Theoretical Model of Residual Stress and Warpage for Wire and Arc Additive Manufacturing Stiffened Panels

Abstract

1. Introduction

2. Theoretical Model and Experimental Procedure

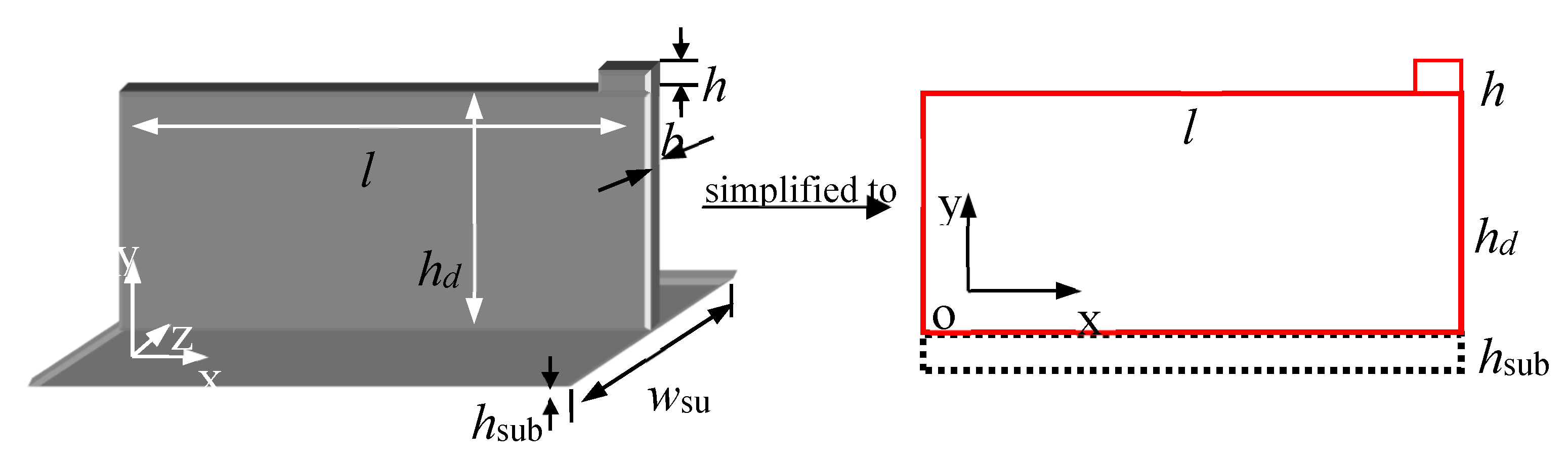

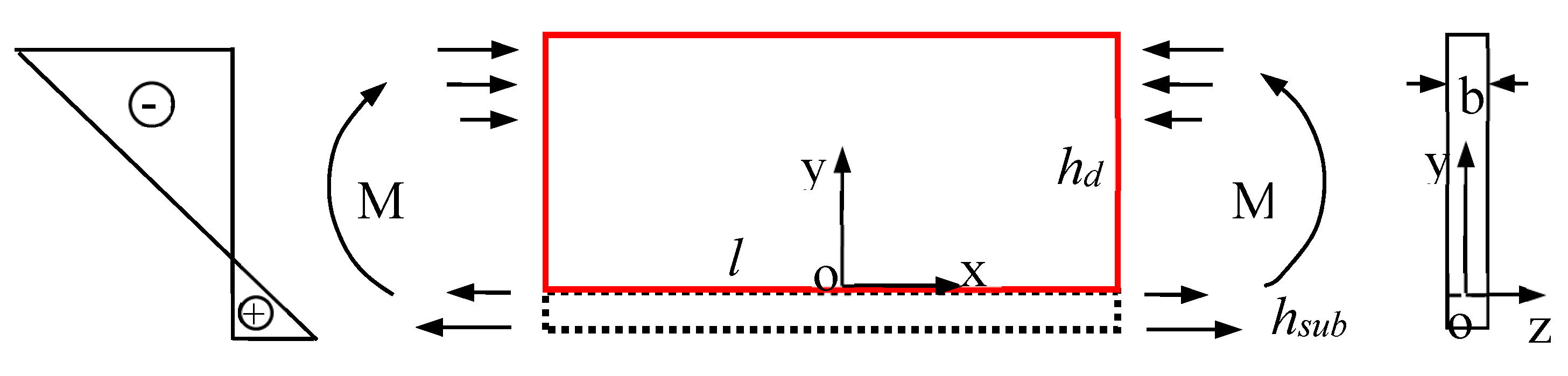

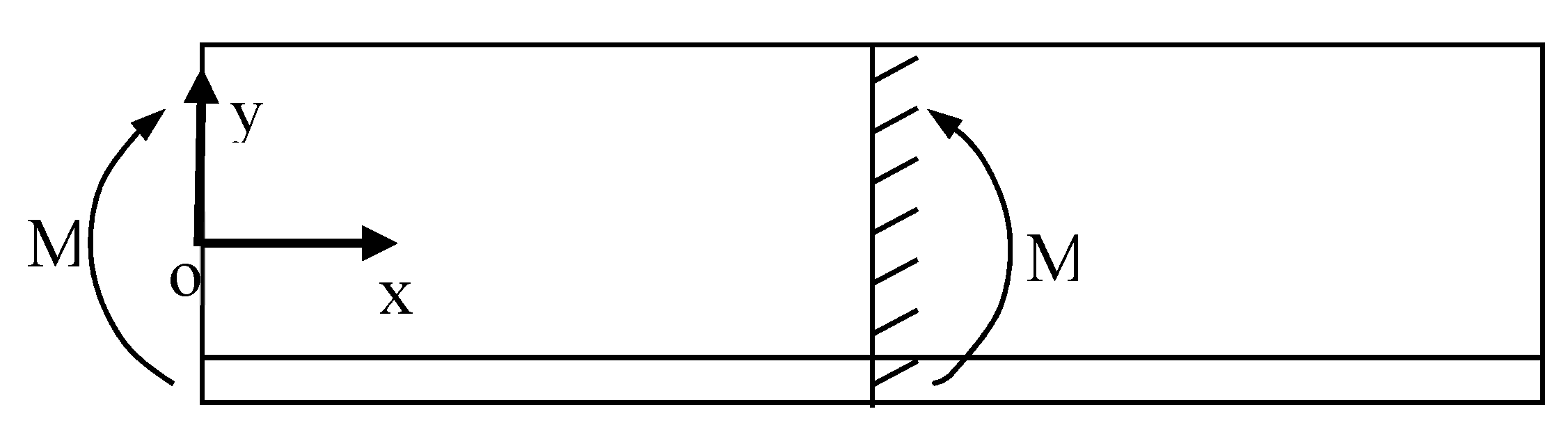

2.1. Set up the Theoretical Model

- i.

- There is no deformation when the base plate is rigidly fixed with clamps;

- ii.

- The deposited material is elastoplastic. The transverse stress is equal to the yield strength at the top layer in the XOY plane;

- iii.

- The base plate is rigidly clamped and in compression-stressed condition to balance the in-plane tensile stress of the single wall. We ignore the local plastic deformation under the weld pass;

- iv.

- We ignore the residual stress variation along thickness, and consider only the 2D in-plane stress distribution;

- v.

- The structure can be abstracted as T-shape beam, so the general beam theory is available for warpage analyzation;

- vi.

- Warping occurs after removing the clamps, the bending moment is reduced to zero.

2.2. Experimental Procedure

2.2.1. Additive Manufacturing Single Wall Rib

2.2.2. Measurement Scheme of Residual Stress

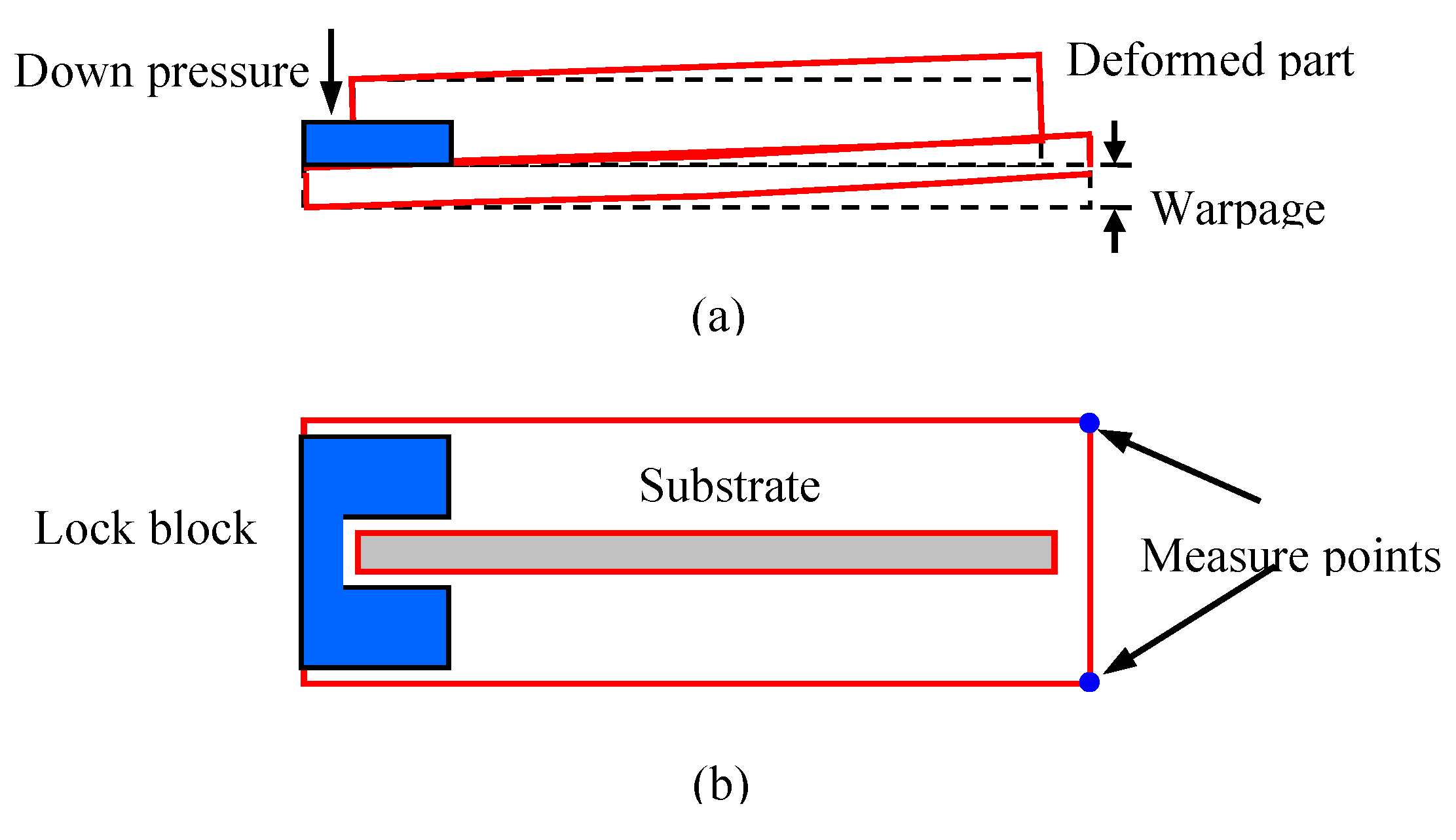

2.2.3. Measurement Scheme of Warpage

3. Results and Discussion

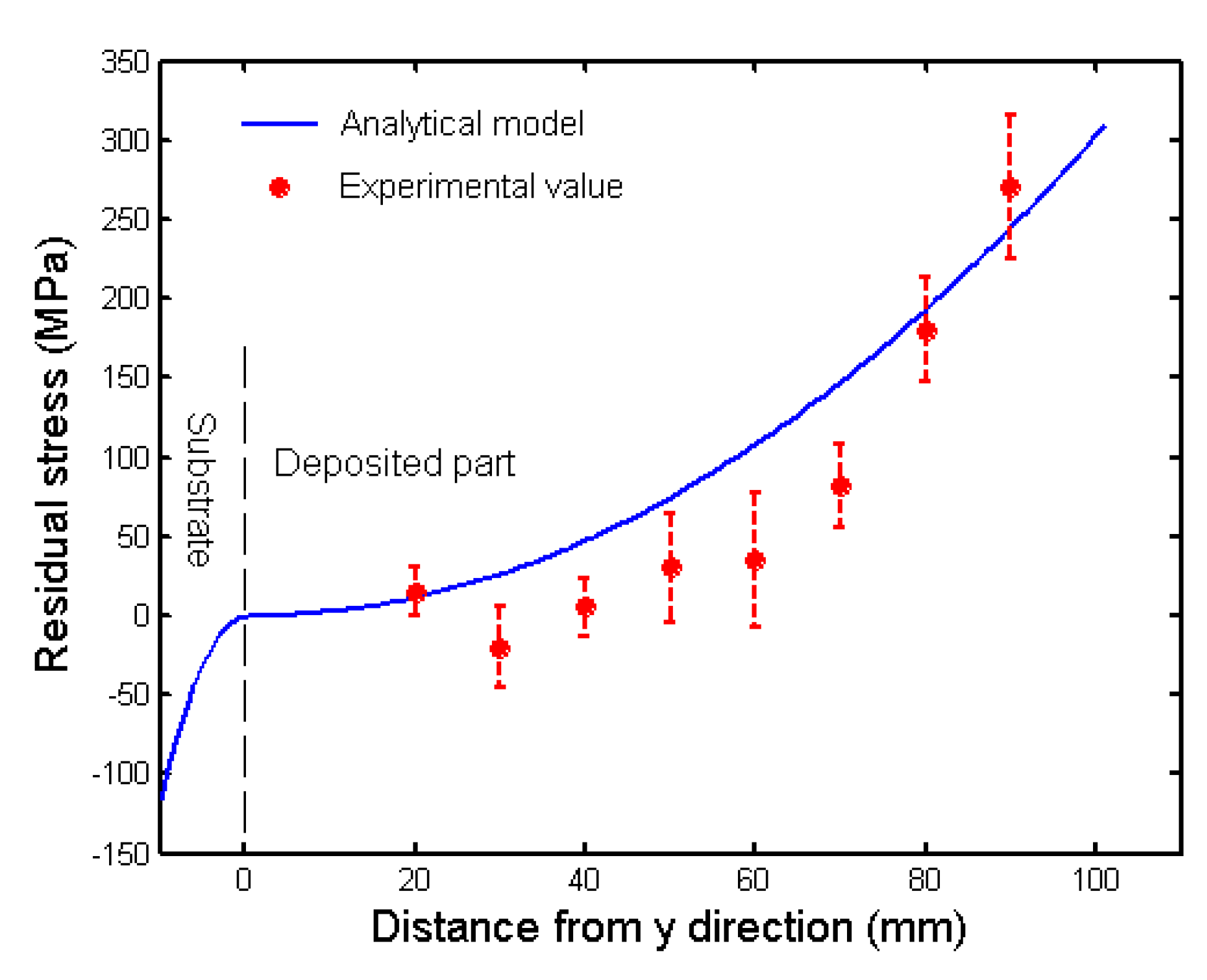

3.1. Theoretical Model Verification

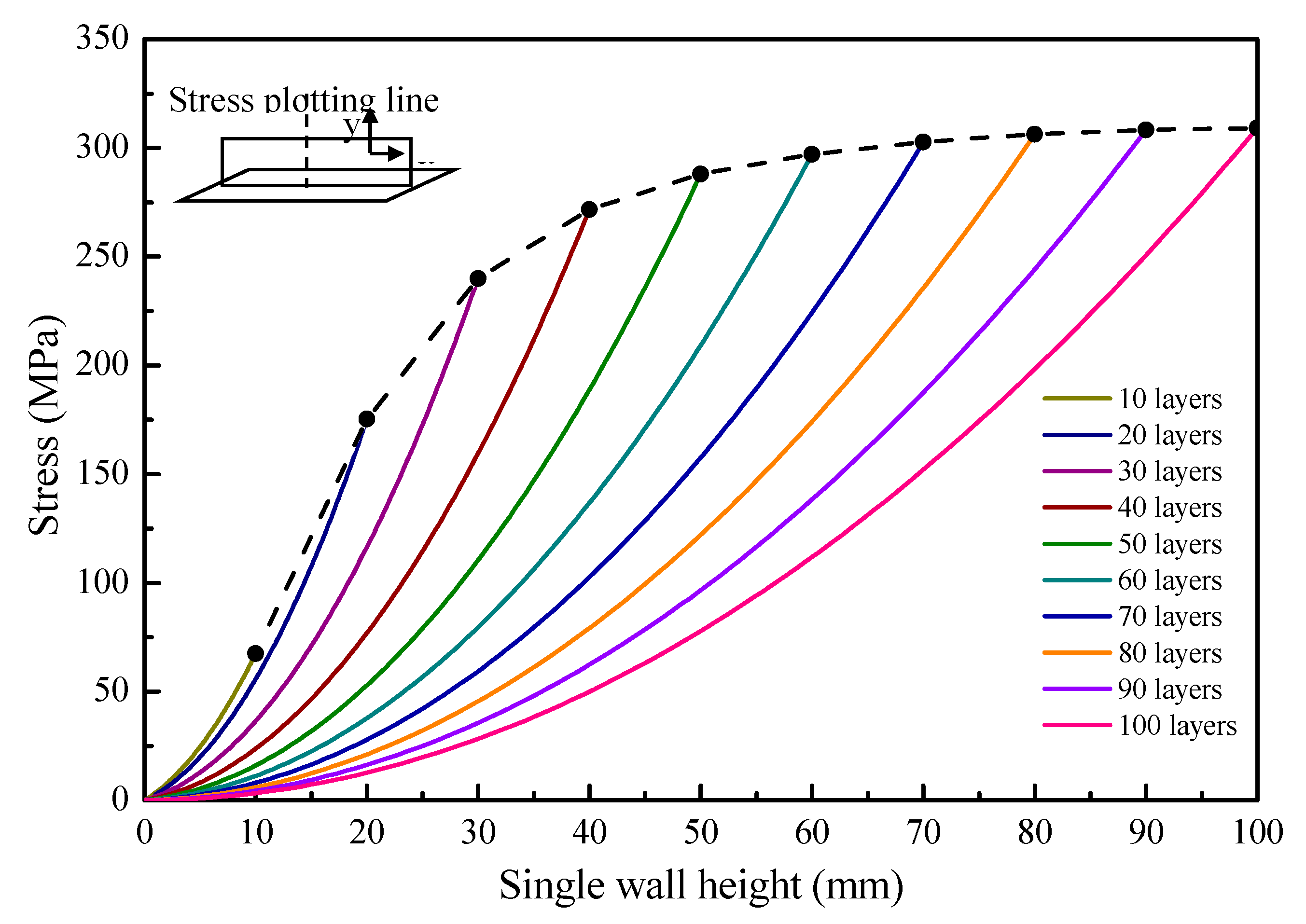

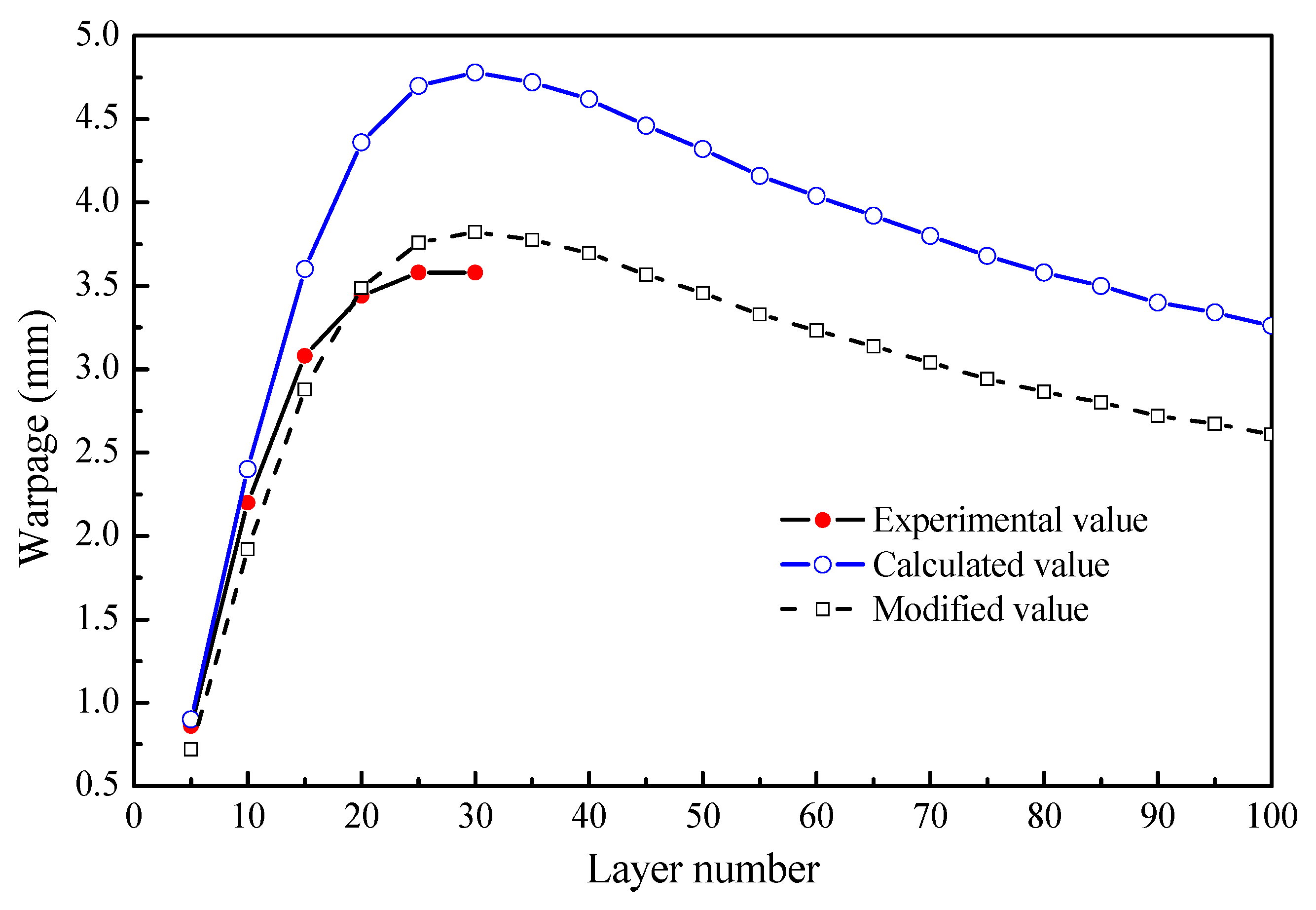

3.2. Stress and Warpage Evolution

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Y.M.; Chen, Y.; Li, P.; Male, A.T. Weld deposition-based rapid prototyping: A preliminary study. J. Mater. Process. Technol. 2003, 135, 347–357. [Google Scholar] [CrossRef]

- Chen, J. Hybrid Design Based on Wire and Arc Additive Manufacturing in the Aircraft Industry. Master’s Thesis, Cranfield University, Bedford, UK, 2012; pp. 1–3. [Google Scholar]

- Ding, D.H.; Pan, Z.X.; Cuiuri, D.; Li, H.J. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Chen, H.; Xu, Y.M.; Hu, J.H. Optimization of lightweight sub-stiffened panels with buckling analysis and imperfection sensitivity analysis. Proc. Inst. Mech. Eng. Parts G J. Aerosp. Eng. 2019, 223, 5507–5521. [Google Scholar] [CrossRef]

- Li, F.; Chen, S.J.; Shi, J.B.; Tian, H.Y.; Zhao, Y. Evaluation and optimization of a hybrid manufacturing process combining wire arc additive manufacturing with milling for the fabrication of stiffened panels. Appl. Sci. Basel 2017, 7, 1233. [Google Scholar] [CrossRef]

- Li, R.; Xiong, J.; Lei, Y.Y. Investigation on thermal stress evolution induced by wire and arc additive manufacturing for circular thin-walled parts. J. Manuf. Process. 2019, 40, 59–67. [Google Scholar] [CrossRef]

- Shen, C.; Reid, M.; Liss, K.D.; Pan, Z.X.; Ma, Y.; Cuiuri, D.; Van Duin, S.; Li, H.J. Neutron diffraction residual stress determinations in Fe3Al based iron aluminide components fabricated using wire-arc additive manufacturing (WAAM). Addit. Manuf. 2019, 29, 100774. [Google Scholar] [CrossRef]

- Fawad, H.; Mughal, M.P.; Mufti, R.A. Effect of constraint on residual stresses and deformations in weld based rapid prototyping. In Proceedings of the 3rd International Conference on Advanced Research in Virtual and Rapid Prototyping: Virtual and Rapid Manufacturing, Advanced Research Virtual and Rapid Prototyping, Leiria, Portugal, 24–29 September 2007; pp. 629–634. [Google Scholar]

- Klingbeil, N.W.; Beuth, J.L.; Chin, R.K.; Amon, C.H. Residual stress-induced warping in direct metal solid freeform fabrication. Int. J. Mech. Sci. 2002, 44, 57–77. [Google Scholar] [CrossRef]

- Vasinonta, A.; Beuth, J.; Griffith, M. Process maps for controlling residual stress and melt pool size in laser-based SFF processes. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2000; pp. 200–208. [Google Scholar]

- Huang, H.; Chen, J.; Carlson, B.E.; Wang, H.P.; Crooker, P.J.; Frederick, G.; Feng, Z. Stress and distortion simulation of additive manufacturing process by high performance computing. In Proceedings of the ASME Pressure Vessels and Piping Conference, Prague, Czech Republic, 15–20 July 2018. [Google Scholar]

- Camilleri, D.; Comlekci, T.; Gray, T.G.F. Computational prediction of out-of-plane welding distortion and experimental investigation. J. Strain Anal. Eng. Des. 2005, 40, 161–176. [Google Scholar] [CrossRef]

- Withers, P.; Bhadeshia, H. Residual stress, part 2-nature and origin. Mater. Sci. Technol. 2001, 17, 366–375. [Google Scholar] [CrossRef]

- Pister, K.S.; Dong, S.B. Elastic bending of layered plates. ASCE J. Eng. Mech. Div. 1959, 84, 1–10. [Google Scholar]

- Mercelis, P.; Kruth, J.P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

| Layer Number | Equation Coefficients | Warpage (mm) | |

|---|---|---|---|

| A | B | ||

| 5 | −0.5686 | −2.7546 | 0.9 |

| 10 | −0.7295 | −3.0875 | 2.4 |

| 15 | −0.7278 | −2.8526 | 3.6 |

| 20 | −0.6396 | −2.3692 | 4.36 |

| 25 | −0.5323 | −1.8773 | 4.70 |

| 30 | −0.4357 | −1.4657 | 4.78 |

| 35 | −0.3569 | −1.1439 | 4.72 |

| 40 | −0.2948 | −0.8974 | 4.62 |

| 45 | −0.2462 | −0.7082 | 4.46 |

| 50 | −0.2080 | −0.7082 | 4.32 |

| 55 | −0.1776 | −0.4470 | 4.16 |

| 60 | −0.1533 | −0.3558 | 4.04 |

| 65 | −0.1334 | −0.2824 | 3.92 |

| 70 | −0.1172 | −0.2226 | 3.80 |

| 75 | −0.1036 | −0.1734 | 3.68 |

| 80 | −0.0923 | −0.1324 | 3.58 |

| 85 | −0.0827 | −0.0980 | 3.50 |

| 90 | −0.0754 | −0.0688 | 3.40 |

| 95 | −0.0675 | −0.0439 | 3.34 |

| 100 | −0.0614 | −0.0225 | 3.26 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, H.; Li, J.; Gao, J.; Lin, X. Theoretical Model of Residual Stress and Warpage for Wire and Arc Additive Manufacturing Stiffened Panels. Metals 2020, 10, 666. https://doi.org/10.3390/met10050666

Geng H, Li J, Gao J, Lin X. Theoretical Model of Residual Stress and Warpage for Wire and Arc Additive Manufacturing Stiffened Panels. Metals. 2020; 10(5):666. https://doi.org/10.3390/met10050666

Chicago/Turabian StyleGeng, Haibin, Jinglong Li, Jianjun Gao, and Xin Lin. 2020. "Theoretical Model of Residual Stress and Warpage for Wire and Arc Additive Manufacturing Stiffened Panels" Metals 10, no. 5: 666. https://doi.org/10.3390/met10050666

APA StyleGeng, H., Li, J., Gao, J., & Lin, X. (2020). Theoretical Model of Residual Stress and Warpage for Wire and Arc Additive Manufacturing Stiffened Panels. Metals, 10(5), 666. https://doi.org/10.3390/met10050666