Energy Density Effect of Laser Alloyed TiB2/TiC/Al Composite Coatings on LMZ/HAZ, Mechanical and Corrosion Properties

Abstract

1. Introduction

2. Materials and Methods

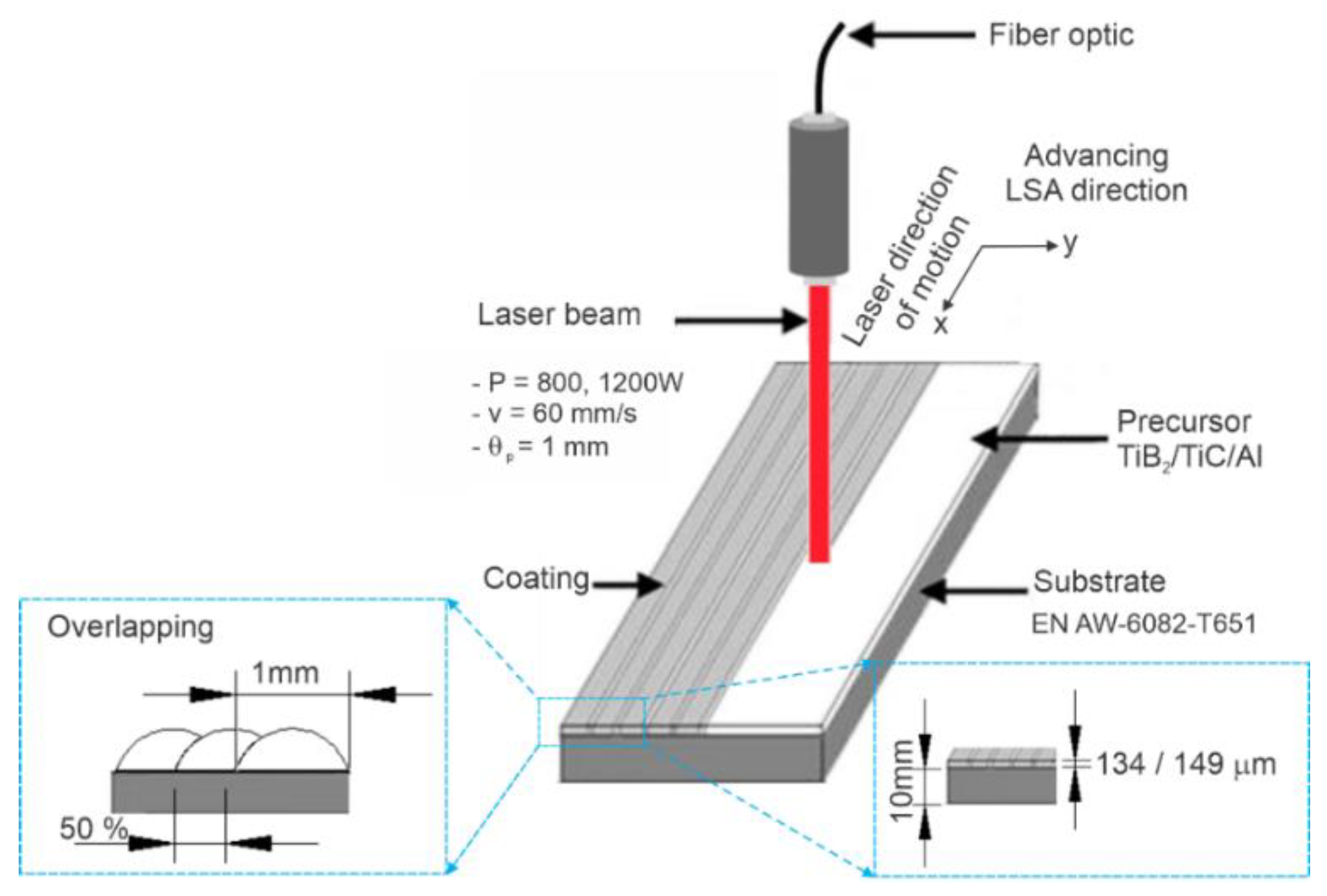

2.1. Sample Preparation and Laser Surface Alloying Process

2.2. Morphological and Microstructural Analysis

2.3. Microhardness, Residual Stress and Wear Analyses

2.4. Corrosion Analysis

3. Results and Discussion

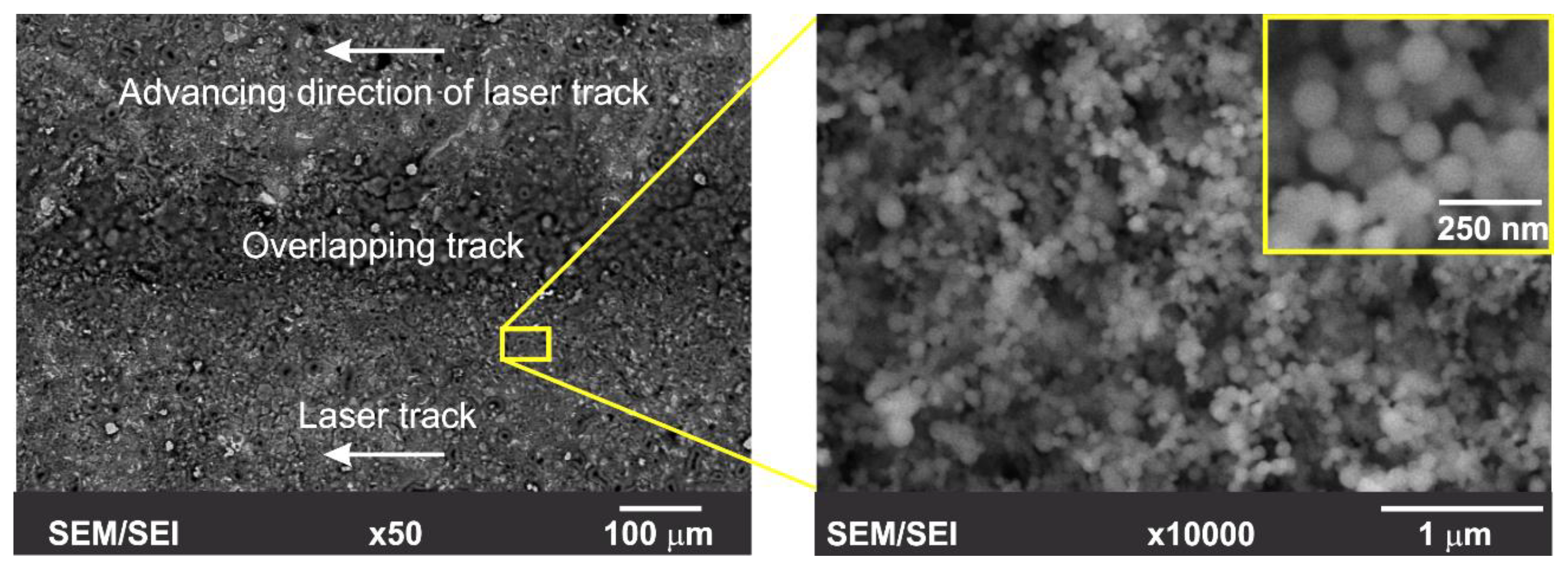

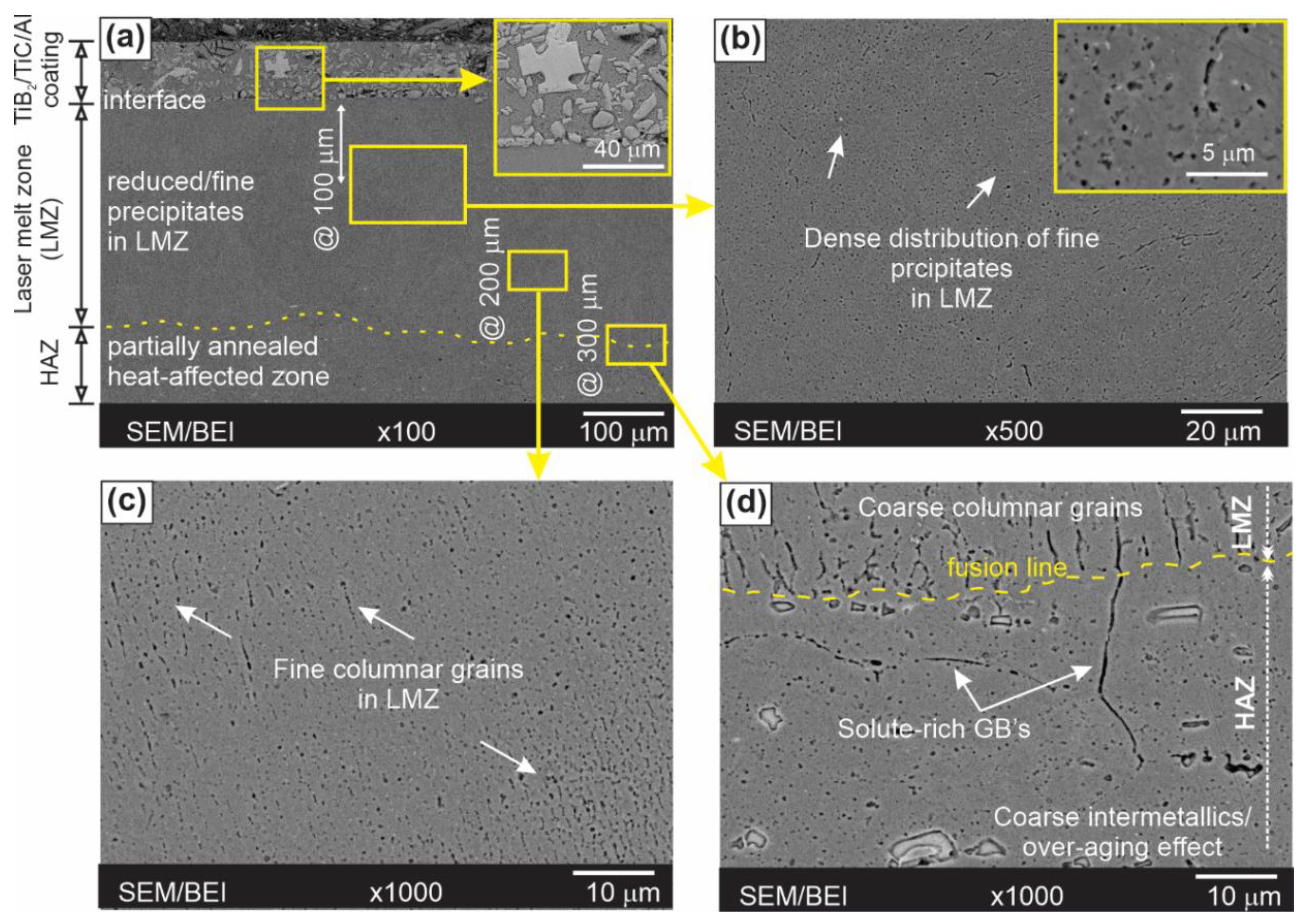

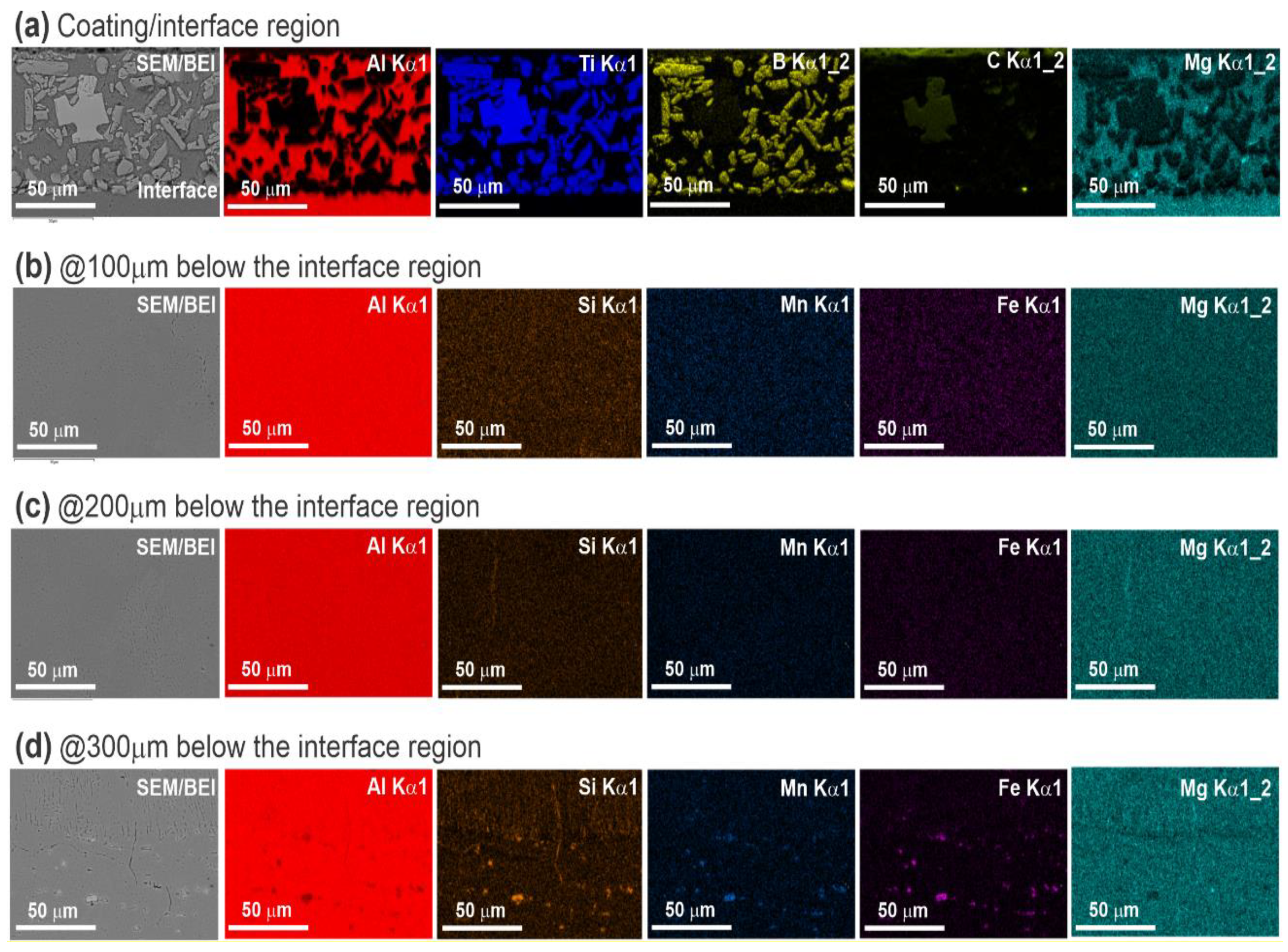

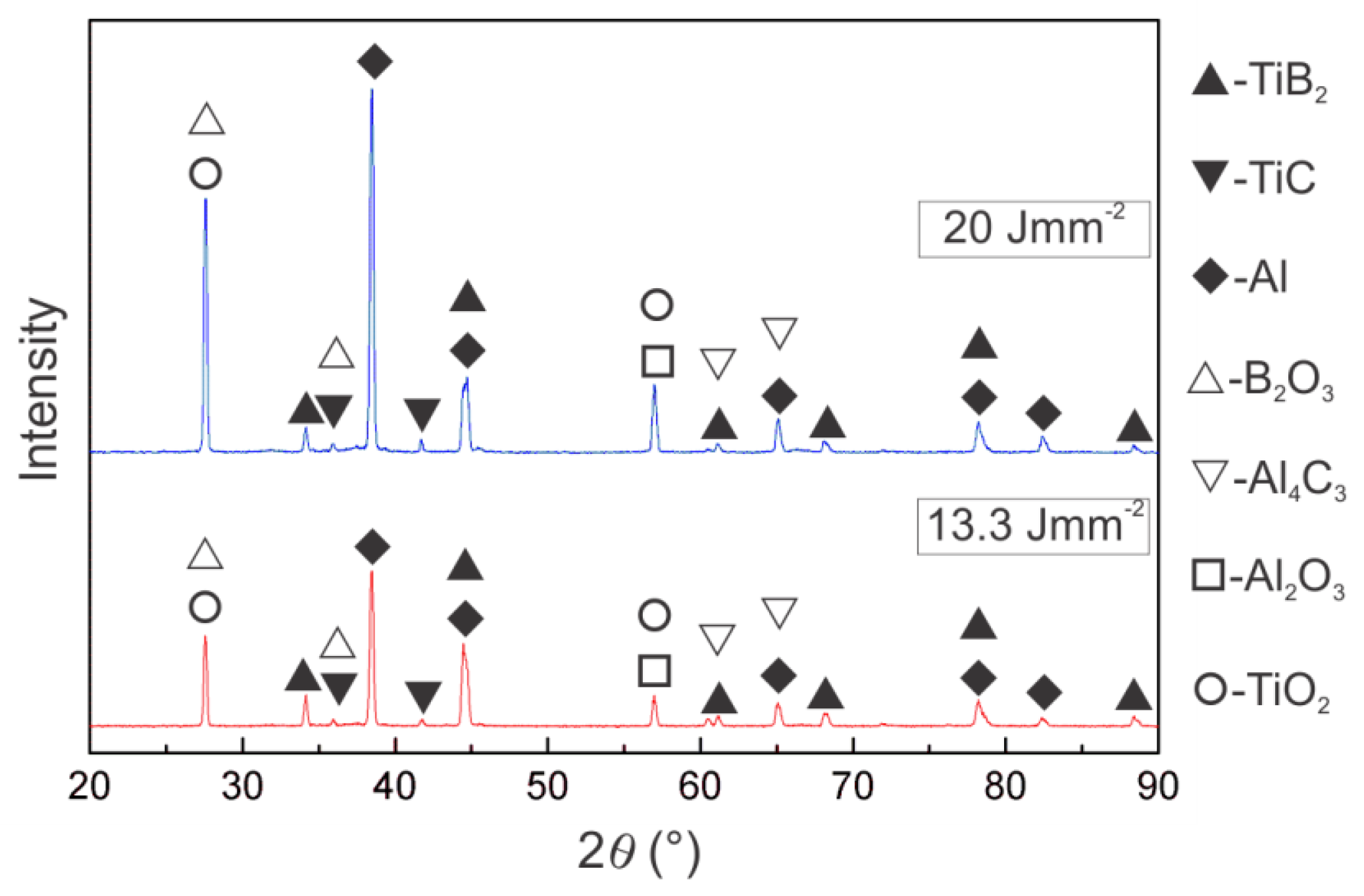

3.1. Surface Morphology and Microstructural Analysis

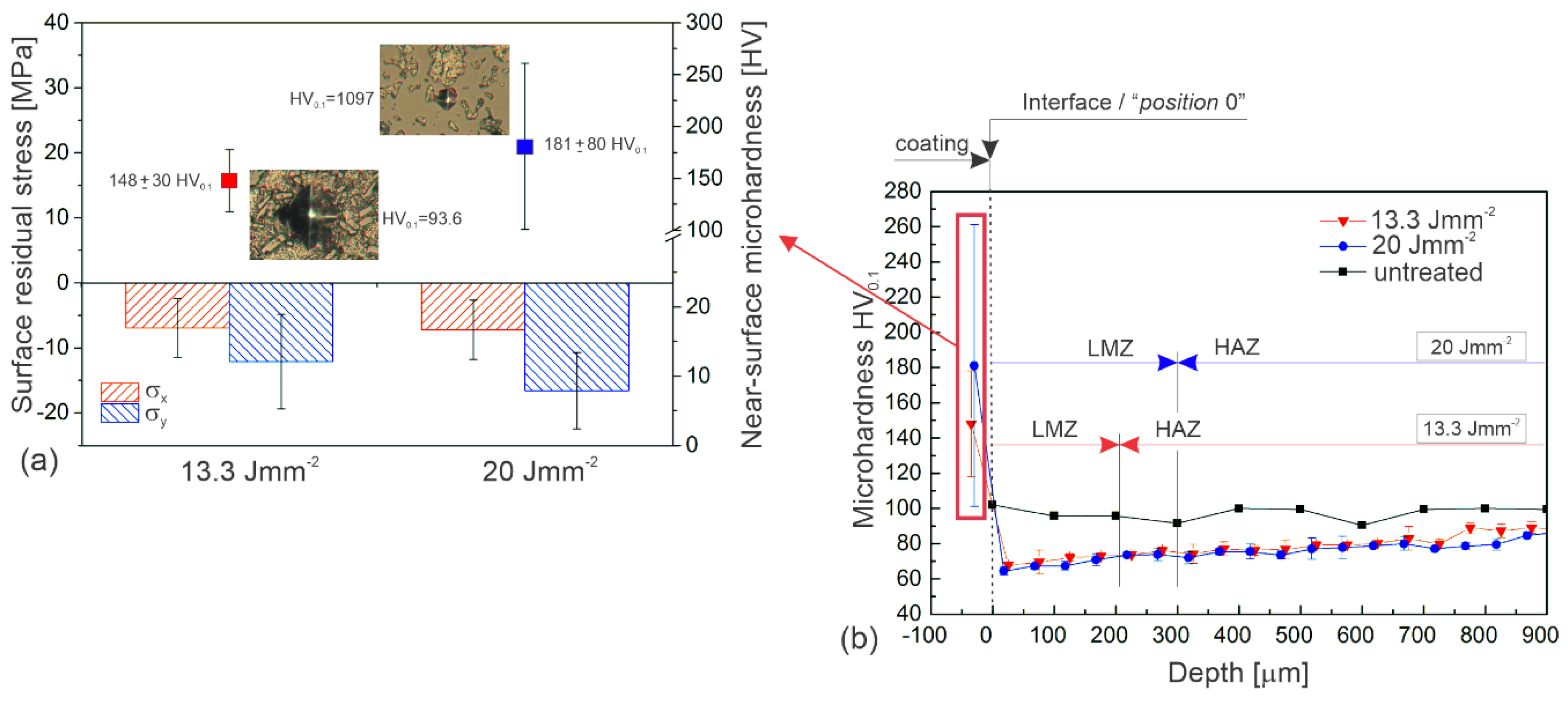

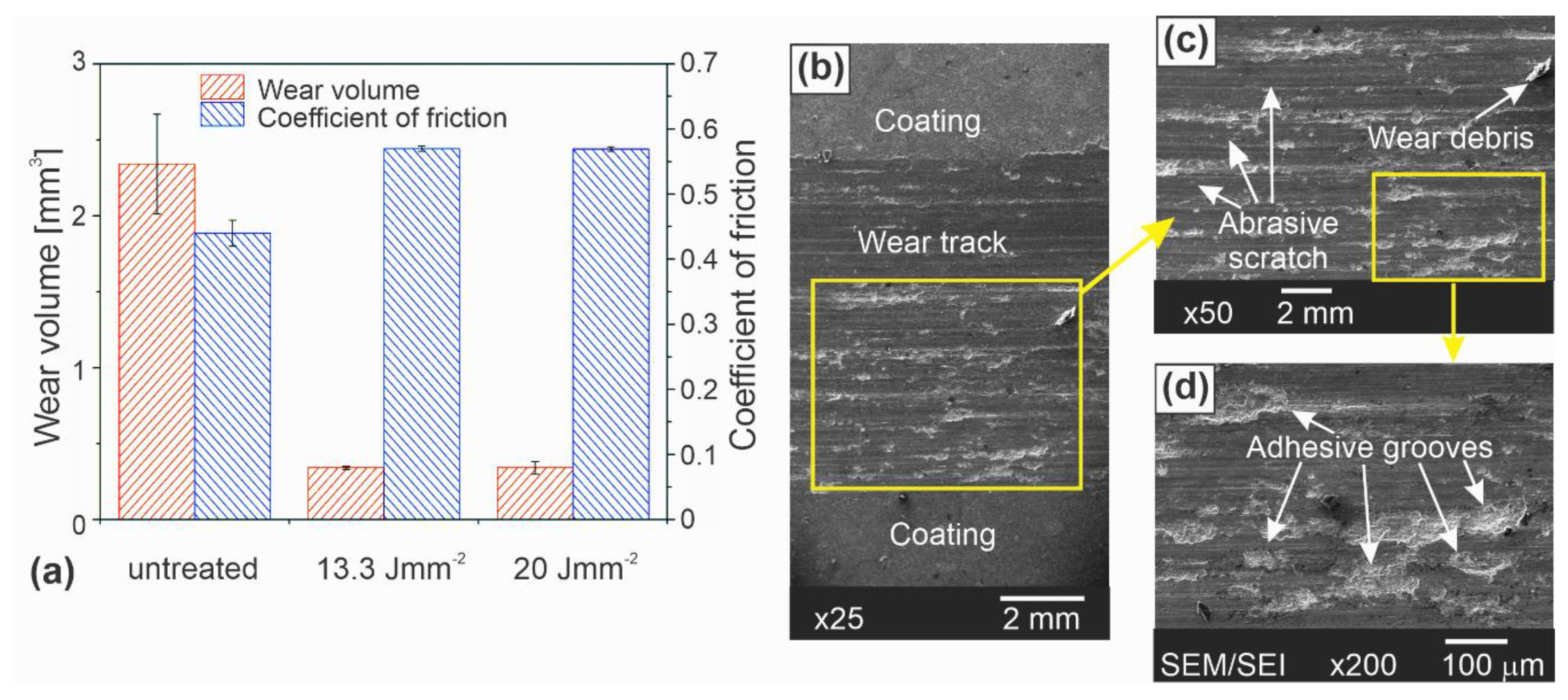

3.2. Microhardness, Residual Stress and Wear Analyses

3.3. Corrosion Analysis

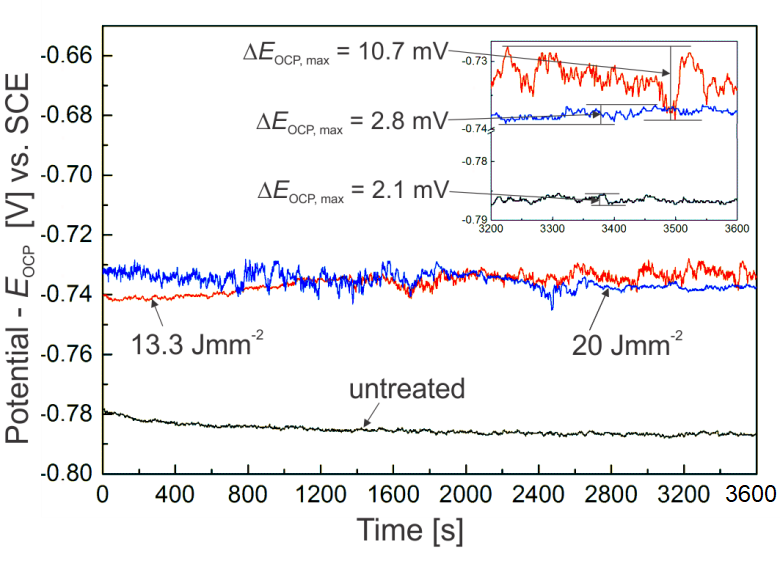

3.3.1. Open Circuit Potential

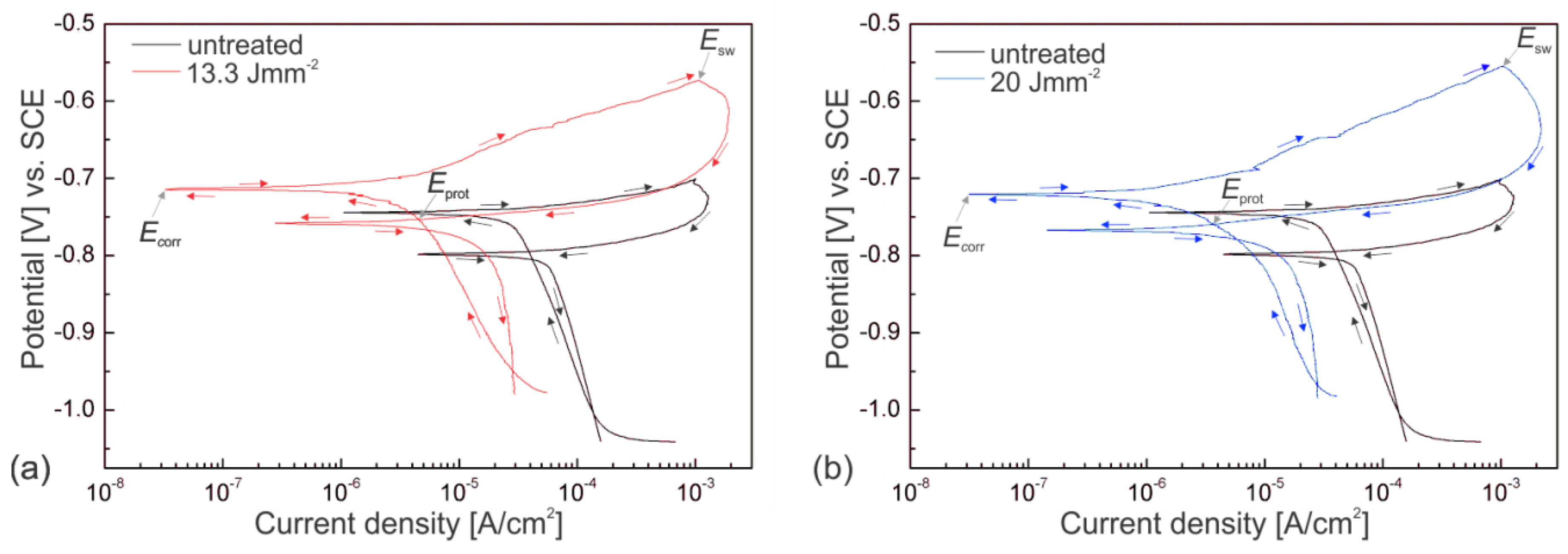

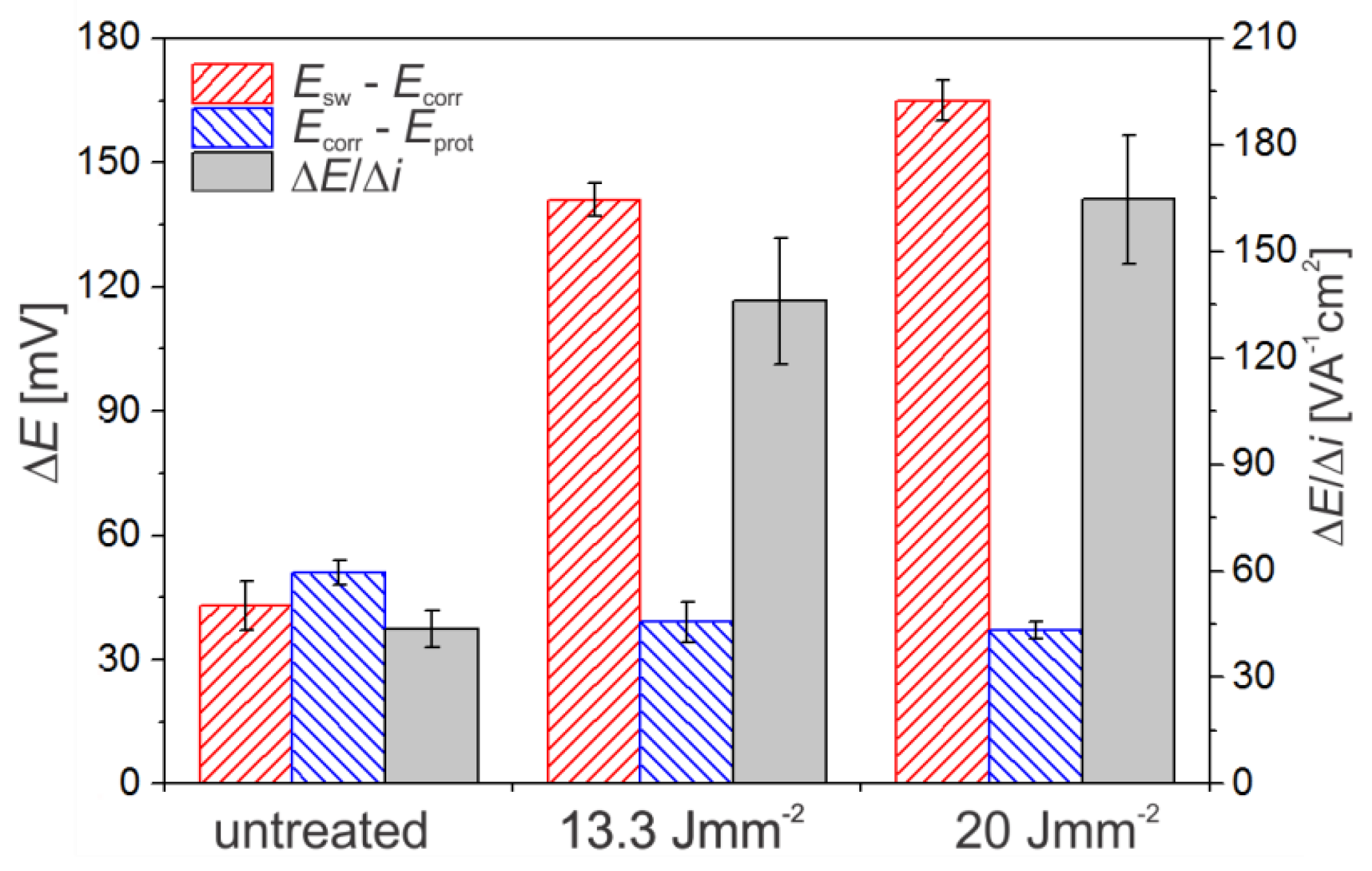

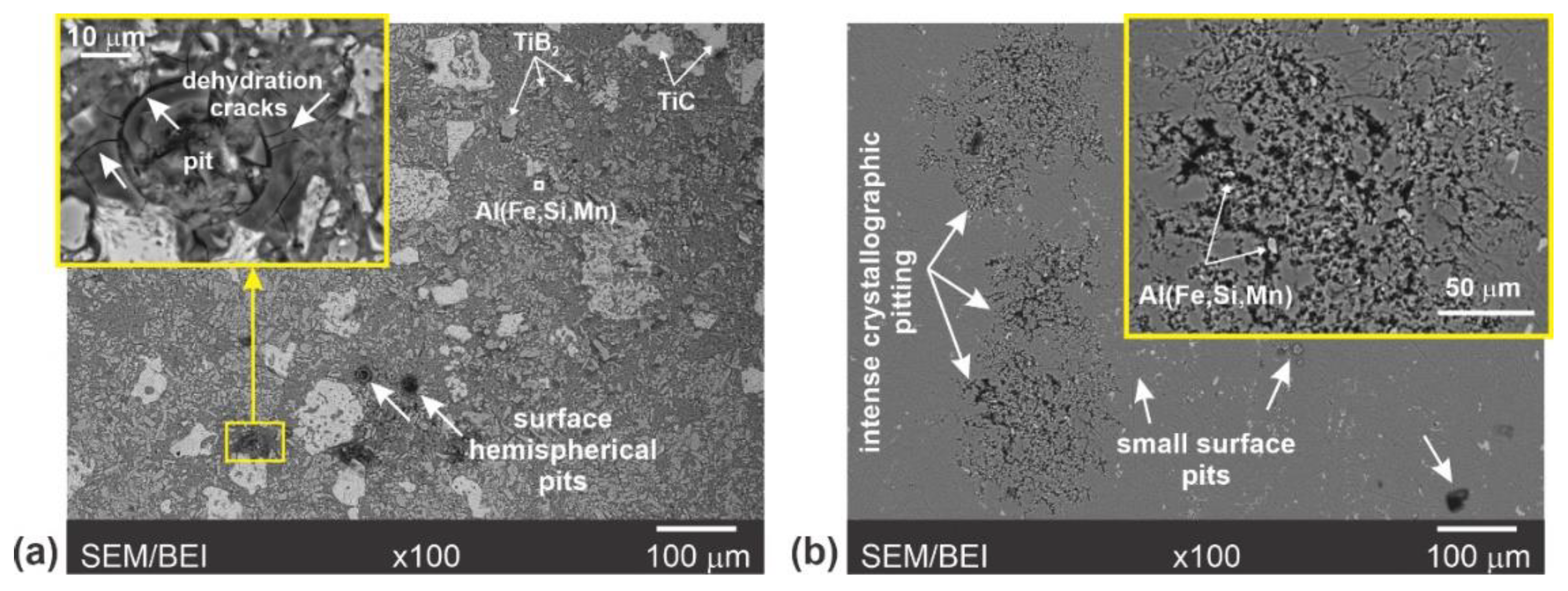

3.3.2. Cyclic Polarization

4. Conclusions

- (1)

- The TiB2/TiC/Al coatings were successfully fabricated with LEDs of 13.3 J/mm2 and 20 J/mm2 and were free of defects with sound bonding to the Al substrate.

- (2)

- The average microhardness of the coating is about 69% higher than the untreated material. LSA of Al alloy with TiB2/TiC/Al does not significantly improve microhardness, due to the addition of Al powder to TiB2-TiC ceramic precursor mixture to improve adhesion properties.

- (3)

- The coating shows exceptional improvement of wear resistance. After the wear test, the LSA coated samples experienced about eight times lower wear volume loss than the substrate.

- (4)

- From the CP results, it is clearly understood that the untreated/substrate Al alloy shows inferior corrosion resistance compared to the laser processed samples, mainly due to the following facts; (i) substrate Al sample revealed no passive behaviour (while the LSA samples exhibited partial passivation); (ii) untreated Al sample has a much higher corrosion current density (8.7 times higher compared to LSA sample processed at 13.3 J/mm2 and 9.4 times higher compared to the LSA sample processed at 20 J/mm2); (iii) higher anodic dissolution (smaller value of Esw − Ecorr) and (iv) more defective surface/higher susceptibility to pitting attack (large value of Ecorr − Eprot) compared to the laser processed TiB2/TiC/Al composite coated samples.

- (5)

- SEM analysis confirmed complete prohibition of crystallographic pitting with LSA samples due to reduced fractional area of liquid-solid interface with chemically more stable surface which prevented the ‘chain-link’ crystallographic corrosion effect, detected with the untreated/substrate material.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- D’Amato, C.; Betts, J.C.; Buhagiar, J. Laser surface alloying of an A356 aluminium alloy using nickel and Ni-Ti-C: A corrosion study. Surf. Coat. Technol. 2014, 244, 194–202. [Google Scholar] [CrossRef]

- Jiru, W.G.; Sankar, M.R.; Dixit, U.S. Investigation of microstructure and microhardness in laser surface alloyed aluminium with TiO2 and SiC powders. Mater. Today Proc. 2017, 4, 717–724. [Google Scholar] [CrossRef]

- Rajamure, R.S.; Vora, H.D.; Srinivasan, S.G.; Dahotre, N.B. Laser alloyed Al-W coatings on aluminum for enhanced corrosion resistance. Appl. Surf. Sci. 2015, 328, 205–214. [Google Scholar] [CrossRef]

- Chi, Y.; Gu, G.; Yu, H.; Chen, C. Laser surface alloying on aluminium and its alloys: A Review. Opt. Laser Eng. 2018, 100, 23–37. [Google Scholar] [CrossRef]

- Vargel, C. Corrosion of Aluminium; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Choudhary, R.K.; Mishra, P.; Kain, V.; Singh, K.; Kumar, S.; Chakravartty, J.K. Scratch behavior of aluminum anodized in oxalic acid: Effect of anodizing potential. Surf. Coat. Technol. 2015, 283, 135–147. [Google Scholar] [CrossRef]

- Nath, S.; Pityana, S.; Majumdar, J.D. Laser surface alloying of aluminium with WC+Co+NiCr for improved wear resistance. Surf. Coat. Technol. 2012, 206, 3333–3341. [Google Scholar] [CrossRef]

- Mabhalli, L.A.B.; Sacks, N.; Pityana, S. Three body abrasion of laser surface alloyed aluminium AA1200. Wear 2012, 209–291, 1–9. [Google Scholar] [CrossRef]

- Katipelli, L.R.; Agarwal, A.; Dahotre, N.B. Laser surface engineered TiC coating on 6061 Al alloy: Microstructure and wear. Appl. Surf. Sci. 2000, 153, 65–78. [Google Scholar] [CrossRef]

- Chong, P.H.; Man, H.C.; Yue, T.M. Laser fabrication of Mo-TiC MMC on AA6061 aluminum alloy surface. Surf. Coat. Technol. 2002, 154, 268–275. [Google Scholar] [CrossRef]

- Katipelli, L.R.; Agarwal, A.; Dahotre, N.B. Interfacial strength of laser surface engineered TiC coating on 6061 Al using four-point bend test. Mater. Sci. Eng. A 2000, 289, 34–40. [Google Scholar] [CrossRef]

- Kadolkar, P.; Dahotre, N.B. Variation of structure with input energy during laser surface engineering of ceramic coatings on aluminum alloys. Appl. Surf. Sci. 2002, 199, 222–233. [Google Scholar] [CrossRef]

- Ravnikar, D.; Rajamure, R.S.; Trdan, U.; Dahotre, N.B.; Grum, J. Electrochemical and DFT studies of laser-alloyed TiB2/TiC/Al coatings on aluminium alloy. Corros. Sci. 2018, 136, 18–27. [Google Scholar] [CrossRef]

- Ravnikar, D.; Dahotre, N.B.; Grum, J. Microstructure and mechanical properties of TiB2/TiC/Al coatings on EN AW-6082 substrate produced with laser coating. Lasers Eng. 2014, 29, 53–68. [Google Scholar]

- Ravnikar, D.; Dahotre, N.B.; Grum, J. Laser coating of aluminum alloy EN AW 6082-T651 with TiB2 and TiC: Microstructure and mechanical properties. Appl. Surf. Sci. 2013, 282, 914–922. [Google Scholar] [CrossRef]

- Song, R.; Li, J.; Shao, J.Z.; Bai, L.L.; Chen, J.L.; Qu, C.C. Microstructural evolution and wear behaviors of laser cladding Ti2Ni/α(Ti) dual-phase coating reinforced by TiB and TiC. Appl. Surf. Sci. 2015, 355, 298–309. [Google Scholar] [CrossRef]

- Lv, Y.H.; Li, J.; Tao, Y.F.; Hu, L.F. High-temperature wear and oxidation behaviors of TiNi/Ti2Ni matrix composite coatings with TaC addition prepared on Ti6Al4V by laser cladding. Appl. Surf. Sci. 2017, 402, 478–494. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.; Yu, H. Research status of laser cladding on titanium and its alloys: A review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Dai, J.; Li, S.; Zhang, H. Microstructure and wear properties of self-lubricating TiB2-TiCxNy ceramic coatings on Ti-6Al-4V alloy fabricated by laser surface alloying. Surf. Coat. Technol. 2019, 369, 269–279. [Google Scholar] [CrossRef]

- Yue, T.M.; Xie, H.; Lin, X.; Yang, H.O.; Meng, G.H. Solidification behaviour in laser cladding of AlCoCrCuFeNi high-entropy alloy on magnesium substrates. J. Alloy Compd. 2014, 587, 588–593. [Google Scholar] [CrossRef]

- Elahi, M.R.; Sohi, M.H.; Safae, A. Liquid phase surface alloying of AZ91D magnesium alloy with Al and Ni powders. Appl. Surf. Sci. 2012, 258, 5876–5880. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, P.L.; Yu, Z.S.; Lu, Q.H.; Yang, S.L.; Li, C.G. Microstructure and tribological properties of laser-clad Ni−Cr/TiB2 composite coatings on copper with the addition of CaF2. Surf. Coat. Technol. 2012, 206, 4046–4053. [Google Scholar] [CrossRef]

- Kukliński, M.; Bartkowska, A.; Przestacki, D. Microstructure and selected properties of Monel 400 alloy after laser heat treatment and laser boriding using diode laser. Int. J. Adv. Manuf. Technol. 2018, 98, 3005–3017. [Google Scholar] [CrossRef]

- Kukliński, M.; Bartkowska, A.; Przestacki, D. Laser Alloying Monel 400 with Amorphous Boron to Obtain Hard Coatings. Materials 2019, 12, 3494. [Google Scholar] [CrossRef] [PubMed]

- Lepule, M.L.; Obadele, B.A.; Andrews, A.; Olubambi, P.A. Corrosion and wear behaviour of ZrO2 modified NiTi coatings on AISI 316 stainless steel. Surf. Coat. Technol. 2015, 261, 21–27. [Google Scholar] [CrossRef]

- Sun, G.F.; Zhang, Y.K.; Zhang, M.K.; Zhou, R.; Wang, K.; Liu, C.S.; Luo, K.Y. Microstructure and corrosion characteristics of 304 stainless steel laser-alloyed with Cr−CrB2. Appl. Surf. Sci. 2014, 295, 94–107. [Google Scholar] [CrossRef]

- Przestacki, D.; Bartkowska, A.; Kukliński, M.; Kieruj, P. The Effects of Laser Surface Modification on theMicrostructure of 1.4550 Stainless Steel. KMATEC Web Conf. 2018, 237, 02009. [Google Scholar]

- Salim, A.A.; Bidin, N.; Islam, S. Low power CO2 laser modified iron/nickel alloyed pure aluminum surface: Evaluation of structural and mechanical properties. Surf. Coat. Technol. 2017, 315, 24–31. [Google Scholar] [CrossRef]

- Ramadan, J.M. Abrasive Wear of continuous fibre reinforced Al and Al-alloy metal matrix composites. JJMIE 2010, 4, 246–255. [Google Scholar]

- Wang, X.; Zhang, Z.; Men, Y.; Li, X.; Liang, Y.; Ren, L. Fabrication of nano-TiC functional gradient wear-resistant composite coating on 40Cr gear steel using laser cladding under starved lubrication conditions. Opt. Laser Technol. 2020, 126, 106136. [Google Scholar] [CrossRef]

- Misra, D.; Dhakar, B.; Anusha, E.; Shariff, S.M.; Mukhopadhyay, S.; Chatterjee, S. Evaluation of nanomechanical and tribological properties of laser surface alloyed boride-nitride-carbide ceramic matrix composite coatings. Ceram. Int. 2018, 44, 17050–17061. [Google Scholar] [CrossRef]

- Vallauri, D.; Atias Adrian, I.C.; Chrysanthou, A. TiC-TiB2 composites: A review of phase relationships, processing and properties. J. Eur. Ceram. Soc. 2008, 28, 1697–1713. [Google Scholar] [CrossRef]

- Telle, R.; Sigl, L.S.; Takagi, K. Boride-Based Hard Materials. In Handbook of Ceramic Hard Materials; Riedel, R., Ed.; Wiley-VCH: Weinheim, Germany, 2000. [Google Scholar]

- Ahin, Y. Abrasive wear behaviour of SiC/2014 aluminium composite. Tribol. Int. 2010, 43, 939–943. [Google Scholar]

- Rajamure, R.S.; Vora, H.D.; Gupta, N.; Karewar, S.; Srinivasan, S.G.; Dahotre, N.B. Laser surface alloying of molybdenum on aluminum for enhanced wear resistance. Surf. Coat. Technol. 2014, 258, 337–342. [Google Scholar] [CrossRef]

- Covino, B.S., Jr.; Alman, D.E. Corrosion of titanium matrix composites. In Proceedings of the 15th International Corrosion Congress, Granada, Spain, 22–27 September 2002. [Google Scholar]

- Lekatoua, A.; Zois, D.; Karantzalis, A.E.; Grimanelis, D. Electrochemical behaviour of cermet coatings with a bond coat on Al7075: Pseudopassivity, localized corrosion and galvanic effect considerations in a saline environment. Corros. Sci. 2010, 52, 2616–2635. [Google Scholar] [CrossRef]

- Shon, Y.; Joshi, S.S.; Katakam, S.; Rajamure, R.S.; Dahotre, N.B. Laser additive synthesis of high entropy alloy coating on aluminum: Corrosion behaviour. Mater. Lett. 2015, 142, 122–125. [Google Scholar] [CrossRef]

- Li, S.; Dong, H.; Shi, L.; Li, P.; Ye, F. Corrosion behavior and mechanical properties of Al-Zn-Mg aluminum alloy weld. Corros. Sci. 2017, 123, 243–255. [Google Scholar] [CrossRef]

- Trdan, U.; Hočevar, M.; Gregorčič, P. Transition from superhydrophilic to superhydrophobic state of laser textured stainless steel surface and its effect on corrosion resistance. Corros. Sci. 2017, 123, 21–26. [Google Scholar] [CrossRef]

- Tiringer, U.; Kovač, J.; Milošev, I. Effects of mechanical and chemical pre-treatments on themorphology and composition of surfaces of aluminium alloys 7075-T6 and 2024-T3. Corros. Sci. 2017, 119, 46–59. [Google Scholar] [CrossRef]

- Trueba, M.; Trasatti, S.P. Study of Al alloy corrosion in neutral NaCl by the pitting scan technique. Mater. Chem. Phys. 2010, 121, 523–533. [Google Scholar] [CrossRef]

- Trdan, U.; Grum, J. Evaluation of corrosion resistance of AA6082-T651 aluminum alloy after laser shock peening by means of cyclic polarisation and ElS methods. Corros. Sci. 2012, 59, 324–333. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Y.; Yang, C. A study on atomic diffusion behaviours in an Al-Mg compound casting process. AIP Adv. 2015, 5, 87147. [Google Scholar] [CrossRef]

- Nie, F.; Dong, H.; Chen, S.; Li, P.; Wang, L.; Zhao, Z.; Li, X.; Zhang, H. Microstructure and mechanical properties of pulse MIG welded 6061/A356 aluminum alloy dissimilar butt joints. J. Mater. Sci. Technol. 2018, 34, 551–560. [Google Scholar] [CrossRef]

- Watkins, K.G.; Liu, Z.; McMahon, M.; Vilar, R.; Ferreira, M.G.S. Influence of the overlapped area on the corrosion behaviour of laser treated aluminium alloys. Mater. Sci. Eng. A 1998, 252, 292–300. [Google Scholar] [CrossRef]

- Yue, T.M.; Yan, L.J.; Chan, C.P.; Dong, C.F.; Man, H.C.; Pang, G.K.H. Excimer laser surface treatment of aluminum alloy AA7075 to improve corrosion resistance. Surf. Coat. Technol. 2004, 179, 158–164. [Google Scholar] [CrossRef]

- Viejo, F.; Coy, A.E.; García-García, F.J.; Merino, M.C.; Liu, Z.; Skeldon, P.; Thompson, G.E. Enhanced performance of the AA2050-T8 aluminium alloy following excimer laser surface melting and anodising processes. Thin Solid Film. 2010, 518, 2722–2731. [Google Scholar] [CrossRef]

- Vieira, A.C.; Rocha, L.A.; Papageorgiou, N.; Mischler, S. Mechanical and electrochemical deterioration mechanisms in the tribocorrosion of Al alloys in NaCl and in NaNO3 solutions. Corros. Sci. 2012, 54, 26–35. [Google Scholar] [CrossRef]

- McCauley, R.A. Corrosion of Ceramic and Composite Materials; M. Dekker: New York, NY, USA, 2004. [Google Scholar]

- Cao, G.J.; Xu, H.Y.; Zheng, Z.-Z.; Geng, L.; Masaaki, N. Grain size effect on cyclic oxidation of (TiB2+TiC)/Ni3Al composites. Trans. Nonferrous Met. Soc. China 2012, 22, 1588–1593. [Google Scholar] [CrossRef]

- Kennedy, A.R.; Weston, D.P.; Jones, M.I.; Enel, C. Reaction in Al-Ti-C powders and its relation to the formation and stability of TiC in Al at high temperatures. Scr. Mater. 2000, 42, 1187–1192. [Google Scholar] [CrossRef]

- Das, D.K. Surface roughness created by laser surface alloying of aluminium with nickel. Surf. Coat. Technol. 1994, 64, 11–15. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, J.D. Effects of laser power density on the microstructure and microhardness of Ni−Al alloyed layer by pulsed laser irradiation. Opt. Laser Technol. 2011, 43, 138–142. [Google Scholar] [CrossRef]

- Kadolkar, P.B.; Watkins, T.R.; De Hosson, J.T.M.; Kooi, B.J.; Dahotre, N.B. State of residual stress in laser-deposited ceramic composite coatings on aluminum alloys. Acta Mater. 2007, 55, 1203–1214. [Google Scholar] [CrossRef]

- Trdan, U.; Skarba, M.; Porro, J.A.; Ocaña, J.L.; Grum, J. Application of massive laser shock processing for improvement of mechanical and tribological properties. Surf. Coat. Technol. 2018, 324, 1–11. [Google Scholar] [CrossRef]

- Dutta Majumdar, J.; Mordike, B.L.; Manna, I. Friction and wear behavior of Ti following laser surface alloying with Si, Al and Si+Al. Wear 2000, 242, 18–27. [Google Scholar] [CrossRef]

- Holmberg, K.; Matthews, A. Coatings Tribology, Properties, Mechanisms, Techniques and Applications in Surface Engineering; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Guo, X.W.; Chang, J.W.; He, S.M.; Ding, W.J.; Wang, X. Investigation of corrosion behaviors of Mg-6Gd-3Y-0.4Zr Alloy in NaCl aqueous solutions. Electrochim. Acta 2007, 52, 2570–2579. [Google Scholar] [CrossRef]

- Darabara, M.; Bourithis, L.; Diplas, S.; Papadimitriou, G.D. Corrosion and wear properties of composite coatings reinforced with TiB2 particles produced by PTA on steel substrate in different atmospheres. ISRN Corros. 2012, 2012, 898650. [Google Scholar] [CrossRef]

- Ferreira, S.C.; Rocha, L.A.; Ariza, E.; Sequeira, P.D.; Watanabe, Y.; Fernandes, J.C.S. Corrosion behaviour of Al/Al3Ti and Al/Al3Zr functionally graded materials produced by centrifugal solid-particle method: Influence of the intermetallics volume fraction. Corros. Sci. 2011, 53, 2058–2065. [Google Scholar] [CrossRef]

- Alkhateeb, E.; Ali, R.; Virtanen, S.; Popovska, N. Electrochemical evaluation of the corrosion behavior of steel coated with titanium-based ceramic layers. Surf. Coat. Technol. 2011, 205, 3006–3011. [Google Scholar] [CrossRef]

- Trdan, U.; Grum, J. SEM/EDS characterization of laser shock peening effect on localized corrosion of Al alloy in a near natural chloride environment. Corros. Sci. 2014, 82, 328–338. [Google Scholar] [CrossRef]

- Trdan, U.; Sano, T.; Klobčar, D.; Sano, Y.; Grum, J.; Šturm, R. Improvement of corrosion resistance of AA2024-T3 using femtosecond laser peening without protective and confining medium. Corros. Sci. 2018, 143, 46–55. [Google Scholar] [CrossRef]

- Krawiec, H.; Vignal, V.; Amar, H.; Peyre, P. Influence of the microstructure and laser shock processing (LSP) on the corrosion behaviour of the AA2050-T8 aluminium alloy. Corros. Sci. 2011, 53, 3215–3221. [Google Scholar]

- Diao, Y.; Zhang, K. Microstructure and corrosion resistance of TC2 Ti alloy by laser cladding with Ti/TiC/TiB2 powders. Appl. Surf. Sci. 2015, 352, 163–168. [Google Scholar] [CrossRef]

| Parameter | Sample Designation | ||

|---|---|---|---|

| Untreated Al Alloy | Laser Treated/13.3 (J/mm2) | Laser Treated/20 (J/mm2) | |

| Ecorr (mVSCE) | −744 ± 17 | −715 ± 12 | −720 ± 11 |

| Esw (mVSCE) | −701 ± 11 | −574 ± 8 | −555 ± 6 |

| Eprot (mVSCE) | −795 ± 14 | −754 ± 7 | −757 ± 13 |

| icorr (μA/cm2) | 29.4 ± 2.86 | 3.38 ± 0.35 | 3.12 ± 0.29 |

| PEF (%) | / | 88.50 | 89.39 |

| Esw − Ecorr (mV) | 43 ± 6 | 141 ± 4 | 165 ± 5 |

| Ecorr − Eprot (mV) | 51 ± 3 | 39 ± 5 | 37 ± 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ravnikar, D.; Trdan, U.; Nagode, A.; Šturm, R. Energy Density Effect of Laser Alloyed TiB2/TiC/Al Composite Coatings on LMZ/HAZ, Mechanical and Corrosion Properties. Metals 2020, 10, 411. https://doi.org/10.3390/met10030411

Ravnikar D, Trdan U, Nagode A, Šturm R. Energy Density Effect of Laser Alloyed TiB2/TiC/Al Composite Coatings on LMZ/HAZ, Mechanical and Corrosion Properties. Metals. 2020; 10(3):411. https://doi.org/10.3390/met10030411

Chicago/Turabian StyleRavnikar, Dunja, Uroš Trdan, Aleš Nagode, and Roman Šturm. 2020. "Energy Density Effect of Laser Alloyed TiB2/TiC/Al Composite Coatings on LMZ/HAZ, Mechanical and Corrosion Properties" Metals 10, no. 3: 411. https://doi.org/10.3390/met10030411

APA StyleRavnikar, D., Trdan, U., Nagode, A., & Šturm, R. (2020). Energy Density Effect of Laser Alloyed TiB2/TiC/Al Composite Coatings on LMZ/HAZ, Mechanical and Corrosion Properties. Metals, 10(3), 411. https://doi.org/10.3390/met10030411