Robust Ag-Cu Sintering Bonding at 160 °C via Combining Ag2O Microparticle Paste and Pt-Catalyzed Formic Acid Vapor

Abstract

1. Introduction

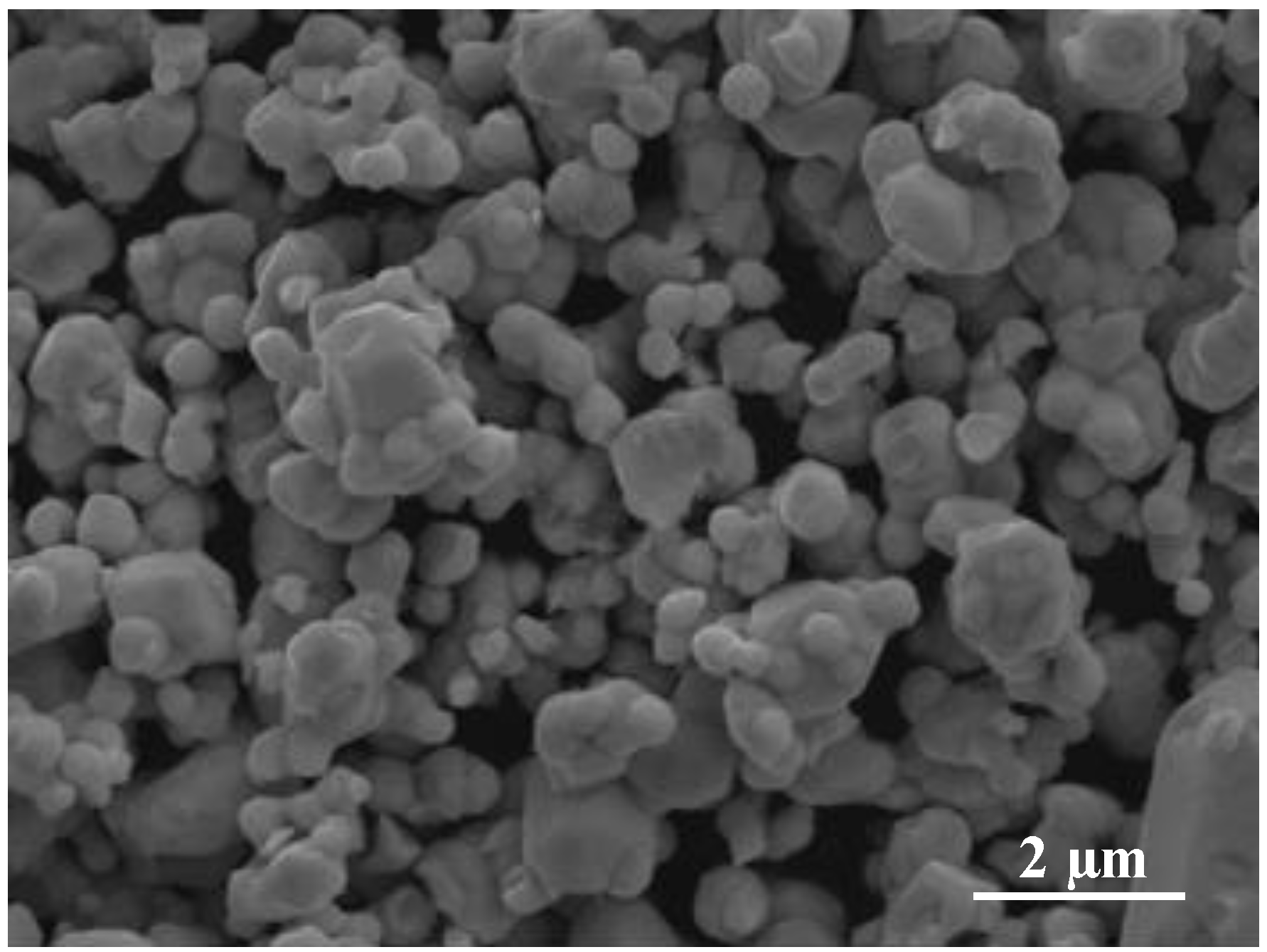

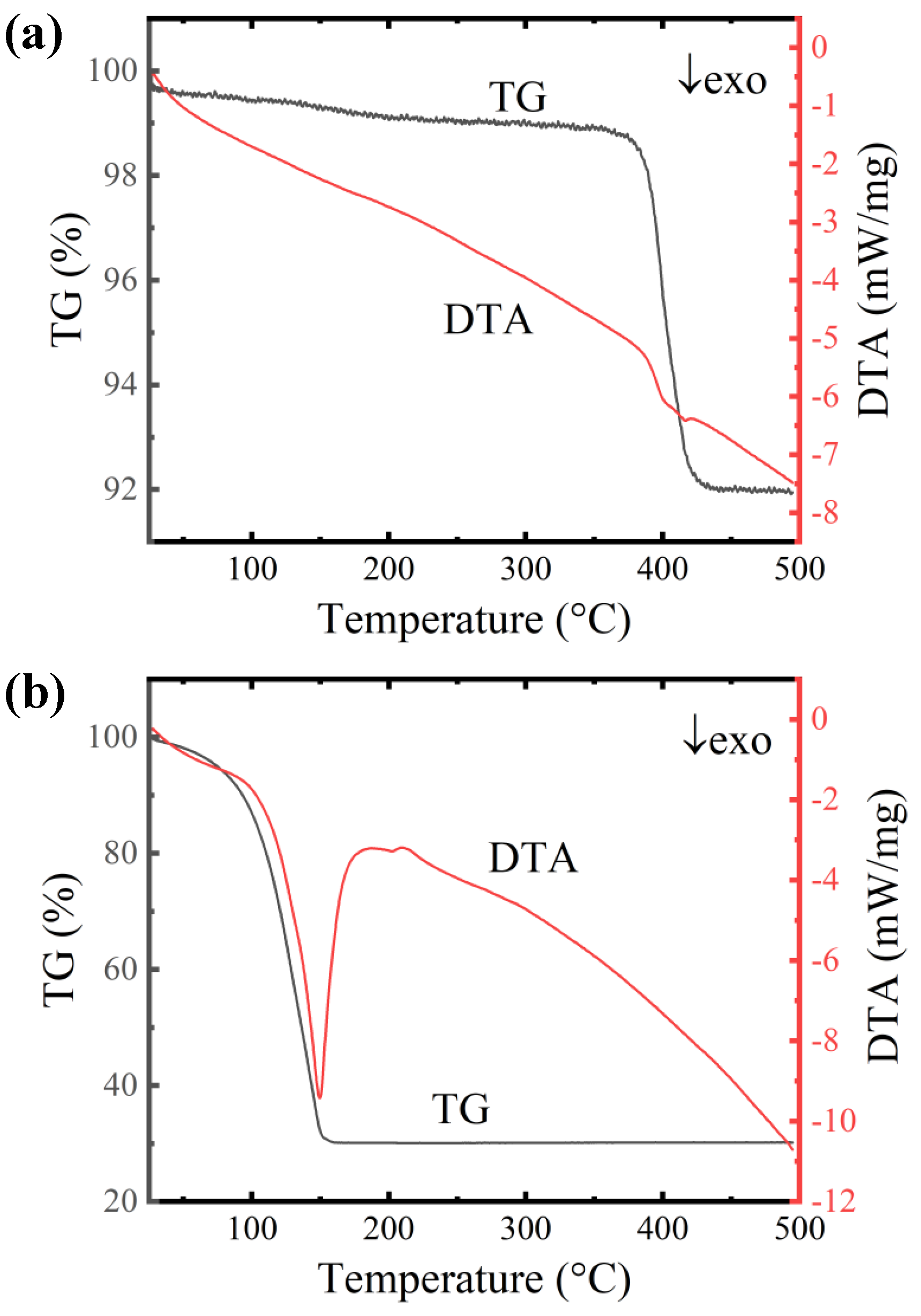

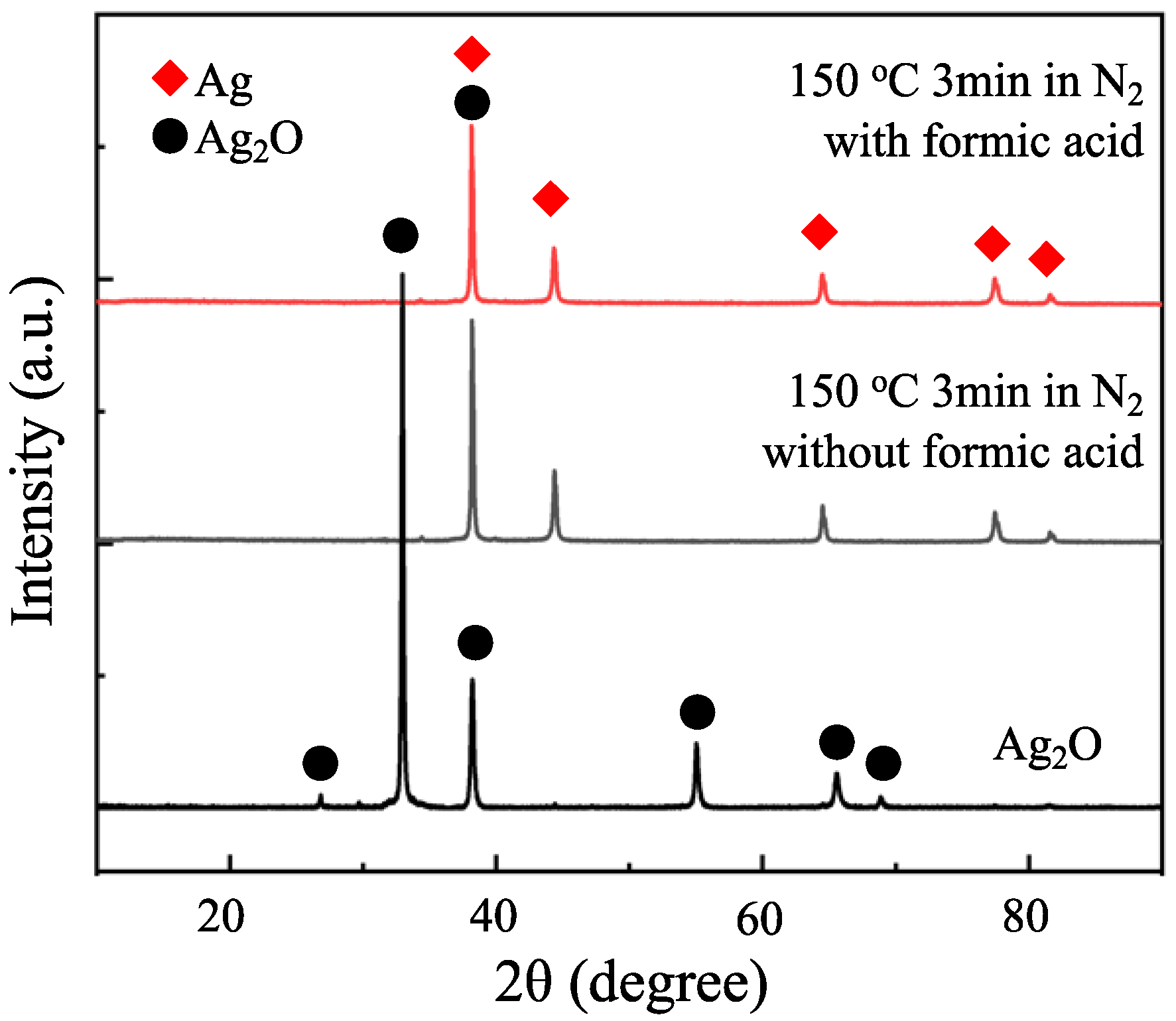

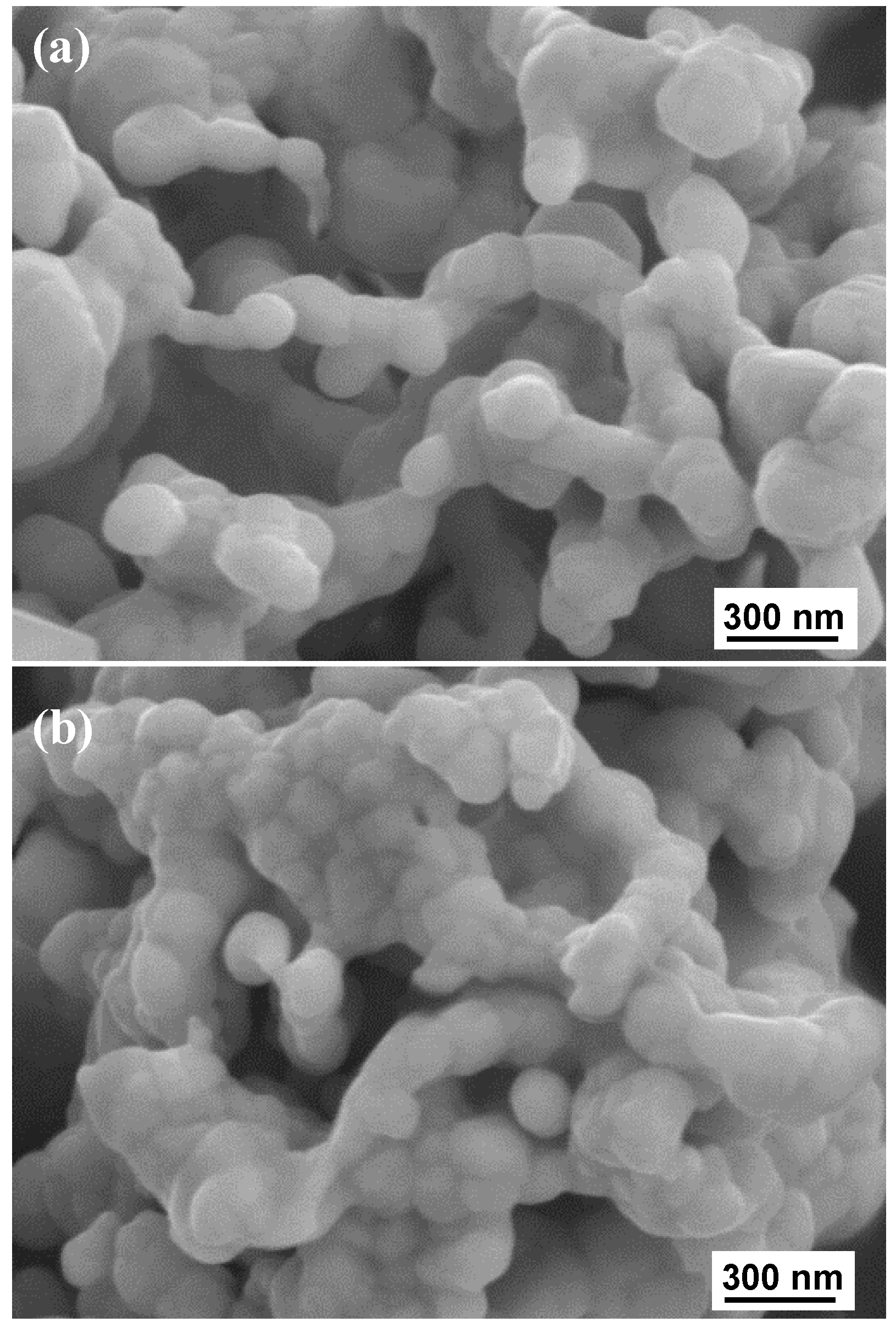

2. Experimental

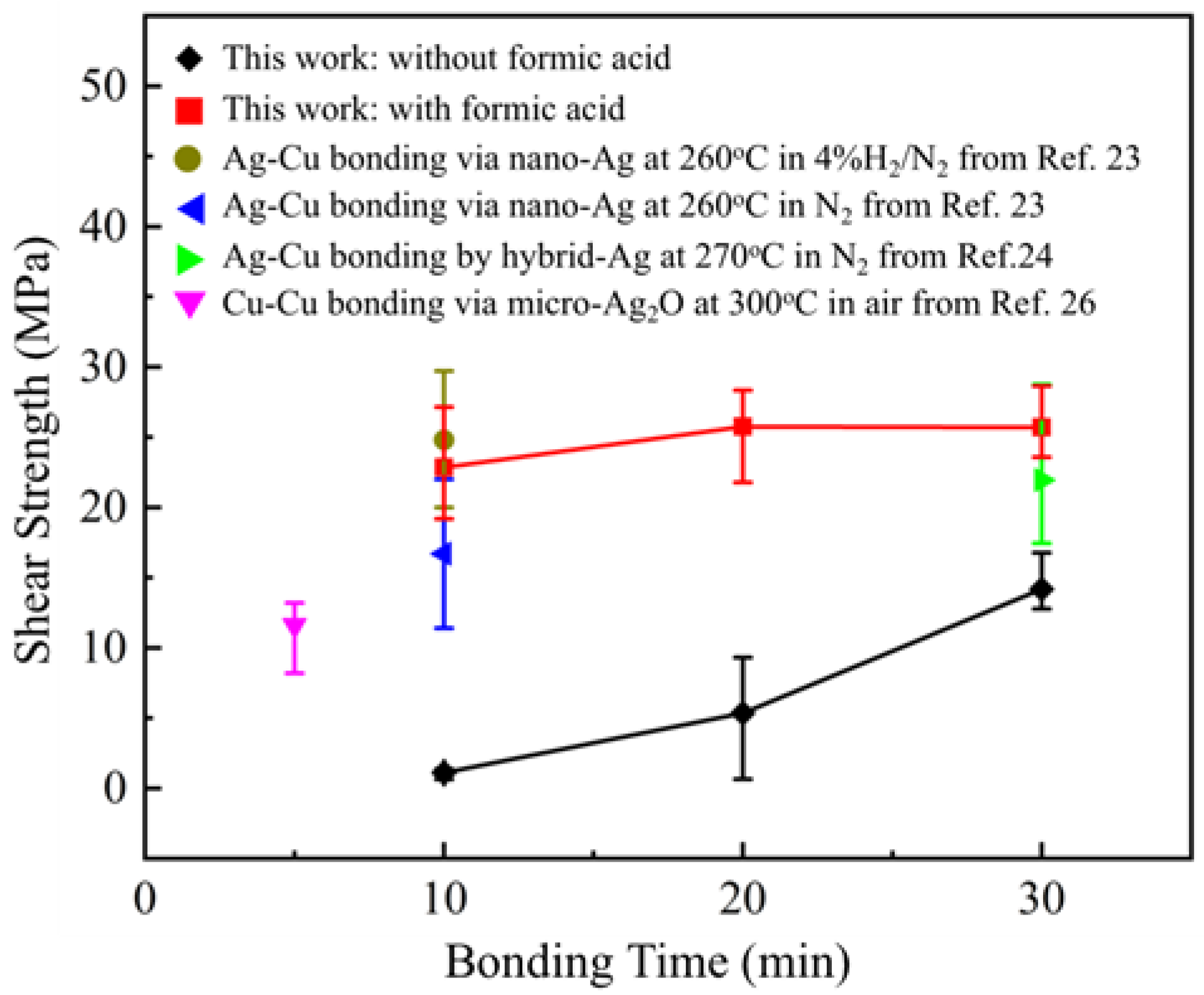

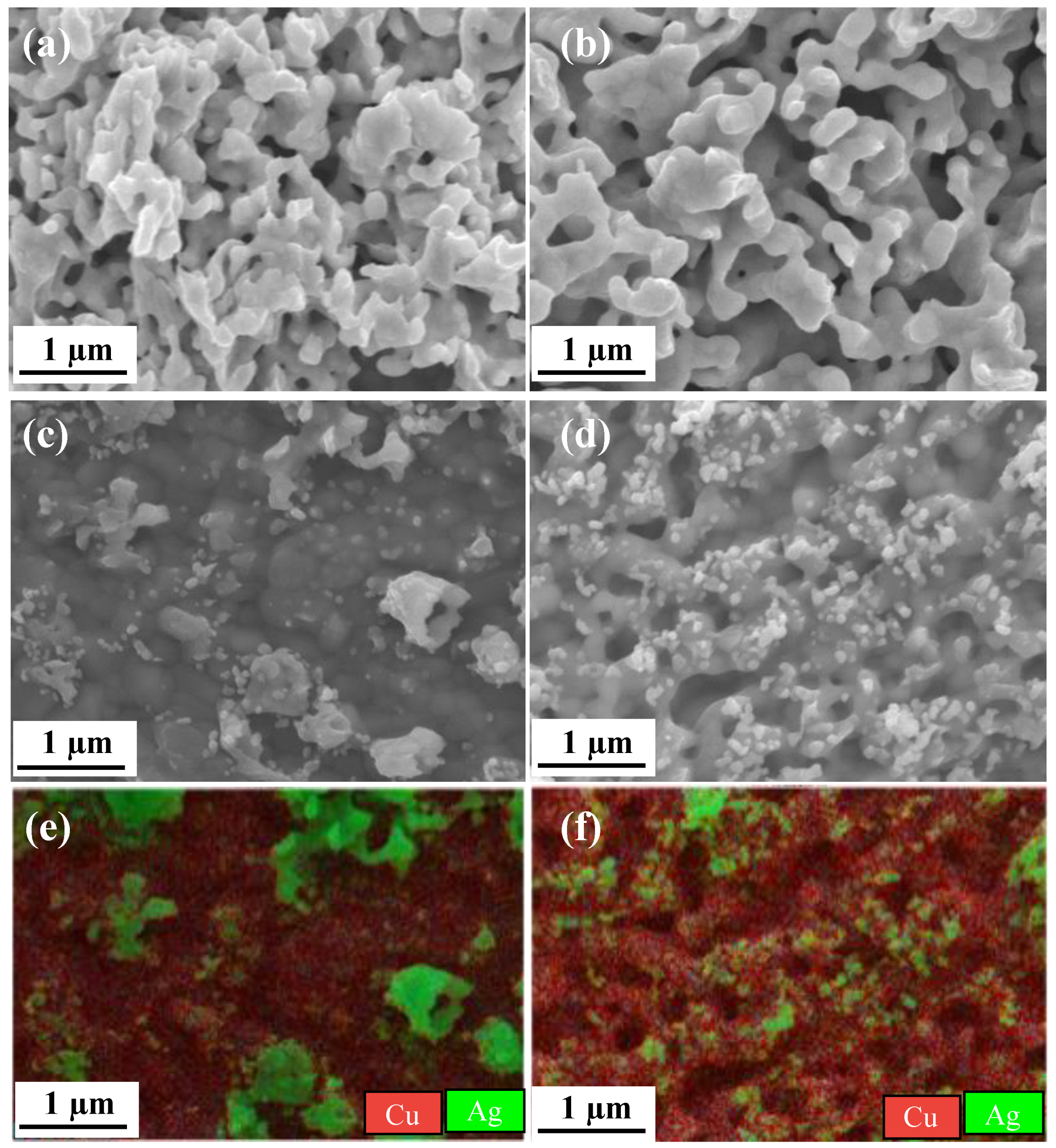

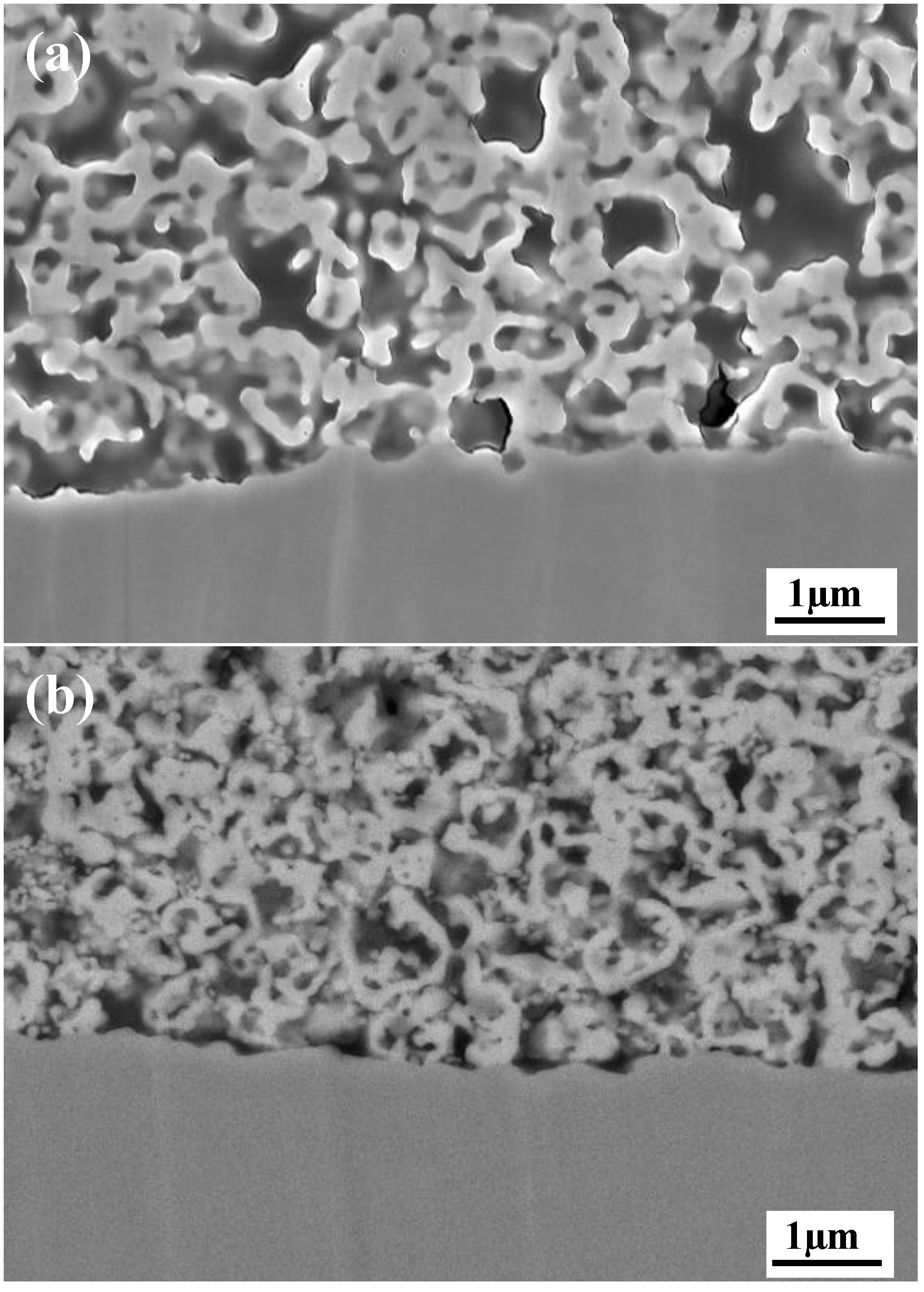

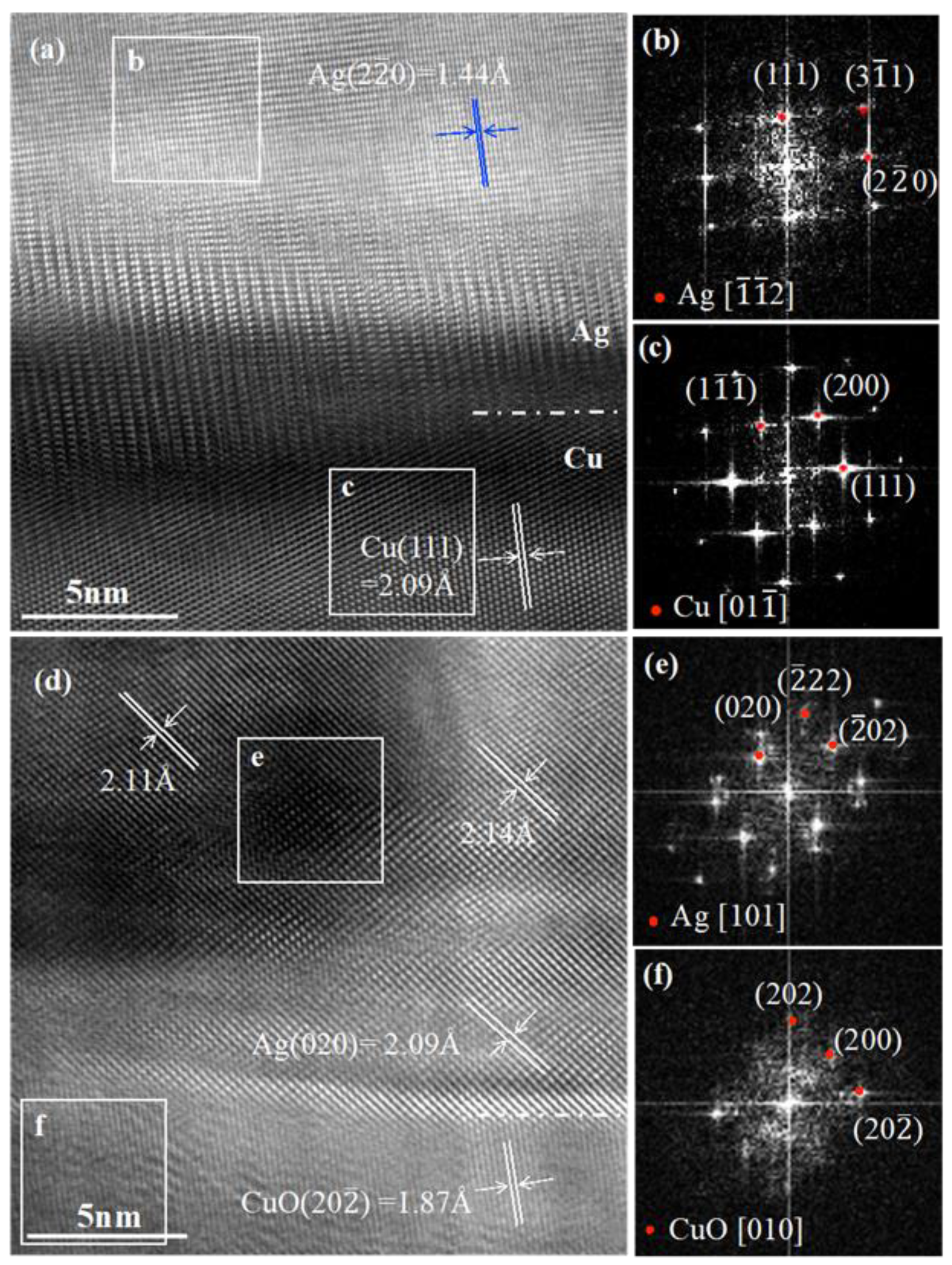

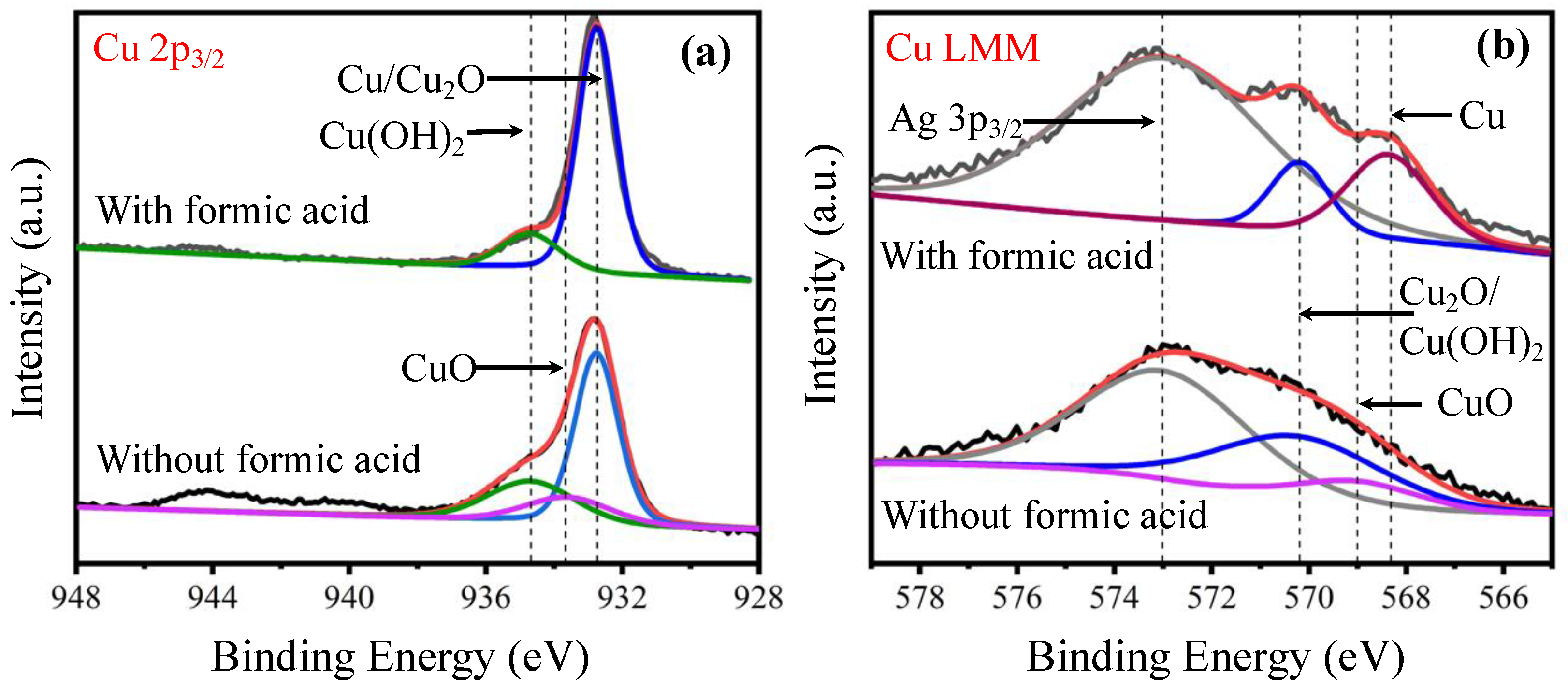

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lu, G.Q.; Calata, J.N.; Zhang, Z.; Bai, J.G. A lead-free, low-temperature sintering die-attach technique for high-performance and high-temperature packaging. In Proceedings of the 6th IEEE CPMT Conference on High Density Microsystem Design and Packaging and Component Failure Analysis (Hdp’04), Shanghai, China, 30 June–3 July 2004; pp. 42–46. [Google Scholar]

- Zhang, H.Q.; Wang, W.G.; Bai, H.L.; Zou, G.S.; Liu, L.; Peng, P.; Guo, W. Microstructural and mechanical evolution of silver sintering die attach for SiC power devices during high temperature applications. J. Alloys Compd. 2019, 774, 487–494. [Google Scholar] [CrossRef]

- Zhang, H.Q.; Bai, H.L.; Peng, P.; Guo, W.; Zou, G.S.; Liu, L. SiC chip attachment sintered by nanosilver paste and their shear strength evaluation. Weld. World 2019, 63, 1055–1063. [Google Scholar] [CrossRef]

- Liu, X.D.; Nishikawa, H. Low-pressure Cu-Cu bonding using in-situ surface-modified microscale Cu particles for power device packaging. Scr. Mater. 2016, 120, 80–84. [Google Scholar] [CrossRef]

- Manikam, V.R.; Cheong, K.Y. Die attach materials for high temperature applications: A review. IEEE Trans. Compon. Packag. Manuf. Technol. 2011, 1, 457–478. [Google Scholar] [CrossRef]

- Zhao, Z.Y.; Zhang, H.Q.; Zou, G.S.; Ren, H.; Zhuang, W.D.; Liu, L.; Zhou, Y.N. A predictive model for thermal conductivity of nano-Ag sintered interconnect for a SiC die. J. Electron. Mater. 2019, 48, 2811–2825. [Google Scholar] [CrossRef]

- Zhao, Z.; Zou, G.; Zhang, H.; Ren, H.; Liu, L.; Norman Zhou, Y. The mechanism of pore segregation in the sintered nano Ag for high temperature power electronics applications. Mater. Lett. 2018, 228, 168–171. [Google Scholar] [CrossRef]

- Jiu, J.T.; Zhang, H.; Nagao, S.; Sugahara, T.; Kagami, N.; Suzuki, Y.; Akai, Y.; Suganuma, K. Die-attaching silver paste based on a novel solvent for high-power semiconductor devices. J. Mater. Sci. 2016, 51, 3422–3430. [Google Scholar] [CrossRef]

- Jiu, J.T.; Zhang, H.; Koga, S.; Nagao, S.; Izumi, Y.; Suganuma, K. Simultaneous synthesis of nano and micro-Ag particles and their application as a die-attachment material. J. Mater. Sci. Mater. Electron. 2015, 26, 7183–7191. [Google Scholar] [CrossRef]

- Guo, W.; Zhang, H.Q.; Zhang, X.Y.; Liu, L.; Peng, P.; Zou, G.S.; Zhou, Y.N. Preparation of nanoparticle and nanowire mixed pastes and their low temperature sintering. J. Alloys Compd. 2017, 690, 86–94. [Google Scholar] [CrossRef]

- Feng, B.; Shen, D.; Wang, W.; Deng, Z.; Lin, L.; Ren, H.; Wu, A.; Zou, G.; Liu, L.; Zhou, Y.N. Cooperative bilayer of lattice-disordered nanoparticles as room-temperature sinterable nanoarchitecture for Device Integrations. ACS Appl. Mater. Interface 2019, 11, 16972–16980. [Google Scholar] [CrossRef]

- Nishikawa, H.; Liu, X.D.; Wang, X.F.; Fujita, A.; Kamada, N.; Saito, M. Microscale Ag particle paste for sintered joints in high-power devices. Mater. Lett. 2015, 161, 231–233. [Google Scholar] [CrossRef]

- Hirose, A.; Tatsumi, H.; Takeda, N.; Akada, Y.; Ogura, T.; Ide, E.; Morita, T. A novel metal-to-metal bonding process through in-situ formation of Ag nanoparticles using Ag2O microparticles. J. Phys. Conf. Ser. 2009, 165, 012074. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, H.; Li, W.L.; Jiu, J.T.; Nagao, S.; Sugahara, T.; Suganuma, K. Die bonding performance using bimodal Cu particle paste under different sintering atmospheres. J. Electron. Mater. 2017, 46, 4575–4581. [Google Scholar] [CrossRef]

- Kobayashi, Y. Preparation of copper nanoparticles and metal-metal bonding process using them. World J. Eng. 2013, 10, 113–118. [Google Scholar] [CrossRef]

- Ren, H.; Mu, F.W.; Shin, S.; Liu, L.; Zou, G.S.; Suga, T. Low temperature Cu bonding with large tolerance of surface oxidation. AIP Adv. 2019, 9, 055127. [Google Scholar] [CrossRef]

- Wu, C.J.; Chen, S.M.; Sheng, Y.J.; Tsao, H.K. Anti-oxidative copper nanoparticles and their conductive assembly sintered at room temperature. J. Taiwan Inst. Chem. Eng. 2014, 45, 2719–2724. [Google Scholar] [CrossRef]

- Zhao, J.; Yao, M.; Lee, N. Nano-Cu sintering paste for high power devices die attach applications. In Proceedings of the 2018 IEEE 68th Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 29 May–1 June 2018; pp. 557–563. [Google Scholar]

- Morita, T.; Yasuda, Y.; Ide, E.; Akada, Y.; Hirose, A. Bonding technique using micro-scaled silver-oxide particles for in-situ formation of silver nanoparticles. Mater. Trans. 2008, 49, 2875–2880. [Google Scholar] [CrossRef]

- Mu, F.W.; Zhao, Z.Y.; Zou, G.S.; Bai, H.L.; Wu, A.P.; Liu, L.; Zhang, D.Y.; Norman Zhou, Y. Mechanism of low temperature sintering-bonding through in-situ formation of silver nanoparticles using silver oxide microparticles. Mater. Trans. 2013, 54, 872–878. [Google Scholar] [CrossRef]

- Chen, C.; Luo, F.; Kang, Y. A review of SiC power module packaging: Layout, material system and integration. CPSS Trans. Power Electron. Appl. 2017, 2, 170–186. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, C.T.; Yang, Y.; Zhang, H.; Kim, D.; Sugahara, T.; Nagao, S.; Suganuma, K. Low-temperature and pressureless sinter joining of Cu with micron/submicron Ag particle paste in air. J. Alloys Compd. 2019, 780, 435–442. [Google Scholar] [CrossRef]

- Zheng, H.; Berry, D.; Ngo, K.D.T.; Lu, G. Chip-bonding on copper by pressureless sintering of nanosilver paste under controlled atmosphere. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 377–384. [Google Scholar] [CrossRef]

- Zhao, S.Y.; Li, X.; Mei, Y.H.; Lu, G.Q. Novel interface material used in high power electronic die-attaching on bare Cu substrates. J. Mater. Sci. Mater. Electron. 2016, 27, 10941–10950. [Google Scholar] [CrossRef]

- Chen, C.T.; Zhang, Z.; Kim, D.; Zhang, B.; Tanioku, M.; Ono, T.; Matsumoto, K.; Suganuma, K. Interfacial oxidation protection and thermal-stable sinter Ag joining on bare Cu substrate by single-layer graphene coating. Appl. Surf. Sci. 2019, 497, 143797. [Google Scholar] [CrossRef]

- Takata, S.; Ogura, T.; Ide, E.; Morita, T.; Hirose, A. Effects of solvents in the polyethylene glycol serieson the bonding of copper joints using Ag2O paste. J. Electron. Mater. 2013, 42, 507–515. [Google Scholar] [CrossRef]

- Suzuki, Y.; Ogura, T.; Takahashi, M.; Hirose, A. Low-current resistance spot welding of pure copper using silver oxide paste. Mater. Charact. 2014, 98, 186–192. [Google Scholar] [CrossRef]

- Ogura, T.; Takata, S.; Takahashi, M.; Hirose, A. Effects of reducing solvent on copper, nickel, and aluminum joining using silver nanoparticles derived from a silver oxide paste. Mater. Trans. 2015, 56, 1030–1036. [Google Scholar] [CrossRef]

- Yang, W.; Shintani, H.; Akaike, M.; Suga, T. Low temperature Cu-Cu direct bonding using formic acid vapor pretreatment. In Proceedings of the 2011 IEEE 61st Electronic Components and Technology Conference (ECTC), Lake Buena Vista, FL, USA, 31 May–3 June 2011; pp. 2079–2083. [Google Scholar]

- Yang, W.H.; Akaike, M.; Fujino, M.; Suga, T. A combined process of formic acid pretreatment for low-temperature bonding of copper electrodes. ECS J. Solid State Sci. Technol. 2013, 2, 271–274. [Google Scholar] [CrossRef]

- Yang, W.; Akaike, M.; Fujino, M.; Suga, T. Formic acid with Pt catalyst combined treatment process for Cu low temperature bonding. In Proceedings of the 2012 13th International Conference on Electronic Packaging Technology and High Density Packaging (ICEPT), Guilin, China, 13–16 August 2012; pp. 147–150. [Google Scholar]

- Yang, W.; Akaike, M.; Suga, T. Effect of formic acid vapor in situ treatment process on Cu low-temperature bonding. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 951–956. [Google Scholar] [CrossRef]

- Yang, W.; Shintani, H.; Akaike, M.; Suga, T. Formic acid vapor treated Cu-Cu direct bonding at low temperature. In Proceedings of the 2011 12th International Conference on Electronic Packaging Technology and High Density Packaging (ICEPT), Shanghai, China, 8–11 August 2011; pp. 1–4. [Google Scholar]

- Yang, W.; Lu, Y.; Tadatomo, S. The study of Cu-Cu low temperature bonding using formic acid treatment with/without Pt catalyst. In Proceedings of the 2016 17th International Conference on Electronic Packaging Technology (ICEPT), Wuhan, China, 16–19 August 2016; pp. 784–787. [Google Scholar]

- Suga, T.; Masakate, A.; Wenhua, Y.; Matsuoka, N. Formic acid treatment with Pt catalyst for Cu direct bonding at low temperature. In Proceedings of the 2014 International Conference on Electronics Packaging (ICEP), Toyama, Japan, 23–25 April 2014; pp. 644–647. [Google Scholar]

- Fujino, M.; Akaike, M.; Matsuoka, N.; Suga, T. Reduction reaction analysis of nanoparticle copper oxide for copper direct bonding using formic acid. Jpn. J. Appl. Phys. 2017, 56, 04CC01. [Google Scholar] [CrossRef]

- Lee, S.K.; Hsu, H.C.; Tuan, W.H. Oxidation behavior of copper at a temperature below 300 degrees C and the methodology for passivation. Mater. Res. 2016, 19, 51–56. [Google Scholar] [CrossRef]

- Bokstein, B.S.; Mendelev, M.I.; Srolovitz, D.J. Thermodynamics and Kinetics in Materials Science a Short Course, 1st ed.; Oxford University Press: Oxford, UK, 2005; pp. 165–188. [Google Scholar]

- Butrymowicz, D.B.; Manning, J.R.; Read, M.E. Diffusion in copper and copper alloys, part II. copper-silver and copper-gold systems. J. Phys. Chem. Ref. Data 1974, 3, 527–602. [Google Scholar] [CrossRef]

- Fukikoshi, T.; Watanabe, Y.; Miyazawa, Y.; Kanasaki, F. Brazing of copper to stainless steel with a low-silver-content brazing filler metal. IOP Conf. Ser. Mater. Sci. Eng. 2014, 61, 012016. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, L.; Li, J.; Wu, X.; Mu, F.; Wang, Y.; Lu, Y.; Suga, T. Robust Ag-Cu Sintering Bonding at 160 °C via Combining Ag2O Microparticle Paste and Pt-Catalyzed Formic Acid Vapor. Metals 2020, 10, 315. https://doi.org/10.3390/met10030315

He L, Li J, Wu X, Mu F, Wang Y, Lu Y, Suga T. Robust Ag-Cu Sintering Bonding at 160 °C via Combining Ag2O Microparticle Paste and Pt-Catalyzed Formic Acid Vapor. Metals. 2020; 10(3):315. https://doi.org/10.3390/met10030315

Chicago/Turabian StyleHe, Liangliang, Junlong Li, Xin Wu, Fengwen Mu, Yinghui Wang, Yangting Lu, and Tadatomo Suga. 2020. "Robust Ag-Cu Sintering Bonding at 160 °C via Combining Ag2O Microparticle Paste and Pt-Catalyzed Formic Acid Vapor" Metals 10, no. 3: 315. https://doi.org/10.3390/met10030315

APA StyleHe, L., Li, J., Wu, X., Mu, F., Wang, Y., Lu, Y., & Suga, T. (2020). Robust Ag-Cu Sintering Bonding at 160 °C via Combining Ag2O Microparticle Paste and Pt-Catalyzed Formic Acid Vapor. Metals, 10(3), 315. https://doi.org/10.3390/met10030315