang, Y.W.; Lee, C.S. Quantitative analysis on boundary sliding and its accommodation mode during superplastic deformation of two-phase Ti-6Al-4V alloy. Metall. Mater. Trans. A 1998, 29, 217–226. [Google Scholar] [CrossRef]

| Sample | Yield Strength (YS) (MPa) | Ultimate Tensile Strength (UTS) (MPa) | Elongation to Failure (EL) (%) |

|---|---|---|---|

| STEP-0 | 1201 | 1263 | 5.4 |

| STEP-5 | 1298 | 1311 | 9.0 |

| STEP-6 | 1243 | 1243 | 12.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, G.; Lee, T.; Lee, Y.; Kim, J.N.; Choi, S.W.; Hong, J.K.; Lee, C.S. Ambivalent Role of Annealing in Tensile Properties of Step-Rolled Ti-6Al-4V with Ultrafine-Grained Structure. Metals 2020, 10, 684. https://doi.org/10.3390/met10050684

Kim G, Lee T, Lee Y, Kim JN, Choi SW, Hong JK, Lee CS. Ambivalent Role of Annealing in Tensile Properties of Step-Rolled Ti-6Al-4V with Ultrafine-Grained Structure. Metals. 2020; 10(5):684. https://doi.org/10.3390/met10050684

Chicago/Turabian StyleKim, Geonhyeong, Taekyung Lee, Yongmoon Lee, Jae Nam Kim, Seong Woo Choi, Jae Keun Hong, and Chong Soo Lee. 2020. "Ambivalent Role of Annealing in Tensile Properties of Step-Rolled Ti-6Al-4V with Ultrafine-Grained Structure" Metals 10, no. 5: 684. https://doi.org/10.3390/met10050684

APA StyleKim, G., Lee, T., Lee, Y., Kim, J. N., Choi, S. W., Hong, J. K., & Lee, C. S. (2020). Ambivalent Role of Annealing in Tensile Properties of Step-Rolled Ti-6Al-4V with Ultrafine-Grained Structure. Metals, 10(5), 684. https://doi.org/10.3390/met10050684