Effect of Post Processing Heat Treatment Routes on Microstructure and Mechanical Property Evolution of Haynes 282 Ni-Based Superalloy Fabricated with Selective Laser Melting (SLM)

Abstract

1. Introduction

2. Materials and Methods

2.1. Heat Treatment

2.2. Microstructure Analysis

2.3. In-Situ TEM Analysis

2.4. Hardness Measurement

2.5. Tensile Testing

3. Results and Discussion

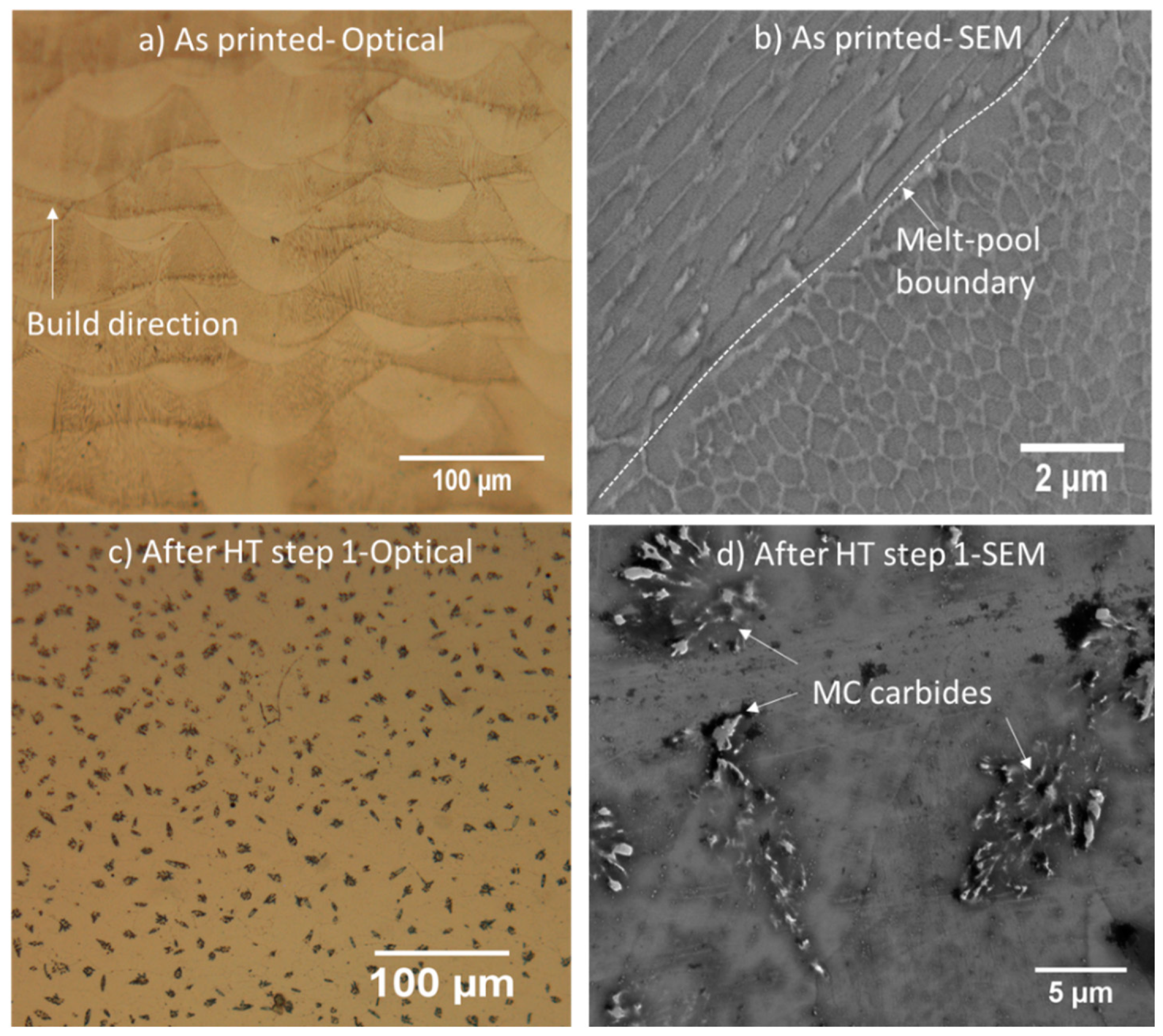

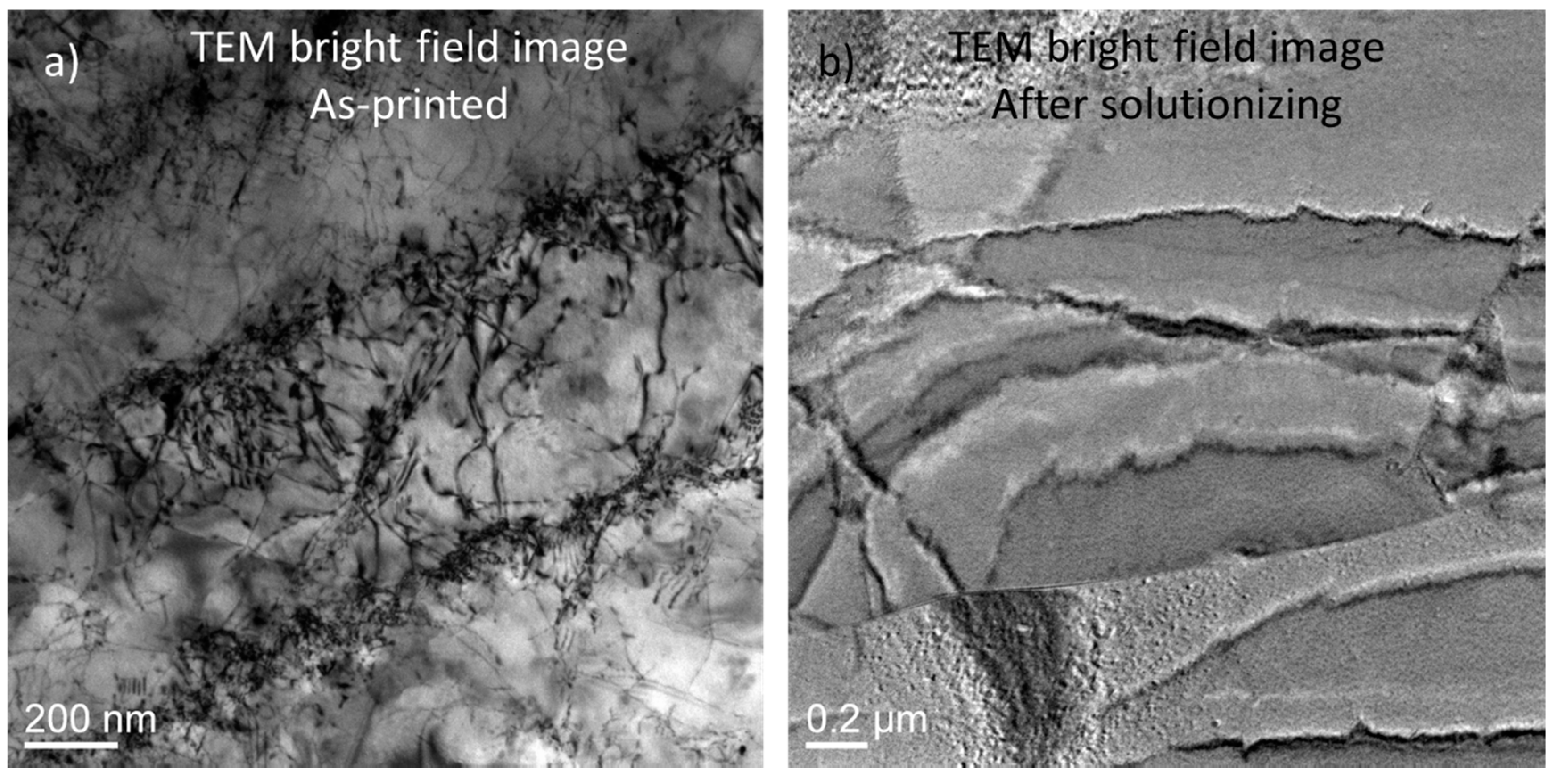

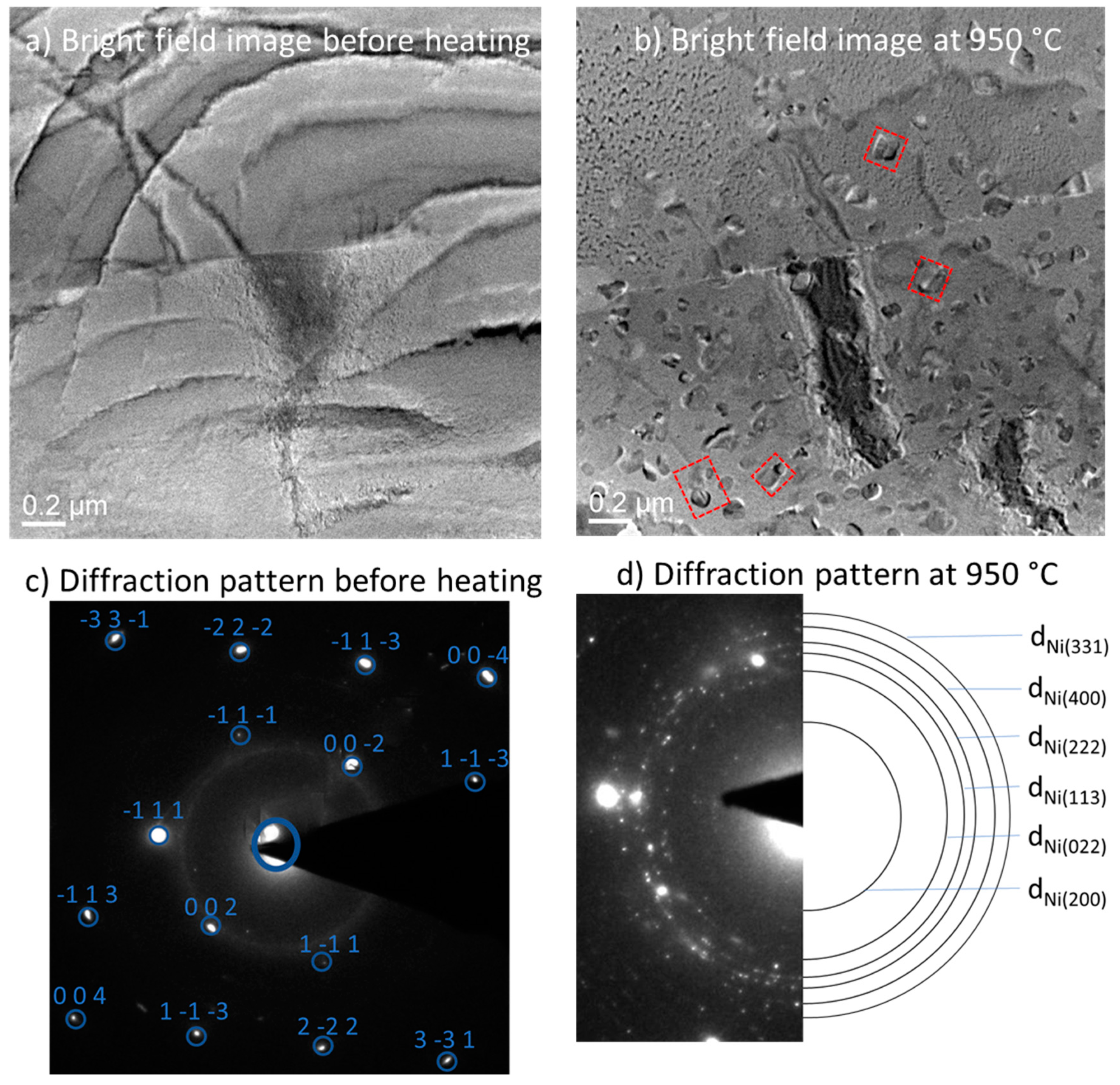

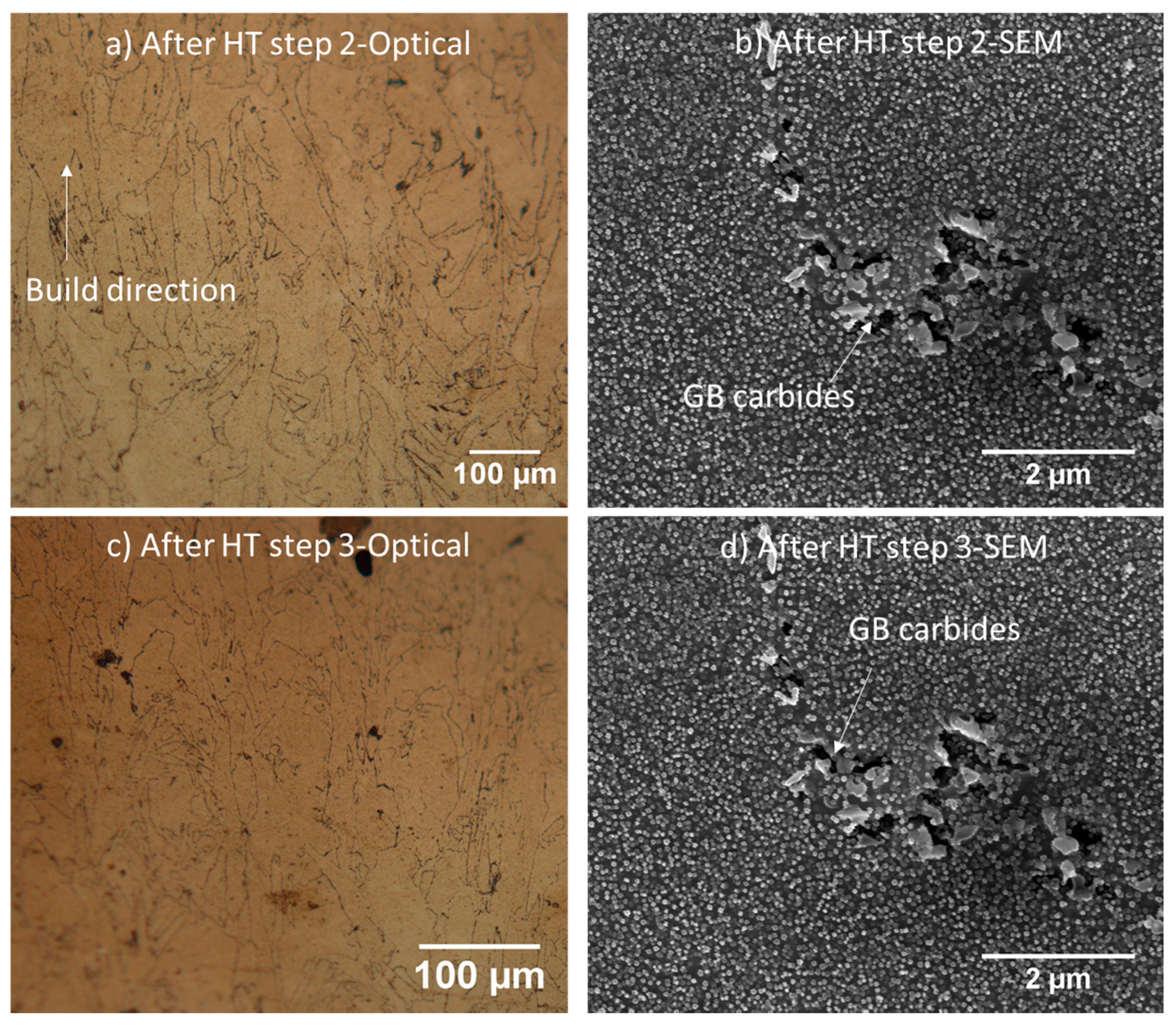

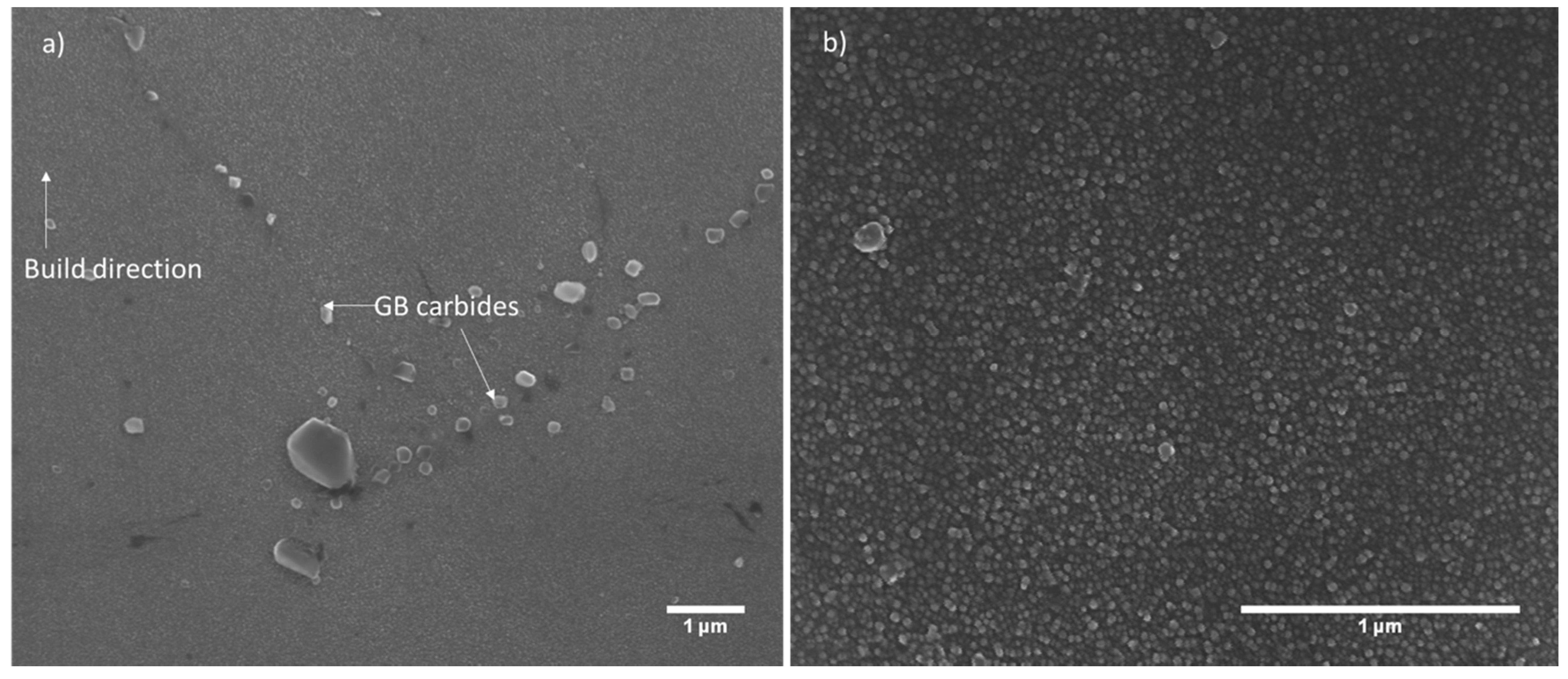

3.1. Microstructure Analysis

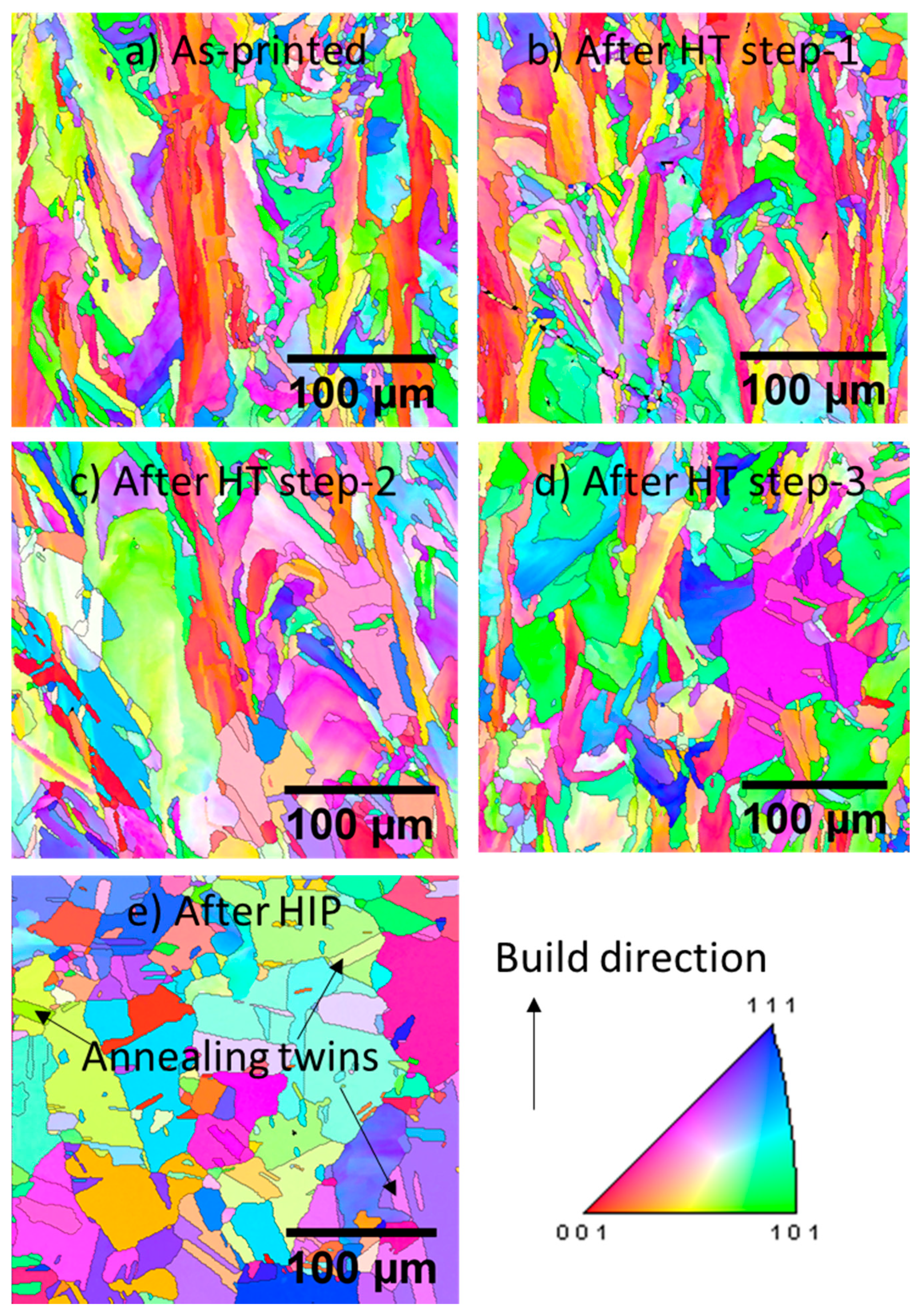

3.2. EBSD Analysis

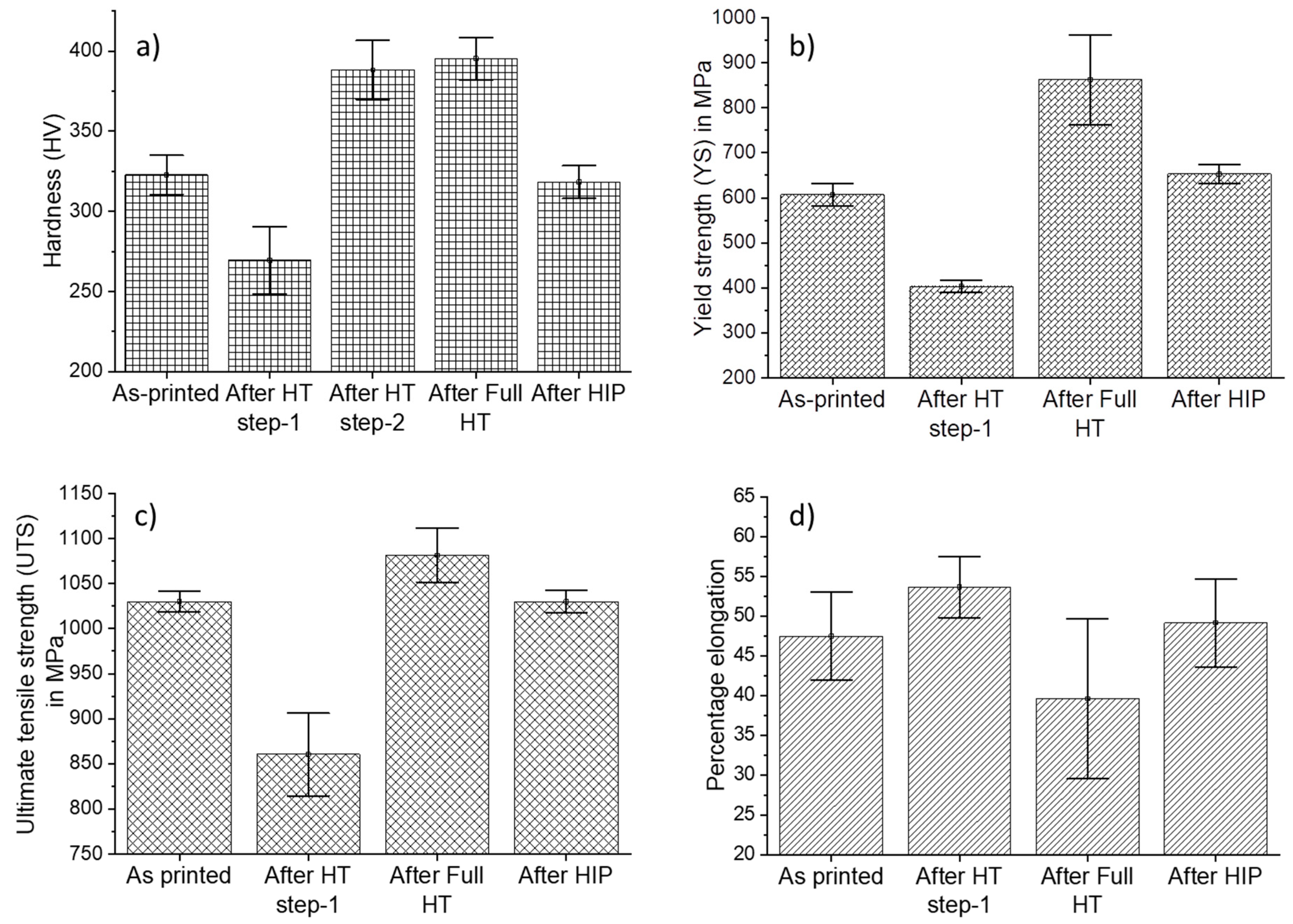

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Raghavan, S.; Raghavan, S.; Zhang, B.; Wang, P.; Sun, C.-N.; Nai, M.L.S.; Li, T.; Wei, J. Effect of different heat treatments on the microstructure and mechanical properties in selective laser melted INCONEL 718 alloy. Mater. Manuf. Process. 2017, 32, 1588–1595. [Google Scholar] [CrossRef]

- Amato, K.; Gaytan, S.M.; Murr, L.E.; Martinez, E.; Shindo, P.W.; Hernandez, J.; Collins, S.; Medina, F. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater. 2012, 60, 2229–2239. [Google Scholar] [CrossRef]

- Li, C.; White, R.; Fang, X.; Weaver, M.; Guo, Y. Microstructure evolution characteristics of Inconel 625 alloy from selective laser melting to heat treatment. Mater. Sci. Eng. A 2017, 705, 20–31. [Google Scholar] [CrossRef]

- Li, S.; Wei, Q.; Shi, Y.; Zhu, Z.; Zhang, D. Microstructure characteristics of Inconel 625 superalloy manufactured by selective laser melting. J. Mater. Sci. Technol. 2015, 31, 946–952. [Google Scholar] [CrossRef]

- Tomus, D.; Tian, Y.; Rometsch, P.A.; Heilmaier, M.; Wu, X. Influence of post heat treatments on anisotropy of mechanical behaviour and microstructure of Hastelloy-X parts produced by selective laser melting. Mater. Sci. Eng. A 2016, 667, 42–53. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.-D.; Nazé, L.; Sennour, M. Microstructural and mechanical approaches of the selective laser melting process applied to a nickel-base superalloy. Mater. Sci. Eng. A 2012, 534, 446–451. [Google Scholar] [CrossRef]

- Seetharaman, S.; Krishnan, M.; Wen, F.G.C.; Khan, N.A.; Lai, G.N.K. Research updates on the additive manufacturing of nickel based superalloys. In Proceedings of the Solid Freeform Fabrication 2016: Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2016; pp. 486–496. [Google Scholar]

- Xiao, H.; Li, S.M.; Xiao, W.J.; Li, Y.Q.; Cha, L.M.; Mazumder, J.; Song, L.J. Effects of laser modes on Nb segregation and Laves phase formation during laser additive manufacturing of nickel-based superalloy. Mater. Lett. 2017, 188, 260–262. [Google Scholar] [CrossRef]

- Wang, X.; Chou, K. Effects of thermal cycles on the microstructure evolution of Inconel 718 during selective laser melting process. Addit. Manuf. 2017, 18, 1–14. [Google Scholar] [CrossRef]

- Zhong, M.; Sun, H.; Liu, W.; Zhu, X.; He, J. Boundary liquation and interface cracking characterization in laser deposition of Inconel 738 on directionally solidified Ni-based superalloy. Scr. Mater. 2005, 53, 159–164. [Google Scholar] [CrossRef]

- Aydinöz, M.; Brenne, F.; Schaper, M.; Schaak, C.; Tillmann, W.; Nellesen, J.; Niendorf, T. On the microstructural and mechanical properties of post-treated additively manufactured Inconel 718 superalloy under quasi-static and cyclic loading. Mater. Sci. Eng. A 2016, 669, 246–258. [Google Scholar] [CrossRef]

- Zhang, D.; Niu, W.; Cao, X.; Liu, Z. Effect of standard heat treatment on the microstructure and mechanical properties of selective laser melting manufactured Inconel 718 superalloy. Mater. Sci. Eng. A 2015, 644, 32–40. [Google Scholar] [CrossRef]

- Zhao, X.; Lin, X.; Chen, J.; Xue, L.; Huang, W. The effect of hot isostatic pressing on crack healing, microstructure, mechanical properties of Rene88DT superalloy prepared by laser solid forming. Mater. Sci. Eng. A 2009, 504, 129–134. [Google Scholar] [CrossRef]

- Han, Q.; Mertens, R.; Montero-Sistiaga, M.L.; Yang, S.; Setchi, R.; Vanmeensel, K.; Van Hooreweder, B.; Evans, S.L.; Fan, H. Laser powder bed fusion of Hastelloy X: Effects of hot isostatic pressing and the hot cracking mechanism. Mater. Sci. Eng. A 2018, 732, 228–239. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Effect of heat treatment and hot isostatic pressing on the microstructure and mechanical properties of Inconel 625 alloy processed by laser powder bed fusion. Mater. Sci. Eng. A 2017, 689, 1–10. [Google Scholar] [CrossRef]

- Joseph, C.; Persson, C.; Colliander, M.H. Influence of heat treatment on the microstructure and tensile properties of Ni-base superalloy Haynes 282. Mater. Sci. Eng. A 2017, 679, 520–530. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Pike, L. Long term thermal exposure of Haynes 282 alloy. In Proceedings of the 7th International Symposium on Superalloy, Pittsburgh, PA, USA, 10–13 October 2010; Volume 718, pp. 645–660. [Google Scholar]

- Pike, L. HAYNES® 282TM alloy: A new wrought superalloy designed for improved creep strength and fabricability. In ASME Turbo Expo 2006: Power for Land, Sea, and Air; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2006; pp. 1031–1039. [Google Scholar]

- Matysiak, H.; Zagorska, M.; Andersson, J.; Balkowiec, A.; Cygan, R.; Rasinski, M.; Pisarek, M.; Andrzejczuk, M.; Kubiak, K.; Kurzydlowski, K.J. Microstructure of Haynes® 282® superalloy after vacuum induction melting and investment casting of thin-walled components. Materials 2013, 6, 5016–5037. [Google Scholar] [CrossRef]

- Ramakrishnan, A.; Dinda, G. Microstructure and mechanical properties of direct laser metal deposited Haynes 282 superalloy. Mater. Sci. Eng. A 2019, 748, 347–356. [Google Scholar] [CrossRef]

- Cao, Y.; Bai, P.; Liu, F.; Hou, X. Investigation on the precipitates of IN718 alloy fabricated by selective laser melting. Metals 2019, 9, 1128. [Google Scholar] [CrossRef]

- Sui, S.; Chen, J.; Fan, E.; Yang, H.; Lin, X.; Huang, W. The influence of Laves phases on the high-cycle fatigue behavior of laser additive manufactured Inconel 718. Mater. Sci. Eng. A 2017, 695, 6–13. [Google Scholar] [CrossRef]

- Bi, G.; Sun, C.-N.; Chen, H.-C.; Ng, F.L.; Ma, C.C.K. Microstructure and tensile properties of superalloy IN100 fabricated by micro-laser aided additive manufacturing. Mater. Des. 2014, 60, 401–408. [Google Scholar] [CrossRef]

- Osoba, L.; Ding, R.; Ojo, O. Microstructural analysis of laser weld fusion zone in Haynes 282 superalloy. Mater. Charact. 2012, 65, 93–99. [Google Scholar] [CrossRef]

- Meher, S.; Rojhirunsakool, T.; Hwang, J.; Nag, S.; Tiley, J.; Banerjee, R. Coarsening behaviour of gamma prime precipitates and concurrent transitions in the interface width in Ni-14 at.% Al-7 at.% Cr. Philos. Mag. Lett. 2013, 93, 521–530. [Google Scholar] [CrossRef]

- Maheshwari, A.; Ardell, A. Anomalous coarsening behavior of small volume fractions of Ni3Al precipitates in binary Ni-Al alloys. Acta Metall. Mater. 1992, 40, 2661–2667. [Google Scholar] [CrossRef]

- Klepser, C. Effect of continuous cooling rate on the precipitation of gamma prime in nickel-based superalloys. Scr. Metall. Mater. 1995, 33. [Google Scholar] [CrossRef]

- Kim, H.; Chun, S.; Yao, X.; Fang, Y.; Choi, J. Gamma prime (γ′) precipitating and ageing behaviours in two newly developed nickel-base superalloys. J. Mater. Sci. 1997, 32, 4917–4923. [Google Scholar] [CrossRef]

- Xu, R. The effect of high pressure on solidification microstructure of Al–Ni–Y alloy. Mater. Lett. 2005, 59, 2818–2820. [Google Scholar] [CrossRef]

- Lopez-Galilea, I.; Huth, S.; Bartsch, M.; Theisen, W. Effect of HIP parameters on the micro-structural evolution of a single crystal Ni-based superalloy. Adv. Mater. Res. 2011, 278, 72–77. [Google Scholar] [CrossRef]

- Antonysamy, A.A.; Meyer, J.; Prangnell, P. Effect of build geometry on the β-grain structure and texture in additive manufacture of Ti6Al4V by selective electron beam melting. Mater. Charact. 2013, 84, 153–168. [Google Scholar] [CrossRef]

- Mostafa, A.; Picazo Rubio, I.; Brailovski, V.; Jahazi, M.; Medraj, M. Structure, texture and phases in 3D printed IN718 alloy subjected to homogenization and HIP treatments. Metals 2017, 7, 196. [Google Scholar] [CrossRef]

- Pham, M.; Dovgyy, B.; Hooper, P. Twinning induced plasticity in austenitic stainless steel 316L made by additive manufacturing. Mater. Sci. Eng. A 2017, 704, 102–111. [Google Scholar] [CrossRef]

- Ni, M.; Chen, C.; Wang, X.; Wang, P.; Li, R.; Zhang, X.; Zhou, K. Anisotropic tensile behavior of in situ precipitation strengthened Inconel 718 fabricated by additive manufacturing. Mater. Sci. Eng. A 2017, 701, 344–351. [Google Scholar] [CrossRef]

- Dudova, N.; Belyakov, A.; Sakai, T.; Kaibyshev, R. Dynamic recrystallization mechanisms operating in a Ni–20% Cr alloy under hot-to-warm working. Acta Mater. 2010, 58, 3624–3632. [Google Scholar] [CrossRef]

- Chen, X.-M.; Lin, Y.; Wu, F. EBSD study of grain growth behavior and annealing twin evolution after full recrystallization in a nickel-based superalloy. J. Alloys Compd. 2017, 724, 198–207. [Google Scholar] [CrossRef]

- Wang, M.; Sun, C.; Fu, M.; Liu, Z.; Wang, C. Microstructure and microtexture evolution of dynamic recrystallization during hot deformation of a nickel-based superalloy. Mater. Des. 2020, 188, 108429. [Google Scholar] [CrossRef]

- Pataky, G.J.; Sehitoglu, H.; Maier, H.J. High temperature fatigue crack growth of Haynes 230. Mater. Charact. 2013, 75, 69–78. [Google Scholar] [CrossRef]

| D10 (μm) | D50 (μm) | D90 (μm) |

|---|---|---|

| 18.9 | 29.3 | 44.3 |

| Ni | Cr | Co | Mo | Ti | Al | Fe | Mn | Si | C | B | O | N | P | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 58.484 | 19.2 | 10.3 | 8.3 | 2.1 | 1.52 | 0 | 0 | 0.02 | 0.05 | 0.005 | 0.007 | 0.005 | <0.005 | 0.004 |

| Laser Power (W) | Speed (mm/s) | Hatch Spacing (mm) | Layer Thickness (mm) | Energy Density (J/m3) |

|---|---|---|---|---|

| 75 | 650 | 0.077 | 0.02 | 75 |

| Method | Step 1 | Step 2 | Step 3 |

|---|---|---|---|

| Heat treatment | 1120 °C/2 h/water quench | 1000 °C/2 h/Furnace cooling | 788 °C/8 h/Furnace cooling |

| Hot isostatic processing (HIP) | 1185 °C/150MPa/3.5 h | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deshpande, A.; Deb Nath, S.; Atre, S.; Hsu, K. Effect of Post Processing Heat Treatment Routes on Microstructure and Mechanical Property Evolution of Haynes 282 Ni-Based Superalloy Fabricated with Selective Laser Melting (SLM). Metals 2020, 10, 629. https://doi.org/10.3390/met10050629

Deshpande A, Deb Nath S, Atre S, Hsu K. Effect of Post Processing Heat Treatment Routes on Microstructure and Mechanical Property Evolution of Haynes 282 Ni-Based Superalloy Fabricated with Selective Laser Melting (SLM). Metals. 2020; 10(5):629. https://doi.org/10.3390/met10050629

Chicago/Turabian StyleDeshpande, Anagh, Subrata Deb Nath, Sundar Atre, and Keng Hsu. 2020. "Effect of Post Processing Heat Treatment Routes on Microstructure and Mechanical Property Evolution of Haynes 282 Ni-Based Superalloy Fabricated with Selective Laser Melting (SLM)" Metals 10, no. 5: 629. https://doi.org/10.3390/met10050629

APA StyleDeshpande, A., Deb Nath, S., Atre, S., & Hsu, K. (2020). Effect of Post Processing Heat Treatment Routes on Microstructure and Mechanical Property Evolution of Haynes 282 Ni-Based Superalloy Fabricated with Selective Laser Melting (SLM). Metals, 10(5), 629. https://doi.org/10.3390/met10050629