Microstructure and Mechanical Properties of M50 Steel by Combining Cold Rolling with Austempering

1. Introduction

2. Experiments and Methods

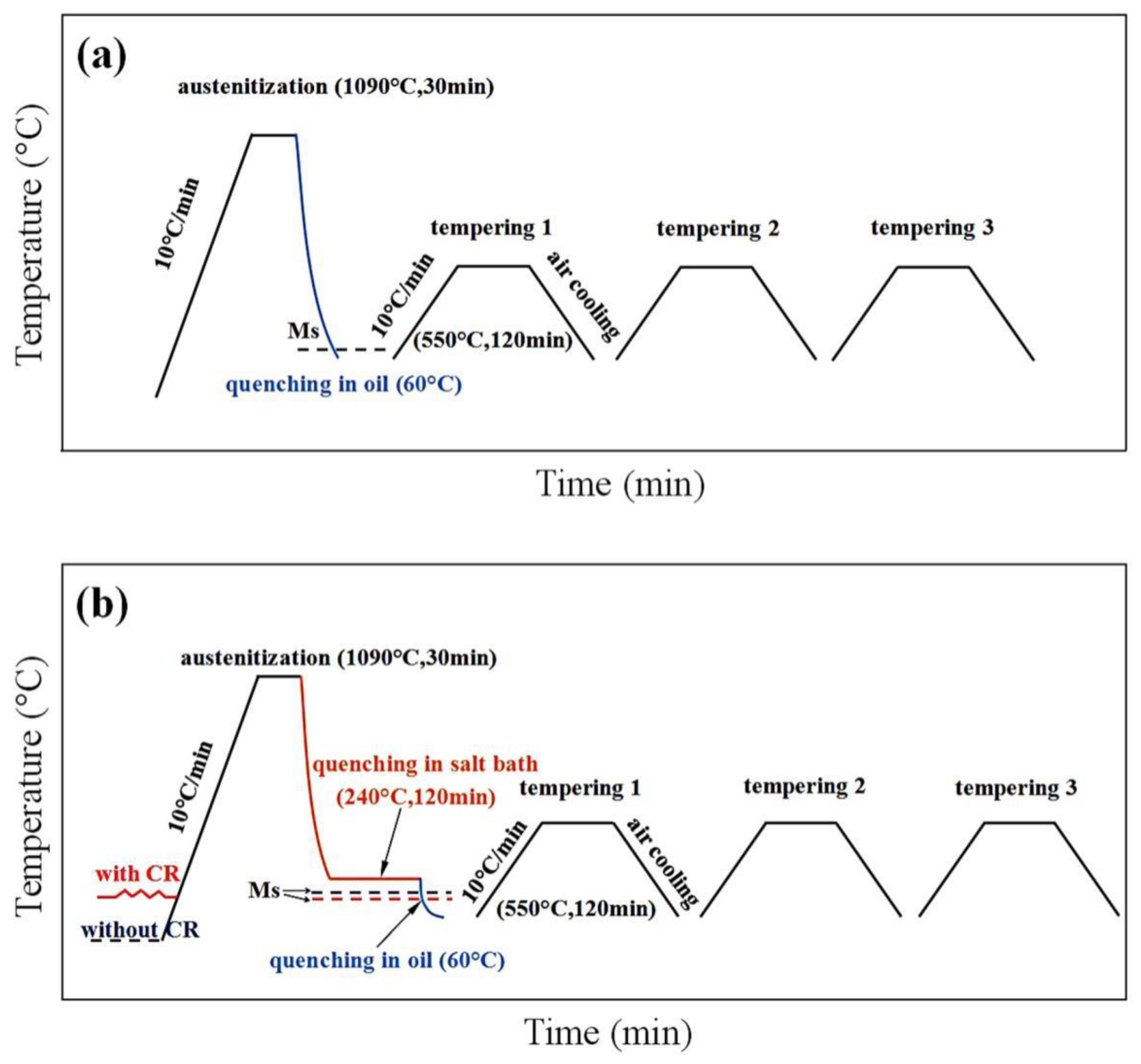

2.1. Specimen Preparation

2.2. Microstructure Characterization

2.3. Mechanical Properties Determination

3. Results and Discussion

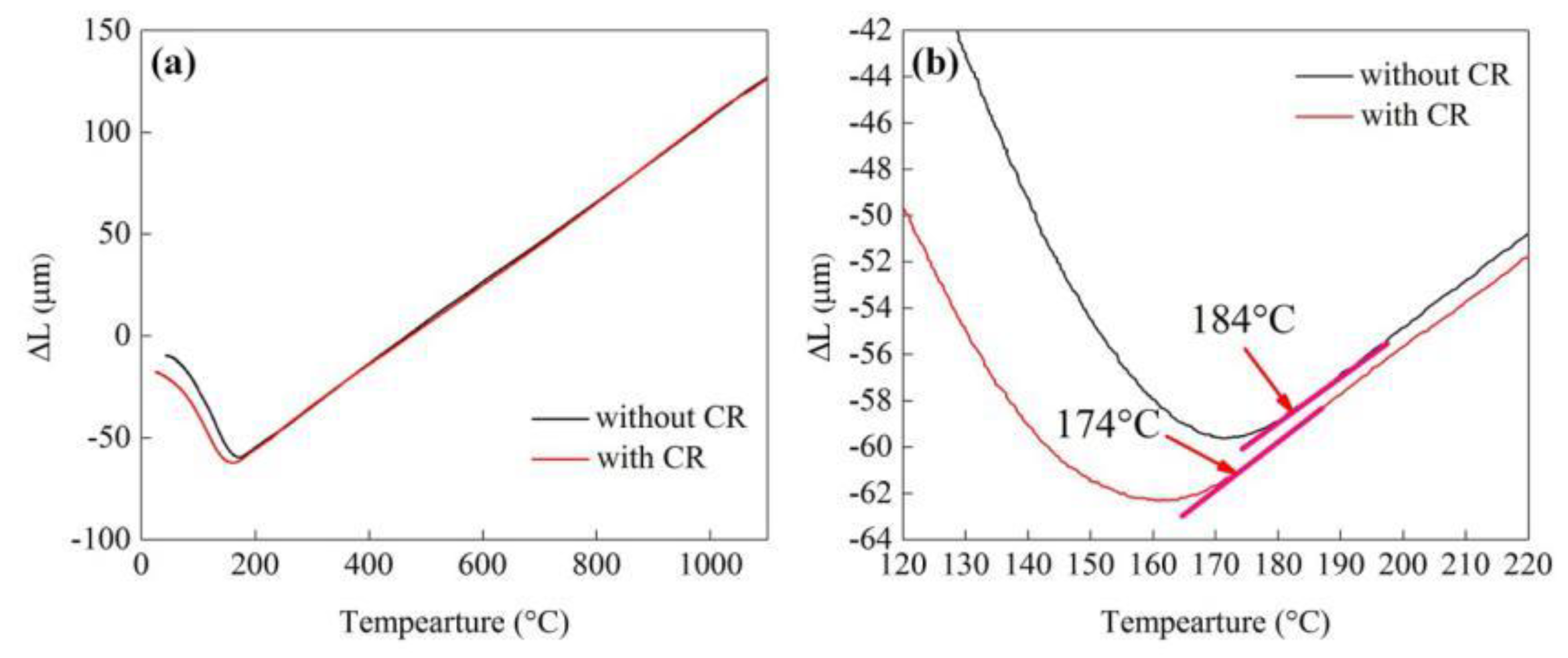

3.1. Dilatometric Analysis

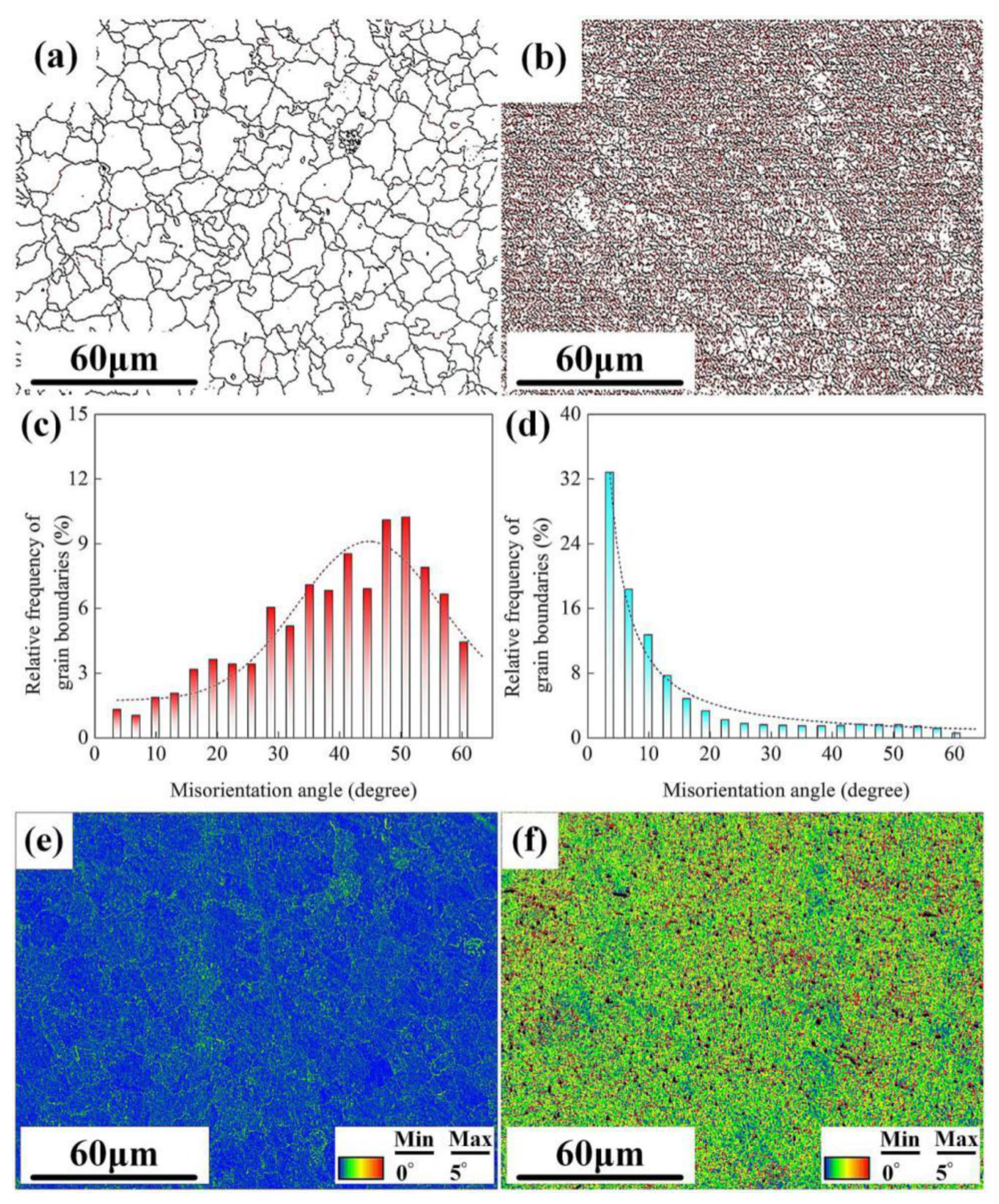

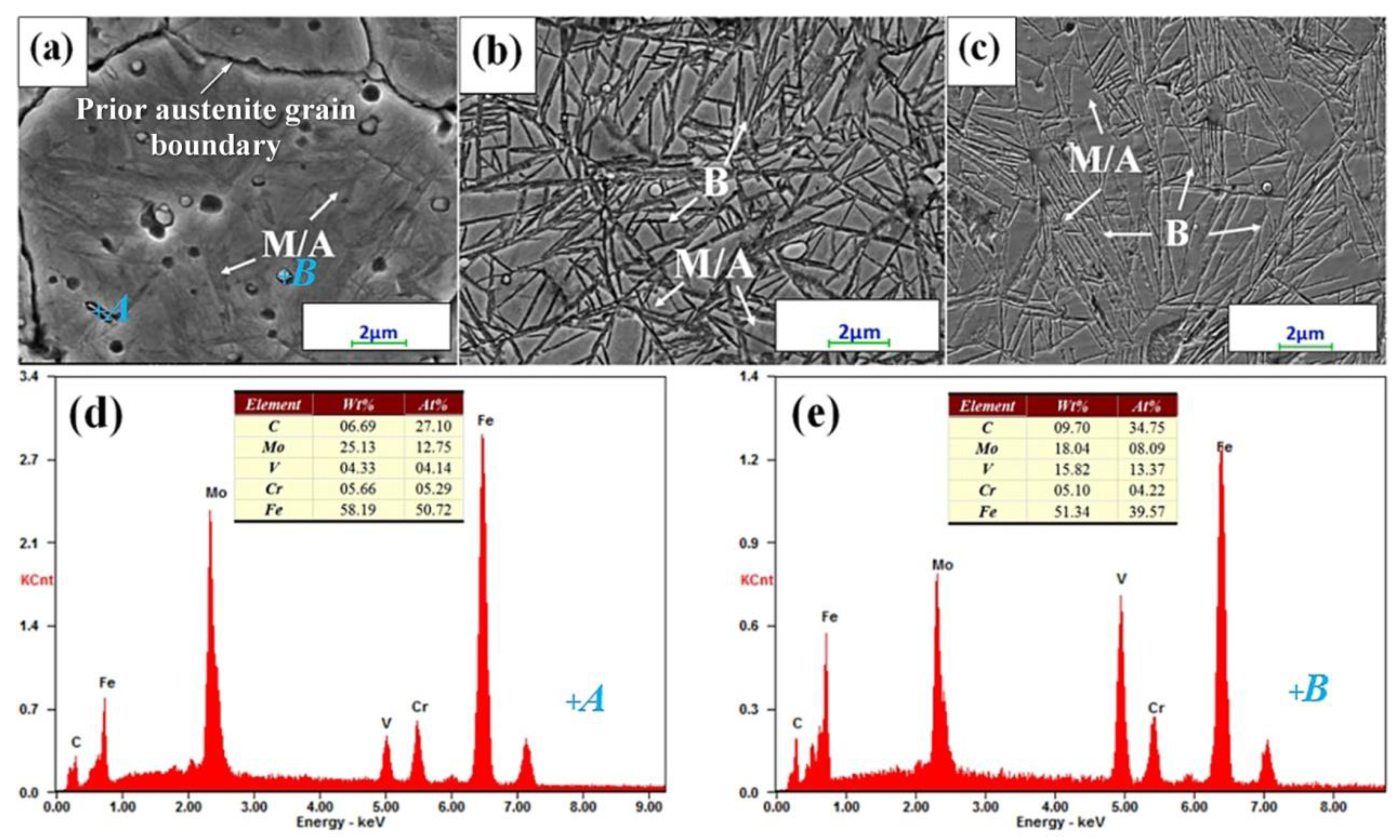

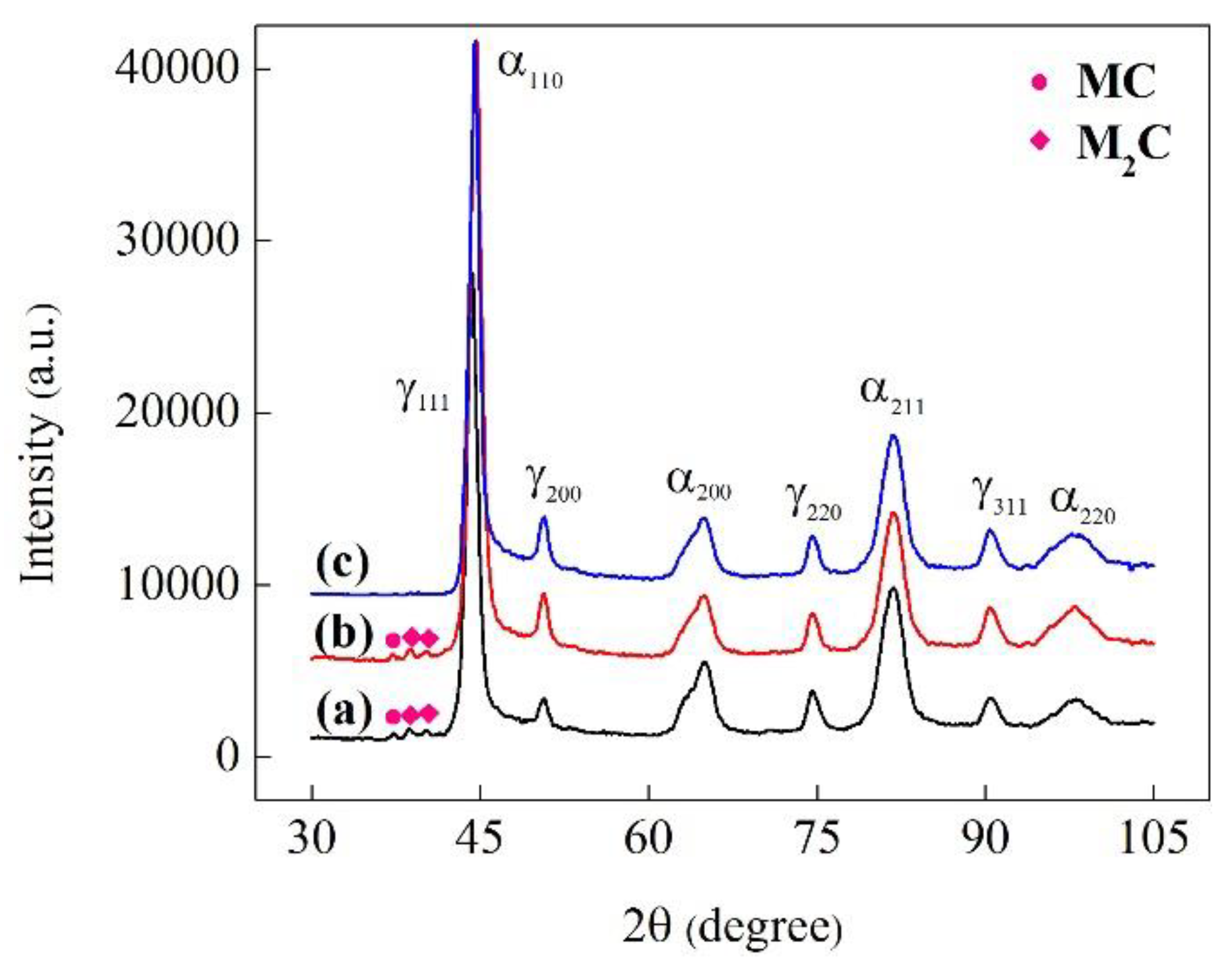

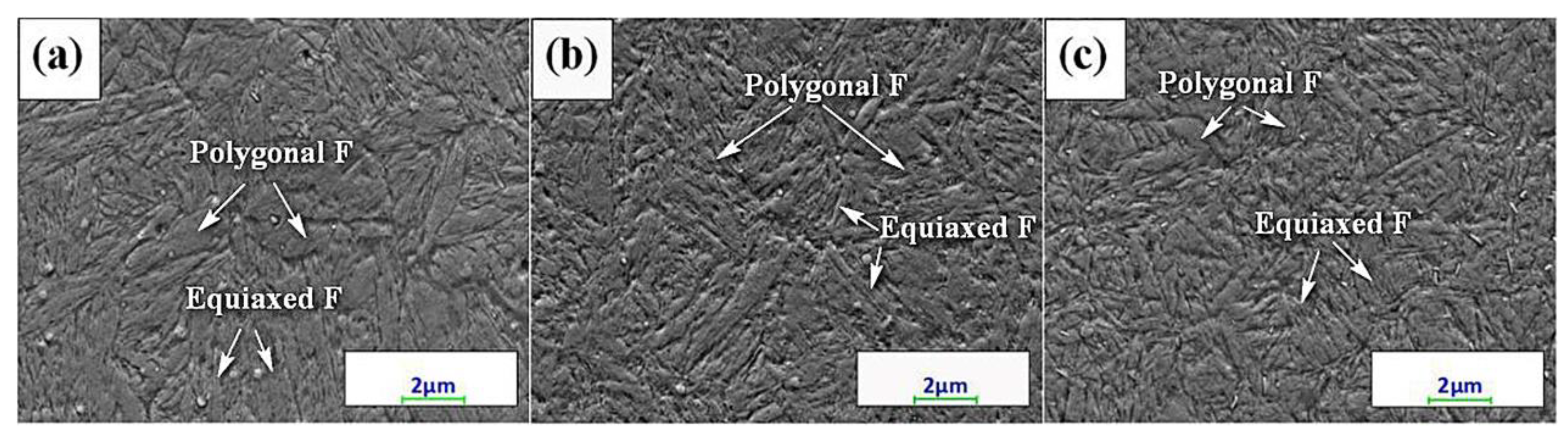

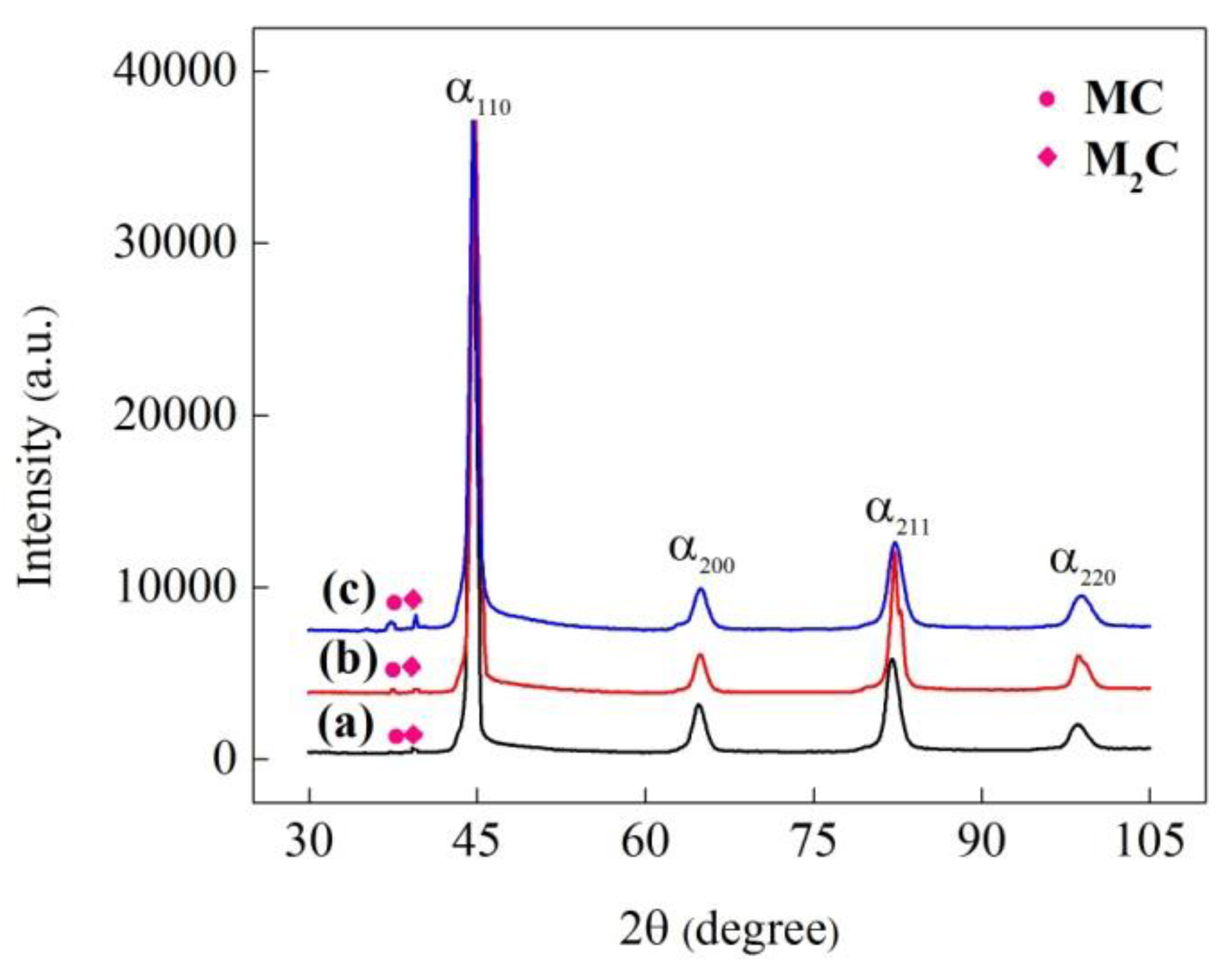

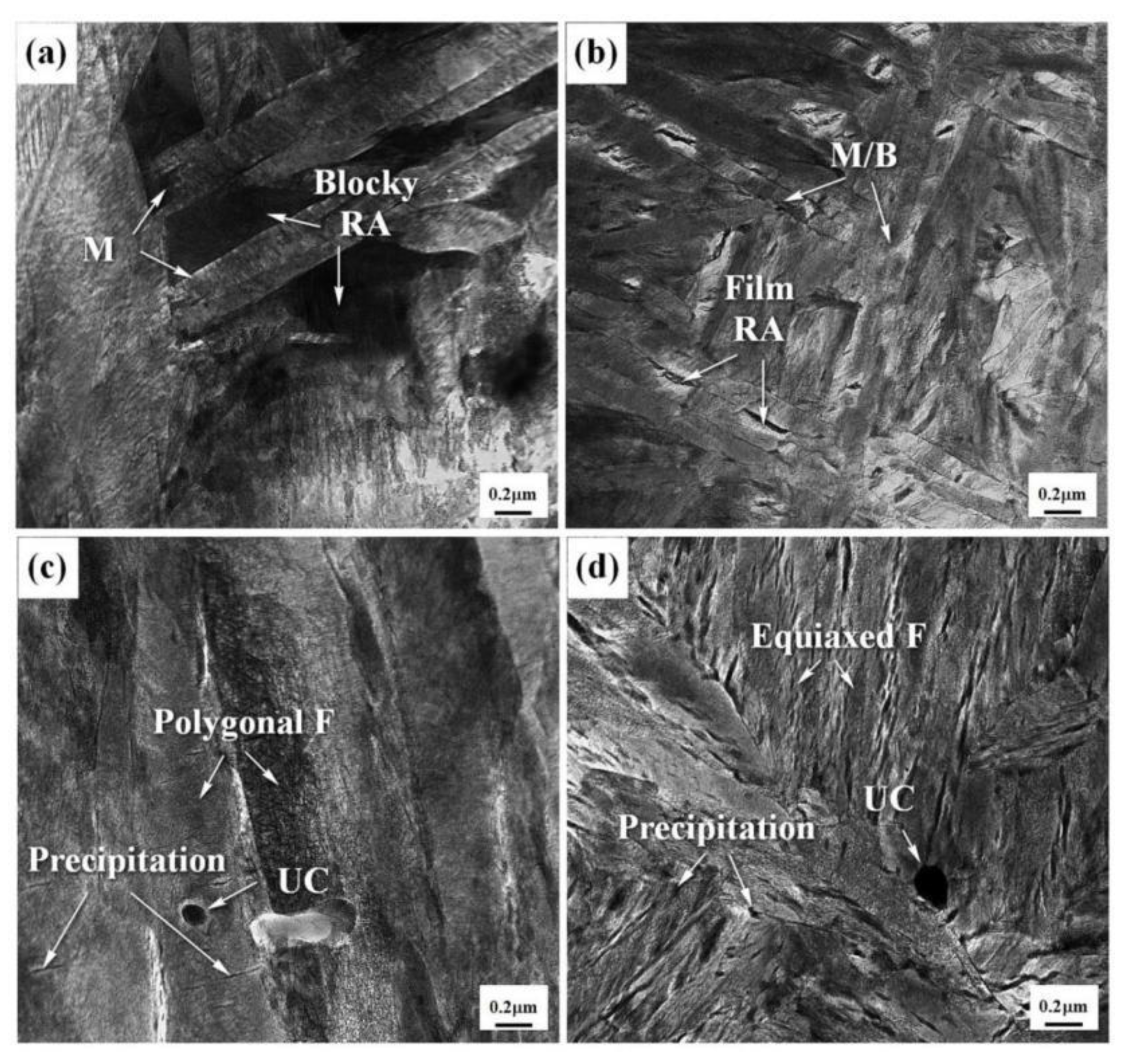

3.2. Microstructure Observation

3.3. Mechanical Properties

4. Conclusions

- (1)

- The microstructural observation shows that CR refines the thickness of bainite sheaves, which would contribute to the formation of ultrafine equiaxed ferrite during subsequent tempering. Meanwhile, it is also found that more carbides precipitated within the ferrite and along ferrite-austenite interfaces.

- (2)

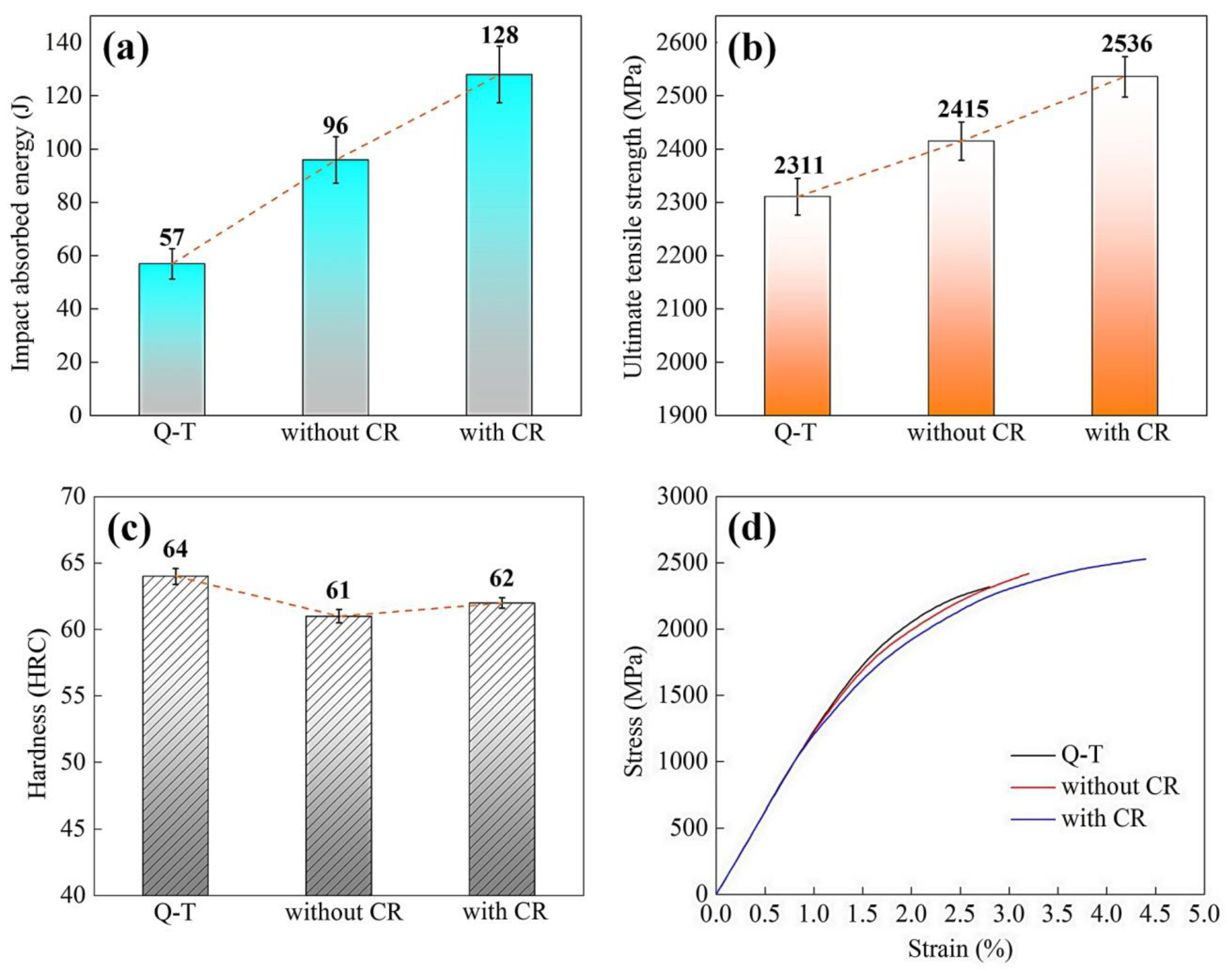

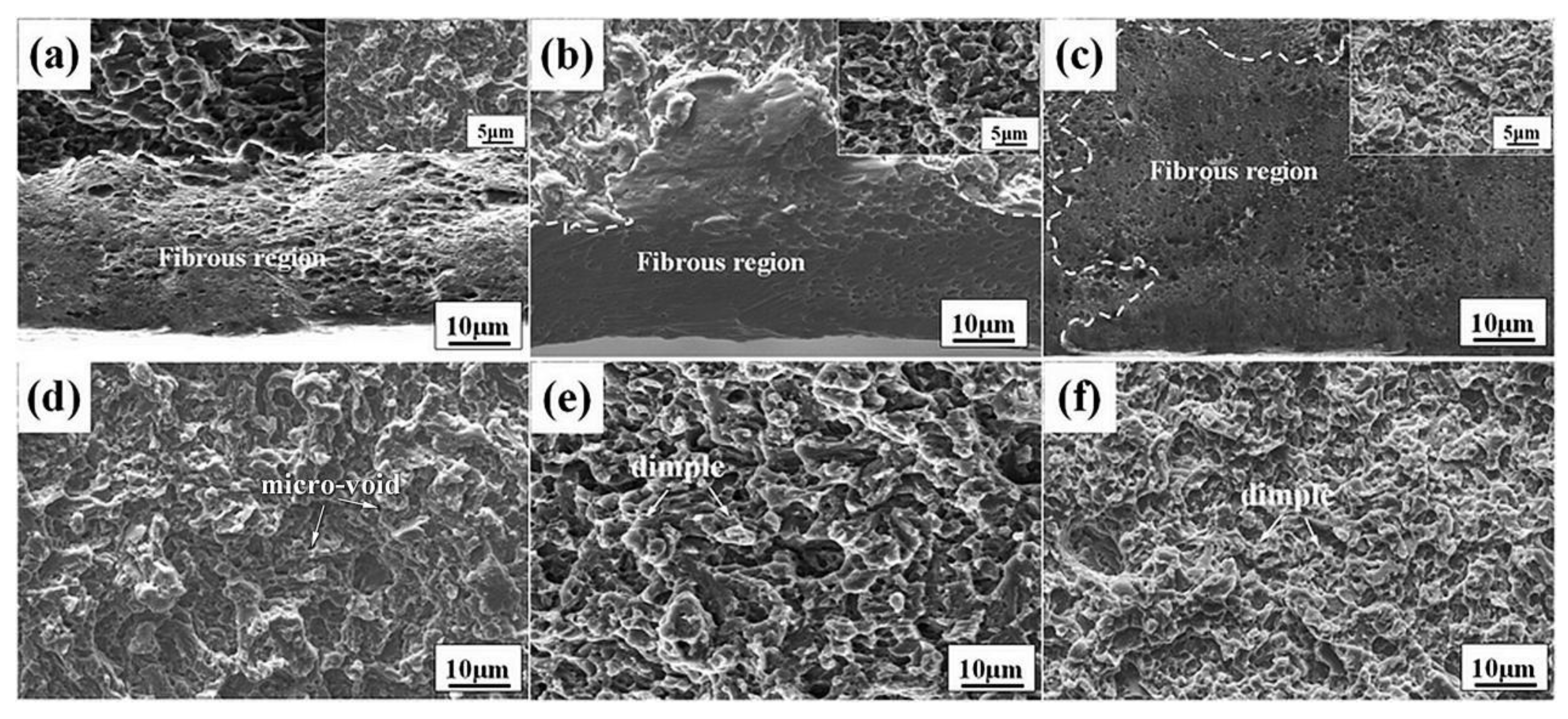

- The results of mechanical properties suggest that an excellent combination of ultimate tensile strength and impact toughness can be realized by combining CR with austempering. The ultimate tensile strength of austempered specimen with CR was increased by 10%, which is attributed to the increased precipitation in the austempered specimen with CR. The elongation of austempered specimen with CR is 2.8%, while that of Q-T specimen only reaches 1.5%. Furthermore, the impact absorbed energy at room temperature exhibited 2.3 times of that in Q-T specimen. The fracture analysis shows that more uniform dimples and wider fibrous regions can be found in the fracture of austempered specimen with CR.

Author Contributions

Funding

Conflicts of Interest

References

- Dodd, A.; Kinder, J.; Torp, B.; Nielsen, B.R.; Rangel, C.M.; da Svila, M.F. The effect of ion implantation on the fatigue life and corrosion resistance of M50 steel bearings. Surf. Coat. Technol. 1995, 74, 754–759. [Google Scholar] [CrossRef]

- Wang, F.; Qian, D.S.; Hua, L.; Mao, H.J.; Xie, L.C.; Song, X.D.; Dong, Z.H. Effect of high magnetic field on the microstructure evolution and mechanical properties of M50 bearing steel during tempering. Mater. Sci. Eng. A 2020, 771, 138623. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Steels for bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Wang, F.; Qian, D.S.; Hua, L.; Lu, X.H. The effect of prior cold rolling on the carbide dissolution, precipitation and dry wear behaviors of M50 bearing steel. Tribol. Int. 2019, 132, 253–264. [Google Scholar] [CrossRef]

- Shen, W.Y.; Zhao, L.I.; Gong, J.X.; Li, G.Q.; Yuan, X. Heat treatment test of size stability for bearing ring of Cr4Mo4V steel. Heat. Treat. Technol. Equip. 2015, 36, 27–29. [Google Scholar]

- Zhao, J.; Wang, T.S.; Lv, B.; Zhang, F.C. Microstructures and mechanical properties of a modified high-C–Cr bearing steel with nano-scaled bainite. Mater. Sci. Eng. A 2015, 628, 327–331. [Google Scholar] [CrossRef]

- Gao, G.H.; Zhang, H.; Tan, Z.L.; Liu, W.B.; Bai, B.Z. A carbide-free bainite/martensite/austenite triplex steel with enhanced mechanical properties treated by a novel quenching-partitioning-tempering process. Mater. Sci. Eng. A 2013, 559, 165–169. [Google Scholar] [CrossRef]

- Dong, J.; Vetters, H.; Hoffmann, F.; Zoch, W.H. Microstructure and fatigue strength of the bearing steel 52100 after shortened bainitic treatment. J. ASTM. Int. 2010, 7, 2–10. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Development of hard bainite. ISIJ Int. 2003, 43, 1238–1243. [Google Scholar] [CrossRef] [Green Version]

- Su, C.H.; Li, Q.G.; Huang, X.F.; Huang, W.G. Effect of bainite microstructure during two-step quenching and partitioning process on strength and toughness properties of a 0.3%C bainitic steel. J. Iron. Steel. Res. Int. 2018, 25, 235–242. [Google Scholar] [CrossRef]

- Sourmail, T.; Smanio, V. Optimisation of the mechanical properties of air cooled bainitic steel components through tailoring of the transformation kinetics. Mater. Sci. Eng. A 2013, 582, 257–261. [Google Scholar] [CrossRef]

- Gui, X.L.; Wang, K.K.; Gao, G.H.; Tan, Z.L.; Misra, R.D.K.; Bai, B.Z. Ultrahigh strength-toughness combination in Bainitic rail steel: The determining role of austenite stability during tempering. Mater. Sci. Eng. A 2016, 662, 162–168. [Google Scholar]

- Wei, D.Y.; Gu, J.L.; Fang, H.S.; Bai, B.Z. Fatigue behavior of 1500 MPa bainite + martensite duplex-phase high strength steel. Int. J. Fatigue 2004, 26, 437–442. [Google Scholar] [CrossRef]

- Li, C.; Wang, J.L. Effect of pre-quenching on martensite-bainitic microstructure and mechanical properties of GCr15 bearing steel. J. Mater. Sci. 1993, 28, 2112–2118. [Google Scholar] [CrossRef]

- Woźniak, T.Z.; Jelenkowski, J.; Rozniatowski, K.; Ranachowski, Z. Effect of microstructure on rolling contact fatigue of bearings. Mater. Sci. Forum 2012, 726, 55–62. [Google Scholar] [CrossRef]

- Zhang, F.C.; Wang, T.S.; Zhang, P.; Zheng, C.L.; Lv, B.; Zhang, M.; Zheng, Y.Z. A novel method for the development of a low-temperature bainitic microstructure in surface layer of low carbon steel. Scr. Mater. 2008, 59, 294–296. [Google Scholar] [CrossRef]

- Qian, D.S.; Deng, J.D.; Hua, L. Recent development of ring rolling theory and technique. Int. J. Mater. Process. Technol. 2017, 54, 65–85. [Google Scholar] [CrossRef]

- Li, Z.X.; Li, C.S.; Ren, J.Y.; Li, B.Z.; Zhang, J.; Ma, Y.Q. Effect of cold deformation on the microstructure and impact toughness during the austenitising process of 1.0C-1.5Cr bearing steel. Mater. Sci. Eng. A 2016, 674, 262–269. [Google Scholar] [CrossRef]

- Okitsu, Y.; Takata, N.; Tsuji, Y.N. A new route to fabricate ultrafine-grained structures in carbon steels without severe plastic deformation. Scr. Mater. 2009, 60, 76–79. [Google Scholar] [CrossRef]

- Sun, J.J.; Jiang, T.; Wang, Y.J.; Guo, S.W.; Liu, Y.N. Effect of grain refinement on high-carbon martensite transformation and its mechanical properties. Mater. Sci. Eng. A 2018, 726, 342–349. [Google Scholar] [CrossRef]

- Young, C.H.; Bhadeshia, H.K.D.H. Strength of mixtures of bainite and martensite. Mater. Sci. Tech. 1994, 10, 209–214. [Google Scholar] [CrossRef]

- Chakraborty, J.; Chattopadhyay, P.P.; Bhattacharjee, D.; Manna, I. Microstructural refinement of bainite and martensite for enhanced strength and toughness in high-carbon low-alloy steel. Metall. Mater. Trans. A 2010, 41, 2871–2879. [Google Scholar] [CrossRef]

- Chakraborty, J.; Bhattacharjee, D.; Manna, I. Development of ultrafine bainite + martensite duplex microstructure in SAE 52100 bearing steel by prior cold deformation. Scr. Mater. 2009, 61, 604–607. [Google Scholar] [CrossRef]

- Beswick, J. Effect of prior cold work on the martensite transformation in SAE 52100. Metall. Trans. A 1984, 15, 299–306. [Google Scholar] [CrossRef]

- Tsuji, N.; Maki, T. Enhanced structural refinement by combining phase transformation and plastic deformation in steels. Scr. Mater. 2009, 60, 1044–1049. [Google Scholar] [CrossRef]

- Lu, X.H.; Qian, D.S.; Li, W.; Jin, X.J. Enhanced toughness of bearing steel by combining prior cold deformation with martensite pre-quenching and bainite transformation. Mater. Lett. 2019, 234, 5–8. [Google Scholar] [CrossRef]

- Li, Y.G.; Zhang, F.C.; Chen, C.; Lv, B.; Yang, Z.N.; Zheng, C.L. Effects of deformation on the microstructures and mechanical properties of carbide–free bainitic steel for railway crossing and its hydrogen embrittlement characteristics. Mater. Sci. Eng. A 2016, 651, 945–950. [Google Scholar] [CrossRef]

- Chae, J.Y.; Jang, J.H.; Zhang, G.H.; Kim, K.H.; Lee, J.S.; Bhadeshia, H.K.D.H.; Suh, D.W. Dilatometric analysis of cementite dissolution in hypereutectoid steels containing Cr. Scr. Mater. 2011, 65, 245–248. [Google Scholar] [CrossRef] [Green Version]

- Beswick, J.M. The effect of chromium in high carbon bearing steels. Metall. Trans. A 1987, 18, 1897–1906. [Google Scholar] [CrossRef]

- Lange, W.F.; Enomoto, M.; Aaronson, H.I. The kinetics of ferrite nucleation at austenite grain boundaries in Fe-C alloys. Metall. Trans. A 1988, 19, 427–440. [Google Scholar] [CrossRef]

- Dyson, D.J.; Holmes, B. Effect of alloying additions on the lattice parameter of austenite. J. Iron. Steel. Inst. 1970, 208, 469–474. [Google Scholar]

- Bhadeshia, H.K.D.H. Bainite in Steels, 2nd ed.; IOM Communications Ltd.: London, UK, 2001. [Google Scholar]

- Podder, A.S.; Lonardelli, I.; Molinari, A.; Bhadeshia, H.K.D.H. Thermal stability of retained austenite in bainitic steel: An in situ study. Proc. R. Soc. A. Phys. Eng. Sci. 2011, 467, 3141–3156. [Google Scholar] [CrossRef] [Green Version]

- Peet, M. Transformation and tempering of low-temperature bainite. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 1 July 2010. [Google Scholar]

- Wang, F.; Qian, D.S.; Lu, X.H. Effect of prior cold deformation on the stability of retained austenite in GCr15 bearing steel. Acta. Metall. Sin. 2018, 3111, 28–37. [Google Scholar] [CrossRef] [Green Version]

- Jimenez-Melero, E.; Blondé, R.; Sherif, M.Y.; Honkimäki, V.; van Dijk, N.H. Time-dependent synchrotron X-ray diffraction on the austenite decomposition kinetics in SAE 52100 bearing steel at elevated temperatures under tensile stress. Acta. Mater. 2013, 6111, 54–66. [Google Scholar] [CrossRef]

- Harish, S.; Bensely, A.; Mohan Lal, D.; Rajadurai, A.; Lenkey, G.B. Microstructural study of cryogenically treated En 31 bearing steel. J. Mater. Process. Technol. 2009, 209, 3351–3357. [Google Scholar] [CrossRef]

| C | Cr | Mo | V | Mn | Si | W | Fe |

|---|---|---|---|---|---|---|---|

| 0.80 | 4.06 | 4.20 | 1.08 | 0.22 | 0.25 | 0.16 | Bal. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, D.; He, Y.; Wang, F.; Chen, Y.; Lu, X. Microstructure and Mechanical Properties of M50 Steel by Combining Cold Rolling with Austempering. Metals 2020, 10, 381. https://doi.org/10.3390/met10030381

Qian D, He Y, Wang F, Chen Y, Lu X. Microstructure and Mechanical Properties of M50 Steel by Combining Cold Rolling with Austempering. Metals. 2020; 10(3):381. https://doi.org/10.3390/met10030381

Chicago/Turabian StyleQian, Dongsheng, Yuangeng He, Feng Wang, Yun Chen, and Xiaohui Lu. 2020. "Microstructure and Mechanical Properties of M50 Steel by Combining Cold Rolling with Austempering" Metals 10, no. 3: 381. https://doi.org/10.3390/met10030381