2. Materials and Methods

Gas-atomized maraging 18Ni-300 steel powder (OPM Maraging, OPM Laboratory Co., Ltd., Kyoto, Japan) was used as the starting material. The morphology of the powder was investigated by scanning electron microscope (SEM, JSM-7200F, Jeol Inc., Tokyo, Japan). As shown in

Figure 1a, the particles of the powder were mostly spherical with few irregular shapes.

Figure 1b shows the particle size distribution, measured using a laser diffraction particle size analyzer (LS 13-320, Beckman Coulter, Miami, FL, USA). The powder had a bimodal particle size distribution with modal diameters centered at 7 and 40 μm, to obtain a good packing density.

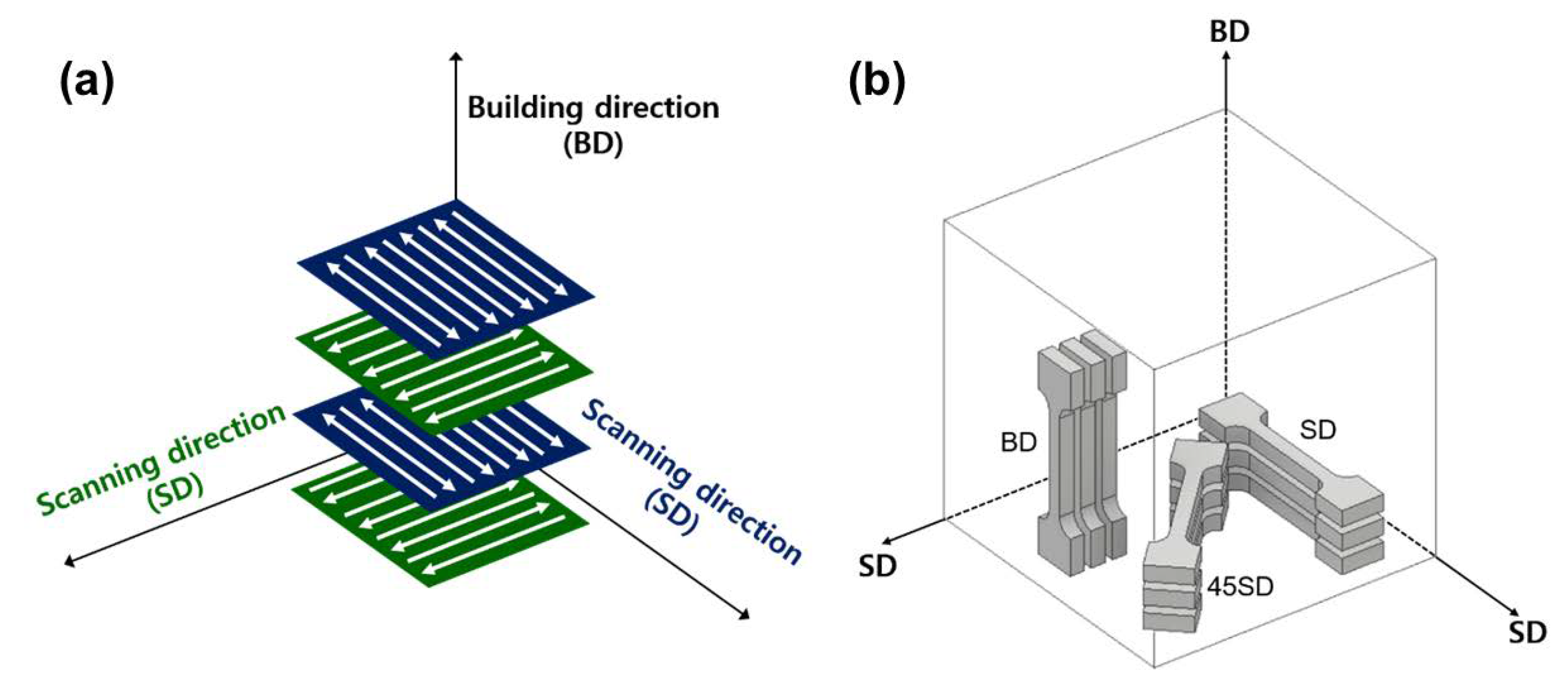

The samples were manufactured using an SLM type metal 3D printer (OPM250L, Sodick Co., Ltd., Kyoto, Japan), equipped with single-mode ytterbium fiber laser with a wavelength of 1,070 nm and a maximum laser output of 500 W (YLR-500-WC, IPG, Laser GmbH, Burbach, Germany). The SLM of the specimen was done under a laser power of 420 W, a scanning speed of 1,000 mm/s, and a hatch spacing of 0.1 mm with a lamination thickness of 0.04 mm. A so-called 90° rotate scanning strategy was used, i.e., the laser scanning lines are 90° tilted between each layer.

Figure 2a shows schematically the scanning strategy used for the SLM. The selective laser-melted samples had a cubic shape with dimensions of 50 × 50 × 50 mm

3, and then were cut into small-sized tensile specimens with a plate shape according to the KS B0801 standard [

18]. The gauge length, width, radius of fillet, and length of the reduced section were 9.8, 2, 4, and 13.2 mm, respectively. To study the anisotropy of the tensile property of the samples, three types of specimens were cut at different directions relative to the SLM building axis, as shown in

Figure 2b. The specimens having a tensile direction parallel to the building direction were designated as BD. The two other types of specimens had tensile directions normal and 45° to the laser scanning directions. These specimens were designated as SD and 45SD, respectively.

Post heat treatments of the specimens were performed in a box-type laboratory furnace. The specimens were wrapped in a protective heat-treatment foil to prevent oxidation of the sample surface. Some specimens underwent solution treatment (ST) for 2 h at two different temperatures of 750 and 850 °C and then aged at various temperatures of 400, 450, and 500 °C for 6 h. Other specimens were directly aged without ST at 450 °C for 6 h. Tensile tests were performed for the as-built and heat-treated specimens in a universal testing machine (RB 301 UNITECH-T, R&B Inc., Daejeon, Republic of Korea), with a constant loading rate of 0.1 mm/min. Strain gauges were attached to the specimens for elongation measurements.

Some test pieces were cut from the cubic block fabricated by SLM and underwent post heat treatments with the same conditions as used in the tensile specimens. The test pieces were ground and polished in order to observe the microstructure. Using the test pieces, phase compositions were determined using an X-ray diffractometer (XRD, EMPYREAN, PANalytical BV, Almelo, Netherlands) with Cu Kα radiation over a two-theta range from 20° to 80°. Vickers microhardness (Hv) was measured as the average of 5 separate tests at the surface of each specimen under a load of 0.1 kgf (HM-220A, Mitutoyo Corp., Kawasaki, Japan). The microstructures of the test pieces were investigated by optical microscope (OM, Eclipse E200, Nikon, Tokyo, Japan), SEM, and electron backscatter diffraction (EBSD, Aztec HKL, Oxford Inc., Abingdon, UK).

3. Results and Discussions

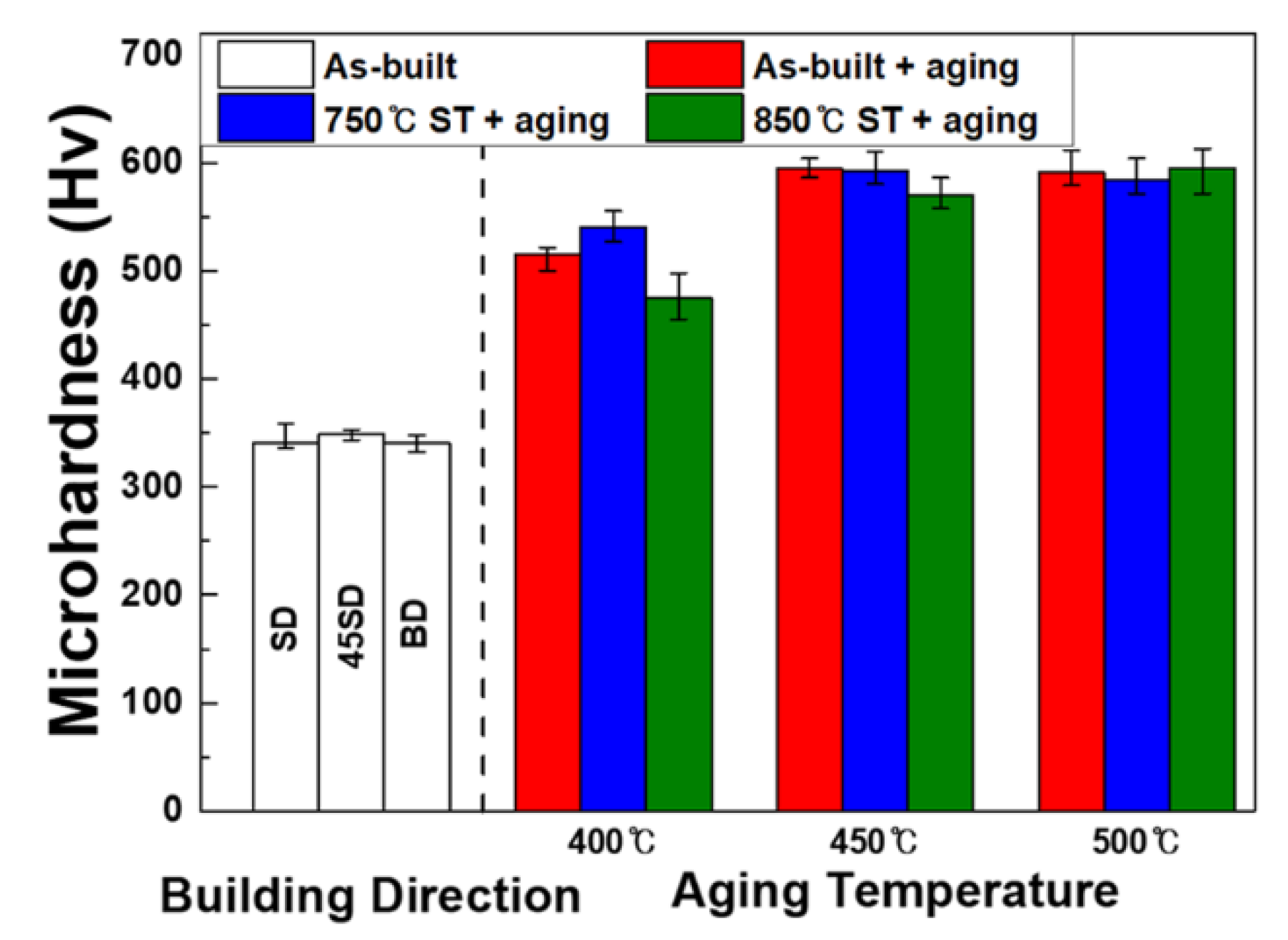

Figure 3 shows the hardness of the test pieces of the maraging steel with different building directions and heat treatment conditions. In the as-built conditions, the hardness of the test pieces remained practically the same regardless of the building direction, at around 340 Hv. This indicates that the effect of the mechanical anisotropy is negligible to the microhardness of the maraging steel fabricated by SLM.

In general, the hardness of the test pieces increased significantly with the heat treatments, as shown in

Figure 3. This behavior can be easily understood from the strengthening mechanism, i.e., by a uniform distribution of fine nickel-rich intermetallic precipitates during the aging of a ductile, low-carbon martensite structure, as previously shown by many other studies [

4,

8,

9,

11]. When a relatively low aging temperature of 400 °C was used, the hardness of the test pieces was raised to 475–545 Hv after 6 h aging, depending on the ST conditions. There was a pronounced difference in hardness among the test pieces that underwent post heat treatments with different ST conditions before the aging. The hardness of the test piece with ST at 850 °C for 2 h before the aging showed the lowest hardness of ~475 Hv, whereas the highest hardness was observed in the test piece treated by 750 °C ST before the aging, at ~545 Hv. When the aging temperature was raised to 450 °C, the hardness of the test pieces increased further, close to 600 Hv. Under this condition, only a slight difference existed in the hardness among the test pieces with different ST conditions, i.e., the sample treated by 850 °C ST showed lower hardness than the other samples by ~20 Hv. The effect of ST condition became negligible with the increased aging temperature of 500 °C, where the hardness of all the test pieces was around 600 Hv.

The results of hardness measurements showed that, almost regardless of the ST condition, a hardness value close to 600 Hv can be obtained by aging at 450 °C for 6 h. The 600 Hv value can be considered as the hardness of the fully hardened maraging steel fabricated by SLM, as no additional hardening effect was observed after increasing the aging temperature to 500 °C, as can be seen in

Figure 3. This indicates that an almost fully hardened state is achievable with an aging temperature of 450 °C for maraging steel fabricated by SLM. It is worth noting that the aging temperature of 450 °C is lower by 30–40 °C in comparison with the aging temperature used for the maraging steel fabricated by the conventional manufacturing process and SLM [

6,

8].

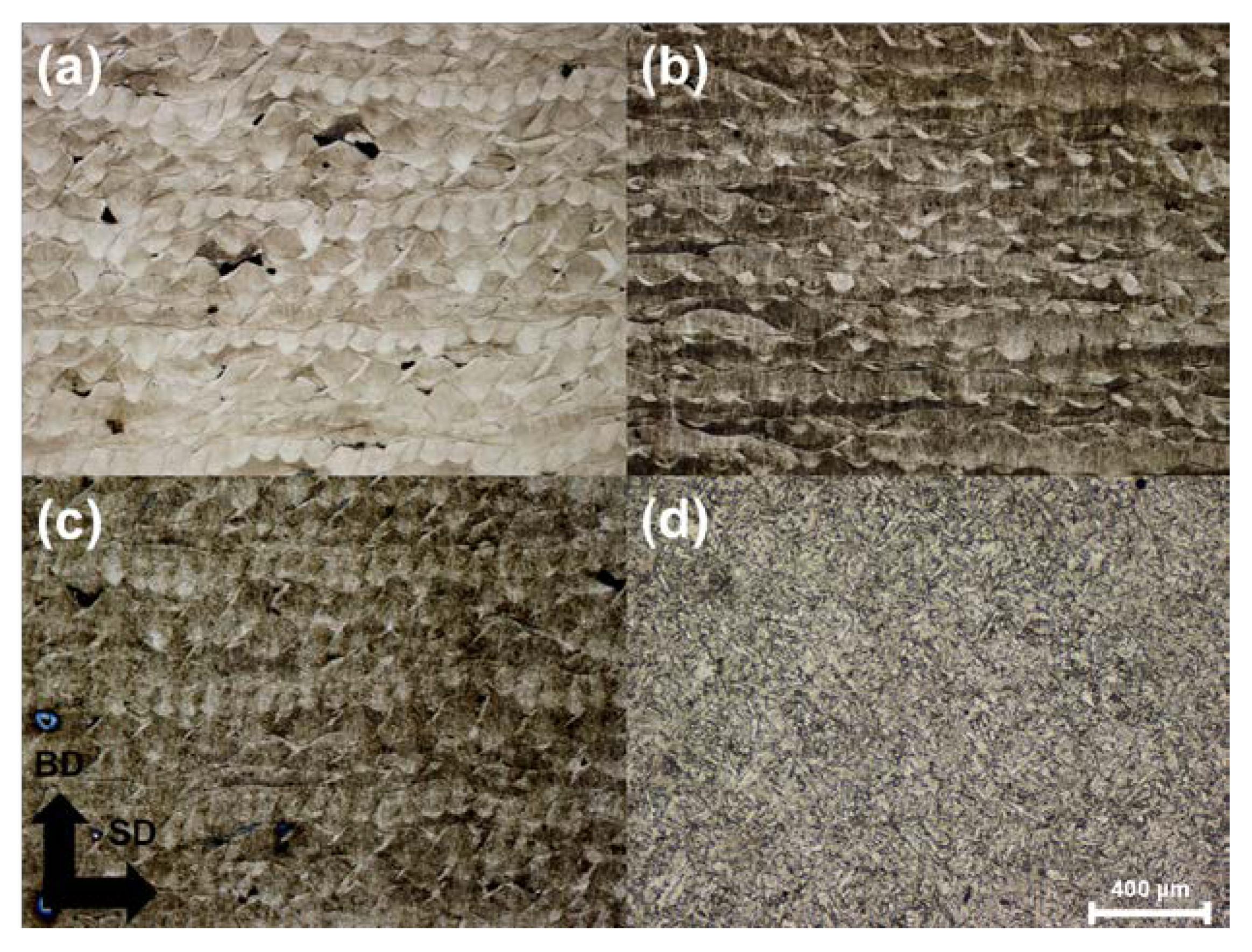

The OM images in

Figure 4 present the microstructural changes during the different heat treatments of the maraging steel samples fabricated by SLM.

Figure 4a shows the macroscopic microstructure in the as-built condition. The melt pool boundaries caused by the 90° rotate scanning strategy can be clearly seen in the microstructure where laser scan tracks of every second layer run parallel. When only the aging heat treatment was done at 450 °C without ST, the melt pool boundaries remain clearly visible, as can be seen in

Figure 4b. The melt pool boundaries became less noticeable when 750 °C ST was done before the aging, as shown in

Figure 4c. The boundaries were no longer visible after ST at 850 °C (

Figure 4d).

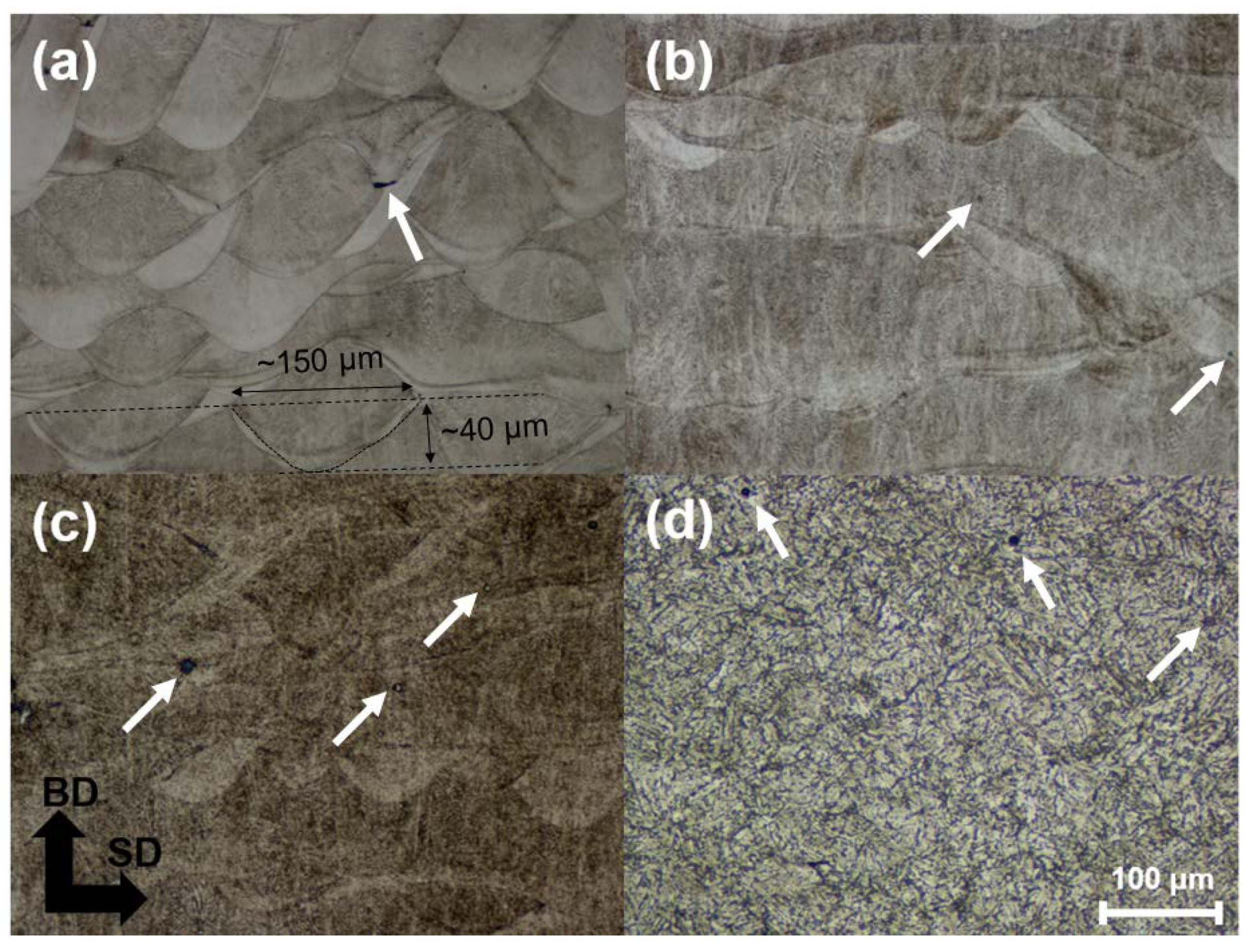

Figure 5 shows higher magnification OM images of the same microstructures shown in

Figure 4. As can be seen in

Figure 5a, the height of the bead was approximately 40 μm, which is equal to the lamination thickness used in the SLM process. The width of the bead was about 150 μm. In the microstructures of the as-built and the heat-treated samples, coarse precipitates are visible in the microstructures, some of which are indicated by white arrows in

Figure 5. In the as-built condition, few precipitations occurred along the melt pool boundaries, as shown in

Figure 5a. In the sample aged at 450 °C without ST, some spherical precipitates are also observed both inside the bead and near the melt pool boundaries (

Figure 5b). When 750 °C ST was done before the aging, further coarsened spherical precipitates were observed in comparison with the sample without the ST, as shown in

Figure 5c. Finally, 850 °C ST and 500 °C aging produced lath-type microstructure by fine precipitates with a few spherical precipitates, as shown in

Figure 5d.

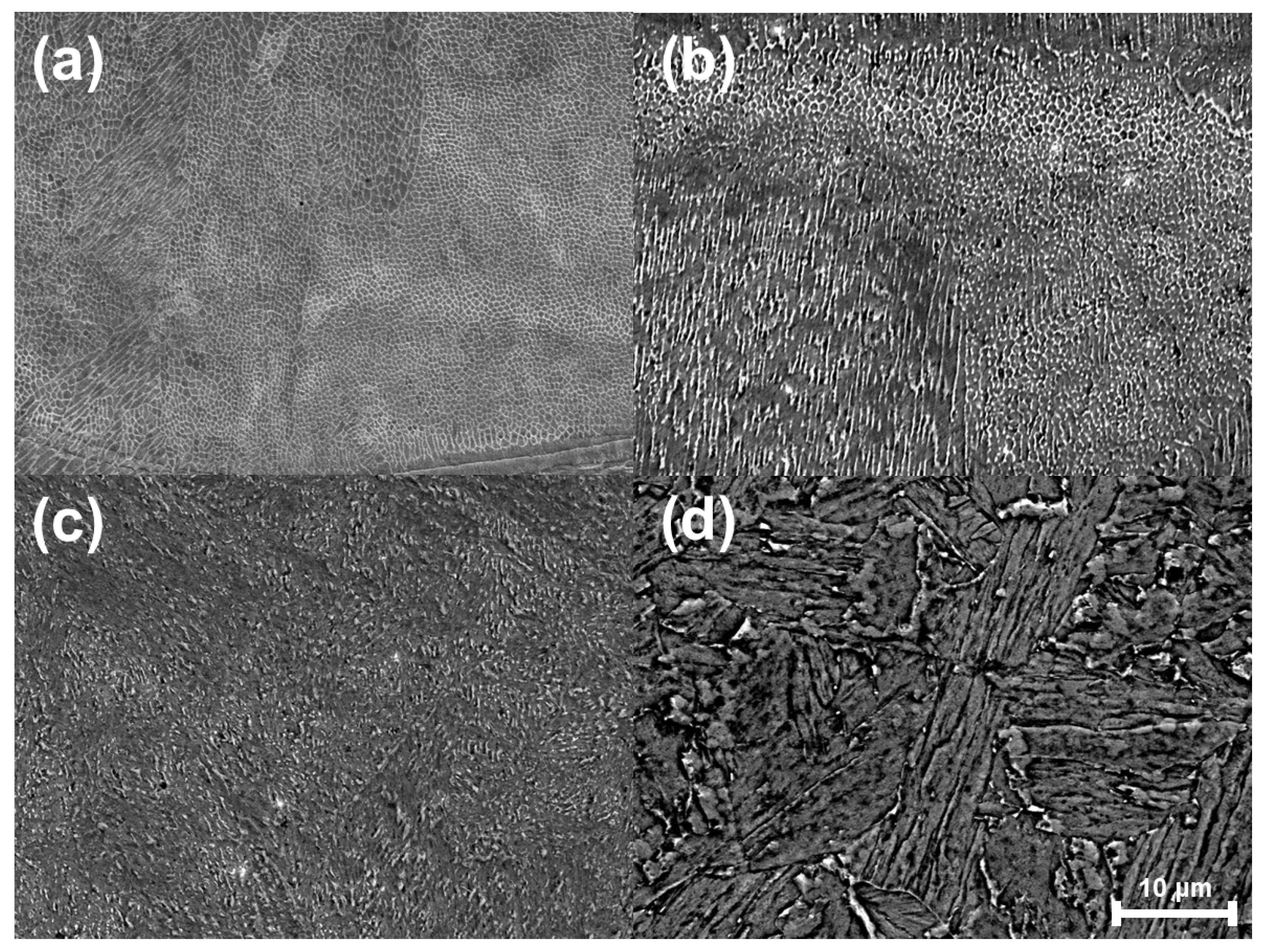

Figure 6 shows high-magnification SEM images (×2500) of the maraging steel samples. Fine cell structures are clearly visible in the microstructures of the as-built and the sample with only aging at 450 °C without ST. It was found that the cell size became slightly larger with the aging heat treatment at 450 °C, as shown in

Figure 6a,b. The samples that underwent the ST before the aging heat treatment did not show a clear cell structure. Very fine intermetallic precipitates are clearly observed in the sample aged at 450 °C with 750 °C ST, as shown in

Figure 6c, whereas comparably large precipitates are shown in the sample aged at 500 °C with 850 °C ST (

Figure 6d).

In order to identify the chemical composition of the coarse precipitates observed in

Figure 5, energy dispersive X-ray mapping was performed.

Figure 7a–e shows the chemical composition maps near the precipitate formed along the melt pool boundary in the as-built condition. It clearly shows that the precipitate contained no other metallic elements nor carbon except a high concentration of titanium. A similar observation was made by Kang et al. [

19], who found a Ti-rich region near melt pool boundaries in SLM-processed maraging steel. One possible explanation for the formation of this precipitate is the segregation of titanium at the melt pool boundary during rapid solidification in the SLM process. The spherical precipitate formed during the heat treatment is also identified as the titanium-rich phase, as shown in

Figure 7f–j. Although the microstructural origin of this type of precipitate is still not fully understood, it is known that the formation of this precipitate is harmful to the mechanical properties of the SLM-processed maraging steel as it can act as the crack initiation site [

20]. In

Figure 7f, some spherical holes are also observed which are thought to be due to the removal of the spherical precipitates during the sample preparation. The lath-shaped fine precipitates are also distinguished in

Figure 7f, which are presumably nickel intermetallic compounds such as Ni

3Al, Ni

3Ti, Ni

3Fe, or Ni

3Mo [

8,

9]. However, no significant difference in the chemical composition maps could be found near the lath-shaped precipitates, probably because of their small size.

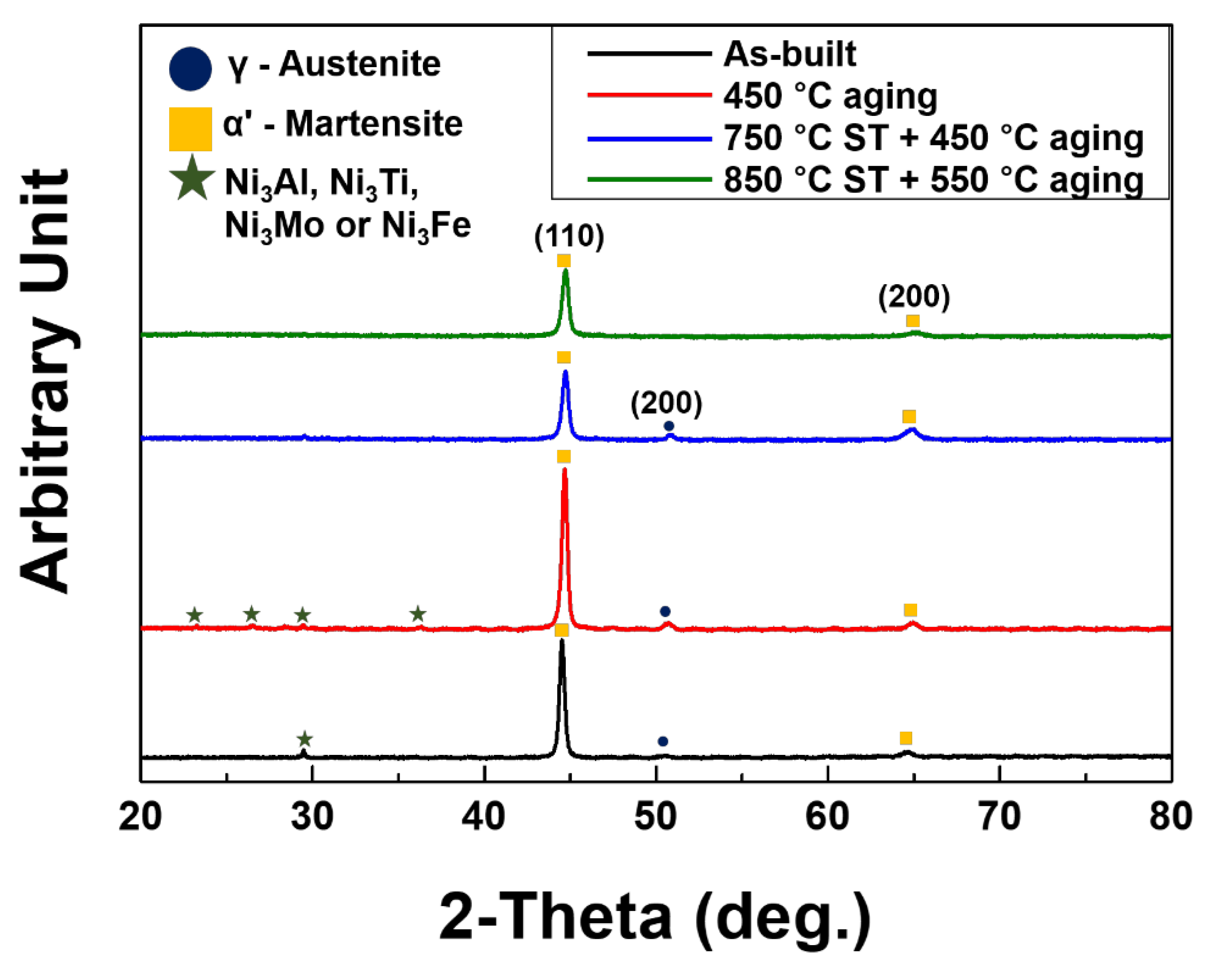

Figure 8 shows XRD patterns for the as-built and differently heat-treated maraging steel samples fabricated by SLM. The major diffraction peak shown in the patterns correspond to the α′-martensite (body-centered cubic) phase for all the samples including the as-built sample, indicating that the maraging steel produced by SLM has an almost full martensite microstructure in the as-built condition due to the rapid cooling. There is a small γ-austenite (face-centered cubic) peak in the as-built, 450 °C aged without ST, and 450 °C aged after 750 °C ST samples, reflecting that the amount of residual austenite is small in the microstructure. which disappears when the sample was aged at 500 °C after 850 °C ST. There are other small peaks corresponding to the nickel intermetallic compounds such as Ni

3Al ((001)-24.94°, (101)-38.52°), Ni

3Ti ((101)-22.84°), Ni

3Fe ((001)-25.08°, (101)-38.75°), or Ni

3Mo ((101)-26.71°, (200)-35.48°), at the positions marked by star signs in

Figure 8. The exact type of the precipitate was difficult to be distinguished from the XRD patterns since the main peaks are close to each other. However, all the small peaks in the range between 20°and 40° are expected to represent nickel intermetallic compounds. These peaks were most clearly seen in the sample aged at 450 °C without ST, but the same peaks were also noticeable in all the other samples. No additional peak occurred that could be indexed to the Ti-rich precipitates, probably due to their small volume fraction.

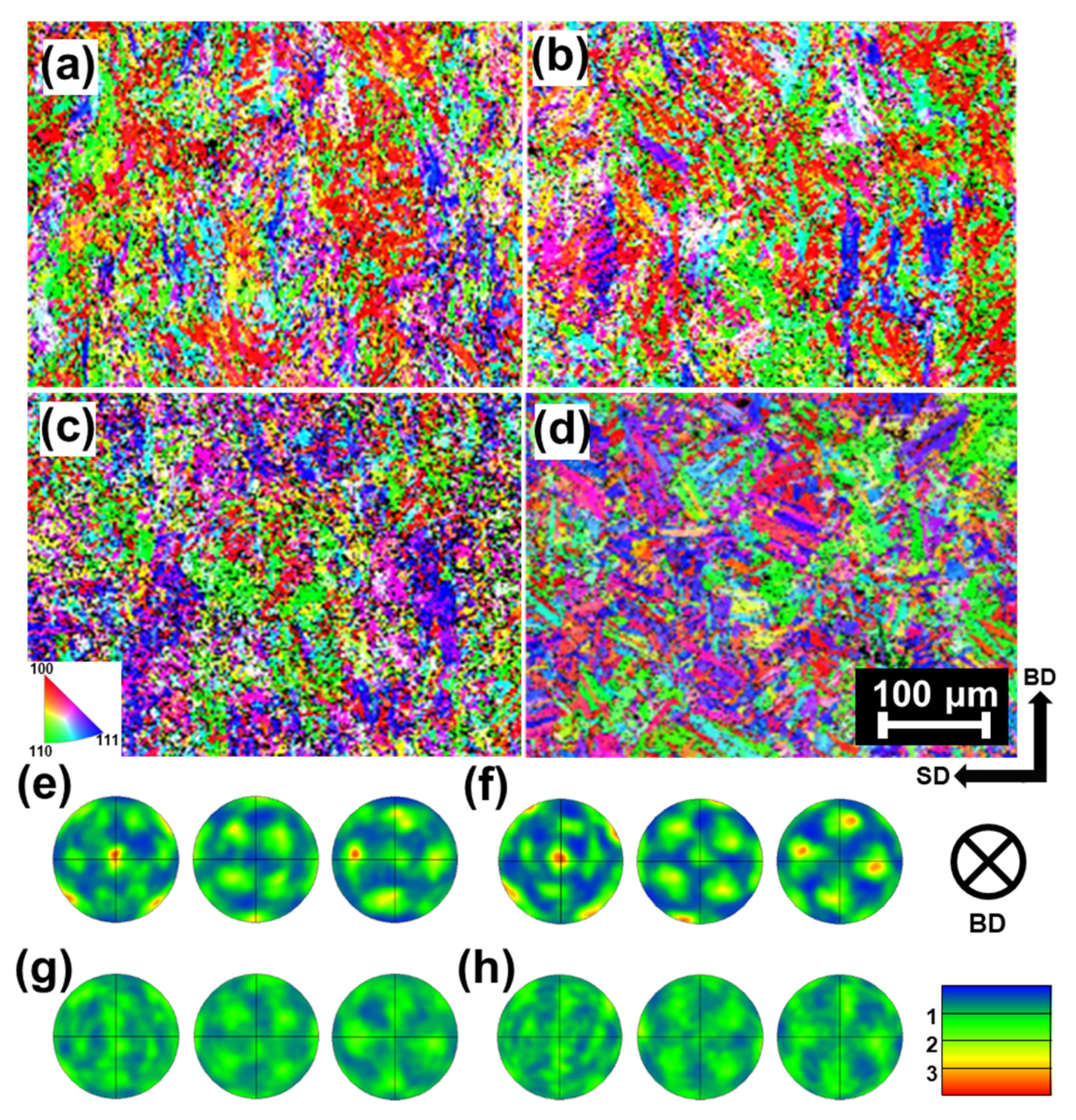

The crystallographic texture analysis was conducted using the EBSD patterns and pole figures for the maraging steels produced by SLM with different heat treatment conditions. For the α′ phase, EBSD BD-inverse pole figure maps and (100), (101), and (111) pole figures are presented in

Figure 9. The inverse pole figure maps shown in

Figure 9a-d represent the orientation of the grains along the BD and the center of all pole figures given in

Figure 9e–h is parallel to the BD of the maraging steel samples produced by SLM. The texture in the as-built condition presented in

Figure 9a,e shows that a clear <100> as well as <110> alignment occurred in the building direction during the SLM process. This reveals that the γ phase texture was formed during the solidification and then crystallographic transformations from γ to α′ phase happened with variant selections. When only 450 °C aging heat treatment was done without ST, the texture was retained almost completely, as shown in

Figure 9b,f. The texture was significantly weakened when ST was done before aging treatment, as is clearly shown in

Figure 9g,h.

When ST was done at 750 °C, there was no pronounced grain growth or grain rearrangement, as observed by comparing the microstructures shown in

Figure 9a–c. However, when the sample was aged at 500 °C after 850 °C ST, the former complex microstructure that occurred by the SLM process disappeared and coarser martensite grains were produced, as shown in

Figure 9d. This may indicate the recrystallization of the γ phase during the ST at 850 °C.

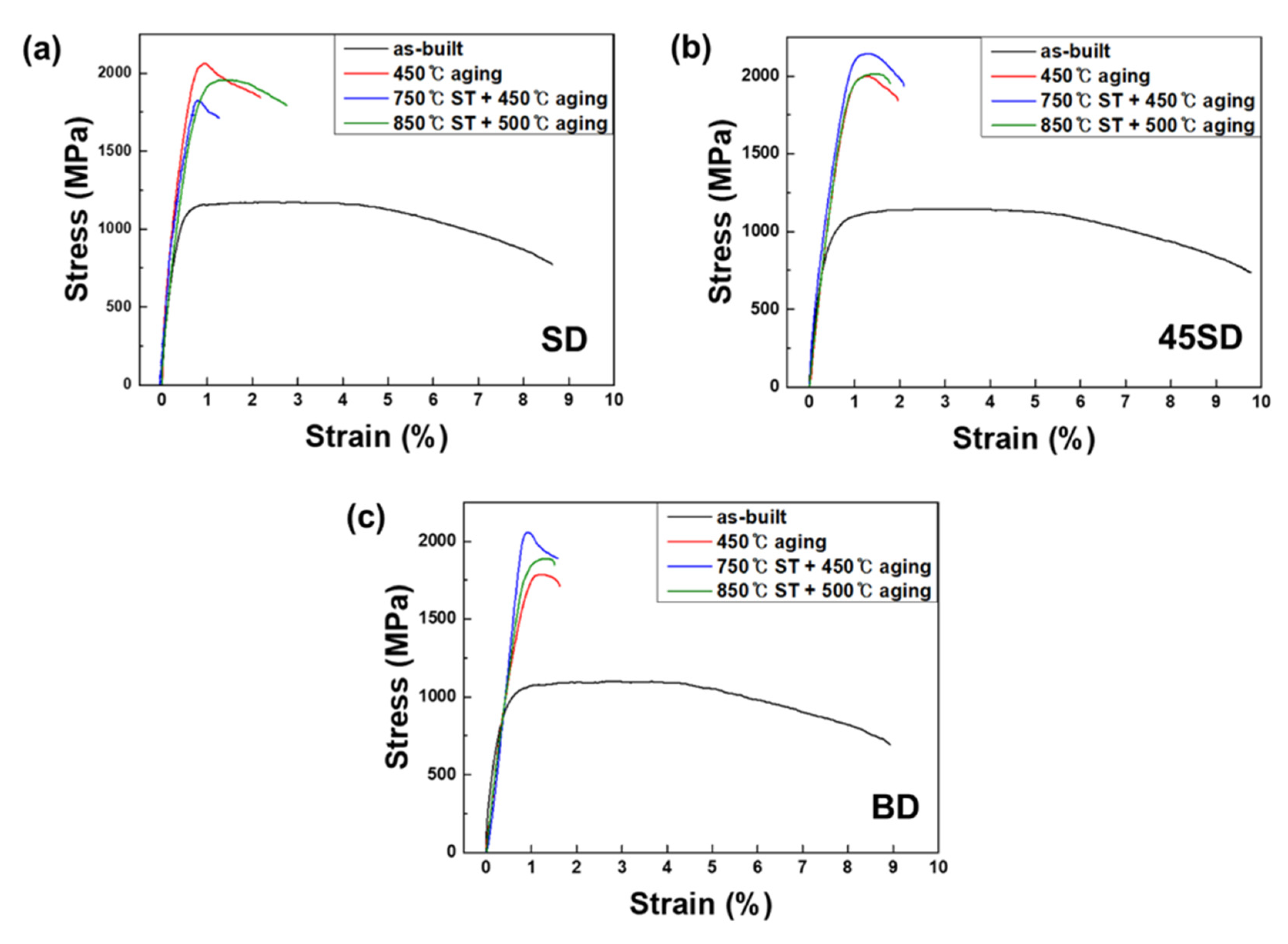

Figure 10 shows the tensile stress–strain curves for the maraging steels produced by SLM with different heat treatments, along with different directions. For all tensile directions tested, the samples in the as-built condition were characterized by relatively high ductility and low strength, with elongations at break of 8.5–9.5% and yield strength of around 1,000 MPa. Heat-treated samples generally exhibited very high strength of up to 2.1 GPa and low elongation less than 3%, indicating that improvements in the alloy’s strength were achieved by fine nickel-rich intermetallic precipitates upon aging heat treatments [

8,

9]. As shown in the figure, it is evident that the heat treatment affects differently the stress–strain behavior of the different sample directions. Along the SD, the yield strength of the maraging steel samples was the highest when only the aging heat treatment was performed at 450 °C without ST. The strength parallel to the 45SD and BD was the highest in the case when 450 °C aging was done after 750 °C ST.

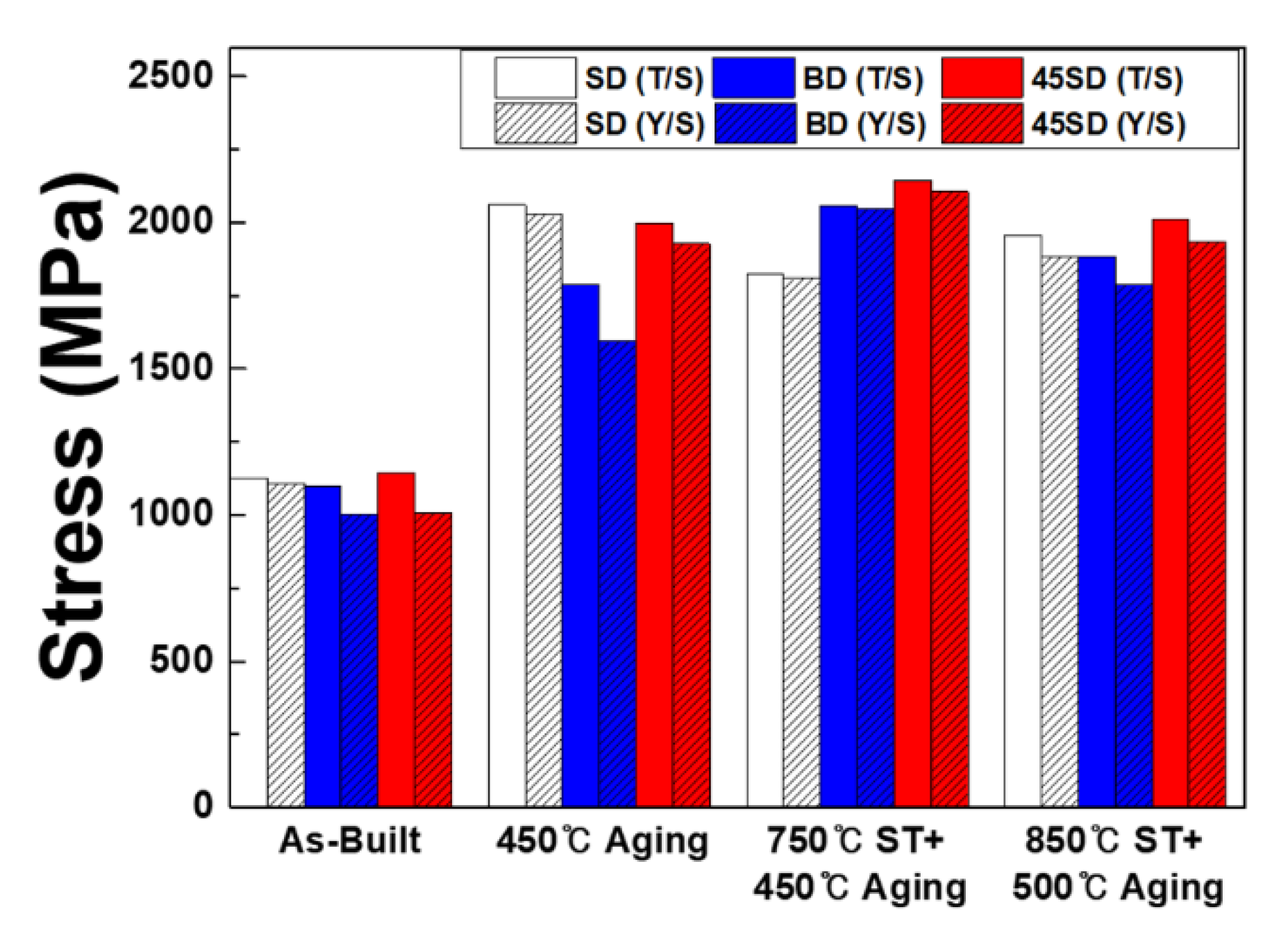

The anisotropic tensile properties of the maraging steels produced by SLM are shown in

Figure 11. In the as-built condition, the results demonstrate a clear anisotropy of the yield strength, i.e., the yield strength of the sample was higher in the SD than the other two directions in an aged specimen at 450 °C. The tensile strength of the sample in the as-built condition was almost isotropic. When the samples were aged at 450 °C without ST, both the yield and tensile strength depended significantly on the tensile direction. The SD and 45SD samples showed markedly higher strength than the BD sample in this case. The strong anisotropy of the as-built sample and the sample aged at 450 °C without ST can be easily understood by considering the high degree of crystallographic texture of these samples. However, the sample aged at 450 °C after 750 °C ST also showed a pronounced anisotropy even though the texture was significantly weakened by this heat treatment. In this case, both yield and tensile strengths were significantly lower in the SD than the other two directions. This indicates that the anisotropy of the maraging steel produced by SLM is not solely from the crystallographic texture but also from the other microstructural factors such as the grain morphology. The samples aged at 500 °C after 850 °C ST showed much less anisotropy in comparison with the sample aged at 450 °C after 750 °C ST. On the other hand, the grain morphology was changed significantly by the heat treatment in this case, as shown in

Figure 9d. This observation supports the fact that the strong mechanical anisotropy of the maraging steel produced by the SLM process is associated with both the unique grain morphology as well as the strong crystallographic texture. Moreover, it is revealed that the strength of the maraging steel is influenced mainly by the precipitation hardening rather than the cell structure. Although the sample only aged at 450 °C without ST showed much finer cell size than the sample aged at 500 °C after 850 °C ST as shown in

Figure 6, the tensile properties after these two different heat treatment conditions showed comparable strengths.

The results presented in

Figure 10 and

Figure 11 indicate that a different heat treatment condition has to be considered to obtain the highest strength of the maraging steel fabricated by SLM. If the highest mechanical strength is required in a direction parallel to the SD direction, the maraging steel should be heat treated only by aging at 450 °C without ST. However, 450 °C aging followed by 750 °C ST would be favorable if the final component is expected to bear the maximum applied load in the BD direction. Another important characteristic of the maraging steel produced by SLM is that the highest strength can be achieved by aging and solution heat treatment temperatures lower than commonly used temperatures, i.e., 500 and 850 °C for aging and solution heat treatments, respectively. This behavior is consistent with the hardness changes observed in

Figure 3, where the highest hardness could be achieved using heat treatment temperatures significantly lower than the commonly used temperatures. This is presumably due to the very fine cell structure of the maraging steel produced by SLM, as shown in

Figure 6a, because the cell boundaries can act as the preferred nucleation sites for precipitates. A finer microstructure in the maraging steel produced by SLM than that produced by conventional methods can provide more nucleation sites for the precipitates and, consequently, can lead to a lower aging temperature for the precipitation hardening.

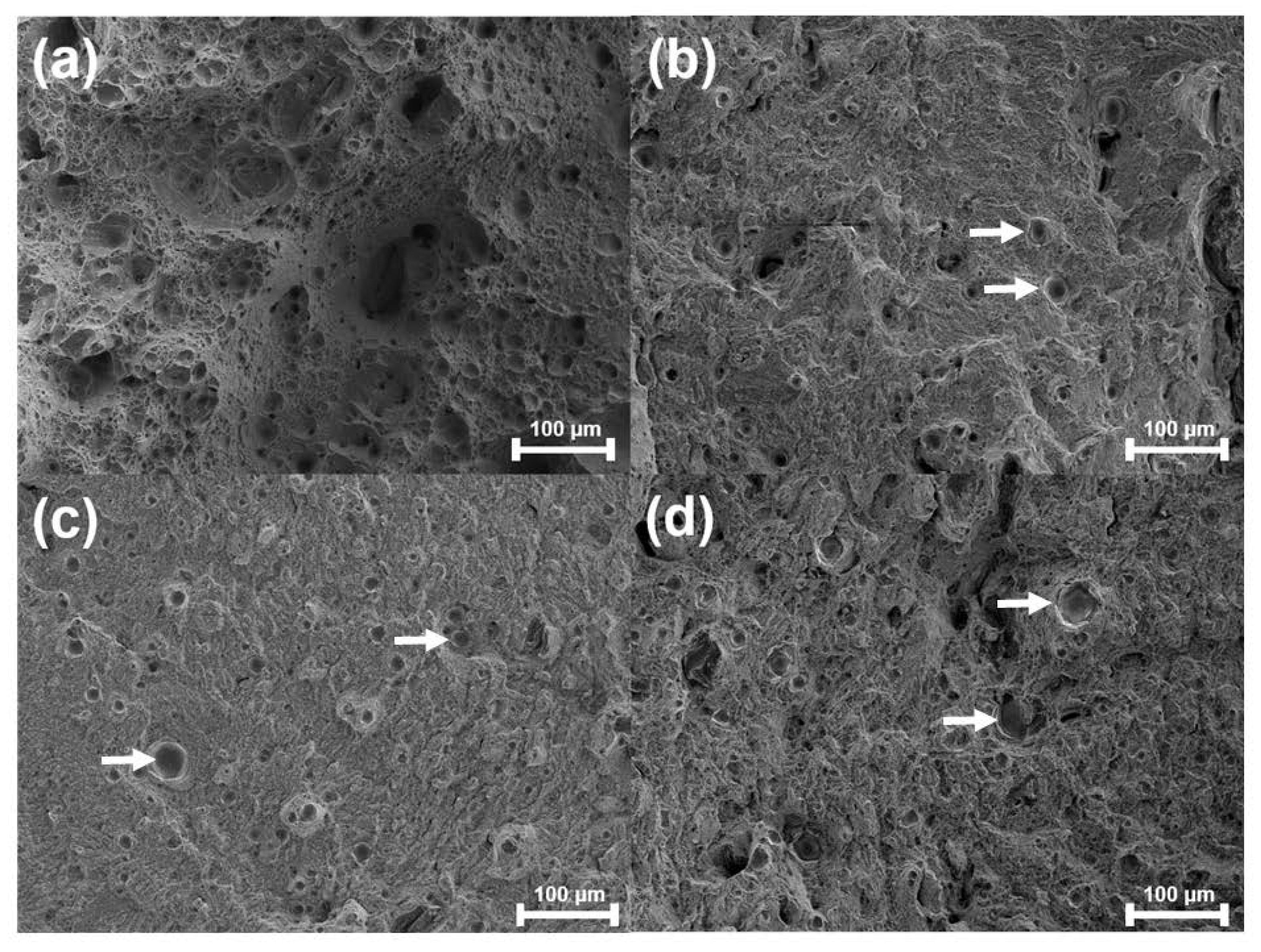

Fractography was performed after the tensile tests using SEM and no noticeable difference was observed between the samples fractured in different directions.

Figure 12 shows the comparison of the fractographic SEM images of the BD samples with different heat treatment conditions. The results are somewhat similar to the previous studies [

4,

9], that the as-built sample reveals a ductile fracture mechanism with dimple-like features, whereas mixed ductile and quasi-cleavage fracture surfaces are observed in all the heat-treated samples. Moreover, the three differently heat-treated samples have very similar fractographies, as shown in

Figure 12b–d. This, together with the observation that the elongation at break does not rely much on the heat treatment conditions, as shown in

Figure 10, reveals that the same failure mechanism is in operation in all the three samples regardless of the heat treatment condition. The fracture surfaces of the heat-treated samples show a large number of coarse spherical precipitates, as indicated by white arrows in

Figure 12. The spherical precipitates appearing in the fracture surface were larger in

Figure 12d than in

Figure 12b,c, indicating the coarsening of spherical precipitates during the heat treatment at high temperature. In

Figure 12c,d, some precipitates as large as 50 μm are also observed in the fractography, which are apparently much larger than the precipitates observed in the cross-sectional micrographs shown in

Figure 4 and

Figure 5. One possible reason for this apparent difference is that the cracks are generated along the matrix/precipitate interfaces, which can make the whole precipitate visible on the fracture surface and the apparent size of the precipitates larger than in the cross-sectional images. This is indicative of cracks propagating along the coarse spherical precipitates, which is presumably responsible for the brittle fracture behavior of the heat-treated samples.